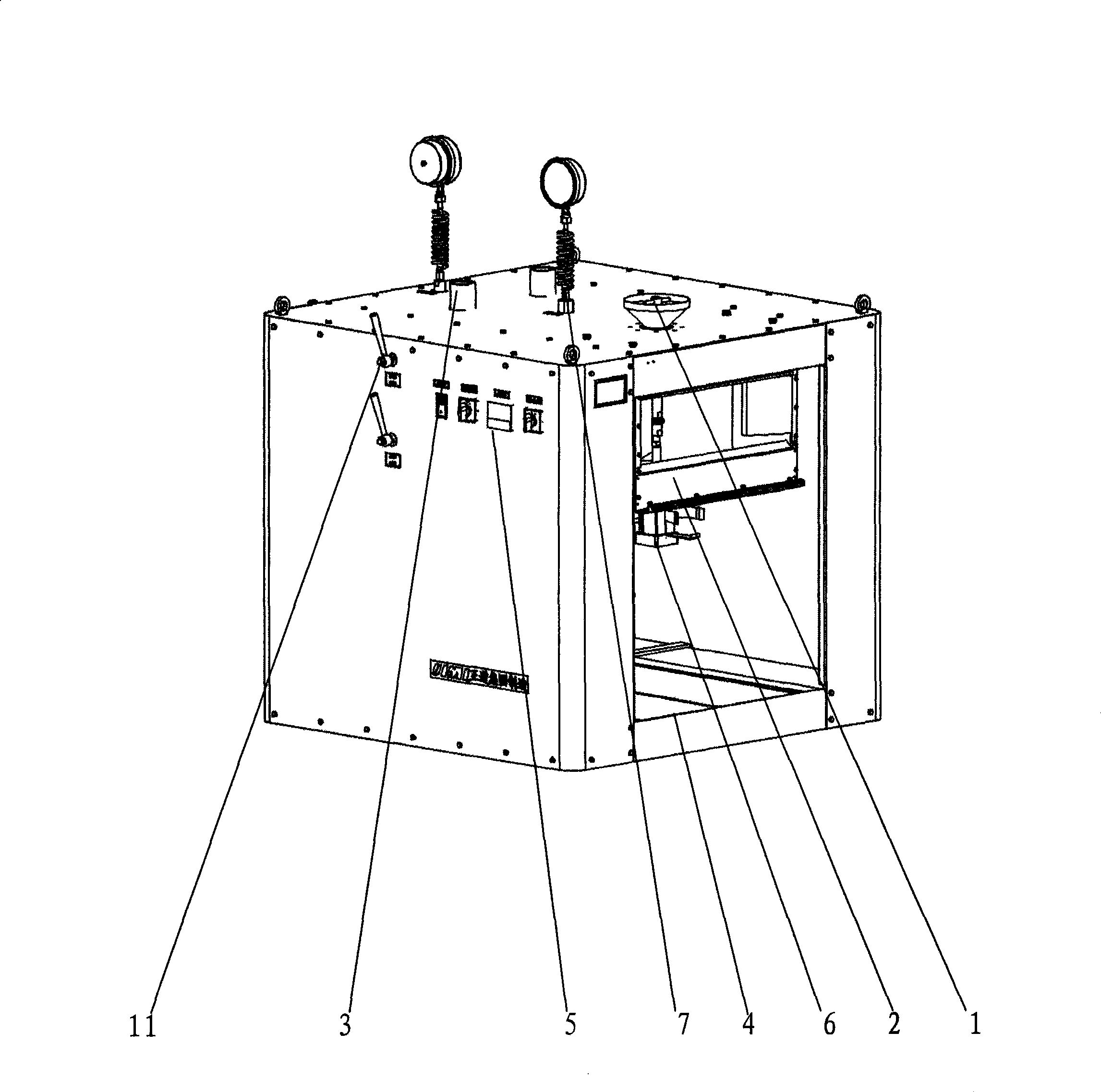

Steam explosion technique testing desk

A kind of process and technology of experimental bench, which is applied in the direction of laboratory equipment, the method of chemically changing substances by using atmospheric pressure, and the shaping of food, etc., can solve the problems of huge power consumption, little help of enzymatic hydrolysis, etc., to achieve The effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The QB-200 steam explosion process test bench is the specific implementation of the above invention. This type of test bench is equipped with a 50KW gas-fired steam generator, the maximum working pressure is 6MPa, the volume of each steam explosion test is 405ml, and an average of 20 sets of tests can be completed per hour, which can provide complete steam explosion process parameters for industrial production of continuous steam explosion equipment .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com