Treatment method for rice/wheat straw waste

A technology of rice straw and waste, which is applied in the field of waste treatment of rice straw, can solve the problems of affecting the growth of seedlings, cost increase, lack of straw microbial agents, etc., and achieves improved utilization rate, added value, and obvious economic benefits , the effect of important social significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

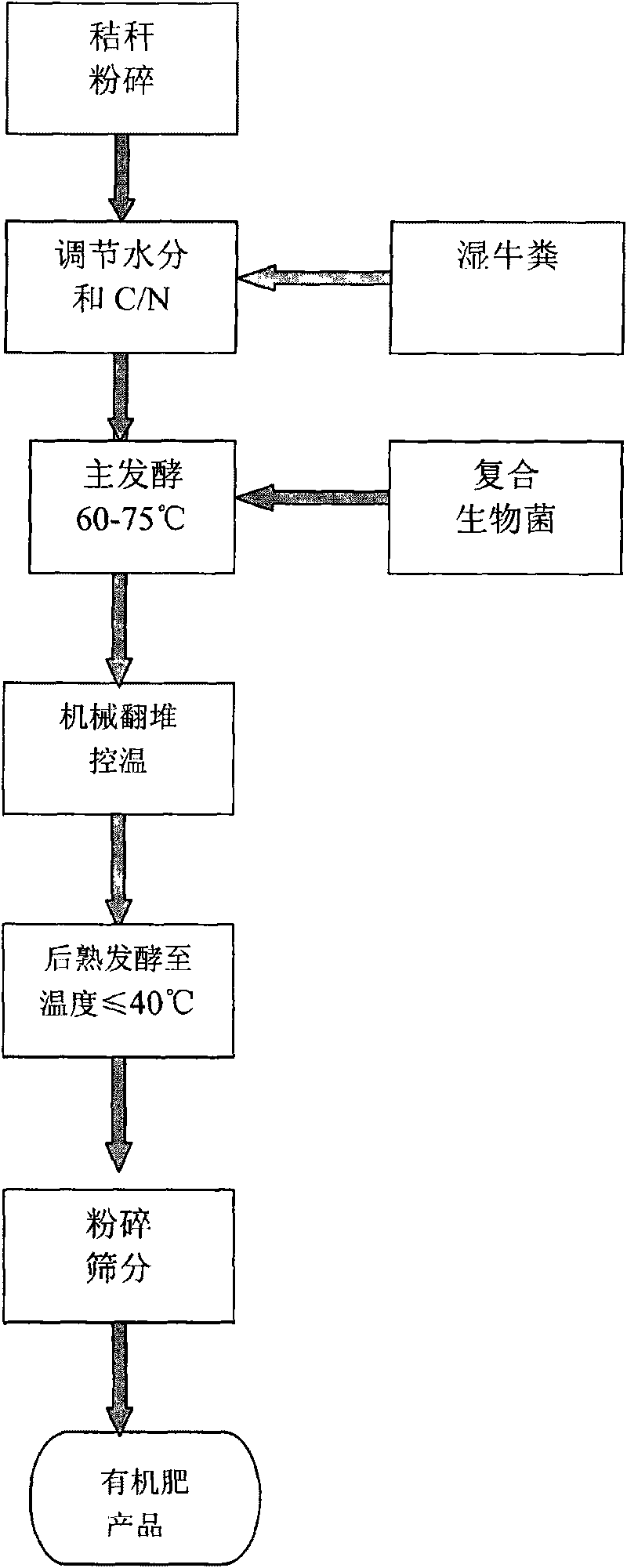

Method used

Image

Examples

Embodiment 1

[0023] The ratio of compound biological bacteria (Bacillus subtilis, Clostridium and Rhizopus by weight ratio is 0.9:1:1.1)

[0024] Pour 1000Kg of rice and wheat straw waste into the mixing tank, add 300Kg of wet cow dung, stir evenly, adjust the water content to 68%, C / N=22:1; add 30Kg of complex biological bacteria and stir, then transfer to the fermentation workshop Main fermentation: turn compost when the temperature rises above 60°C, control the temperature in the range of 60°C to 70°C, transfer to after-ripening fermentation after 10 days of fermentation, after 8 days, the internal temperature of the compost is lower than 40°C, and the fermentation ends; Pulverizer pulverizes and sieves, obtains total nutrient is 6.7%, and organic matter is 620Kg of the finished product organic fertilizer of 48%.

Embodiment 2

[0026] The ratio of compound biological bacteria (Bacillus subtilis, Clostridium and Rhizopus by weight ratio is 1:1:1)

[0027] Pour 2000Kg of rice and wheat straw waste into the mixing tank, add 500Kg of wet cow dung, stir evenly, adjust the water content to about 70%, C / N=23:1; add 60Kg of complex biological bacteria and stir, then transfer to the fermentation workshop Main fermentation: turn compost when the temperature rises above 60°C, control the temperature in the range of 60°C to 70°C, and transfer to after-ripening fermentation after 12 days of fermentation. After 10 days, the internal temperature of the compost is lower than 40°C, and the fermentation ends; Pulverizer pulverizes and sieves, and obtains total nutrient is 6.5%, and organic matter is 1100Kg of finished product organic fertilizers of 47%.

Embodiment 3

[0029] The ratio of compound biological bacteria (Bacillus subtilis, Clostridium and Rhizopus by weight ratio is 1:1.1:0.9)

[0030] Pour 3000Kg of rice and wheat straw waste into the mixing tank, add 920Kg of wet cow dung, stir evenly, adjust the water content to 72%, C / N=21:1; add 45Kg of complex biological bacteria and stir, then transfer to the fermentation workshop Main fermentation: turn compost when the temperature rises above 60°C, control the temperature in the range of 60°C to 70°C, and transfer to after-ripening fermentation after 20 days of fermentation. After 4 days, the internal temperature of the compost is lower than 40°C, and the fermentation ends; Pulverizer pulverizes and sieves, and obtains total nutrient is 7.0%, and organic matter is 1800Kg of the finished product organic fertilizer of 48%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com