Method for reducing surface blasting dust

A dust and open-air technology, applied in blasting and other directions, can solve the problems of many dust generating points, large dust production, and low dust concentration, and achieve the effects of convenient operation, simple structure and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

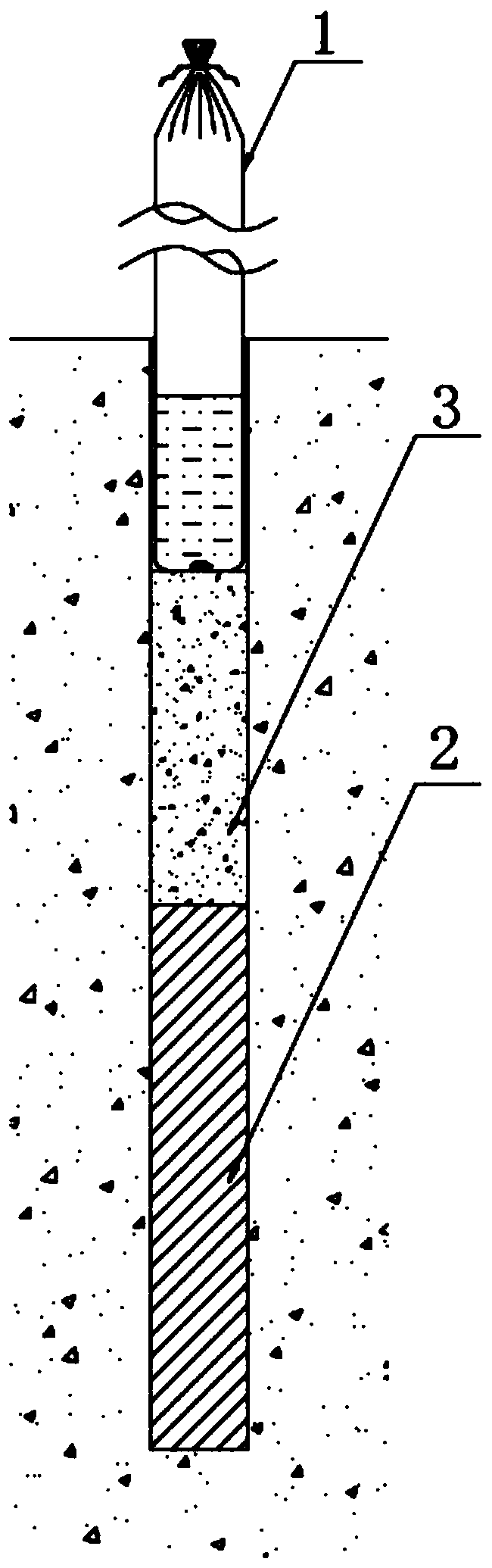

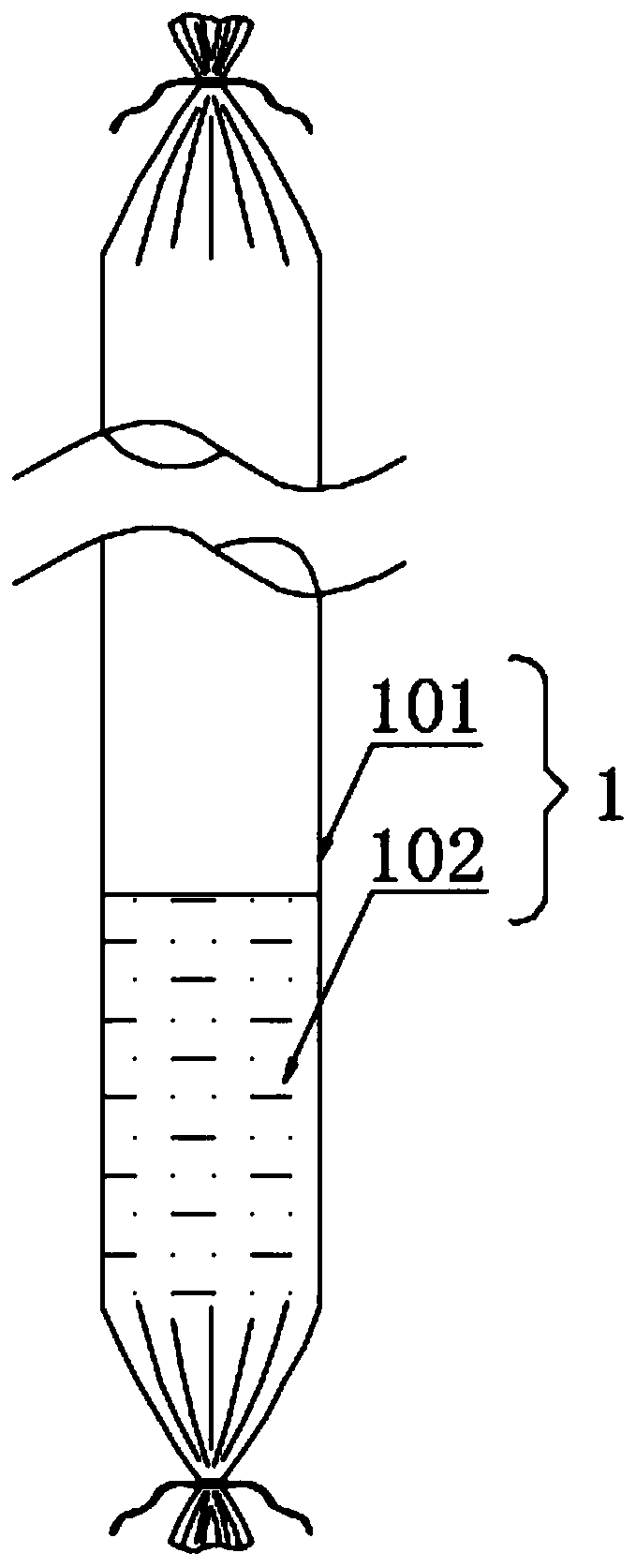

[0034] according to Figure 1-2 The shown method for reducing dust in open-air blasting includes a dust blocking mechanism 1, the dust blocking mechanism 1 includes a water bag 101 and a water seal 102, the water seal 102 is arranged inside the water bag 101, and the water seal 102 including water and surfactants;

[0035] The water bag 101 is set in a cylindrical shape, and the diameter of the water bag 101 is smaller than the diameter of the blast hole, so as to avoid the water bag 101 from being too compressed and bursting;

[0036] Described water bag 101 is made of transparent plastic cloth, is convenient to observe the height that water seal 102 is poured into;

[0037] The method of blasting using the dust blocking mechanism 1 is as follows:

[0038] S1. According to the actual blasting situation, determine the blasting force, blasting position, and the amount of explosives and mud required for blasting, and then dig a blast hole with an appropriate diameter and depth...

Embodiment 2

[0045] according to Figure 1-2 The shown method for reducing dust in open-air blasting includes a dust blocking mechanism 1, the dust blocking mechanism 1 includes a water bag 101 and a water seal 102, the water seal 102 is arranged inside the water bag 101, and the water seal 102 including water and surfactants;

[0046] The water bag 101 is set in a cylindrical shape, and the diameter of the water bag 101 is smaller than the diameter of the blast hole, so as to avoid the water bag 101 from being too compressed and bursting;

[0047] Described water bag 101 is made of transparent plastic cloth, is convenient to observe the height that water seal 102 is poured into;

[0048] The method of blasting using the dust blocking mechanism 1 is as follows:

[0049]S1. According to the actual blasting situation, determine the blasting force, blasting position, and the amount of explosives and mud required for blasting, and then dig a blast hole with an appropriate diameter and depth ...

Embodiment 3

[0056] according to Figure 1-2 The shown method for reducing dust in open-air blasting includes a dust blocking mechanism 1, the dust blocking mechanism 1 includes a water bag 101 and a water seal 102, the water seal 102 is arranged inside the water bag 101, and the water seal 102 including water and surfactants;

[0057] The water bag 101 is set in a cylindrical shape, and the diameter of the water bag 101 is smaller than the diameter of the blast hole, so as to avoid the water bag 101 from being too compressed and bursting;

[0058] Described water bag 101 is made of transparent plastic cloth, is convenient to observe the height that water seal 102 is poured into;

[0059] The method of blasting using the dust blocking mechanism 1 is as follows:

[0060] S1. According to the actual blasting situation, determine the blasting force, blasting position, and the amount of explosives and mud required for blasting, and then dig a blast hole with an appropriate diameter and depth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com