Process for preparing purely-natural nano supermicro calcium powder

A preparation process, nano-scale technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of cumbersome operation steps, cumbersome calcination operation, high calcination temperature, etc., achieve low calcination temperature, reduce calcination temperature, The effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

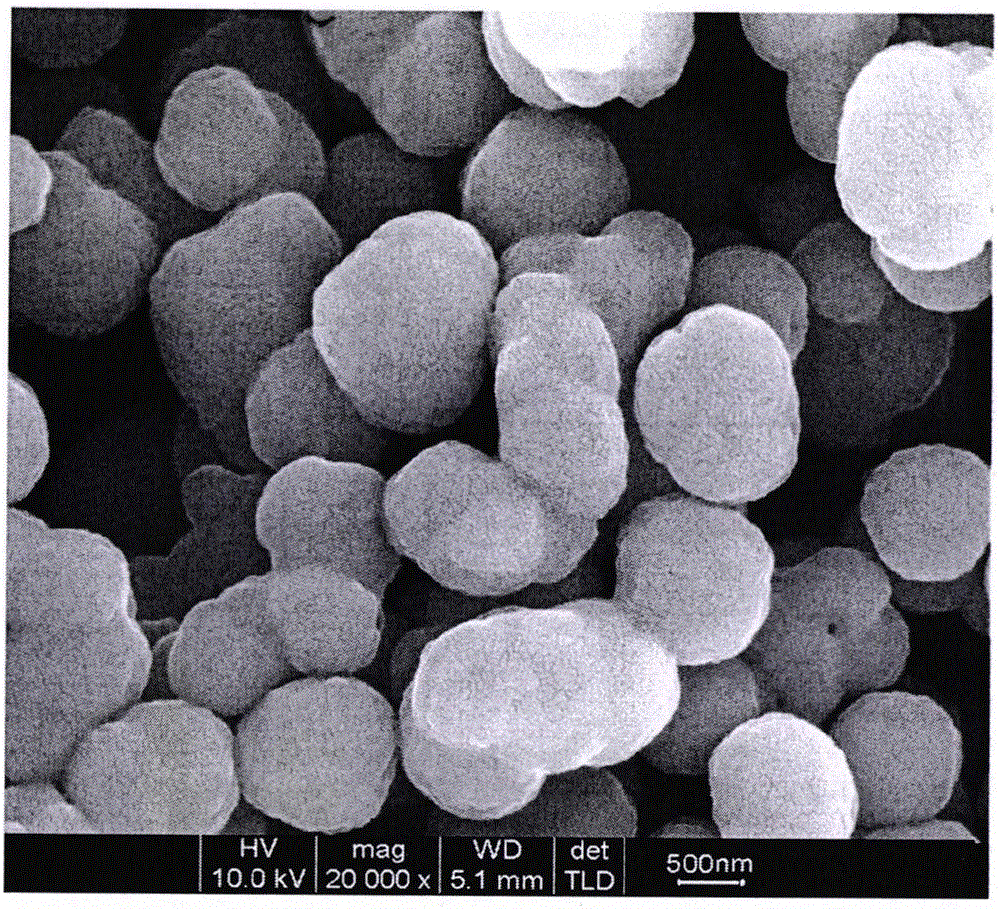

[0035] A preparation process of pure natural nano-scale ultrafine calcium powder, including: material selection, cleaning, crushing, grinding, calcining, regrinding, hydrolysis, ultrafine grinding, and drying;

[0036] Material selection: Tridacna shells are used as raw materials;

[0037] Cleaning: including water washing, ultrasonic pickling and high-pressure water washing, water washing removes sludge on the surface of raw materials, ultrasonic pickling removes skin, difficult-to-wash stains and heavy metals of raw materials, the specific operation of ultrasonic pickling is: put giant clams at a concentration of 0.01 Ultrasonic pickling in mol / L dilute HCl solution for 30 minutes, ultrasonic frequency is 20KHz; high-pressure water washing removes the products of ultrasonic pickling, and sprays the raw materials with a nozzle with a pressure of 60 psi and a flow rate of 4 gallons per minute, and the spray time is 8 minutes ;

[0038] Crush: Crush the cleaned raw materials t...

Embodiment 2

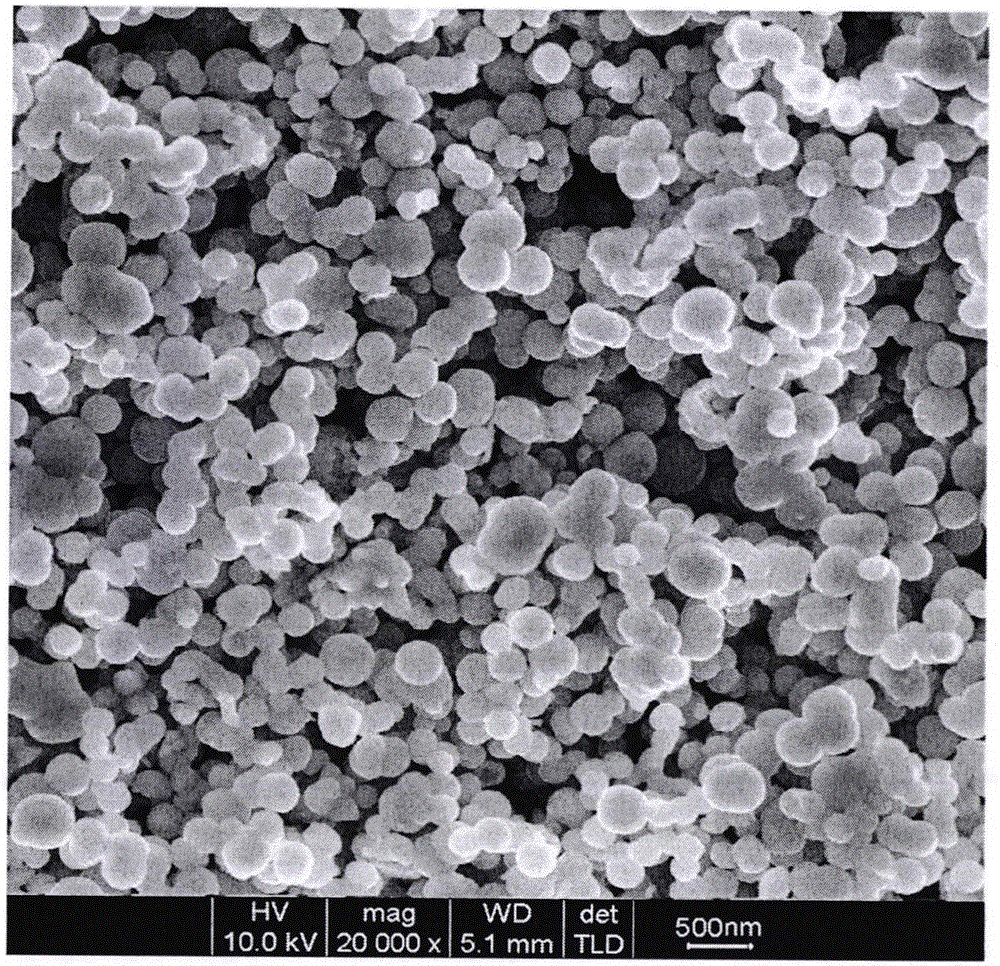

[0047] A preparation process of pure natural nano-scale ultrafine calcium powder, including: material selection, cleaning, crushing, grinding, calcining, regrinding, hydrolysis, ultrafine grinding, and drying;

[0048] Material selection: pearls are used as raw materials;

[0049] Cleaning: including water washing, ultrasonic pickling and high-pressure water washing, water washing removes sludge on the surface of raw materials, ultrasonic pickling removes the skin, difficult-to-wash stains and heavy metals of raw materials, the specific operation of ultrasonic pickling is: put giant clams at a concentration of 0.02 Ultrasonic pickling in mol / L dilute HCl solution for 40 minutes, ultrasonic frequency is 30KHz; high-pressure water washing removes the products of ultrasonic pickling, and sprays the raw materials with a nozzle with a pressure of 70 psi and a flow rate of 5 gallons per minute, and the spraying time is 10 minutes ;

[0050] Crush: Crush the cleaned raw materials to a...

Embodiment 3

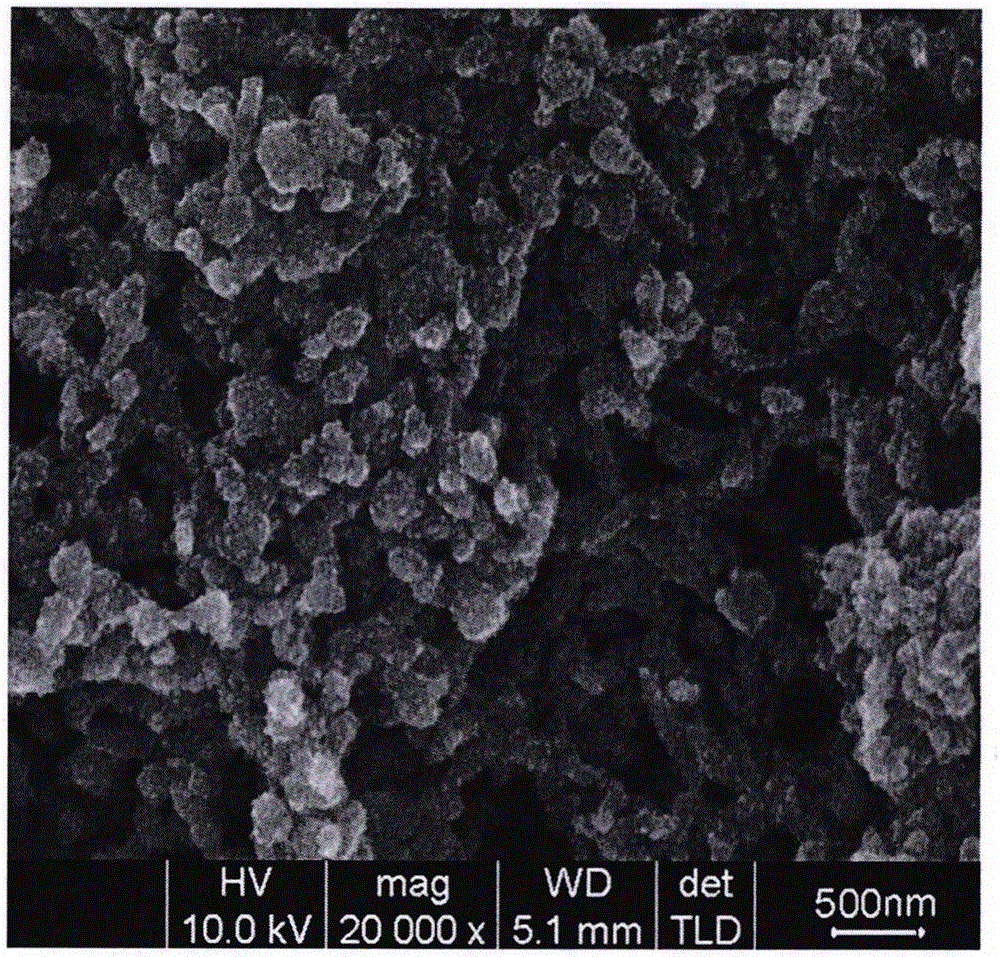

[0059] A preparation process of pure natural nano-scale ultrafine calcium powder, including: material selection, cleaning, crushing, grinding, calcining, regrinding, hydrolysis, ultrafine grinding, and drying;

[0060] Material selection: oyster shells are used as raw materials;

[0061] Cleaning: including water washing, ultrasonic pickling and high-pressure water washing, water washing removes sludge on the surface of raw materials, ultrasonic pickling removes skin, difficult-to-wash stains and heavy metals of raw materials, the specific operation of ultrasonic pickling is: put giant clams at a concentration of 0.03 Ultrasonic acid pickling in mol / L dilute HCl solution for 50 minutes, the ultrasonic frequency is 40KHz; high-pressure water washing removes the products of ultrasonic pickling, and the raw materials are sprayed with a nozzle with a pressure of 80 psi and a flow rate of 3 gallons per minute, and the spray time is 10 minutes ;

[0062] Crush: Crush the cleaned ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com