Method for cutting silicon rod

A cutting method and silicon rod technology, which are applied in stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems of silicon wafer TTV and warpage, and achieve the effect of simple method, easy operation and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

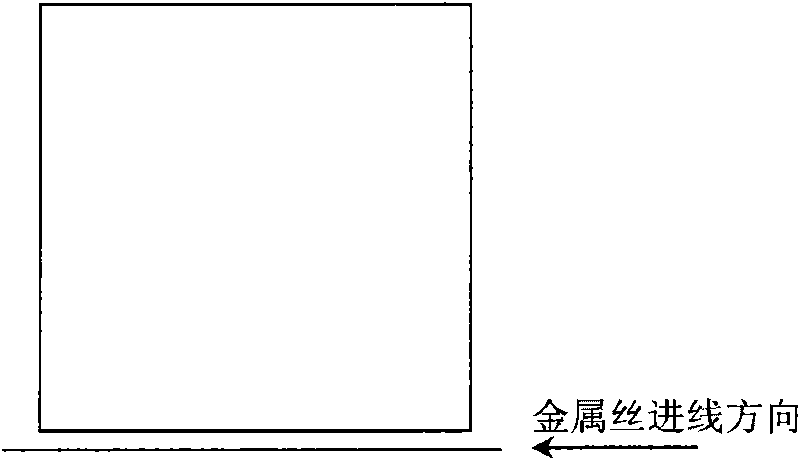

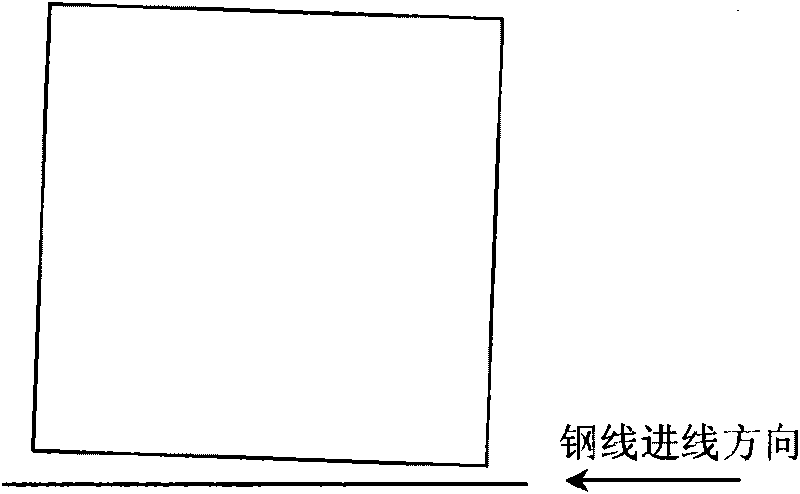

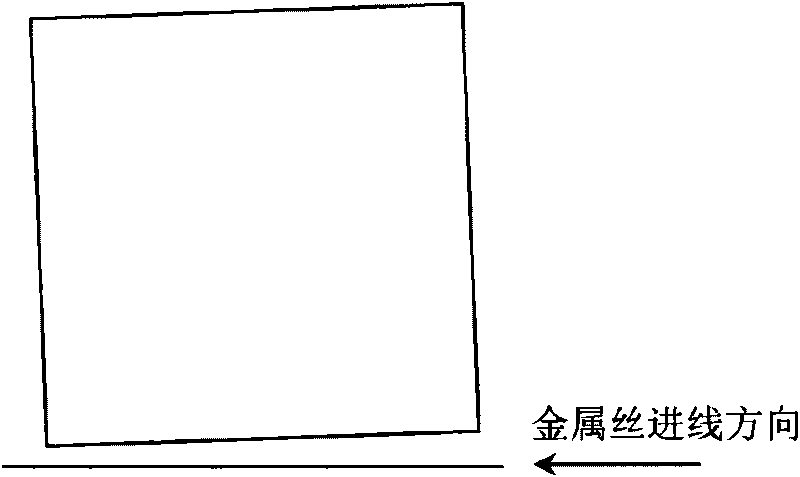

[0019] See attached image 3 As shown, a cutting method of a silicon rod includes wire cutting by using a metal wire and matching abrasives, and setting the silicon rod obliquely so that the side of the cutting surface located downstream of the wire travel direction is in contact with the wire first, The angle between the feed face and the wire is 3 degrees.

[0020] In the above, other operation methods are the same as the existing multi-wire cutting method, and the improvement of the present invention is only that the cutting surface of the silicon rod and the metal wire are deliberately formed at a relatively large angle, so as to avoid the The impact of the angle difference between the cutting surface and the metal wire; let one side of the silicon rod participate in the cutting first. Facts have proved that this cutting method will not produce any adverse effects, and can completely solve the defects of silicon wafer TTV and warpage. , getting qualified silicon wafers wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com