Novel sea cucumber processing equipment

A processing equipment and sea cucumber technology, which is applied in the field of new sea cucumber processing equipment, can solve the problems of inconvenient transportation of fresh water, lower work efficiency, and affect the quality of sea cucumbers, and achieve the effects of improved flexibility, increased workload, and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

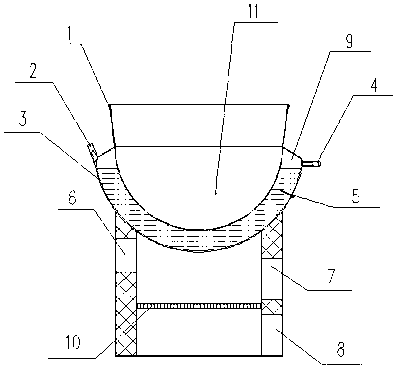

[0025] Embodiment 1: with reference to attached figure 1 . A new type of sea cucumber processing equipment, including a stainless steel interlayer pot and a coal-fired furnace 10. A coal-fired furnace 10 is installed at the bottom of the stainless steel interlayer pot. The coal-fired furnace 10 is equipped with a blower. For cooperation, the stainless steel sandwich pot includes an inner tank 1, an outer wall 3 and an interlayer 9. The interlayer 9 is hemispherical with built-in heat transfer oil. One side of the interlayer 9 is provided with a fuel port 4, and the other side is provided with an exhaust port 2. The interlayer 9 has a wall 9 Put the oil temperature sensor 5, the upper part of the inner tank 1 extends outward at an angle of 83 degrees with the horizontal line to the pot edge of the inner tank 1 to reach a diameter of 850mm, the lower half of the inner tank 1 is a hemispherical shape with a radius of 400mm, and the inner tank 1 wall A water temperature sensor is...

Embodiment 2

[0026] Embodiment 2: with reference to attached figure 1 , a new type of sea cucumber processing equipment, the oil temperature sensor 4 in the interlayer 9 of the stainless steel sandwich pot is arranged at the middle and lower part of the interlayer 9, and the display end of the oil temperature sensor 4 is exposed on the outer wall 3 of the stainless steel interlayer pot, and the water temperature sensor 11 is located in the inner tank 1 wall, the display end of the water temperature sensor 11 is exposed at the opening of the inner tank 1.

Embodiment 3

[0027] Embodiment 3: with reference to attached figure 1 , a new type of sea cucumber processing equipment, the upper end of the coal-fired furnace 10 is provided with a circular opening with a diameter of 800mm, and the interior is divided into upper and lower layers by a hollowed-out partition, and a circular smoke exhaust with a diameter of 155mm-165mm is opened above the left end of the upper layer There is a square carbon-filled air inlet 7 with a height of 195mm-205mm under the right end of the upper layer, and a square ash outlet 8 with a height of 195mm-205mm is opened at the bottom of the right end of the lower layer. The furnace wall is a heat insulation wall with a thickness of 95mm-105mm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com