Oil tank capable of detecting oil quality

A fuel tank and fuel tank port technology is applied in the field of detectable fuel tanks, which can solve the problems of oil quality problems, economic losses of the owner, and inability to take out, etc., to achieve good corrosion resistance and shock resistance, small size and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

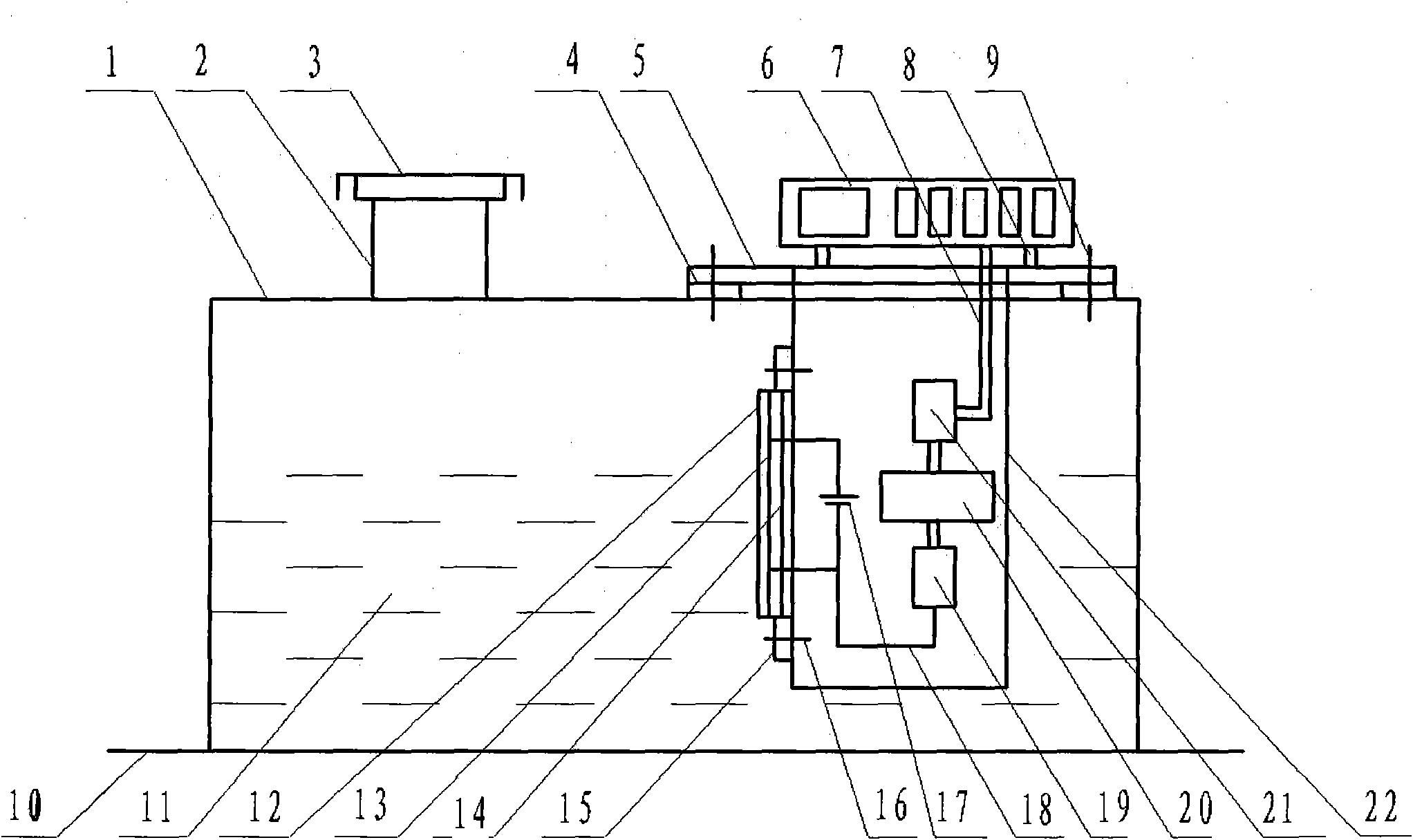

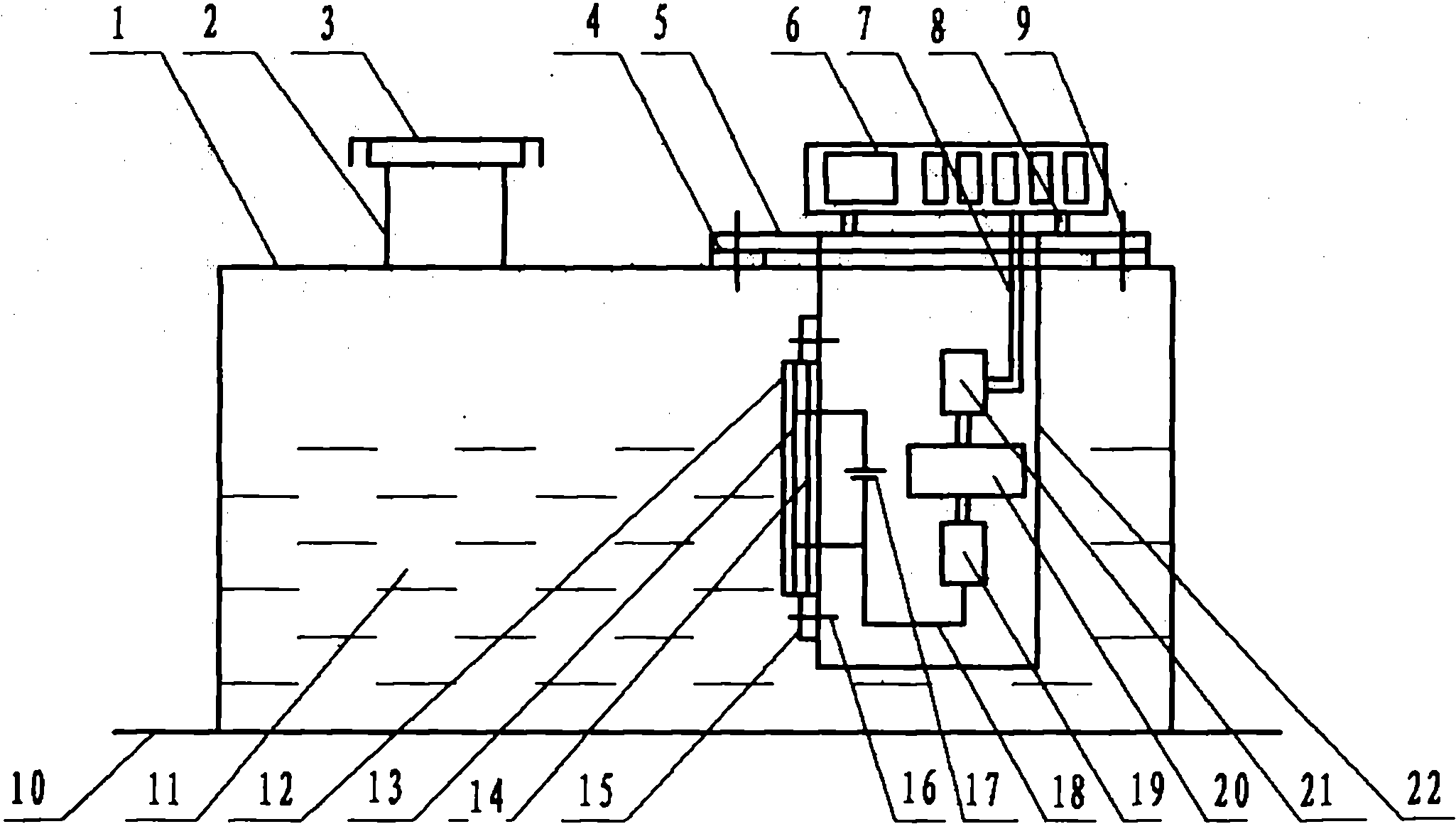

[0007] A detectable oil tank, which is composed of a fuel tank 1, a fuel tank port 2, a fuel tank cover 3, a gasket 4, a cover plate 5, a display screen 6, a cable bundle 7, a display screen bracket 8, and a cover plate fastener combination 9 , mounting plate 10, oil 11, substrate 12, sensitive grid 13, cover layer 14, strain gauge fixing plate 15, fixing plate fastener combination 16, built-in power supply 17, electric wire 18, analog-to-digital converter 19, microprocessor 20, a display module 21, and an installation barrel 22; the fuel tank port 2 is connected to the fuel tank 1, the fuel tank cover 3 is connected to the fuel tank port 2, the gasket 4 is connected to the cover plate 5 and the installation barrel 22, and the cover plate 5 is connected to the fuel tank 1 and sealed Pad 4, cover plate fastener combination 9 is connected with installation bucket 22, display screen 6 is connected with display screen bracket 8, display screen bracket 8 is connected with cover plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com