Method for calcining limestone by using low-calorific-value fuel in double-hearth kiln

A technology for calcining limestone and double-chamber kiln, which is applied in the field of double-chamber kiln for calcining limestone with low calorific value fuel and industrial furnace kiln, can solve the problems such as insufficient utilization of low calorific value fuel, incomplete decomposition of limestone, inability to decompose limestone, etc. Conducive to environmental protection, improved calcination effect, easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

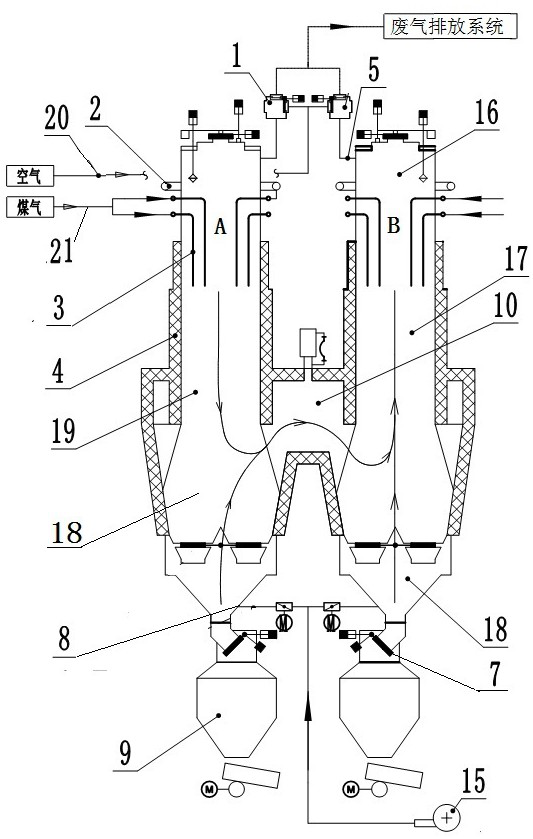

[0022] A double-chambered kiln for the production of lime such as figure 1 As shown, it includes double chamber kiln body 4, feeding equipment, discharging equipment, air pipeline 20, gas pipeline 21, cooling fan 15 and exhaust gas discharge system. The double-chambered kiln body includes kiln chamber A and kiln chamber B. The upper parts of kiln chamber A and kiln chamber B are respectively provided with air inlet and outlet ports 5 , and the lower parts are provided with material outlet ports 7 and cooling air inlets 8 . The cooling air inlet is connected to the cooling fan 15, the discharge port is connected to the lime bin 9, and a flue gas channel 10 is arranged between the two kiln bodies. Each chamber of the double chamber kiln is provided with a preheating zone 16 , a calcination zone 17 , a cooling zone 18 and a second calcination zone 19 , and the second calcination zone 19 is located between the calcination zone 17 and the flue gas channel 10 . The air inlet and ou...

Embodiment 2

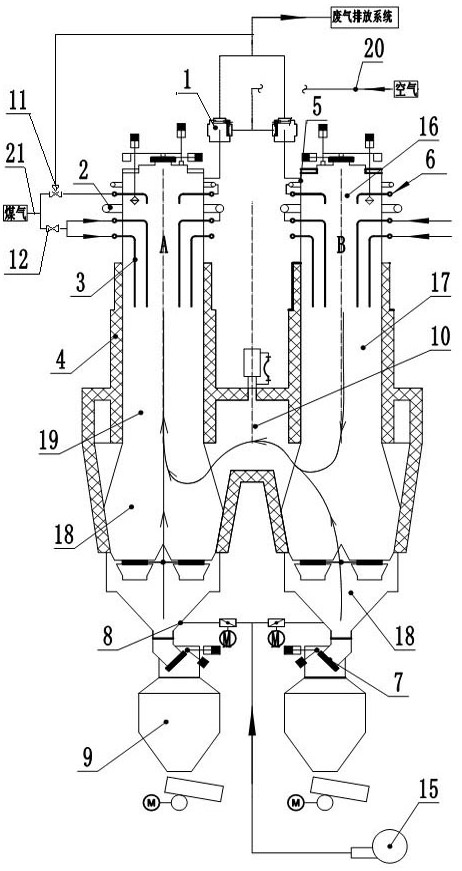

[0031] Another embodiment of the present invention is as figure 2 As shown, it includes double chamber kiln body 4, feeding equipment, discharging equipment, air pipeline 20, gas pipeline 21, cooling fan 15 and exhaust gas discharge system. The double-chambered kiln body includes kiln chamber A and kiln chamber B. The upper parts of kiln chamber A and kiln chamber B are respectively provided with air inlet and outlet ports 5 , and the lower parts are provided with material outlet ports 7 and cooling air inlets 8 . The cooling air inlet is connected to the cooling fan 15, the discharge port is connected to the lime bin 9, and a flue gas channel 10 is arranged between the two kiln bodies. Each chamber of the double chamber kiln is provided with a preheating zone 16 , a calcination zone 17 , a cooling zone 18 and a second calcination zone 19 , and the second calcination zone 19 is located between the calcination zone 17 and the flue gas channel 10 . The air inlet and outlet 5 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com