Patents

Literature

115results about How to "No increase in workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

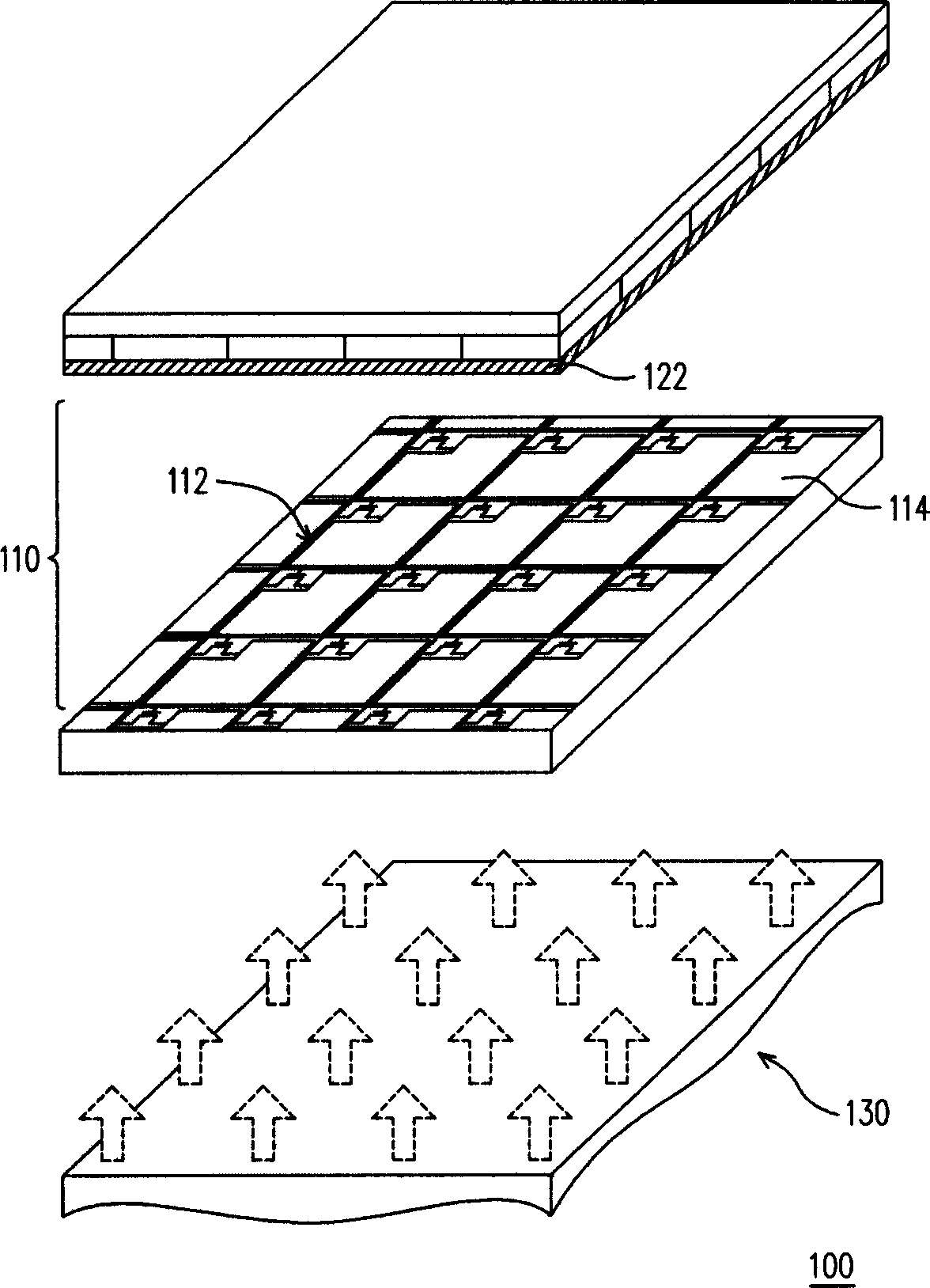

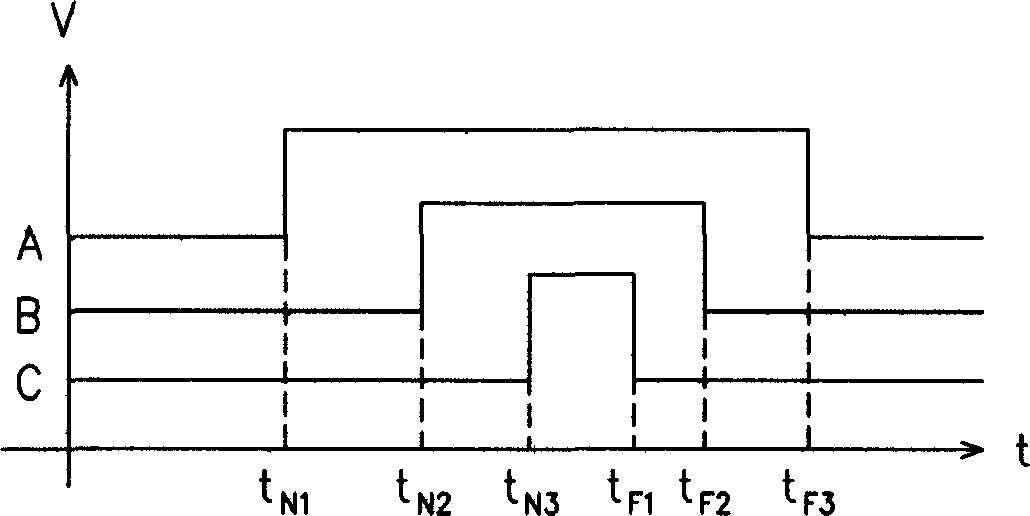

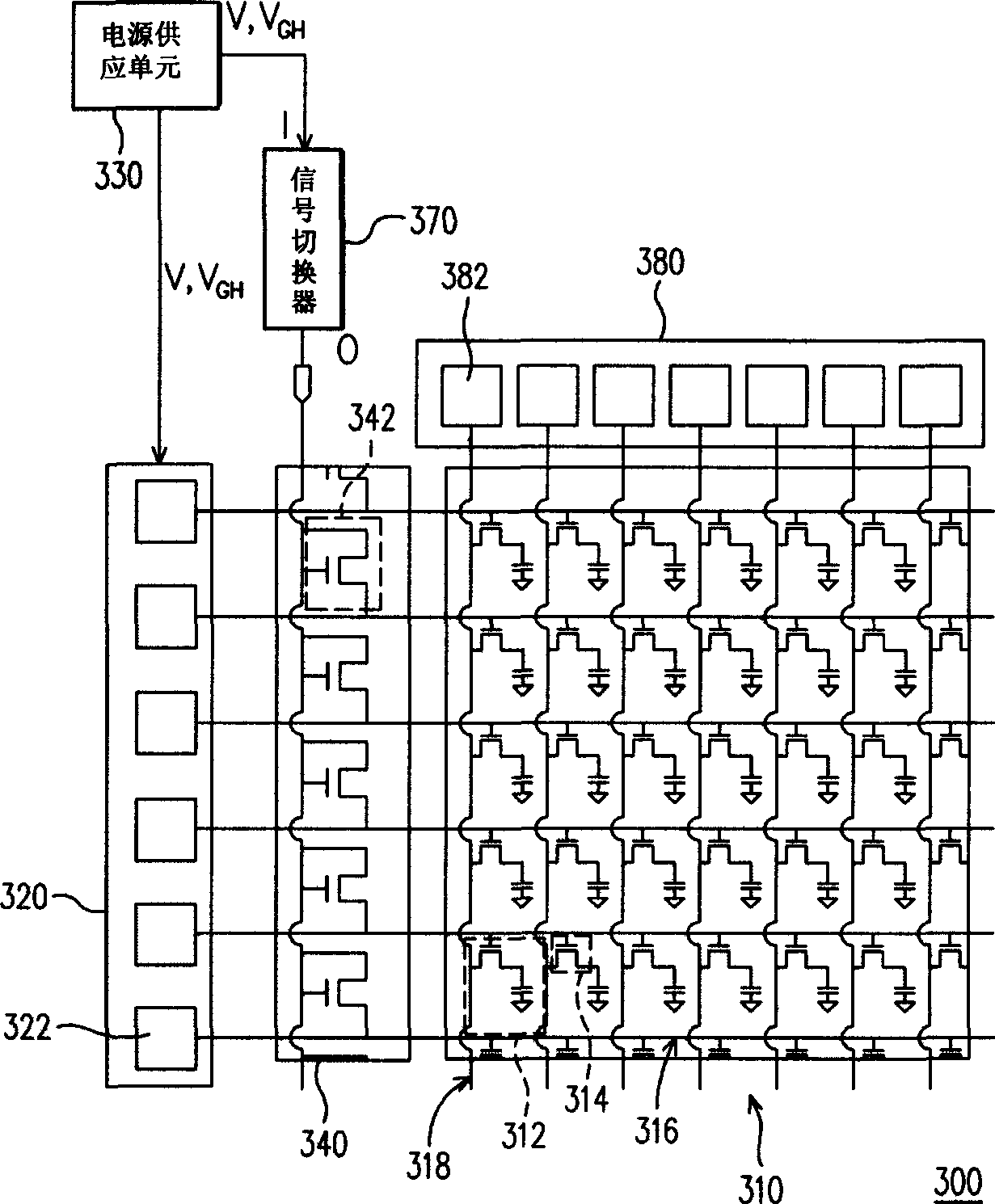

LCD and method for improving its ghost phenomenon

InactiveCN1845233AAvoid image stickingNo increase in workloadCathode-ray tube indicatorsLiquid-crystal displayEngineering

A method of improving the afterimage phenomena for LCD is suitable for improving the afterimage phenomena produced after the LCD is shut off. The LCD consists of grid driver element, control circuit and pixel array, in which the said control circuit and grid driver element individually are coupled on the pixel array, moreover, when the LCD is shut on, the control circuit is shut off. The method activates the control circuit to get the control circuit to activate the pixel array to discharge when the LCD is shut off, then eliminates the charges remained in the pixel array to avoid the afterimage phenomena when LCD is shut off.

Owner:CHUNGHWA PICTURE TUBES LTD

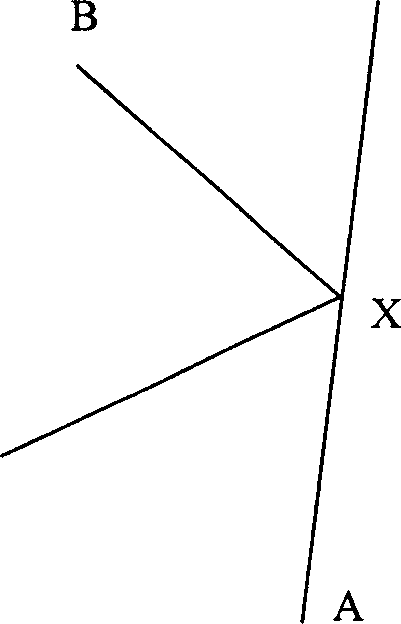

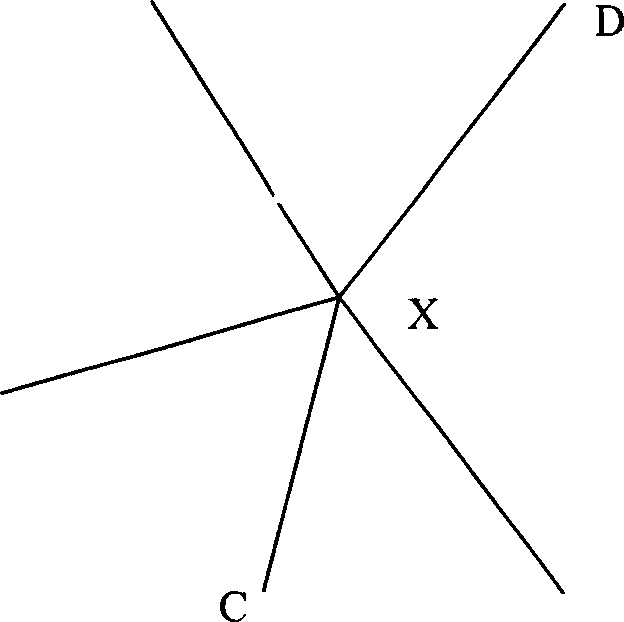

Speech sound guiding method of vehicle satellite guiding system at complex road intersection

InactiveCN1493851ASolve the problem of voice promptsNo increase in workloadInstruments for road network navigationSatelliteReal-time computing

A speech navigation method of the vehicle's satellite navigation system for the complex cross of road includes inputting the start position and destination to the system by user, choosing the optimal path on a digital navigatino map, receiving GPS signals to determine the current position on said digital map, and speech prompting of the running direction at complex cross when the distance threshold of speech prompting reaches.

Owner:深圳市易凯数码有限公司

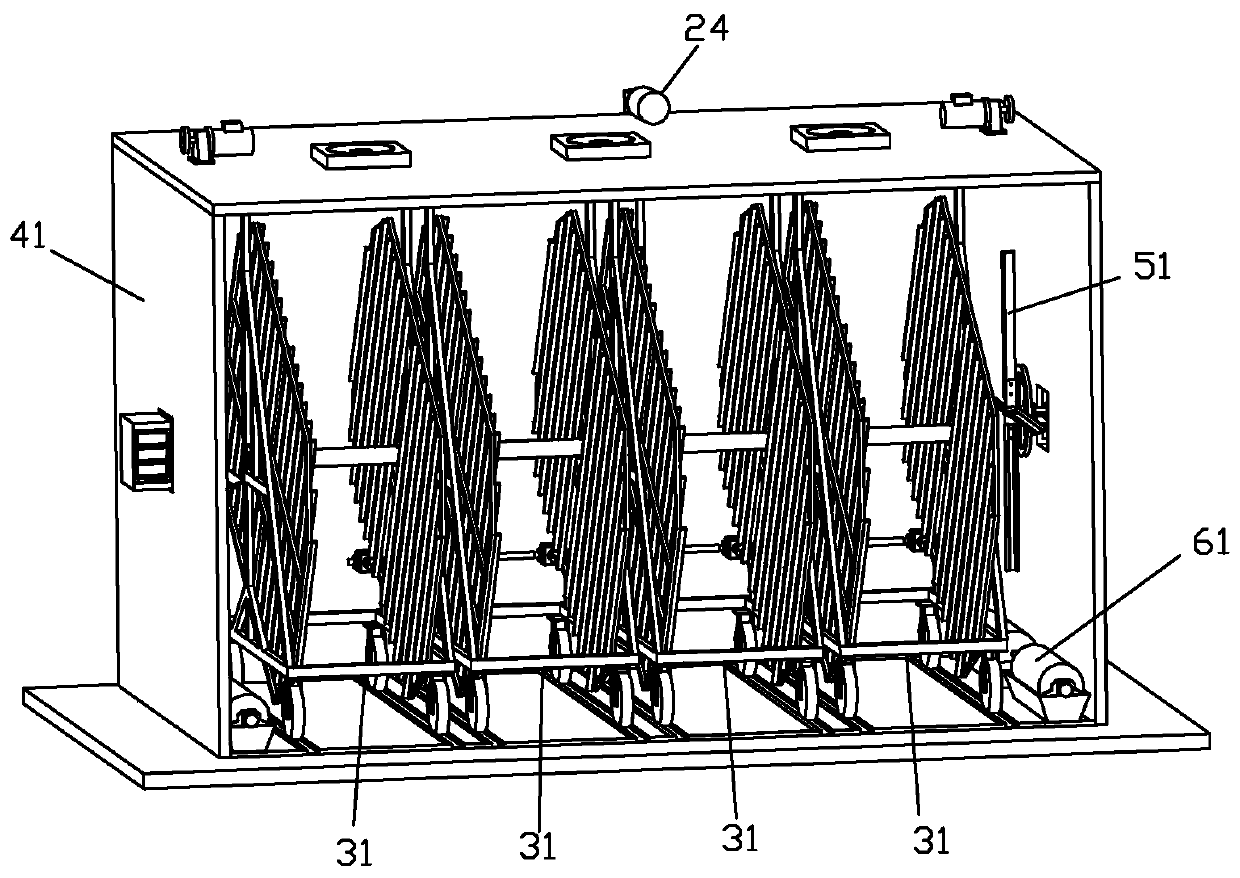

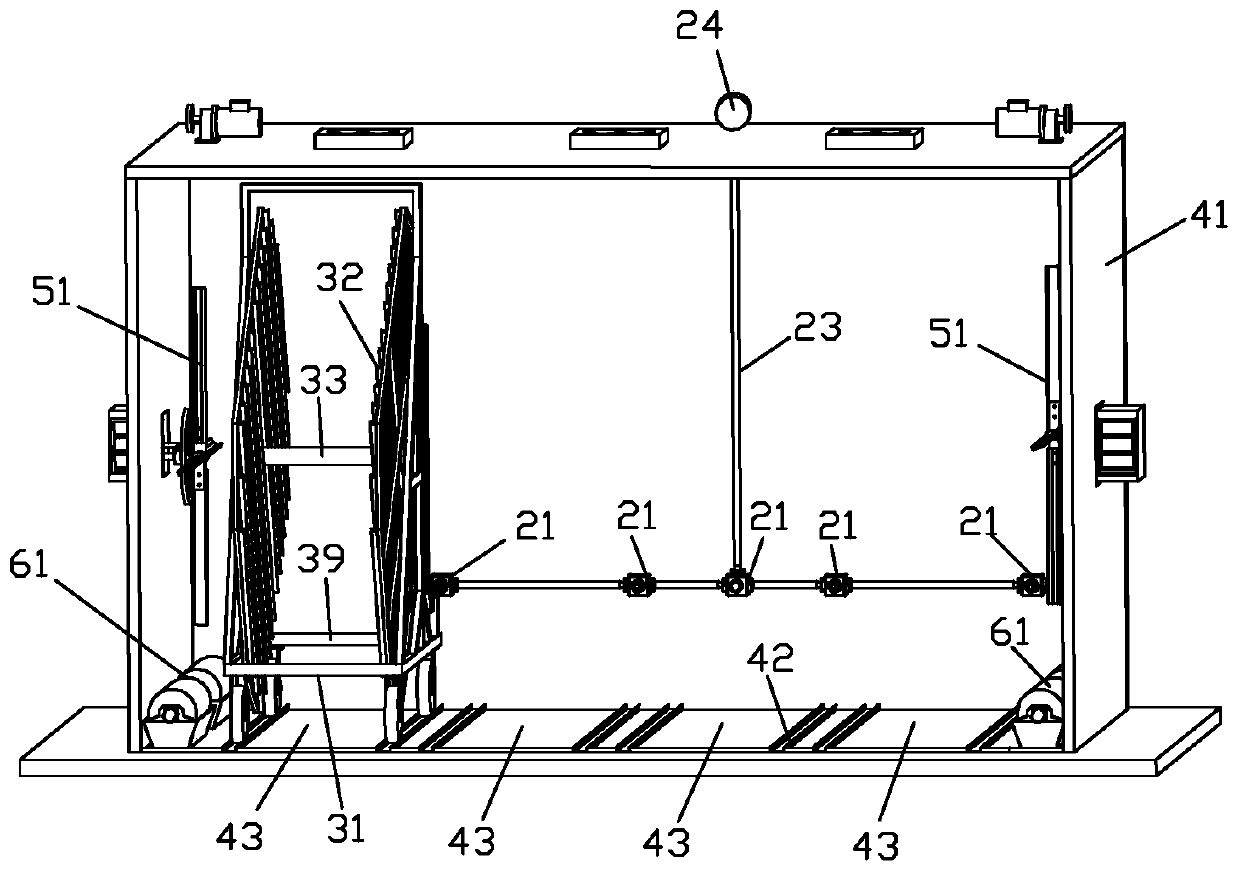

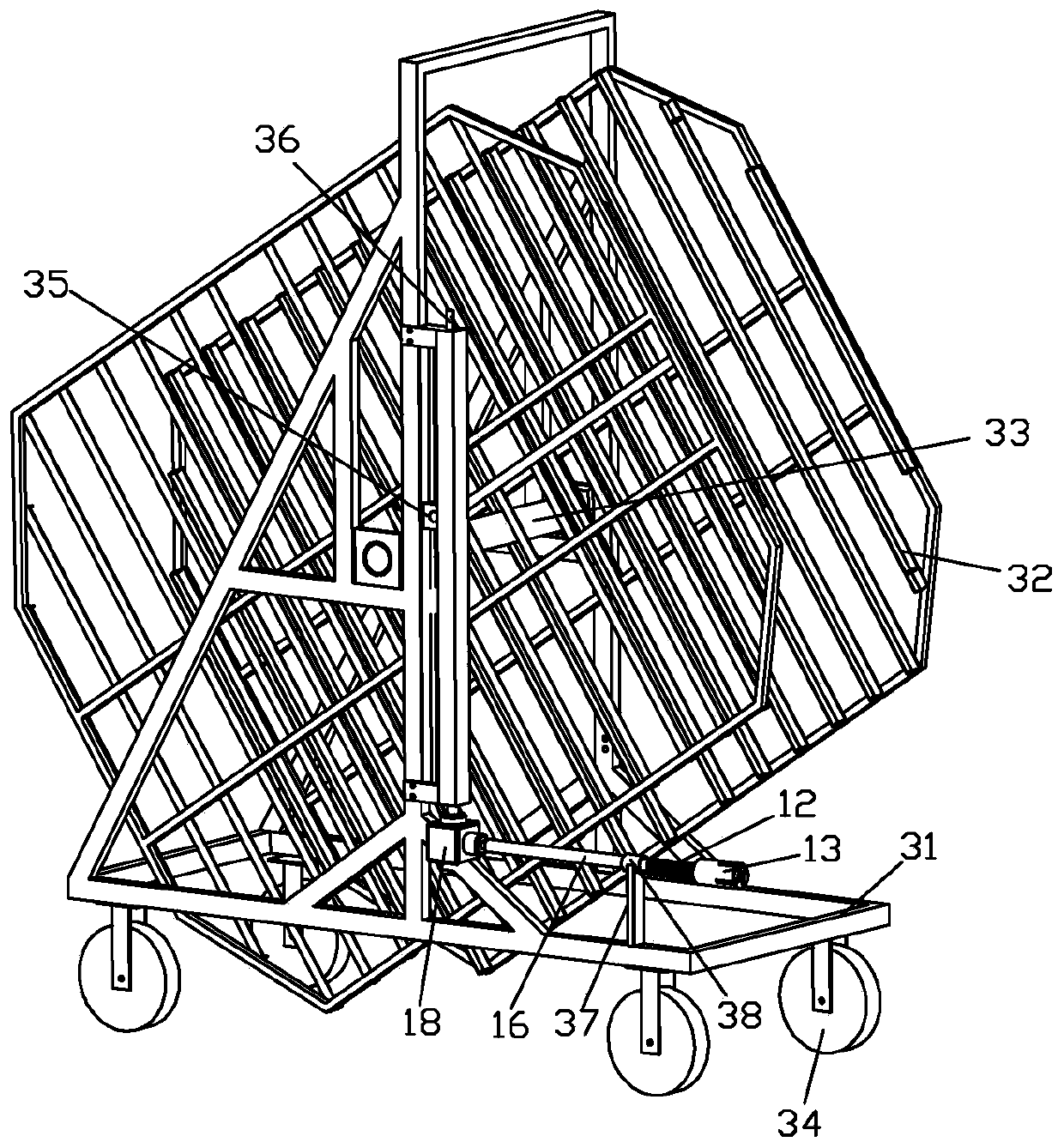

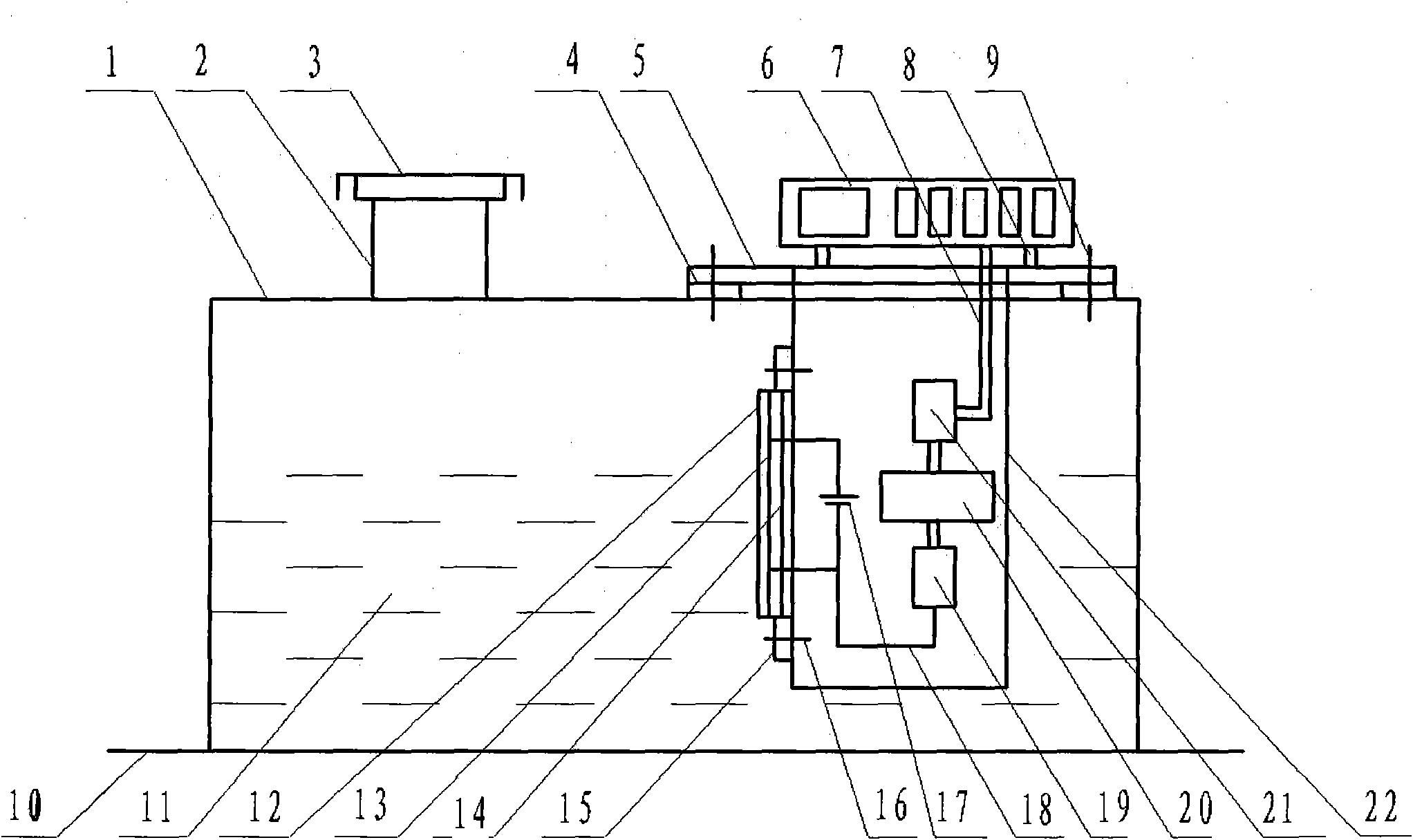

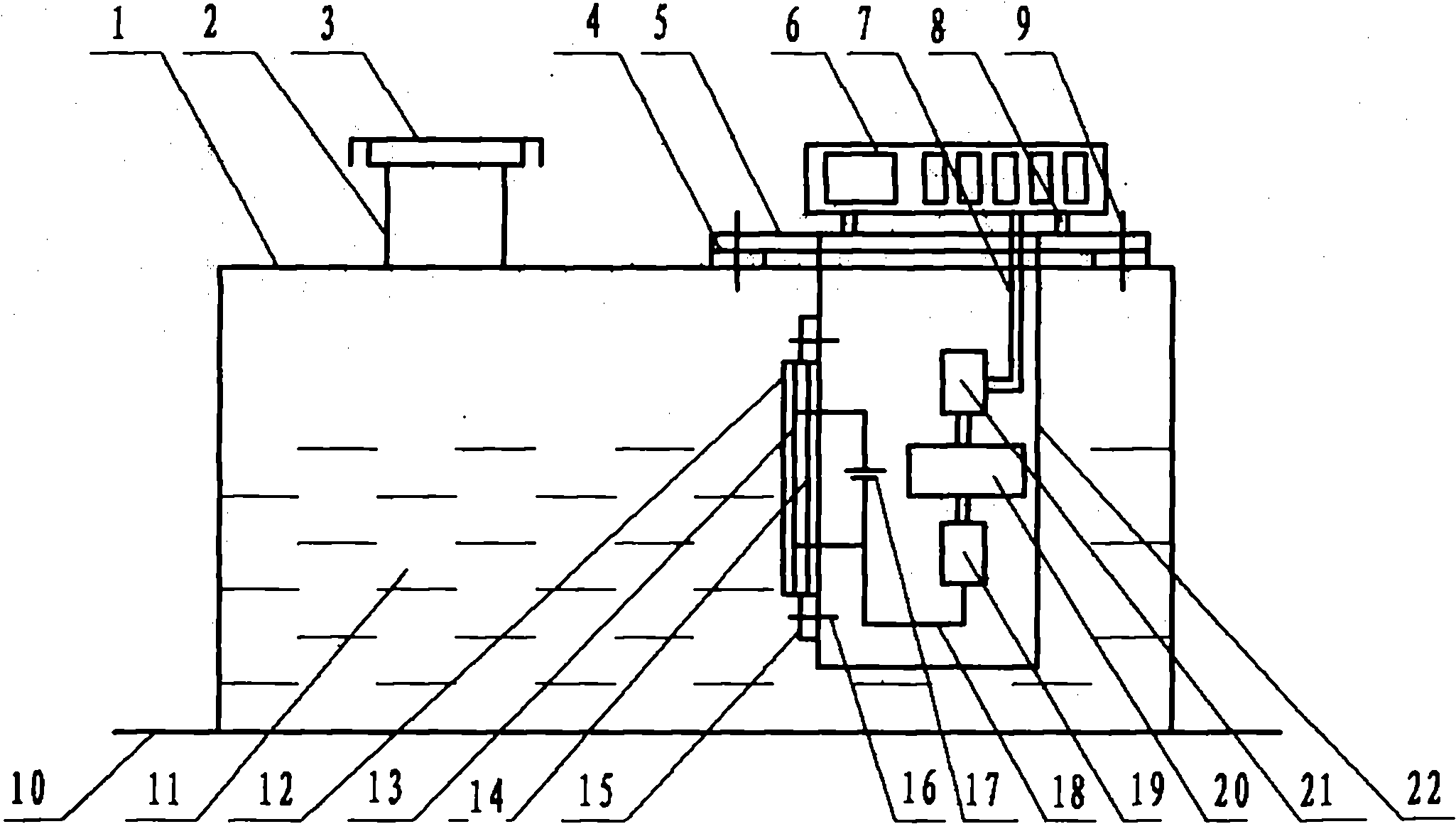

Movable egg car hatcher

The invention discloses a movable egg car hatcher which comprises an incubator, a hatching adjustment system, at least one egg rack, at least one movable egg car, a power source and a transmission shaft component. The egg racks are erected on the corresponding movable egg cars in a suspended manner through rotating spindles, transmission mechanisms are arranged on the movable egg cars, parking spaces corresponding to the movable egg cars are arranged in the incubator, both the transmission shaft component and the power source are fixedly mounted on the incubator, the power source is connectedwith an input shaft of the transmission shaft component, the transmission shaft component is provided with output shafts corresponding to the parking spaces, a fixed butt joint part is arranged at theend of each output shaft, a butt joint shaft connected with the transmission mechanism of each movable egg car is arranged on each movable egg car, and a movable butt joint part is arranged at the end of each butt joint shaft. The movable egg car hatcher is reasonable in structure and simple to operate.

Owner:佛山市任氏机械科技有限公司

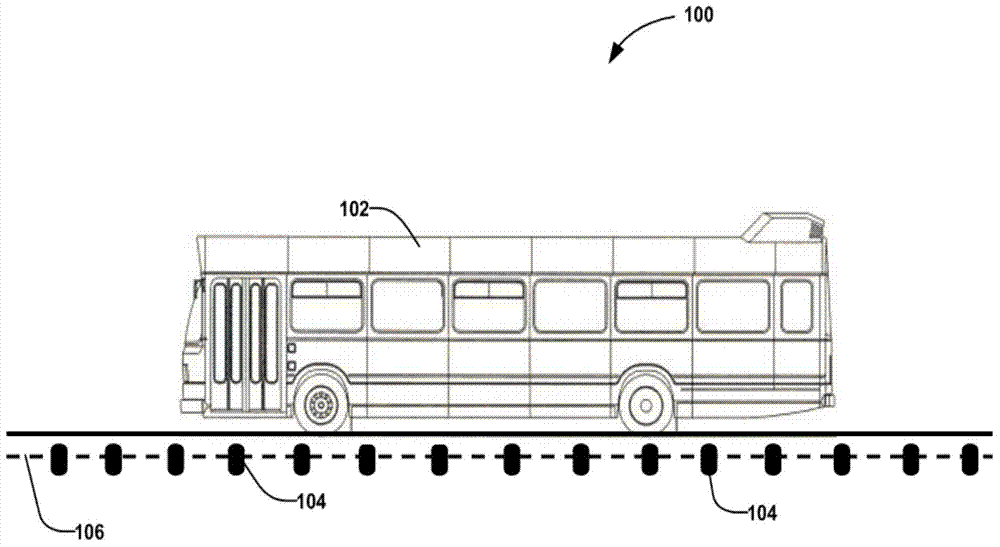

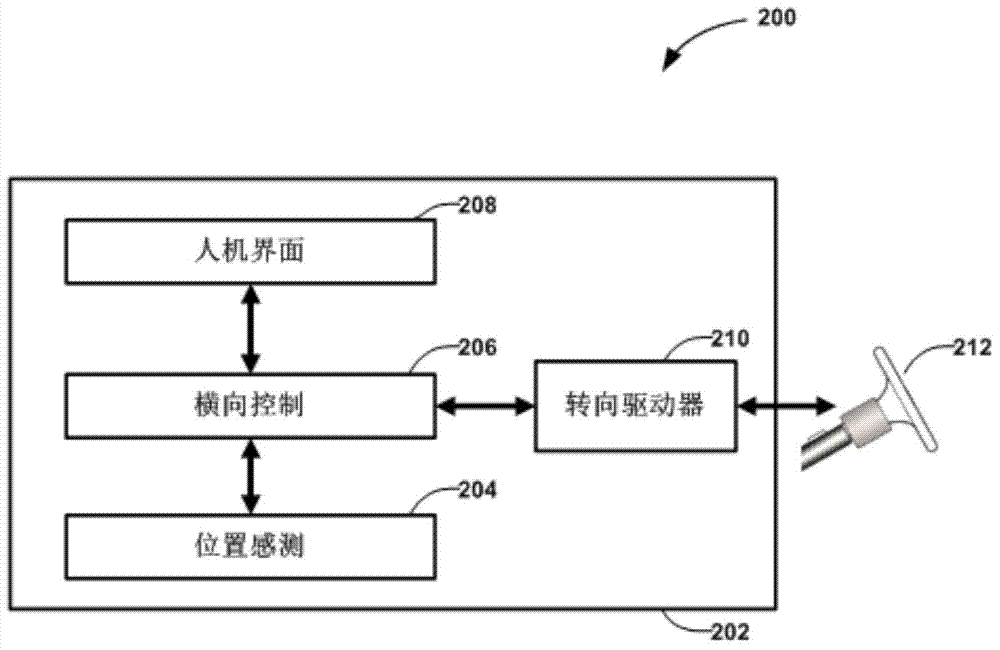

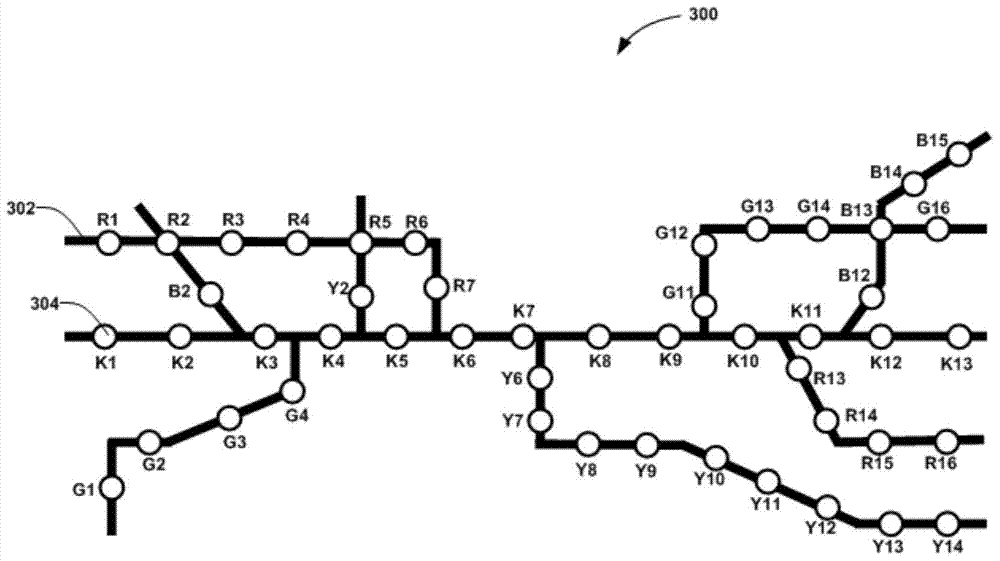

Travel route planning and managing method of intelligent bus system

InactiveCN104298236ANo increase in workloadPassenger flow needs metRoad vehicles traffic controlPosition fixationRoad crossingRoute planning

The invention provides a travel route managing method for an electronic navigation bus capable of following an electronic track automatically. The method comprises the steps of receiving a distributed travel route from a bus dispatching system, obtaining related road crossing information according to the distributed travel route, obtaining a current position of the electronic navigation bus, identifying a road crossing where the bus is located according to the current position of the bus and the road crossing information, and setting the track along which the bus needs to follow according to a main track of the identified crossing. The method can be used for developing an intelligent traffic system. A dispatching processor of the system can estimate the passenger traffic demand according to travel route information of passengers, arrange multiple travel routes based on the estimated passenger traffic demand, generate a bus number dispatching time table for each travel route, distribute a travel route bus number to the electronic navigation bus, and transmit the distribution to the distributed electronic navigation bus through communication equipment.

Owner:TOMORROWS TRANSPORTATION TODAY

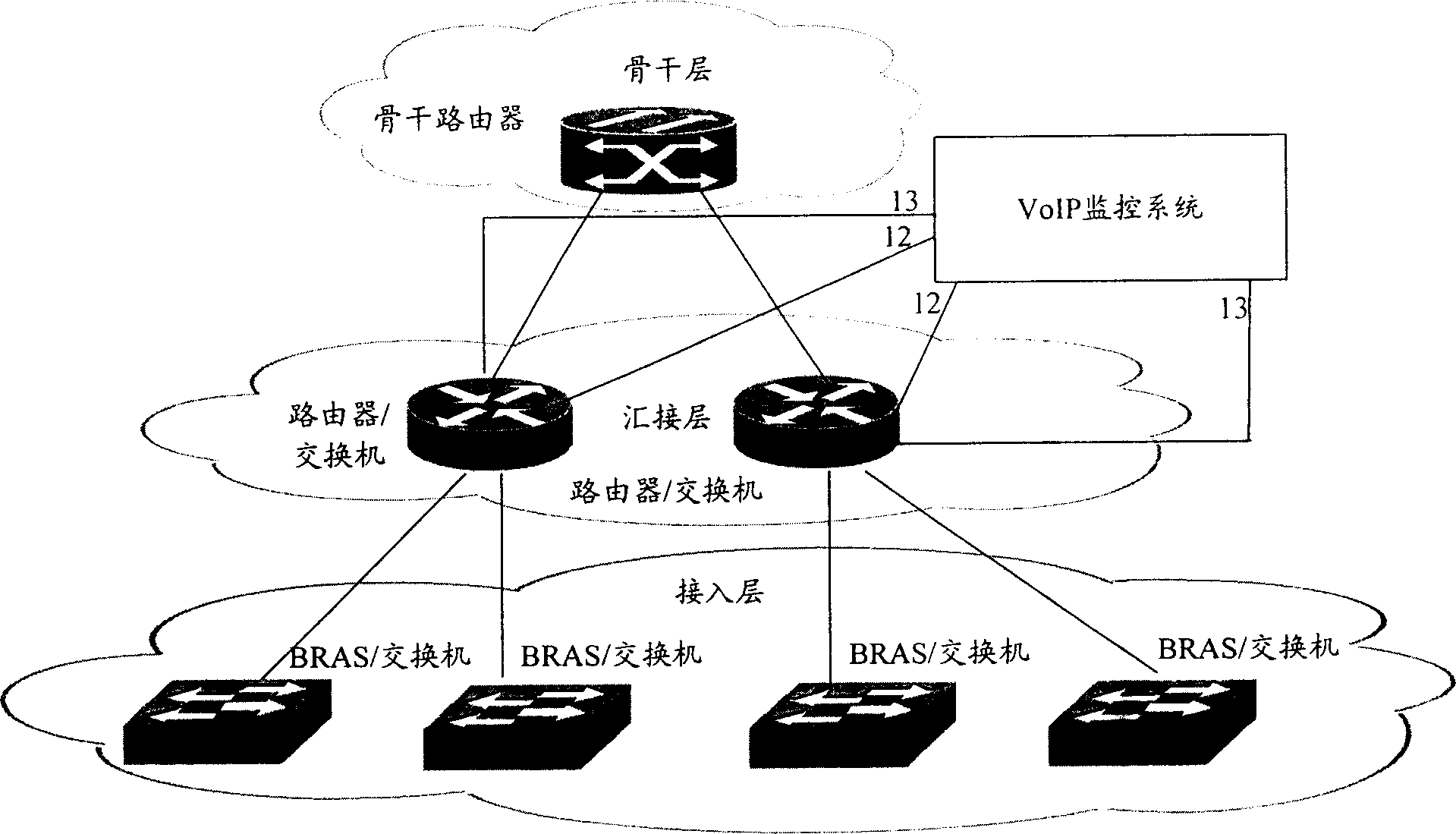

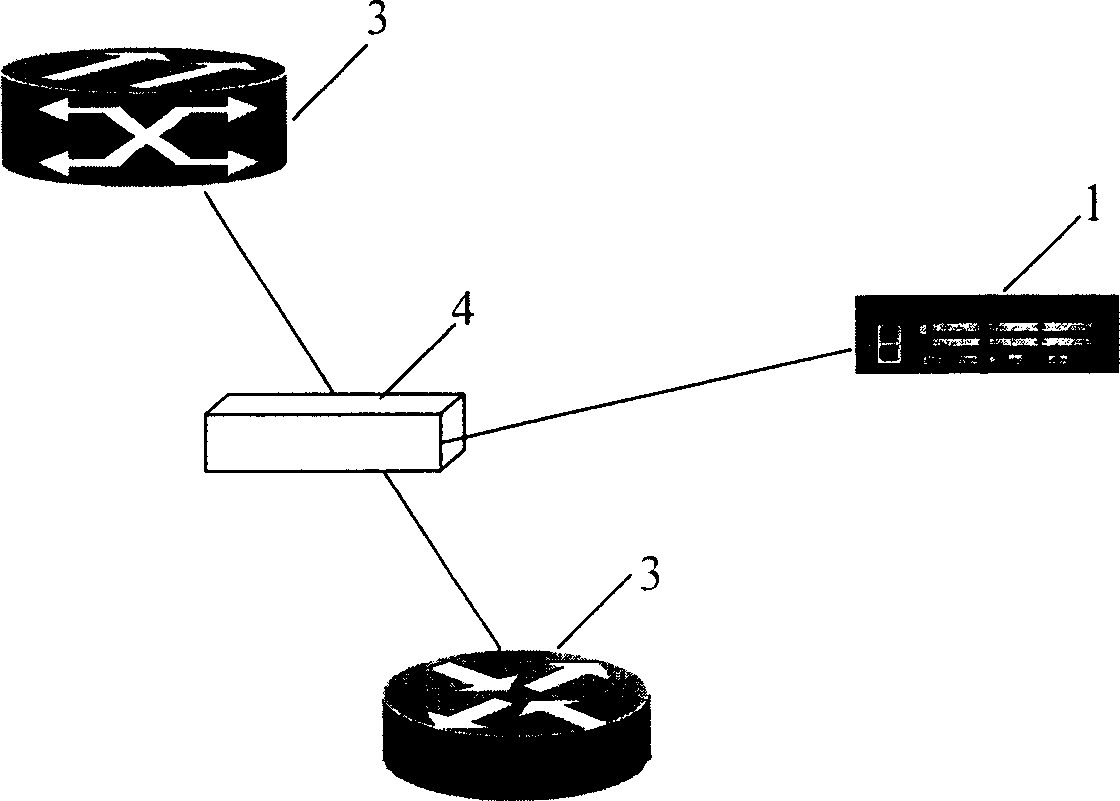

Monitor system and its monitor method for internet network telephone

ActiveCN1750488ASolve monitoring problemsRealize the purpose of value preservation and income generationData switching networksTraffic volumeTraffic capacity

A monitor system for network telephone, which contains one or plurality of VoIP monitor equipment and VoIP monitor centralized platform, the former sampling data stream of network equipment, analyzing VoIP flow, sending analyzed result to VoIP centralized platform and monitoring VoIP flow according to strategy sent from centralized platform, the latter including database, Web service software unit and monitor strategy software unit, adopting expandable customized protocol to communicate with VoIP monitor equipment, monitoring and controlling the data stream among each network equipment and main layers of network tandem layer. Said invention has simple structure and easy operation without complicate configuring to router or exchanger.

Owner:CHINA TELECOM CORP LTD

Mixed milk replacer and preparation method thereof

InactiveCN103750068AReduce wasteNo increase in workloadAnimal feeding stuffFood shapingAmylaseCalcium formate

The invention discloses a mixed milk replacer and a preparation method thereof; the mixed milk replacer comprises the following raw materials in parts by weight: 16-20 parts of hulled corn, 15-20 parts of extruded corn, 6-10 parts of flour, 3-5 parts of white fish meal, 4-8 parts of debarked bean pulp, 2-5 parts of chyle fat powder, 2-3 parts of fermented bean pulp, 5-10 parts of whey powder, 3-6 parts of milk powder, 1-3 parts of white sugar, 2-3 parts of glucose, 0.4-0.5 part of monocalcium phosphate, 0.012-0.015 part of calcium formate, 0.01-0.03 part of high-temperature protease, 0.2-0.5 part of amino acid, 2-5 parts of thermostable amylase and culture thereof, 0.04-0.06 part of decavitamin and 0.2-0.6 part of compound microelements. The raw materials are mixed after being prepared to have the particle diameters of 2.0-3.0 mm and 10-15 mm; the mixed milk replacer pays attention to weak piglets and healthy piglets, reduces the feed waste, improves the food calling capacity and the food consumption, modifies the daily gain, and reduces the phenomena of negative gain and growth retardation caused by the weaning stress.

Owner:LIAONING WELLHOPE AGRI TECH

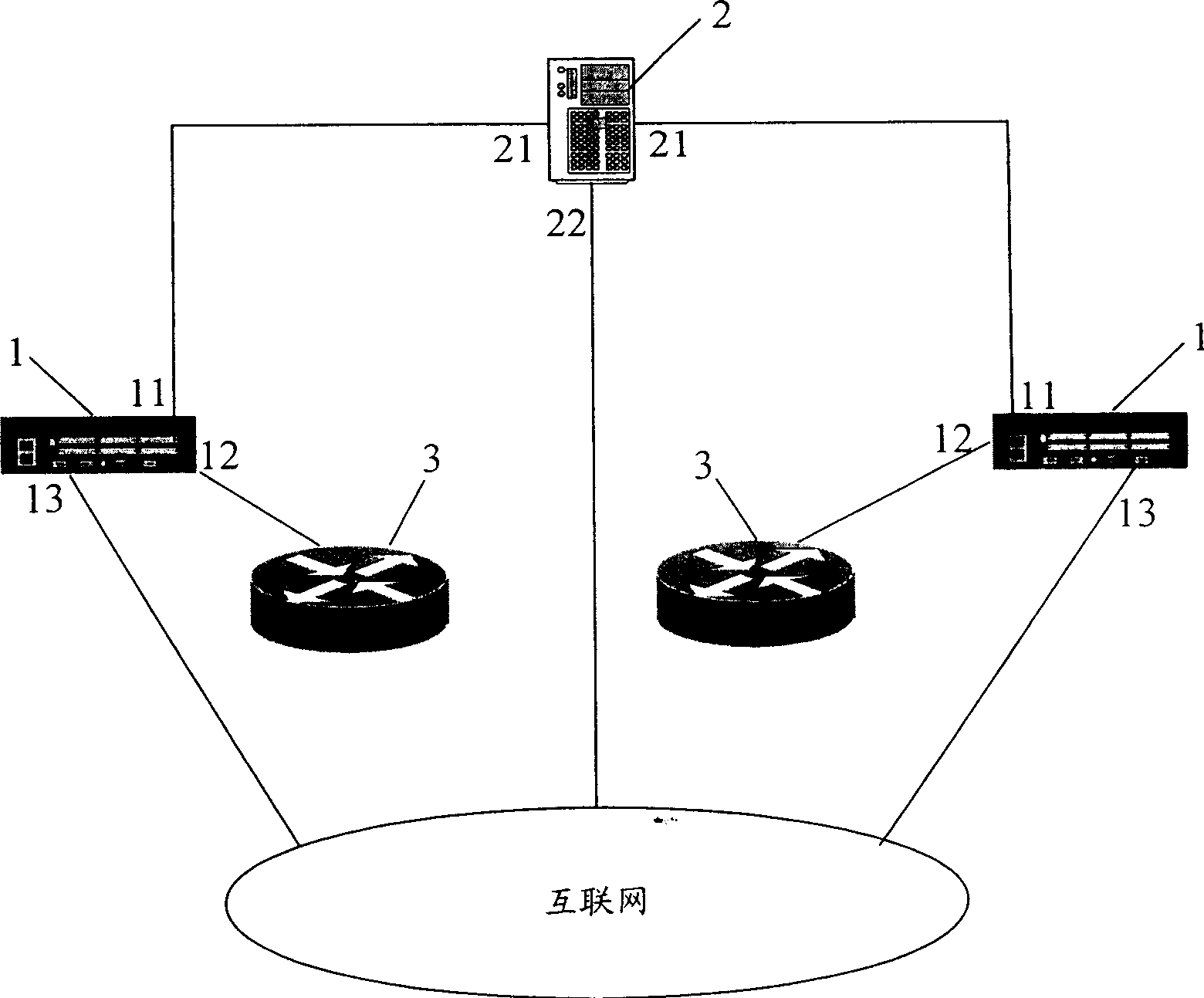

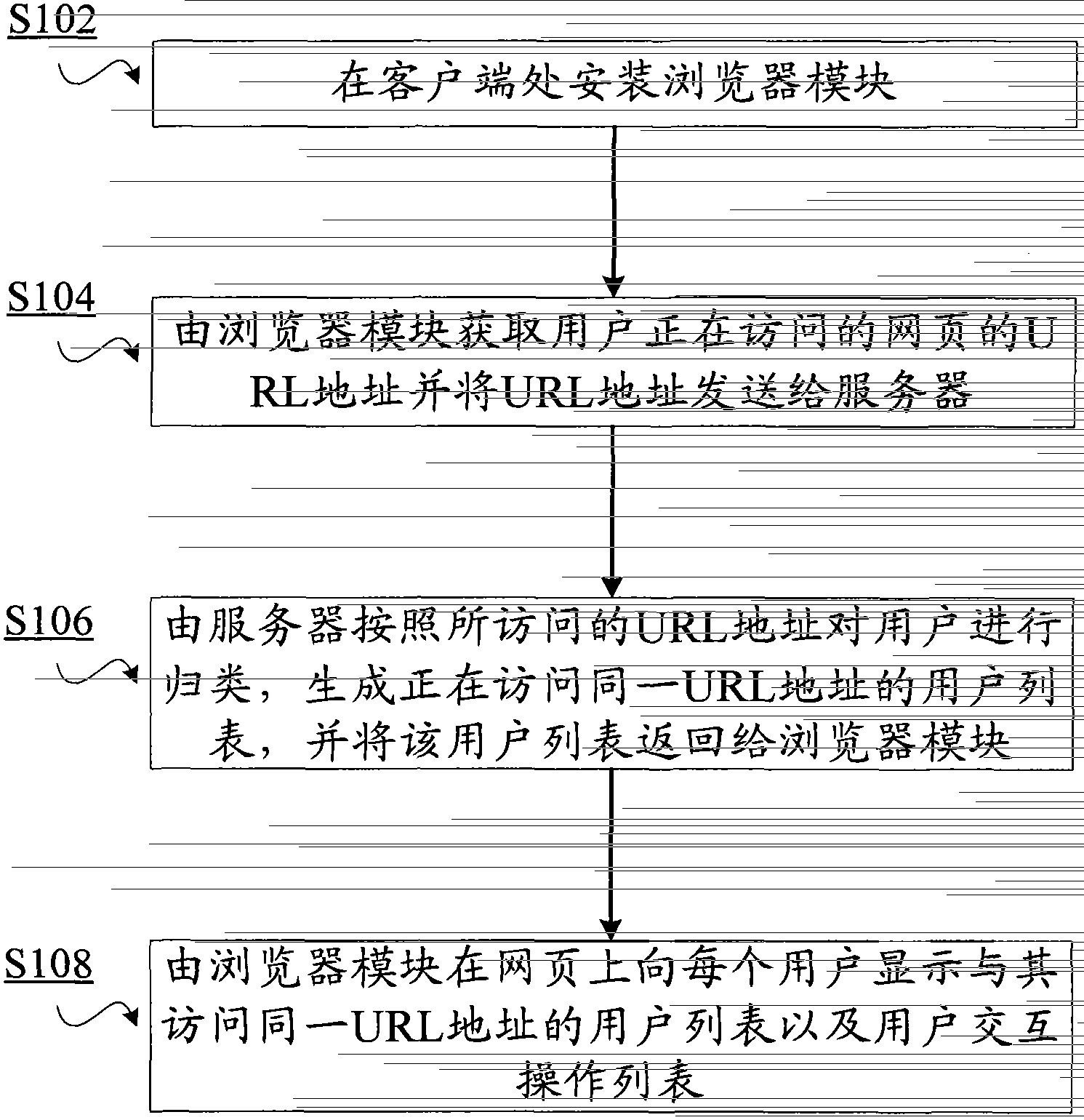

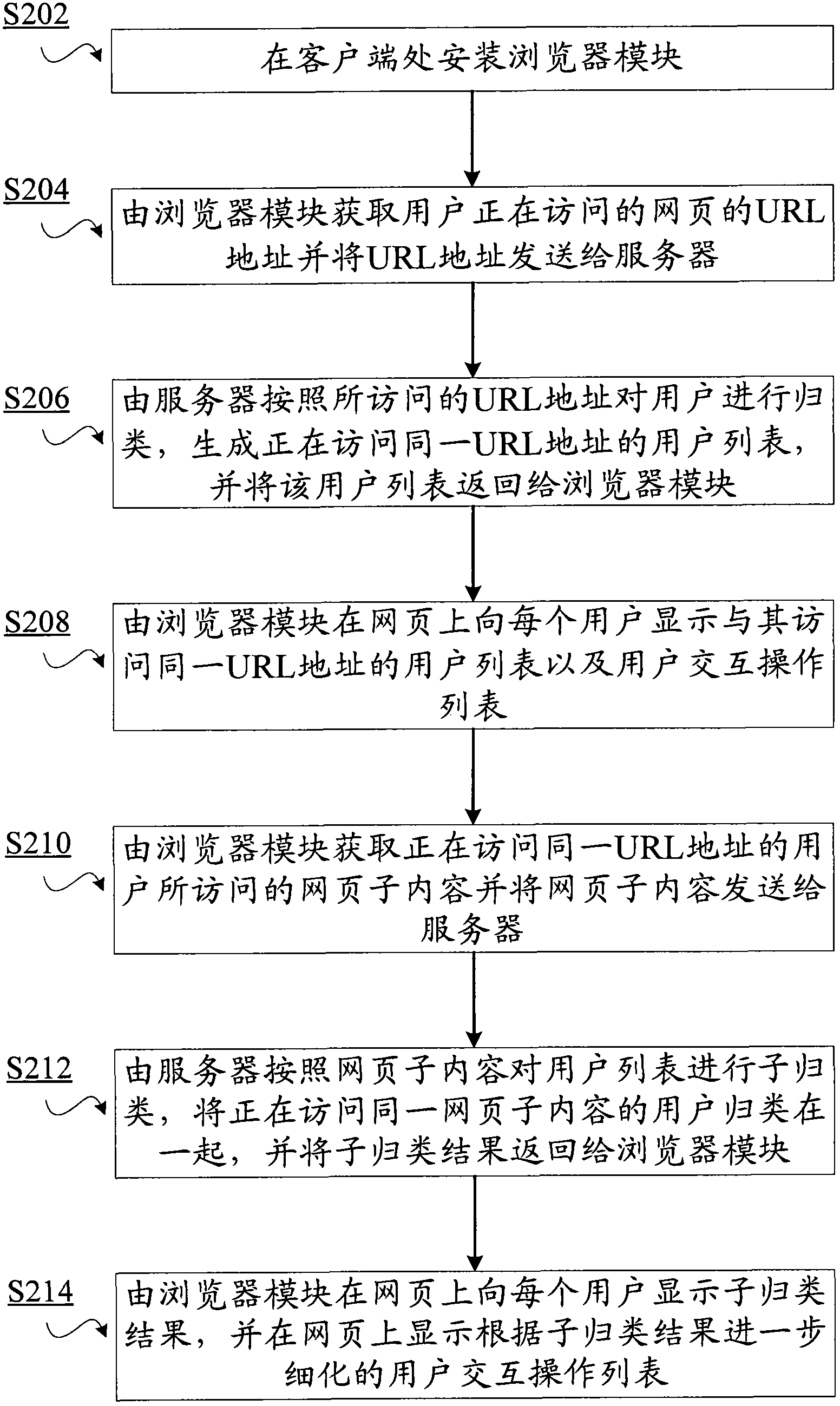

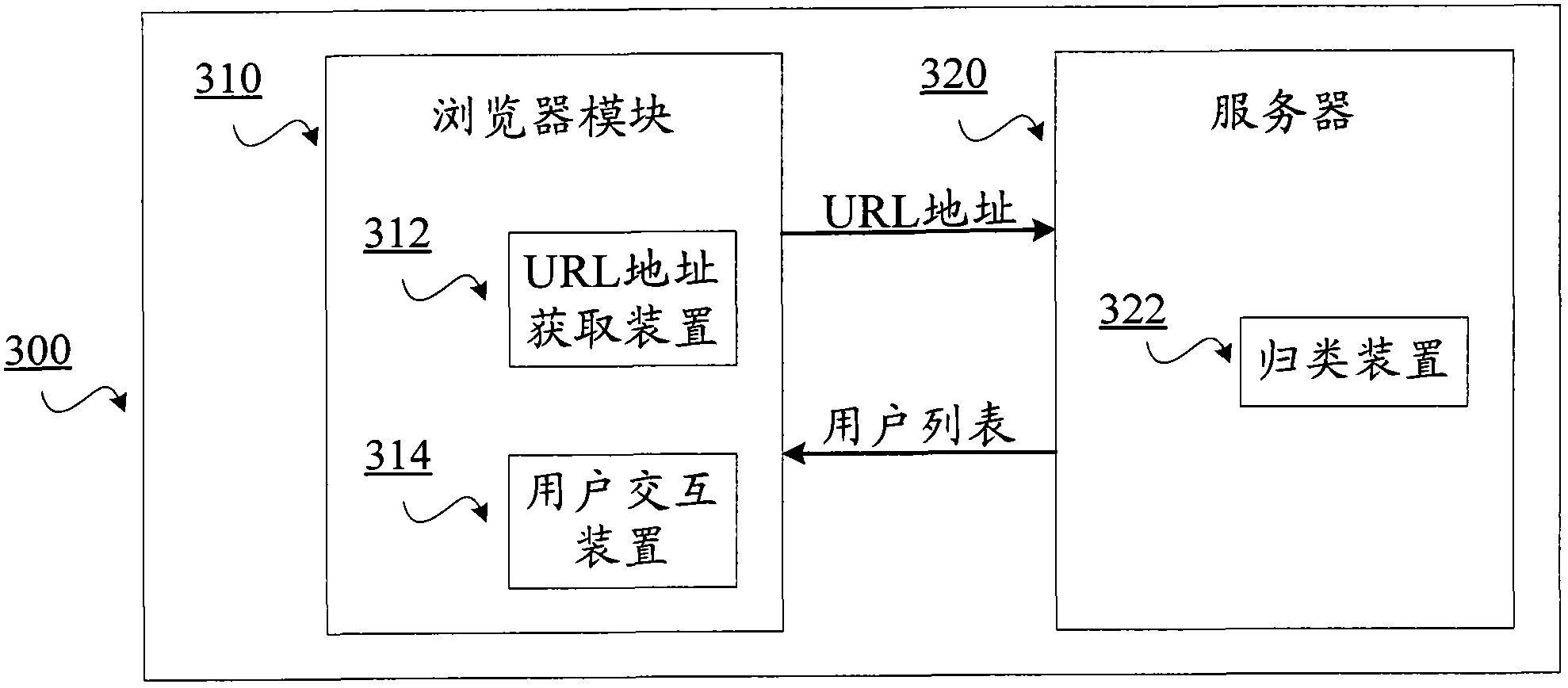

User interacting method and system based on browser module

The invention relates to a user interacting method and system based on a browser module. The method includes that the browser module is arranged at the client position; the browser module obtains an uniform resource locator (URL) of a webpage being accessed by a user and sends the URL to a server; the server sorts the user according to the accessed URL, generates a list of users accessing the same URL and returns the list of the users to the browser module; the browser module displays the list of the users accessing the same URL and a user interacting operation list to each user on the webpage, and the user interacting operation list shows which interaction each user can conduct with other users in the list of the users. By means of the user interacting method and system based on the browser module, any webpage with a fixed URL can be used as a topic to build a forum and provide chatting service, and friend gathering based on interests can be built fast.

Owner:BEIJING OAK PACIFIC NETSCAPE TECH DEV

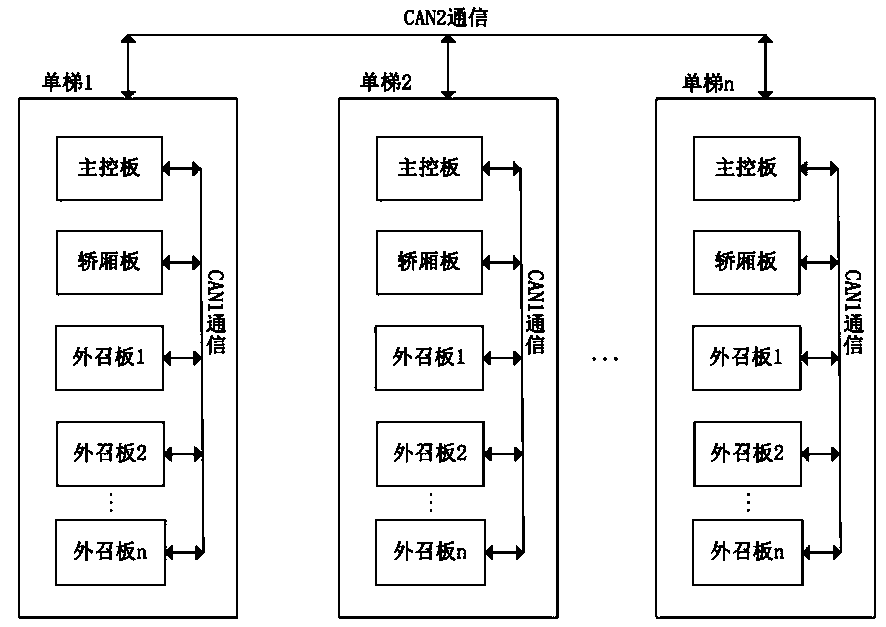

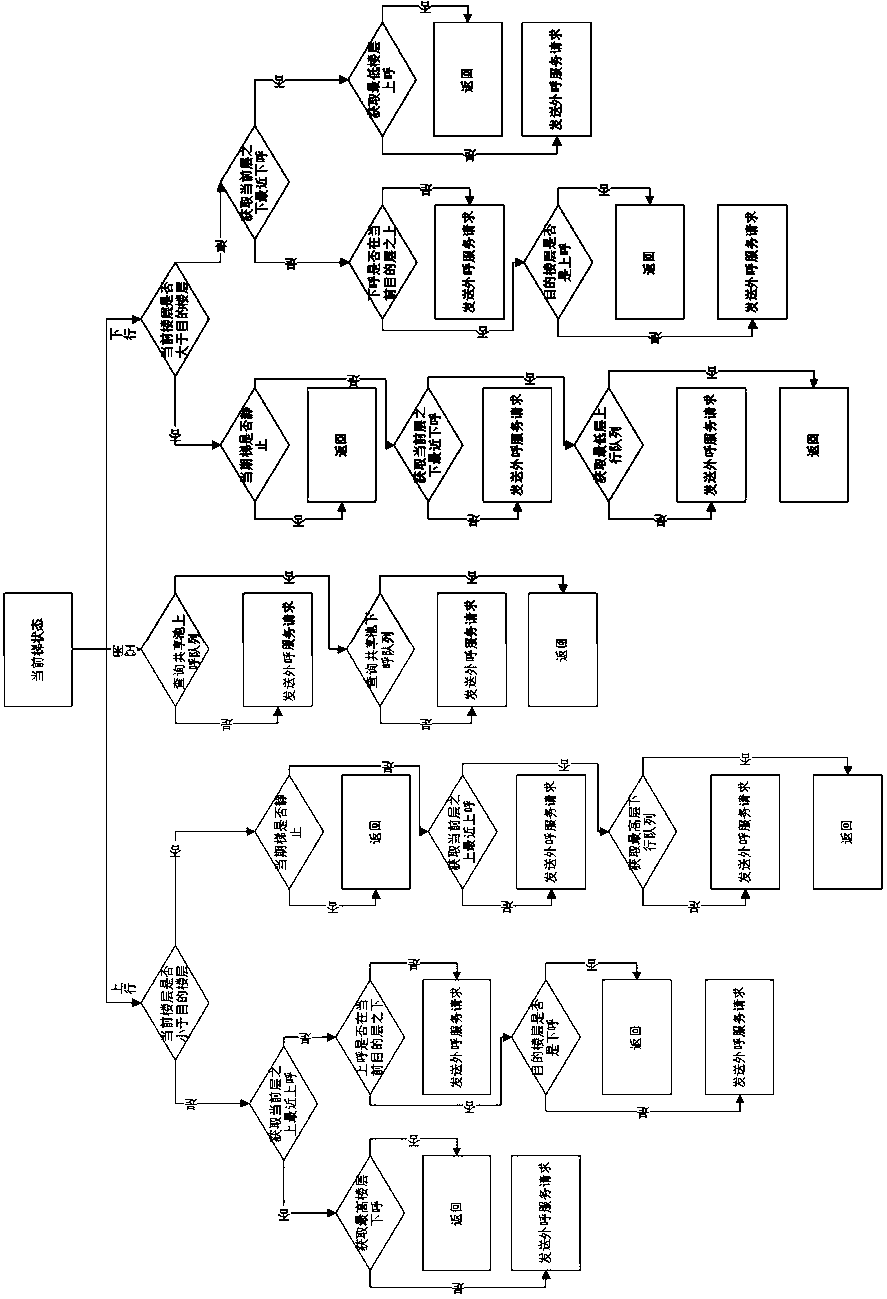

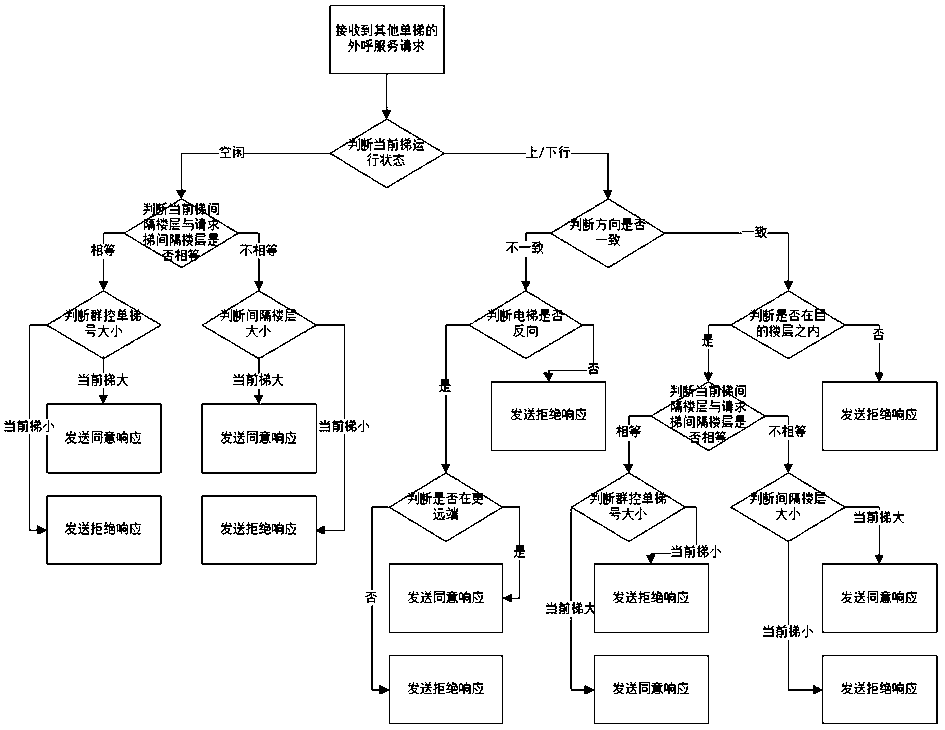

Elevator group control method

The invention discloses an elevator group control method. A storage area used for storing all outbound requests which are not served in a whole group control system is arranged in a main control panel of each elevator to form a group control outbound shared pool, and the main control panels of all the elevators are connected through a second communication circuit. The elevator group control method includes the following steps: (1) building an elevator group; (2) the outbound service requests sent by outbound boards are added to the group control outbound shared pool of each elevator after being received; (3) polling group control is carried out by the main control panels of the elevators on outbound service request queues in the outbound shared pools in real time, and the main control panels of the elevators send group control outbound service request instructions; and (4) loopback group control outbound service request response instructions of other elevators are collected, whether the outbound service requests succeed is determined, and if the outbound service requests succeed, the group control outbound service requests are completed. According to the elevator group control method, the concept of a 'leader' is abandoned, the concept of the 'group control outbound shared pools' is introduced, all the elevators compete freely to acquire the outbound requests, task load statistics are balanced, and the optimal outbound allocation is achieved.

Owner:SUZHOU UNIV

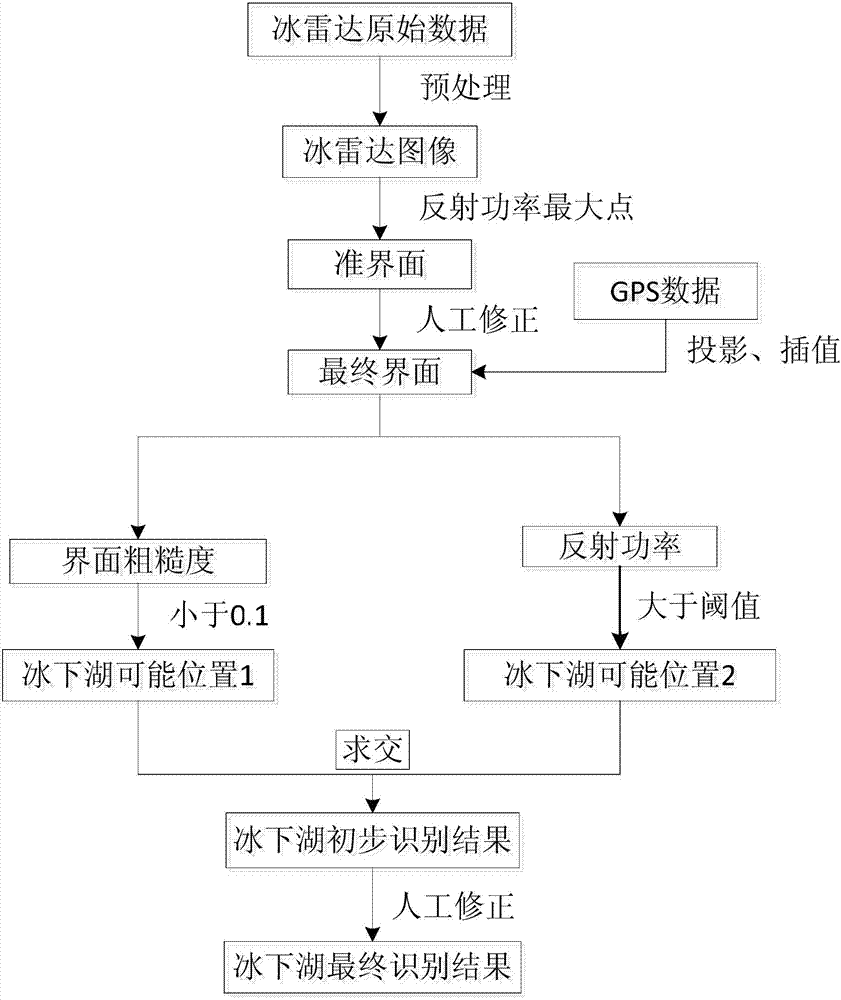

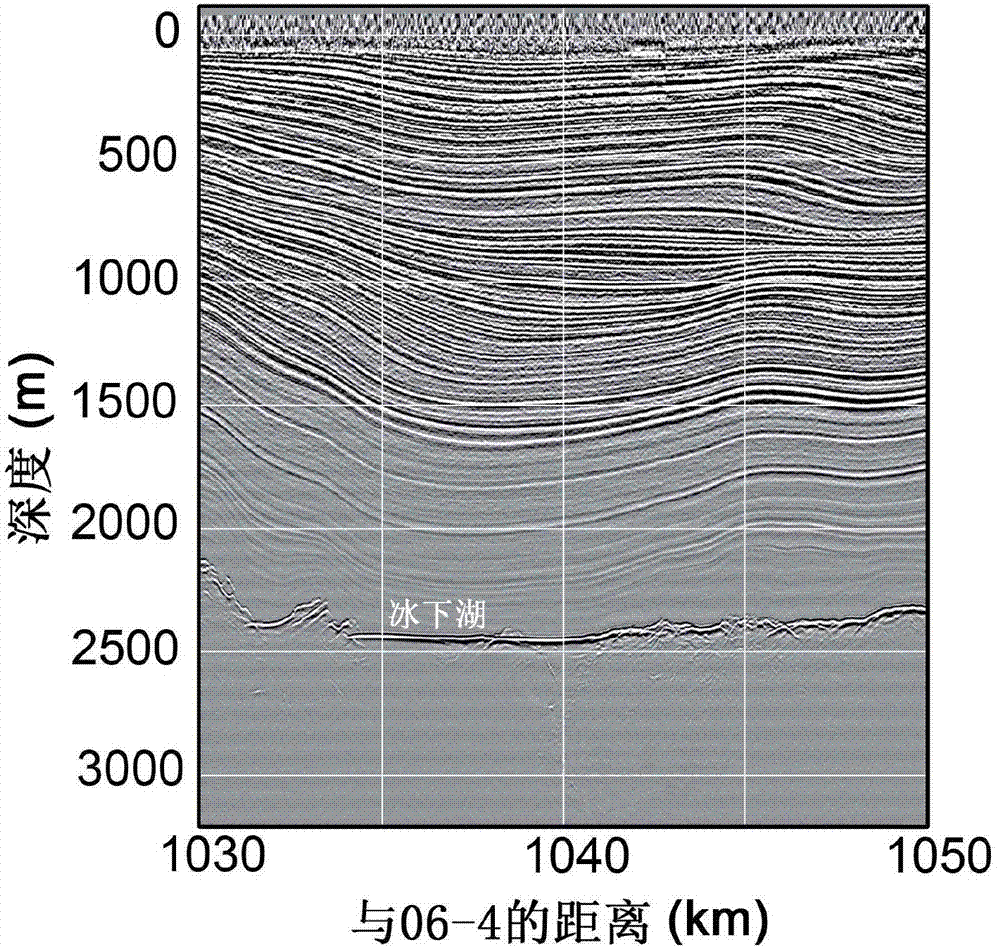

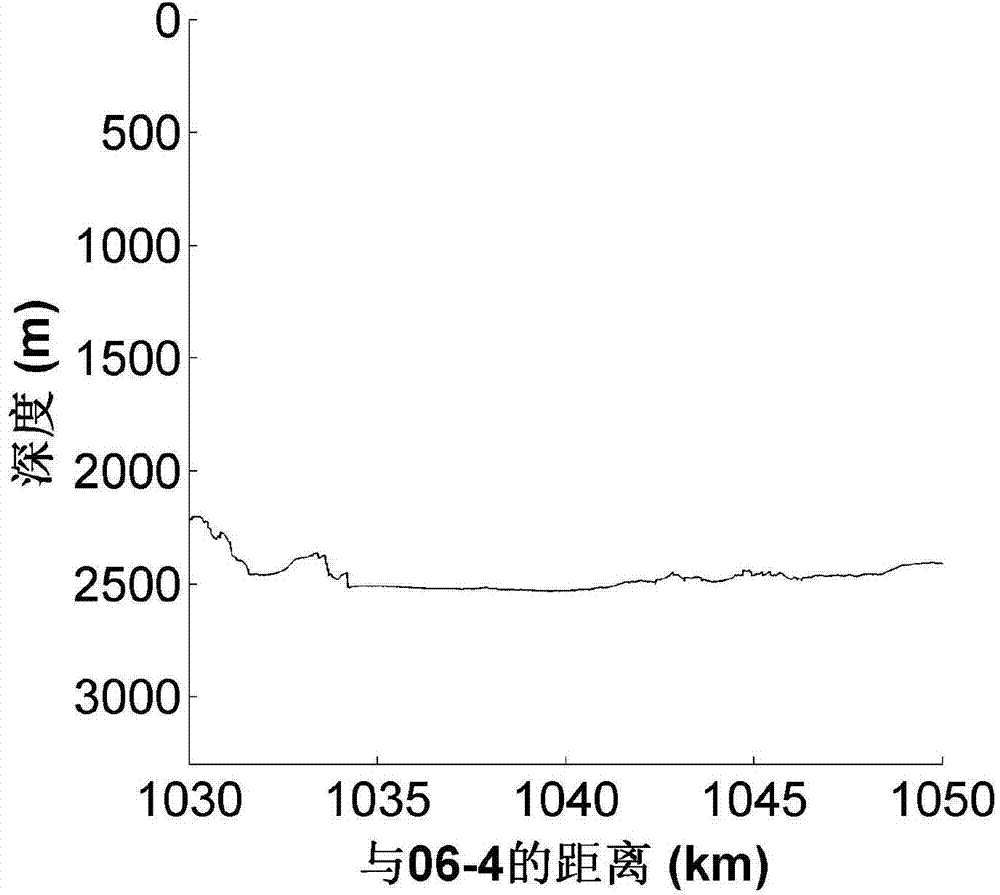

Semi-automatic antarctic subglacial lake recognition method based on ice radar technology

InactiveCN103487804AGuaranteed uniformityThe result is objectiveRadio wave reradiation/reflectionSubglacial lakeWorkload

The invention relates to a semi-automatic antarctic subglacial lake recognition method based on an ice radar technology. The semi-automatic antarctic subglacial lake recognition method based on the ice radar technology has the advantages that in consideration of the characteristics that the interface between a subglacial lake and ice on an ice radar fracture surface image has high echo signal intensity and is flat, the initial computer recognition of a subglacial lake surface is realized by using an automatic extraction method in which the surface roughness and the radar reflection power are combined, so that the recognition efficiency and the recognition accuracy are greatly improved; the location of a subglacial lake is corrected through manual modification, no excessive workload is increased, errors caused by automatic extraction can also be made up, so that the final recognition result is relatively accurate, and the speed and the reliability are relatively high.

Owner:NANJING UNIV

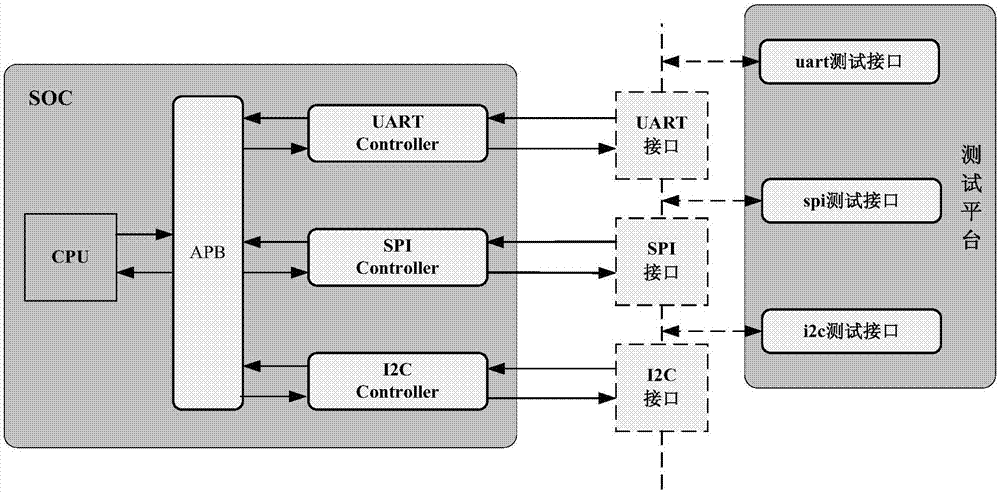

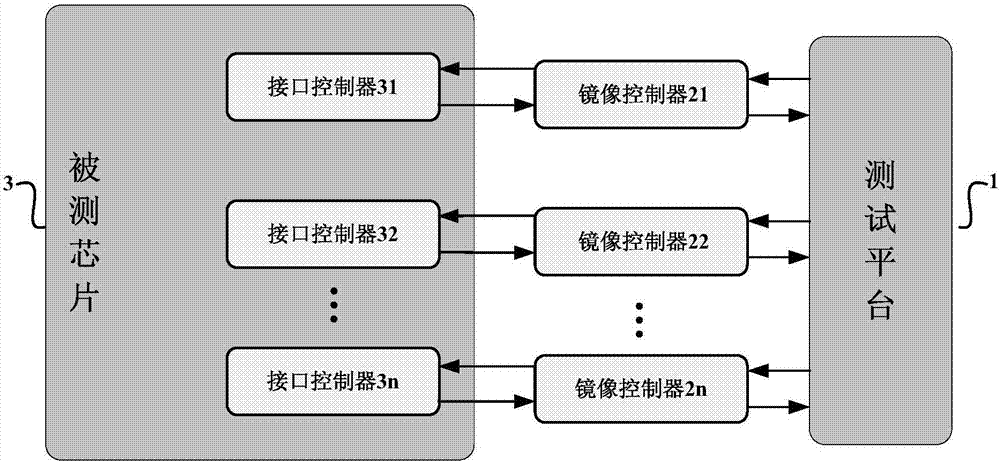

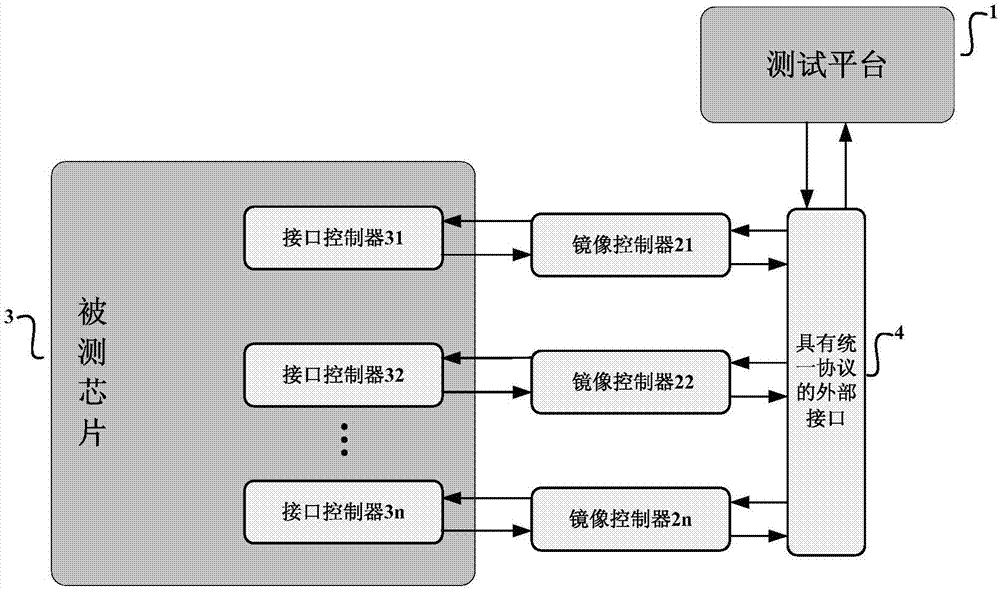

Verification method and verification system for interface controller

ActiveCN107341083AImprove verification efficiencyTiming is simpleFunctional testingVerification systemData validation

The invention discloses a verification method and a verification system for an interface controller. The method comprises the steps of when any interface controller in a chip to be tested is verified, sending generated initial test data to a mirror image controller corresponding to the interface controller by using a simple drive program, triggering the mirror image controller to perform data format conversion on the initial test data to acquire first test data, and sending the first test data to the tested chip; receiving fourth test data returned by the mirror image controller, wherein the fourth test data is acquired through performing data format conversion on third test data by the mirror image controller, and the third test data is acquired through further performing data format conversion on second test data by the interface controller in the tested chip; comparing the initial test data with the fourth test data; and determining a verification result of the interface controller according to a comparison result. Therefore, the interface controllers with different protocols can be verified by using the data with simple protocols.

Owner:北京东土军悦科技有限公司 +1

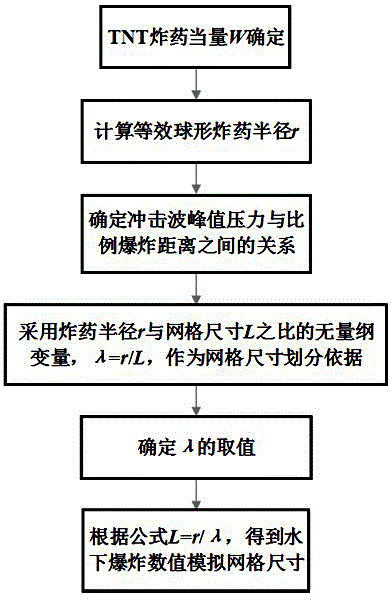

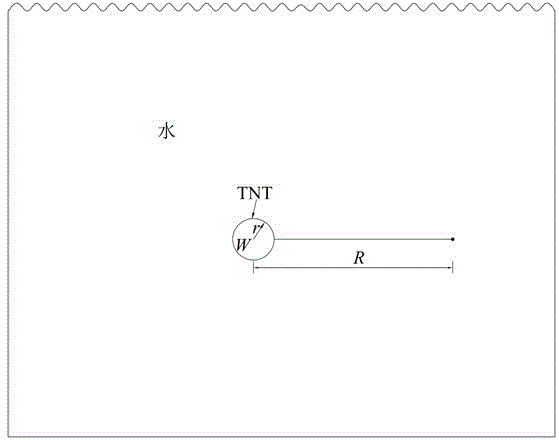

Method for determining grid sizes for underwater explosion numerical simulation

InactiveCN104699984AEasy numerical grid sizeEasy to calculate and program embedded anti-knock performance analysis softwareSpecial data processing applicationsNumeric ValueUnderwater explosion

The invention discloses a method for determining grid sizes for underwater explosion numerical simulation. The method includes steps of 1, setting a series of dimensionless variable values and respectively acquiring corresponding integral average errors for the various values; 2, acquiring value ranges with the integral average errors not larger than error thresholds; 3, combining formulas with one another according to the value ranges and acquiring the grid sizes according to given explosive equivalent weights and given explosive density of underwater explosion numerical simulation. The thresholds are set according to engineering experience. The method has the advantages that the method is efficient, convenient and speedy, and the inconsistent grid sizes can be adopted under different conditions, so that simulation results are accurate and reliable, and the method is applicable to underwater explosion numerical values under conditions of different underwater explosion environments and the different explosive equivalent weights.

Owner:WUHAN UNIV

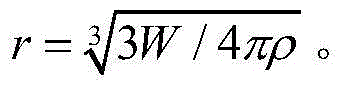

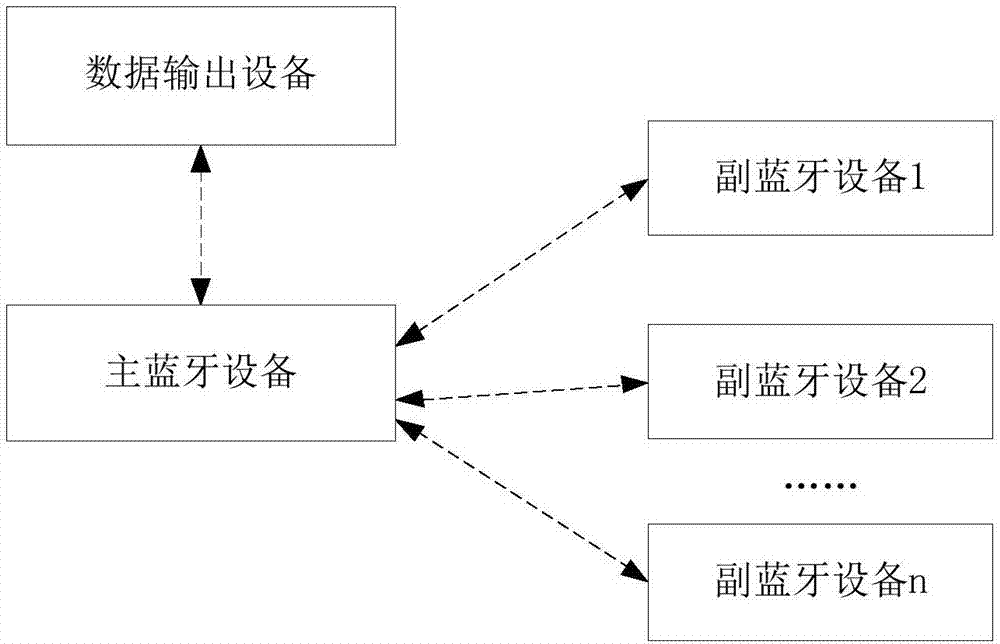

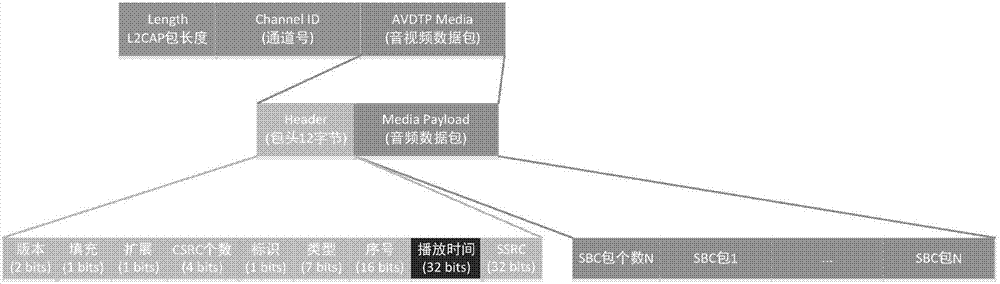

Synchronization parameter transmission method, device and equipment of AVDTP protocol

InactiveCN107040848ANo increase in workloadGood synchronizationSignal processingLoudspeaker signals distributionData transmissionTimestamp

The invention is applicable to the technical field of Bluetooth communication, and provides a synchronization parameter transmission method, a synchronization parameter transmission device and synchronization parameter transmission equipment of an AVDTP protocol. The method comprises the steps of receiving an AVDTP data packet from data output equipment during a Bluetooth communication process, wherein the AVDTP data packet comprises an audio / video data packet, and the audio / video data packet comprises a packet header part and an audio data packet; acquiring a reference clock of a local Bluetooth to serve as a synchronization parameter; replacing a timestamp included in the packet header part into the synchronization parameter; and forwarding the replaced AVDTP data packet. According to the method, the device and the equipment provided by the invention, the main Bluetooth equipment only uses the synchronization parameter to replace the timestamp in the original data packet without changing the format and length of existing Bluetooth data, the workload of data transmission is not increased, the transmission of the synchronization parameter is completed, and thus audio is synchronized.

Owner:BUILDWIN SEMICON SHENZHEN CO LTD

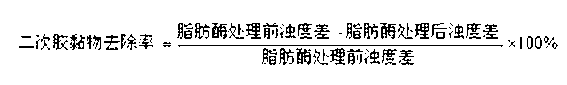

Method of controlling secondary gummy substances by using lipase

InactiveCN103061184AEliminate hazardsImprove the authenticity ratePaper recyclingWaste paper working-upPulp treatmentDe esterification

The invention discloses a method of using lipase to treat secondary gummy substances in paper pulp and white water produced in papermaking with waste paper. The lipase is alkaline lipase with a pH value of 7.5 to 9.0, enzyme activity of more than 100 U / mL, a hydrolysis rate of triglyceride of no less than 95% and transesterification and lipogenesis rates of less than 3%. A treating method for the paper pulp comprises steps consisting of adding the lipase accounting for 0.001 to 0. 5% of dry weight of the paper pulp into the paper pulp having a concentration adjusted to be 2 to 5%, carrying out treating and filtering, centrifuging and detecting the treated pulp. A treating method for the white water comprises steps consisting of adding the lipase accounting for 0.001 to 0. 5% of dry weight of the white water into the papermaking white water, carrying out treating and filtering, centrifuging and detecting the treated white water. According to the invention, the lipase is utilized to fundamentally degrade the gummy substances and mitigate deposition tendency of the gummy substances so as to remove the gummy substances, so the problem of pollution by secondary gummy substances is thoroughly overcome; and the method is simple to operate, has a substantial removal effect and enables the quality of papermaking with waste paper to be improved and production cost to be reduced.

Owner:TAIXING YIMING BIOLOGICAL PRODS

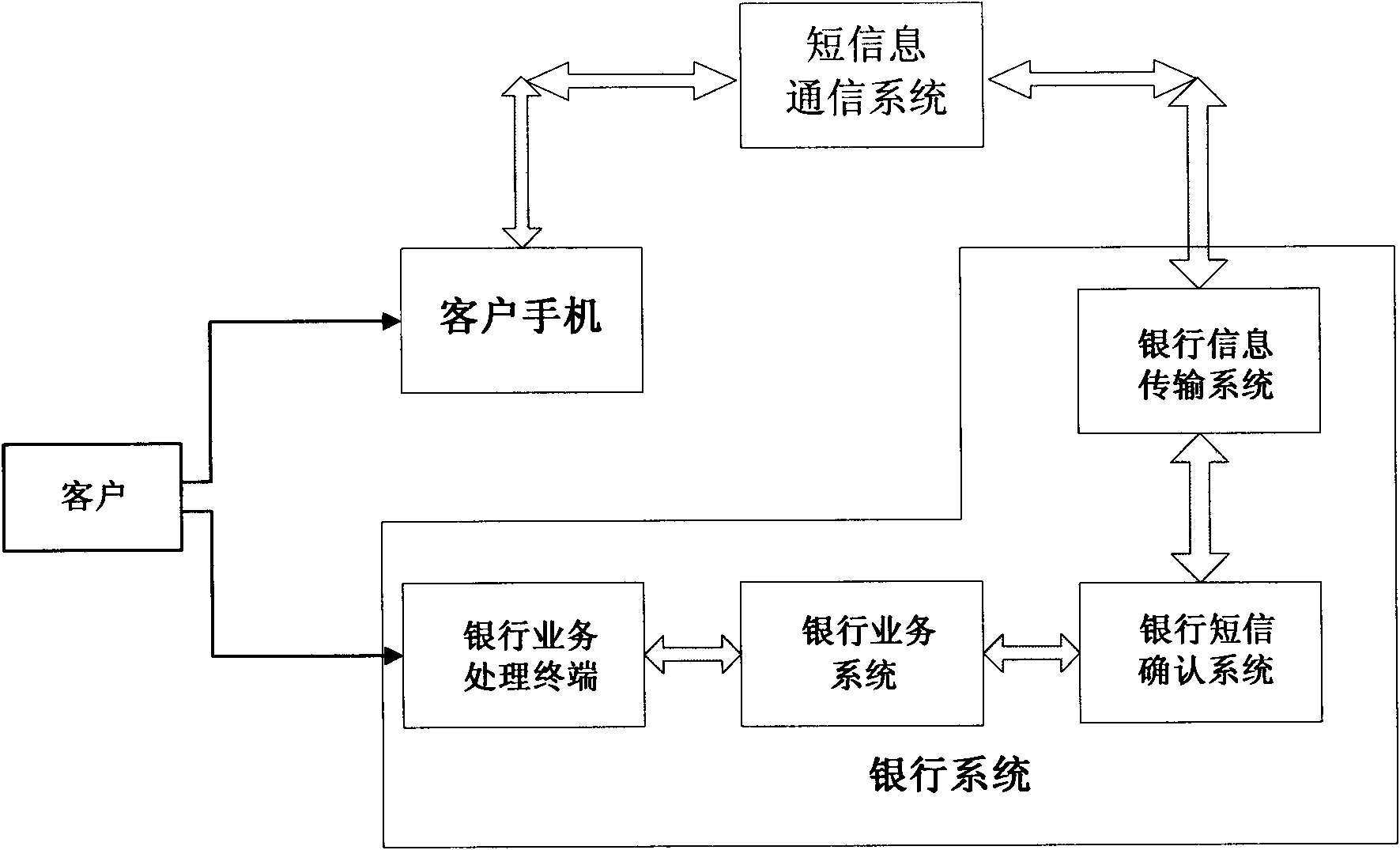

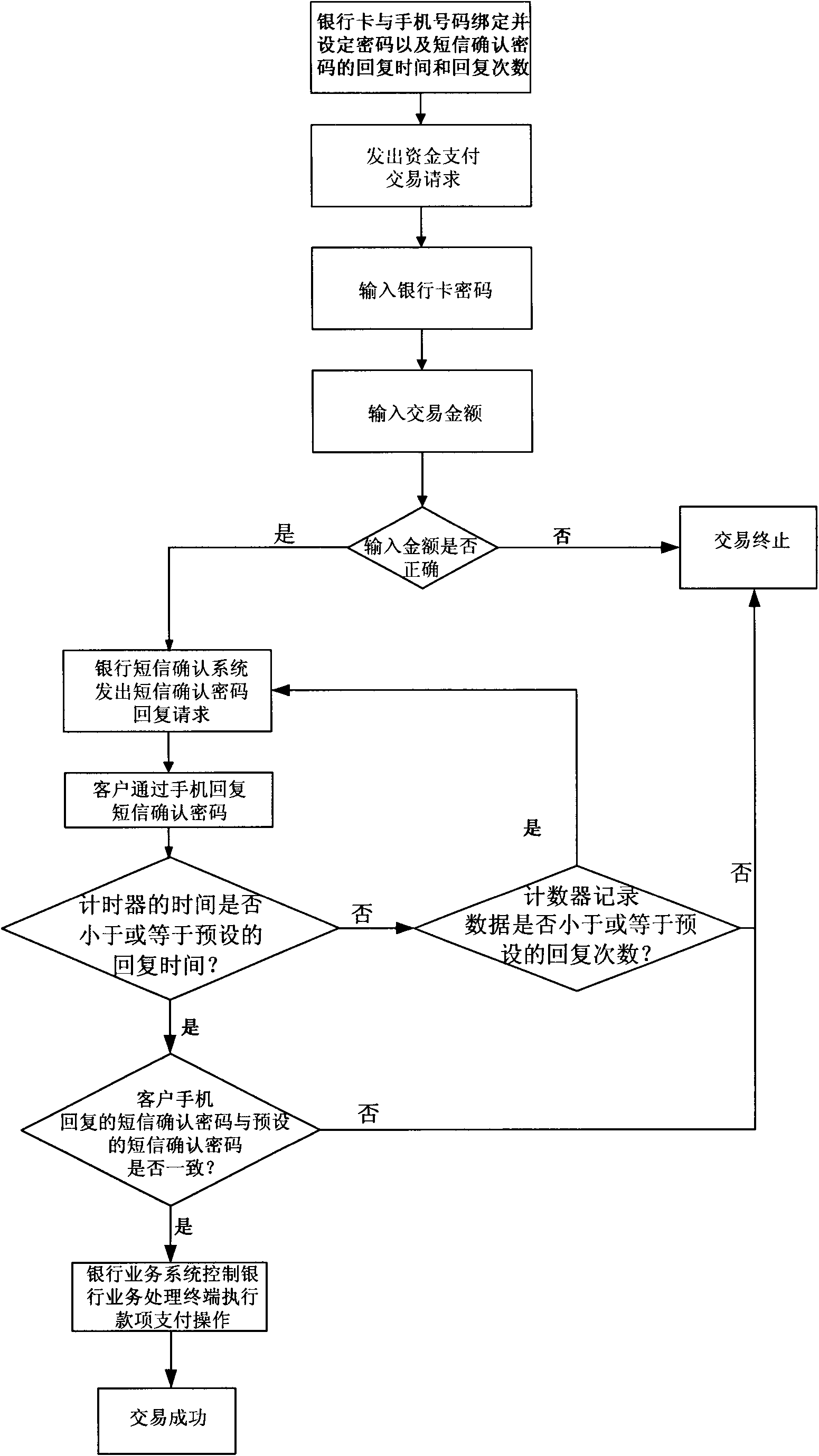

Bank payment confirmation system and confirmation method thereof

InactiveCN101667276AGuarantee the safety of fundsNo increase in workloadComplete banking machinesPayment architectureCredit cardTransport system

The invention discloses a bank payment confirmation system, comprising a client cellphone, a short message communication system, a bank information transmitting system, a bank business system, a bankbusiness processing terminal and a bank short message confirmation system. Information interaction of short message password confirmation is performed between the client cellphone and the bank short message confirmation system by the short message communication system and the bank information transmitting system; the bank business system controls the bank business processing terminal to perform corresponding operation according to the information interaction result of the client cellphone and the bank short message confirmation system. According to the above system, the invention also discloses a confirmation method for the bank payment confirmation system, which realizes multiple safe control on the bank payment by a secondary password and a short message reply to confirm the password, thus greatly improving safe performance of the bank payment system and avoiding possible economic losses caused by losing of bank cards or credit cards.

Owner:SICHUAN JUNTONG NETWORK TECH SERVICE

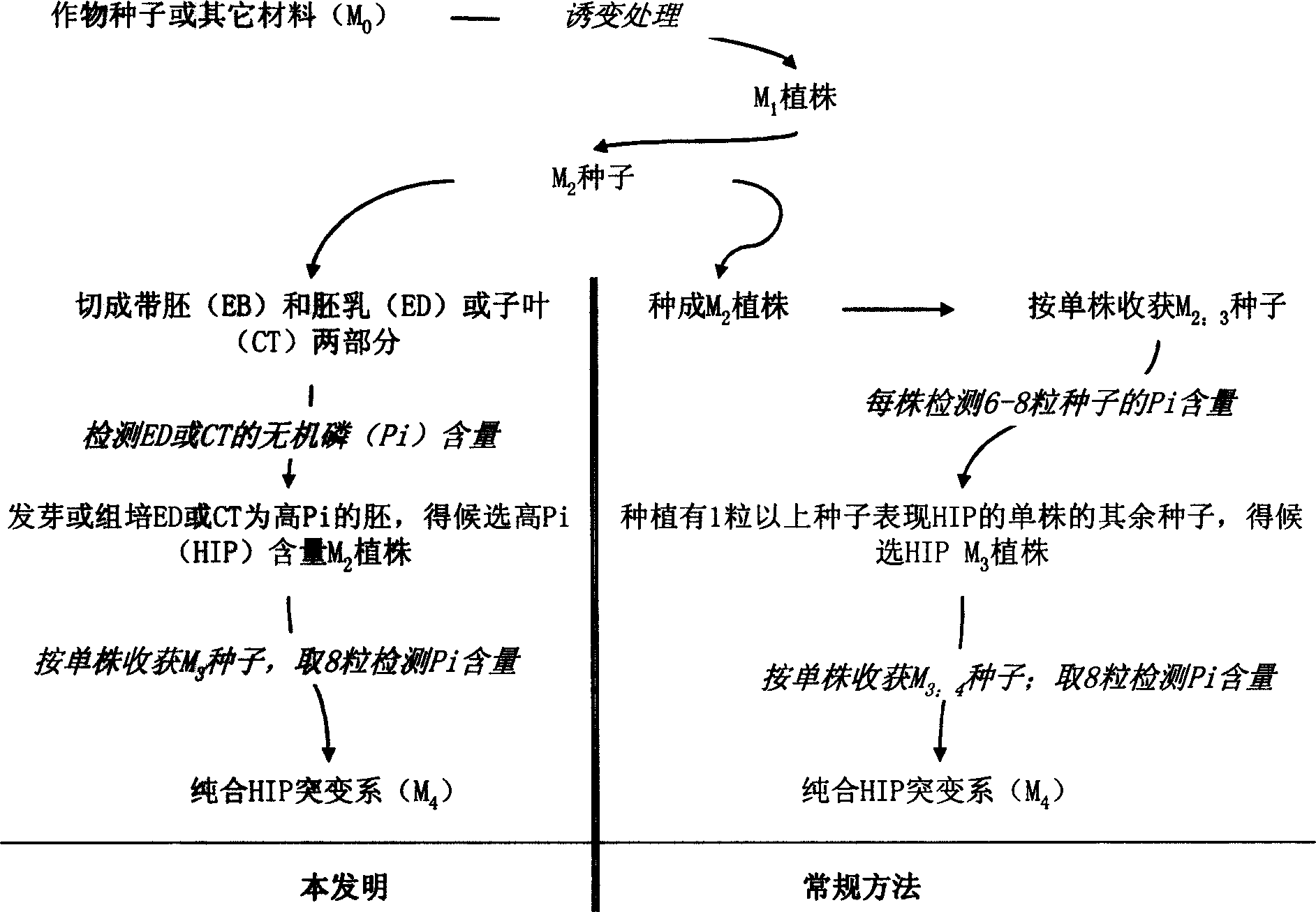

Quick cultivating method for low phytic acid crop

InactiveCN101011026ASpeed up the processImprove work efficiencyPlant tissue cultureHorticulture methodsPhosphorPhytic acid

The invention relates to a method for quickly planting low-acid crop, which comprises that 1, planting induced M1 generation seed, harvesting the M2 generation seed; 2, on the part of M2 generation seed without blast is sampled to test the inorganic phosphor content of M2 generation seed to select out the seed with high content; 3, accelerating germination of left part with blast, planting to obtain the M2:3 generation seed; 4, measuring the inorganic phosphor content of M2:3 generation seed to find the change of low-acid body. The invention can shorten the time that inducing object into low-acid one, with wide application.

Owner:ZHEJIANG UNIV

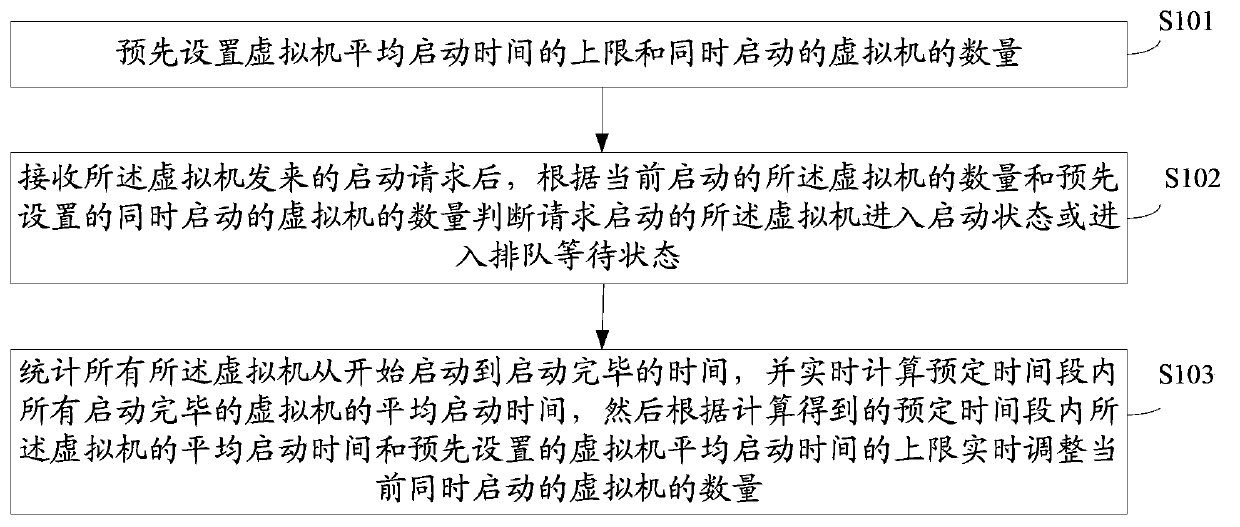

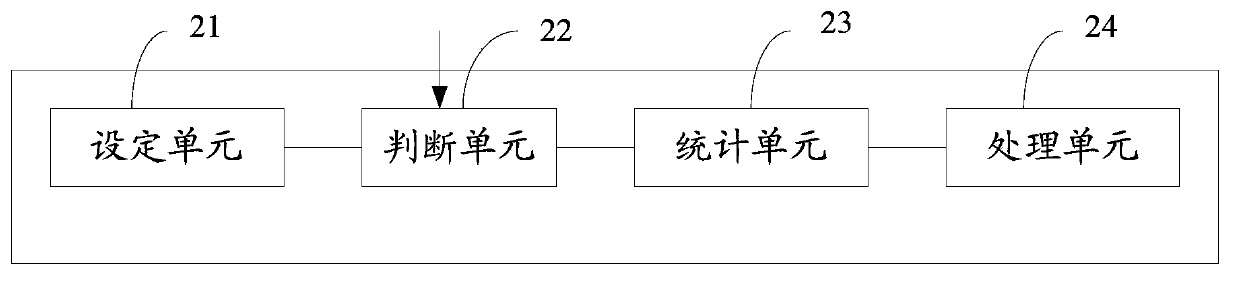

Self-adapting virtual machine start control method and device

ActiveCN103970555AReal-time monitoring of average startup timeGuaranteed startup speedBootstrappingProgram loading/initiatingStart timeWait state

The invention discloses a self-adapting virtual machine start control method and a self-adapting virtual machine start control device. The method comprises the following steps: presetting the upper limit of average start time of virtual machines and the number of the virtual machines which are started simultaneously, and judging whether the virtual machines requesting to be started go into a start state or a queuing waiting state according to the number of the virtual machines which are currently started and the preset number of the virtual machines which are started simultaneously; counting durations from start beginning to start ending of all the virtual machines, calculating the average start time of all the virtual machines which are completely started in a preset time period in real time, and adjusting the number of the virtual machines which are currently and simultaneously started in real time according to the calculated average start time of the virtual machines in the preset time period. The method is simple, unified one-time setting according to a user experience is only needed, and one-by-one calculation according to different software / hardware environments is not needed; moreover, the start speed of the virtual machines in a starting process currently can be effectively guaranteed, and the problem of over-long start time of each virtual machine is avoided.

Owner:ZTE CORP

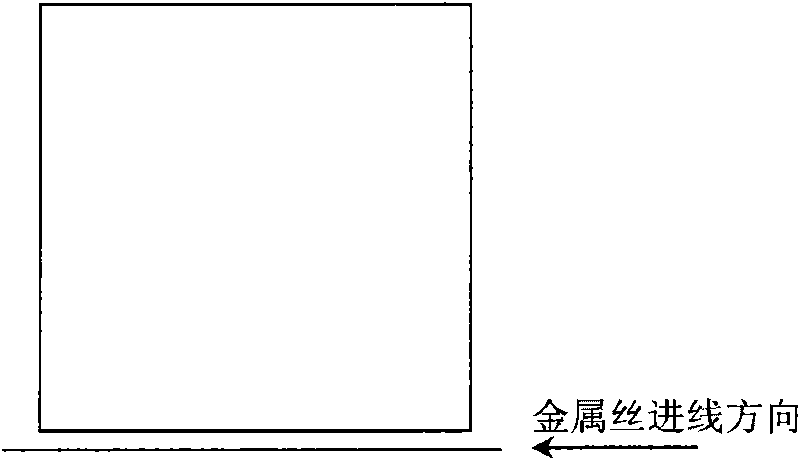

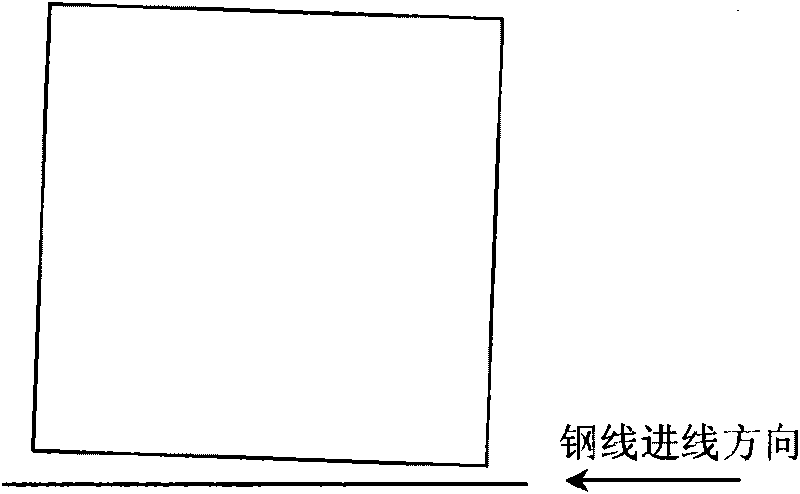

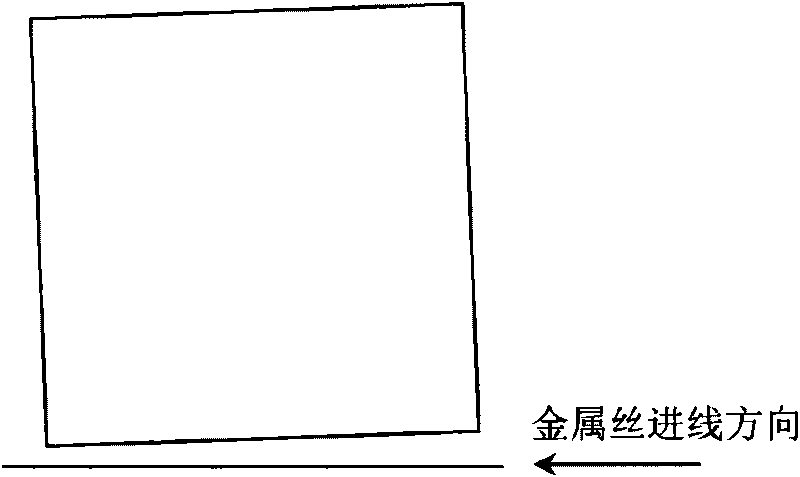

Method for cutting silicon rod

InactiveCN101733849ASolve TTVSolve defects such as warpingStone-like material working toolsSiliconMetal

The invention discloses a method for cutting a silicon rod, which comprises the steps of: performing wire-electrode cutting by utilizing a metal wire and a matched grinding material; and arranging the silicon rod slantwise, so that one side, positioned at the downstream of an advance direction of the metal wire, of a cutting feed surface of the silicon rod comes into contact with the metal wire firstly, wherein an included angle between the cutting feed surface and the metal wire is 1 to 5 degrees. The cutting mode of the method can thoroughly solve problems of TTV, warping and the like of silicon wafers and achieves an unforeseeable effect.

Owner:CSI SOLAR POWER GROUP CO LTD +1

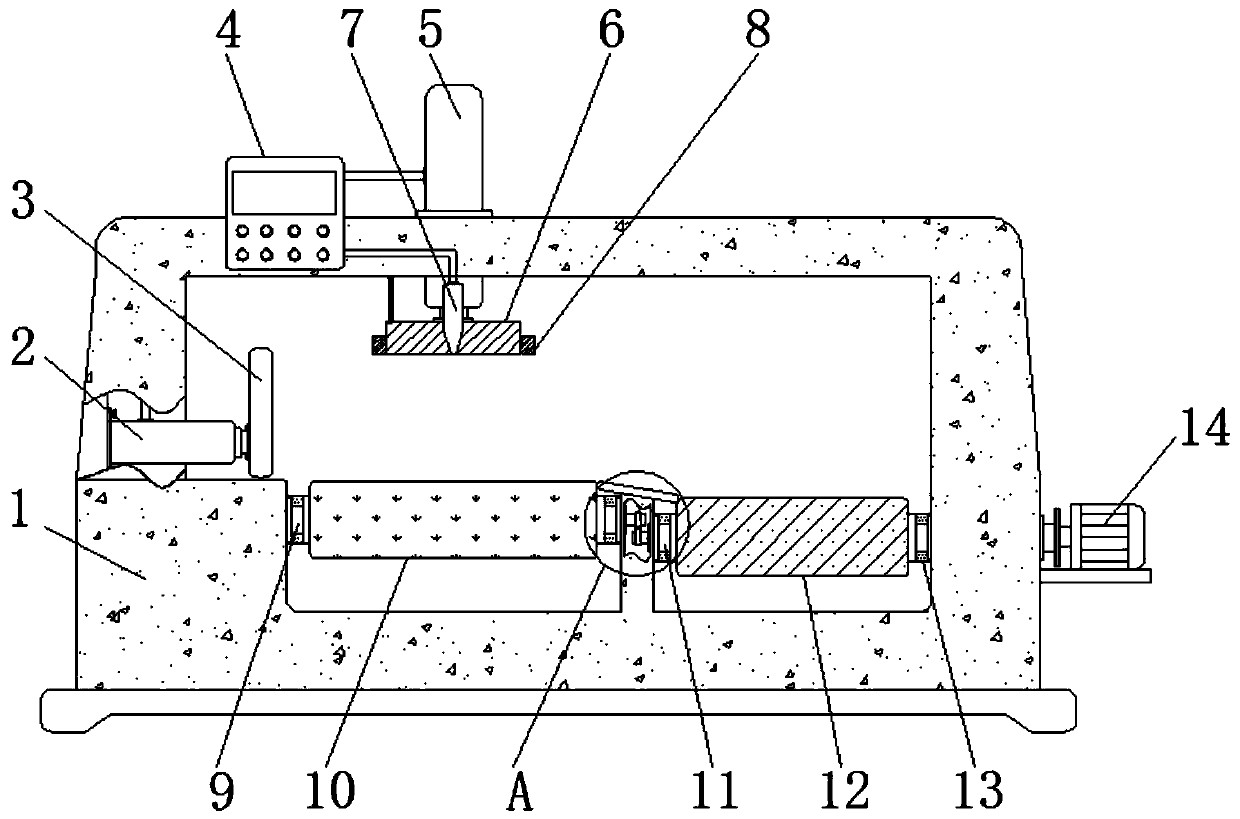

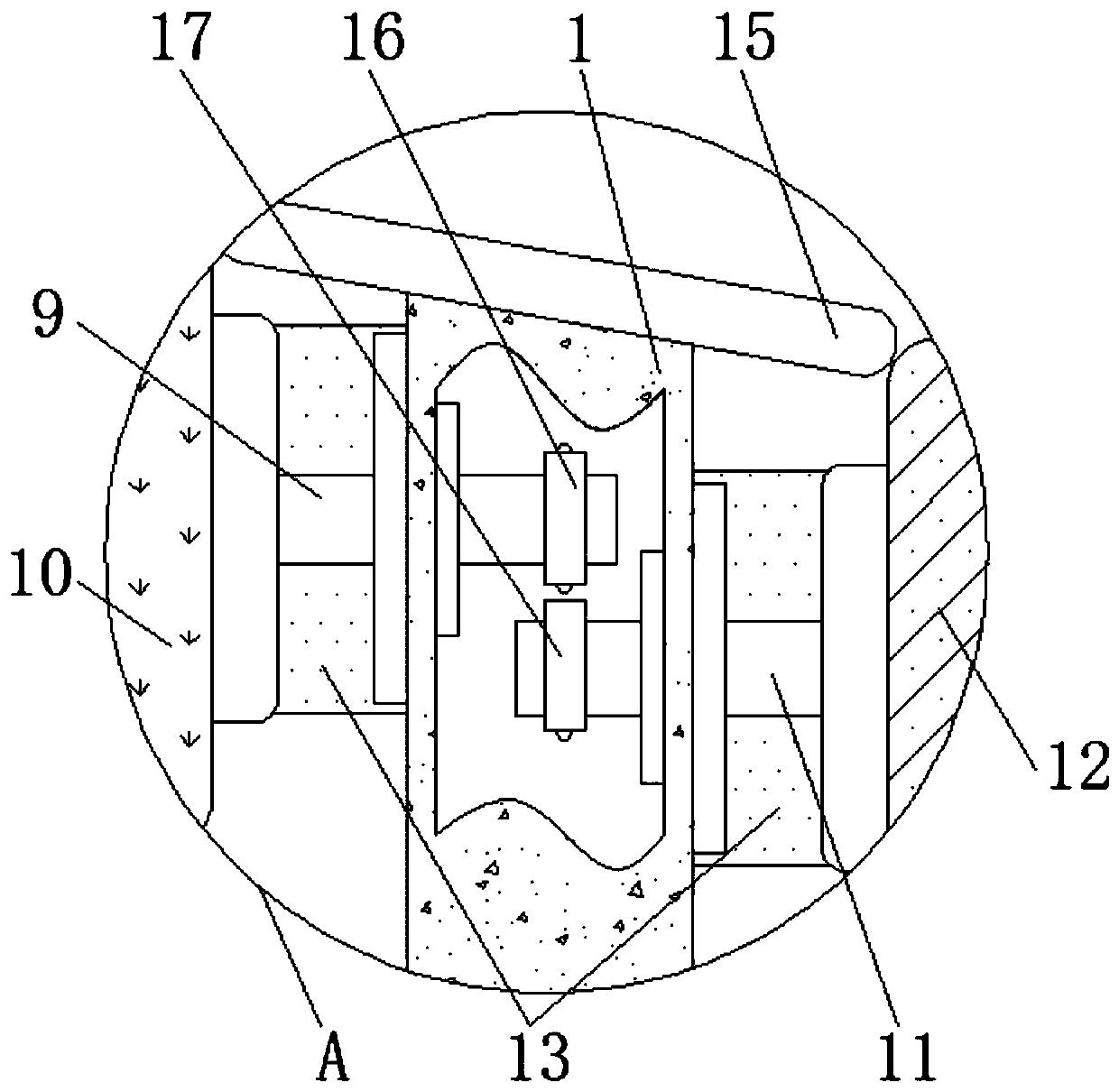

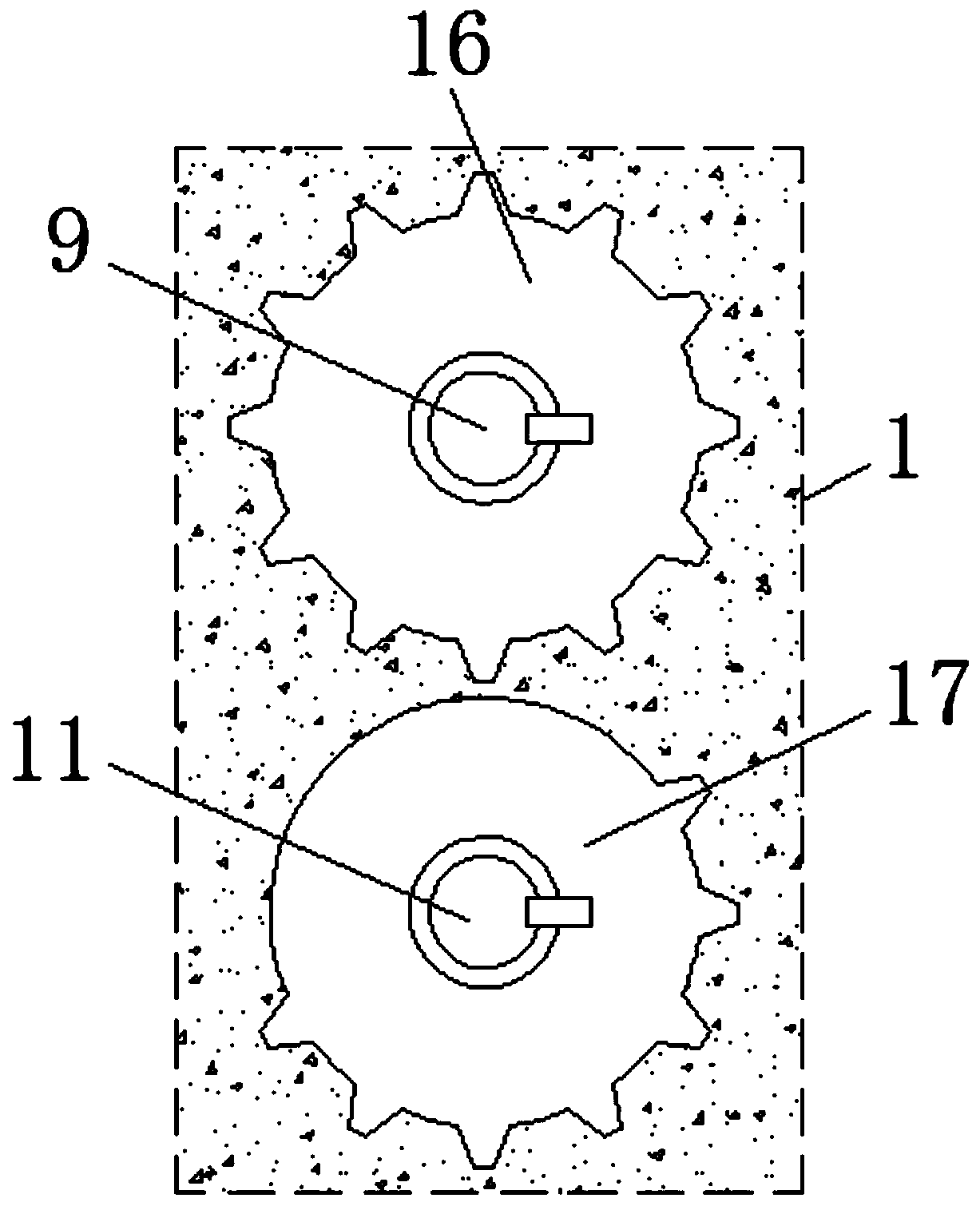

Food processing packaging bag air leakage detection equipment capable of automatically screening

ActiveCN111169735AEasy squeezeEasy to detectPackaging automatic controlSortingLaser rangingEngineering

The invention discloses food processing packaging bag air leakage detection equipment capable of automatically screening. The food processing packaging bag air leakage detection equipment capable of automatically screening comprises a shell body, a first electric push rod, a PLC control panel, a second electric push rod and a laser range finder. The first electric push rod is fixed to the interiorof the left end of the shell body through screws. The output end of the first electric push rod penetrates through the shell body to be in screw connection with a push plate. The PLC control panel ismounted on the front side face of the upper portion of the shell body through screws. The second electric push rod is arranged on the right side of the PLC control panel. The output end of the secondelectric push rod penetrates through the shell body to be in screw connection with a first squeezing plate. The second electric push rod is in screw connection with the shell body. The food processing packaging bag air leakage detection equipment capable of automatically screening controls the first electric push rod through the PLC control panel to automatically carry out screening of air leakage packaging bags, and workers do not need to manually take the air leakage packaging bags. The food processing packaging bag air leakage detection equipment capable of automatically screening is easyand convenient to operate, and reduces the workload of the workers.

Owner:上海小慕食品有限公司

Modifier for preventing bittern scaling

The invention discloses a modifier for preventing bittern scaling. The modifier comprises the following ingredients (by weight): 10-20 parts of 2-phosphonobutane-1,2,4-tetrasodium trihydroxy, 5-10 parts of sodium polyacrylate, 2-3 parts of coco fatty acid diethanol amide, 0.2-0.5 part of polyether modified silicone and the rest of water. The modifier has a good effect of preventing scaling and has strong flowback performance. By the use of the modifier, construction is simple, and workload is not increased, and cost is saved.

Owner:PETROCHINA CO LTD

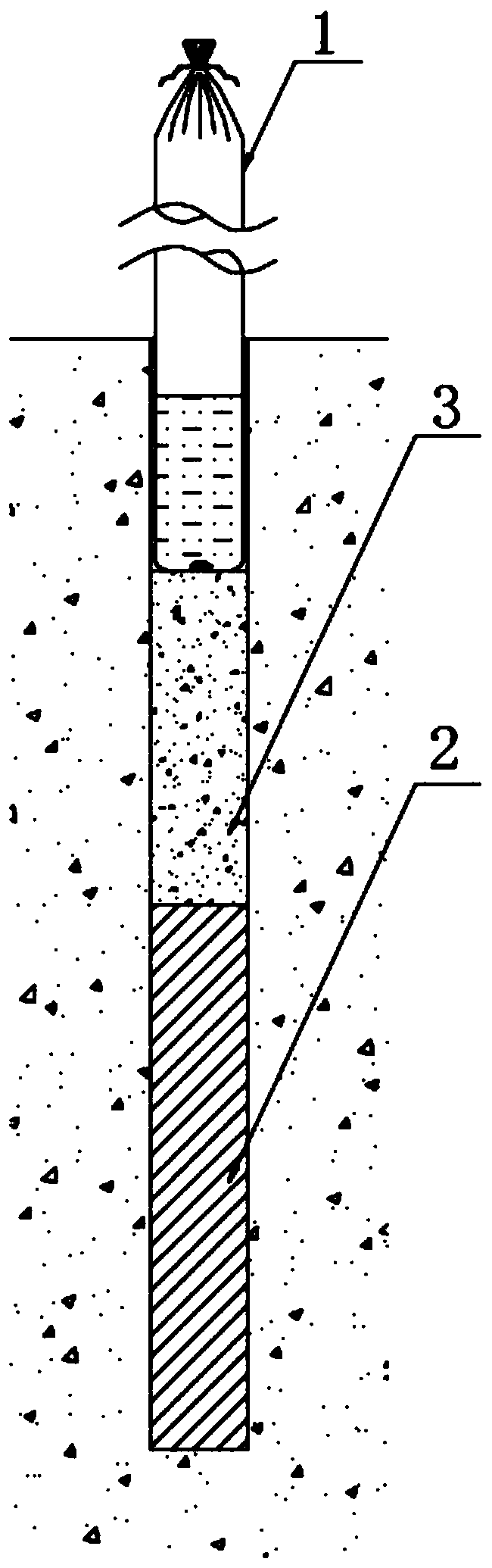

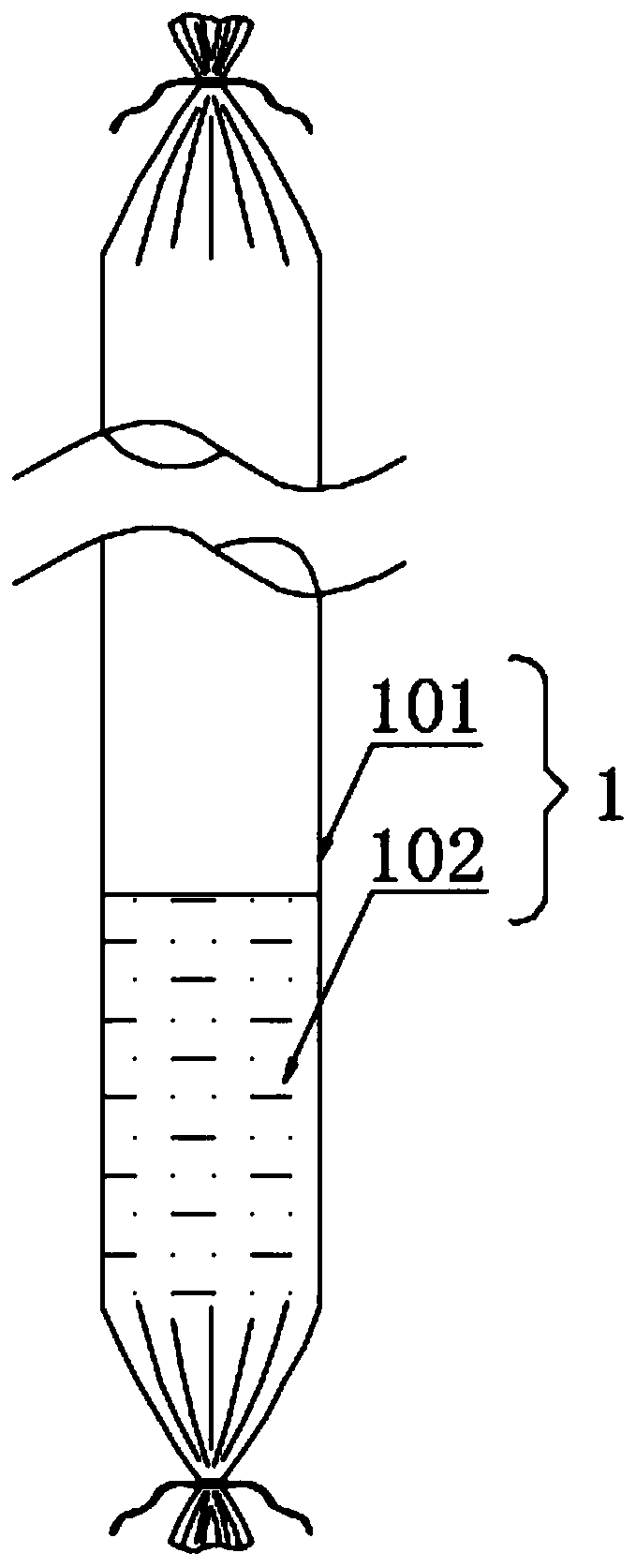

Method for reducing surface blasting dust

The invention discloses a method for reducing surface blasting dust, and particularly relates to the field of engineering blasting. A dust blocking mechanism is included, the dust blocking mechanism includes a water bag and a water seal, the water seal is arranged inside the water bag, and the water seal includes water and surfactants. The method for blasting by using the dust blocking mechanism is that the water bag is manufactured, the water bag is filled with a certain number of surfactants, then a small amount of water is injected, and the water bag is slowly put into a gun hole; water iscontinuously poured into the water bag until the water is flush with the ground; and the top end of the water bag is tied to complete the water seal, and then a user needs to wait for explosion. By means of the method, the water bag containing the water seal is used as the dust blocking mechanism to be placed in the gun hole, gunpowder and gun mud at the bottom are blocked, when the gunpowder is ignited and detonated, the gun hole cannot be punched, the explosive dust can be wrapped with the water seal, the ground surface after explosion has a layer of light water mist, the dust concentrationis very low, and the open-air step blasting dust concentration can be effectively reduced.

Owner:NORTH BLASTING TECH

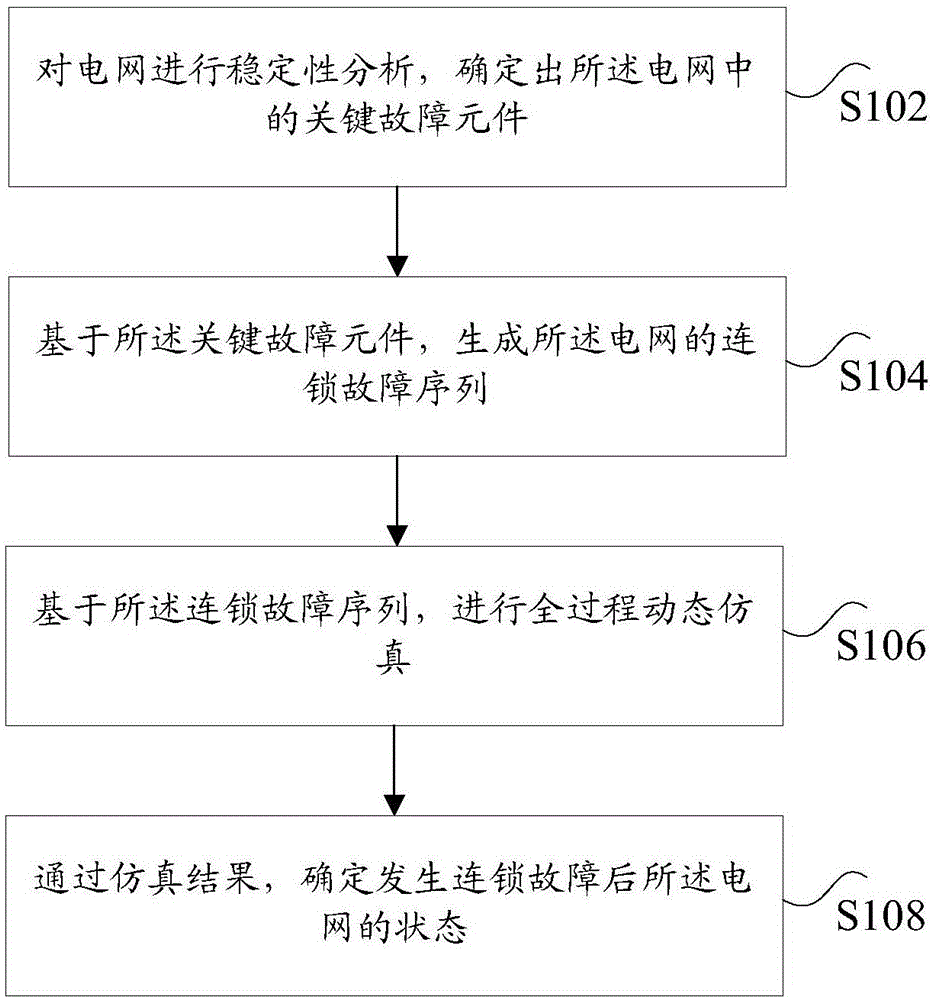

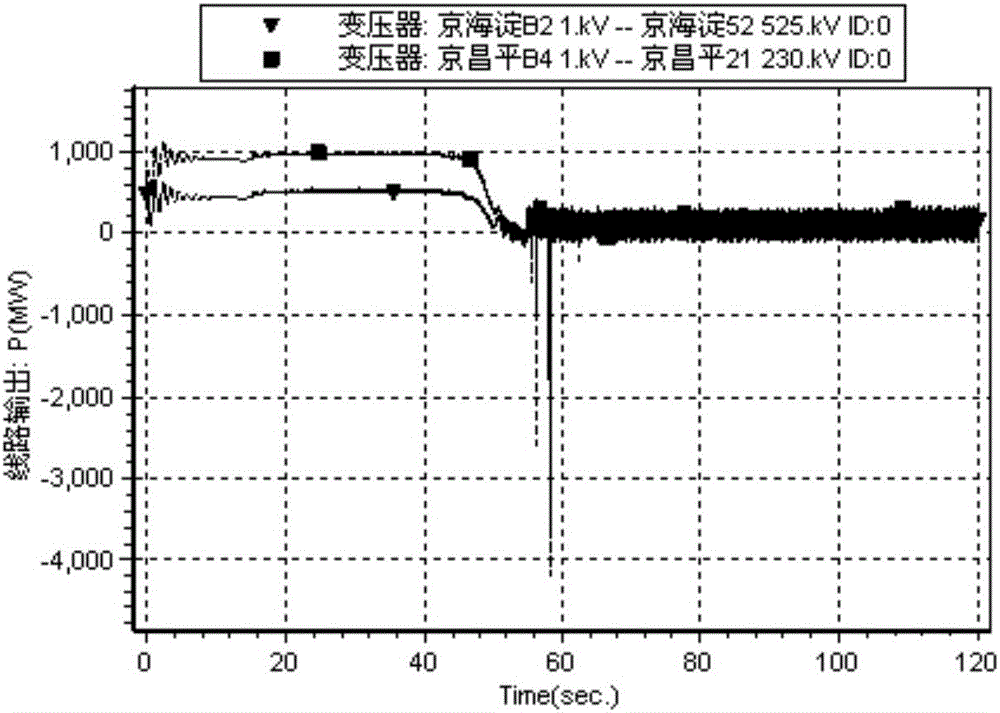

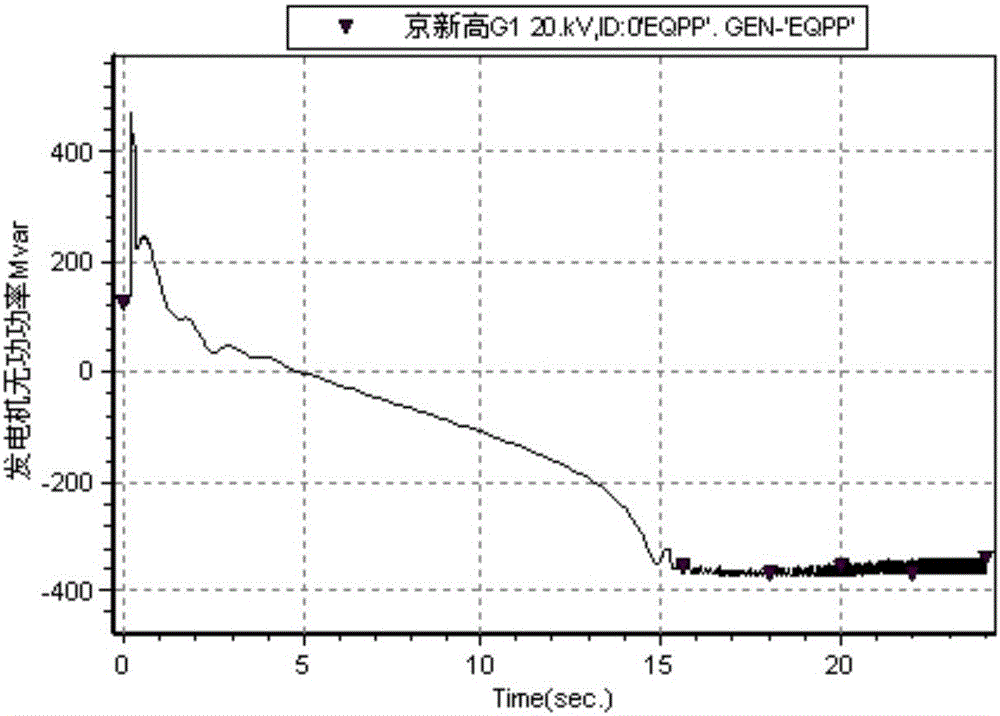

Simulation method and device for cascading failures of power grid

ActiveCN106655167ASolve the workloadFast, efficient and comprehensive power grid cascading failure simulationDesign optimisation/simulationSpecial data processing applicationsDynamic simulationPower grid

The invention discloses a simulation method and device for cascading failures of a power grid. The method comprises the steps of carrying out stability analysis on the power grid and determining a key failure component in the power grid; generating a cascading failure sequence of the power grid on the basis of the key failure component; carrying out dynamic simulation for a whole process on the basis of the cascading failure sequence; and determining the state of the power grid after the cascading failures through a simulation result. According to the simulation method and device, the technical problem of high workload of cascading failure simulation of the power grid is solved.

Owner:STATE GRID BEIJING ELECTRIC POWER +1

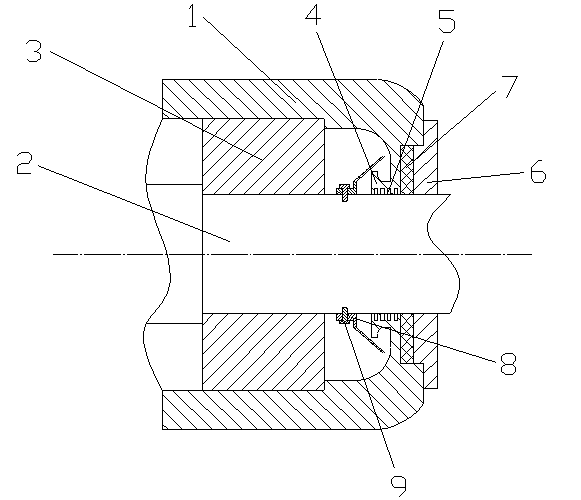

Oil leakage prevention device of air feeder bearing box

The invention discloses an oil leakage prevention device of an air feeder bearing box. The oil leakage prevention device comprises the air feeder bearing box, a main shaft, a bearing, a hook-shaped structure, a labyrinth seal, a bearing box end cover and a seal ring. The main shaft is arranged in the air feeder bearing box, the bearing is mounted on the main shaft, the hook-shaped structure is arranged at an opening end of the air feeder bearing box, and the labyrinth seal is arranged in the hook-shaped structure. The bearing box end cover is arranged at the opening end of the air feeder bearing box, the seal ring is arranged between the bearing box end cover and the air feeder bearing box, and an oil blocking ring is arranged between the bearing and the hook-shaped structure. The outer ring of the oil blocking ring is in a tilt shape. The oil blocking ring is in a split type and connected to the main shaft through a bolt. The distance between the outer ring of the oil blocking ring and the hook-shaped structure is no less than 3mm. The oil leakage prevention device of the air feeder bearing box thoroughly solves the oil leakage problem, obtains good effects, and reaches guarantee of purposes of good condition and safe operation of equipment.

Owner:宋炜赓

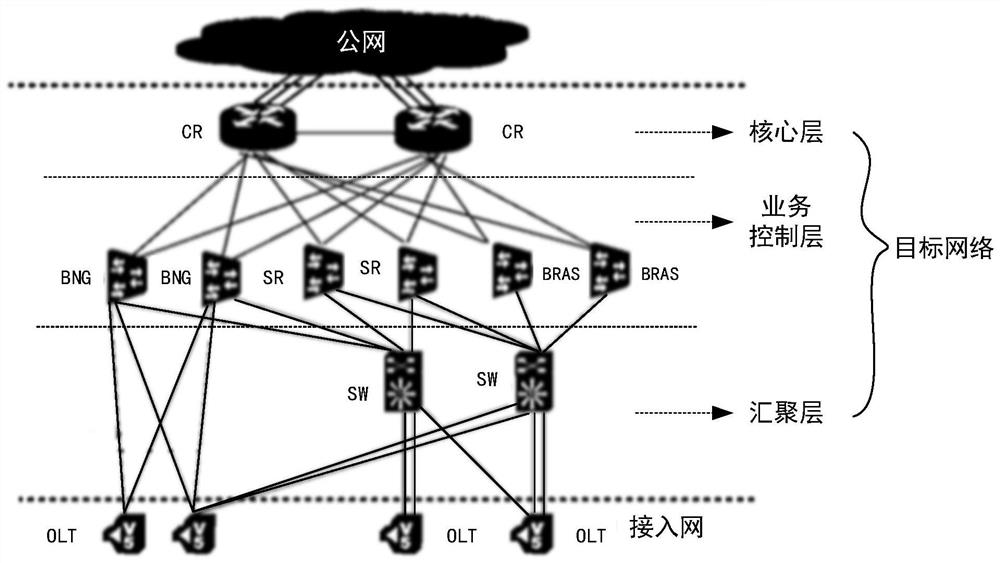

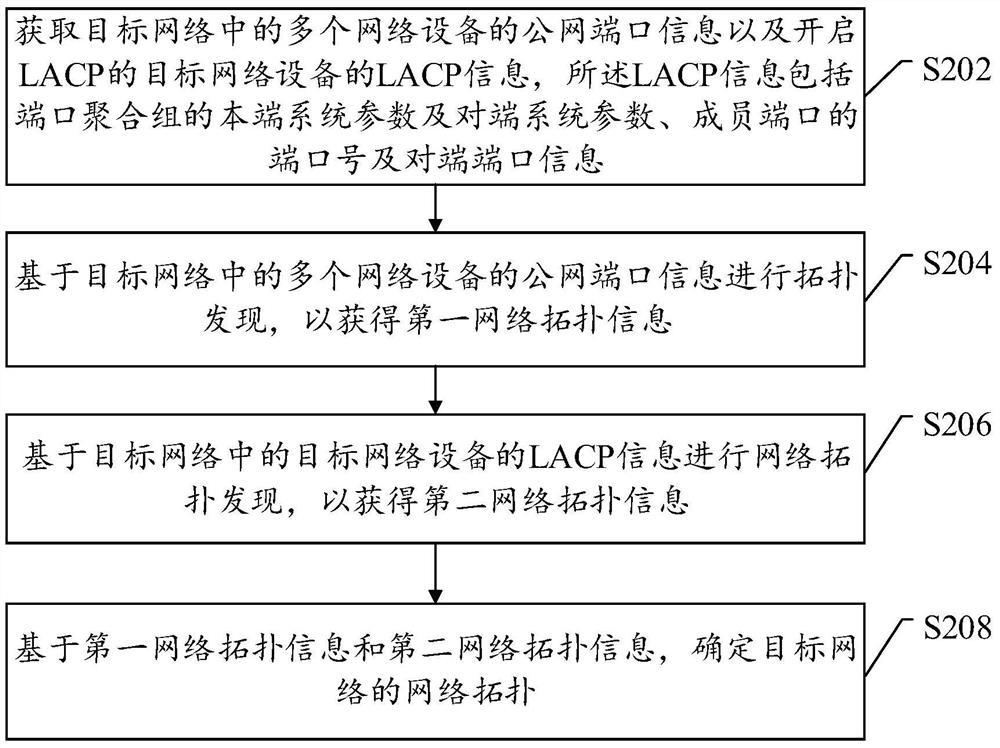

Network topology discovery method and device and electronic equipment

ActiveCN114553706ANo increase in workloadTransmissionHigh level techniquesTopology informationEngineering

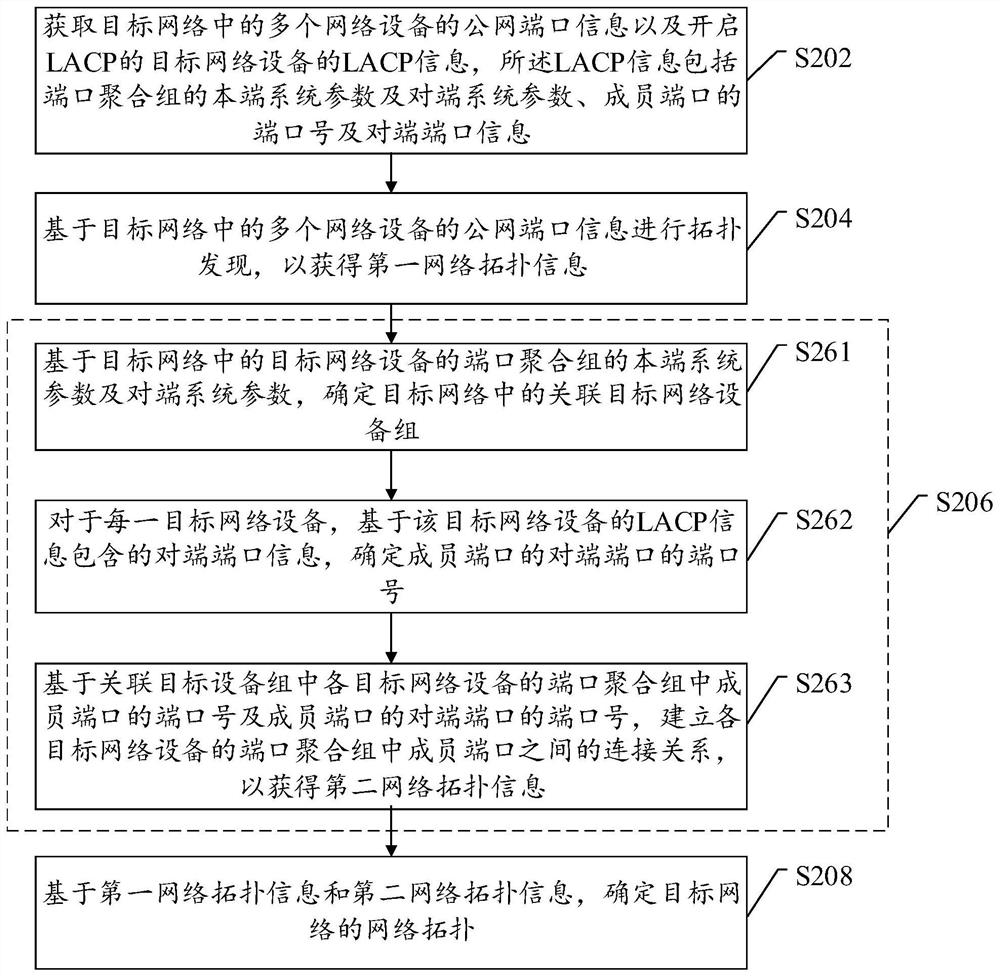

The invention discloses a network topology discovery method and device and electronic equipment, and aims to at least solve the problems that an existing network topology discovery method is low in accuracy, and configuration complexity and operation load of network equipment are increased. The method comprises: acquiring public network port information of a plurality of network devices in a target network and LACP information of a target network device that opens a link aggregation control protocol LACP, the LACP information comprising home terminal system parameters and opposite terminal system parameters of a port aggregation group, port numbers of member ports in the port aggregation group and opposite terminal port information; performing network topology discovery based on the public network port information of the plurality of network devices to obtain first network topology information; performing network topology discovery based on the LACP information of the target network device in the target network to obtain second network topology information; and determining the network topology of the target network based on the first network topology information and the second network topology information.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD +1

Electronic answering sheet/take-up/score recoder

InactiveCN1680984ASave typing timeSimple and fast operationElectrical appliancesInternal memoryEeg data

An electronic question answering / examination paper taking - up / mark logging device comprises electronic question answering unit used by examinee, electronic examination paper taking up unit used by monitor and electronic mark logging unit used by teacher going over the examination paper. Each said unit consists of operation panel, keyboard, input screen, internal storage and data transmission port for up - transmitting data to computer.

Owner:胡德良

Novel sea cucumber processing equipment

InactiveCN103141870AIncrease workloadImprove work efficiencyFood preparationHeating timeSea cucumber

The invention relates to novel sea cucumber processing equipment which is practical and convenient to use. According to the novel sea cucumber processing equipment, temperature of water in a pot can be observed visually, fire power of a coal-fired furnace can be adjusted rapidly, heating time can be changed, and the quality of sea cucumber is guaranteed. The novel sea cucumber processing equipment comprises a stainless steel jacketed pot and the coal-fired furnace, wherein the coal-fired furnace is arranged on below the stainless steel jacketed pot in a supporting mode. An air blower is arranged by being matched with the coal-fired furnace. A coal filling air inlet of the coal-fired furnace is matched with an air outlet of the air blower. The stainless steel jacketed pot comprises a liner, an outer wall, and an interlayer, wherein the interlayer is semi-spherical and conduction oil is filled in the interlayer. An oil filling mouth is arranged in one side of the interlayer and an air exhaust mouth is arranged in the other side of the interlayer. An oil temperature sensor is arranged on the wall of the interlayer. The novel sea cucumber processing equipment has the advantages that real-time temperature data can be displayed, a user can adjust output wind power of the air blower according to the temperature displayed, stability of water temperature and stability of oil temperature are maintained, the sea cucumber and the water in the pot are enabled to be heated evenly, quality and taste of the sea cucumber are guaranteed, the water does not need to be changed frequently, working efficiency is high, time for boiling the sea cucumber can be prolonged, and the quality of the sea cucumber is improved.

Owner:WENZHOU VOCATIONAL COLLEGE OF SCI & TECH

Modifying agent for preventing calcium halide scaling

ActiveCN105419761AStrong anti-scaling performanceReduce dosageDrilling compositionDocusate SodiumDioctyl Sulfosuccinic Acid

The invention discloses a modifying agent for preventing calcium halide scaling. The modifying agent is prepared from, by mass, 15-25 parts of amino trimethylene phosphonic acid, 4-8 parts of docusate sodium, 2-3 parts of cetyltrimethylammonium chloride, 0.1-0.3 part of tributyl phosphate and the balance water. The modifying agent has the advantages of being high in scaling resistance, small in use amount, easy to construct, not capable of increasing operation workloads, high in flow-back capacity, capable of saving cost, and the like.

Owner:PETROCHINA CO LTD

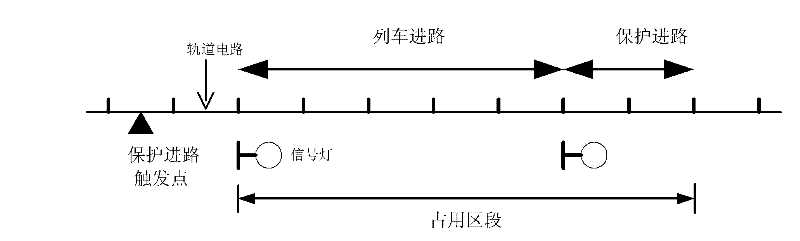

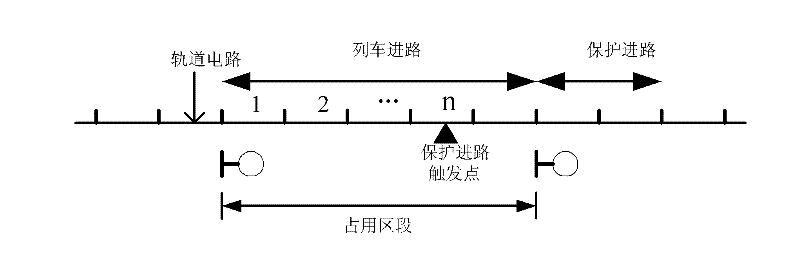

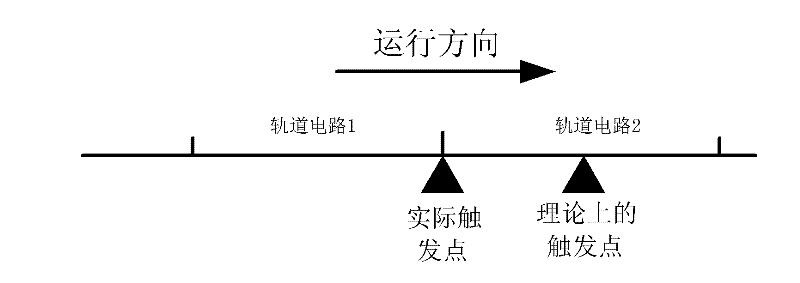

Interlock protective route trigger method for metrovehicle

ActiveCN102381339AImprove efficiencyNo increase in workloadSignal boxes station blockingEngineeringAvailability factor

An interlock protective route trigger method for metrovehicle provides each protective route trigger point in a corresponding train route and comprises the following specific steps: step one: an interlock system detects running position of a train according to an occupied condition of a track circuit; step two: when the train is detected to enter a train route, the system prepares a protective route with the arrangement being corresponded to the train route; step three: the train continuing running, when the train is detected to enter a zone in which the trigger point of the protective route is located, the interlock system starts the protective route; step four: the interlock discharges the protective route, and the train continues running. The interlock protective route trigger method for metrovehicle divides a zone occupied in one time into two times of occupations, then the interlock protective route trigger method for metrovehicle improves availability factor of zones and does not change the original interlock and opposite relationships, so the the interlock protective route trigger method for metrovehicle does not add extra amount of work.

Owner:CRRC NANJING PUZHEN CO LTD

Oil tank capable of detecting oil quality

InactiveCN102029896AReduce weightReduce volumeUnderstructuresMaterial testing goodsFuel tankEngineering

The invention relates to an oil tank capable of detecting oil quality, a display screen (6) is connected with a display module (21) through a cable bundle (7), a sensitive grid (13) is arranged between a substrate (12) and a covering layer (14), the substrate (12) and the covering layer (14) are combined together and connected with a strain gage fixing plate (15), the covering layer (14) is connected with the strain gage fixing plate (15), and the strain gage fixing plate (15) is connected with a mounting barrel (22). An analog-digital converter (19) is connected with a built-in power supply (17) through a wire (18), a microprocessor (20) is connected with the analog-digital converter (19) and a display module (21), and all components are arranged in the mounting barrel (22). The oil tank capable of detecting the oil quality has the benefits of being capable of precisely detecting and displaying the quality of gasoline, diesel and other oil materials, ensuring the safety of oil consumption of vehicles, being lighter in weight, having good corrosion resistance and earthquake resistance, being capable of storing the oil materials like the ordinary oil tank, and meeting the using demands of various vehicles.

Owner:郝亮

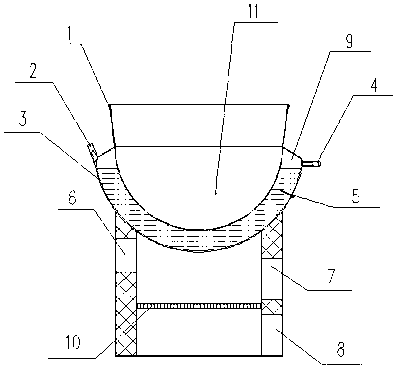

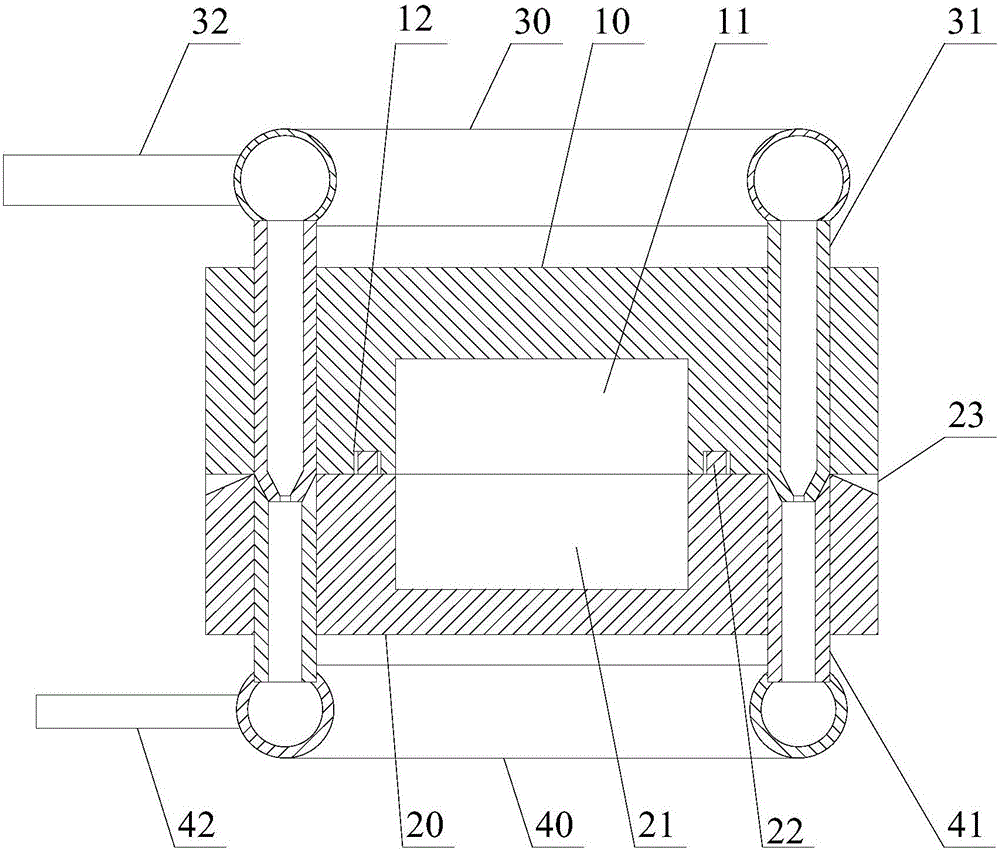

Casting mold cooling structure

InactiveCN106424629APrevent leakageNo increase in workloadFoundry mouldsFoundry coresWater pipeEngineering

The invention discloses a casting mold cooling structure which comprises an upper die, a lower die, a water inlet ring pipe, water inlet straight pipes, a water inlet pipe, a return water ring pipe, return water straight pipes and a return water pipe. The plurality of water inlet straight pipes penetrate the upper die and are arranged around an upper die cavity; the lower ends of the water inlet straight pipes are in a cone shape with the diameter gradually reduced from top to bottom, the upper ends of the water inlet straight pipes are connected with the water inlet ring pipe above the top surface of the upper die, and the water inlet pipe is connected with the water inlet ring pipe. The plurality of return water straight pipes penetrate the lower die and are arranged around an lower die cavity. The end faces of the upper ends of the return water straight pipes are level with the top surface of the lower die, the upper ends of the return water straight pipes are conical, the lower ends of the return water straight pipes are located below the bottom surface of the lower die and connected with the return water ring pipe below the bottom surface of the lower die, and the return water pipe is connected with the return water ring pipe. The upper die and the lower die are buckled with each other, the bottom surface of the upper die adheres to the top surface of the lower die, and the peripheral surfaces of the lower ends of the water inlet straight pipes adhere to the inner circumferences of the upper ends of the return water straight pipes. According to the casting mold cooling structure, a die and workblank can be quickly cooled.

Owner:重庆淬智机械有限公司

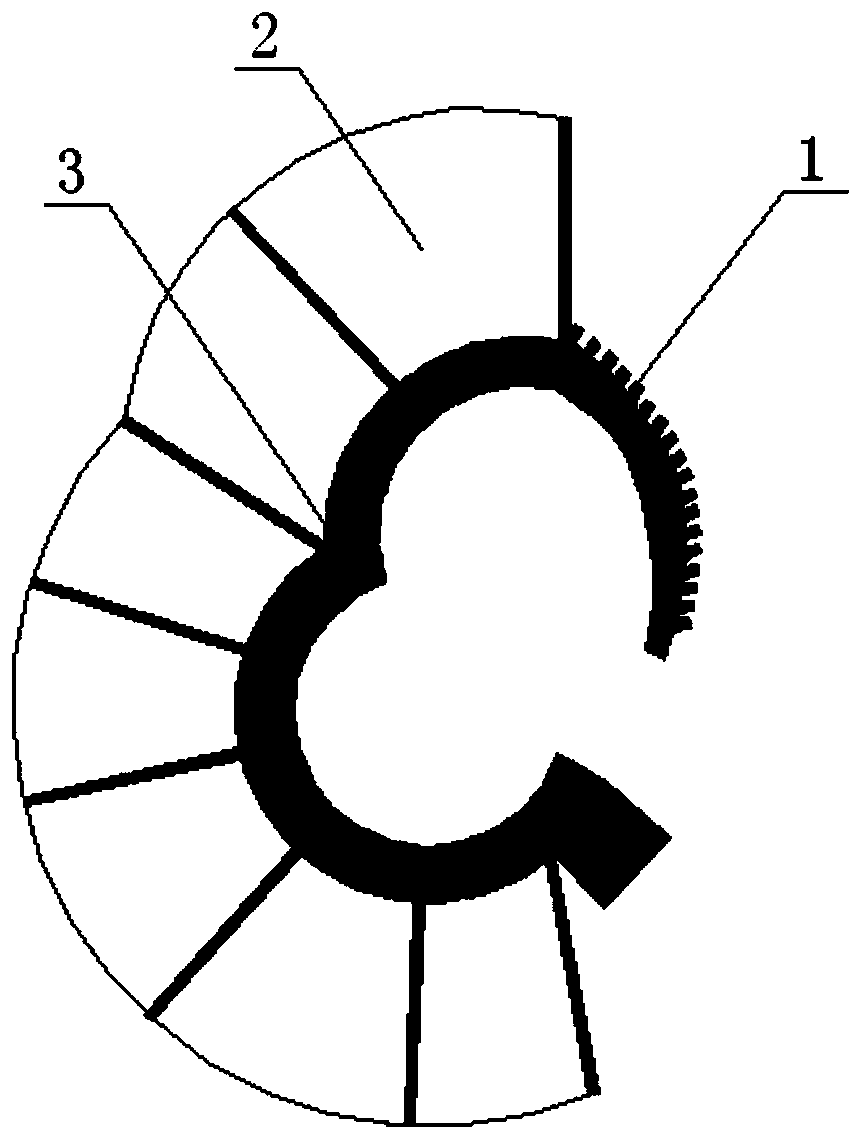

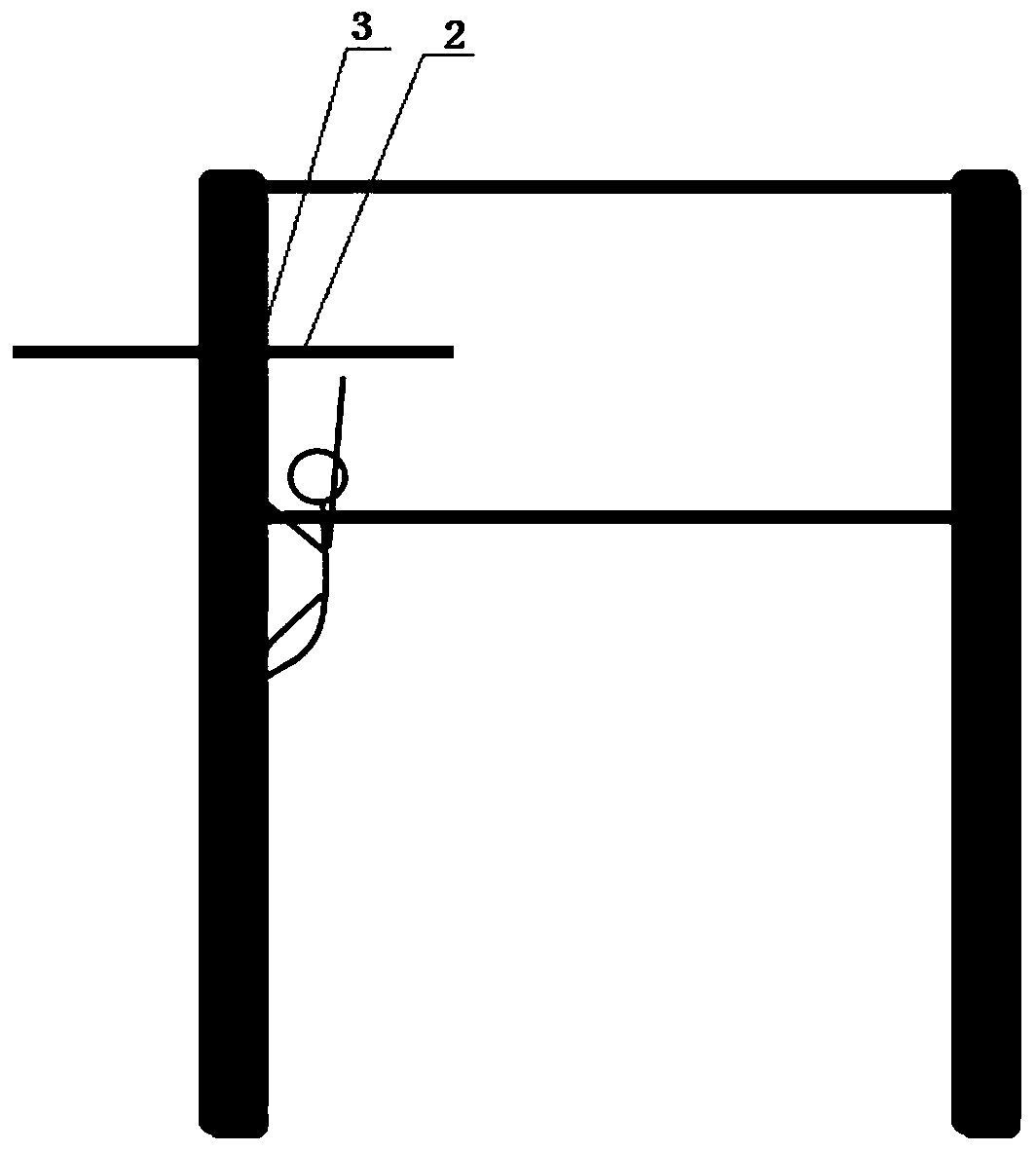

On-pole folding insulation shielding device

InactiveCN110912018AEasy to carryReliable shielding of live equipmentInsulating bodiesApparatus for overhead lines/cablesEngineeringStructural engineering

The invention relates to a folding insulation shielding device used on a pole. The device comprises an insulation hoop, an insulation shield and a telescopic insulation ruler, the insulation shield isinstalled on the insulation hoop, the insulation shield can be folded and unfolded to form an annular plane, the insulation shield and the insulation hoop are connected in a sliding mode, and the telescopic insulation ruler is fixedly installed on the insulation hoop and is perpendicular to the insulation shield. According to the invention, the technical blank is filled up, and the device is foldable, convenient to carry, selectable in various types, suitable for various voltage classes, capable of safely measuring distance and capable of reliably shielding electrified equipment. Meanwhile, the operation is extremely simple, and the workload is not increased while the safety is guaranteed.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com