Patents

Literature

718results about How to "Small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

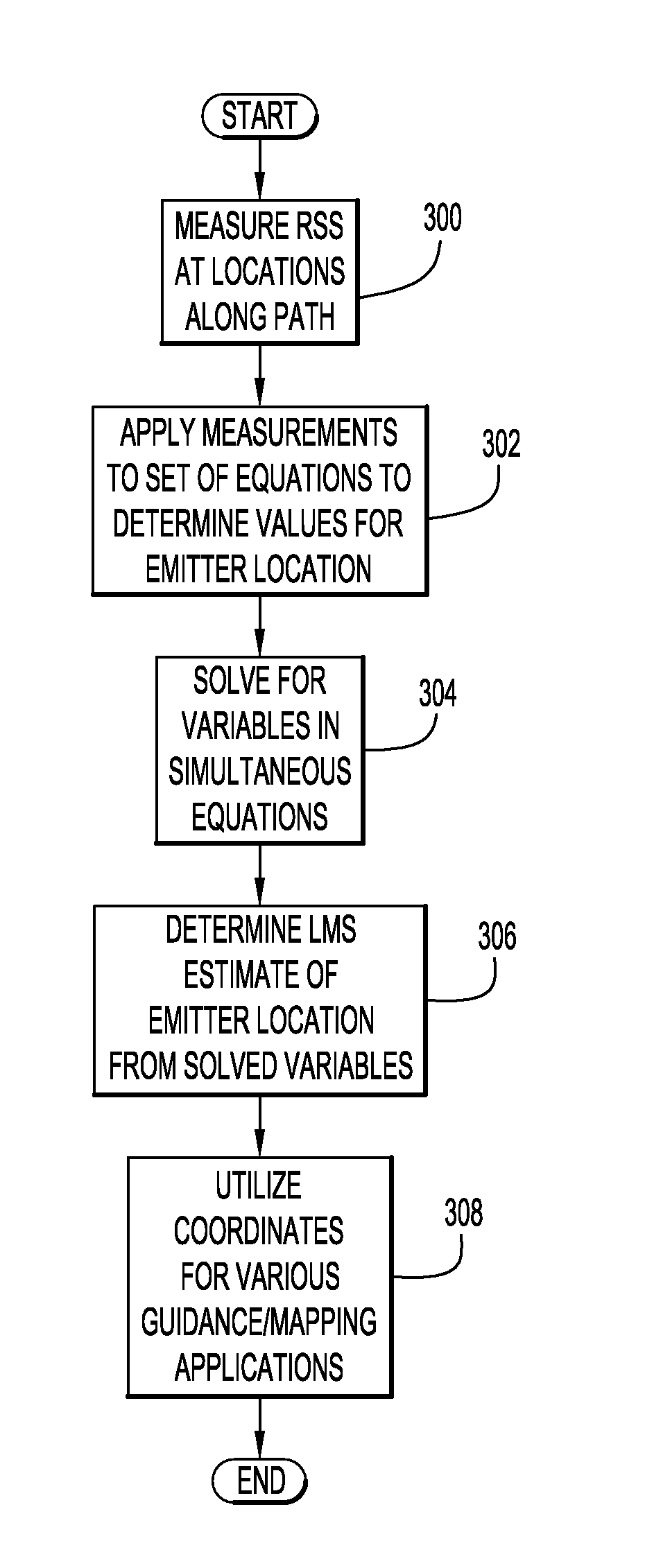

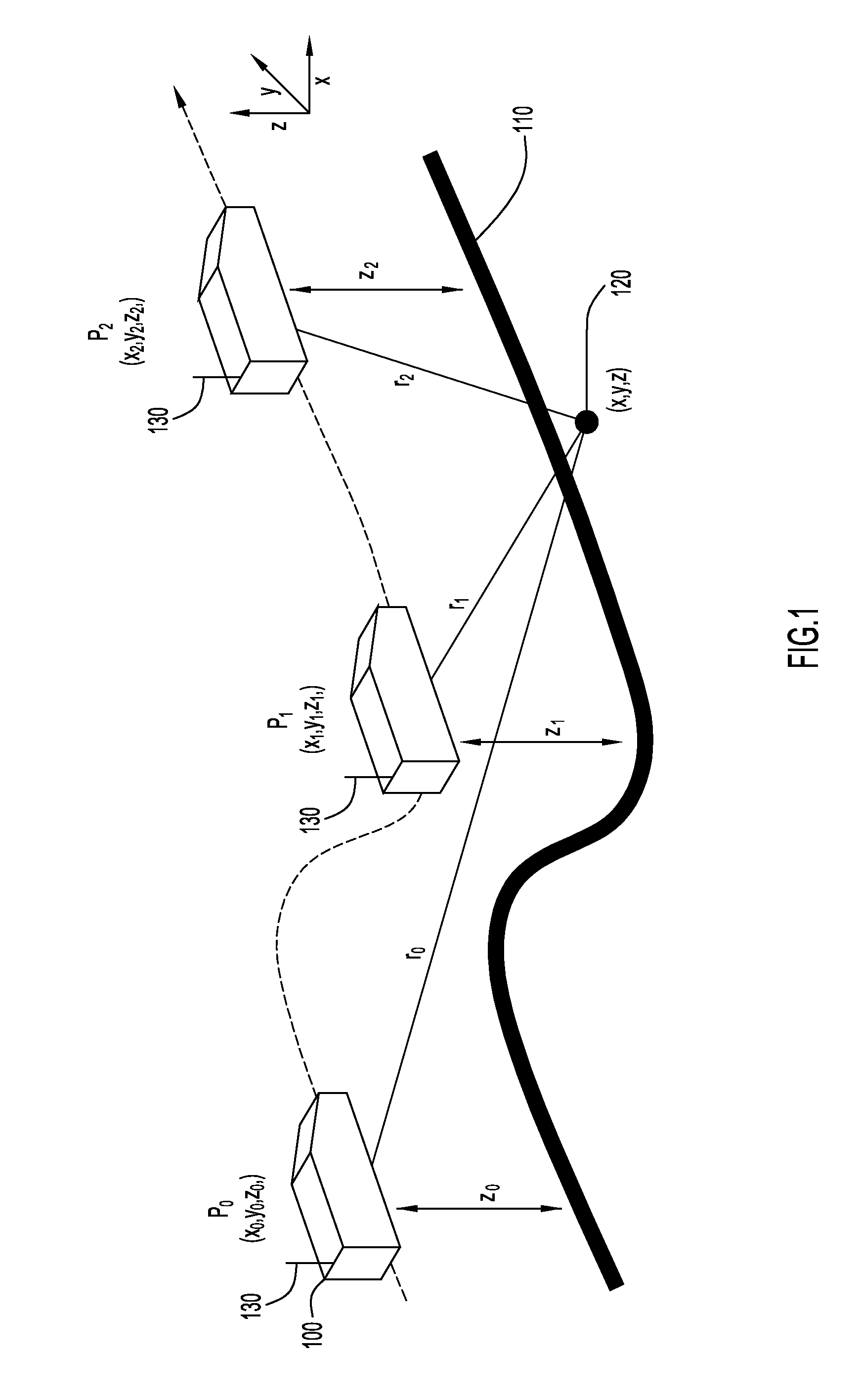

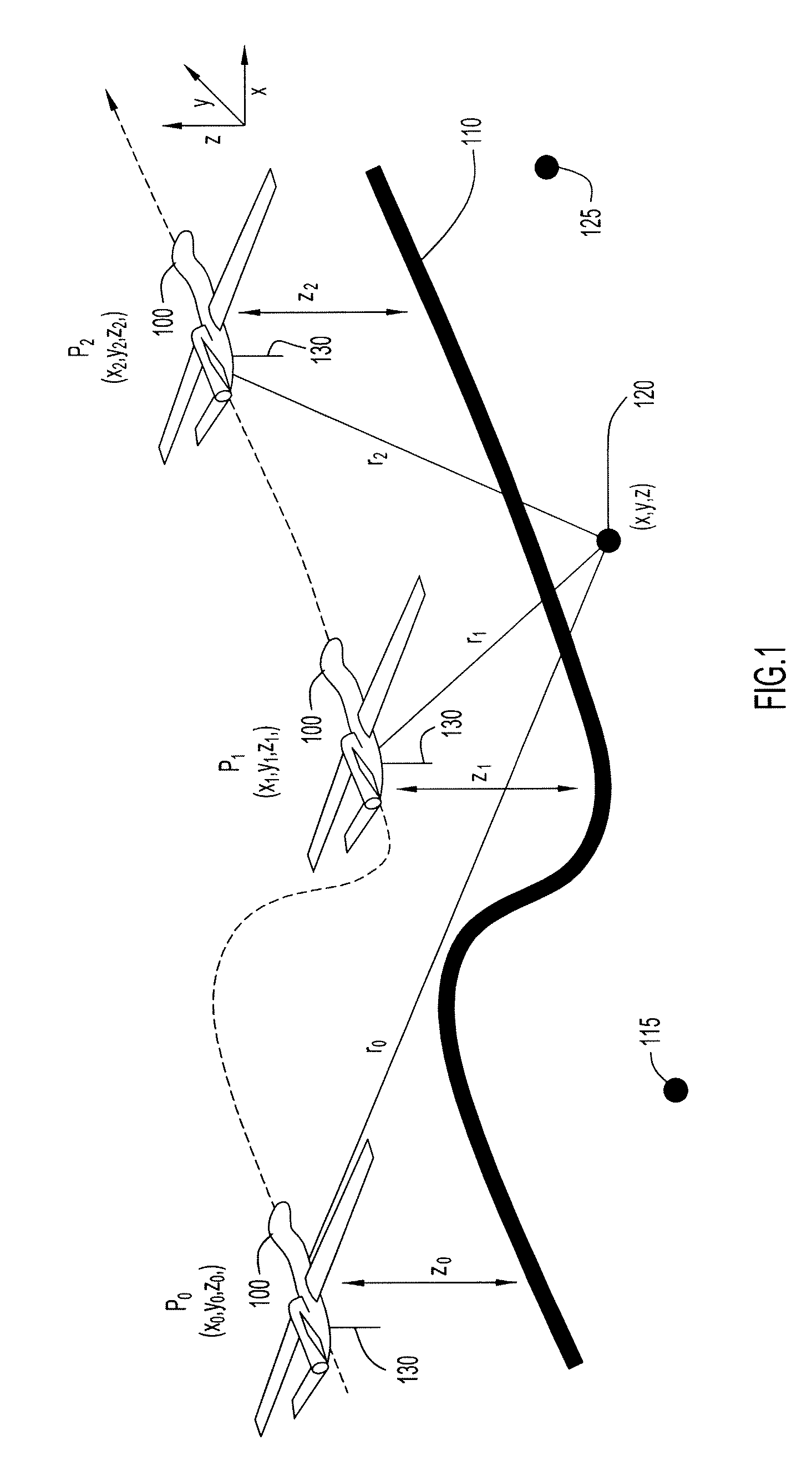

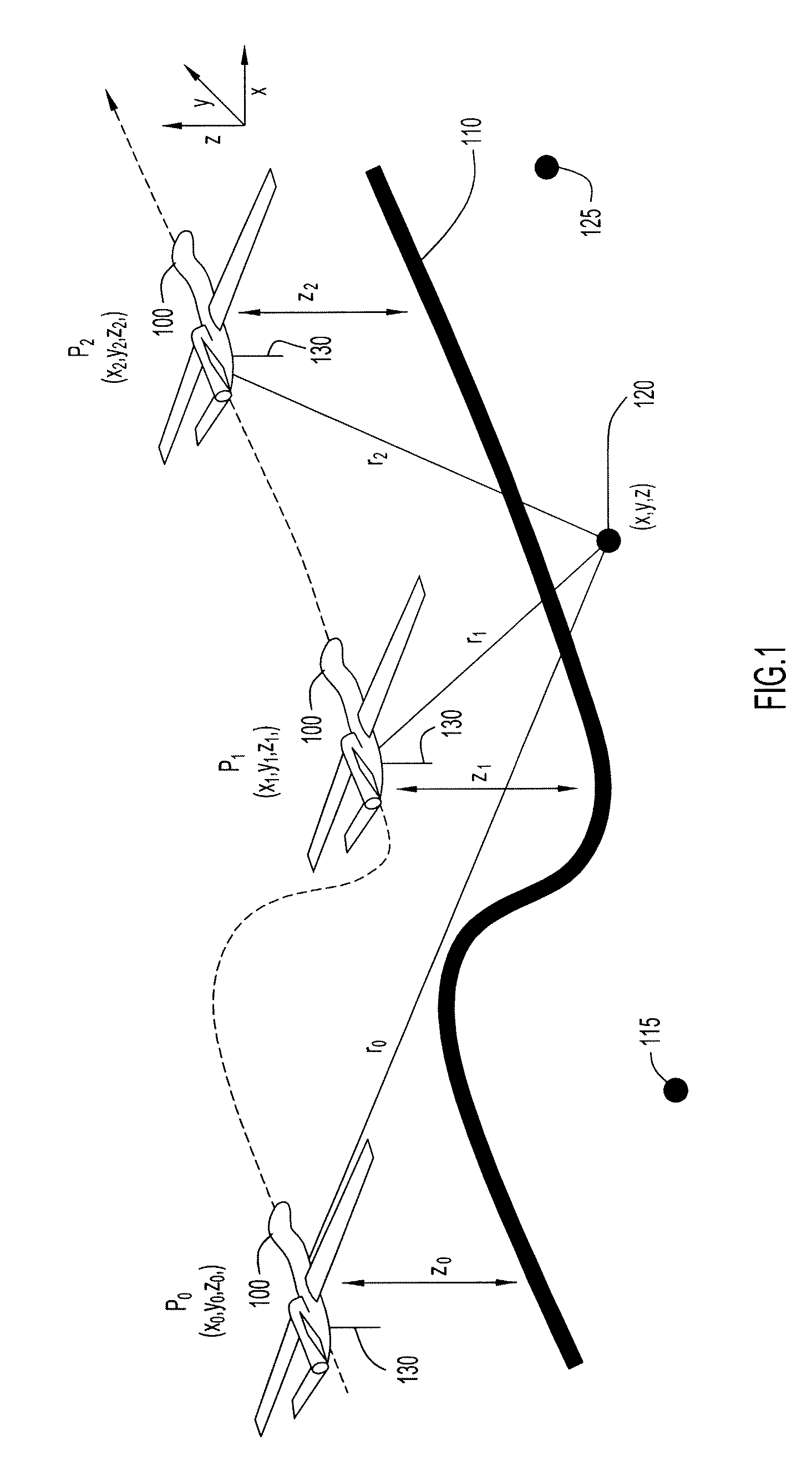

System and Method for Three-Dimensional Geolocation of Emitters Based on Energy Measurements

ActiveUS20120235864A1Reliably obtainError minimizationDirection finders using radio wavesPosition fixationEnergy basedGeolocation

According to an embodiment of the present invention, a three-dimensional (3-D) energy-based emitter geolocation technique determines the geolocation of a radio frequency (RF) emitter based on energy or received signal strength (RSS) of transmitted signals. The technique may be employed with small unmanned air vehicles (UAV), and obtains reliable geolocation estimates of radio frequency (RF) emitters of interest.

Owner:EXCELIS INC

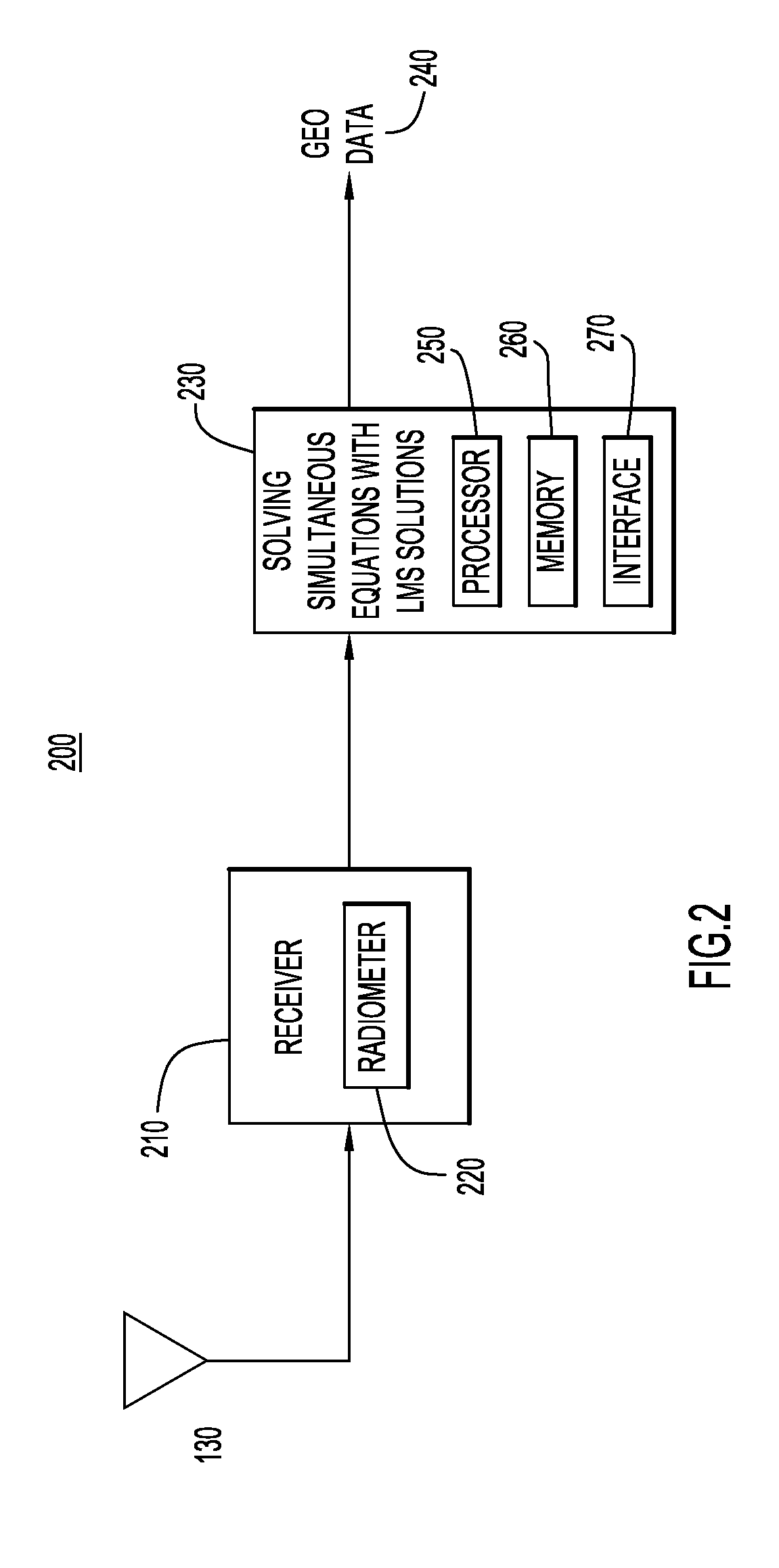

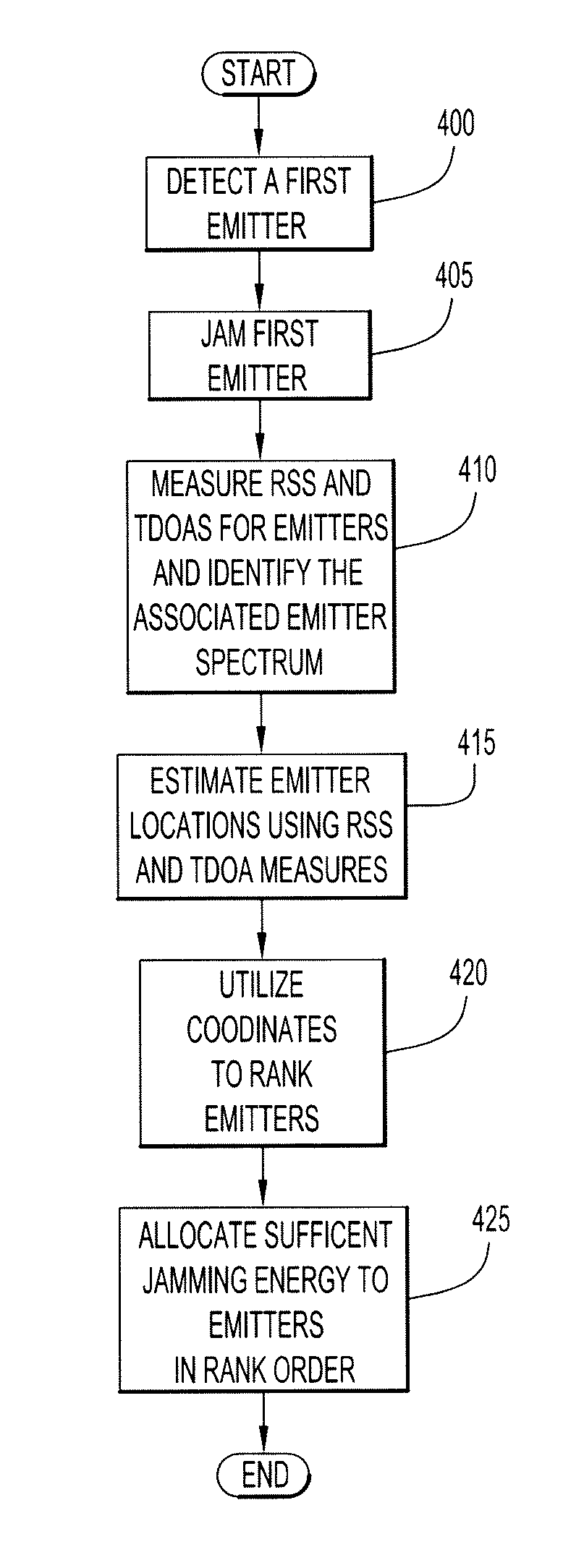

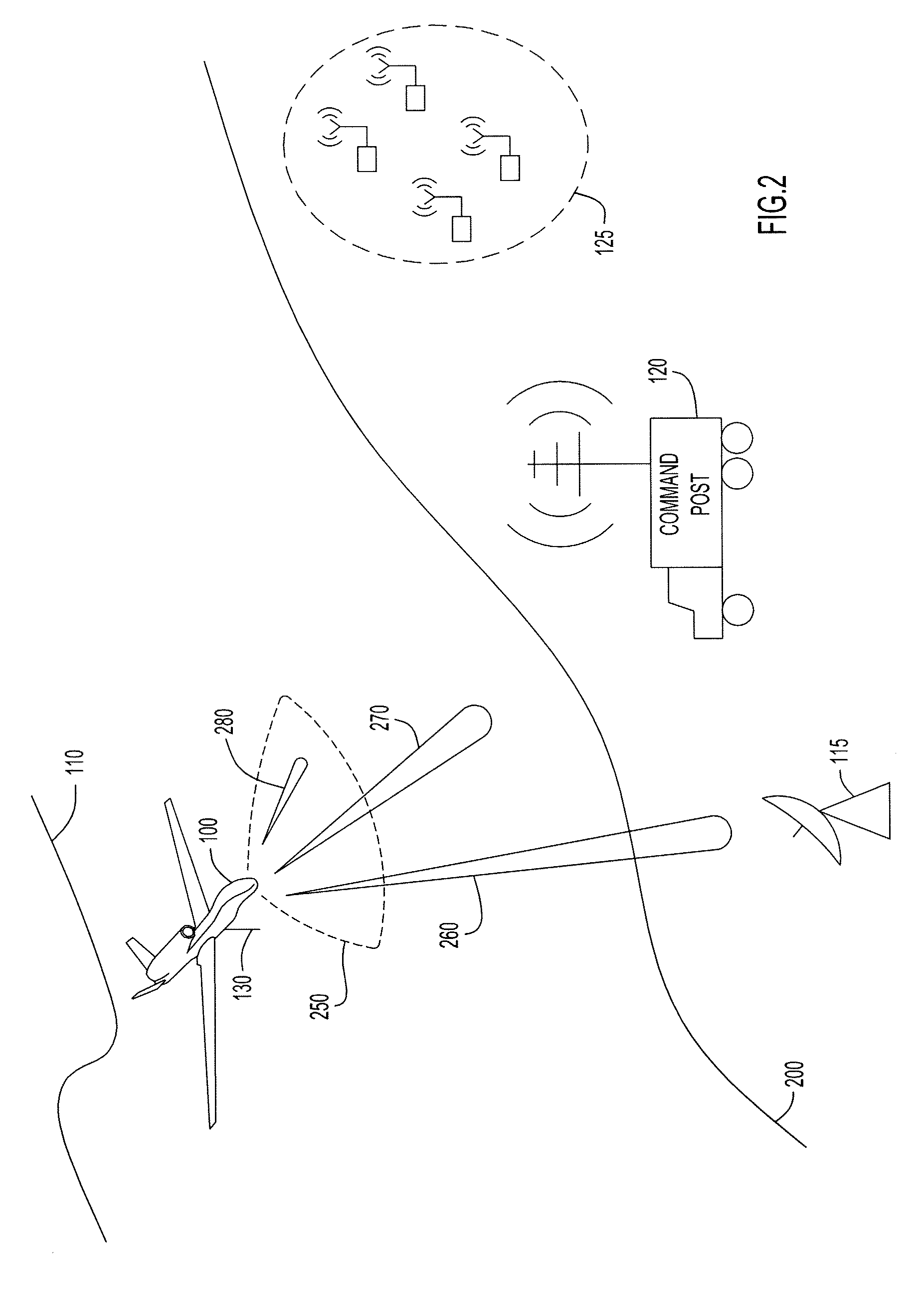

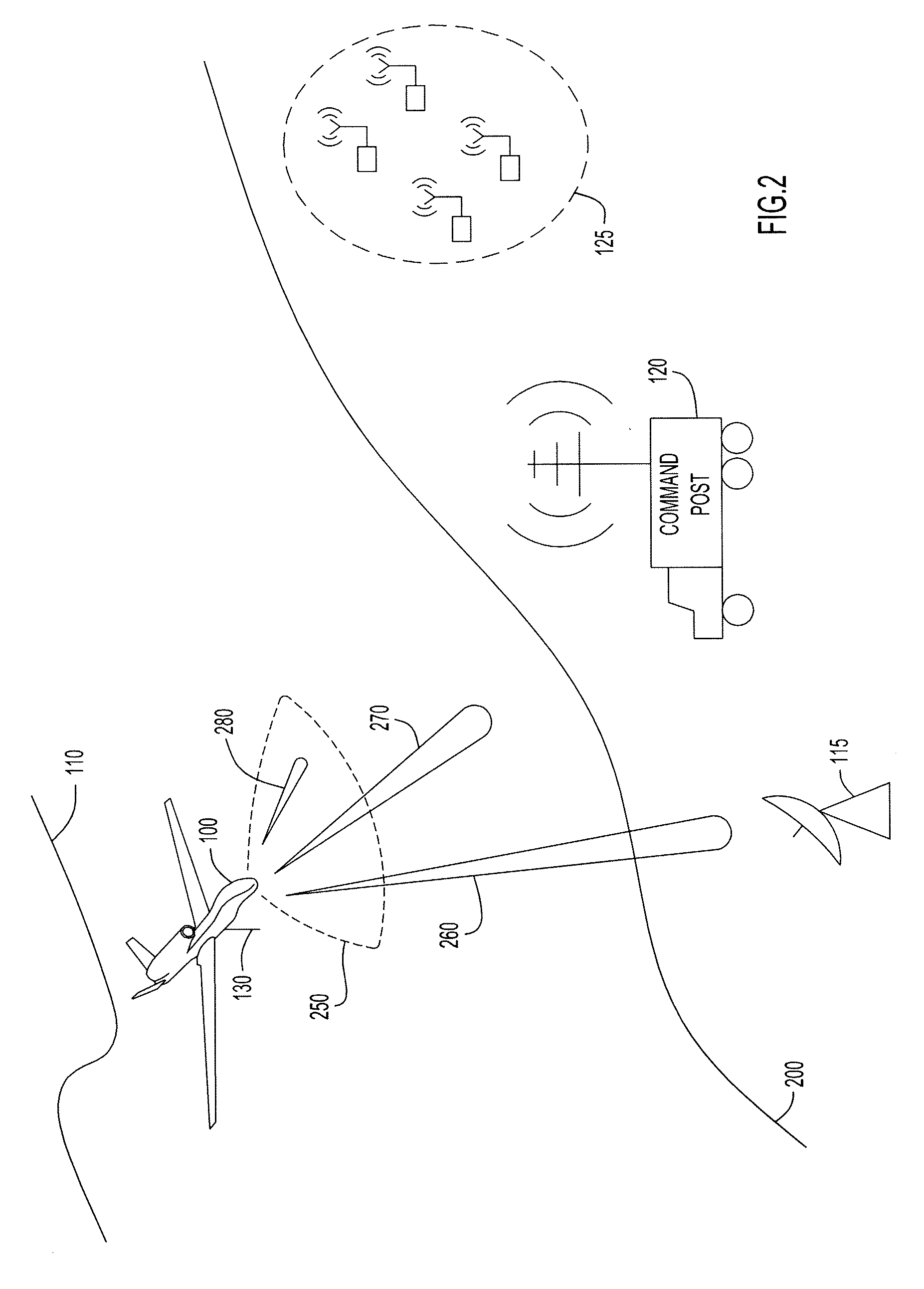

System and method for allocating jamming energy based on three-dimensional geolocation of emitters

ActiveUS8615190B2Cost-effectiveSmallWave based measurement systemsTelephonic communicationGeolocationEnergy based

According to an embodiment of the present invention jamming energy is allocated to a plurality of emitters based on a three-dimensional (3-D) emitter geolocation technique that determines the geolocation of radio frequency (RF) emitters based on energy or received signal strength (RSS) and / or time differences of arrival (TDOAs) of transmitted signals. The three-dimensional (3-D) emitter geolocations are used to rank emitters of interest according to distance and available radio frequency (RF) jamming energy is allocated to the emitters in rank order. The techniques may be employed with small unmanned air vehicles (UAV), and obtains efficient use of jamming energy when applied to radio frequency (RF) emitters of interest.

Owner:HARRIS CORP

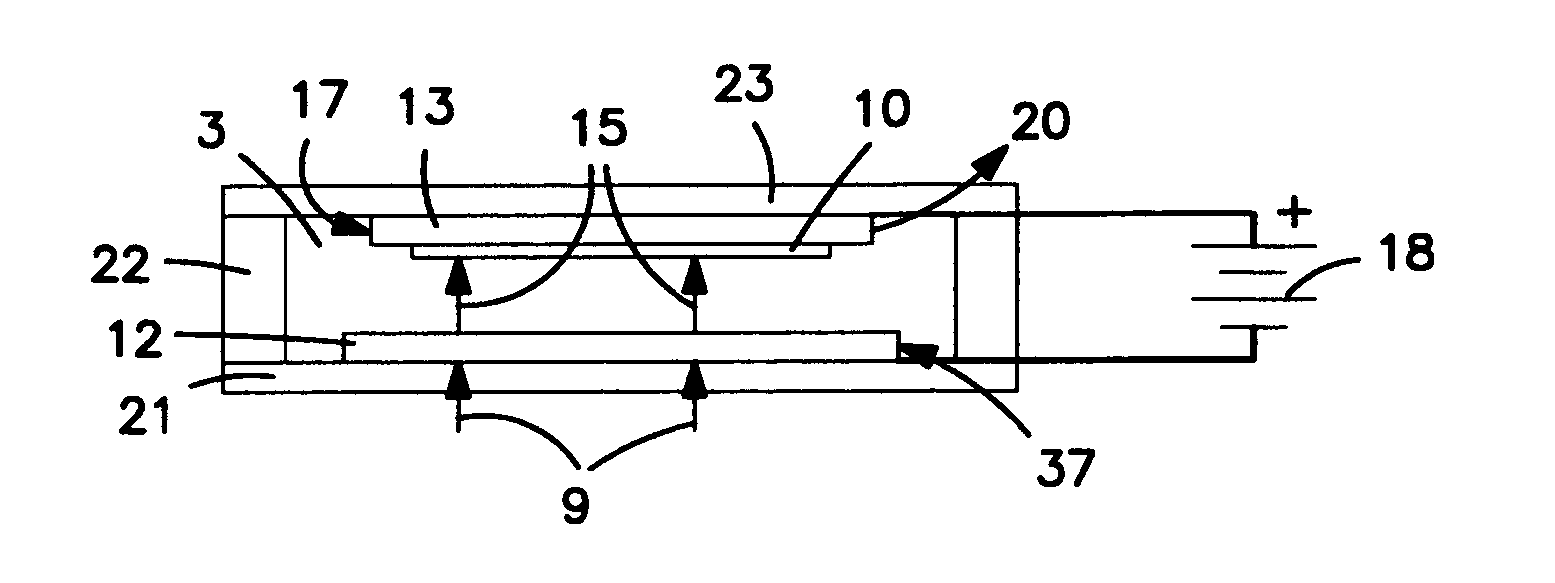

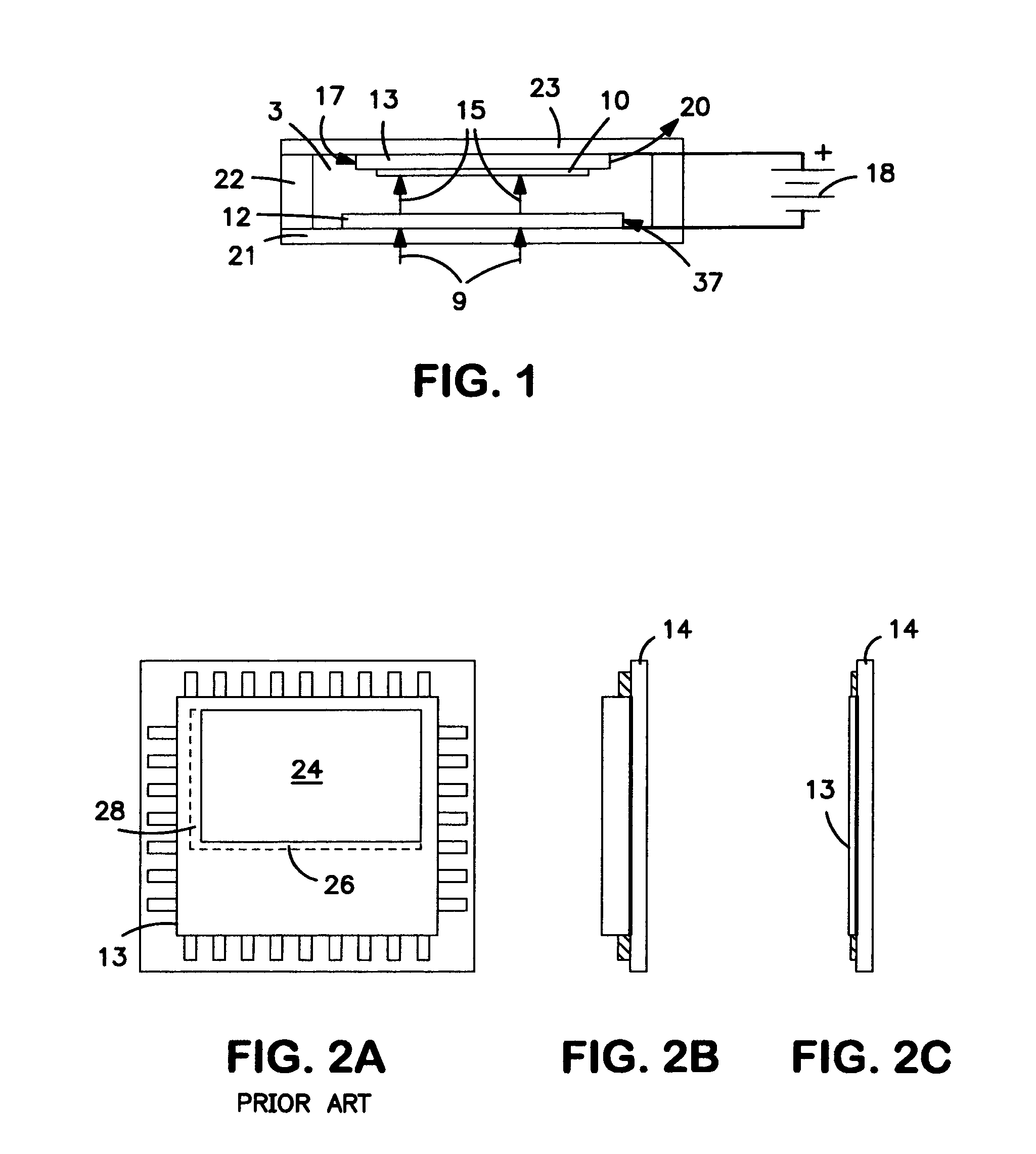

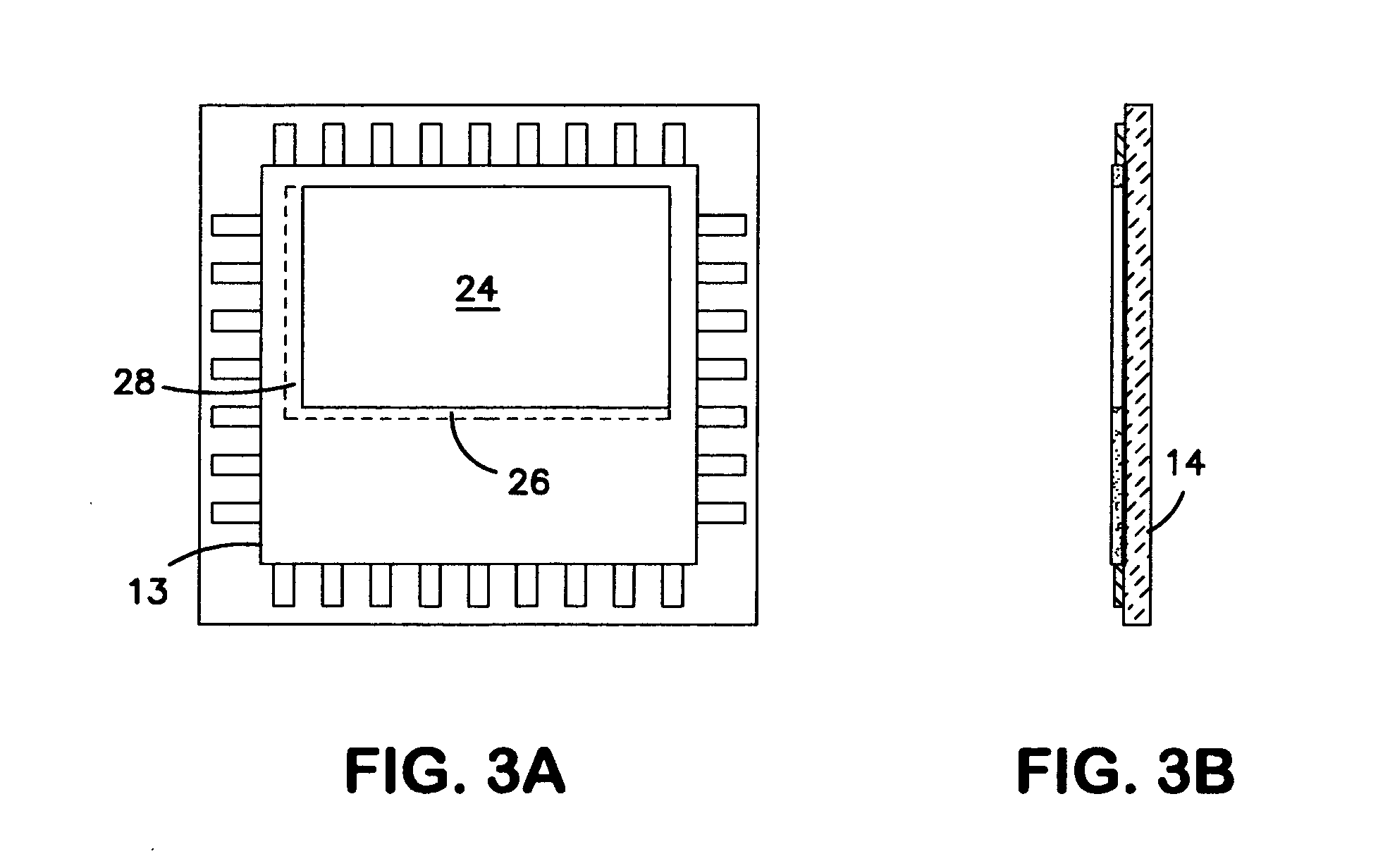

Backside imaging through a doped layer

ActiveUS20060138322A1Improve imaging effectImprove device yieldSolid-state devicesMaterial analysis by optical meansCMOSImage resolution

Backthinning in an area selective manner is applied to CMOS imaging sensors 12 for use in electron bombarded active pixel array devices. A further arrangement results in an array of collimators 51 aligned with pixels 42 or groups of pixels of an active pixel array providing improved image contrast of such image sensor. Provision of a thin P-doped layer 52 on the illuminated rear surface provides both a diffusion barrier resulting in improved resolution and a functional shield for reference pixels. A gradient in concentration of P-doped layer 52 optimizes electron collection at the pixel array.

Owner:EOTECH LLC

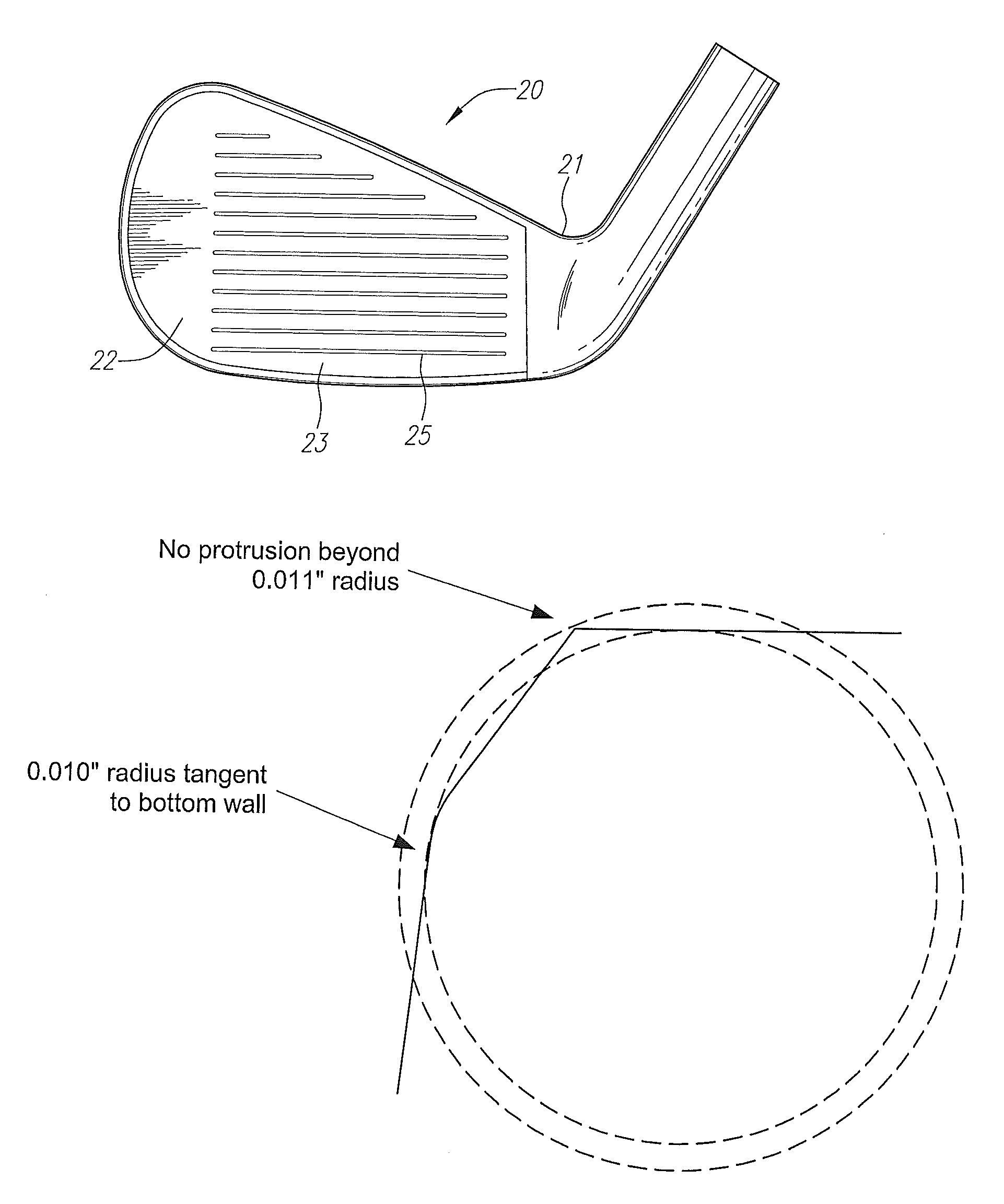

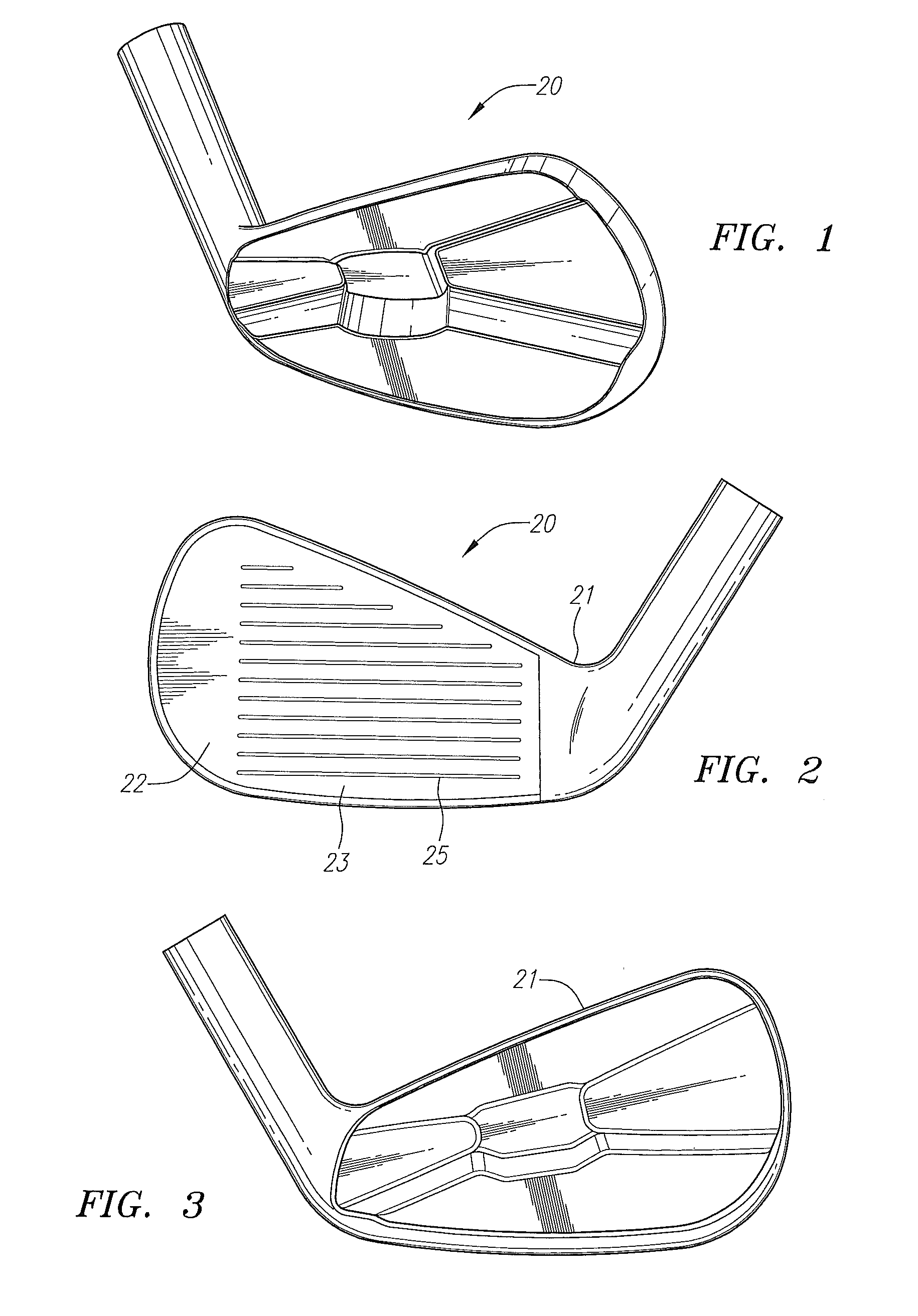

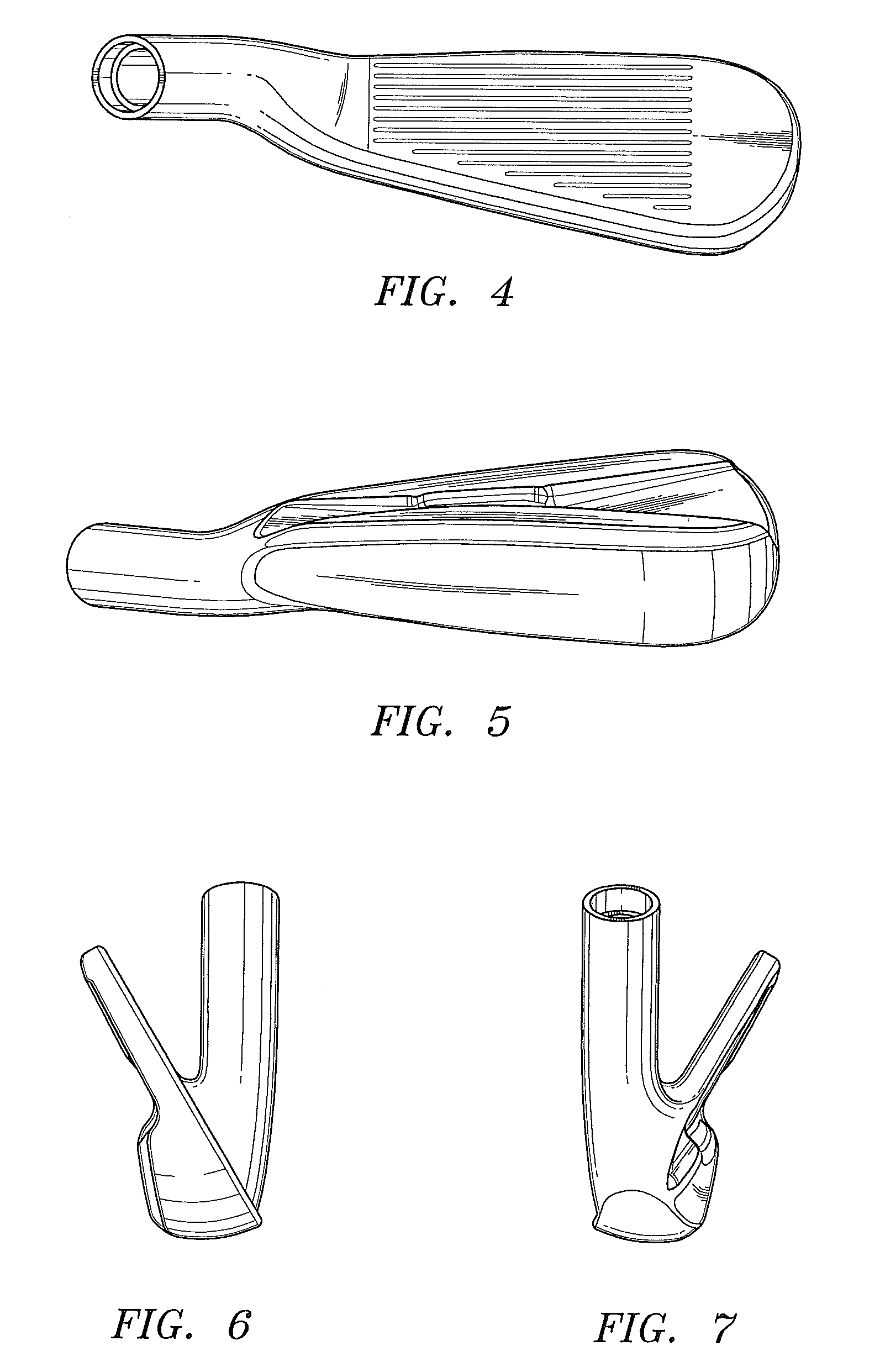

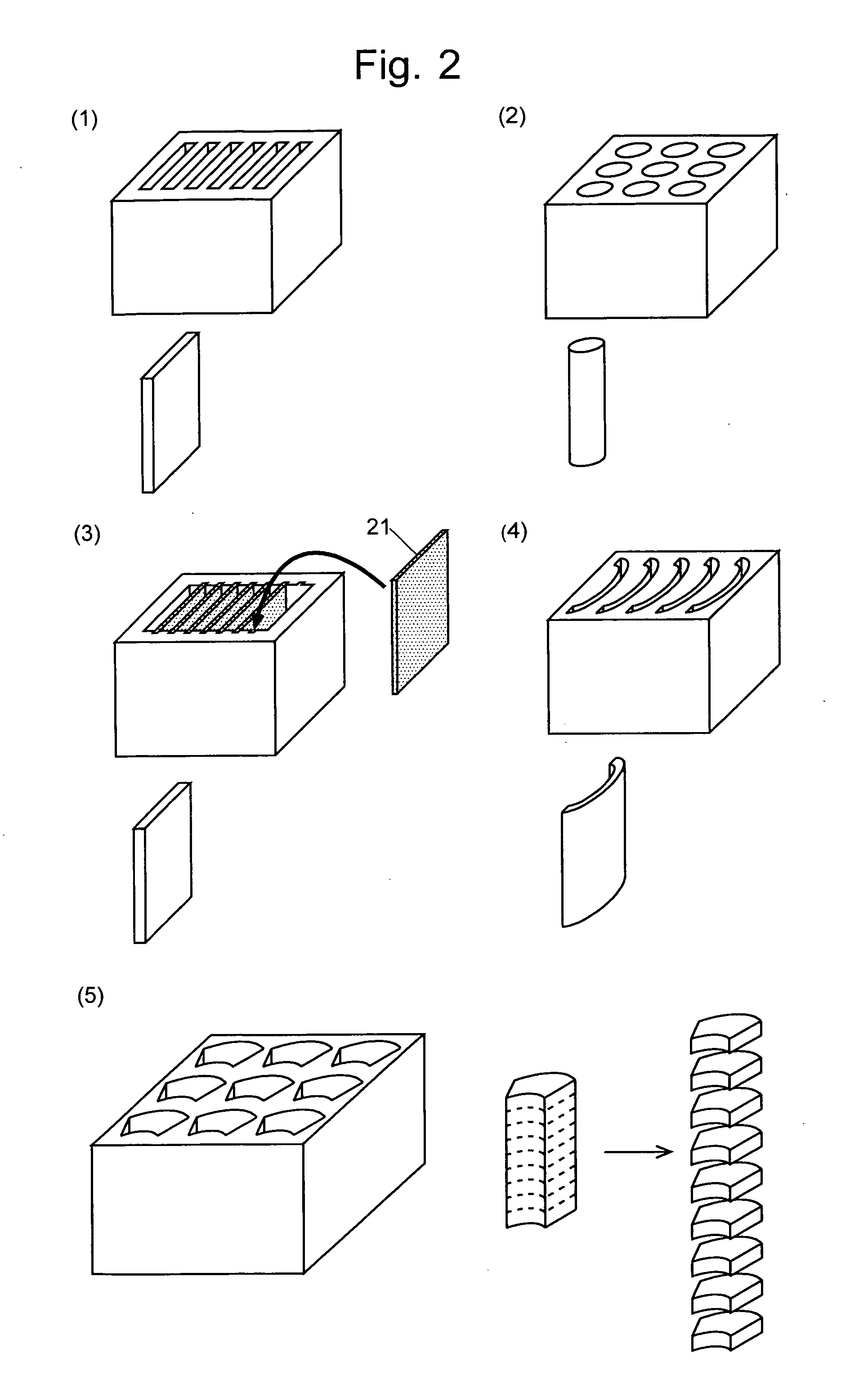

Iron-type golf club head with groove profile in ceramic face

The present invention provides a method of manufacture and design such that very small detail features can be produced within the groove profile on an iron or wedge. The advantage in being able to do this is that spin will be enhanced for a variety of shot types and conditions when striking a golf ball with cover composed of a urethane-based material.

Owner:TOPGOLF CALLAWAY BRANDS CORP

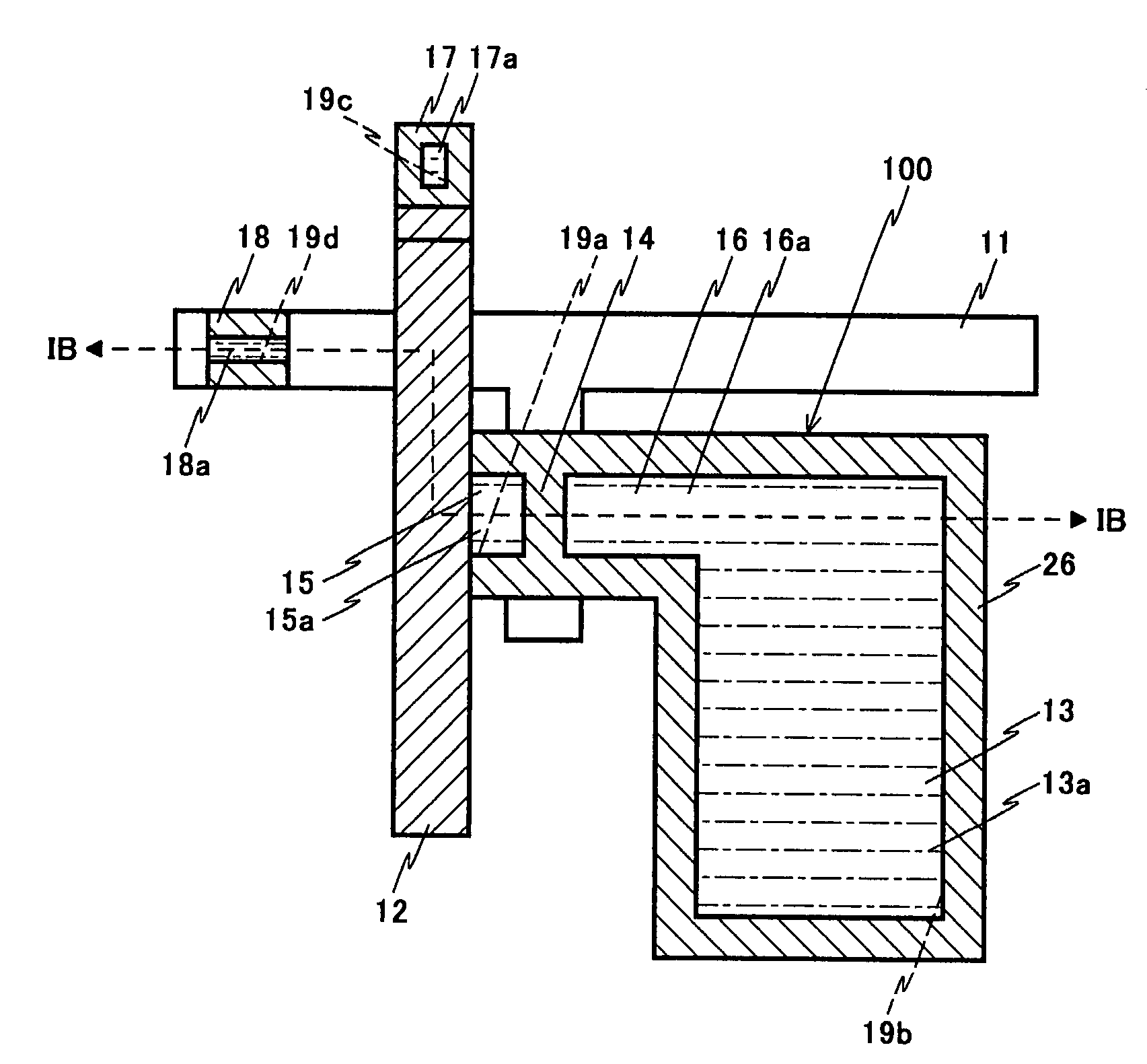

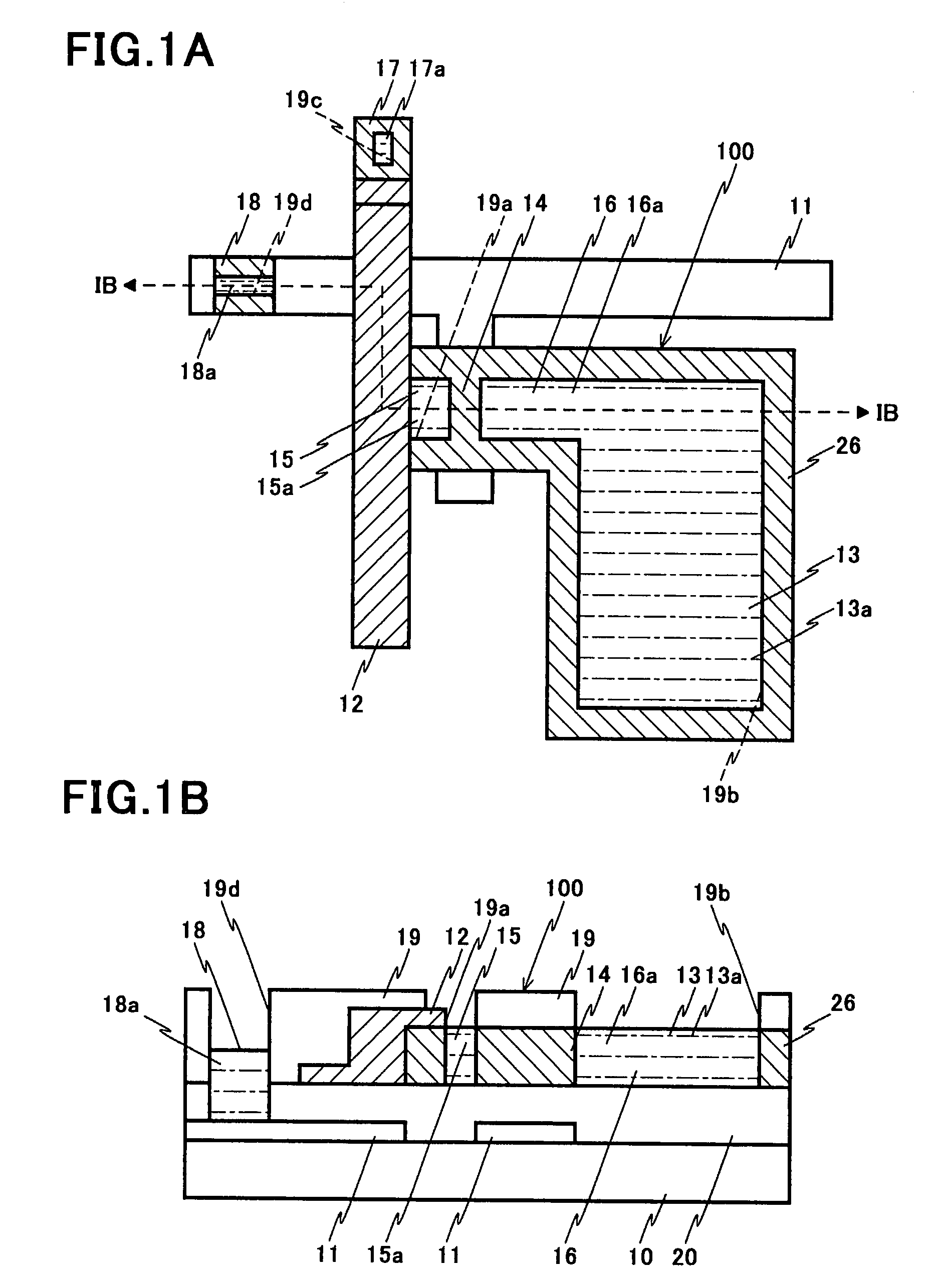

Thin-film transistor array, method of fabricating the same, and liquid crystal display device including the same

ActiveUS20080035920A1Improve electrical connection reliabilityReduce conductivitySolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A thin-film transistor array includes an electrically insulating substrate, a plurality of thin-film transistors arranged in a matrix on the substrate, and each including a channel, a source, and a drain each comprised of an oxide-semiconductor film, a pixel electrode integrally formed with the drain, a source signal line through which a source signal is transmitted to a group of thin-film transistors, a gate signal line through which a gate signal is transmitted to a group of thin-film transistors, a source terminal formed at an end of the source signal line, and a gate terminal formed at an end of the gate signal line. The source terminal and the gate terminal are formed in the same layer as a layer in which the channel is formed. The source terminal and the gate terminal have the same electric conductivity as that of the pixel electrode.

Owner:NEC LCD TECH CORP

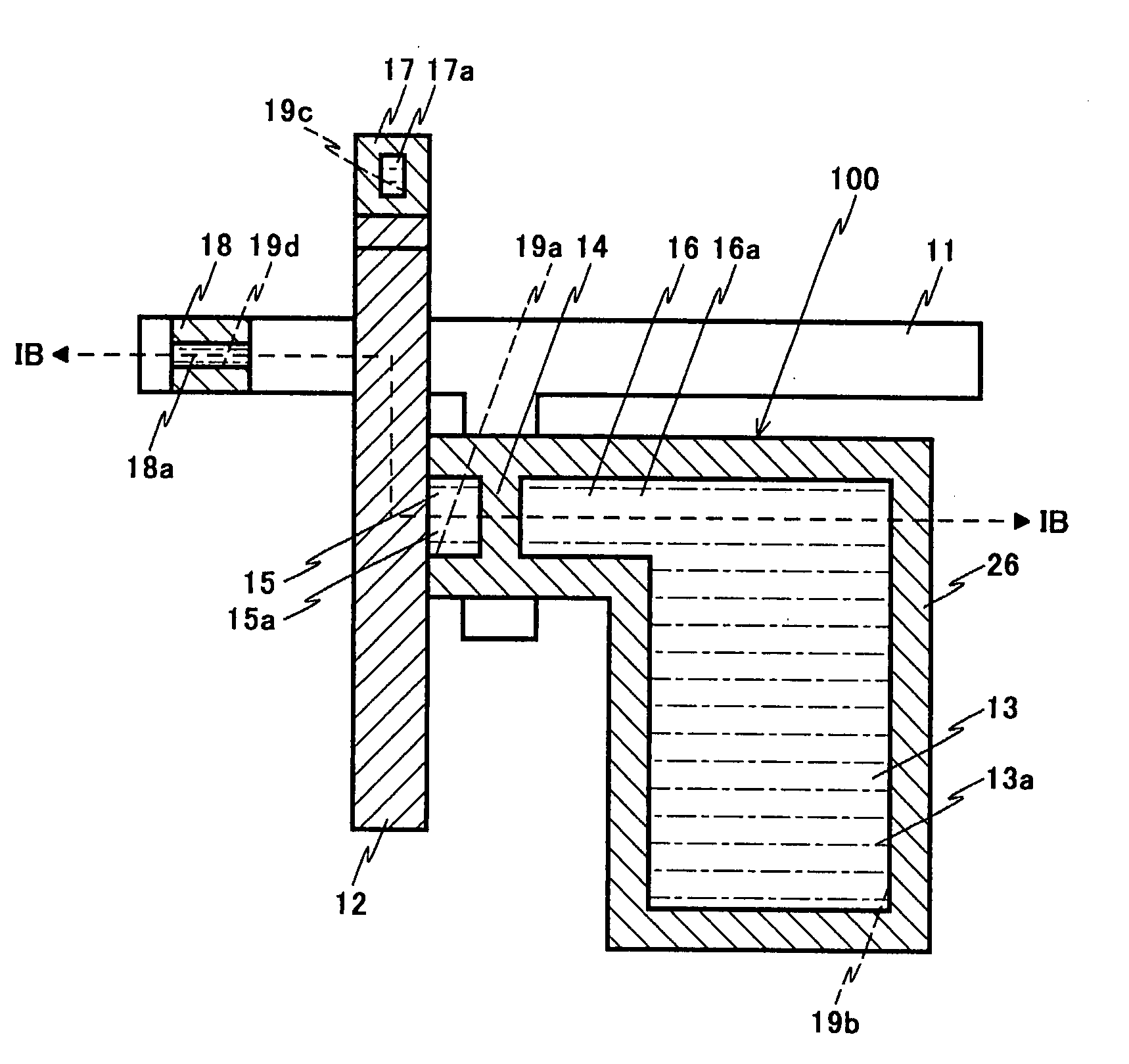

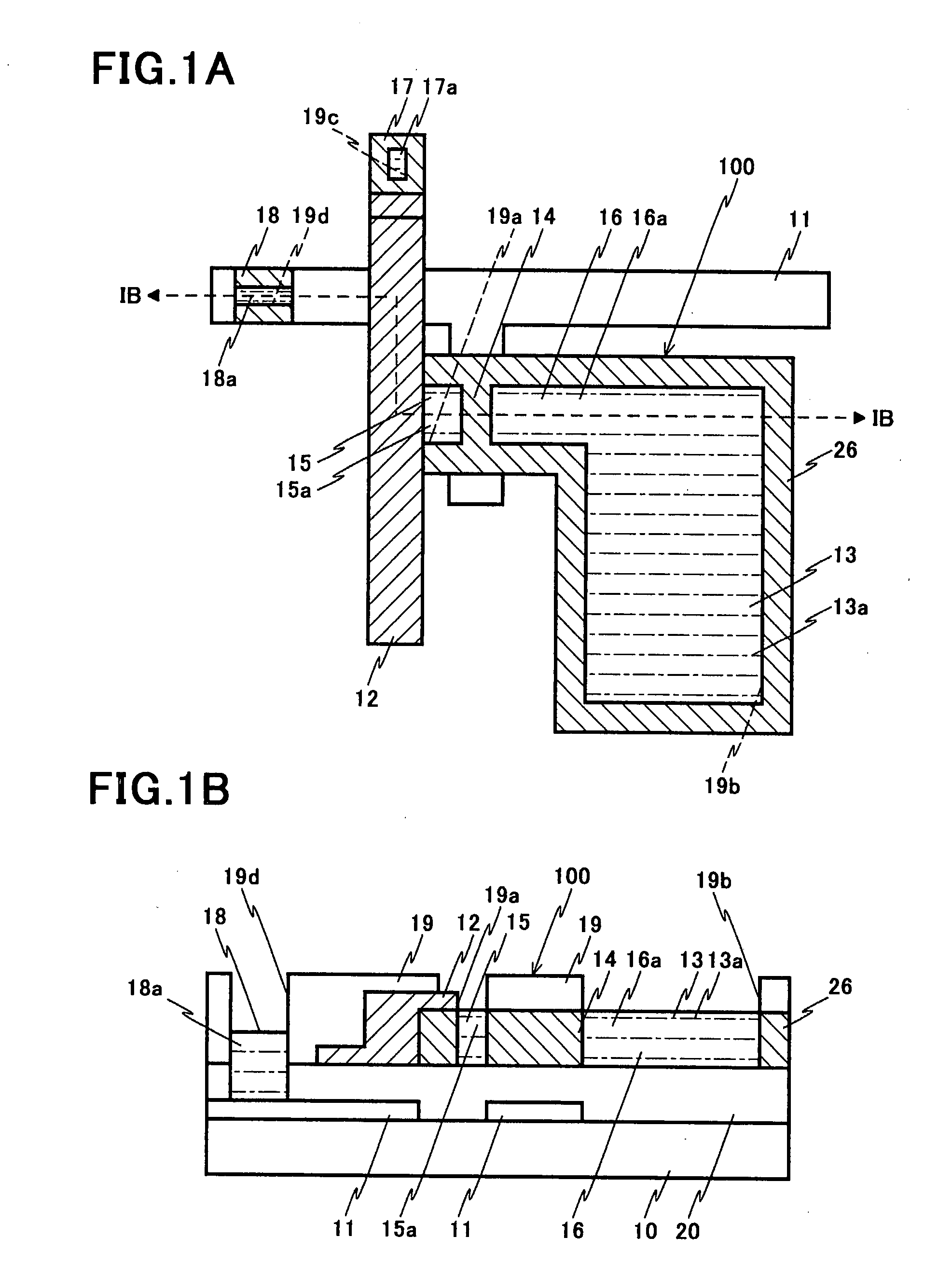

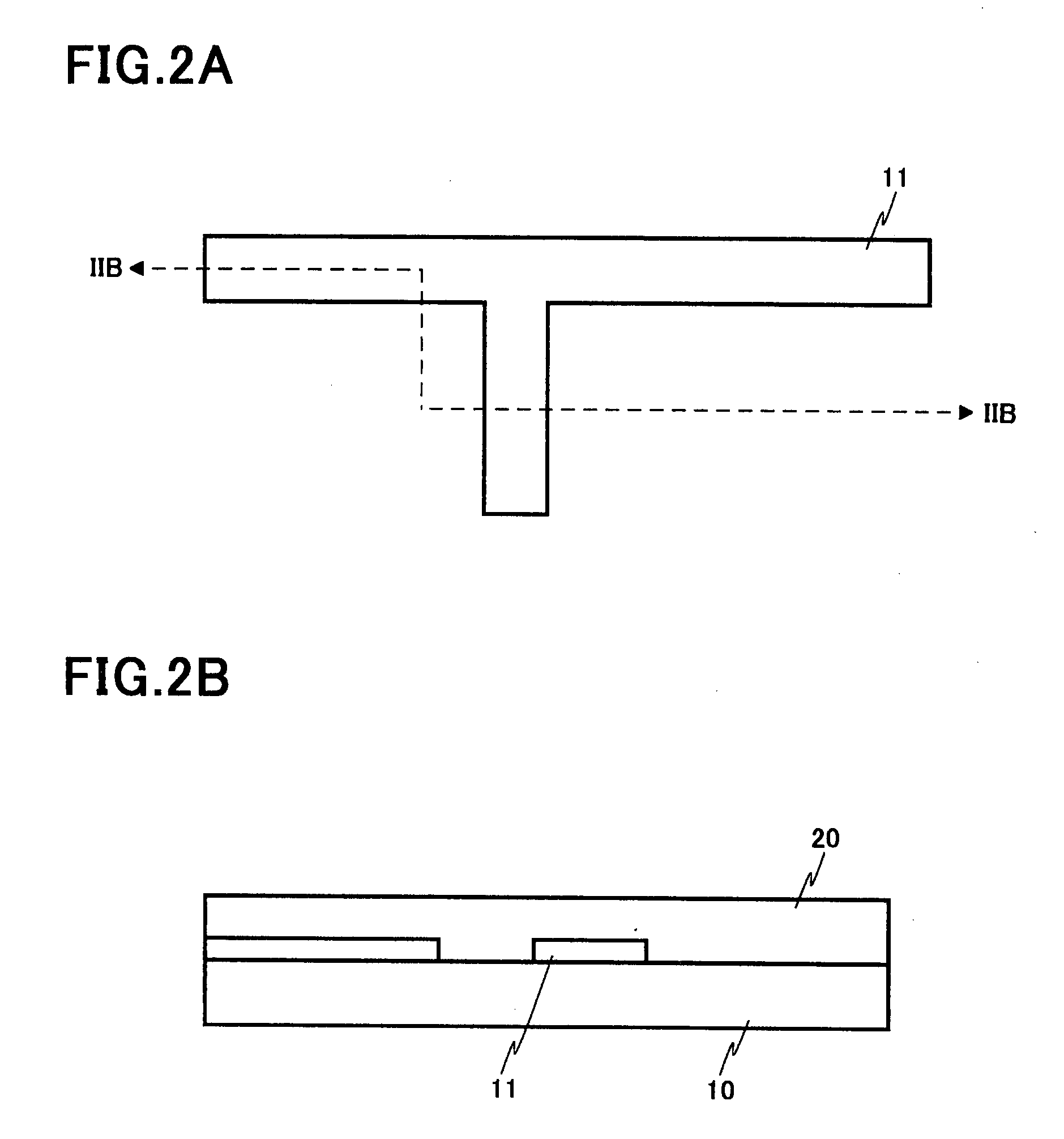

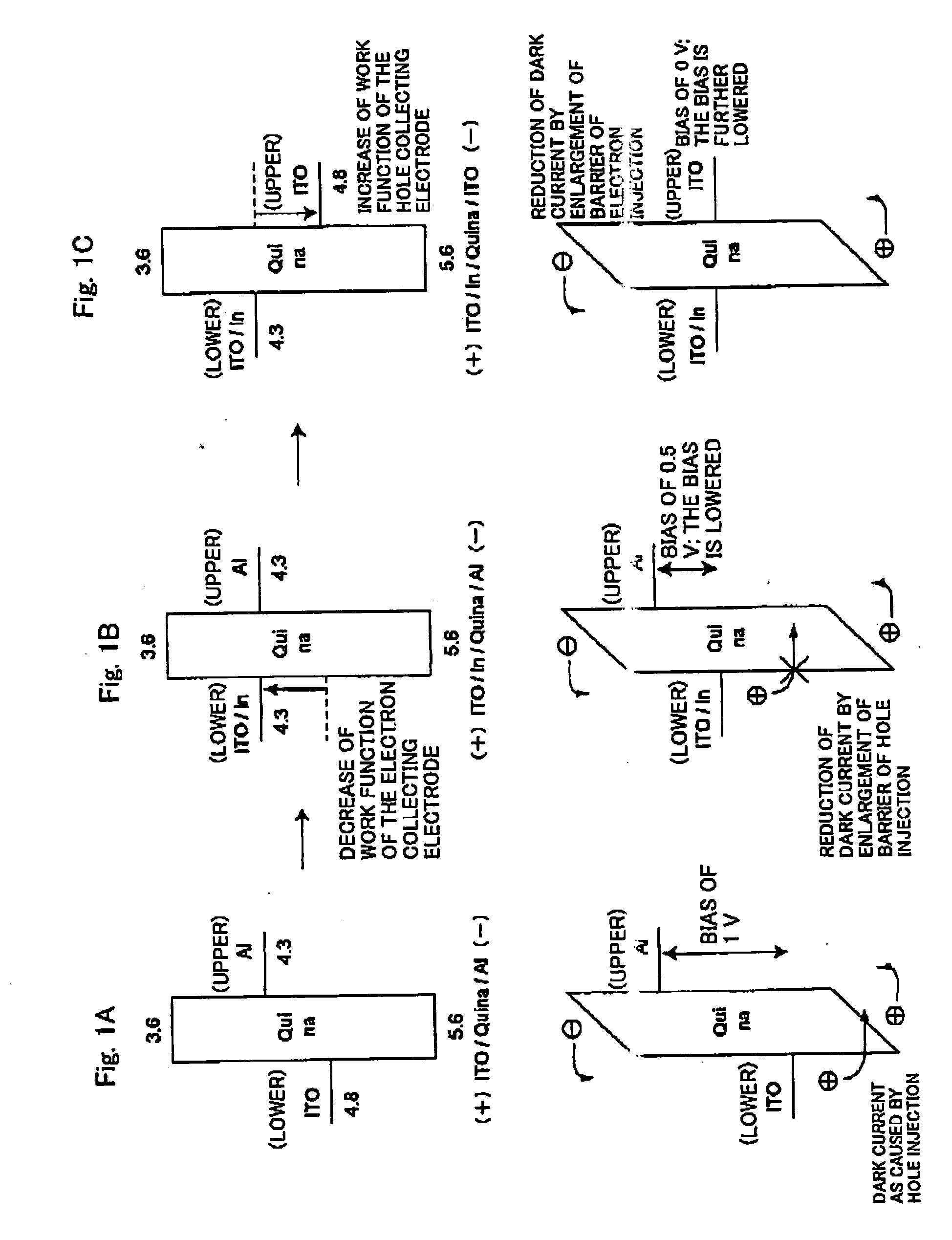

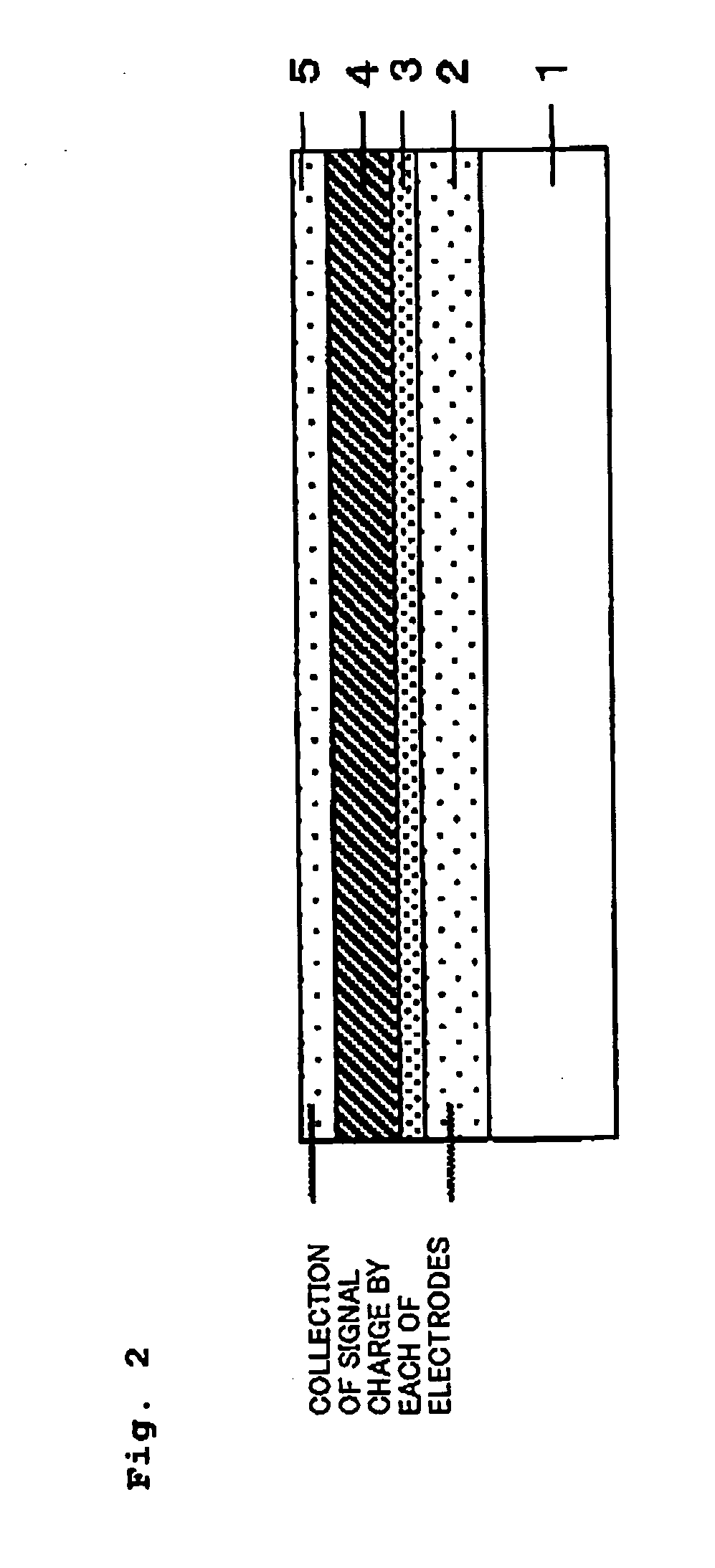

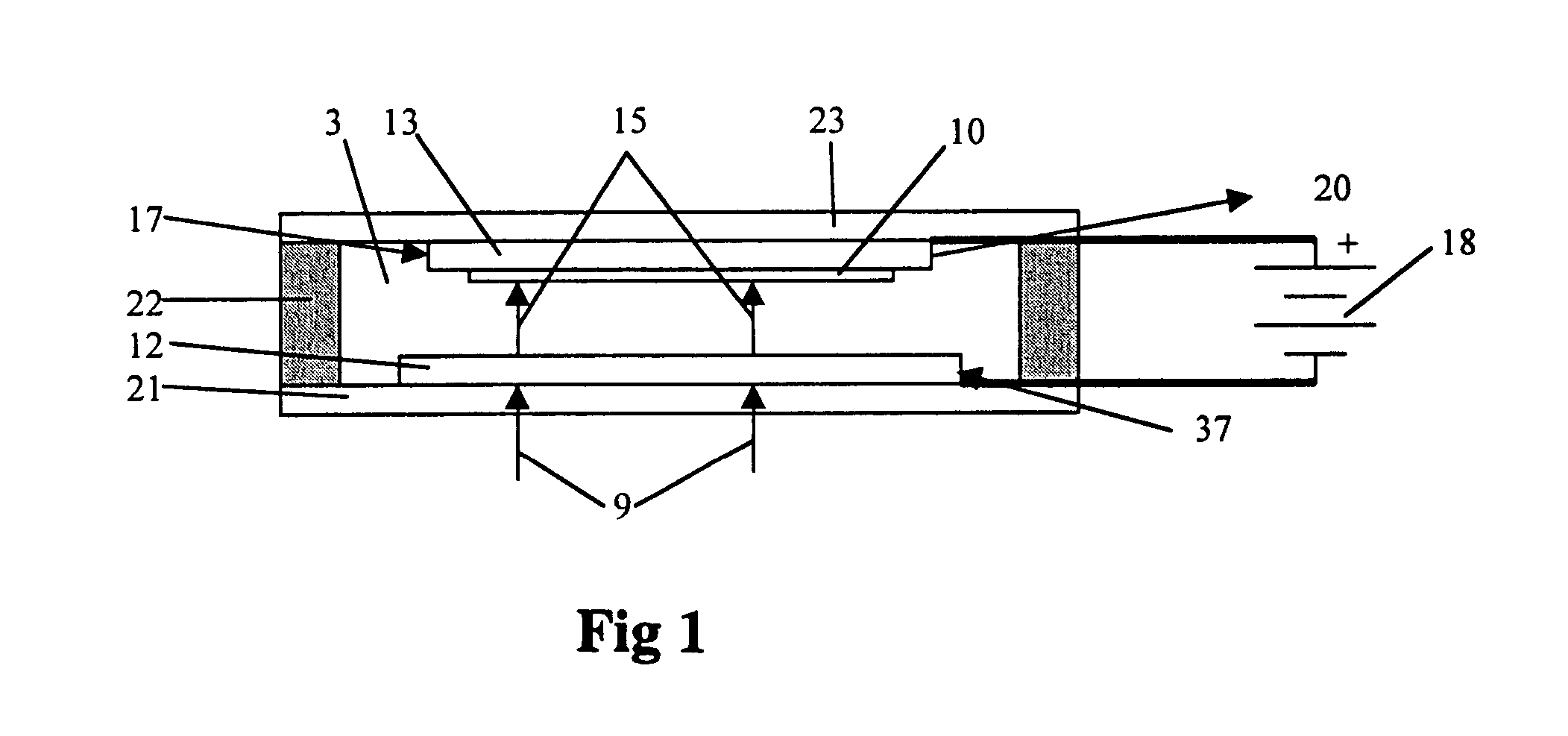

Organic photoelectric conversion device and stack type photoelectric conversion device

InactiveUS20070120045A1Total current dropReduce noiseSolid-state devicesMaterial analysis by optical meansOrganic layerPhotoelectric conversion

An organic photoelectric conversion device comprising; a lower electrode; an organic layer; and an upper electrode provided in this order, in which at least one of the lower electrode and the upper electrode is a transparent electrode and an electron is collected in a side of one of the lower electrode and the upper electrode and a hole is collected in a side of other of the lower electrode and the upper electrode so as to read out photocurrent, wherein the electrode in the side of collecting an electron is the transparent electrode and has a word function of 4.5 eV or less.

Owner:FUJIFILM CORP +1

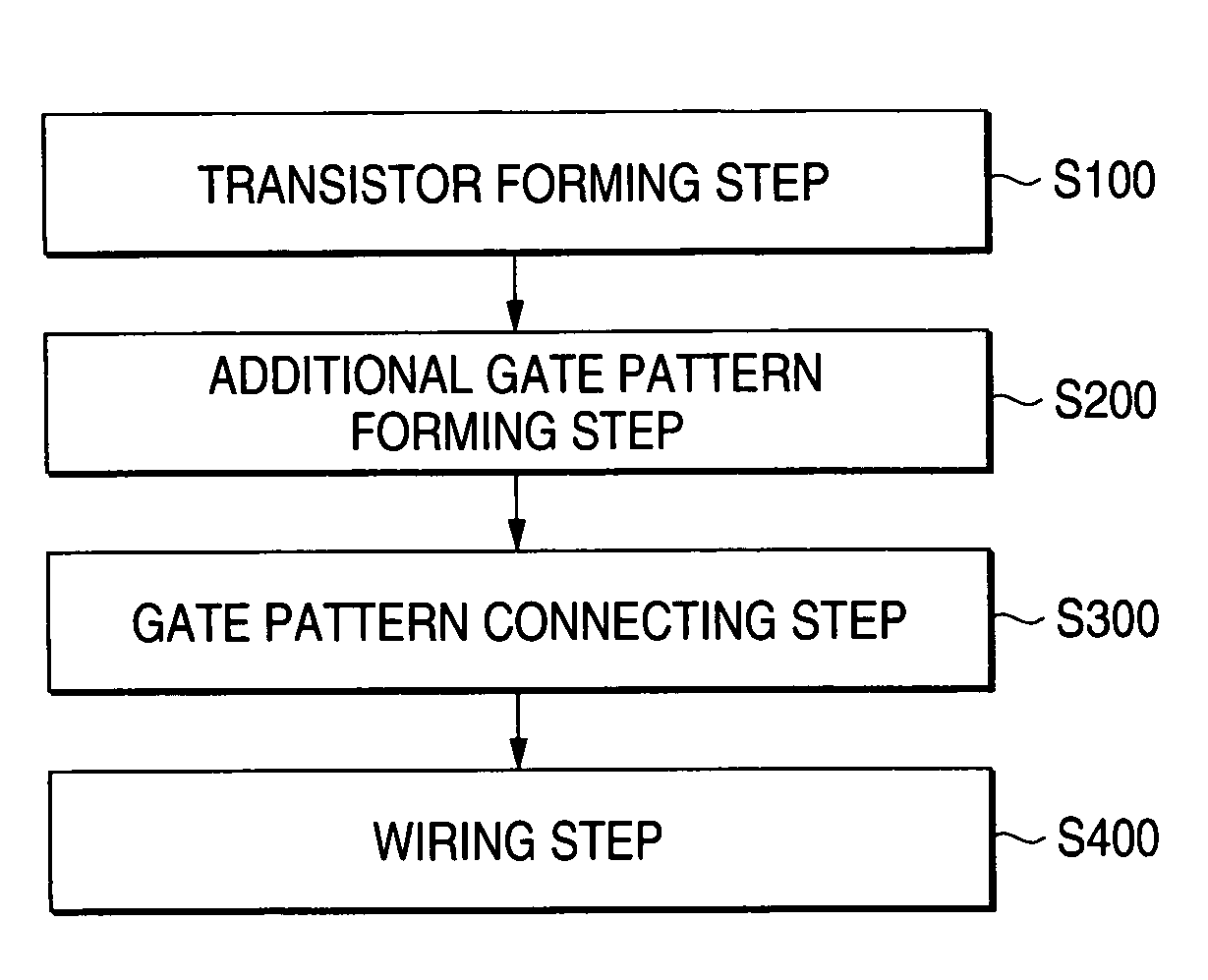

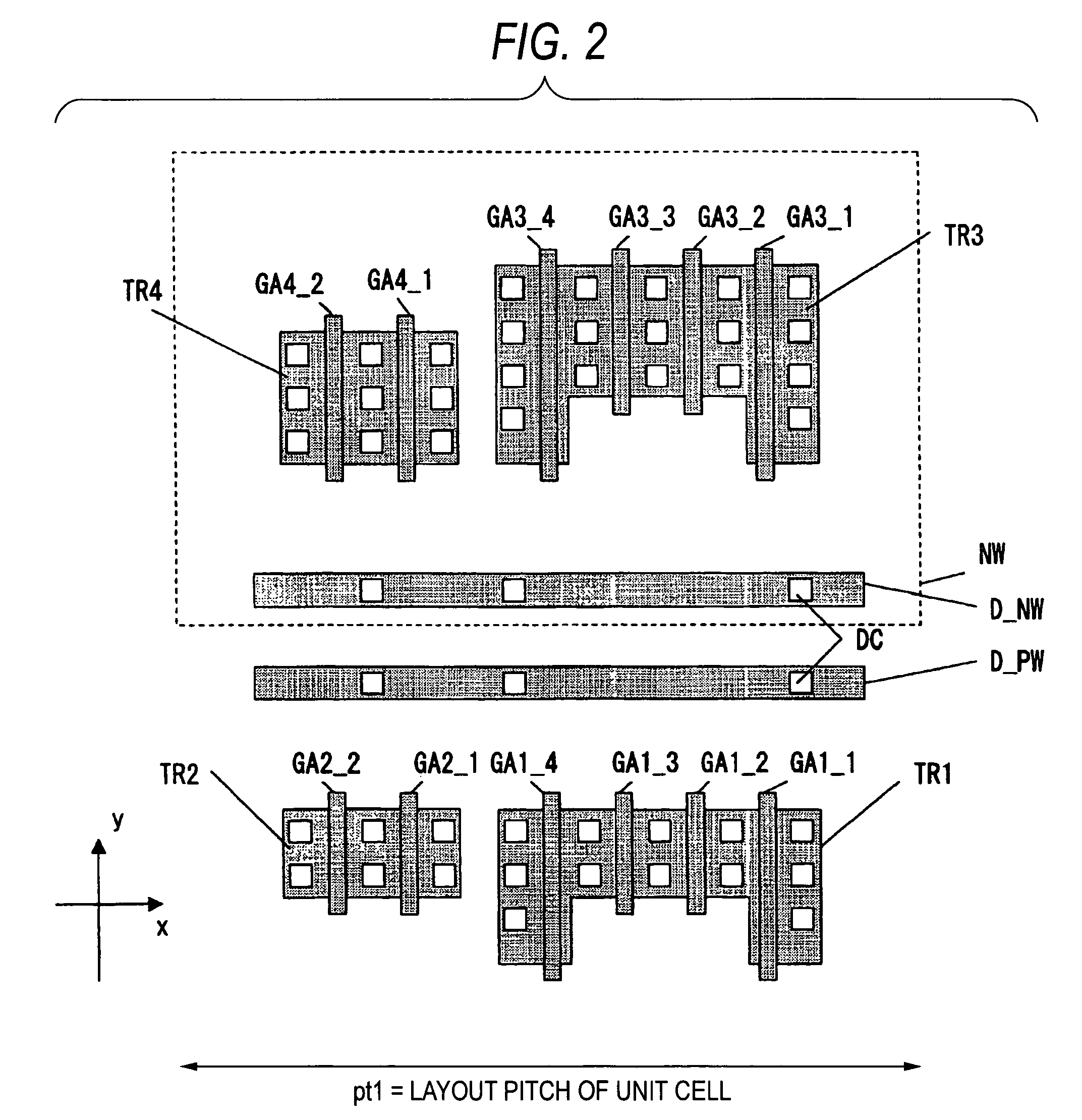

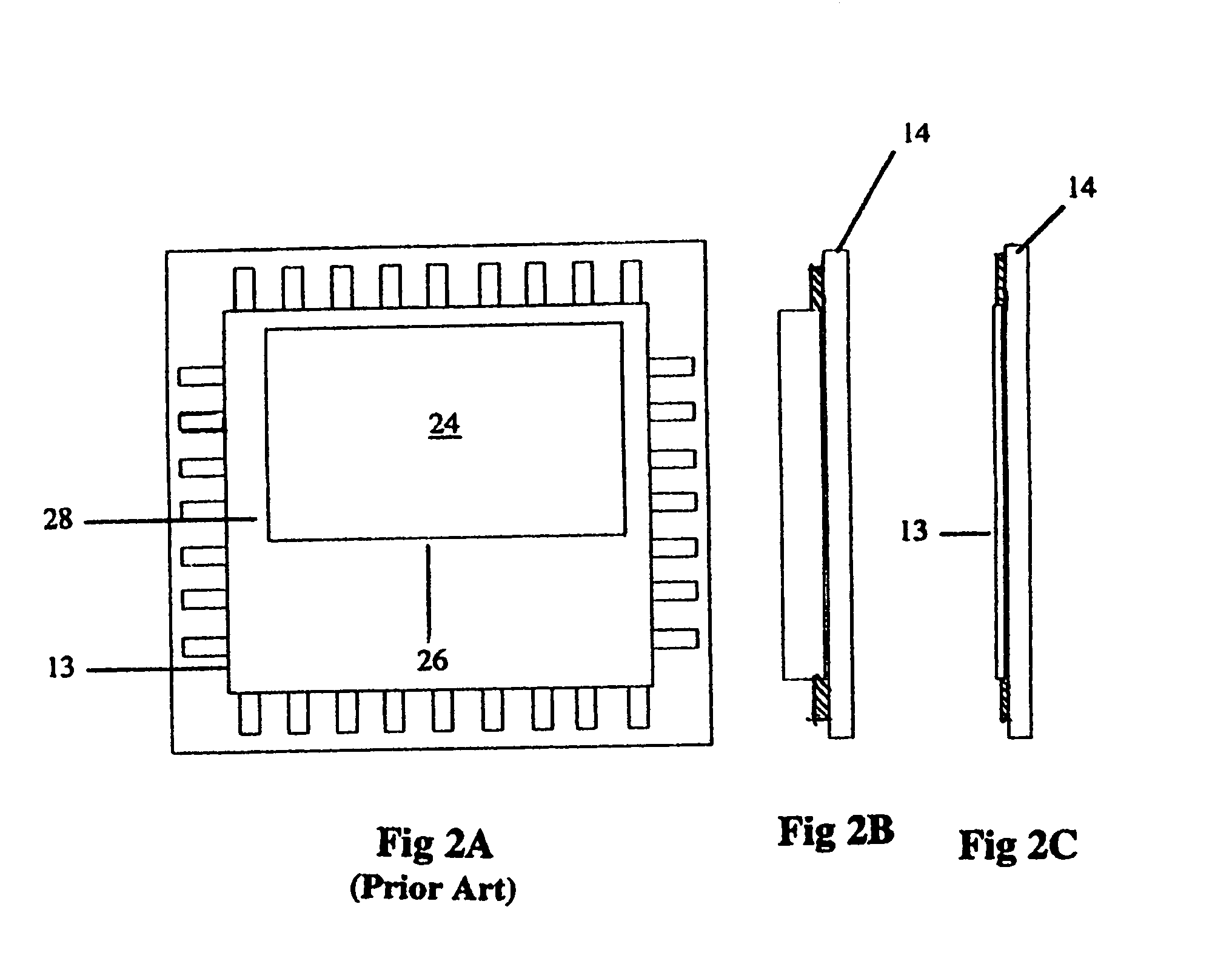

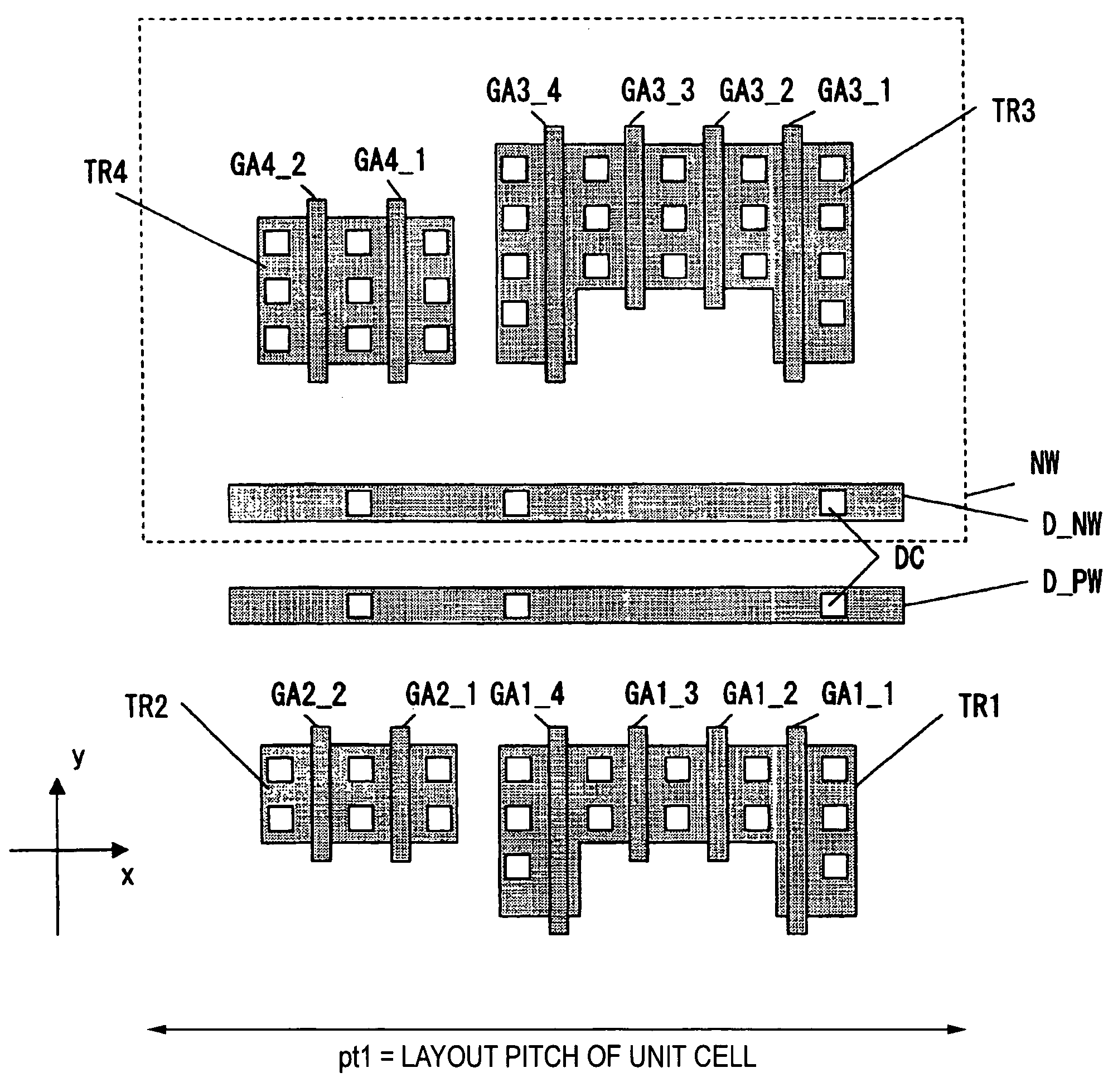

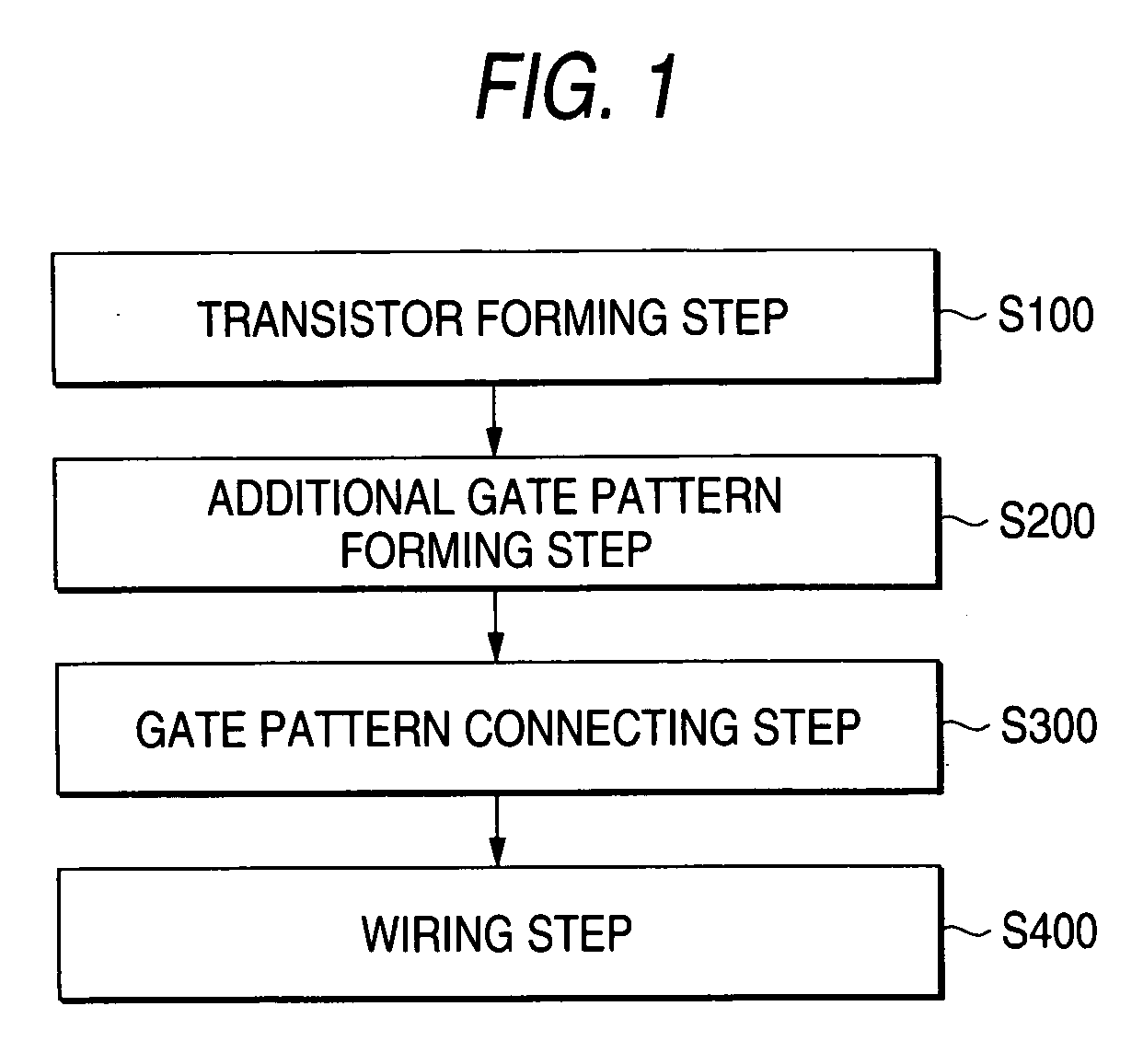

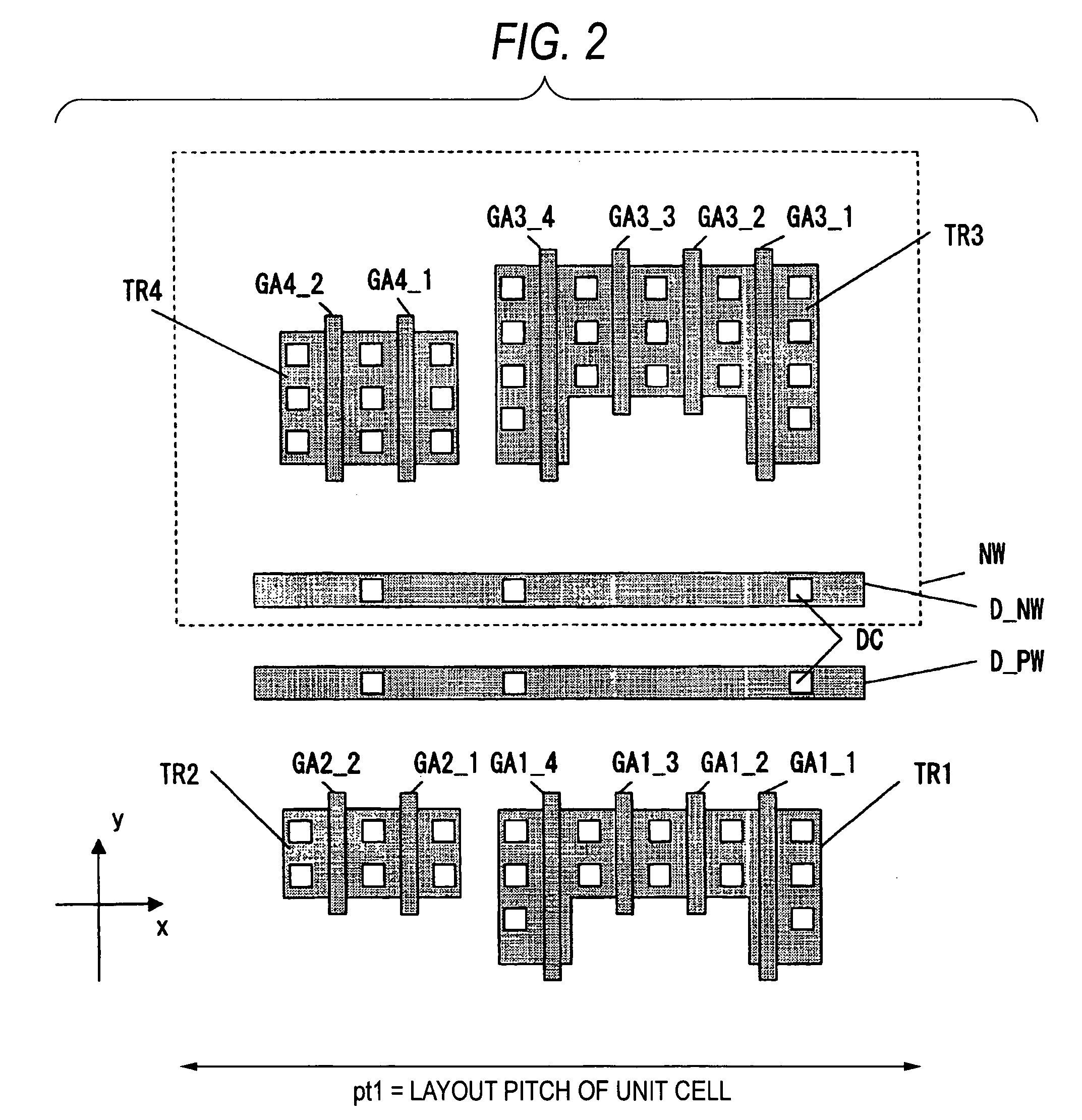

Semiconductor device and layout design method therefor

A layout design method for a semiconductor device includes a step of arranging transistors, a dummy gate forming step of forming dummy gates, which has a shape identical with a shape including gate electrodes or the gate electrodes and projected parts from active regions of the gate electrodes, in positions in parallel with and a fixed distance apart from the gate electrodes arranged at both ends in a gate length direction on active regions of the transistors and, when the transistors have plural gate electrodes with different gate widths, extending the projected parts to the outside of the active regions by a necessary length, a gate connecting step of, when gate patterns and contact regions are connected to the gate electrodes of the transistors, connecting the gate electrodes and the dummy gates according to a positional relation between the gate electrodes and the dummy gates, and a wiring step of wiring a metal layer. It is possible to design a semiconductor device having a smaller area than that in the past and with a less design man-hour.

Owner:SOCIONEXT INC

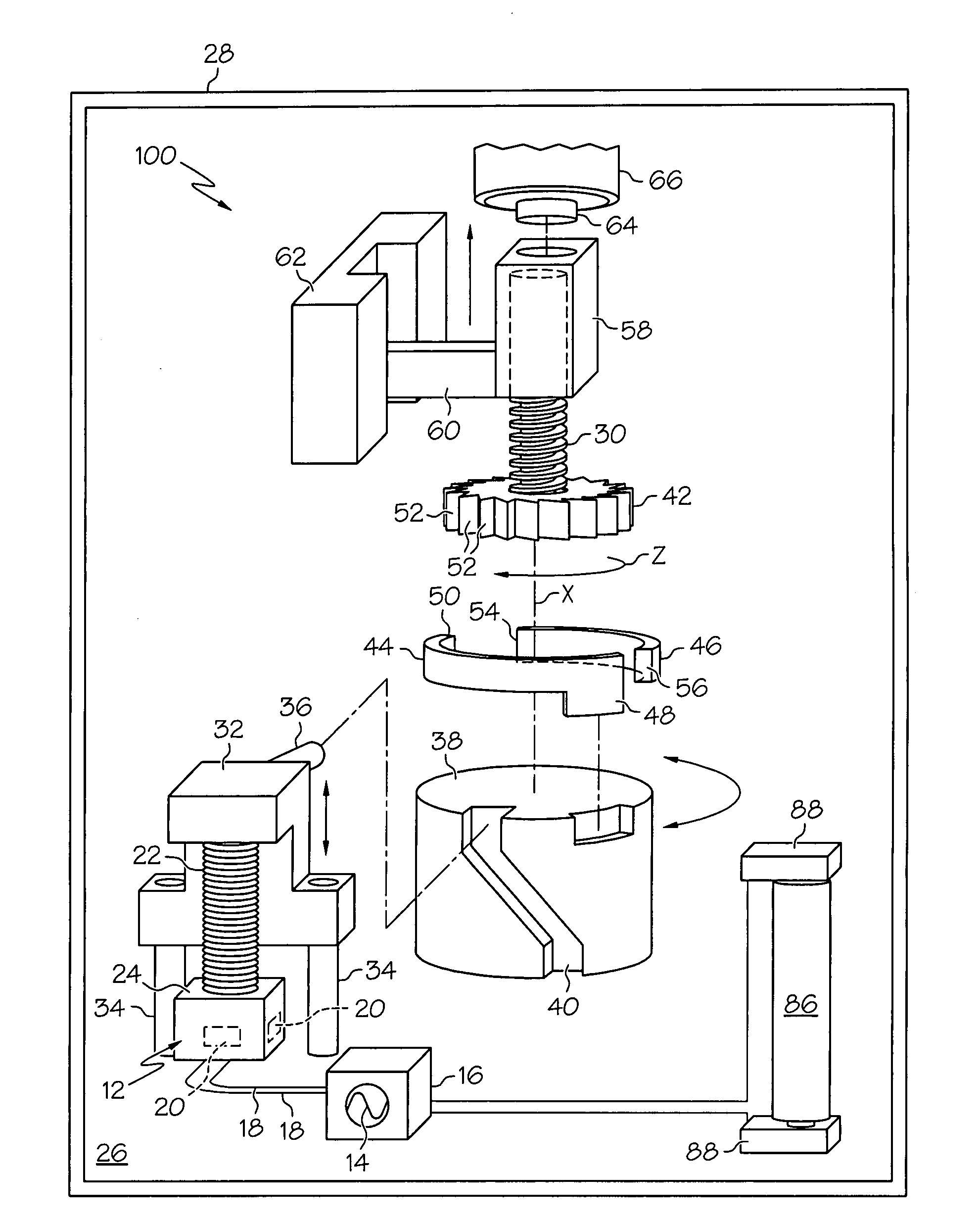

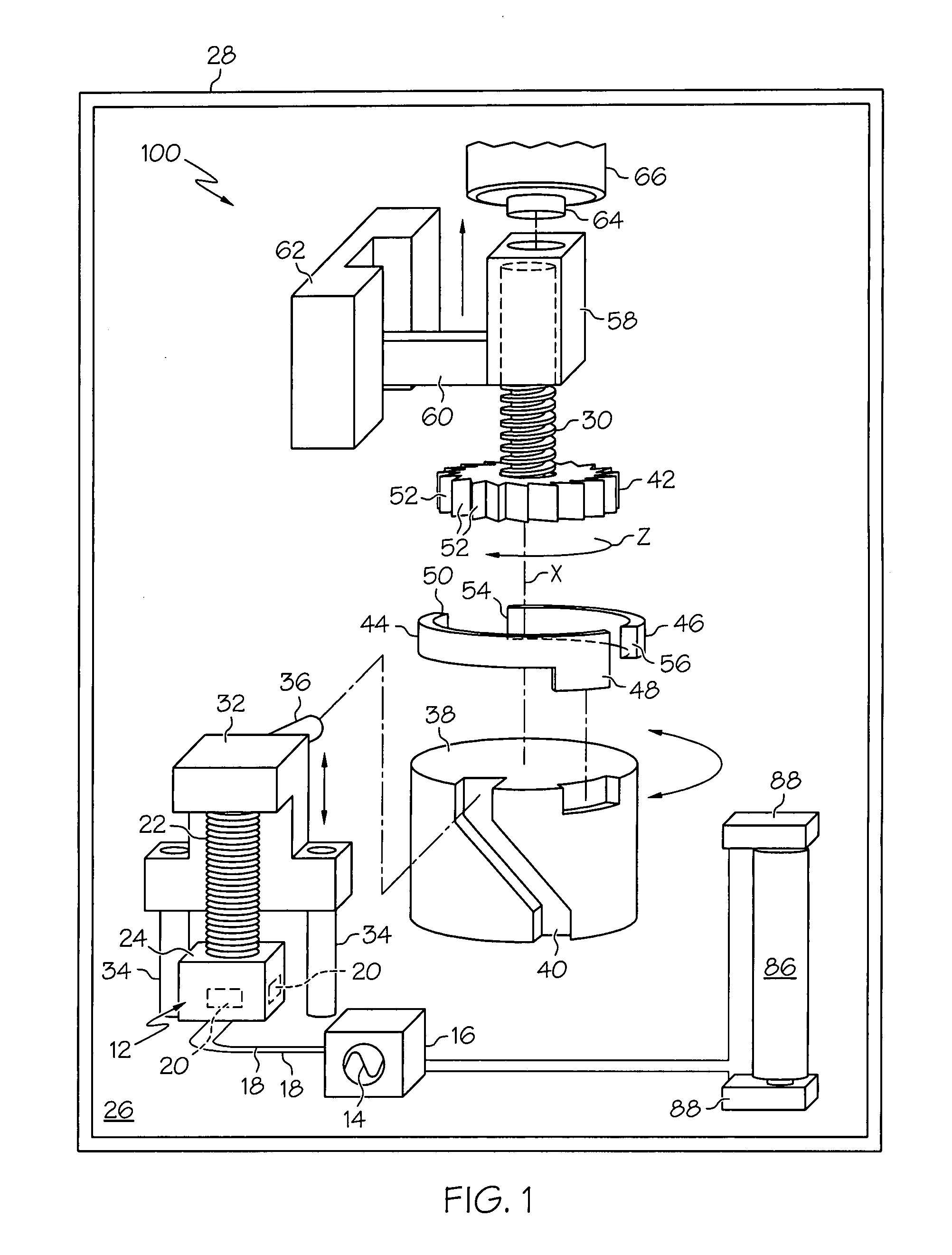

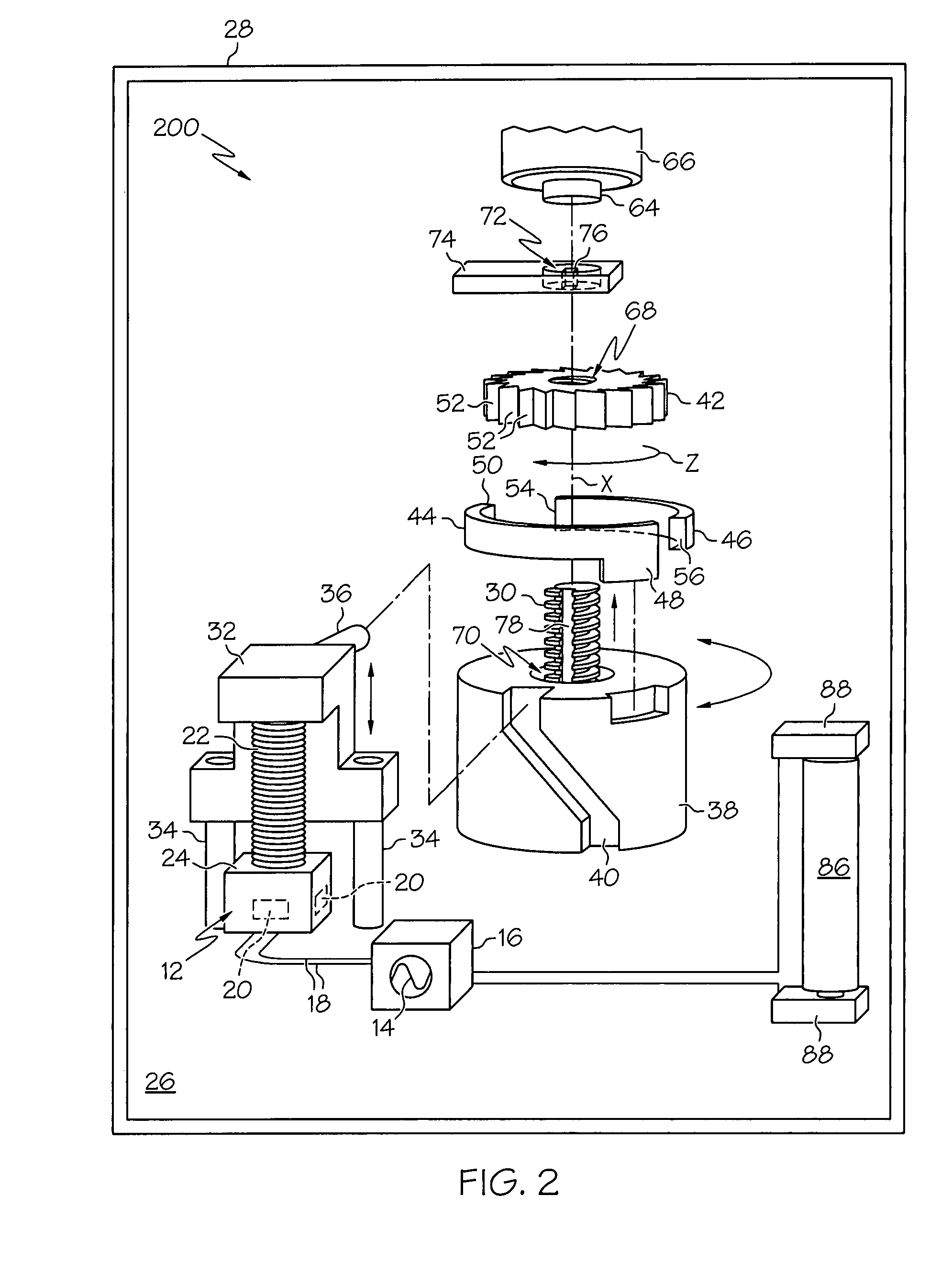

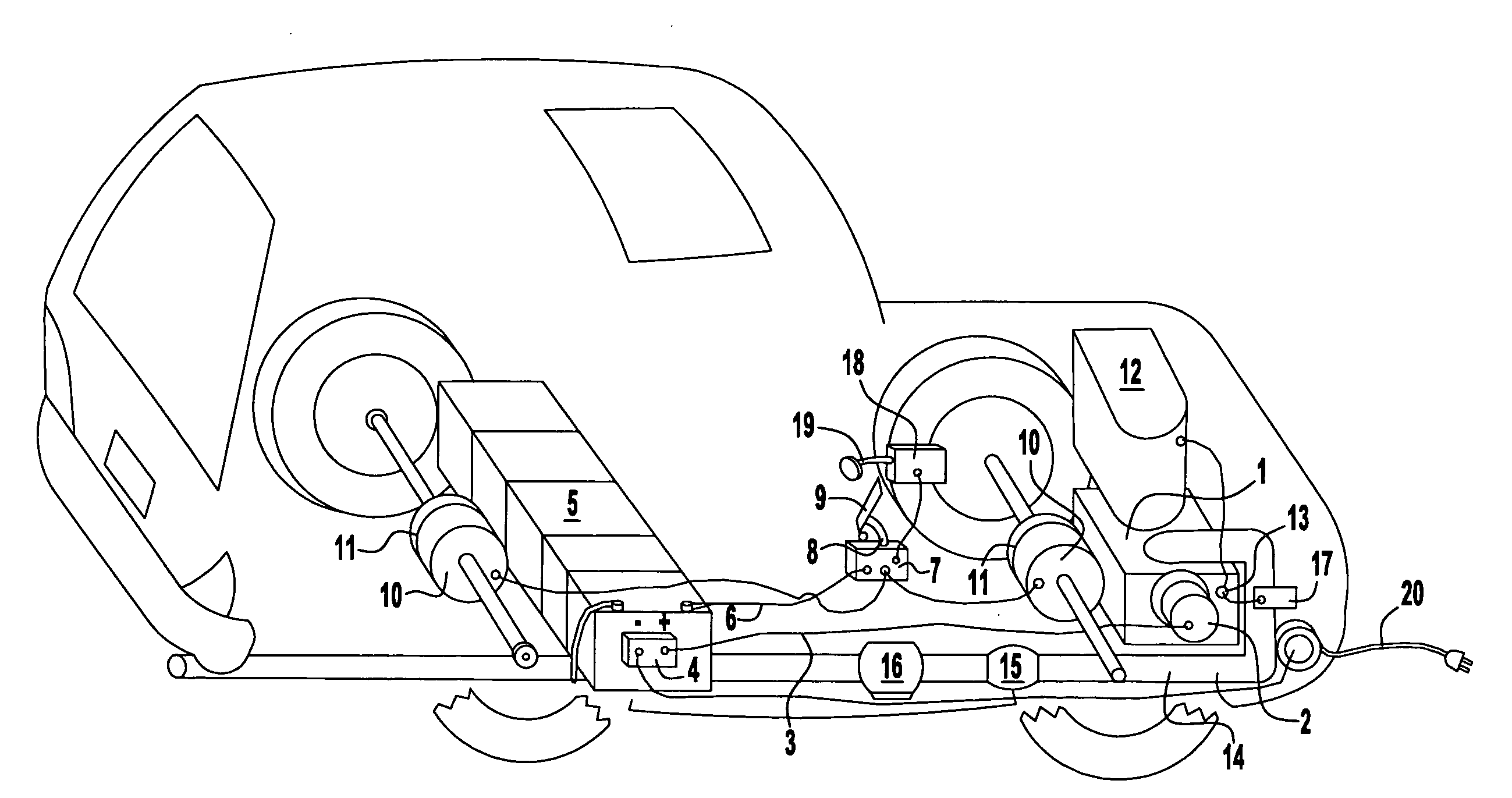

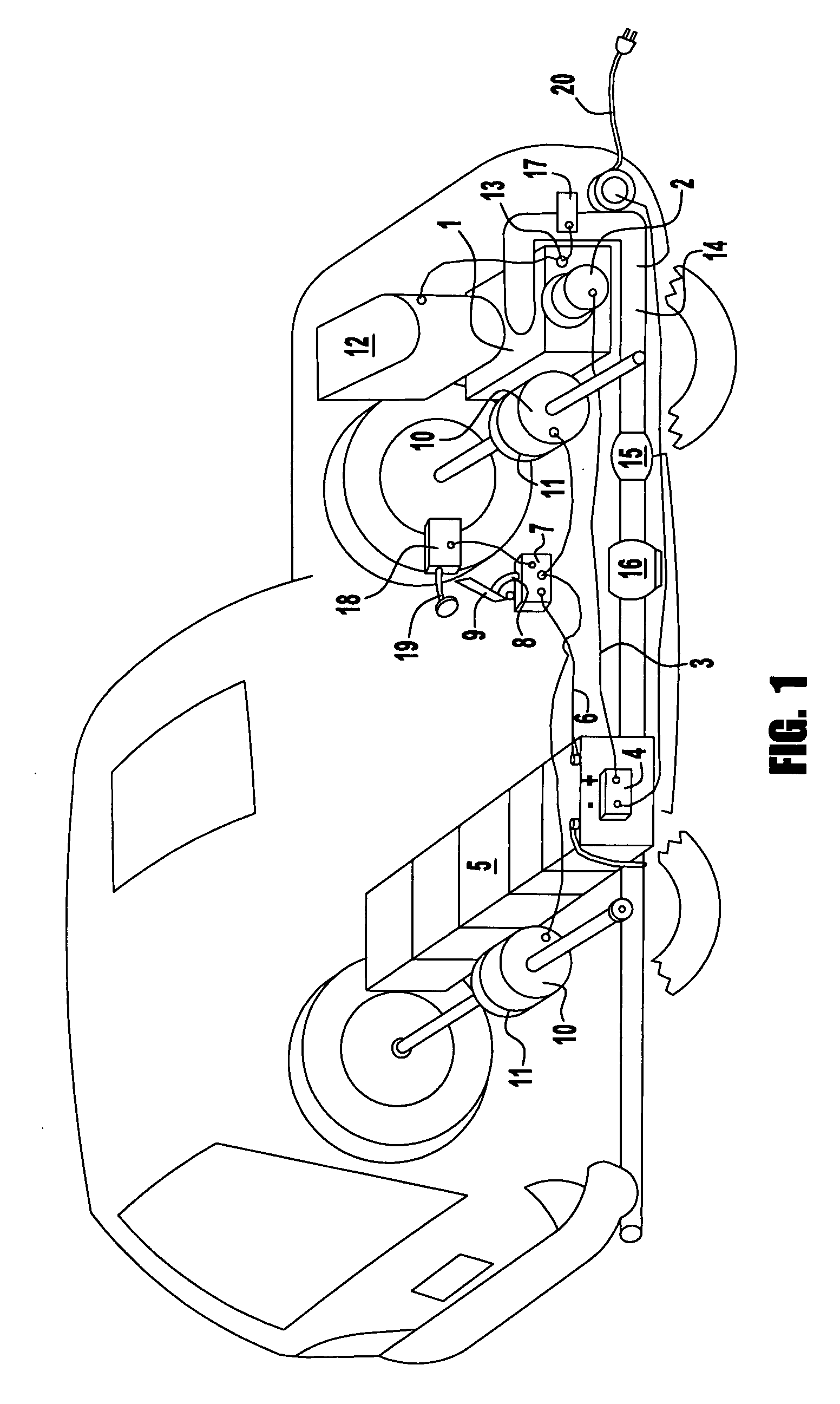

Drug delivery pump drive using linear piezoelectric motor

ActiveUS20090105650A1Reduce energy consumptionReduce size of pumpPiezoelectric/electrostriction/magnetostriction machinesAutomatic syringesElectricityElectric machine

A drug delivery pump drive which uses a linear piezoelectric motor to advance a syringe piston to deliver a liquid drug and a method thereof are disclosed. The pump drive, provided in a drug delivery pump, provides silent operation and very low energy consumption compared to electric motor-based drives. The small size of the motor helps also to reduce overall size of the pump drive and the resulting drug deliver pump.

Owner:ROCHE DIABETES CARE INC +1

Thin-film transistor array, method of fabricating the same, and liquid crystal display device including the same

ActiveUS7804091B2Improve electrical connection reliabilityReduce conductivitySolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A thin-film transistor array includes an electrically insulating substrate, a plurality of thin-film transistors arranged in a matrix on the substrate, and each including a channel, a source, and a drain each comprised of an oxide-semiconductor film, a pixel electrode integrally formed with the drain, a source signal line through which a source signal is transmitted to a group of thin-film transistors, a gate signal line through which a gate signal is transmitted to a group of thin-film transistors, a source terminal formed at an end of the source signal line, and a gate terminal formed at an end of the gate signal line. The source terminal and the gate terminal are formed in the same layer as a layer in which the channel is formed. The source terminal and the gate terminal have the same electric conductivity as that of the pixel electrode.

Owner:NEC LCD TECH CORP

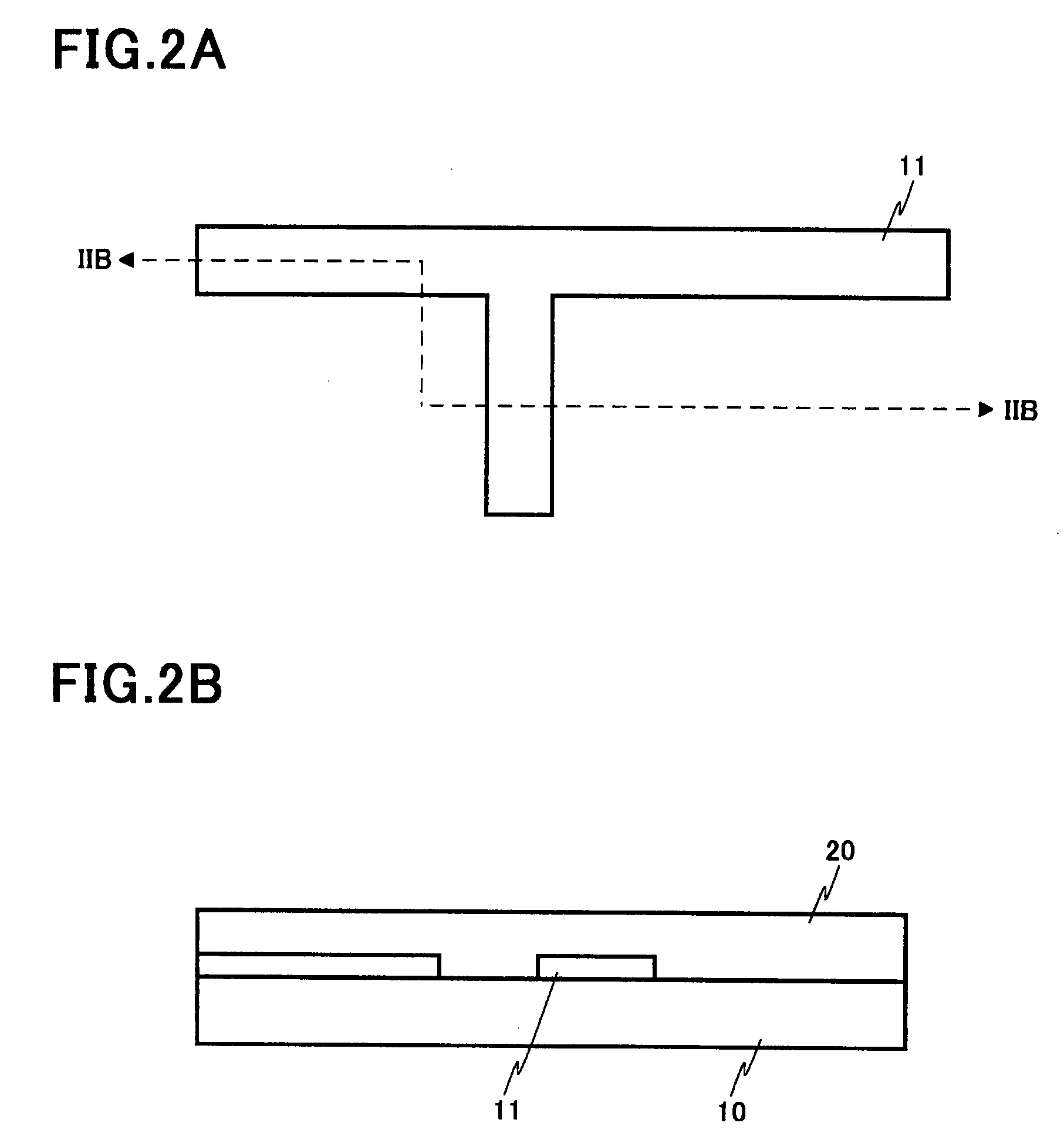

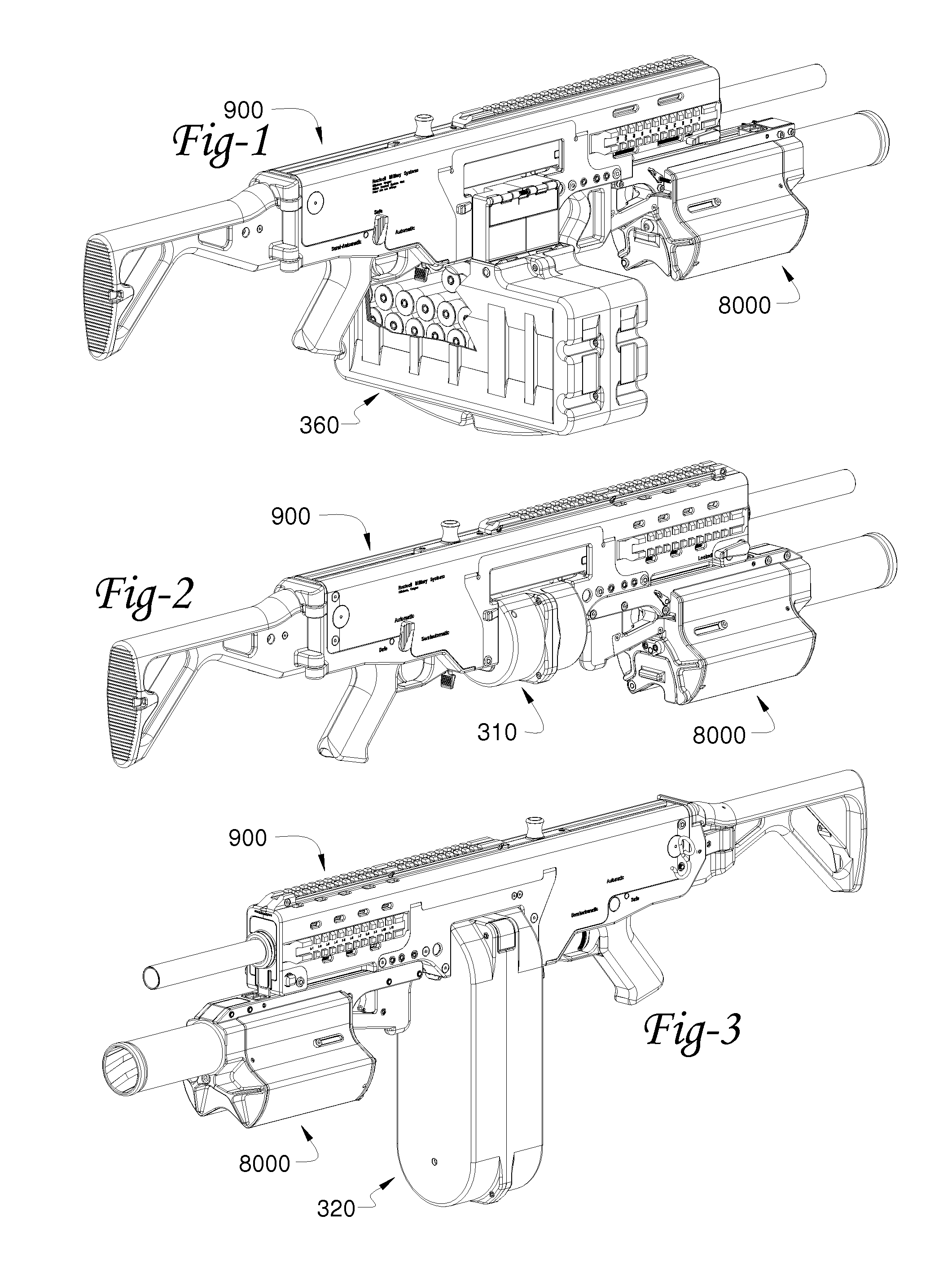

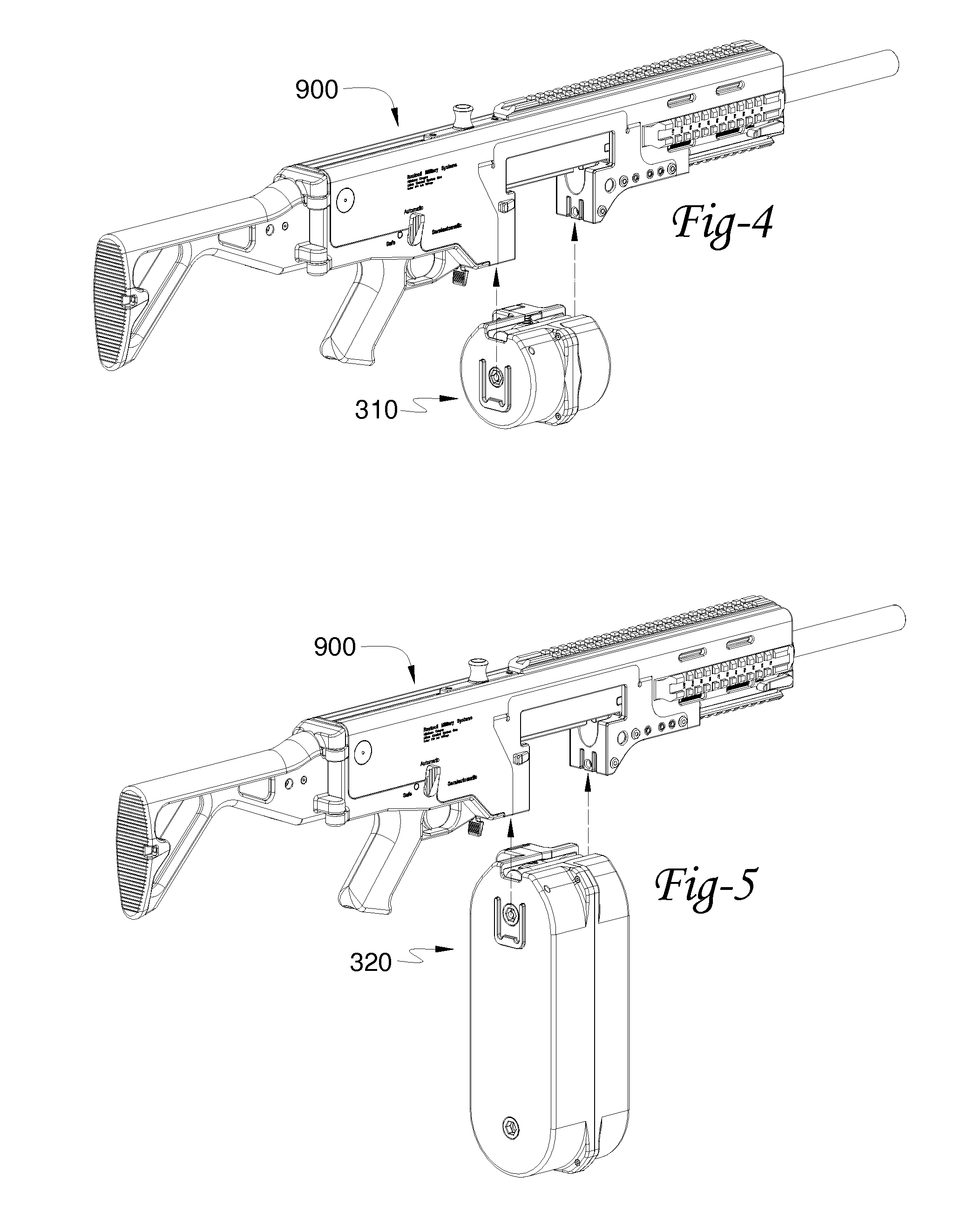

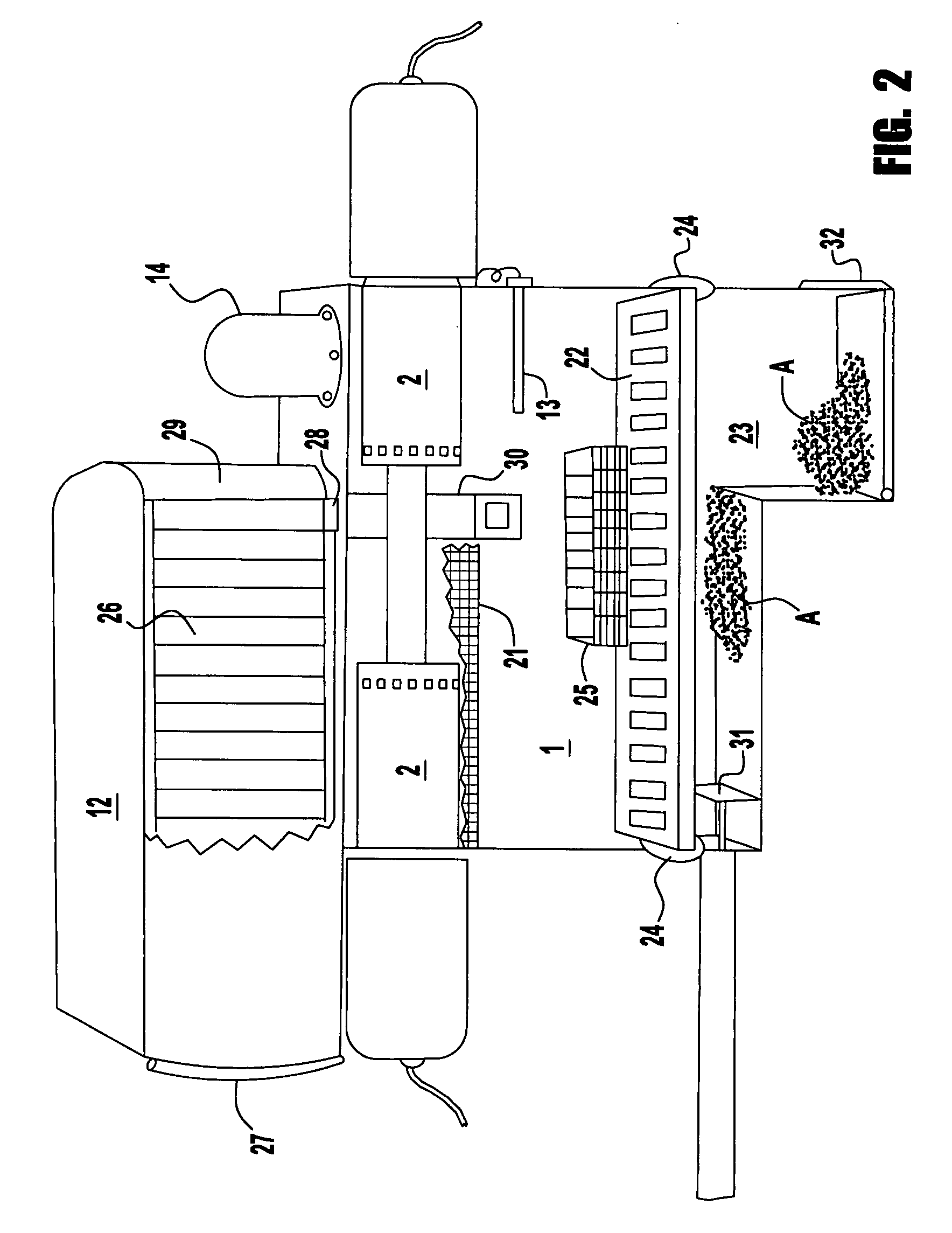

Urban combat system automatic firearm having ammunition feed controlled by weapon cycle

ActiveUS20120144712A1Reducing felt-recoilIncrease distanceAmmunition projectilesWeapon assembly/disassemblyFire controlEngineering

A weapon system for urban combat incorporating an automatic gun having a short recoil, a feed system with gun driven box magazines of different capacities, a detachable link-belt feed, spring buffered barrel and bolt recoil absorbing arrangement, and simplified fire control.

Owner:ROSTOCIL CHARLES EDWARD

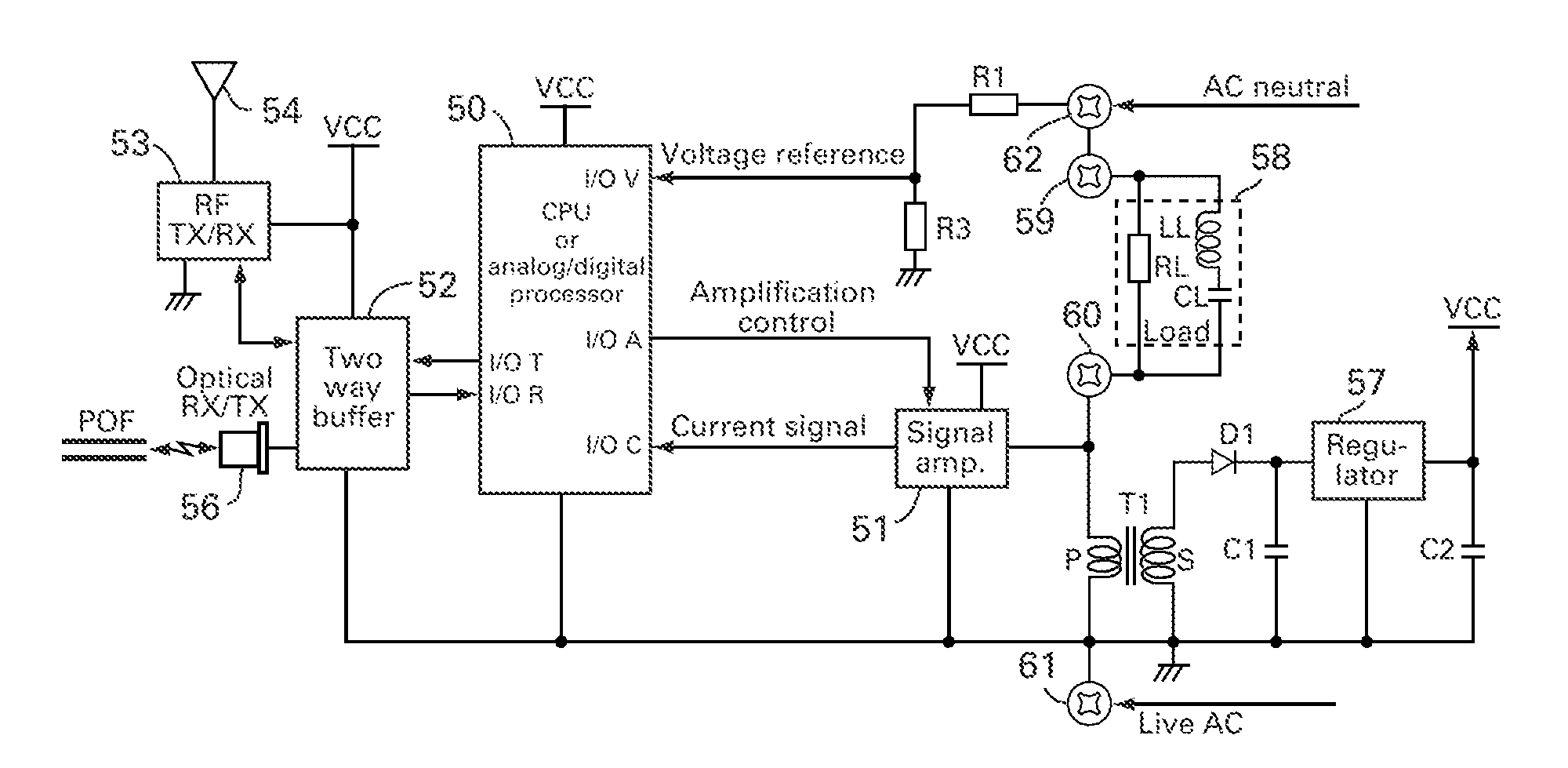

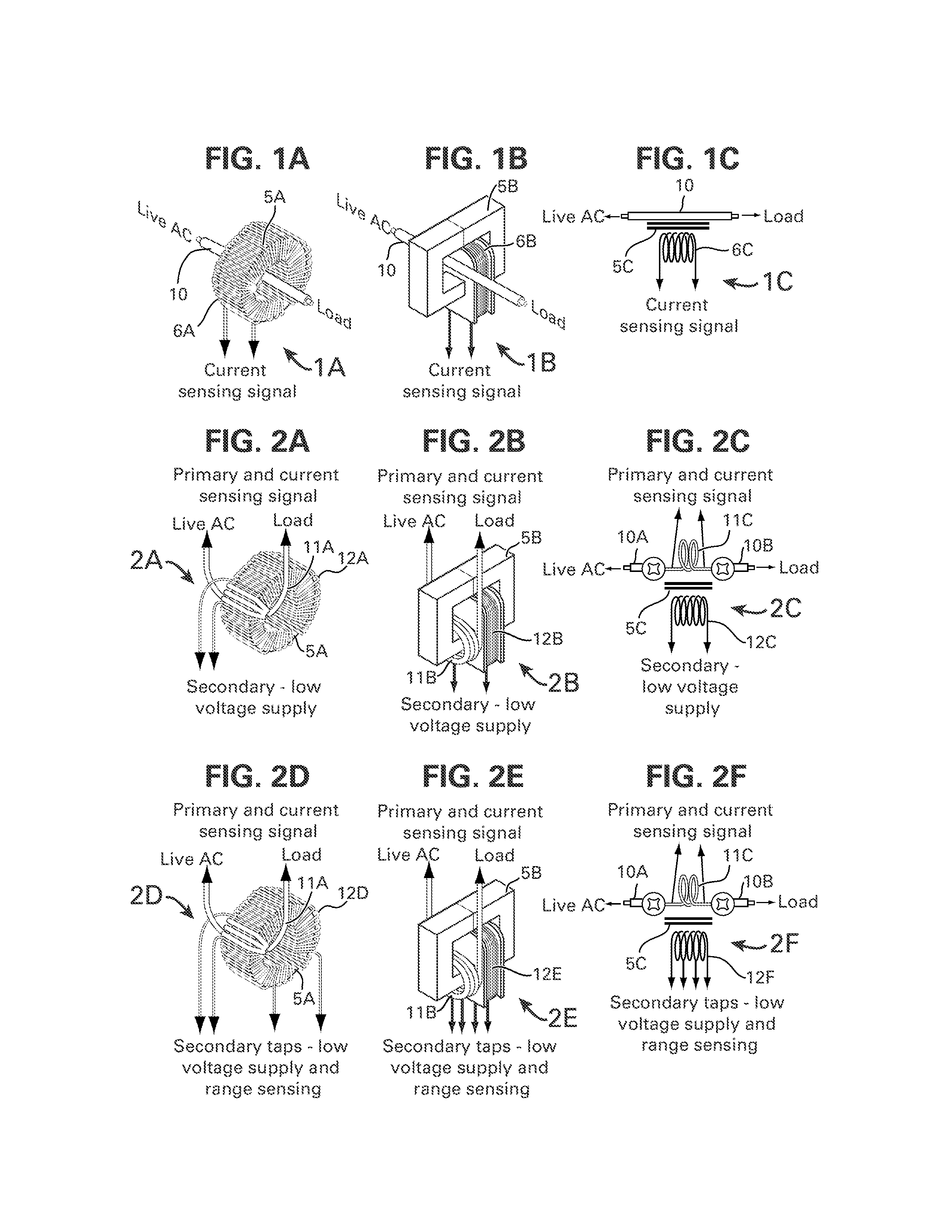

Apparatus for employing low ohmic alloy conductors and method for simplifying current drain data retrieval

ActiveUS20130183043A1Decrease in Q-factorSmallAc-dc conversionTransformers/inductances coils/windings/connectionsElectrical conductorData retrieval

Apparatus and method for measuring current drain and reporting power consumption using current transformer with primary windings made of low ohmic alloy, enabling the use of the secondary coil to power the sensing and reporting circuits eliminating the power wasted by AC-DC power adaptors used for the current sensors. The saving is substantial as the current sensors will not drain a current when the AC outlets are disconnected from a load or when the load is switched off. The apparatus using low ohmic alloy is extended to the structuring of terminals, including power pins, power sockets and combinations to provide a low ohmic sensing elements in AC plugs, outlets, adaptors and extension cables with multi outlets, dissipating the heat from the sensing elements by the plugs and the larger metal heat dissipation.

Owner:ELBEX VIDEO LTD

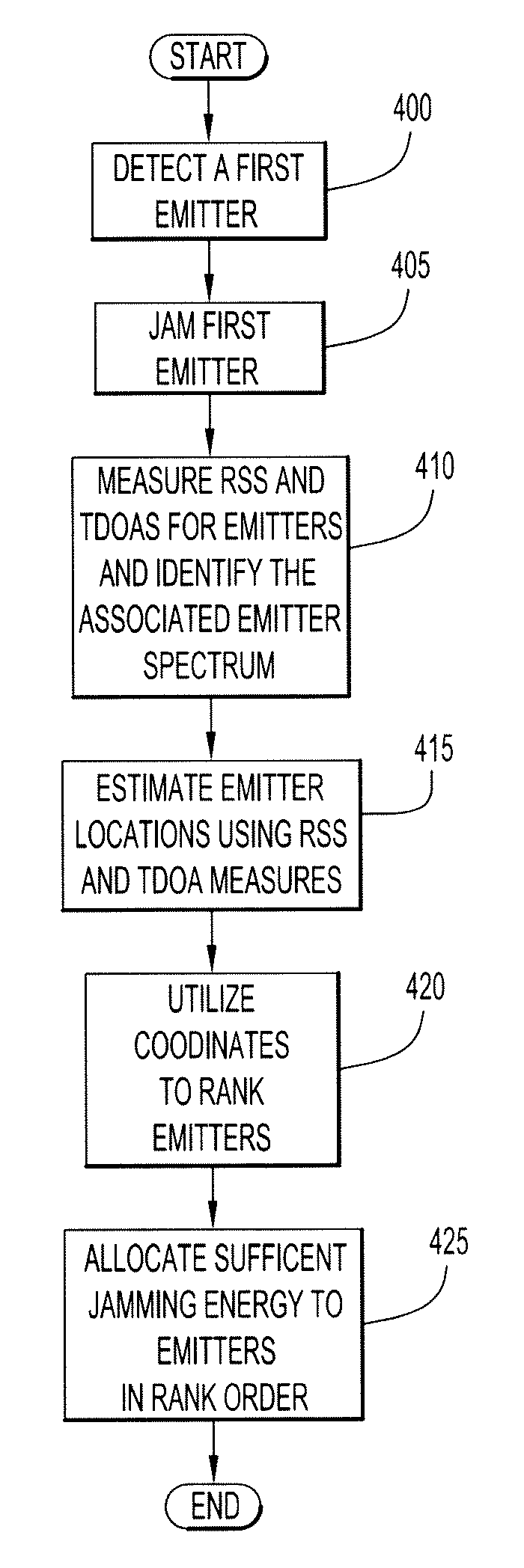

System and Method for Allocating Jamming Energy Based on Three-Dimensional Geolocation of Emitters

ActiveUS20120309288A1Rapid identificationMaximize overall jamming effectWave based measurement systemsTelephonic communicationGeolocationEnergy based

According to an embodiment of the present invention jamming energy is allocated to a plurality of emitters based on a three-dimensional (3-D) emitter geolocation technique that determines the geolocation of radio frequency (RF) emitters based on energy or received signal strength (RSS) and / or time differences of arrival (TDOAs) of transmitted signals. The three-dimensional (3-D) emitter geolocations are used to rank emitters of interest according to distance and available radio frequency (RF) jamming energy is allocated to the emitters in rank order. The techniques may be employed with small unmanned air vehicles (UAV), and obtains efficient use of jamming energy when applied to radio frequency (RF) emitters of interest.

Owner:HARRIS CORP

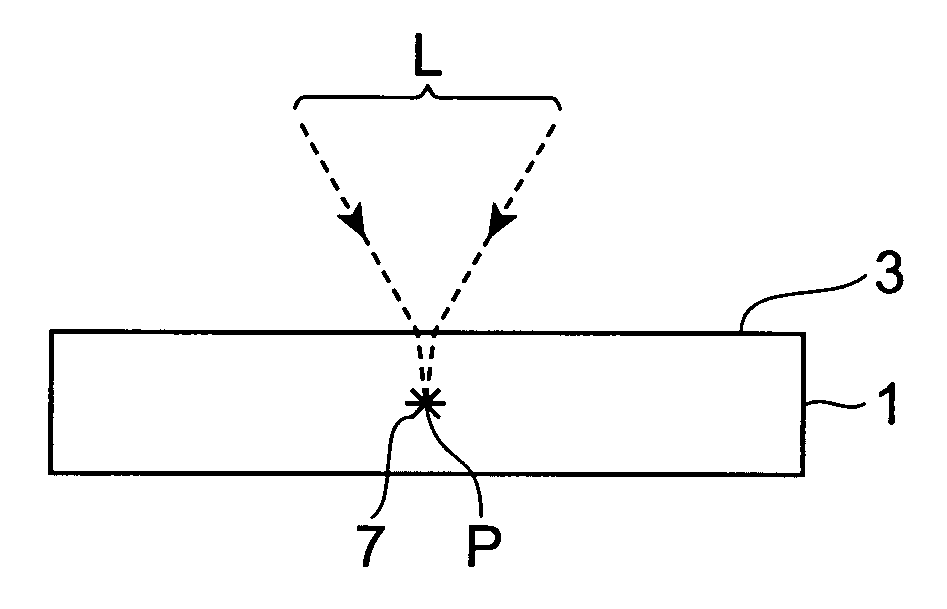

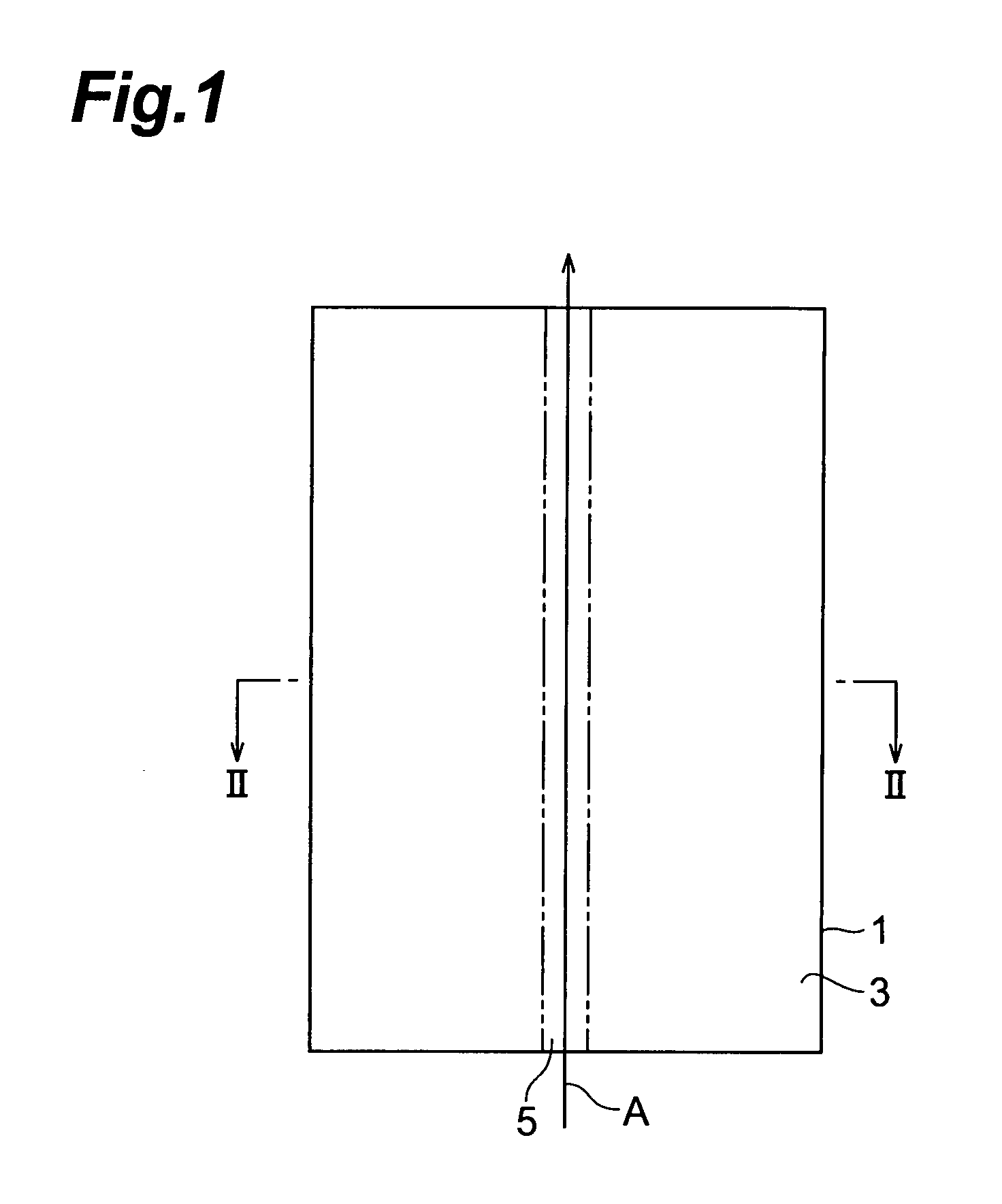

Laser processing method and chip

ActiveUS20080000884A1Avoid fracturesShorten the timeSemiconductor/solid-state device manufacturingFine working devicesLaser processingLaser light

An object to be processed can be cut highly accurately along a line to cut.An object to be processed 1 is irradiated with laser light while locating a converging point within a silicon wafer 11, and the converging point is relatively moved along a line to cut 5, so as to form modified regions M1, M2 positioned within the object 1 along the line to cut 5, and then a modified region M3 positioned between the modified regions M1, M2 within the object 1.

Owner:HAMAMATSU PHOTONICS KK

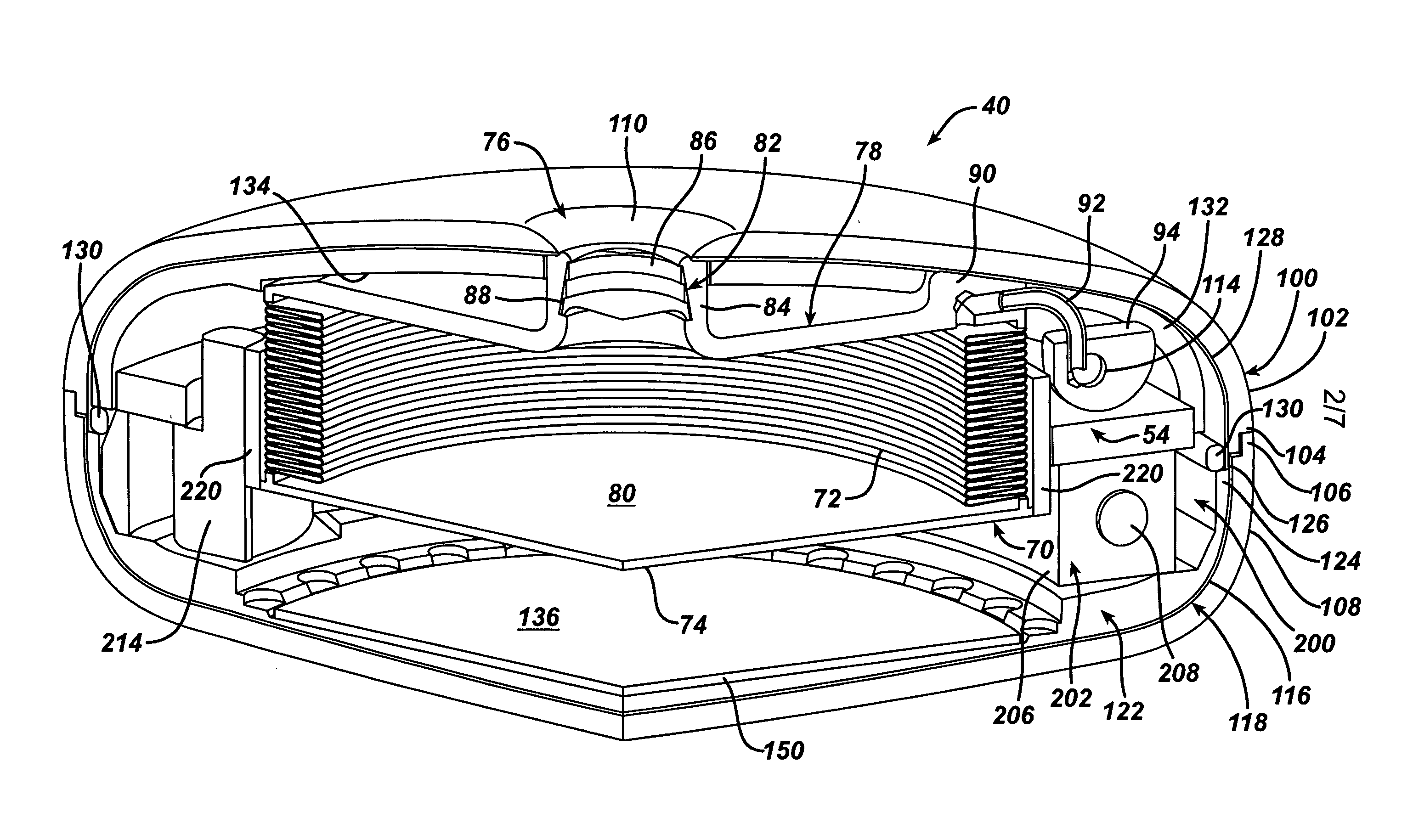

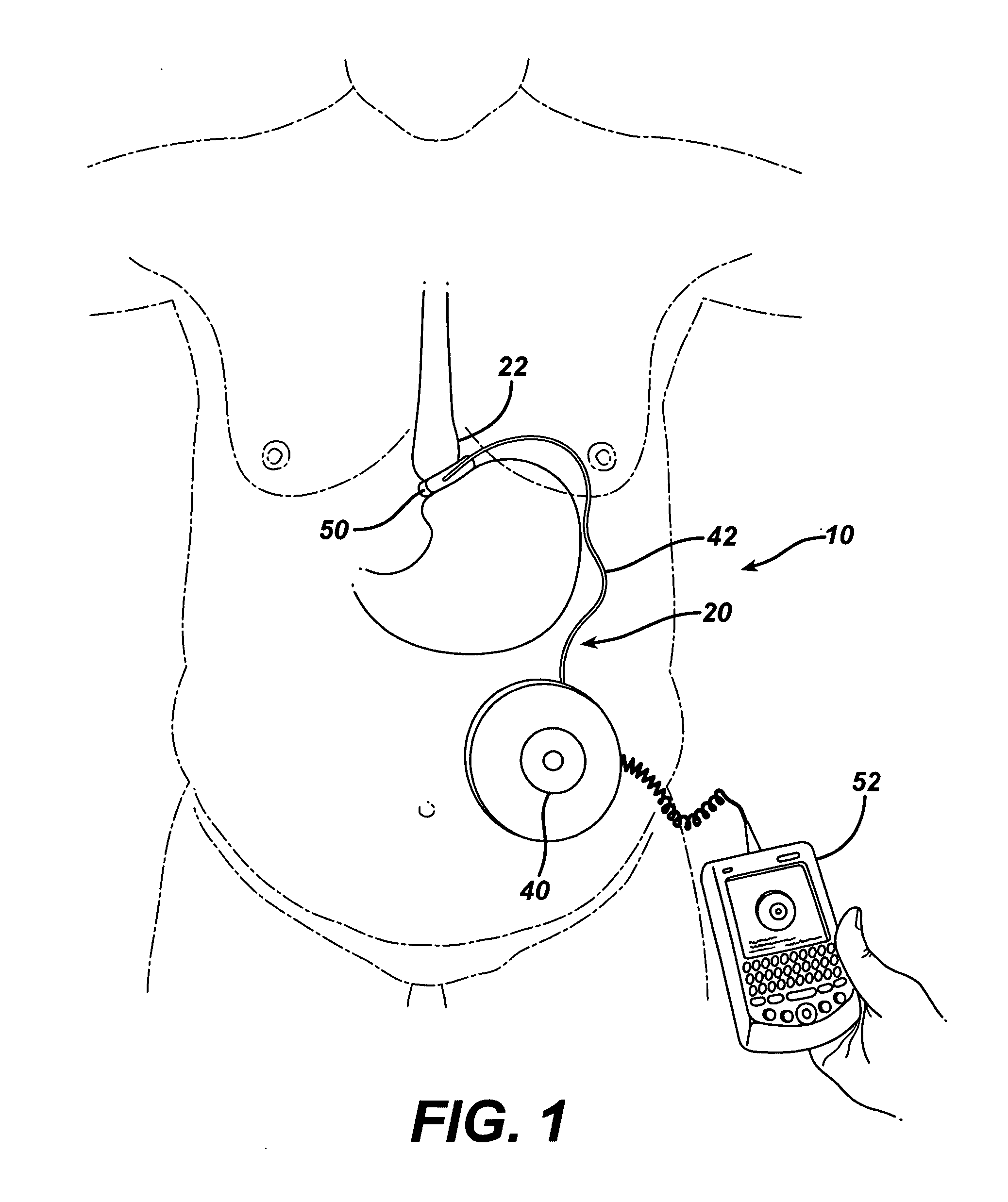

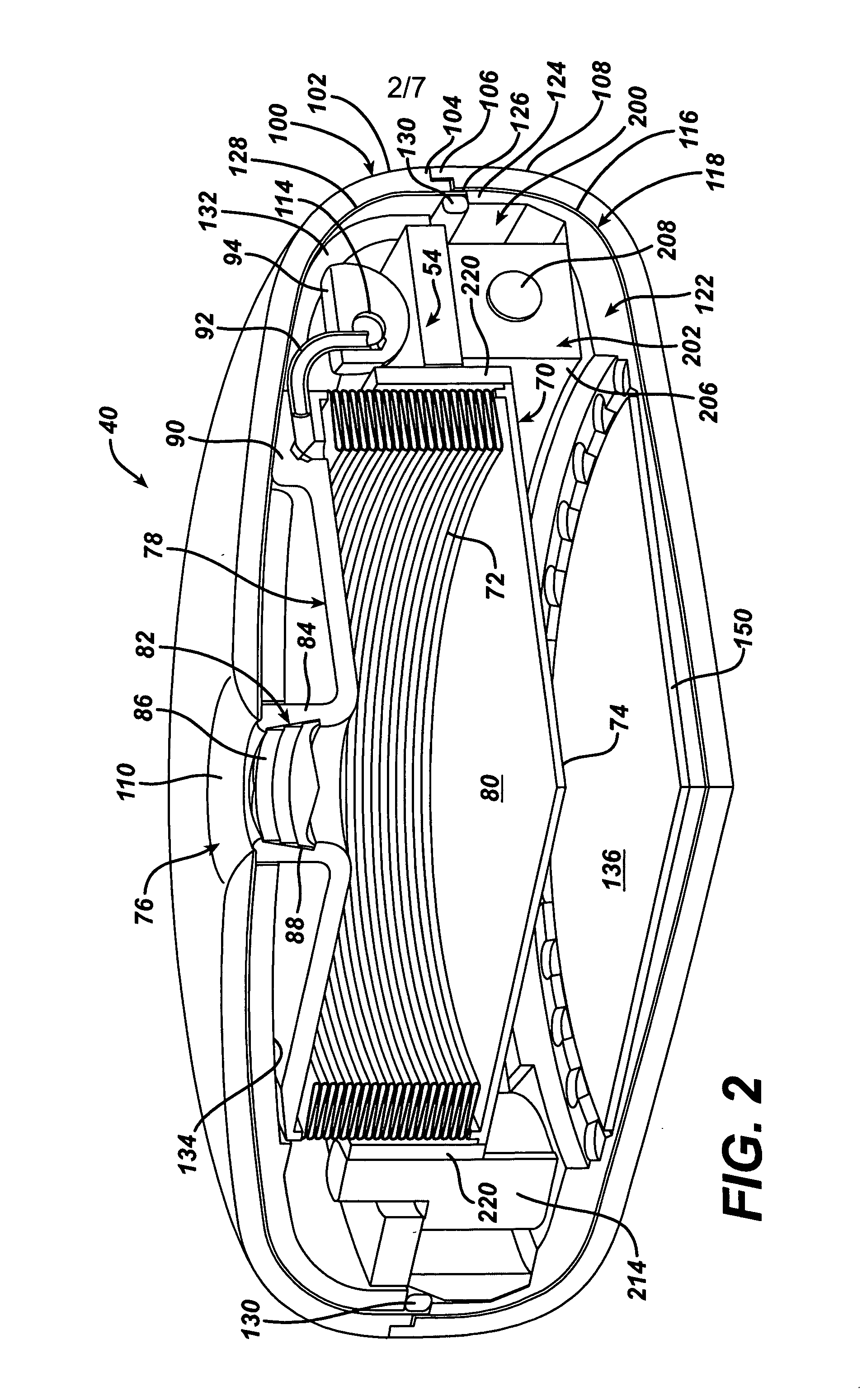

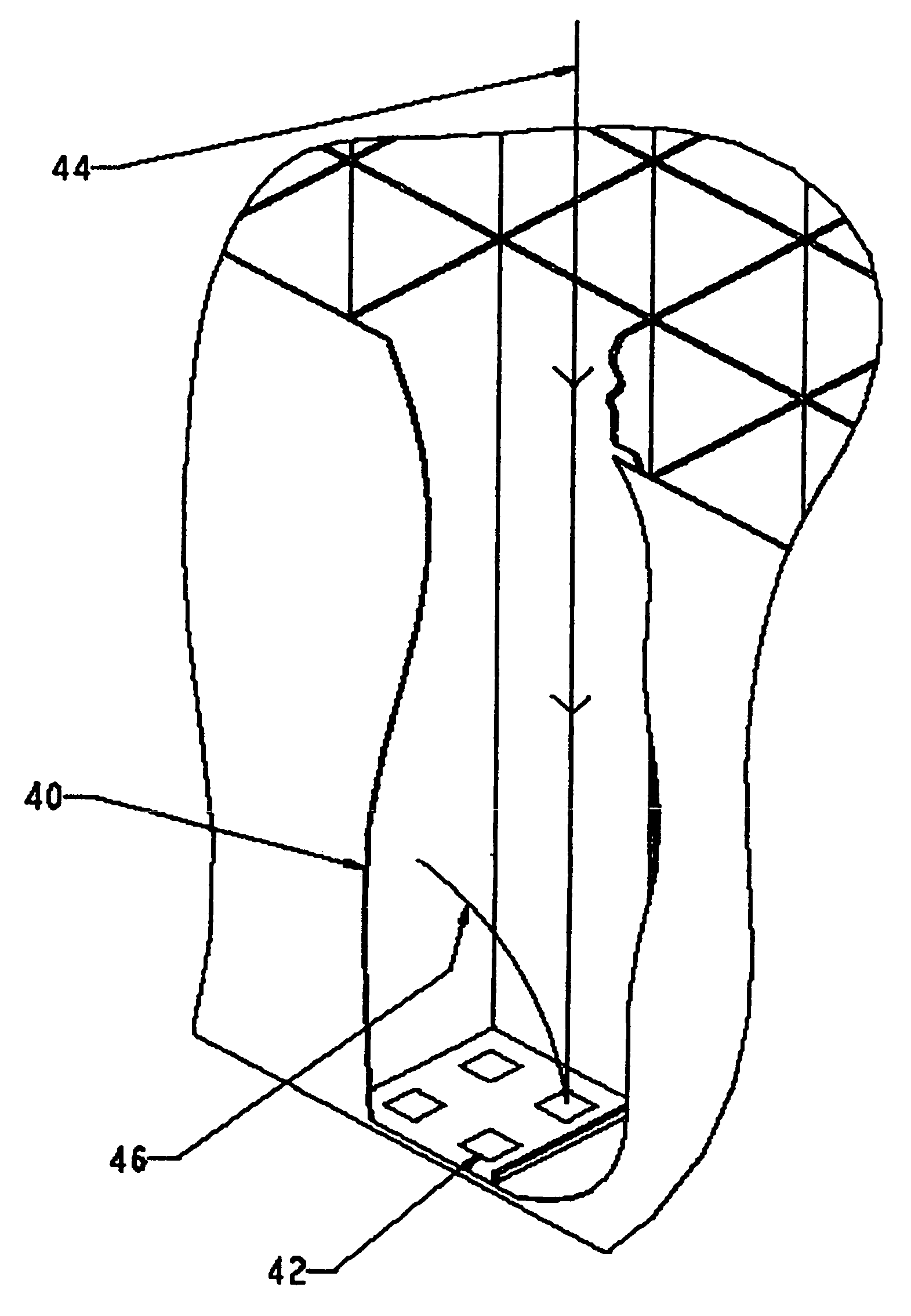

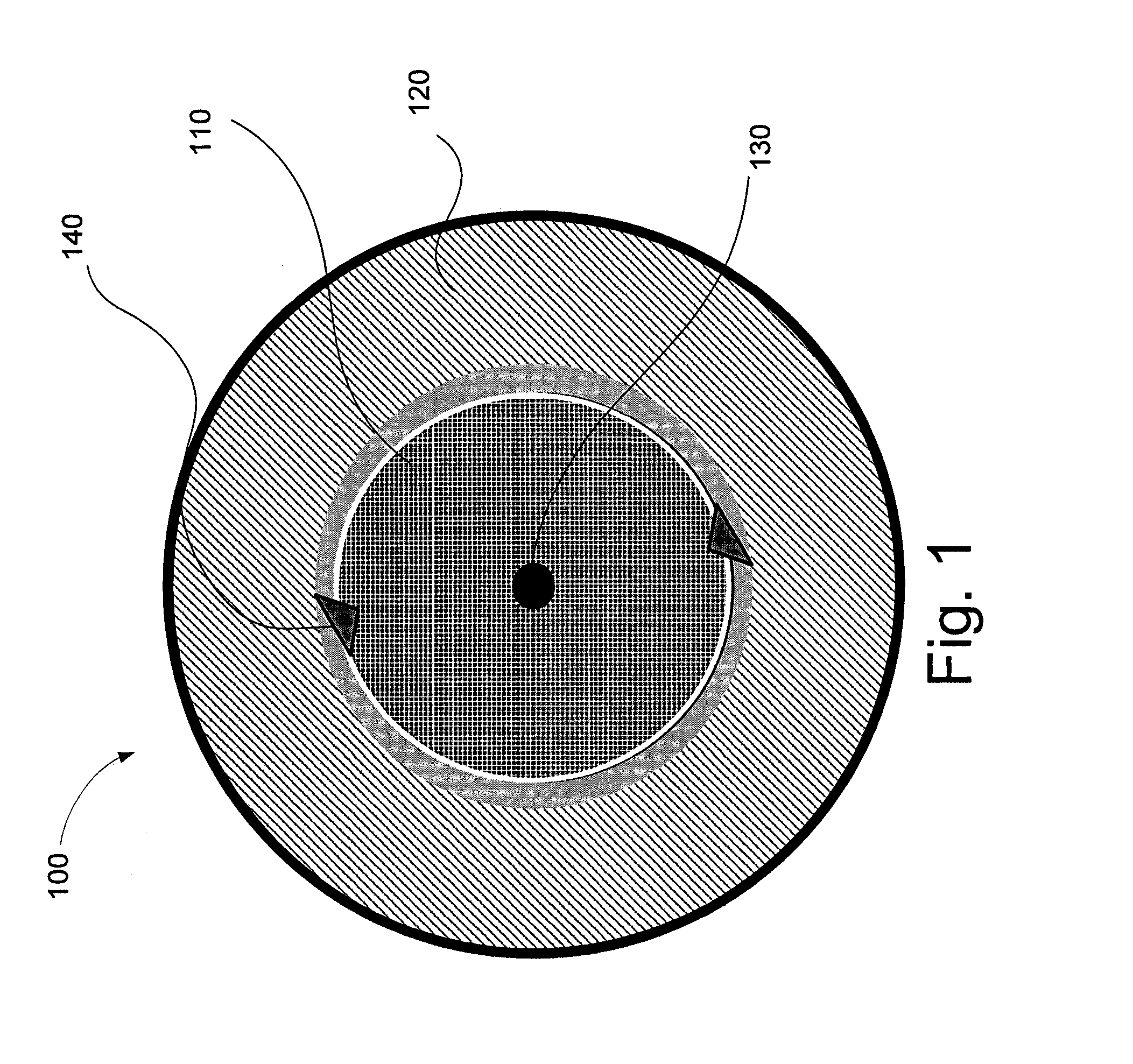

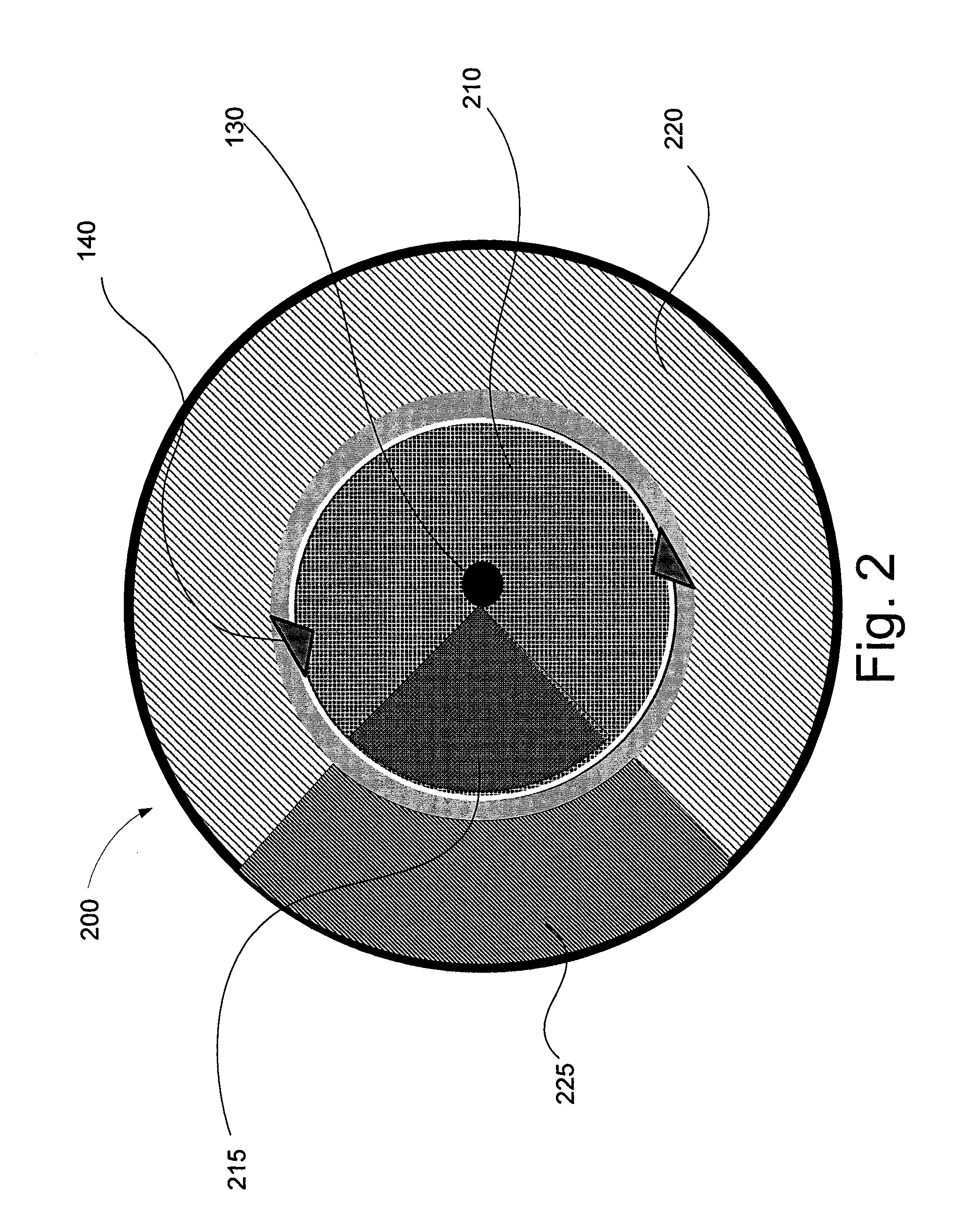

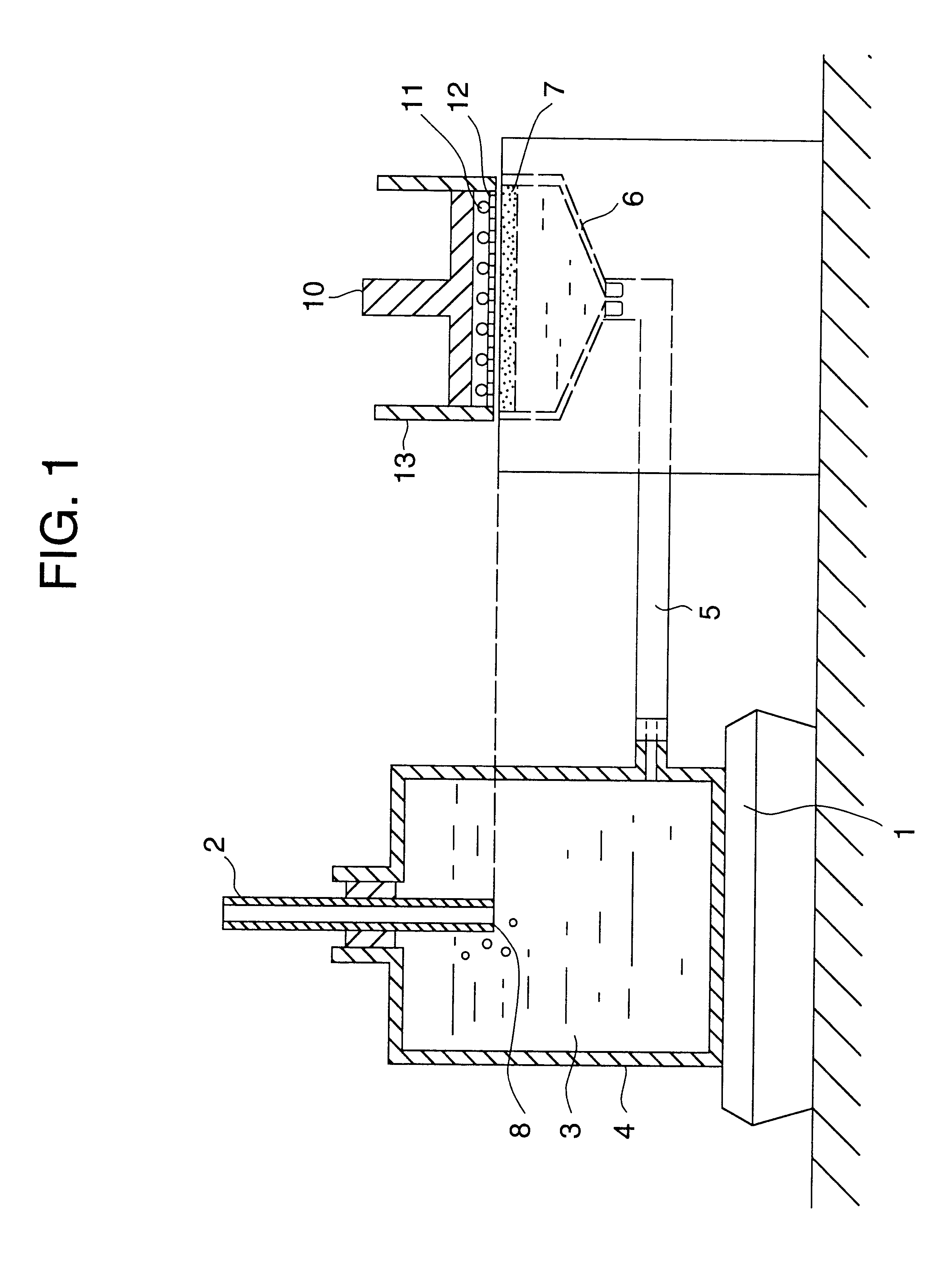

Thermodynamically driven reversible infuser pump for use as a remotely controlled gastric band

InactiveUS20050277974A1Avoid inconvenienceSmallAnti-incontinence devicesFlexible member pumpsEngineeringPiezo electric

An implantable artificial sphincter system provides long-term adjustment via transcutaneous energy transfer (TET), minimizing invasive adjustment through adding or removing fluid via a syringe. An infuser device provides bi-directional fluid transfer via a flexible conduit to a sphincter band, such as a gastric band, by a combination of thermodynamic actuation and a piezo-electrically disengaged drum brake assembly that thereby achieves a desirable small volume device. A propellant within a propellant cavity surrounds a metal bellows accumulator biased at body temperature to either expand or collapse the bellows accumulator with the opposite direction of movement effected by a thermal element that heats in combination with a negatively-biased propellant or cools in combination with a positively-biased propellant. A drum brake assembly locks the metal bellows accumulator in place between adjustments by thermodynamic actuation by activating piezo-electric stack actuators that disengage calipers from a brake drum attached to the bellows accumulator.

Owner:ETHICON ENDO SURGERY INC

Backside thinning of image array devices

InactiveUS7005637B2Improve imaging effectImprove device yieldSolid-state devicesSemiconductor/solid-state device manufacturingImage resolutionImage contrast

Backthinning in an area selective manner is applied to imaging sensors 12 for use in electron bombarded devices. A further arrangement results in an array of collimators 51 aligned with pixels 42 or groups of pixels providing improved image contrast of such image sensor. Provision of a thin P-doped layer 52 on the illuminated rear surface provides both a diffusion barrier resulting in improved resolution and a functional shield for reference pixels. A gradient in concentration of P-doped layer 52 optimizes electron collection at the pixel array.

Owner:EOTECH LLC

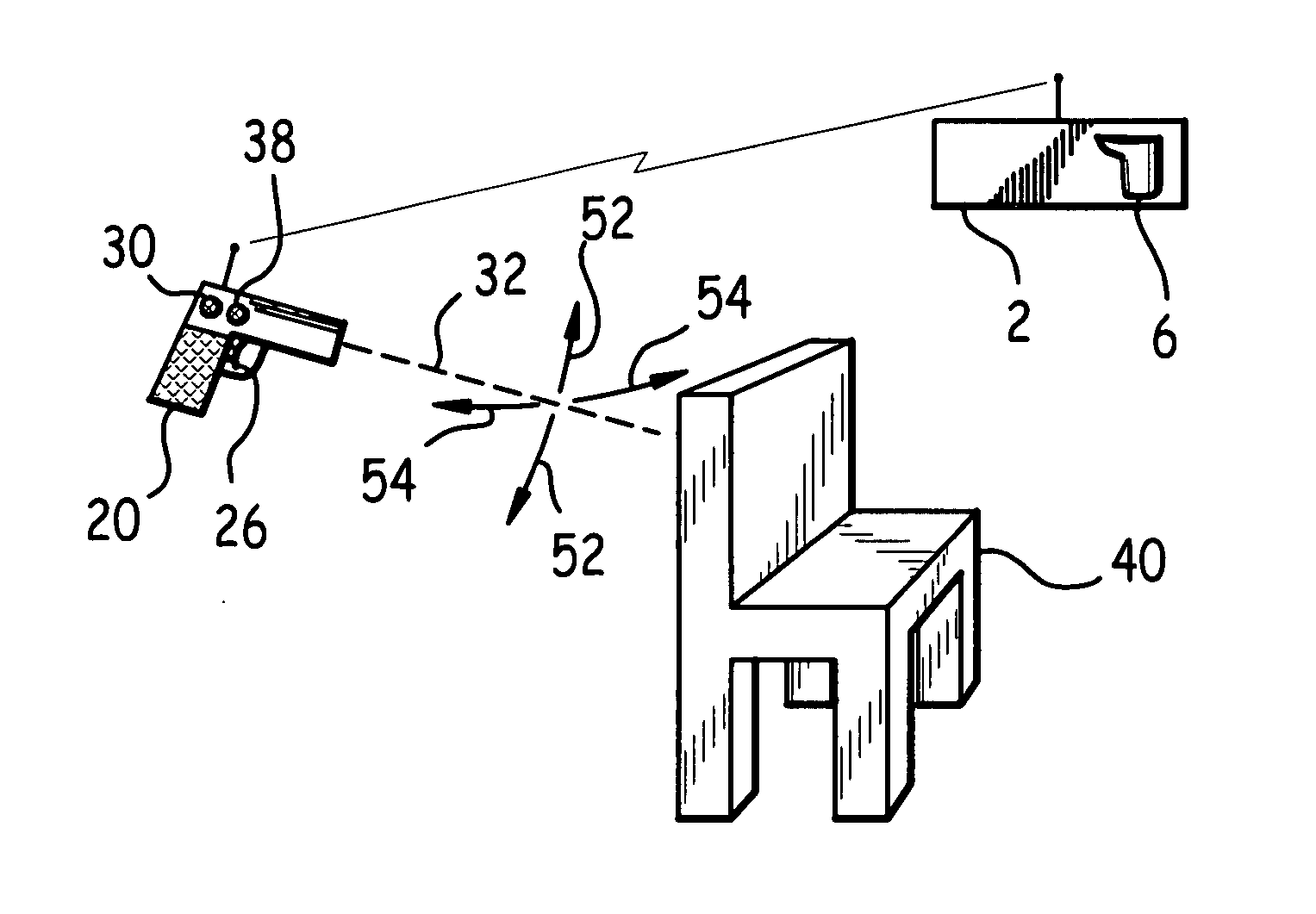

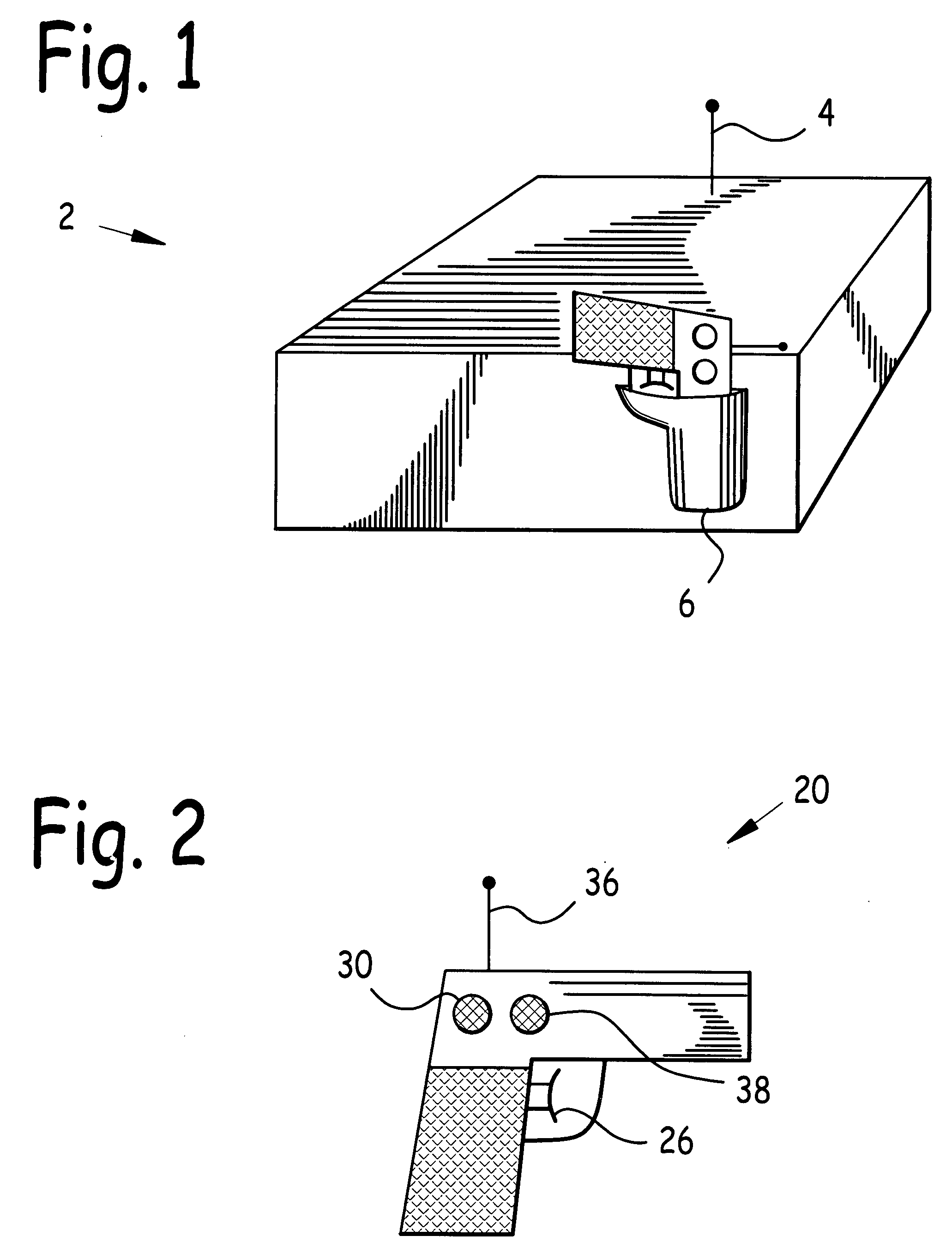

Apparatus and method fro measuring volumes

ActiveUS20080079955A1Accurate measurementImprove transportInvestigating moving sheetsPhotoelectric discharge tubesEngineeringTransmitter

An apparatus and method for measuring volumes. The apparatus includes a base having a central processing unit, a receiver and a dock; and a scanner having an inertial navigation system, a transmitter, a sensor, a reset control, and a trigger in communication with a microprocessor. An alternate embodiment scanner may include an exclude control, which instructs the central processing unit to exclude floor, ceiling, and walls from the volume calculation. The method of measuring volumes includes the steps of placing the scanner in the dock, actuating a reset control which establishes a reference point for the inertial navigation system, scanning objects, transmitting the data points scanned to the central processing unit, and calculating the volume of the object(s) scanned.

Owner:WHISMAN ELIZABETH A MS

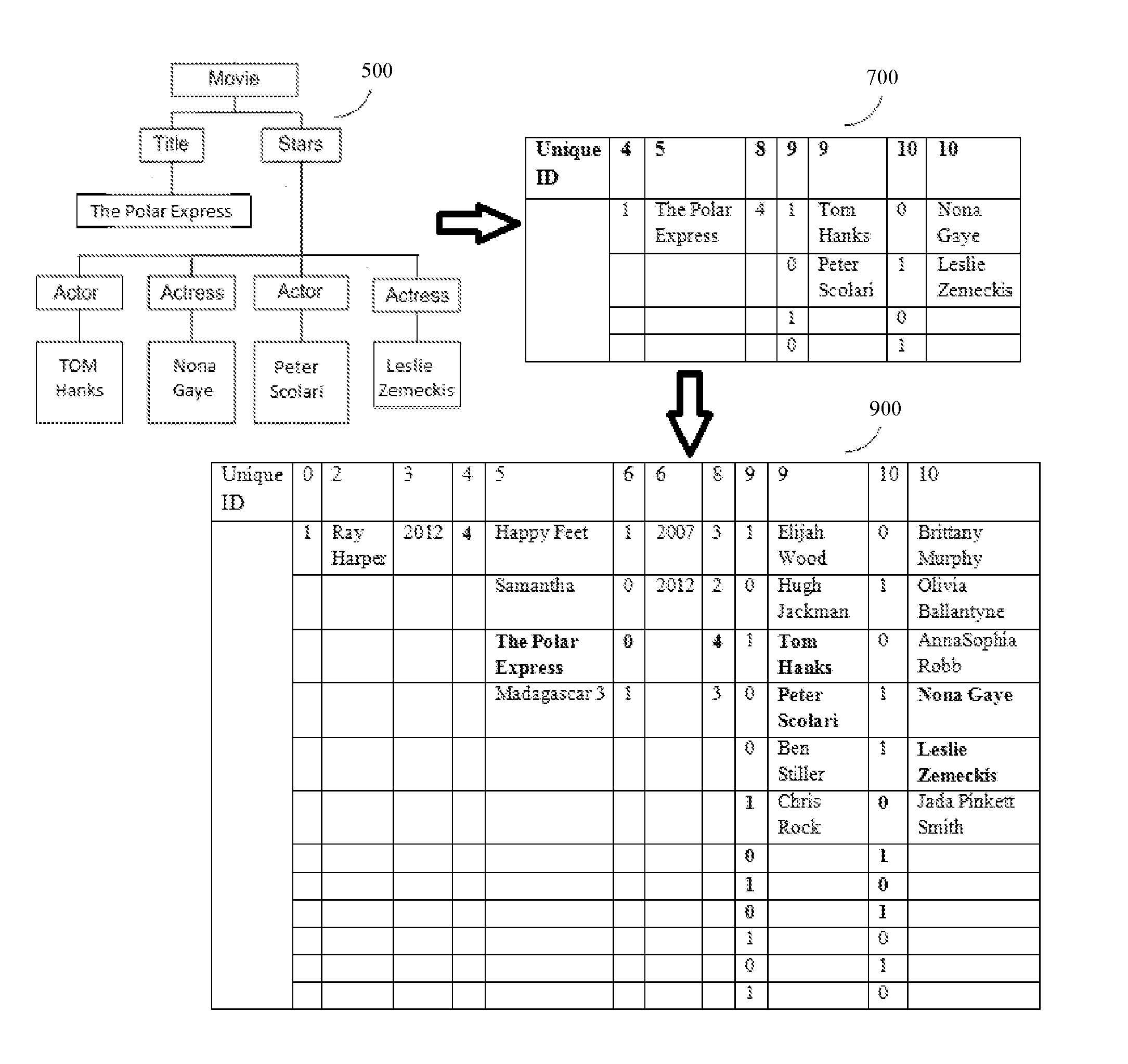

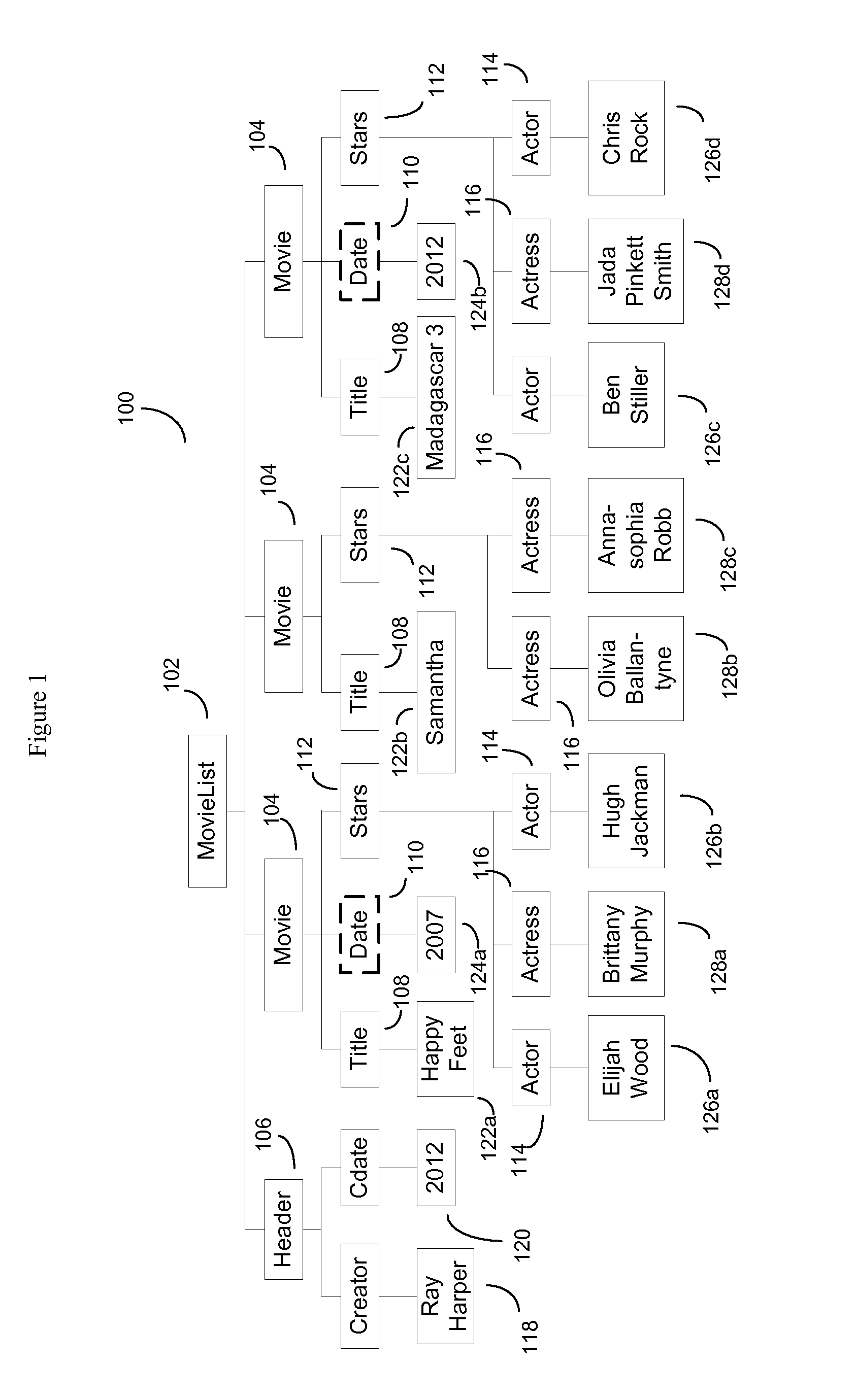

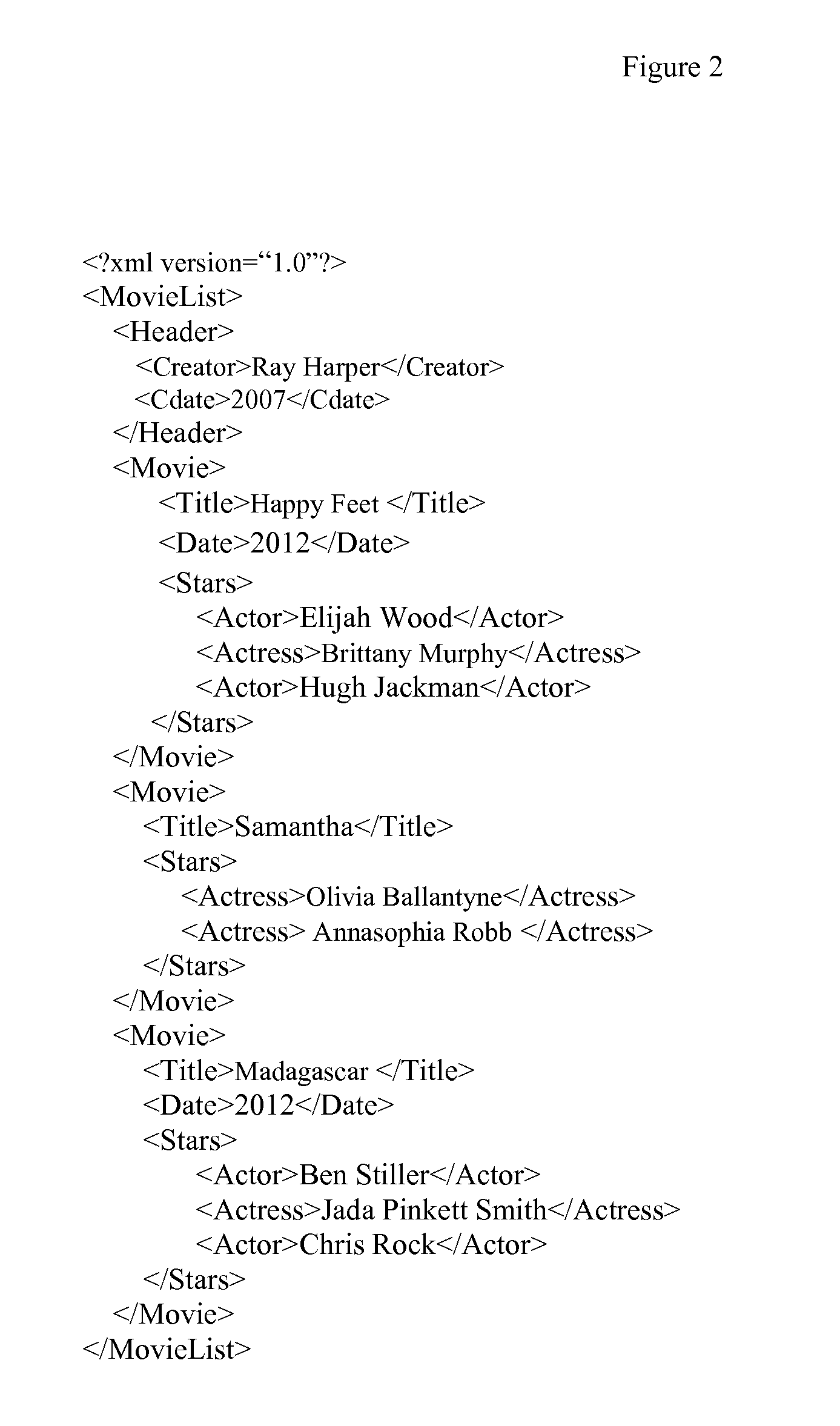

Method for representing and storing hierarchical data in a columnar format

ActiveUS20140201244A1SmallImprove system performanceDigital data processing detailsHierarchical databasesManagement systemData library

A computer implemented system, program product, and method that organizes hierarchical data into a plurality of columns is disclosed. A schema interface is defined for the data and two types of columns, value columns and occurrence columns, are used. Each value column stores the values for a field. Each occurrence column stores the occurrence numbers for a node that is repeatable, or optional, or in a choice group. The hierarchical relationship of the data is jointly preserved by the schema interface and the occurrence numbers in the occurrence columns. A database management system built upon the method is capable of operating at higher efficiency by combining some of the best aspects of relational database and hierarchical database management systems. The computer implemented method also provides a new and efficient method of exchanging data over networks.

Owner:ZHOU XIAOFAN

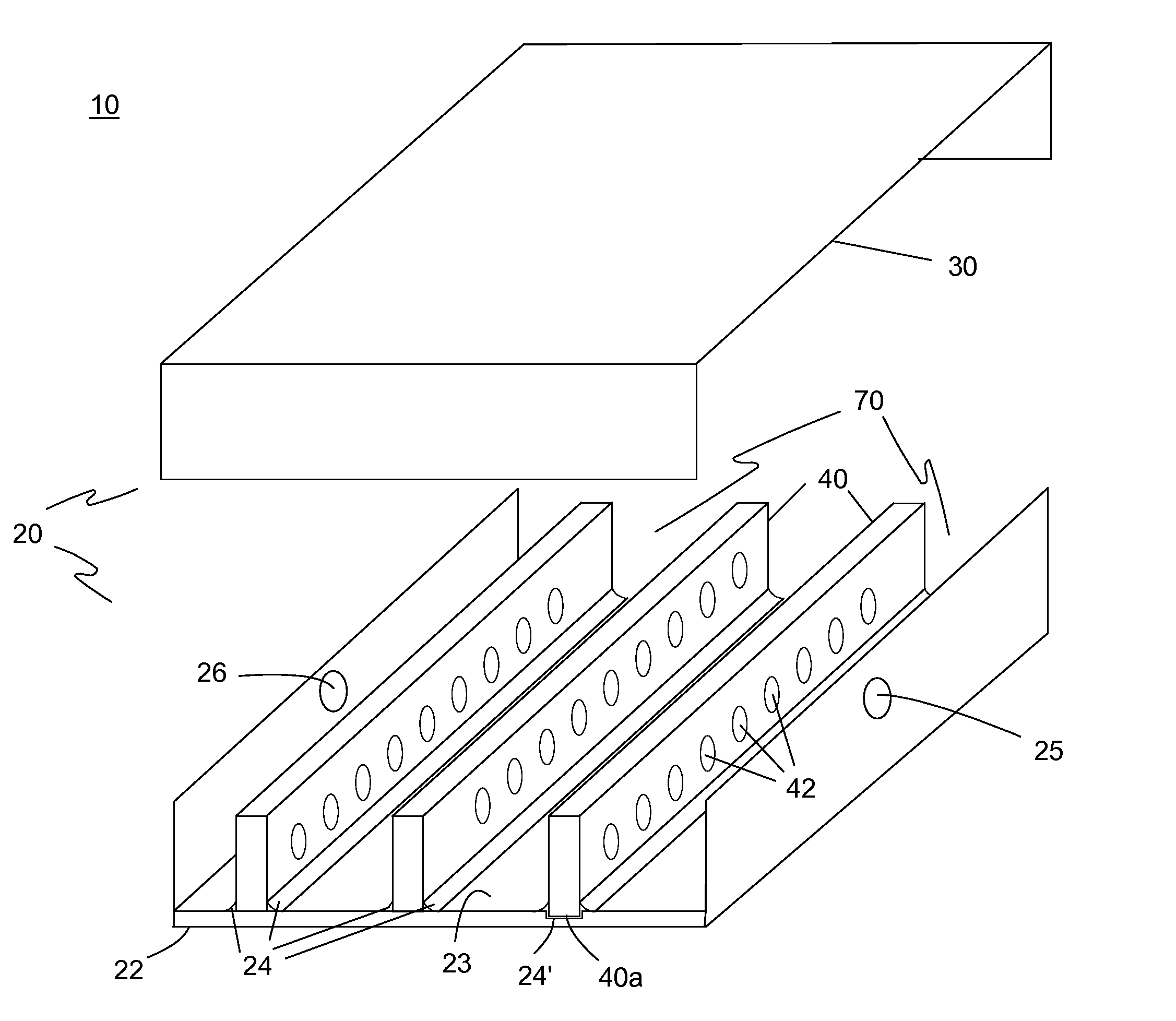

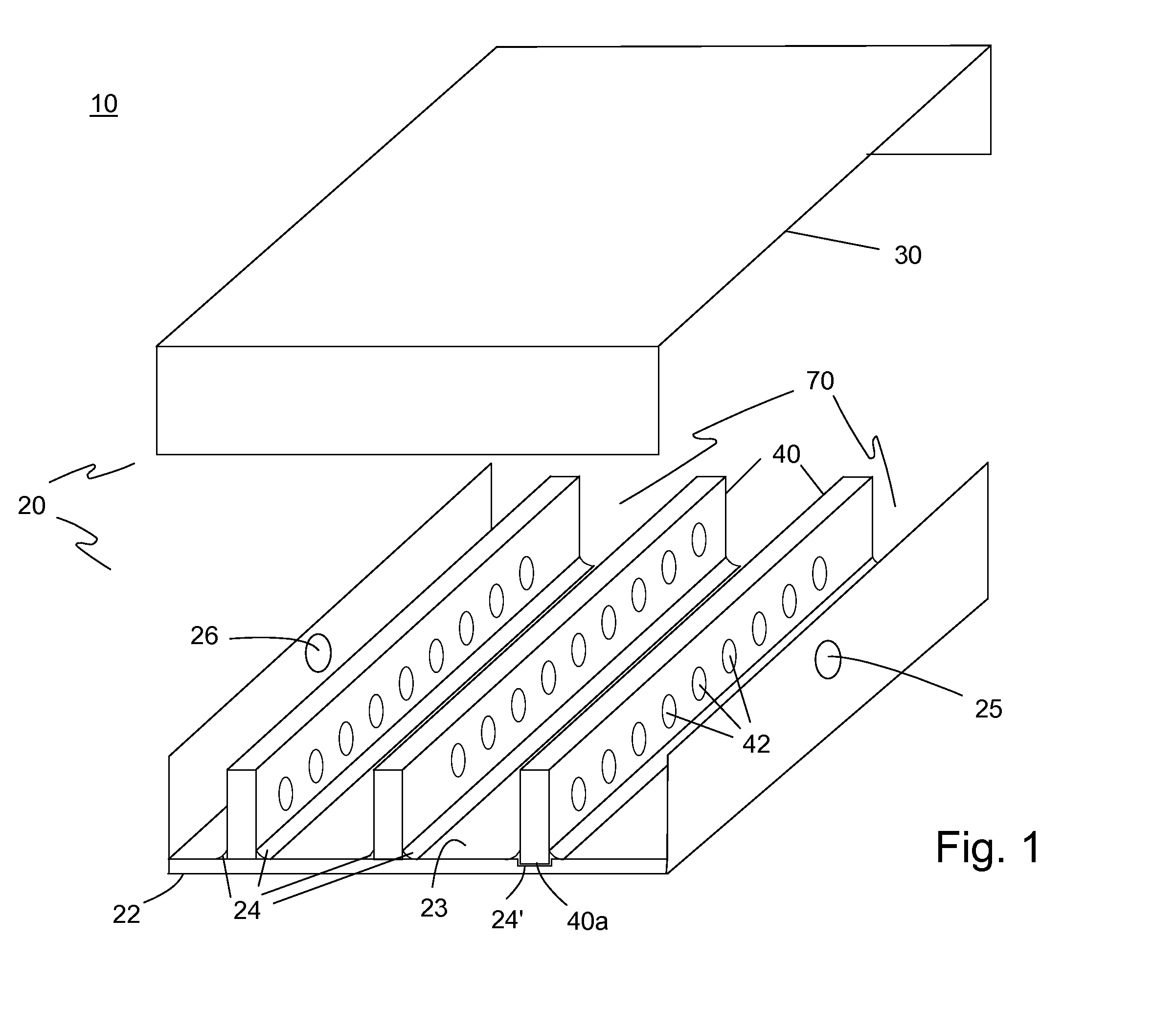

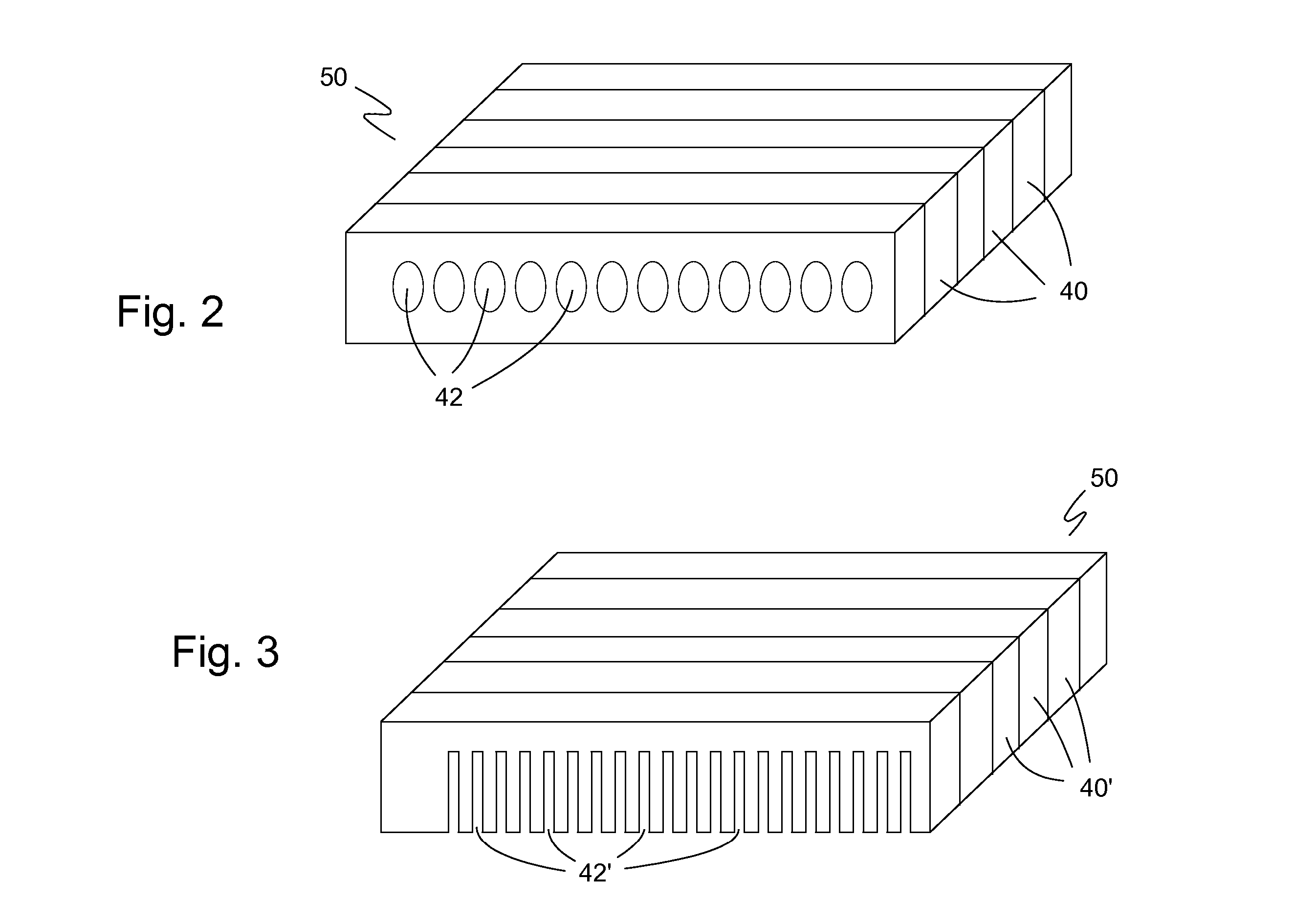

High Efficiency Fluid Heat Exchanger and Method of Manufacture

InactiveUS20060237166A1Good thermally conductive bondIncrease surface areaMetal-working apparatusHeat exhanger finsEngineeringHeat exchanger

A fluid heat exchanger has a housing having a thermally conductive base, a plurality of fin members connected to the base in a parallel, spaced relationship, a heat exchanger fluid inlet on one side of the plurality of fin members, and a heat exchanger fluid outlet on the opposite side of the plurality of fin members. The plurality of fin members each have a plurality of passageways and are arranged in the housing so that the passageways of one fin member are offset from the passageways of adjacent fin members.

Owner:FERROTEC USA CORP

Semiconductor device and layout design method therefor

A layout design method for a semiconductor device includes a step of arranging transistors, a dummy gate forming step of forming dummy gates, which has a shape identical with a shape including gate electrodes or the gate electrodes and projected parts from active regions of the gate electrodes, in positions in parallel with and a fixed distance apart from the gate electrodes arranged at both ends in a gate length direction on active regions of the transistors and, when the transistors have plural gate electrodes with different gate widths, extending the projected parts to the outside of the active regions by a necessary length, a gate connecting step of, when gate patterns and contact regions are connected to the gate electrodes of the transistors, connecting the gate electrodes and the dummy gates according to a positional relation between the gate electrodes and the dummy gates, and a wiring step of wiring a metal layer. It is possible to design a semiconductor device having a smaller area than that in the past and with a less design man-hour.

Owner:SOCIONEXT INC

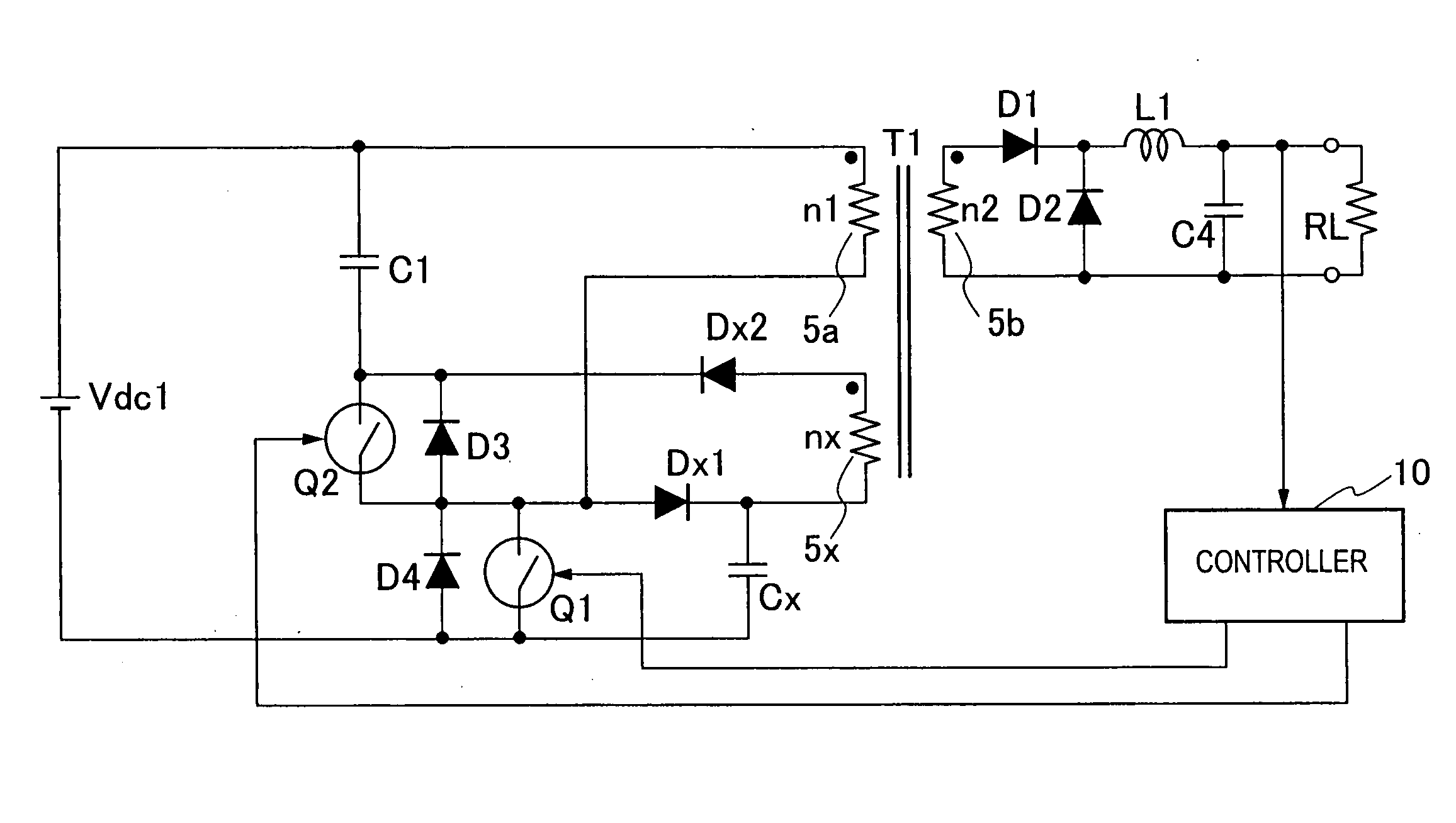

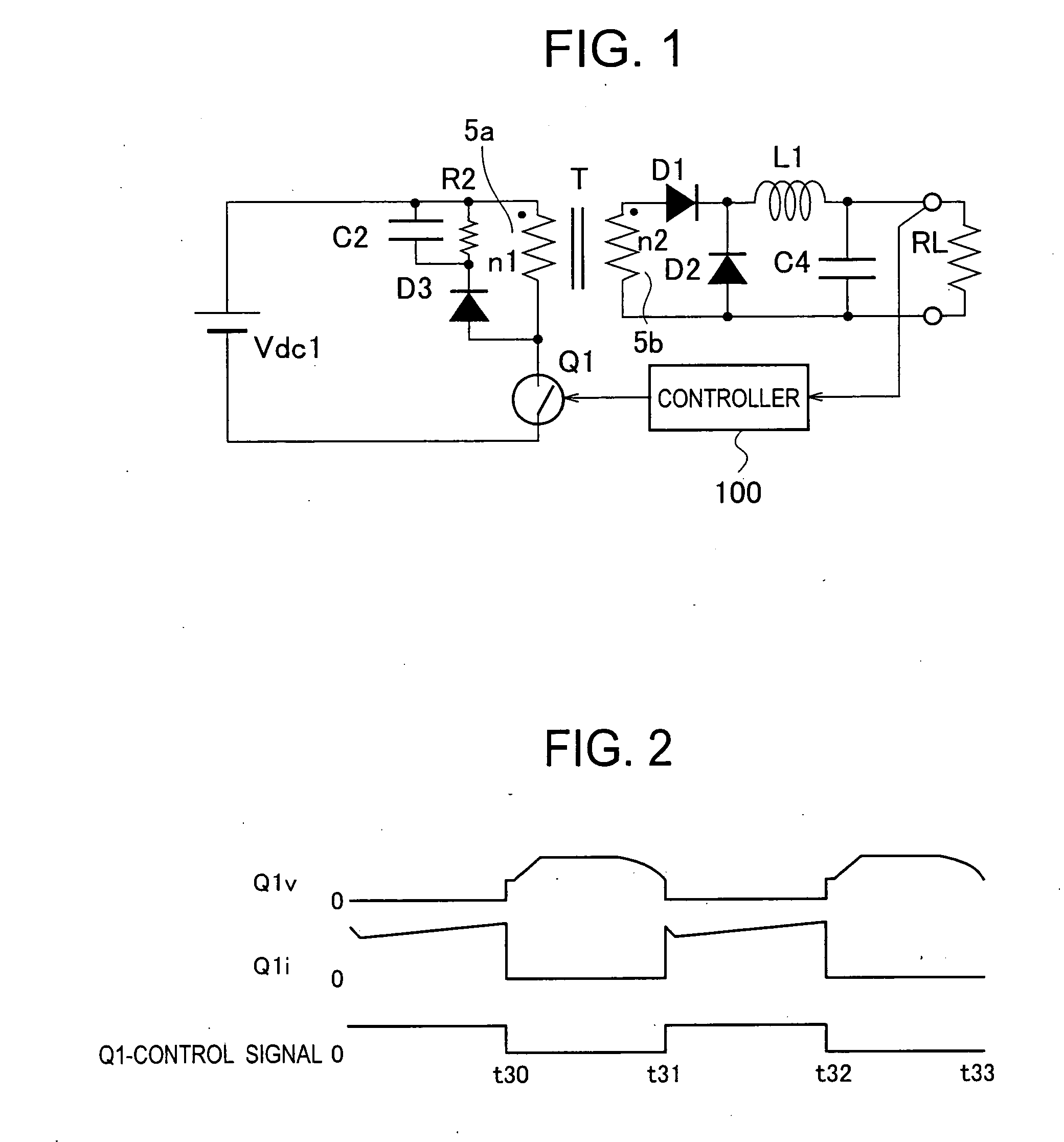

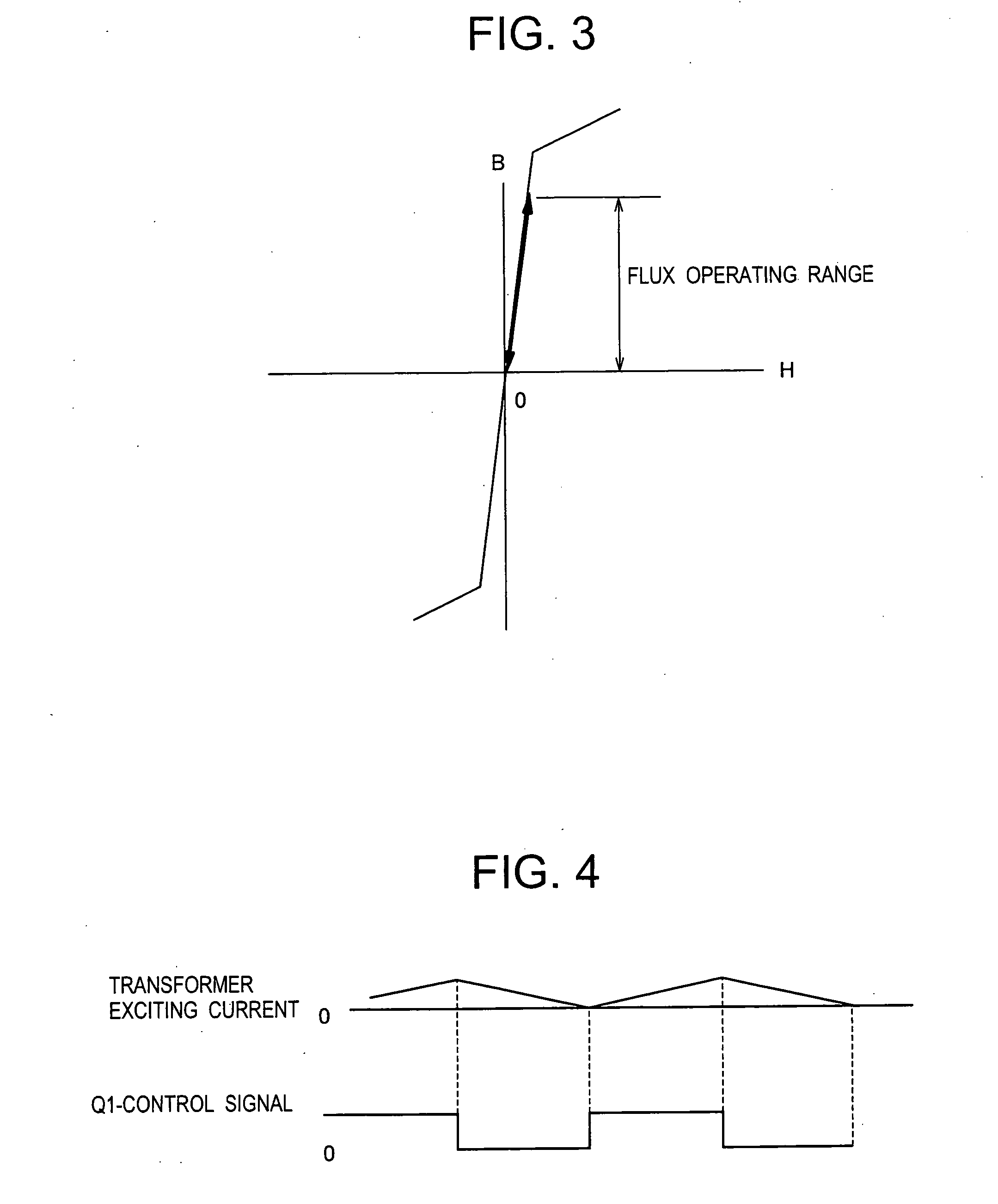

Switching power supply apparatus

InactiveUS20060187688A1Increase usageSmall sizeEmergency protective circuit arrangementsTransformers/inductances coils/windings/connectionsClamp capacitorSnubber capacitor

A switching power source apparatus can reduce the size of a transformer and realize the zero-voltage switching of a switch. The apparatus is compact, highly efficient, and low in noise. The apparatus has a series circuit connected to each end of a DC power source (Vdc1) and including a primary winding (5a) of a transformer (T) and a main switch (Q1), a rectifying-smoothing circuit to rectify and smooth a voltage that is outputted from a secondary winding (5b) when the main switch (Q1) is turned on, a series circuit connected to each end of the primary winding (5a) and including an auxiliary switch (Q2) and a clamp capacitor (C1), a series circuit connected to each end of the main switch (Q1) and including a diode (Dx1) and a snubber capacitor (Cx), a series circuit connected to a node between the diode (Dx1) and the snubber capacitor (Cx) and a node between the auxiliary switch (Q2) and the clamp capacitor (C1) and including an auxiliary winding (5x) and a diode (Dx2), and a control circuit (10) to alternately turn on / off the main switch (Q1) and auxiliary switch (Q2). When the main switch (Q1) is turned on, the snubber capacitor (Cx) is discharged through the auxiliary winding (5x) to the clamp capacitor (C1). When the main switch (Q1) is turned off, the snubber capacitor (Cx) is charged, to relax the inclination of a voltage increase of the main switch (Q1).

Owner:SANKEN ELECTRIC CO LTD

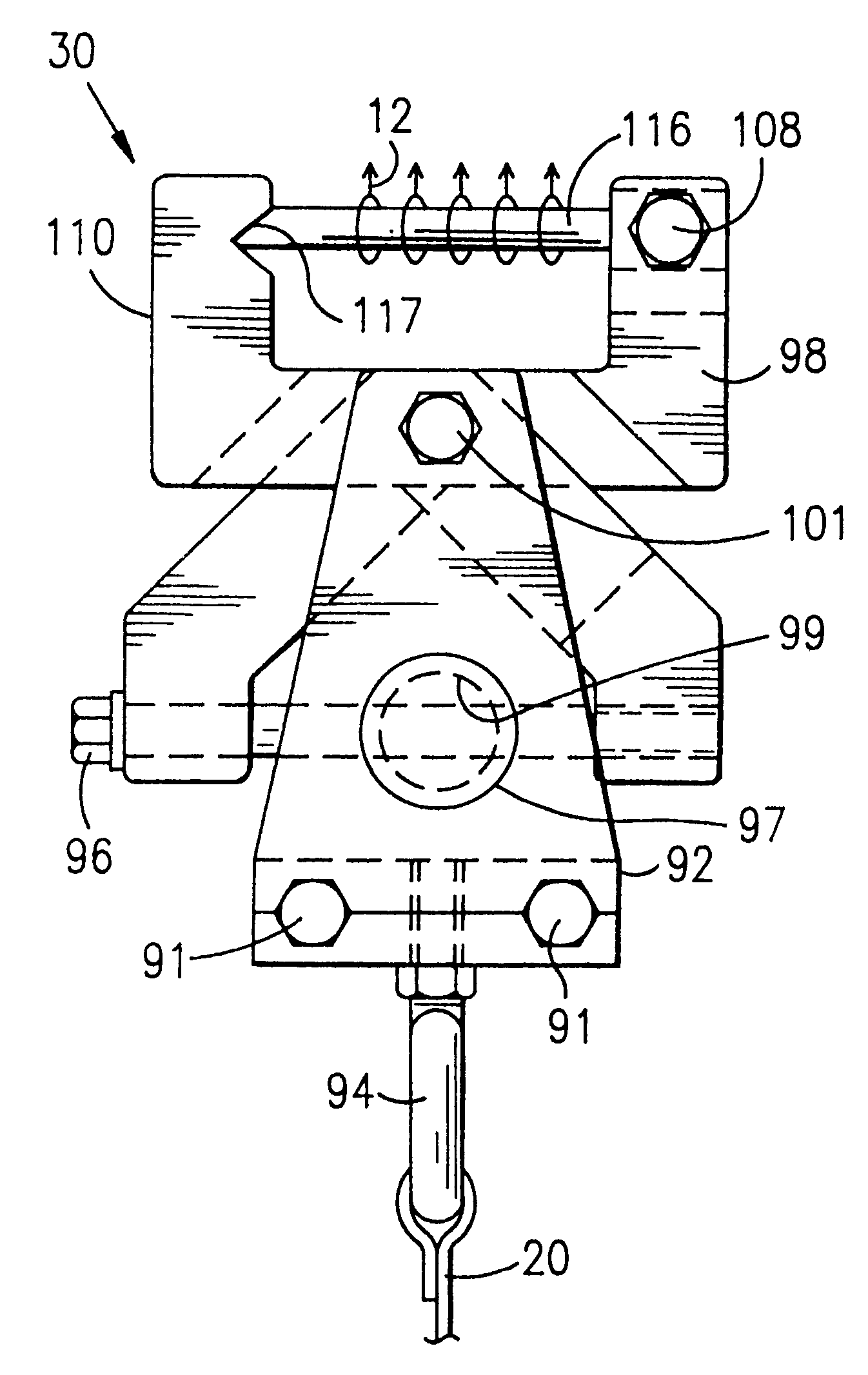

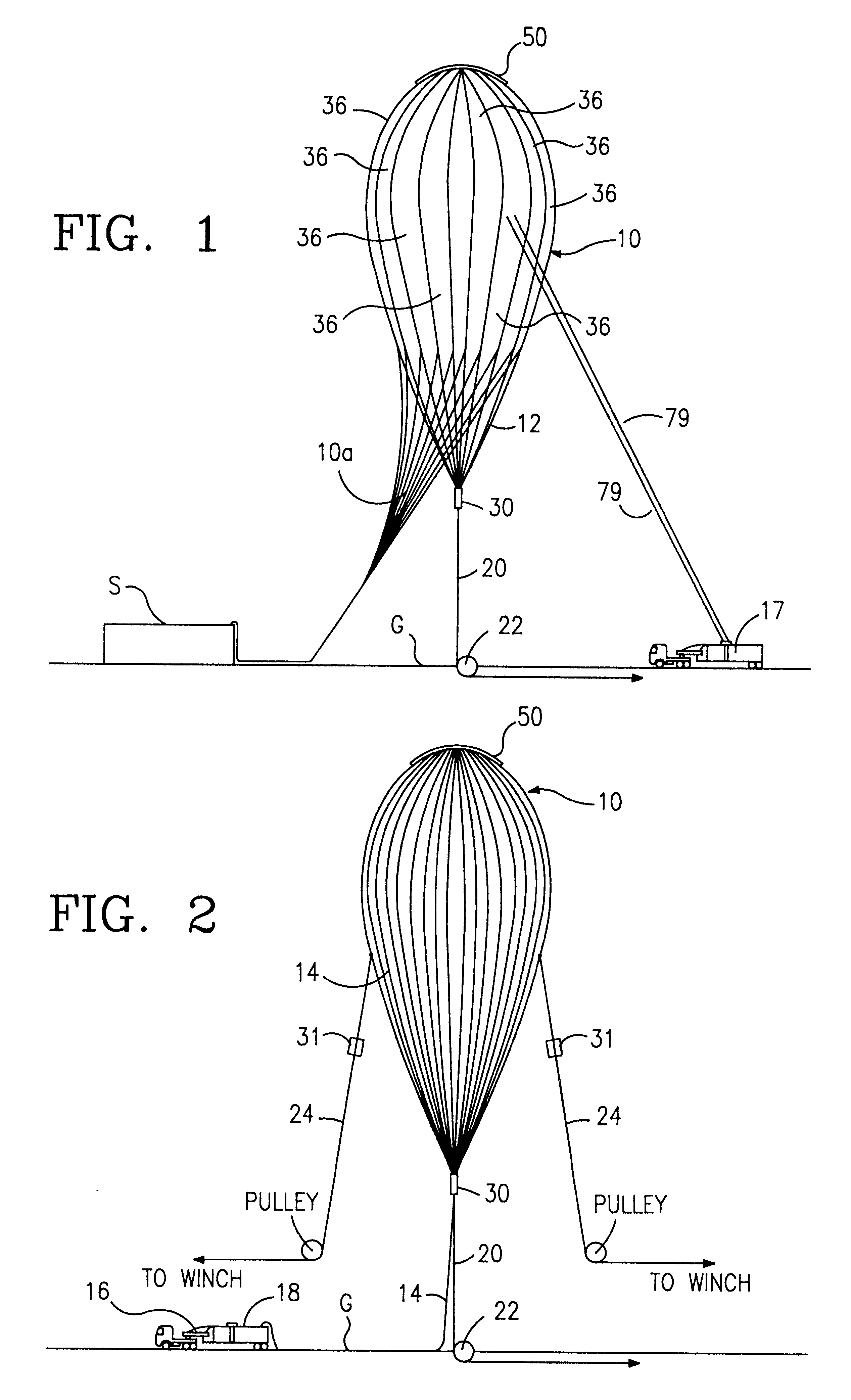

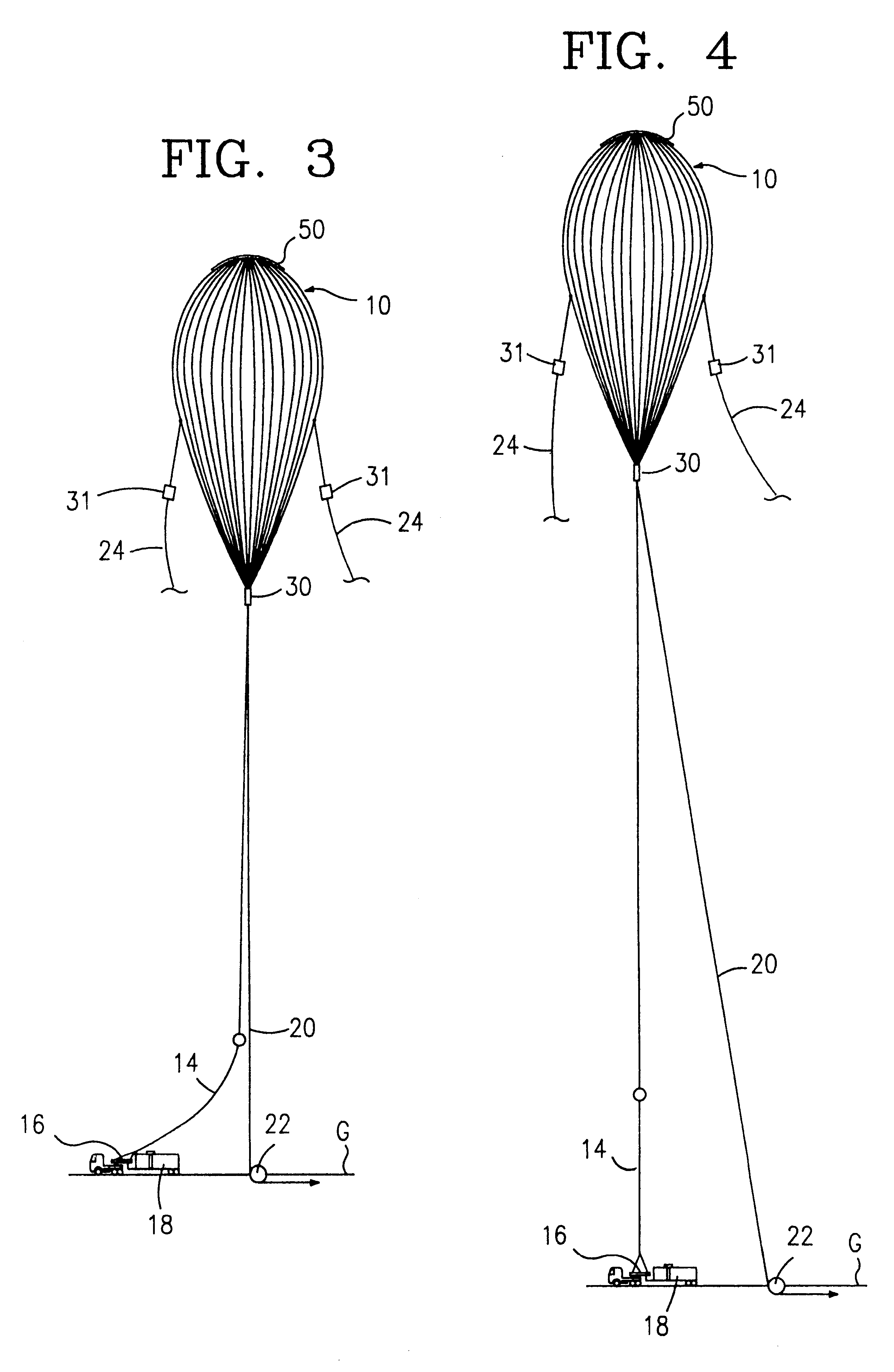

Release fitting for balloons

InactiveUS6234425B1SmallReduced and eliminated range safety costLaunch systemsCosmonautic partsBolt cutterEngineering

A release fitting for releasably holding at least one line to at least one item, the release fitting having a first body part, a second body part, and a third body part, the first and second body parts pivotably secured to the third body part, a bolt with a first bolt portion connected to a first portion of the first body part and a second bolt portion connected to a first portion of the second body part, at least one pin suitable for attaching thereto the at least one line, the first body part having a recess for releasably receiving an end of the pin, the bolt initially holding apart the first portion of the first body part and the first portion of the second body part to thereby maintain a second pin end in the recess, the third body part connected to the at least one item, bolt cutter apparatus for selectively cutting the bolt to release the at least one line from the pin.

Owner:WINZEN ENG

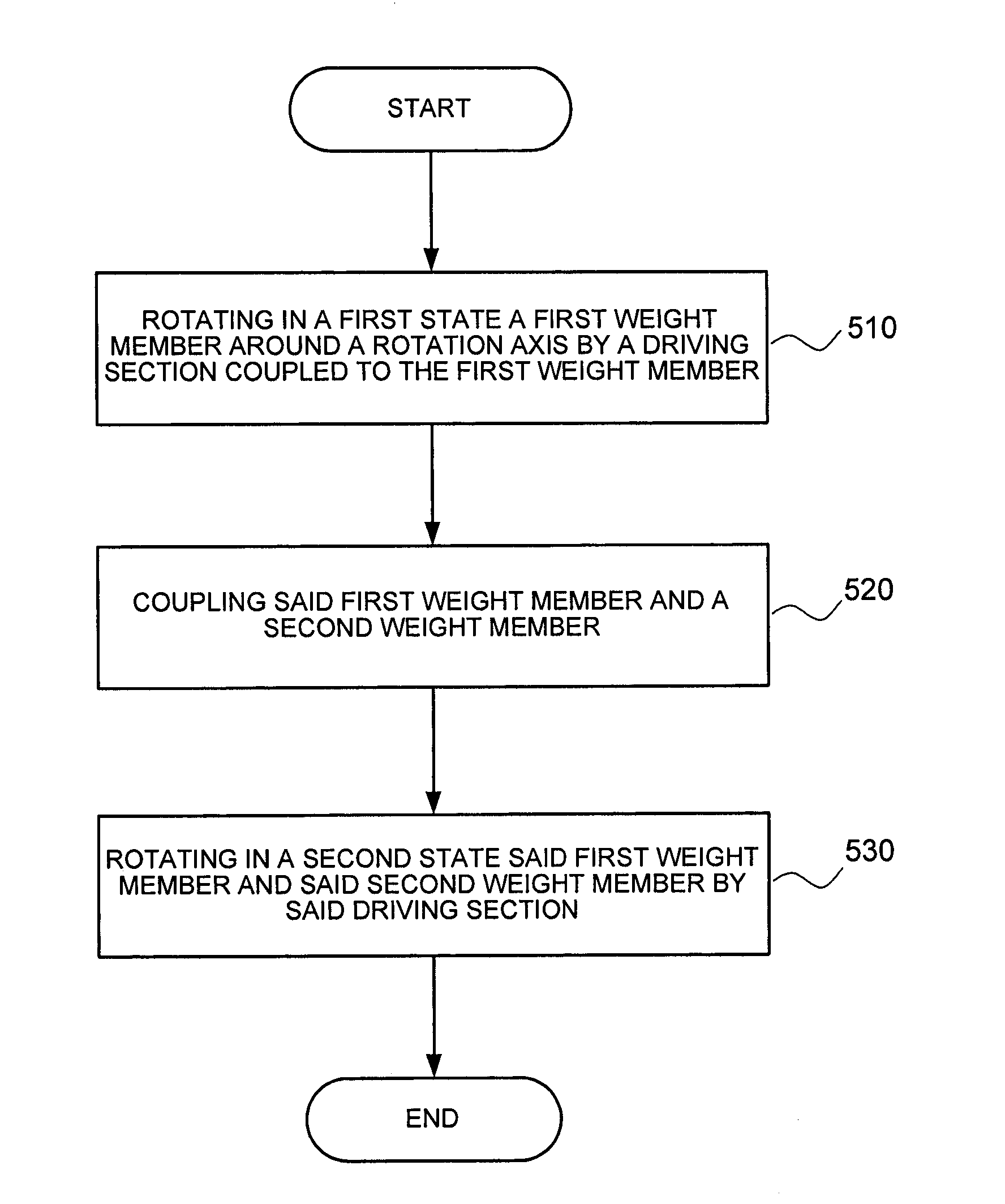

Vibration apparatus for a hand-held mobile device, hand-held mobile device comprising the vibration apparatus and method for operating the vibration apparatus

InactiveUS20110132114A1Strong mechanical forceImprove the vibration effectGearingMechanical vibrations separationCouplingHand held

The present invention relates to a vibration apparatus, a hand-held mobile device and a method for operating the vibration apparatus with which the time to obtain a detectable vibration effect is reduced while still being able to provide also a strong vibration effect. The vibration apparatus comprises a first weight member; a second weight member; a driving section coupled to said first weight member and operable to rotate at least said first weight member around a rotation axis; and a coupling mechanism adapted to provide coupling between said first weight member and said second weight member so that in a first state said first weight member is rotated by said driving section and in a second state said first weight member and said second weight member are rotated by said driving section.

Owner:SONY ERICSSON MOBILE COMM AB

Method and System for Manufacturing Sintered Rare-Earth Magnet Having Magnetic Anisotropy

ActiveUS20070245851A1Improve coercive forceEfficient productionFoundry mouldsInorganic material magnetismManufacturing efficiencyCrystallite

To improve the performance of a rare-earth magnet, it is effective to use a low-oxidized powder having a small grain size. One objective of the present invention is to provide a method for manufacturing a sintered rare-earth magnet having a magnetic anisotropy, in which a very active powder having a small grain size can be safely used in a low-oxidized state. Another objective is to provide a method capable of efficiently manufacturing products having various shapes. In a weighing and loading section 41 and a high-density loading section 42, a fine powder as a material of the sintered rare-earth magnet having a magnetic anisotropy is loaded into a mold until its density reaches a predetermined level. Then, in a magnetic orientation section 43, the fine powder is oriented by a pulsed magnetic field. Subsequently, the fine powder is not compressed but immediately sintered in a sintering furnace 44. The present method enables the mass-producing machine to be simple in its operation and its housing to be accordingly smaller, so that it will be possible to eliminate the danger of oxidization or burning of the powder, which has been a serious problem for a conventional method that uses a large-scale die-pressing machine. Furthermore, the manufacturing efficiency can be improved by using a multi-cavity mold for manufacturing a sintered rare-earth magnet having an industrially important shape, such as a plate magnet or an arched plate magnet.

Owner:DAIDO STEEL CO LTD

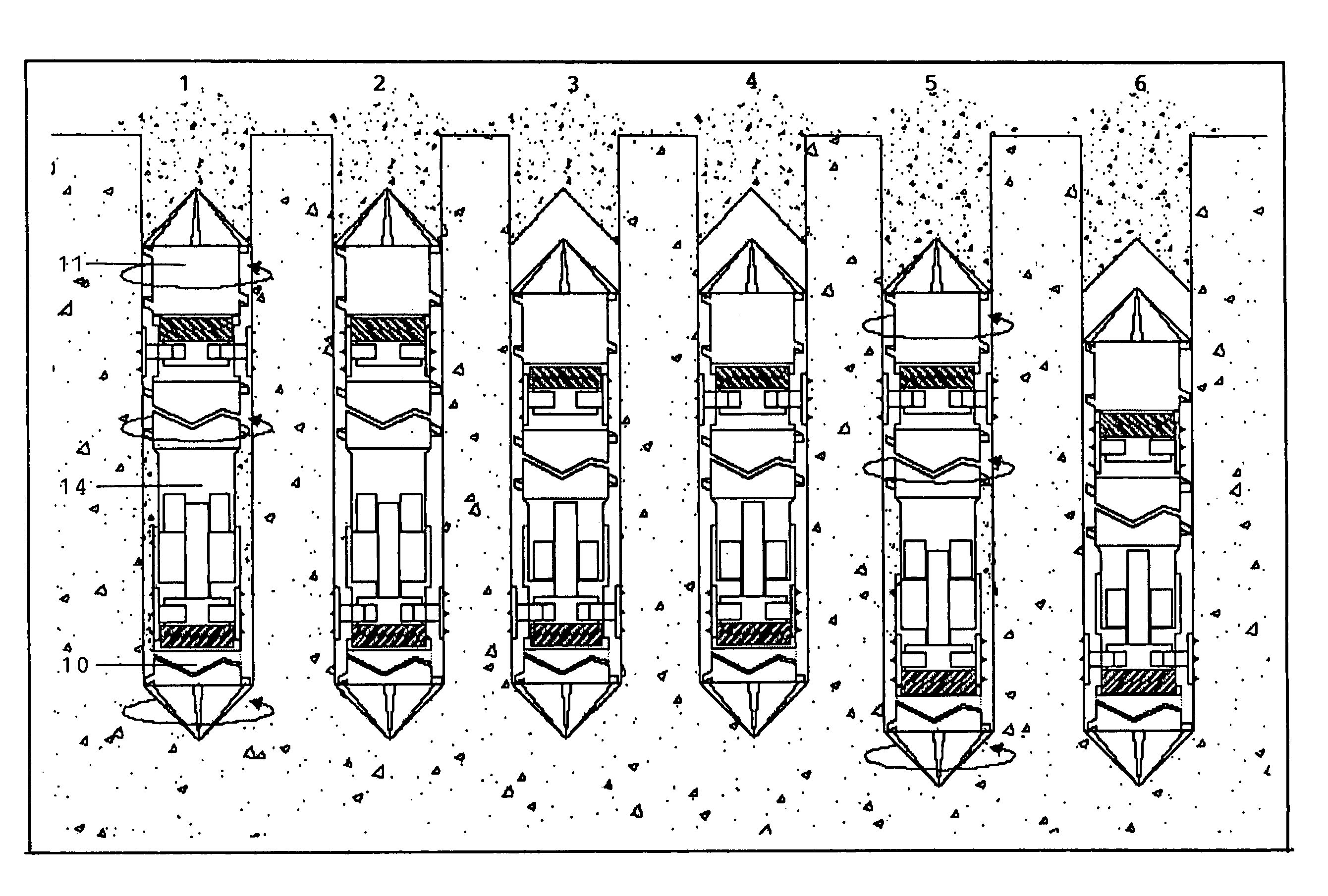

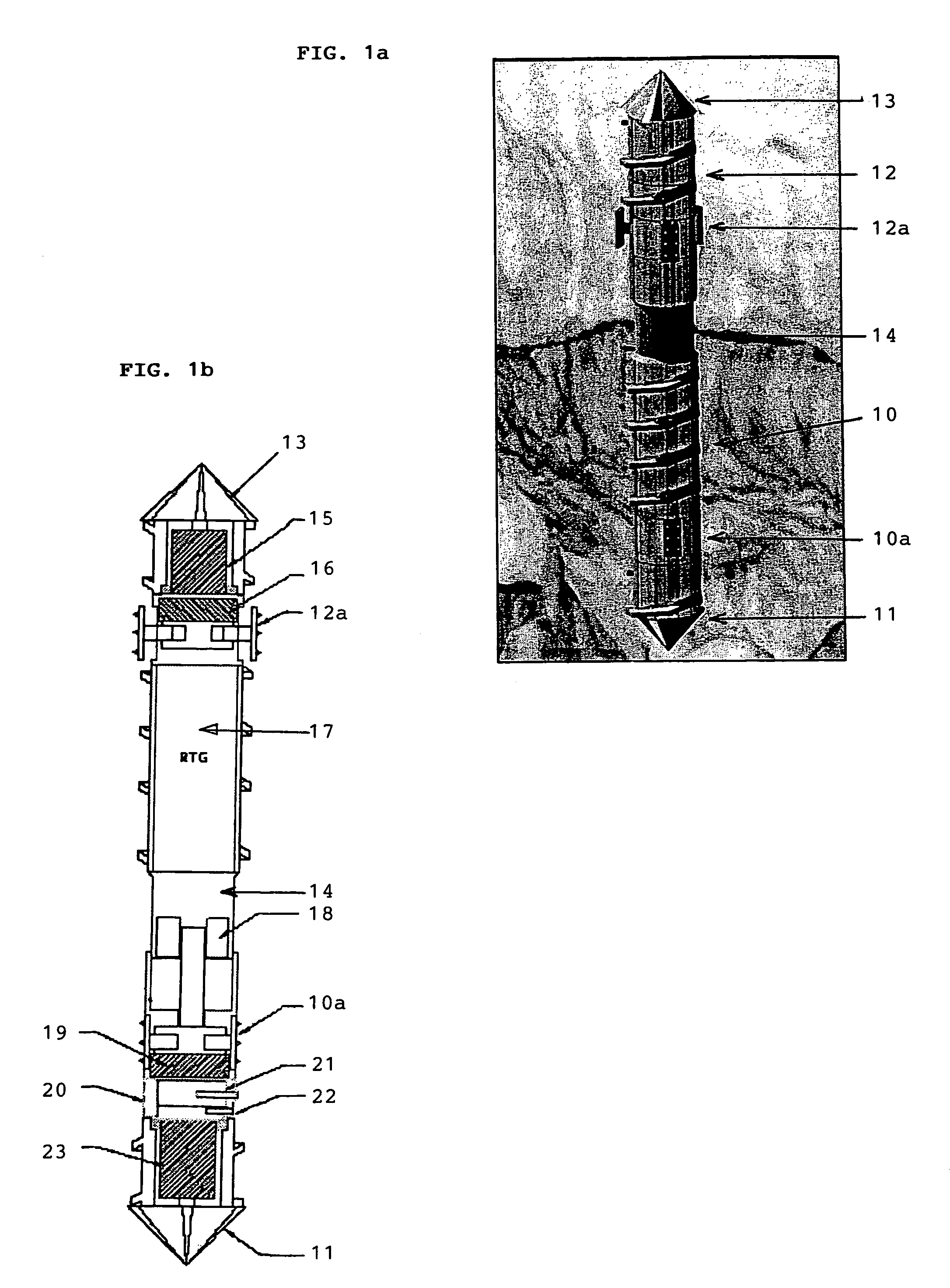

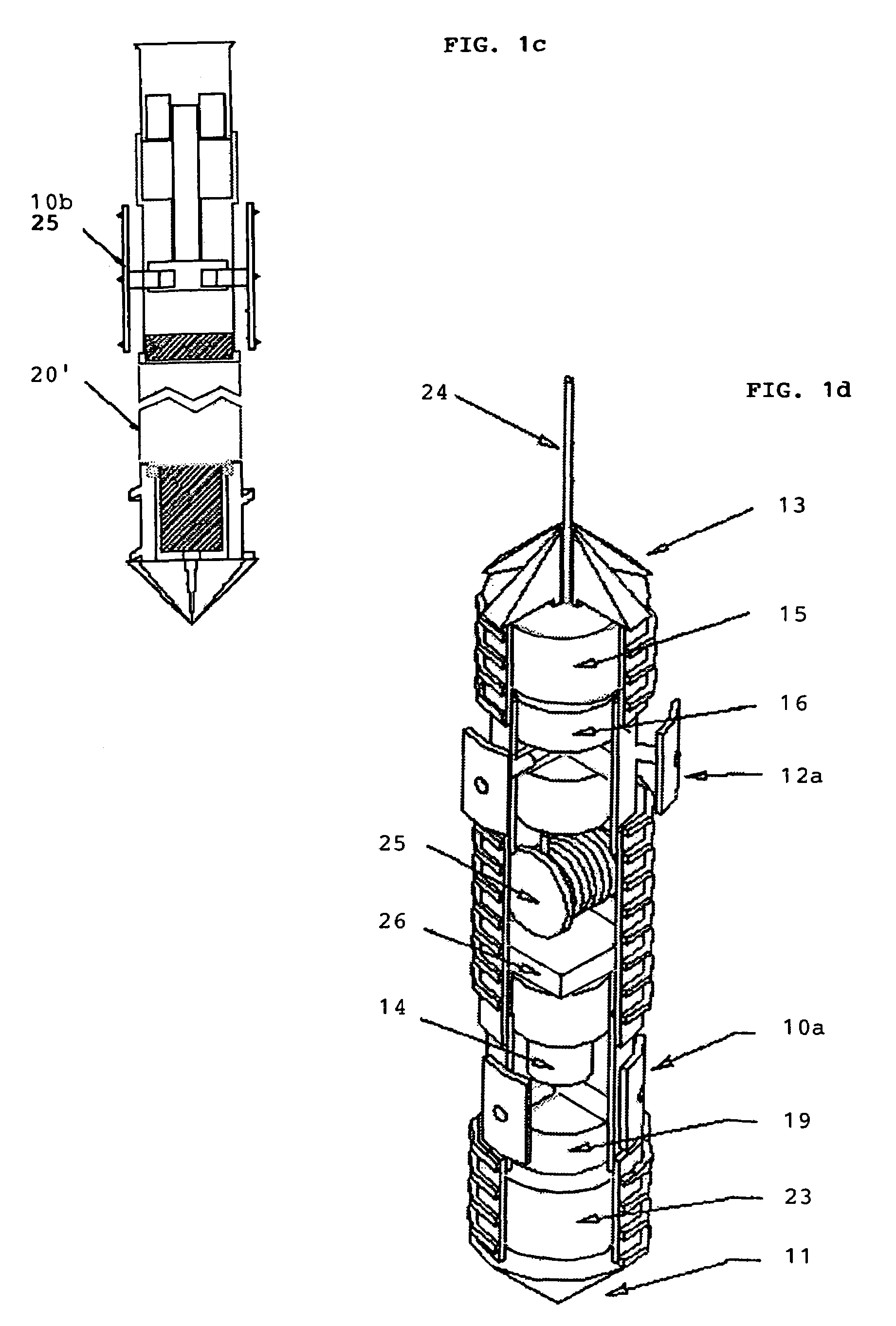

Self-propelled instrumented deep drilling system

InactiveUS7055625B1Improve mobilityEnergy self-sufficientDrilling rodsBorehole drivesOn boardAxial thrust

An autonomous subsurface drilling device has spaced-apart forward and rearward “feet” sections coupled to an axial thruster mechanism between them to operate using an inchworm method of mobility. In one embodiment, forward and rearward drill sections are carried on forward and rearward “feet” sections for drilling into material in the borehole in both forward and rearward directions, to allow the device to maneuver in any direction underground. In another embodiment, a front drill section has a drill head for cutting into the borehole and conveying cuttings through a center spine tube to an on-board depository for the cuttings. The feet sections of the device employ a foot scroll drive unit to provide radial thrust and synchronous motion to the feet for gripping the borehole wall. The axial thrust mechanism has a tandem set of thrusters in which the second thruster is used to provide the thrust needed for drilling, but not walking. A steering mechanism composed of concentric inner and outer eccentric rings provided with the rearward feet section allow small corrections in both direction and magnitude to the drilling direction as drilling commences.

Owner:HONEYBEE ROBOTICS

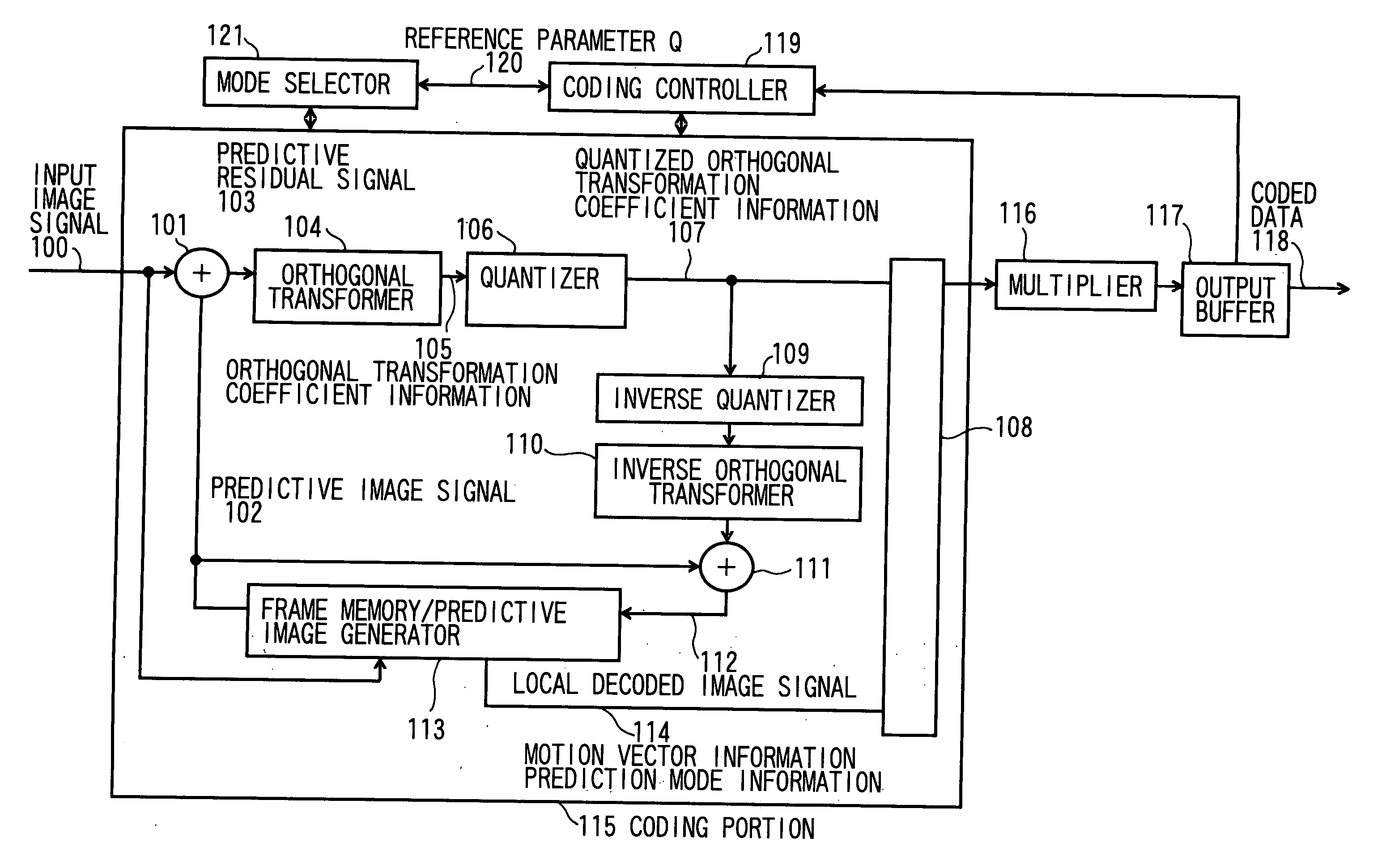

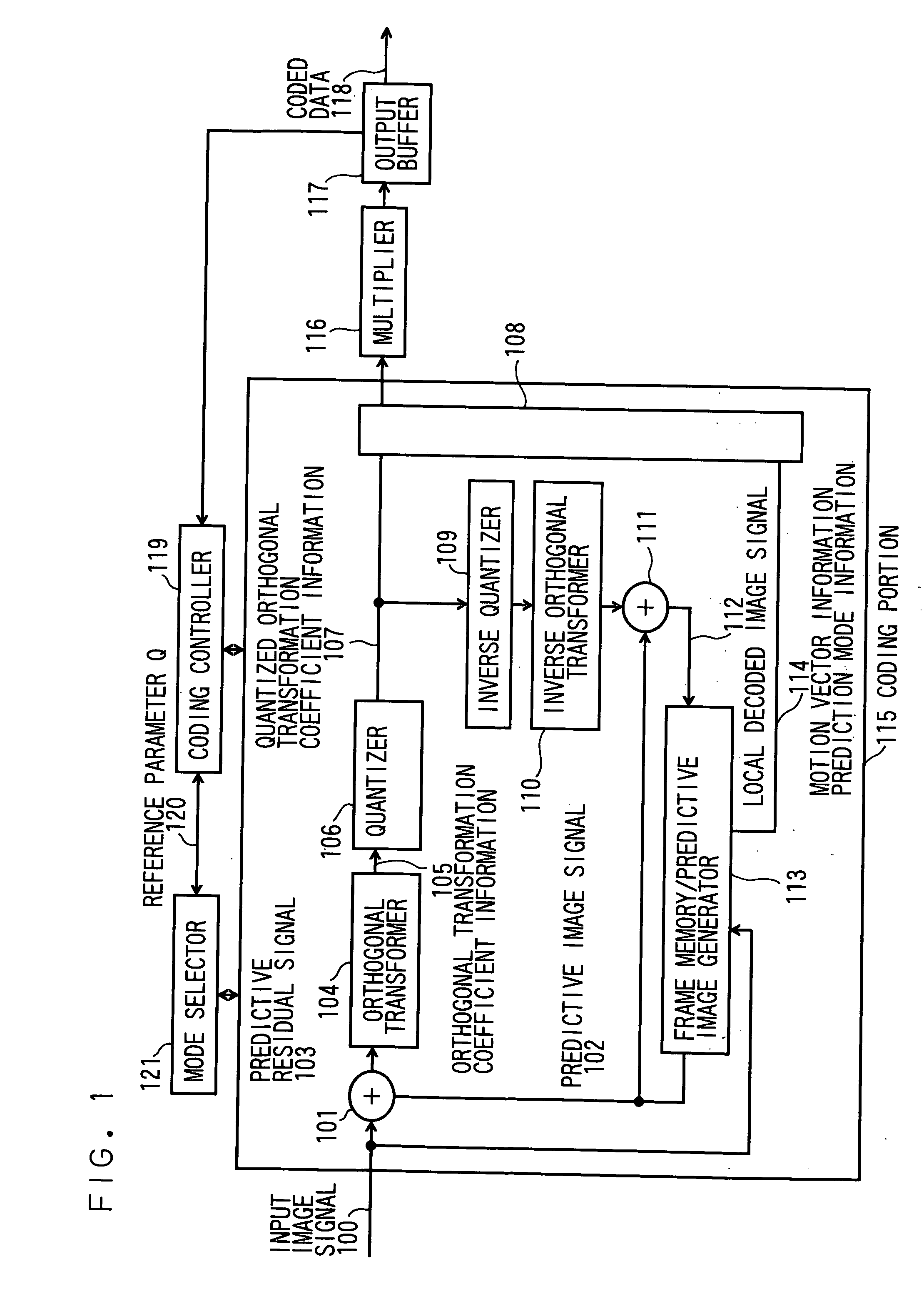

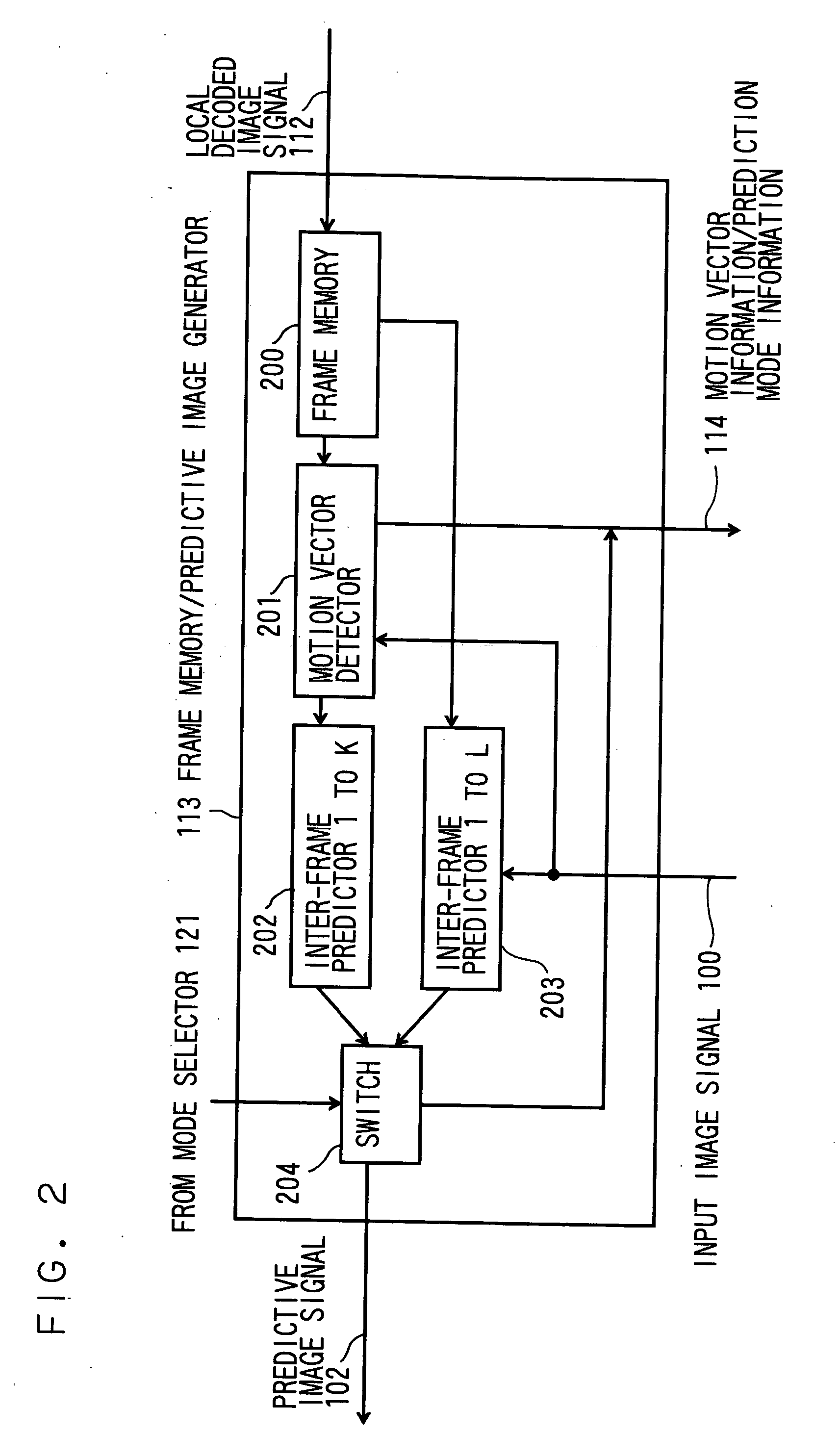

Image coding control method and device

InactiveUS20060133481A1Improve coding efficiencySimple processColor television with pulse code modulationColor television with bandwidth reductionComputation complexityComputer science

Image coding having high coding efficiency is provided with a small computational complexity by properly determining a prediction mode and a quantization parameter. When an image is coded by a prediction mode selected from plural prediction modes every any coding unit, an undetermined multiplier λ is first calculated from a quantization parameter (function S301) Subsequently, the cost of each of R-D points (pairs of number of coded bits and coding distortion that correspond to plural combinations of prediction modes and quantization parameters) is calculated (function S305) on the basis of the undetermined multiplier λ while generation and estimation of the R-D points and deletion of the points (functions S302-S304) are repeated every coding unit, for example, every macroblock, and the optimal combination of the prediction mode and the quantization parameter is determined on the basis of the R-D point providing the minimum cost.

Owner:KK TOSHIBA

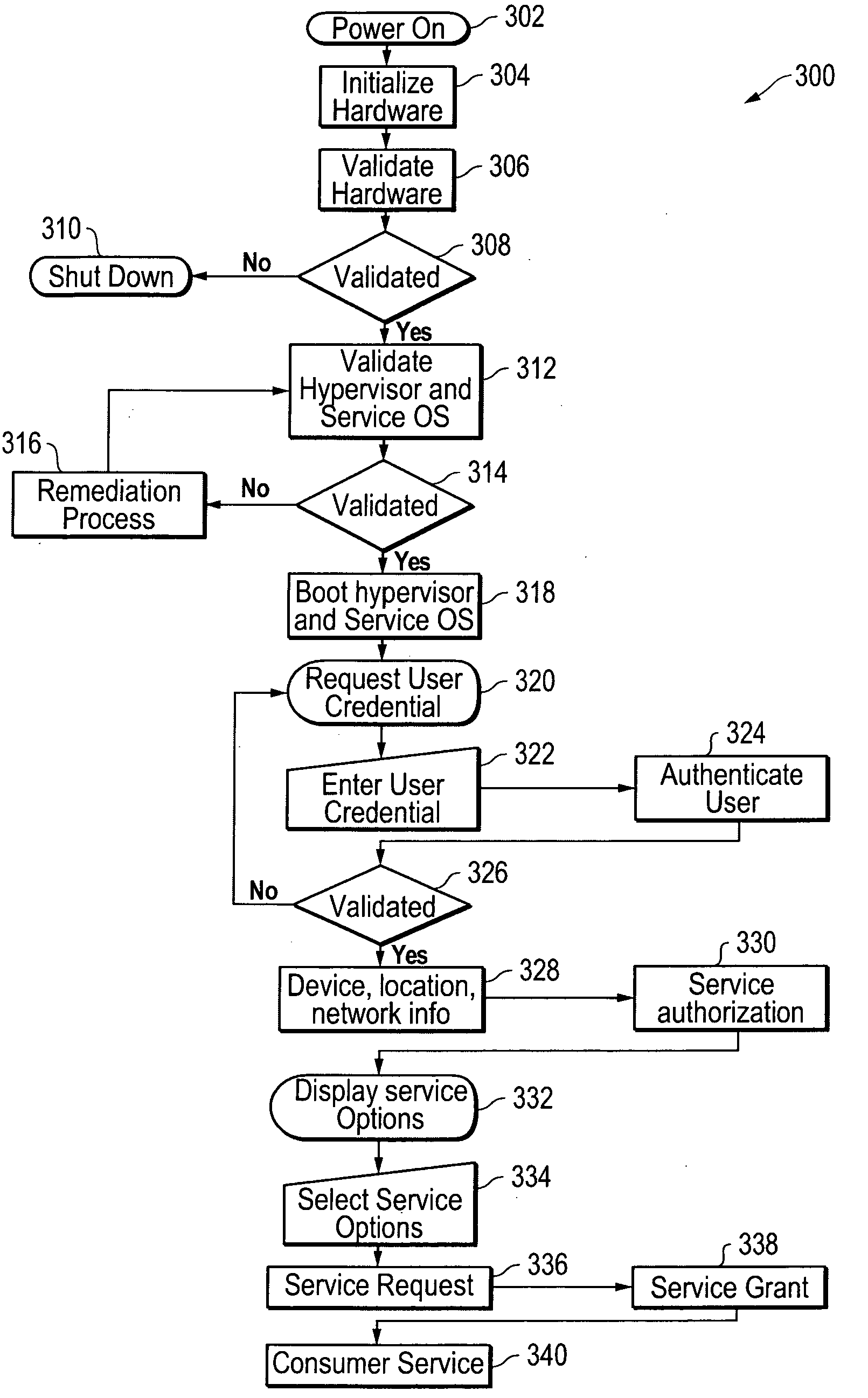

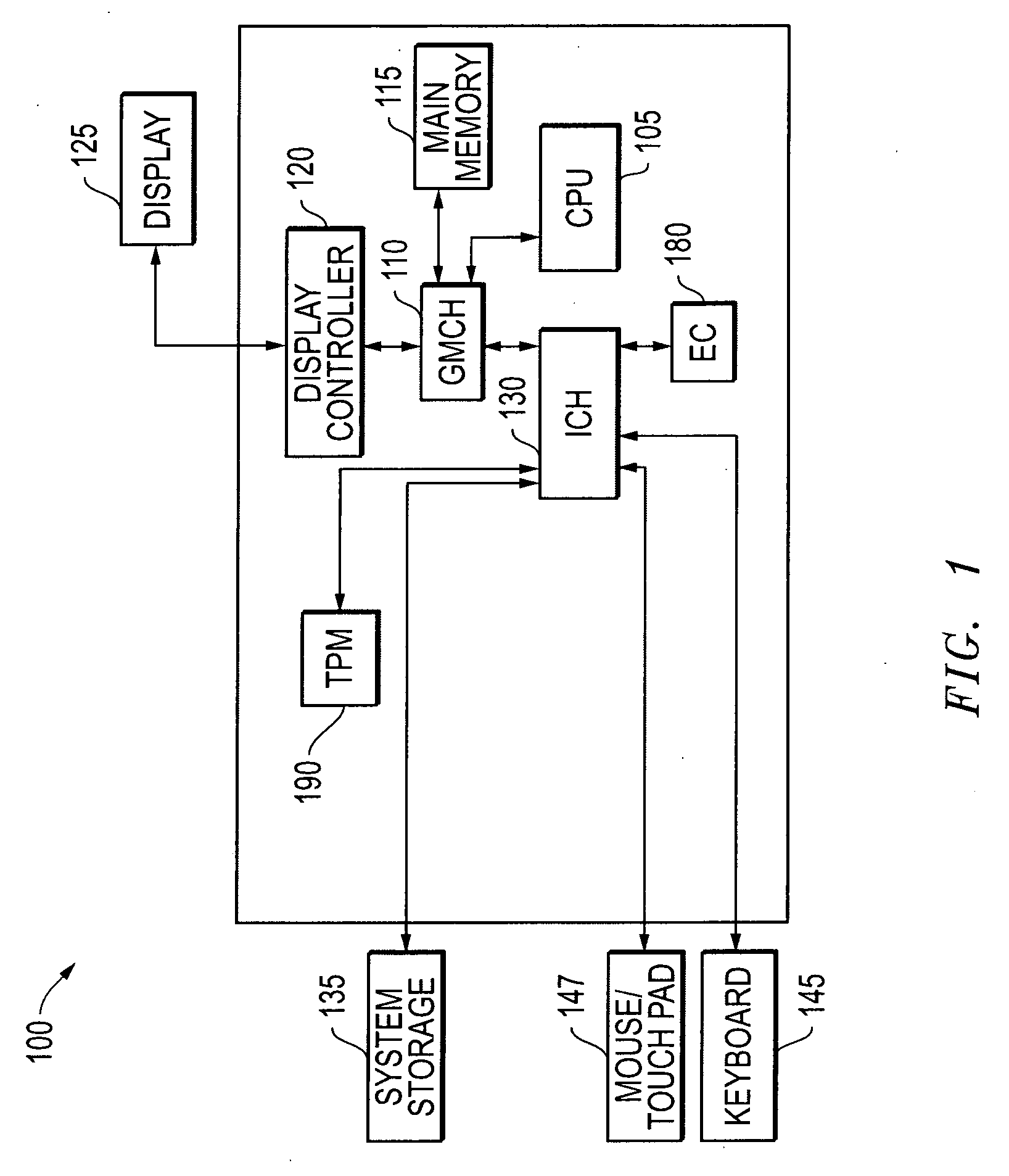

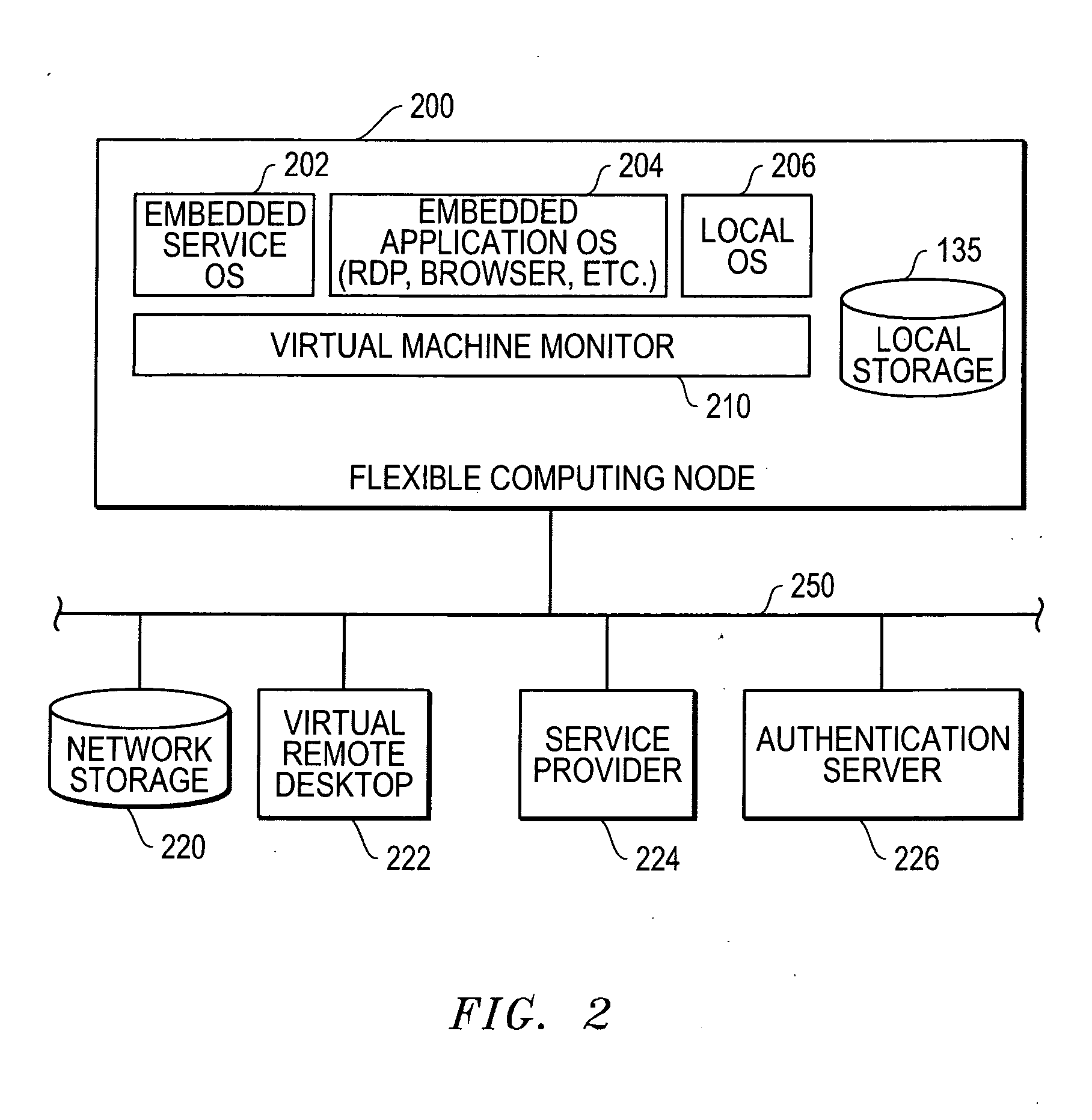

Methods and systems for embedded user authentication and/or providing computing services using an information handling system configured as a flexible computing node

ActiveUS20100153697A1Easy to storeSmallDigital data processing detailsUser identity/authority verificationNetwork connectionWorking environment

Methods and systems for providing embedded user authentication and / or providing computing services using an information handling system configured as flexible computing node, and which may be implemented to perform preboot authentication of users. The flexible computing node may also be configured to provision the appropriate work environment for a given user based on one or more user parameters (e.g. entitlements, location, network connection, and / or other parameters).

Owner:DELL PROD LP

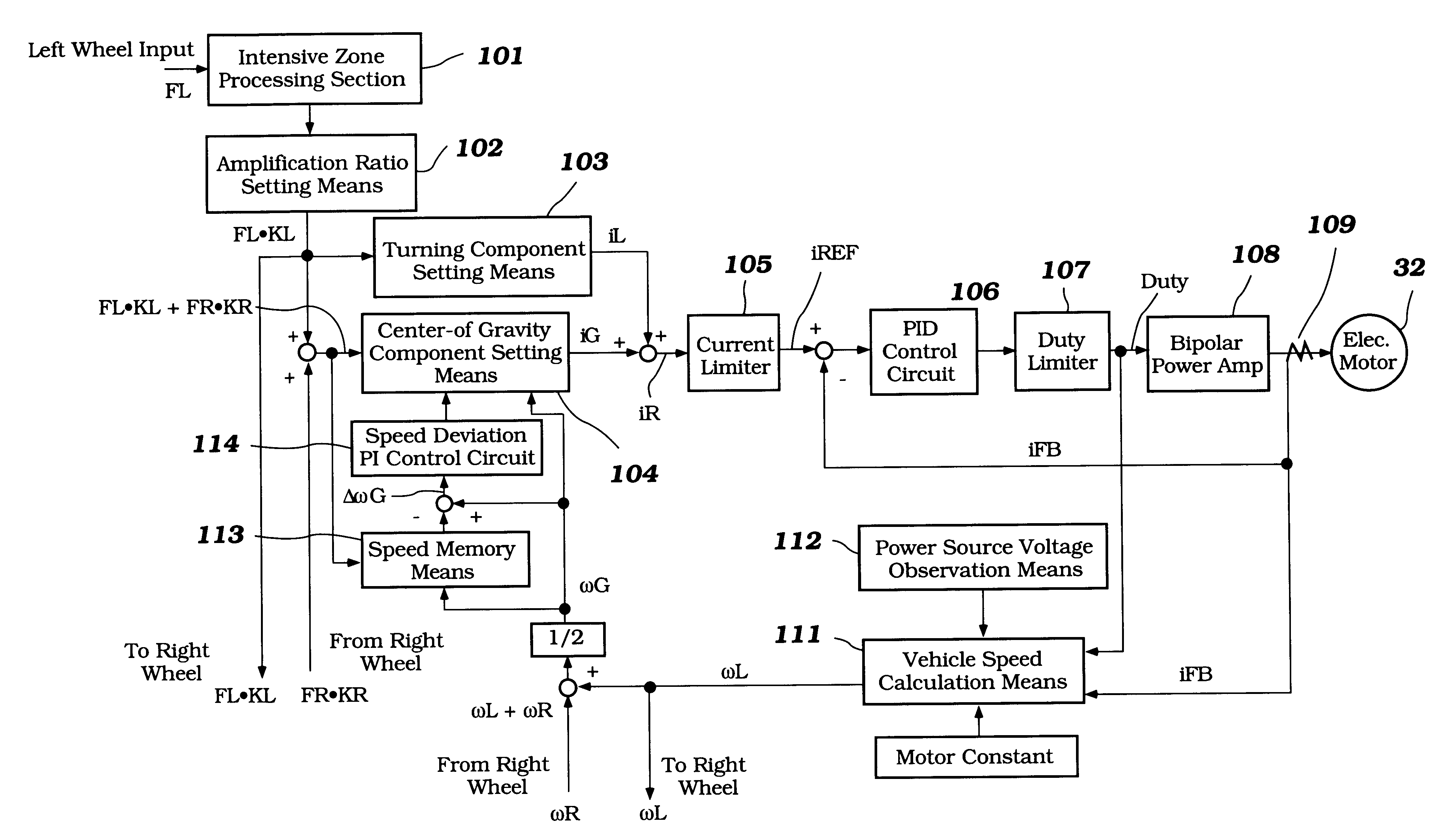

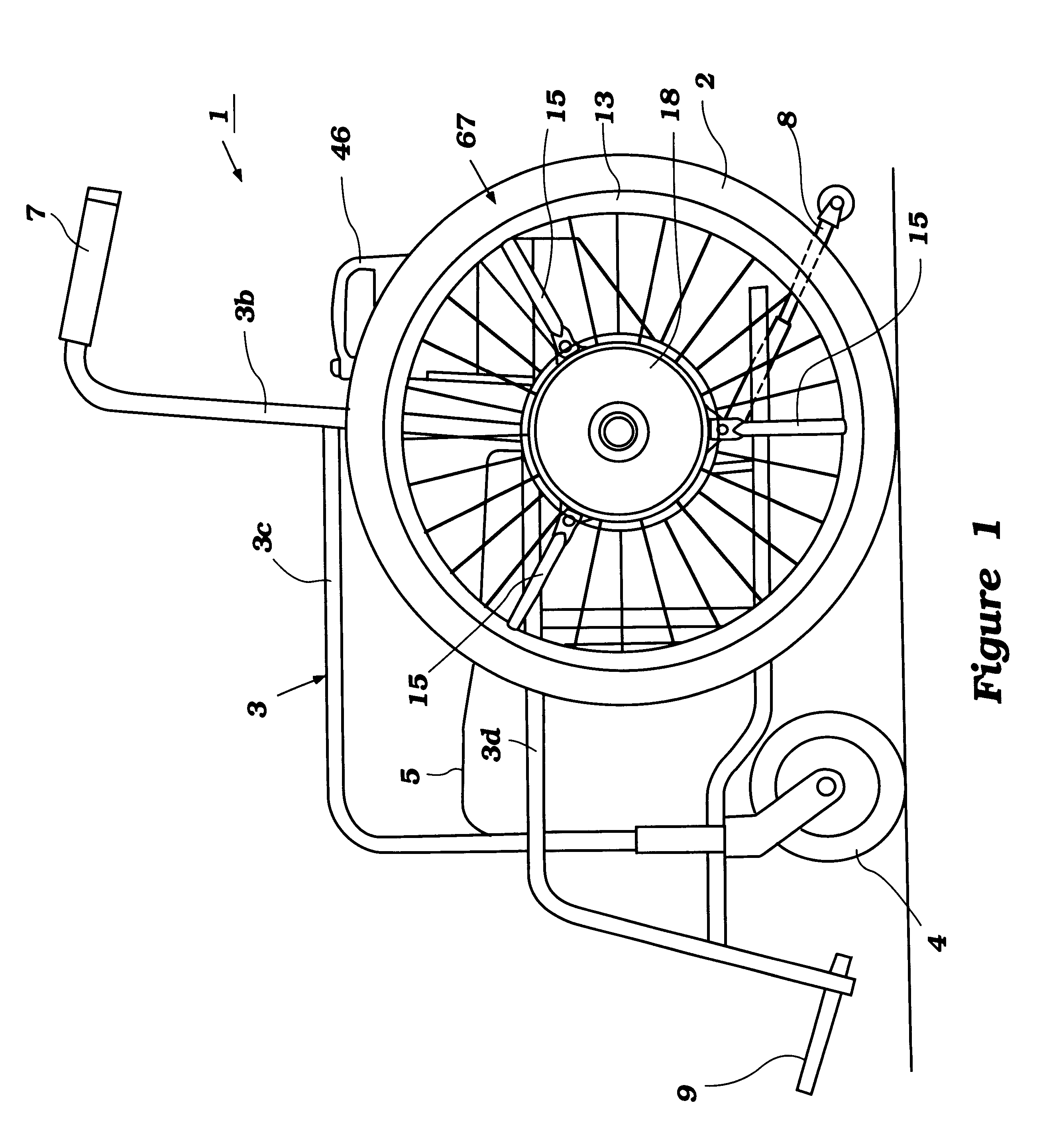

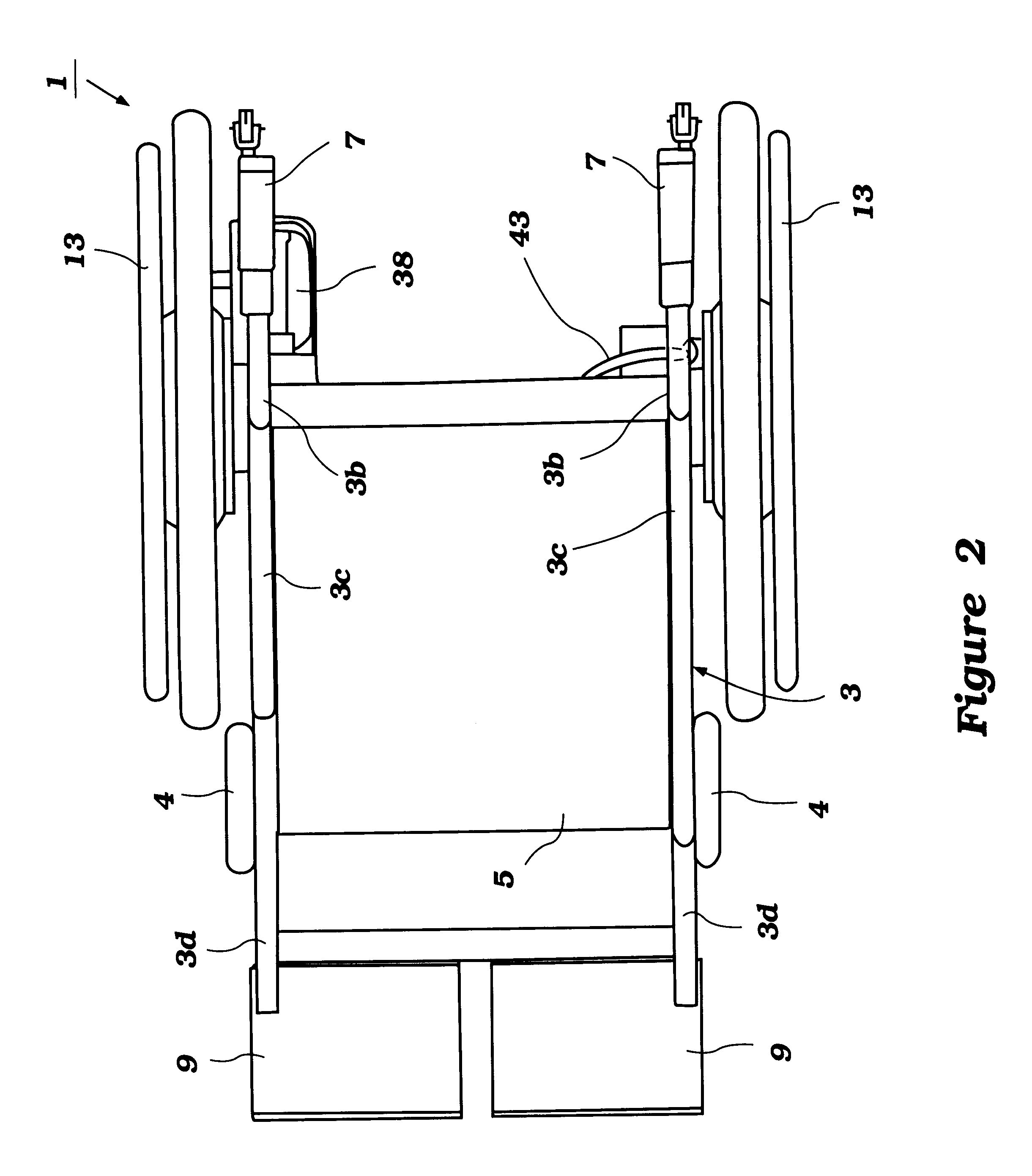

Wheel chair with auxiliary power

InactiveUS6230831B1Reduce physical exertionSmall amountMotor/generator/converter stoppersDC motor speed/torque controlUltrasound attenuationWheelchair

A power-assisted wheelchair (1) having an electric motor (32), a potentiometer (27) as means for detecting human power applied to wheels (2), and a controller (31) as means for controlling the electric motor (32) according to the detected human power so as to set the time-attenuation rate of the assist power to be greater as the human power is smaller, and to be smaller as the human power is greater.Therefore, the coasting amount of the wheelchair (1) for small indoor movements for example is restricted to a small value. As a result, small indoor movements with a small turning radius are made possible, a sufficient coasting amount is secured for an outdoor running. Therefore, along with the possibility of a comfortable running on a level road, a steep uphill running is made easy, and the physical effort of the rider is alleviated.

Owner:YAMAHA MOTOR CO LTD

Water-absorbing resin and process for producing same

InactiveUSRE37021E1Small amountImprove securityBaby linensWood layered productsCarboxyl radicalOxidation-Reduction Agent

A process for producing a water-absorbing resin, which comprises polymerizing (D) an aqueous solution comprising (A) at least one monomer component selected from the group consisting of an unsaturated carboxylic acid and salts thereof; (B) a compound having two or more unsaturated groups in a molecule; and (C) a compound having two or more functional groups which are capable of reacting with carboxyl groups in a molecule, the polymerization being conducted in such a manner that the following conditions (a) to (c) are simultaneously satisfied: (a) the molar ratio (B) / (C) being in the range of from 2x10-3 to 300, (b) the polymerization being initiated by a redox polymerization initiator, and (c) the maximum reaction temperature being in the range of from 60° to 100° C., and a water-absorbing resin having a degree of reduction in absorption magnification of from 1 to 16, and n absorption magnification under pressure of from 20 to 40.

Owner:NIPPON SHOKUBAI CO LTD

Hybrid electric vehicle and towable trailer that uses renewable solid fuel

InactiveUS20090090573A1SmallIncrease mileageInternal combustion piston enginesElectric propulsion mountingCelluloseElectrical battery

A hybrid electric vehicle having an array of batteries that recharge with a generator connected to a Stirling engine, steam engine and / or steam turbine powered by combusting a solid fuel product. The battery array for this vehicle, which is a series hybrid, can be recharged using residential electrical current. A preferred solid fuel product for burning in the generator-charging engine of this vehicle is selected from cellulose, lignin and combinations thereof, most preferably in the form of pellets or small logs.

Owner:BOONE DANIEL J

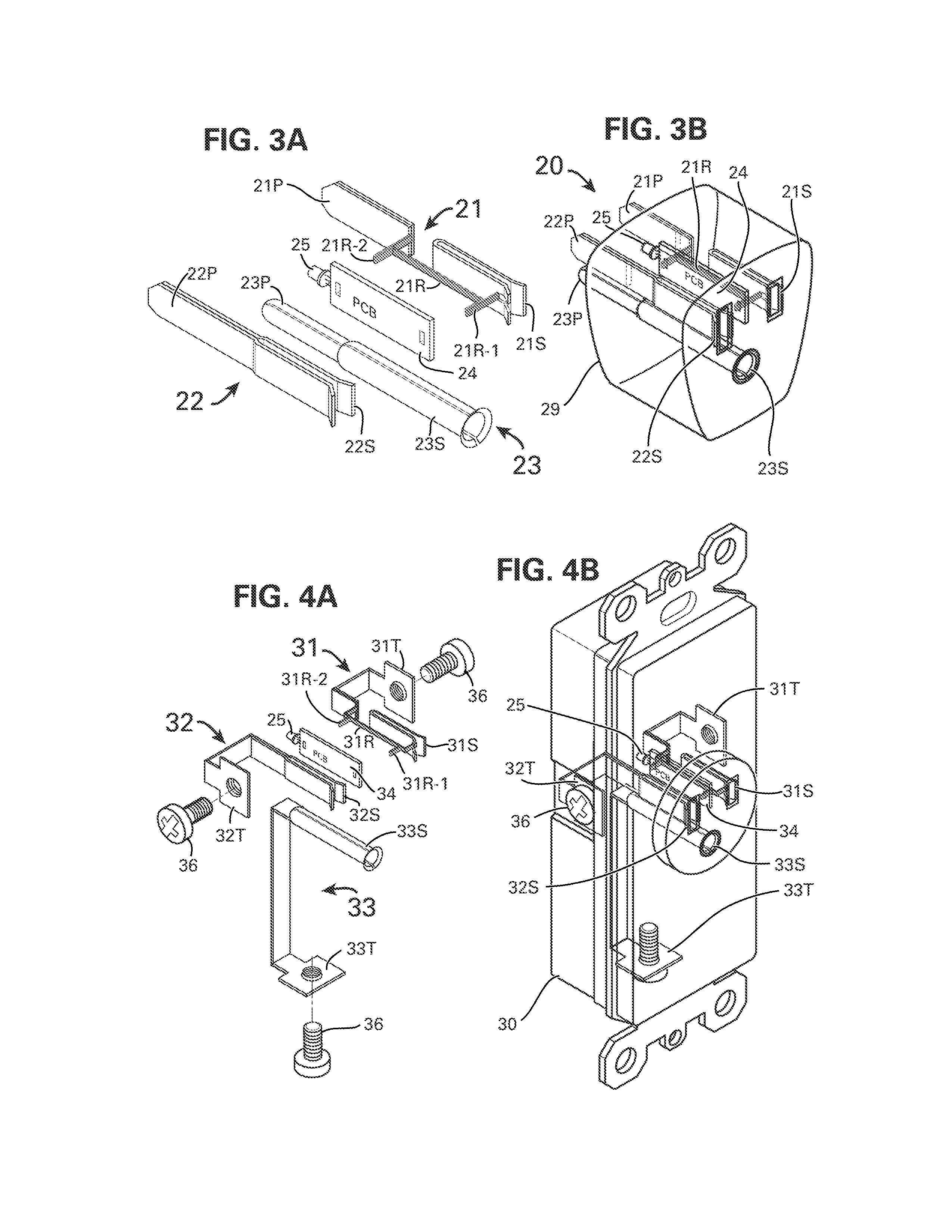

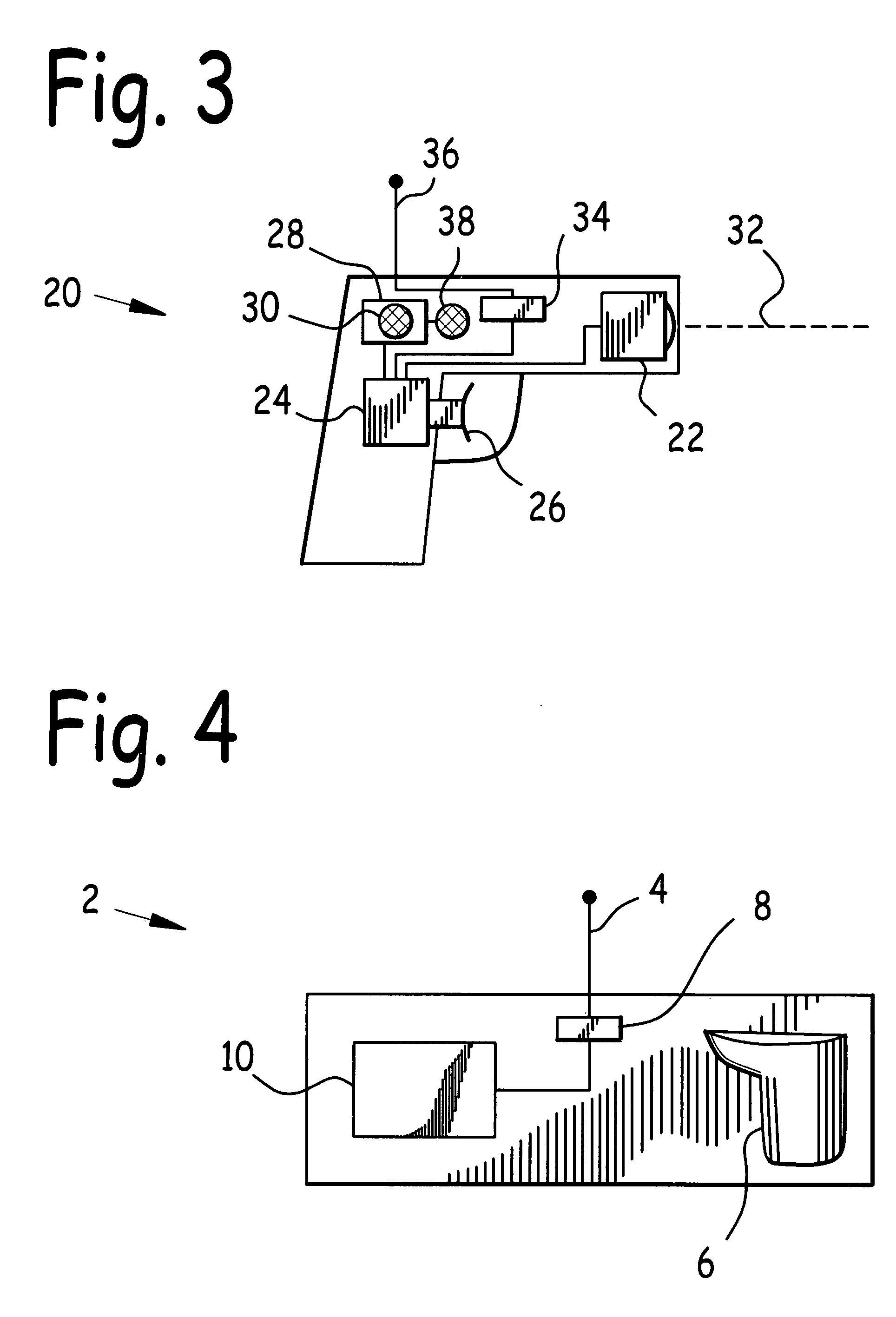

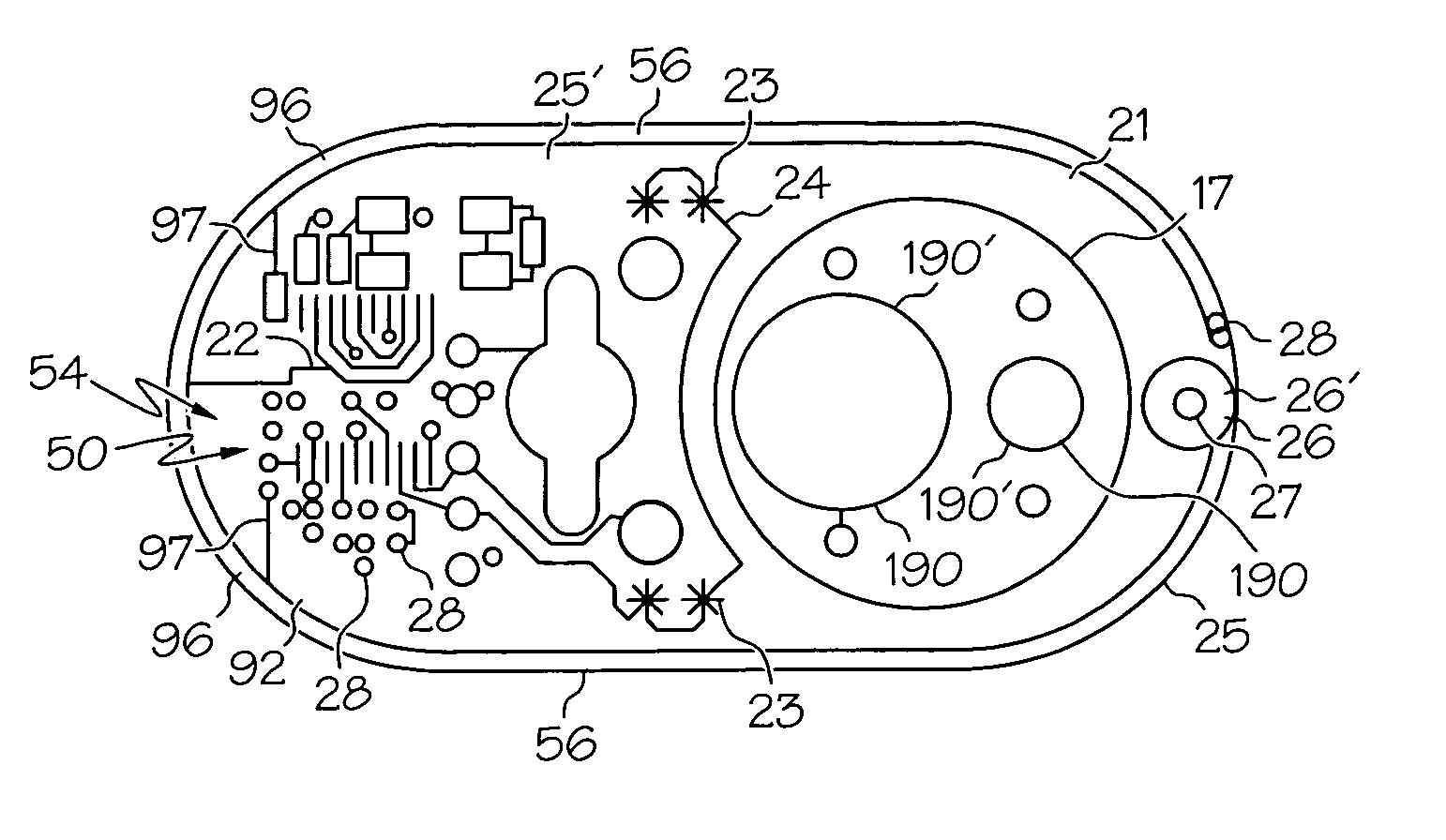

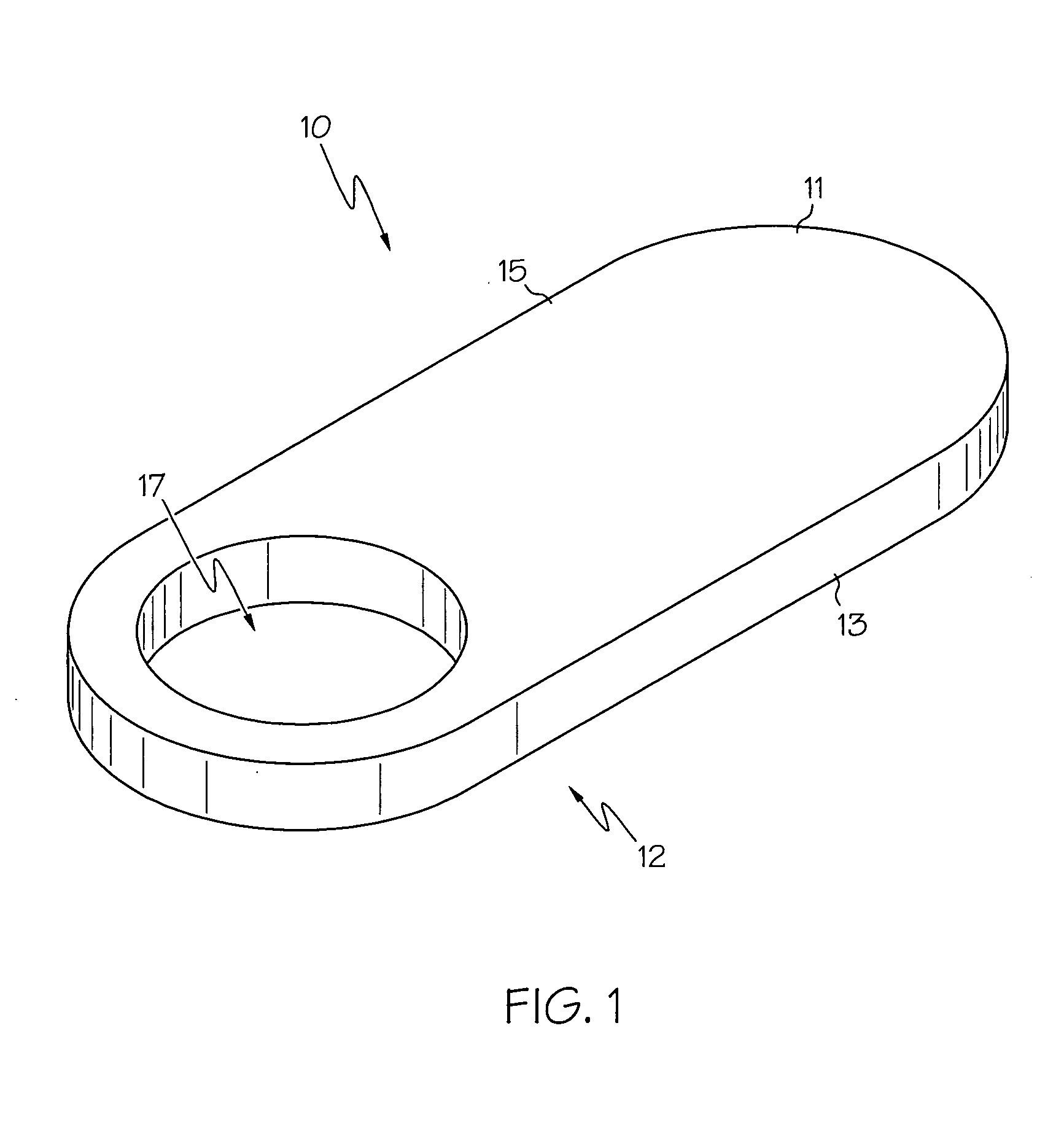

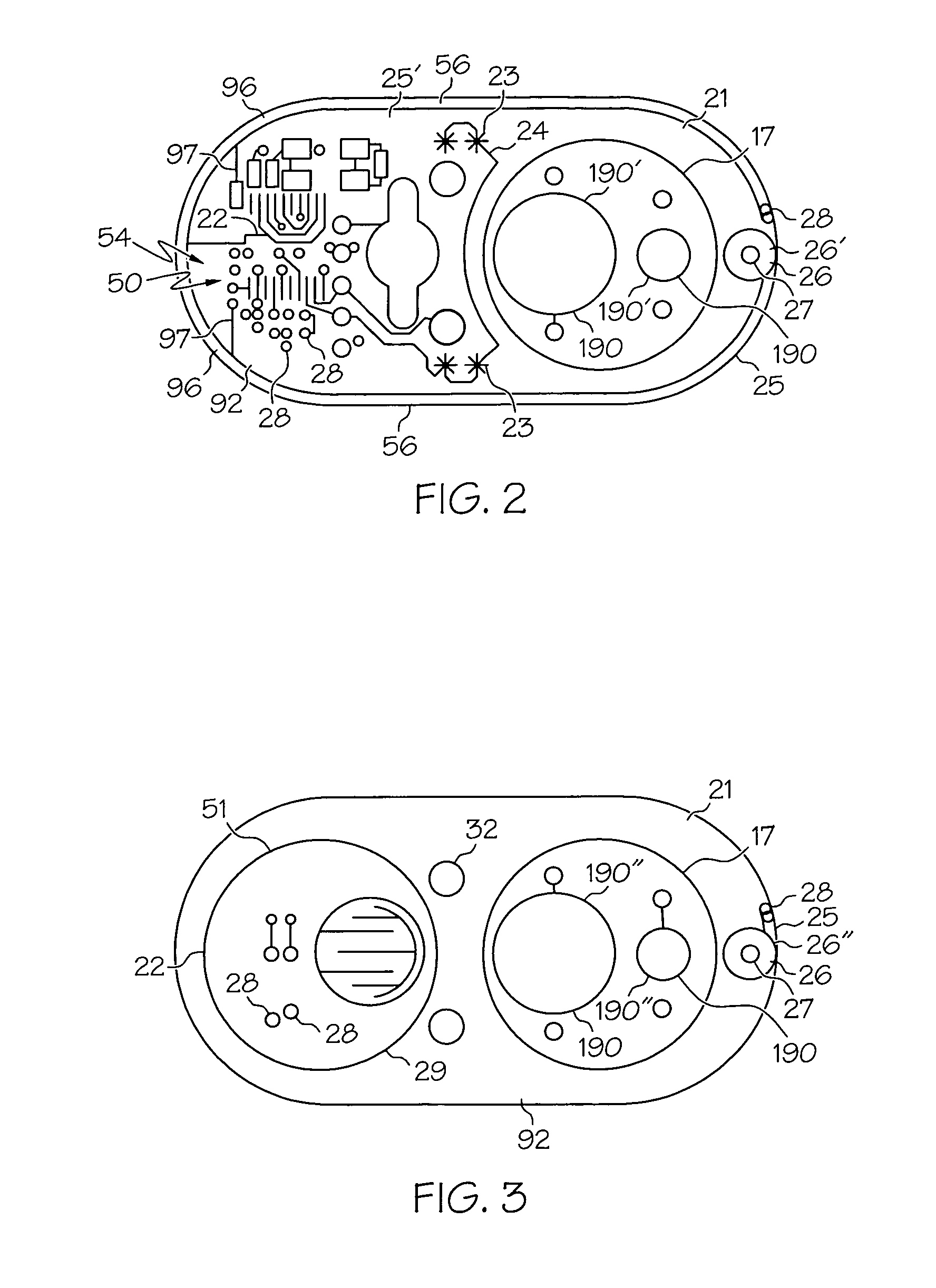

RF communications apparatus and manufacturing method therefor

ActiveUS7109863B2Facilitate communicationImprove methodResonant long antennasAnti-theft devicesResonanceDielectric substrate

Described herein are a transient event detector (35) comprising electrical circuitry (50) suitable to detect a transient event, and a container (34) having a wall with at least two electrically conductive contacts (23, 44) electrically connected to the electrical circuitry (50), each of the at least two electrically conductive contacts (23, 44) being electrically isolated from each other, and a movable electrically conductive piece (36) that intermittently connects at least two of the at least two electrically conductive contacts when the electrically conductive piece (36) is in motion. An RF circuit (54) couples to a loop antenna (25) having a tuning capacitor (26) formed as conductive pads (26′, 26″) juxtaposed on opposing sides of a planar dielectric substrate (92). The tuning capacitor (26) has a hole (27) through it, and the hole has a size that is selected to cause the loop antenna (25) to exhibit a desired resonance frequency.

Owner:NUVO HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com