Temperature-controlled suspension roaster

A suspension roasting furnace and cooler technology, applied in lime production and other directions, can solve the problems of high heat consumption and increase product cost in magnesia production, and achieve the effects of good calcination effect, small footprint and low operation and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

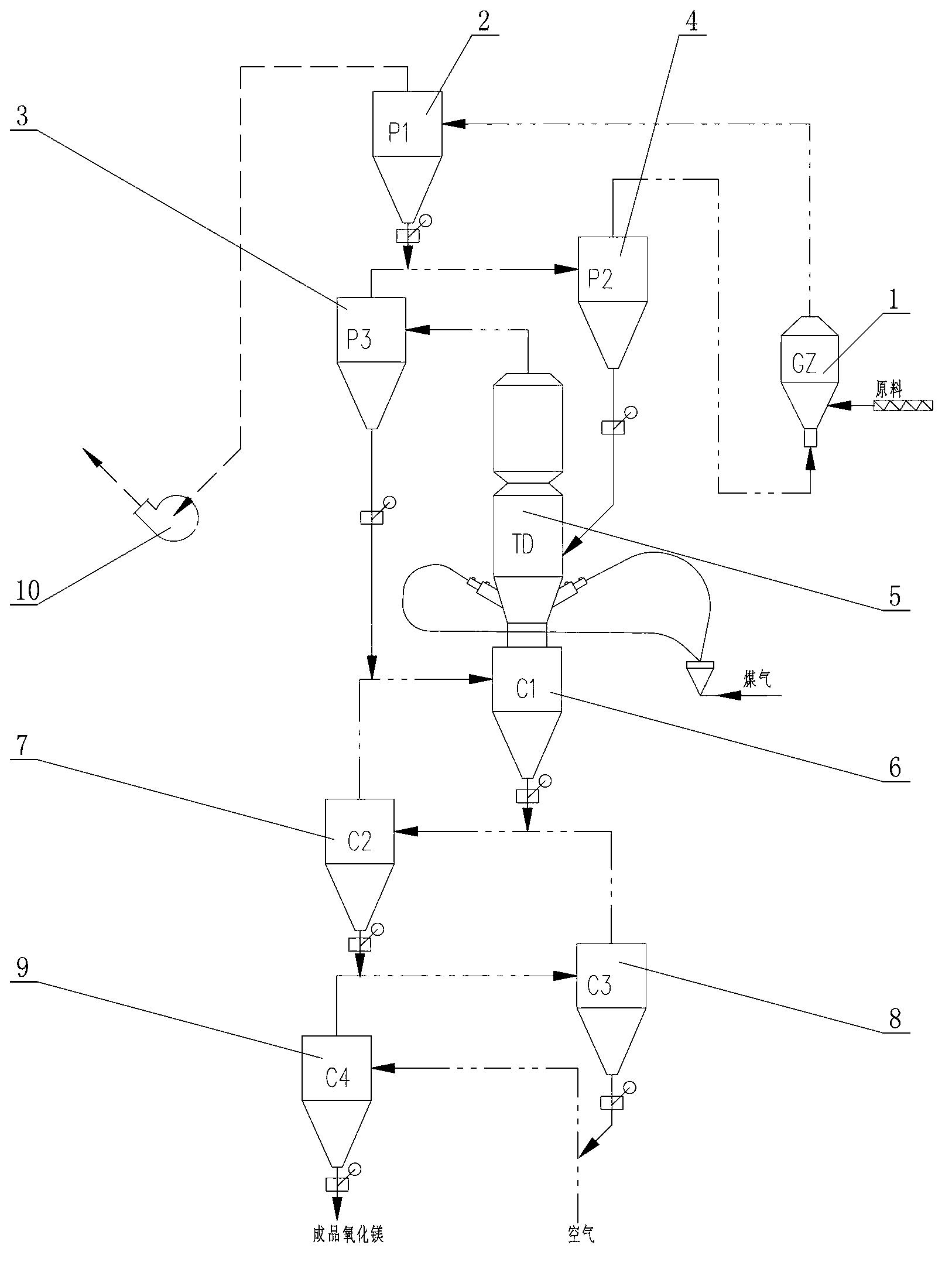

[0020] In order to further understand the utility model content, characteristics and effects of this patent, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0021] see figure 1 , in the figure, the solid line plus the arrow indicates the flow direction of the solid material, the double-dot dash line plus the arrow indicates the flow direction of the dusty gas, and the dotted line indicates the flow direction of the waste gas.

[0022] A temperature-controllable suspension roaster is composed of a cyclone separator, a preheating cyclone cylinder 4, a temperature-controllable roaster 5, a dryer 1, and a multi-stage cyclone cooler, wherein the cyclone separator includes a two-stage cyclone separator, which is The primary cyclone separator 2 and the secondary cyclone separator 3. The multi-stage cooler includes a primary cooler, an intermediate cooler and a final cooler from the upstream to the downstream ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com