Patents

Literature

234results about How to "Improve electrical connection reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

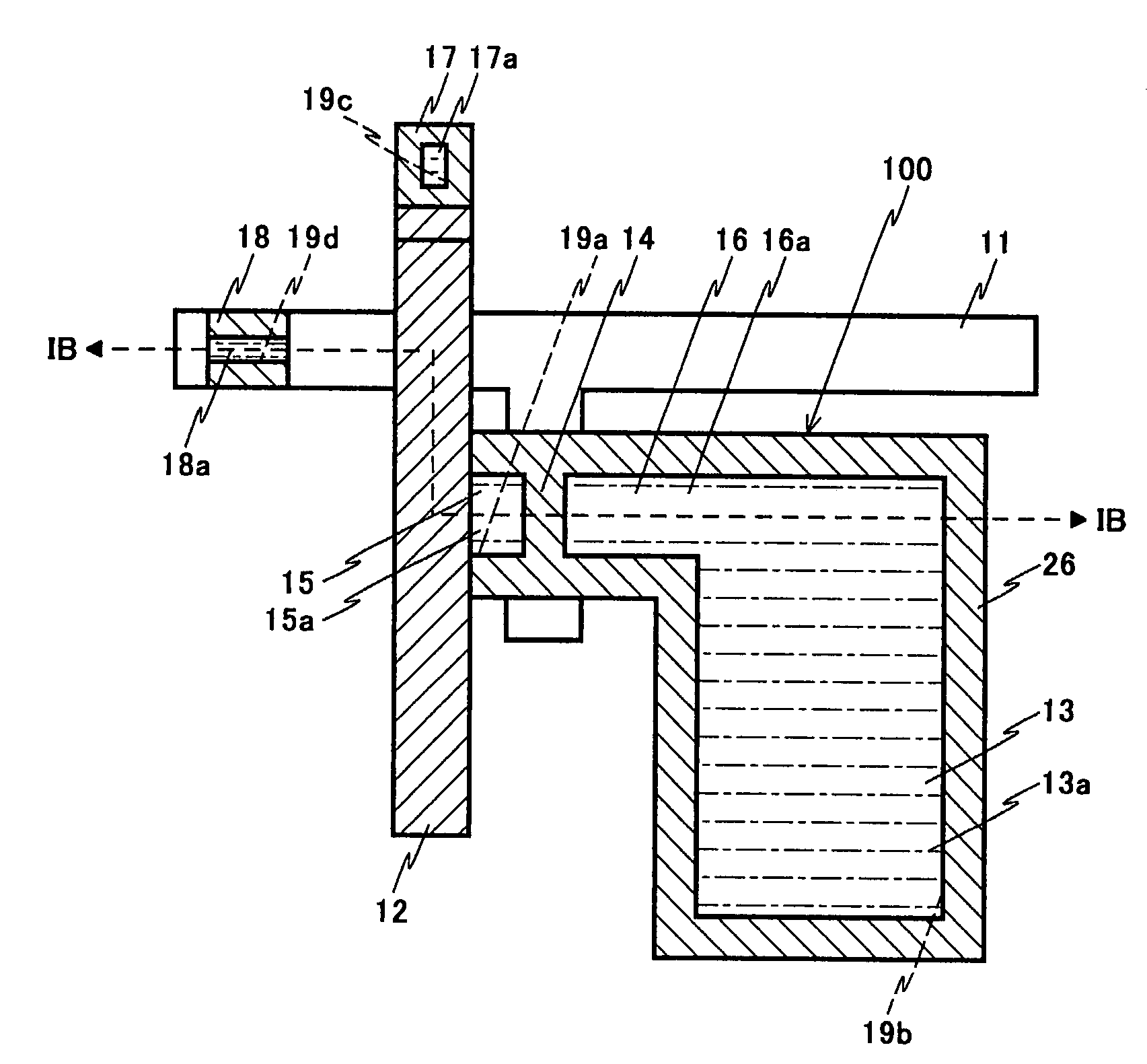

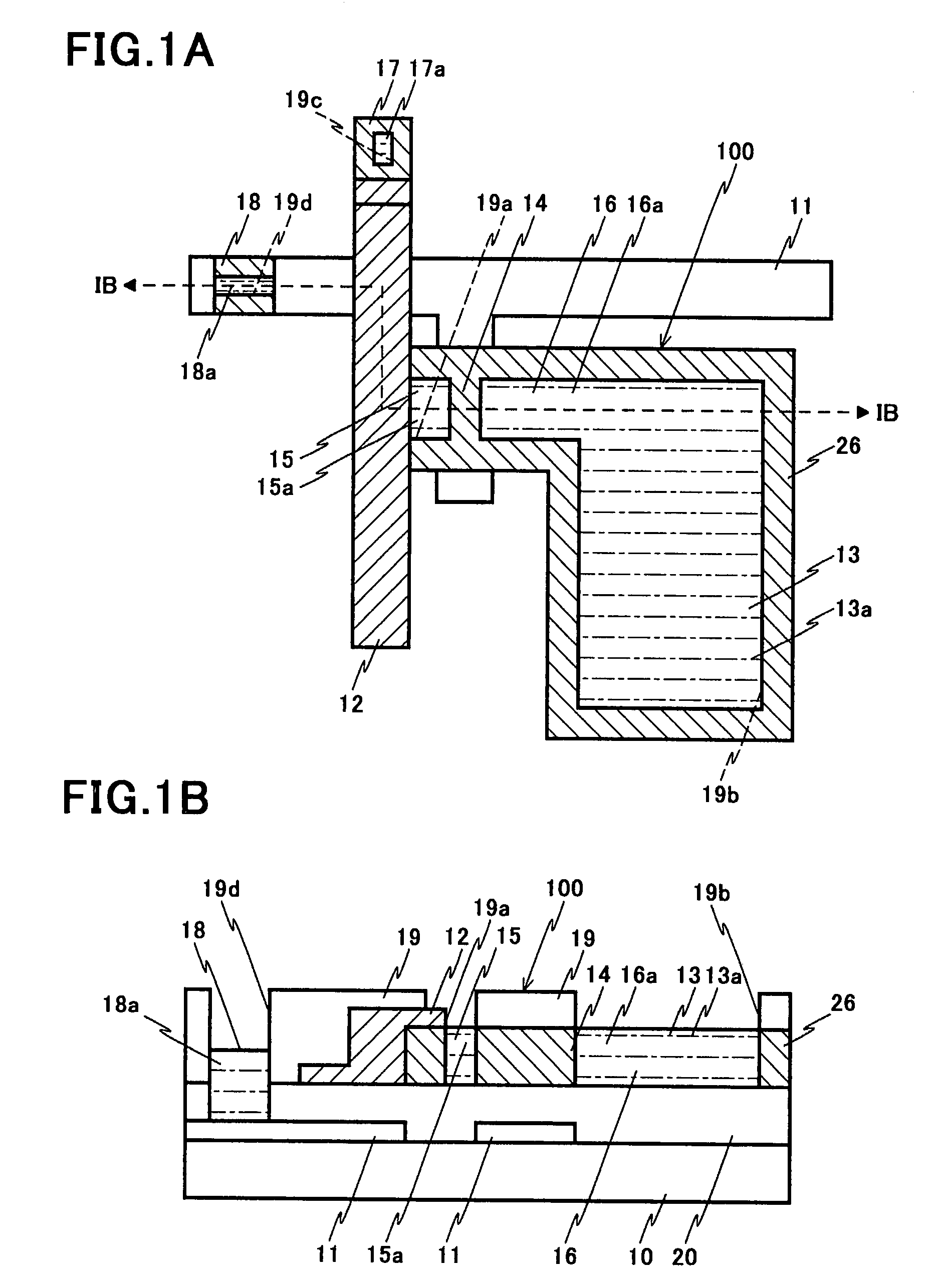

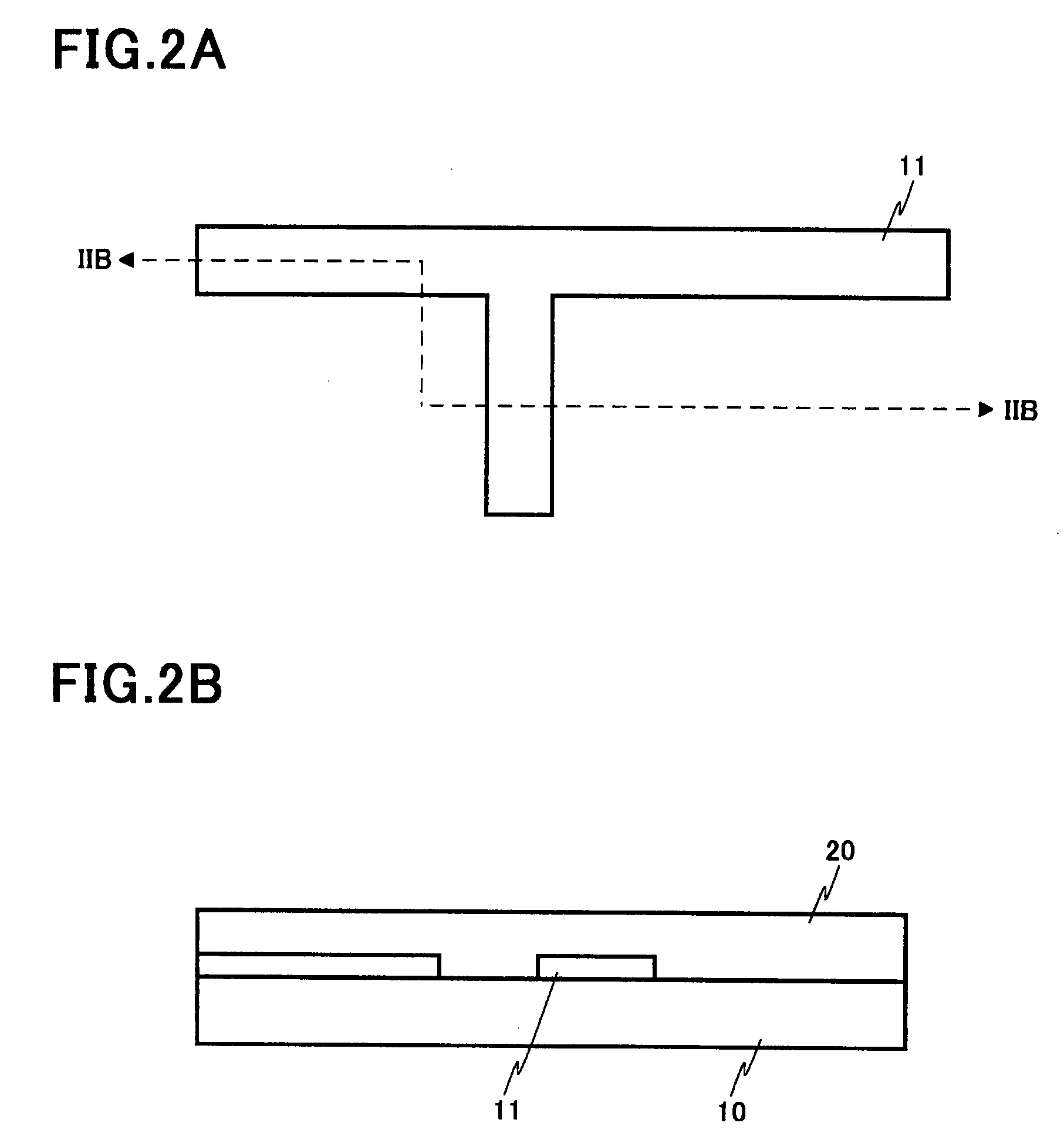

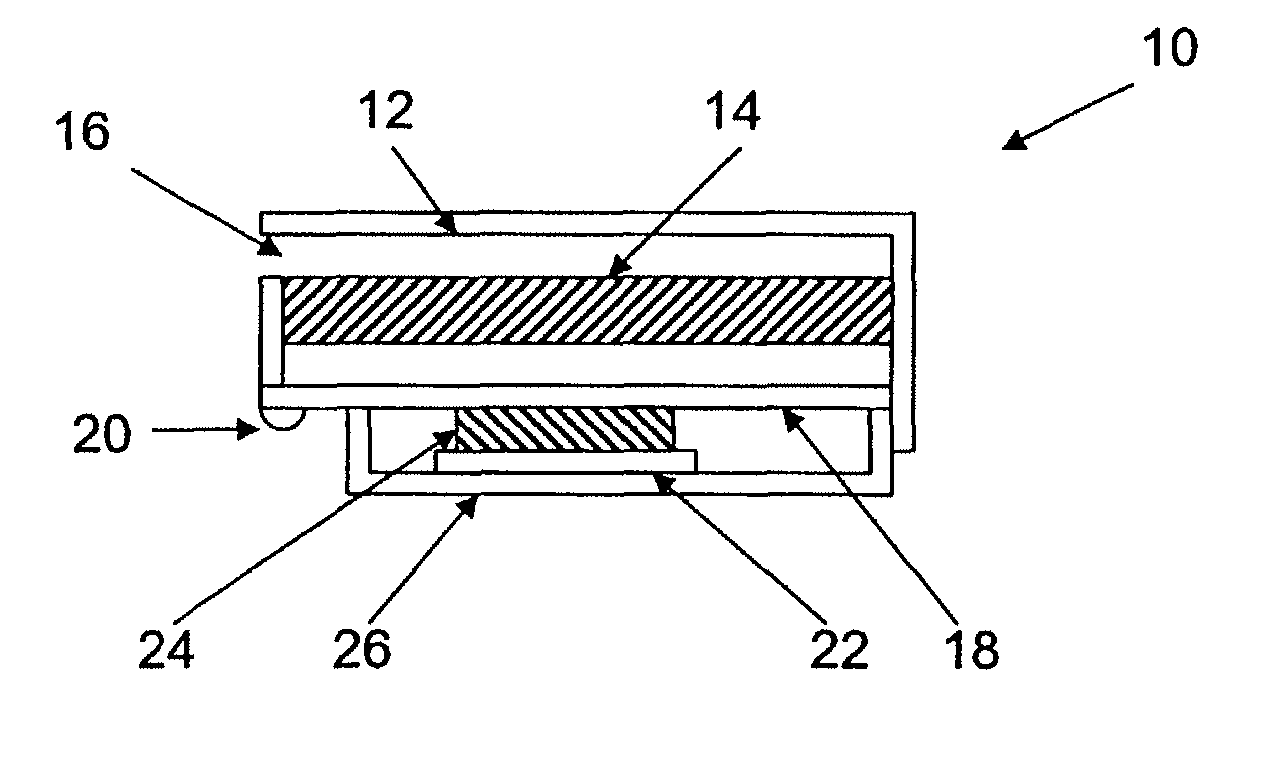

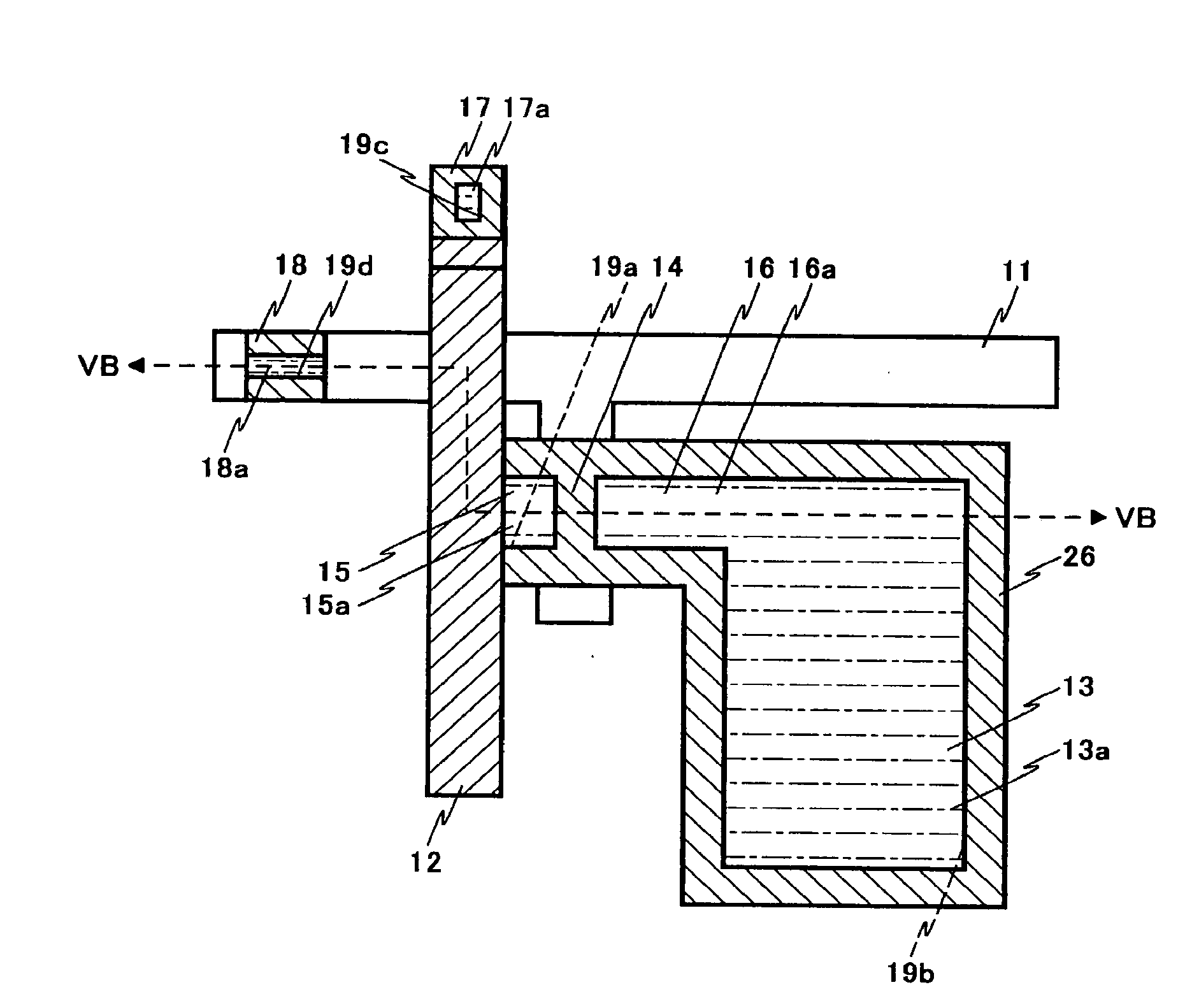

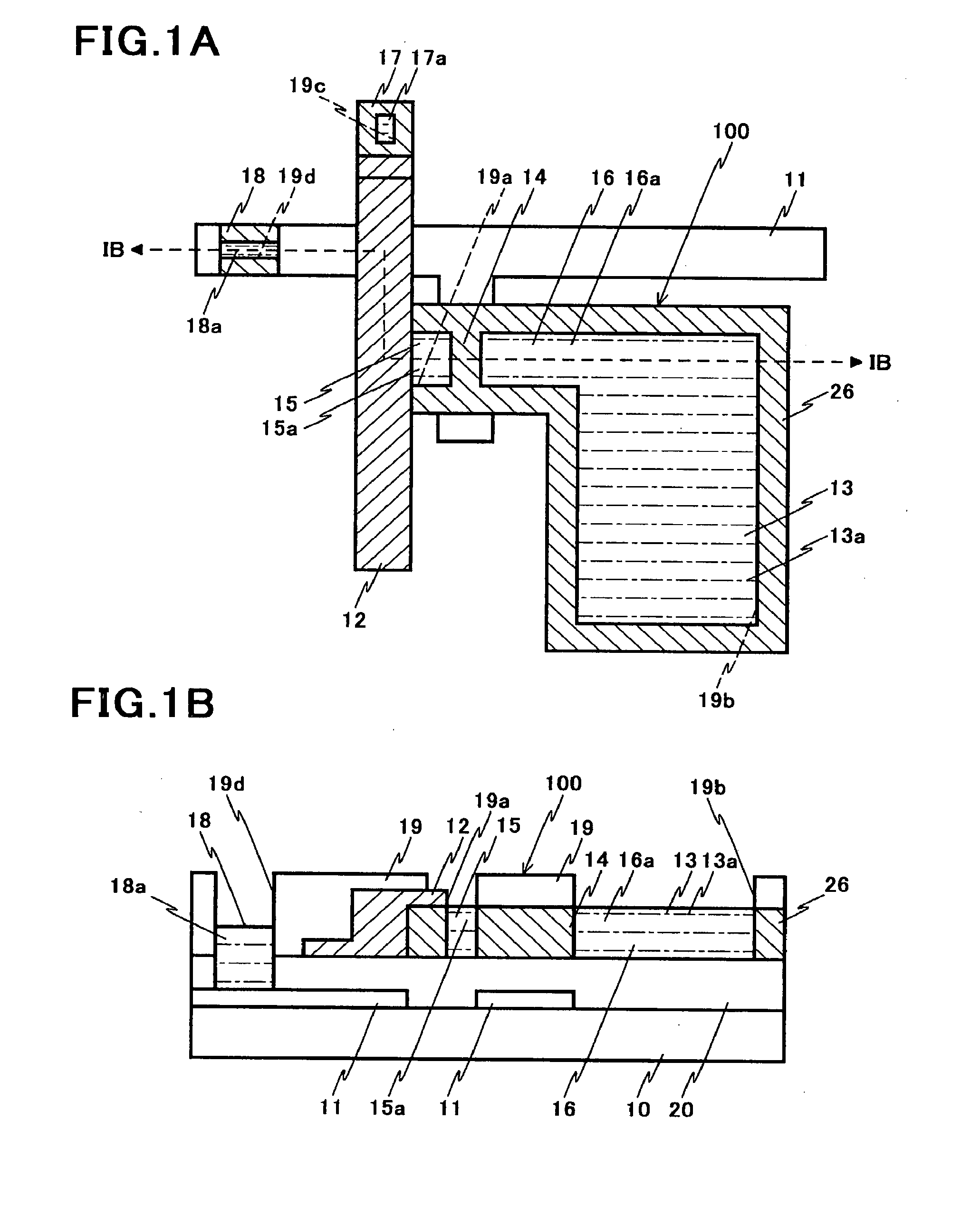

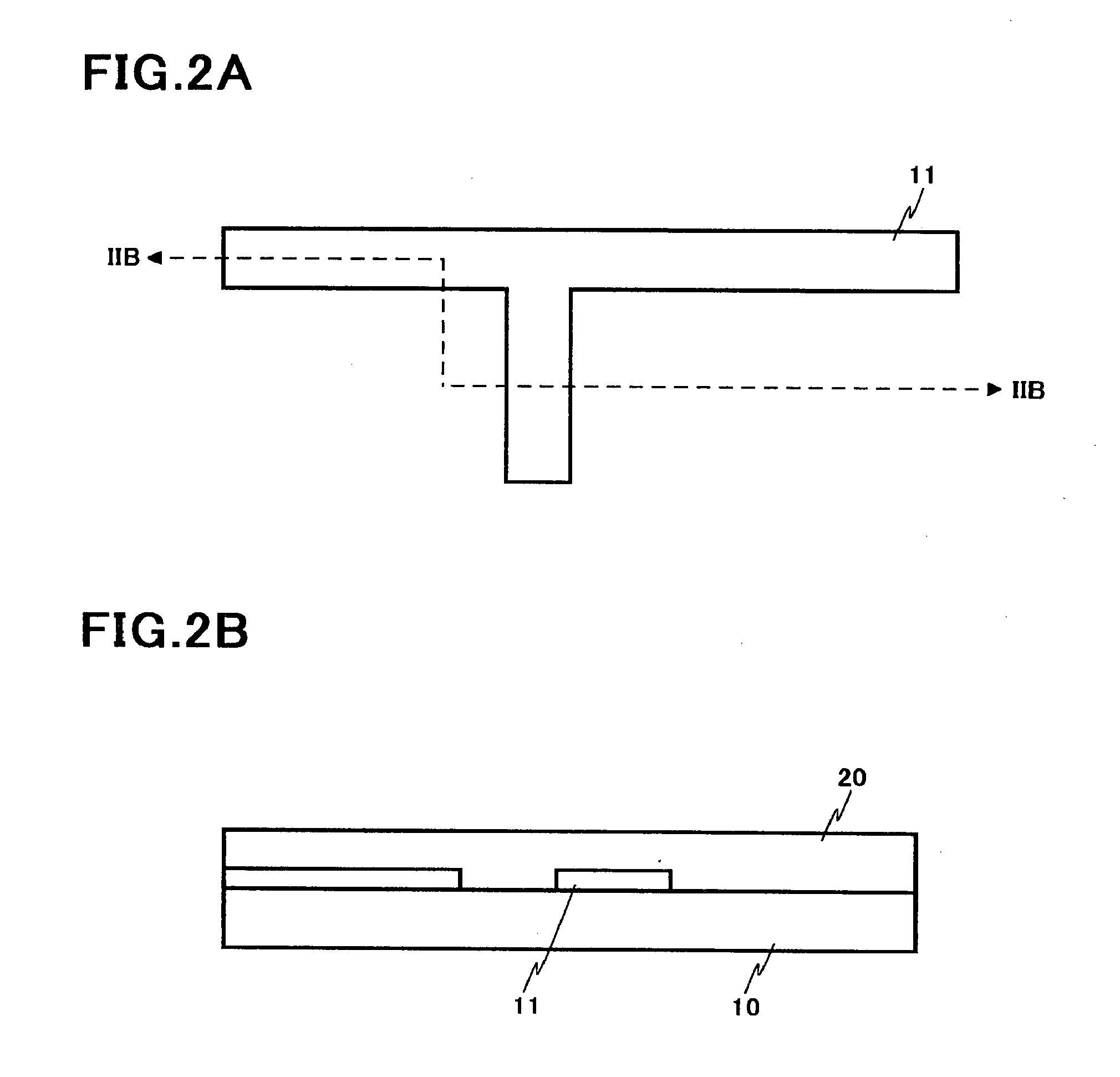

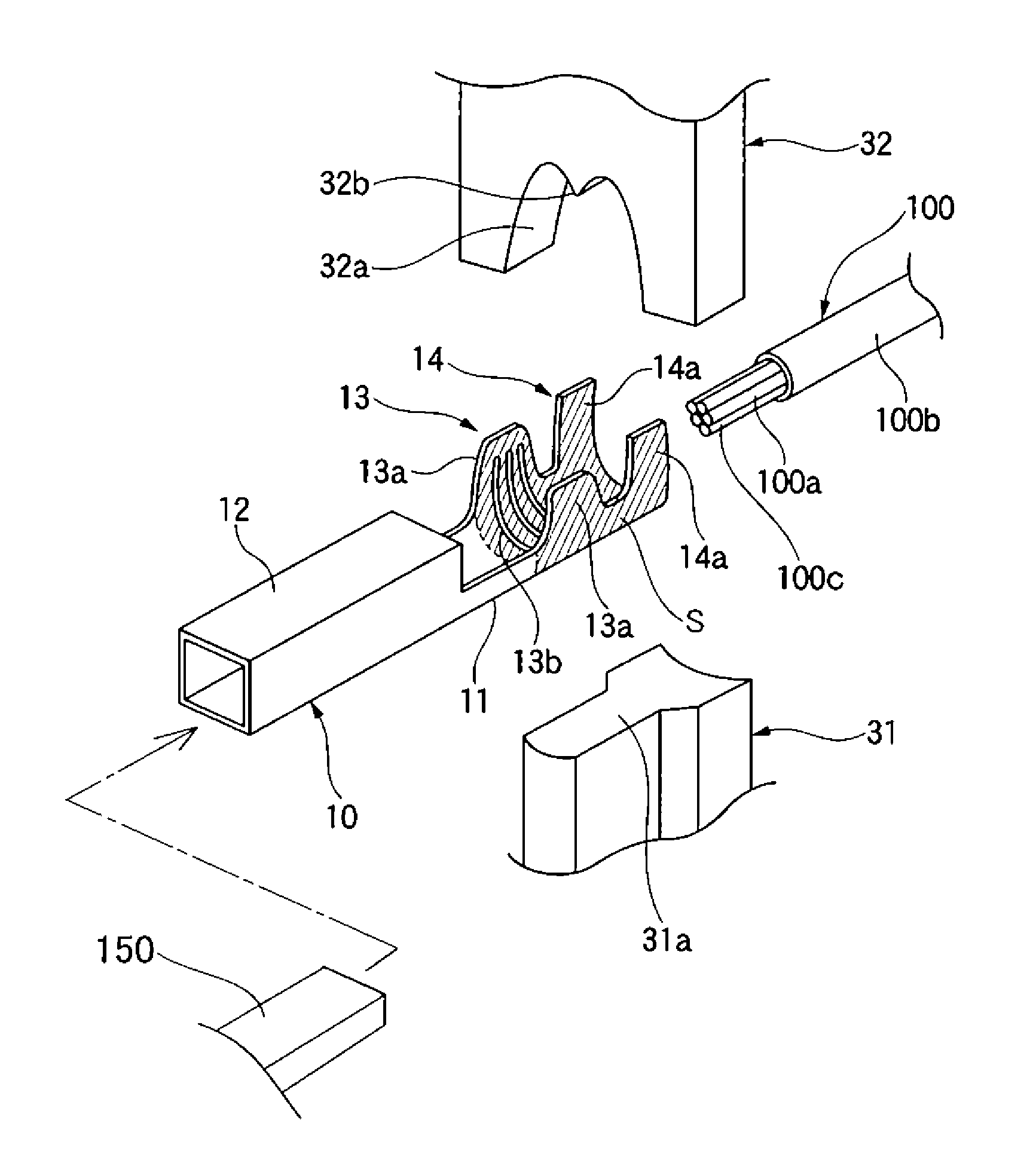

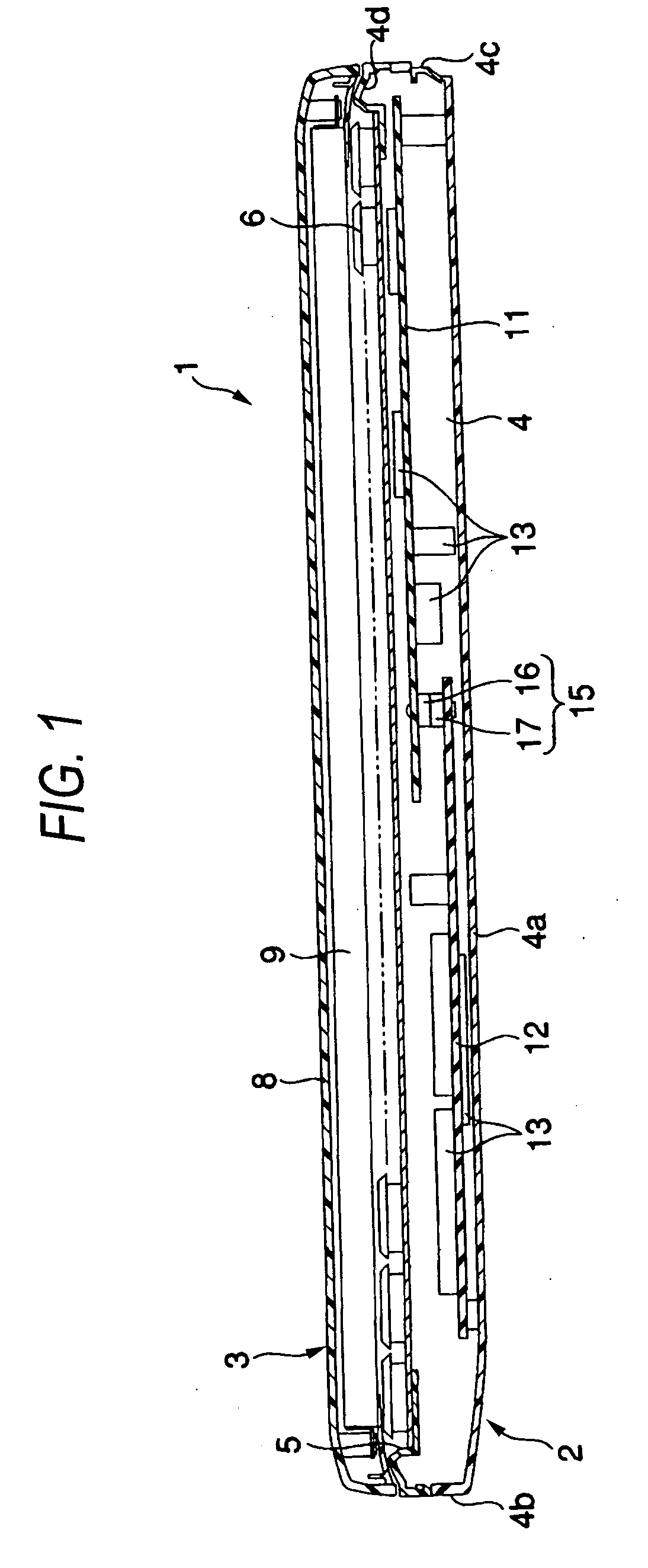

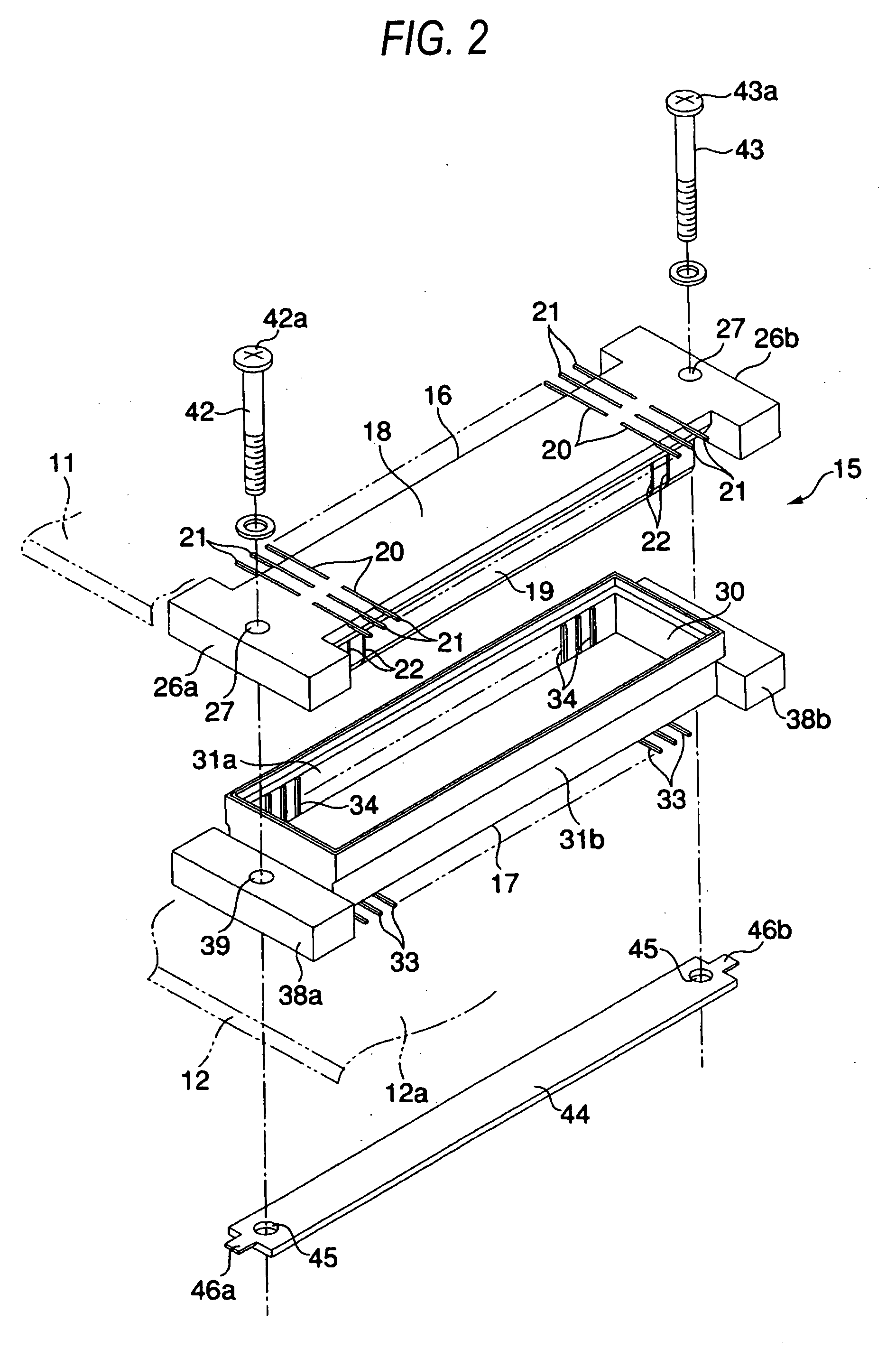

Thin-film transistor array, method of fabricating the same, and liquid crystal display device including the same

ActiveUS7804091B2Improve electrical connection reliabilityReduce conductivitySolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A thin-film transistor array includes an electrically insulating substrate, a plurality of thin-film transistors arranged in a matrix on the substrate, and each including a channel, a source, and a drain each comprised of an oxide-semiconductor film, a pixel electrode integrally formed with the drain, a source signal line through which a source signal is transmitted to a group of thin-film transistors, a gate signal line through which a gate signal is transmitted to a group of thin-film transistors, a source terminal formed at an end of the source signal line, and a gate terminal formed at an end of the gate signal line. The source terminal and the gate terminal are formed in the same layer as a layer in which the channel is formed. The source terminal and the gate terminal have the same electric conductivity as that of the pixel electrode.

Owner:NEC LCD TECH CORP

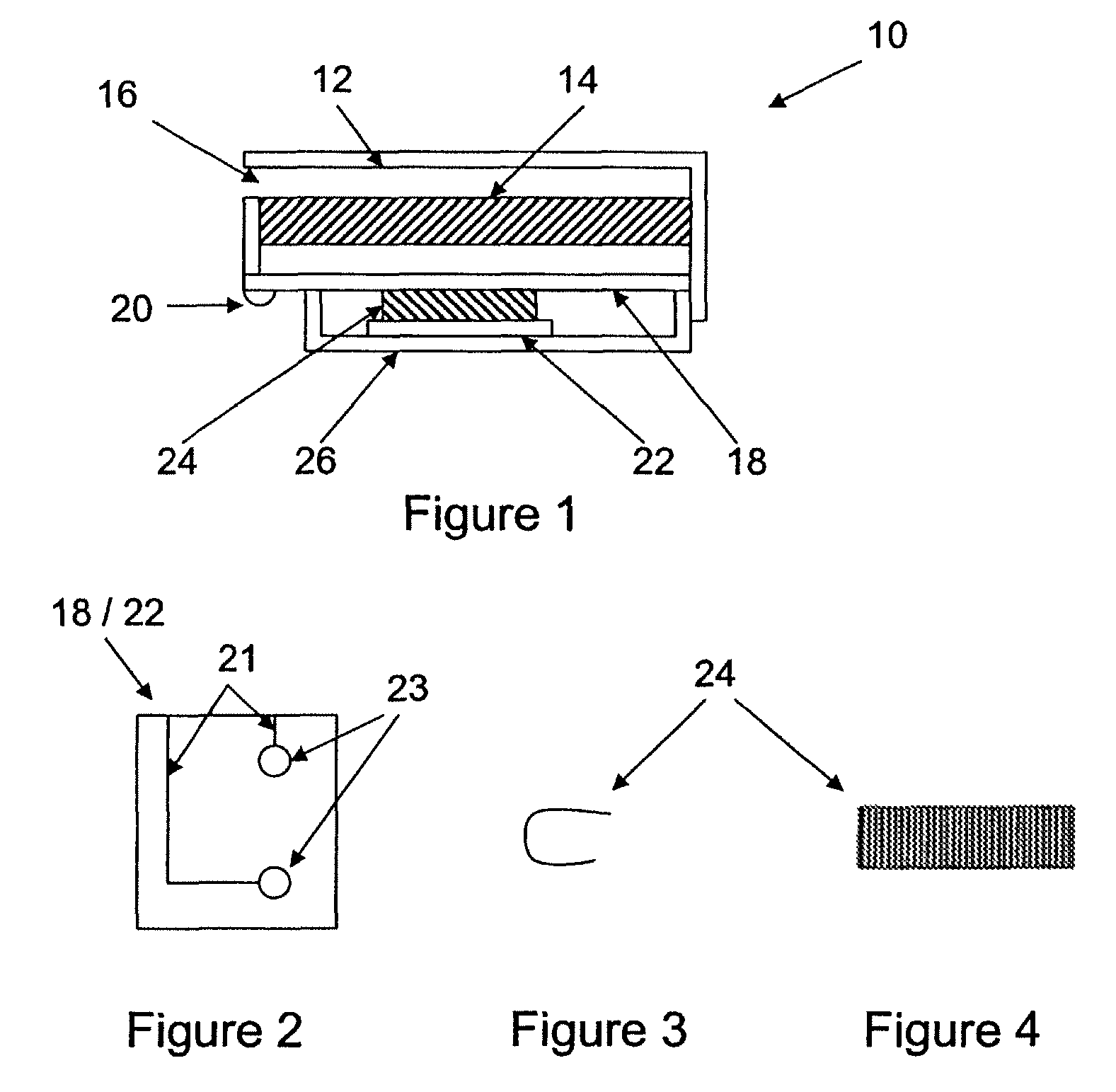

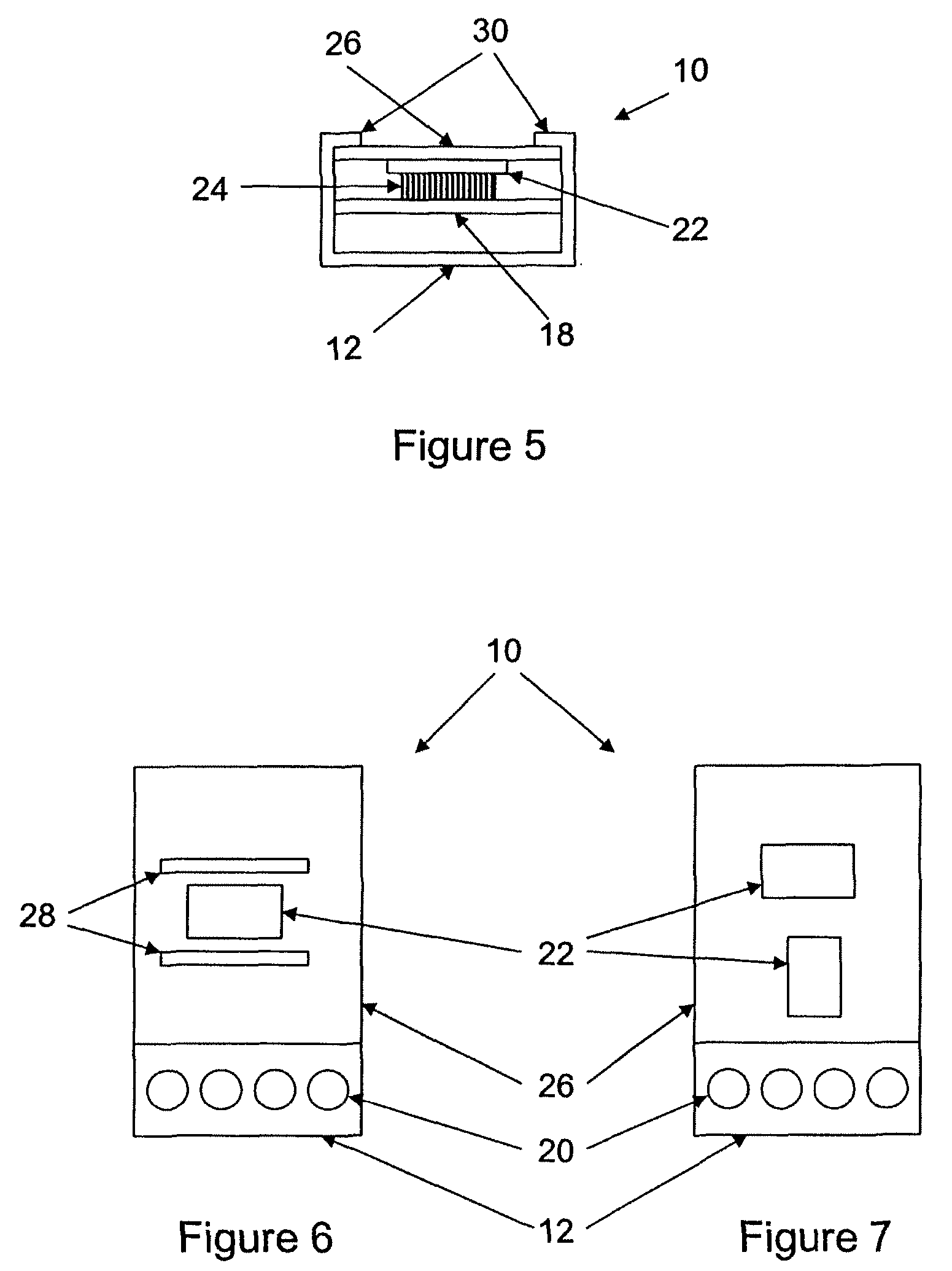

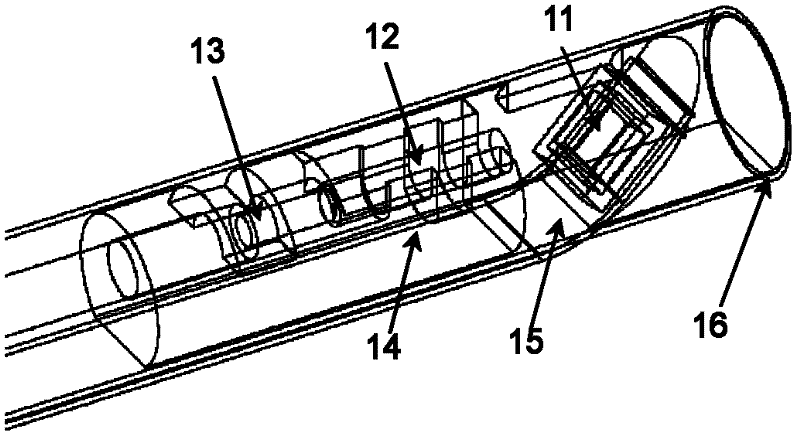

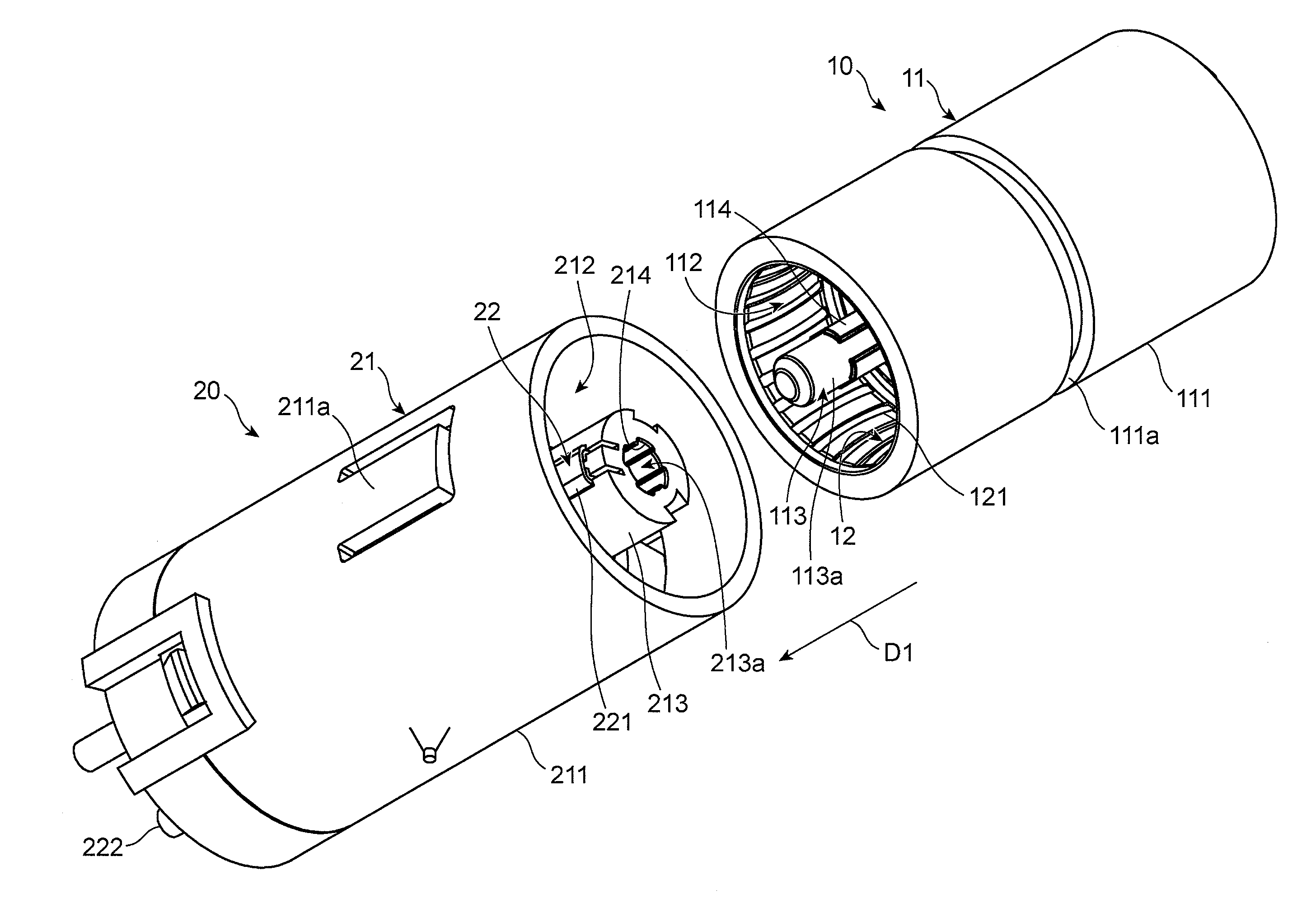

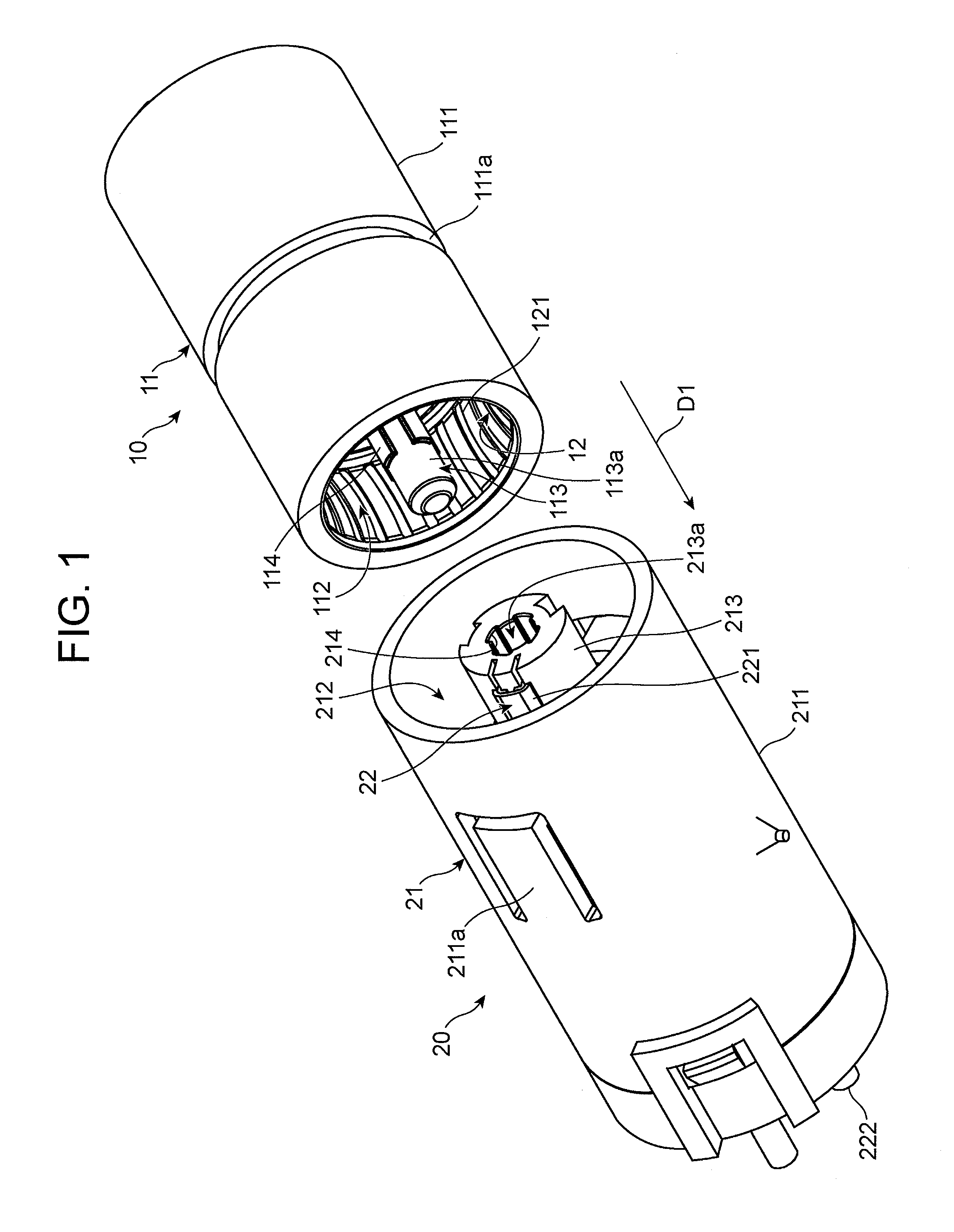

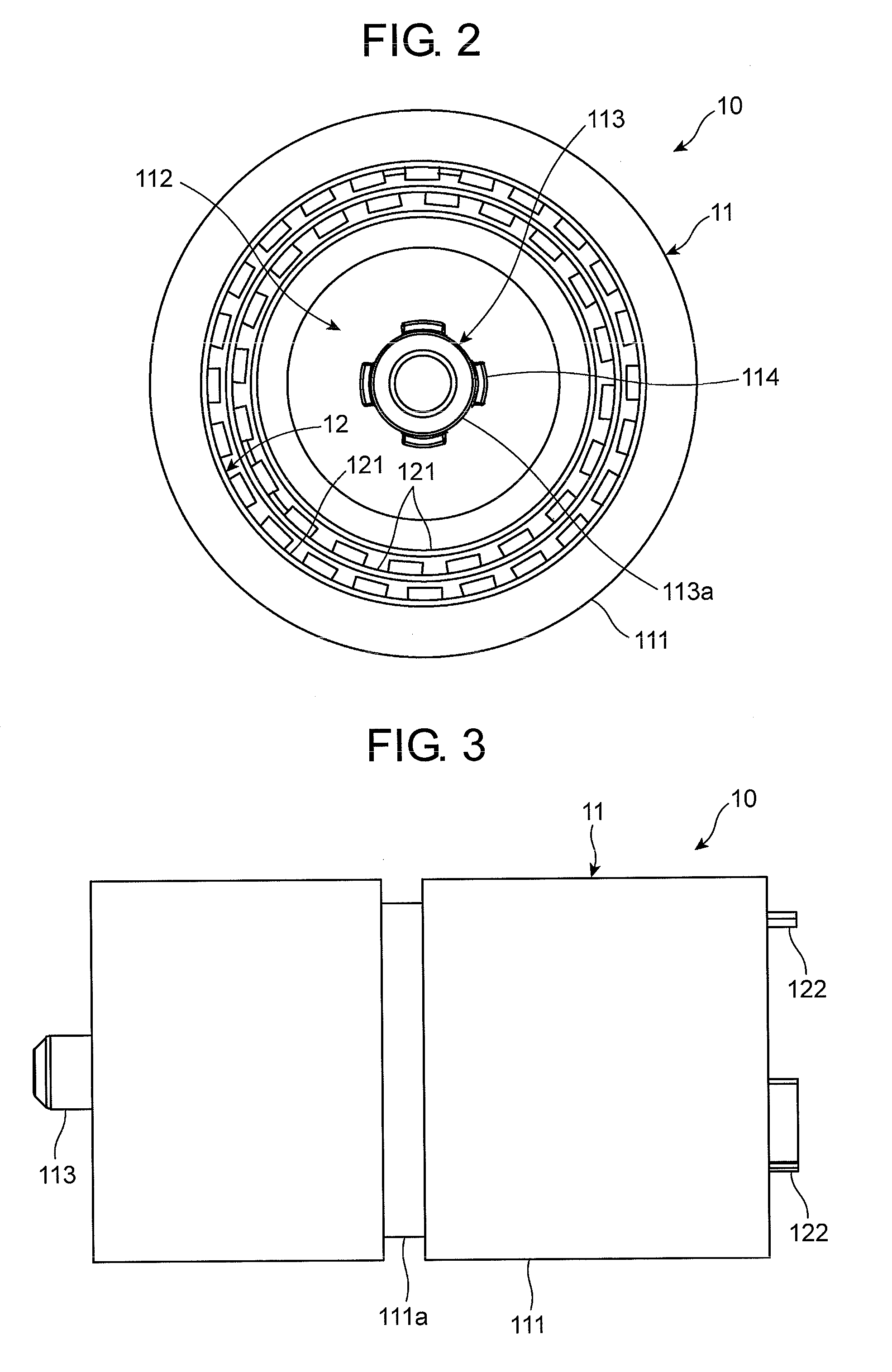

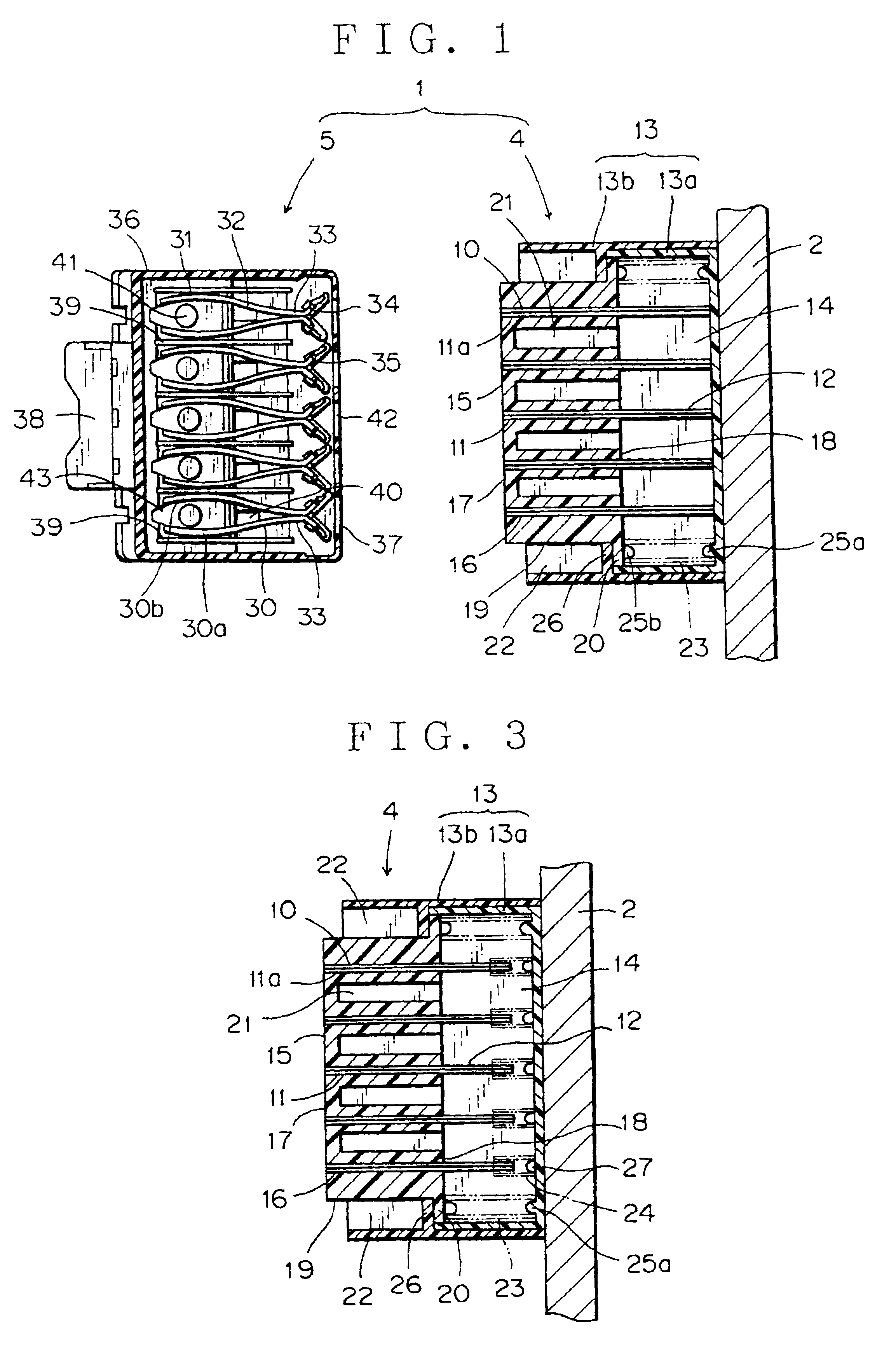

Microphone assembly with a replaceable part

ActiveUS8103039B2Simplifies electrical connectionsImprove electrical connection reliabilityPiezoelectric/electrostrictive microphonesCoupling device detailsElectrical conductorElectrical connection

The invention relates to a microphone assembly comprising a housing, a microphone element within the housing, a base element, contacting elements, a removable element, and connecting means. The housing is configured such that it may be opened and re-closed. The base element is positioned inside the housing and comprises one or more first electrical conductors. The base element comprises one or more first conducting surface parts connected to one or more of the first conductors. The contacting elements facilitate electrical contact between one or more of the first conductors and one or more conductors positioned outside the housing. The removable element is positioned within the housing and comprises one or more second electrically conductive surface parts. The connecting means provides an easily breakable / removable electrical connection between a first surface part and a second surface part.

Owner:SONION NEDERLAND

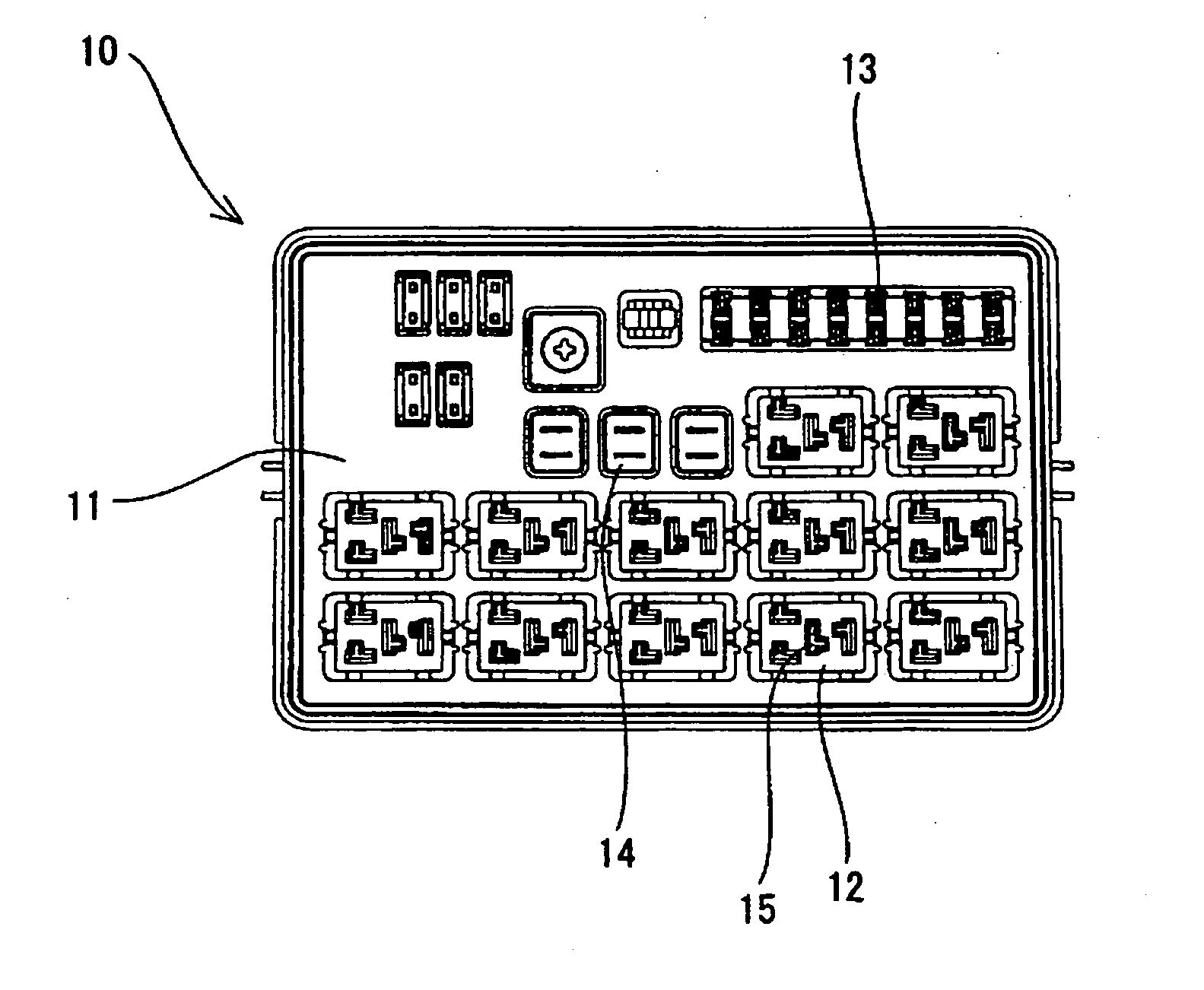

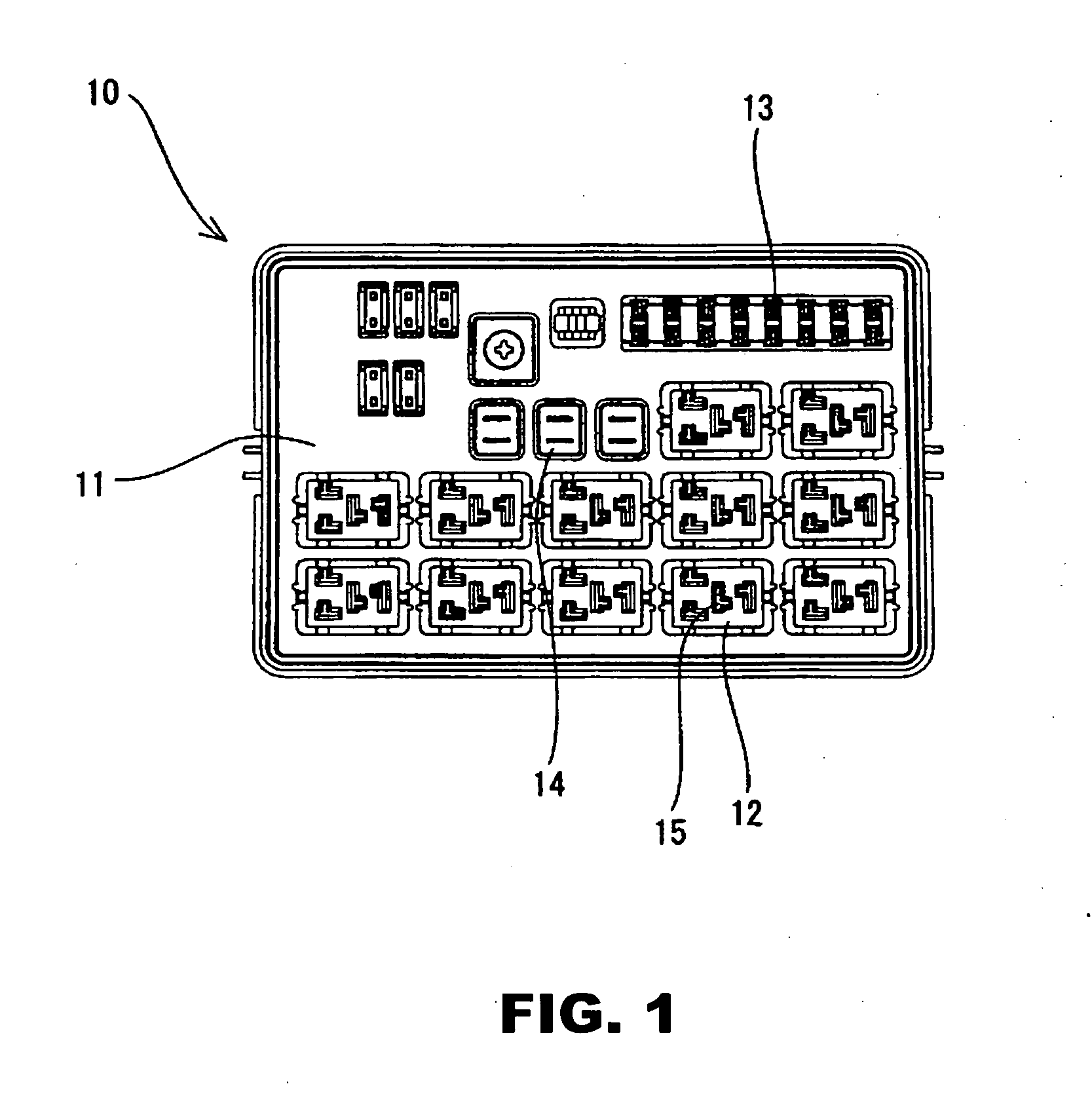

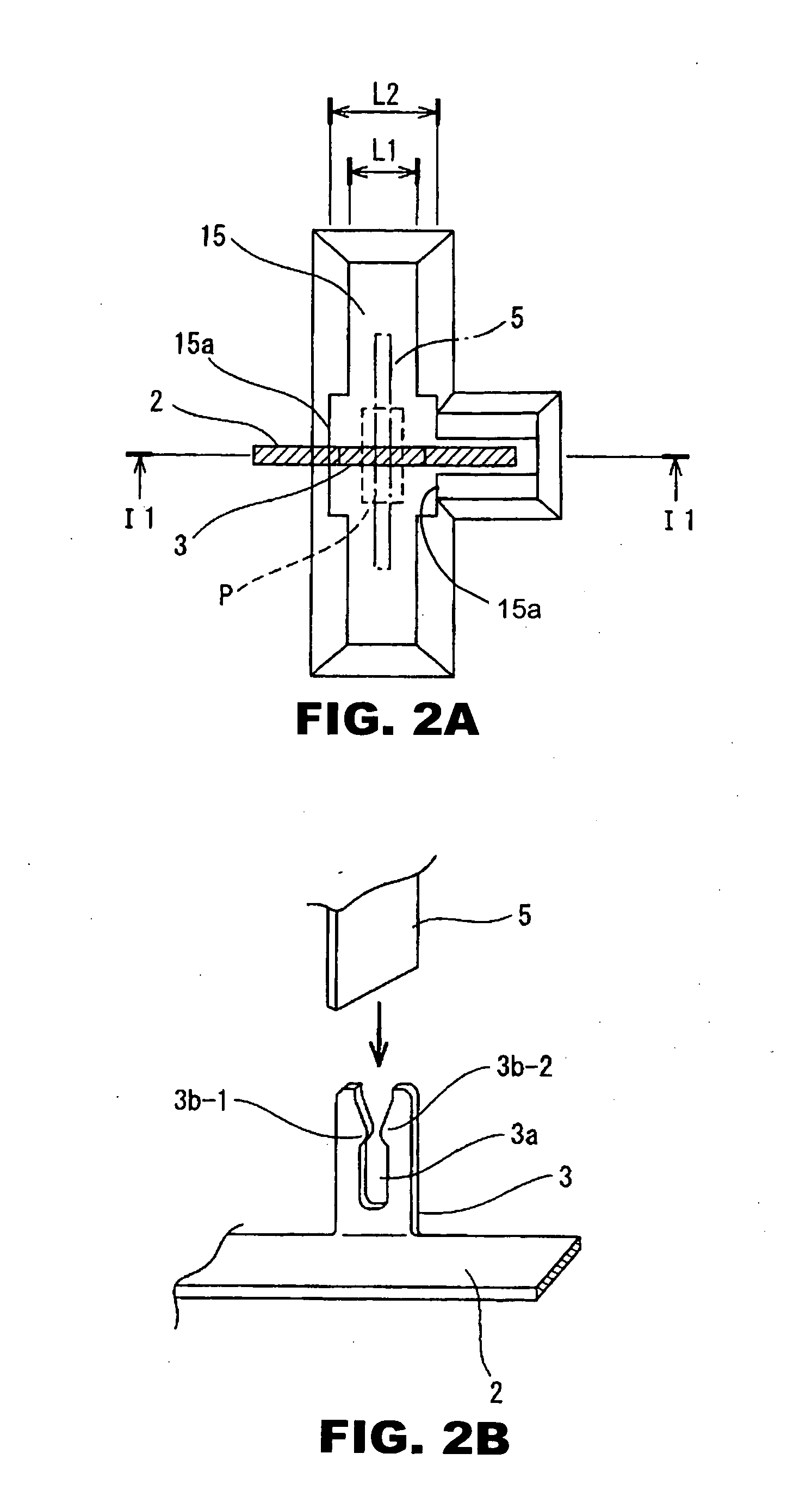

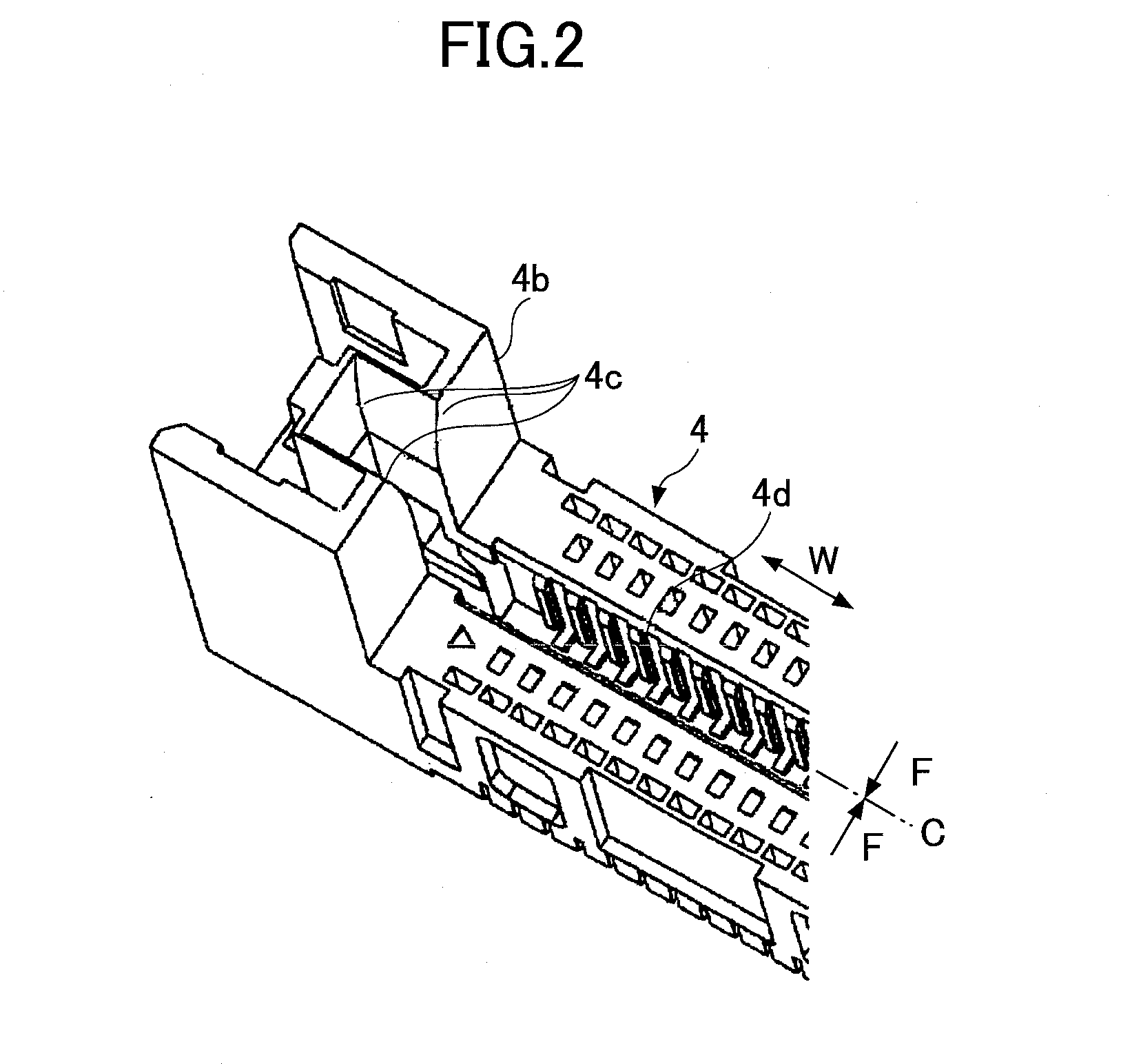

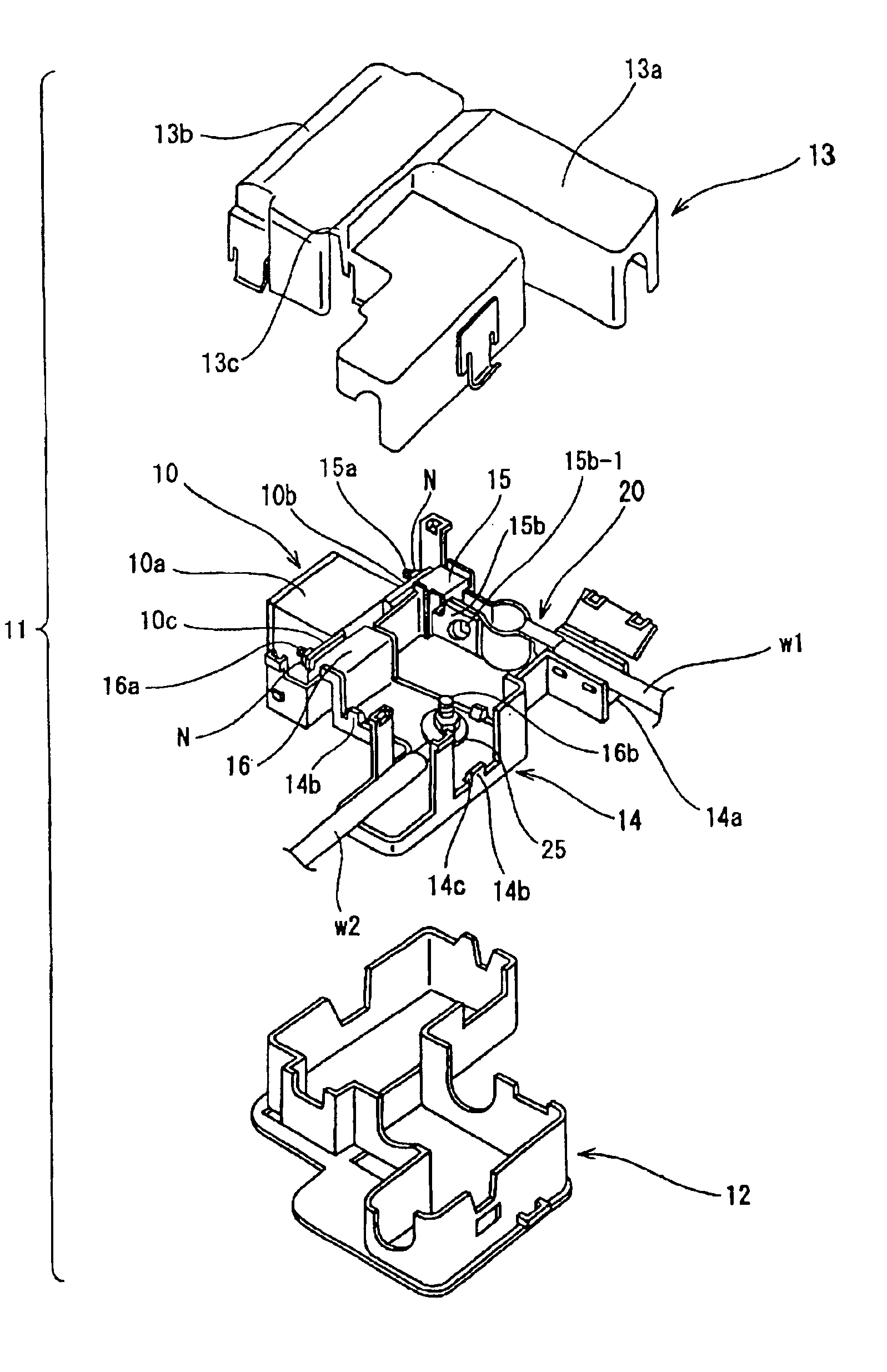

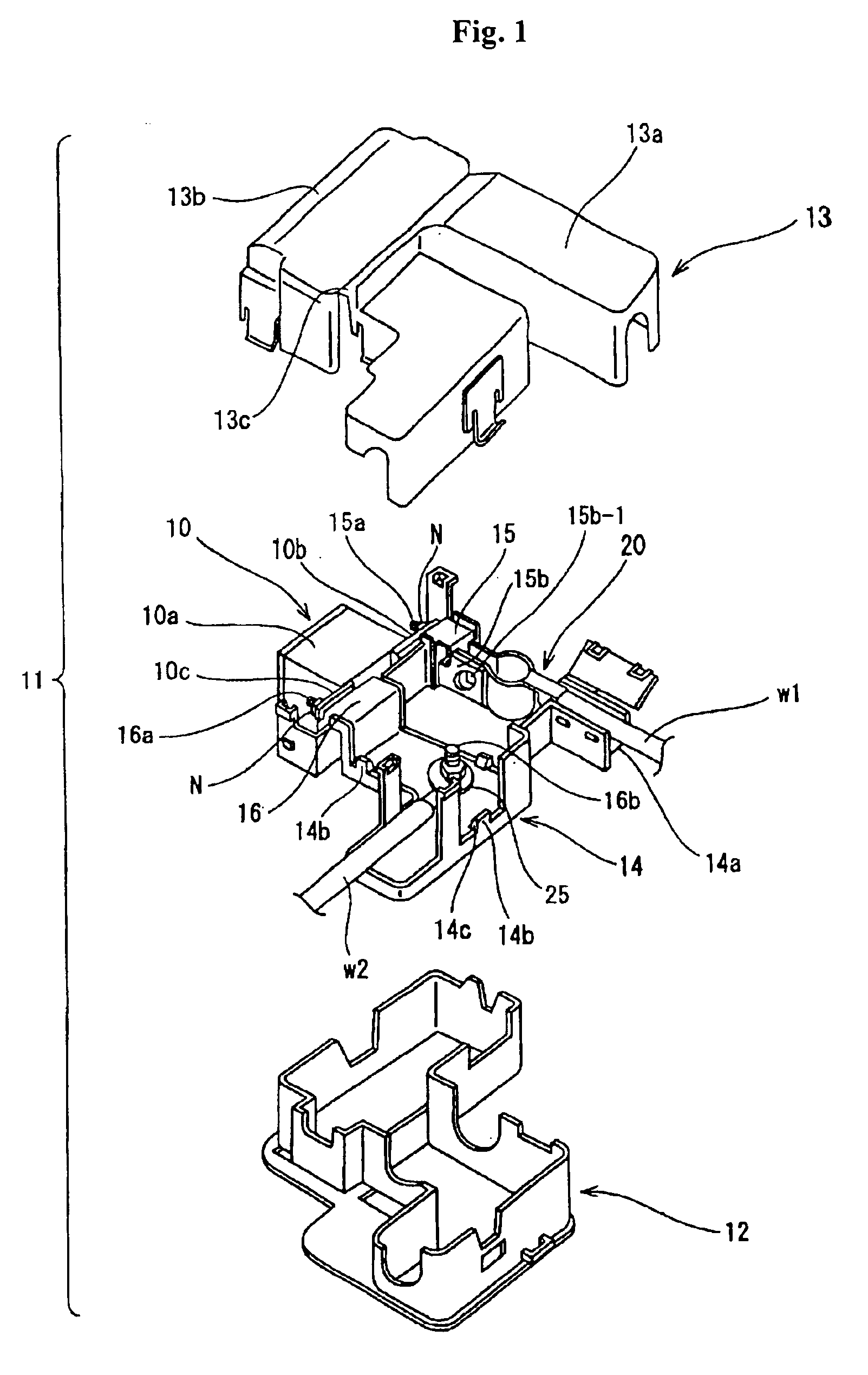

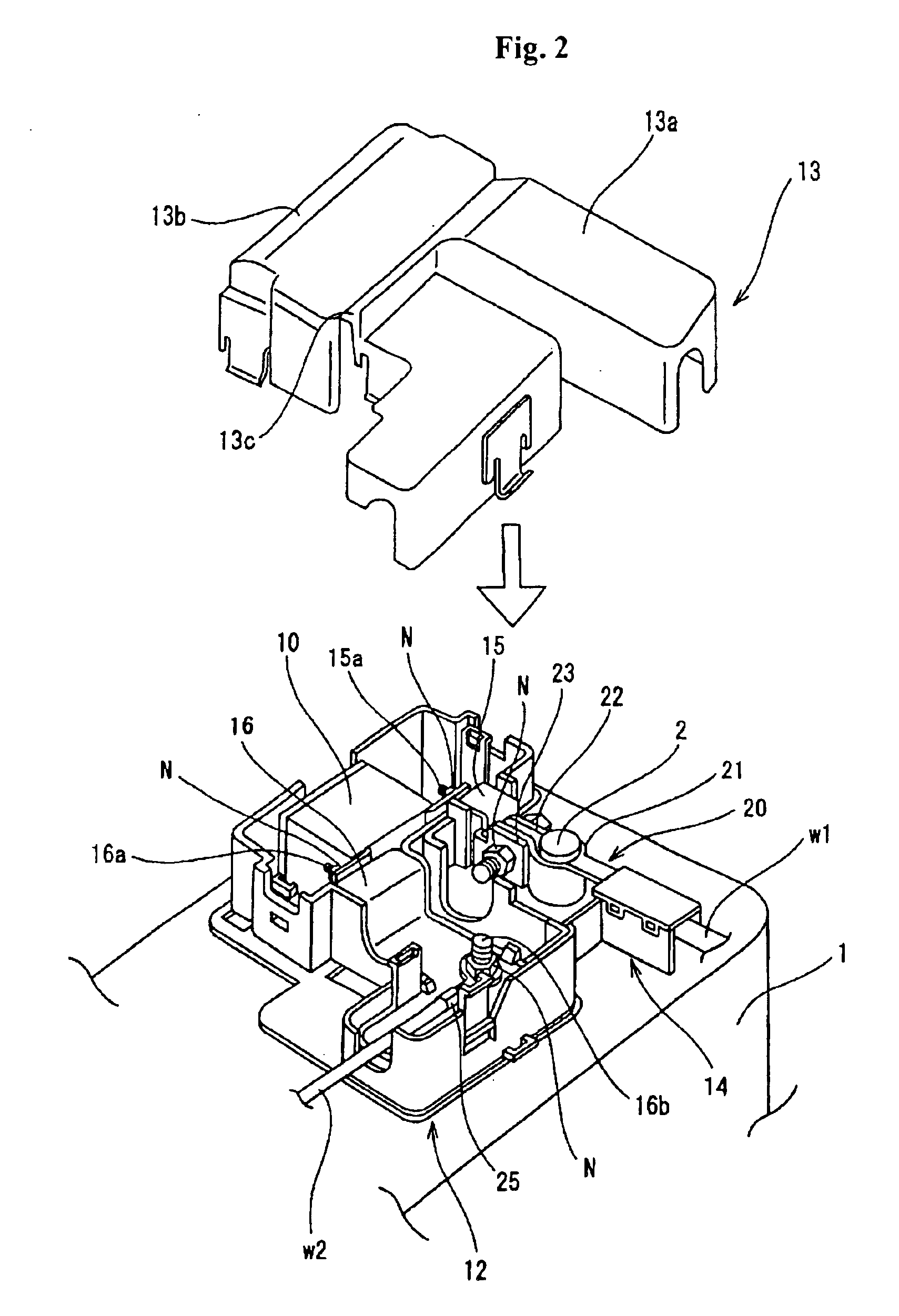

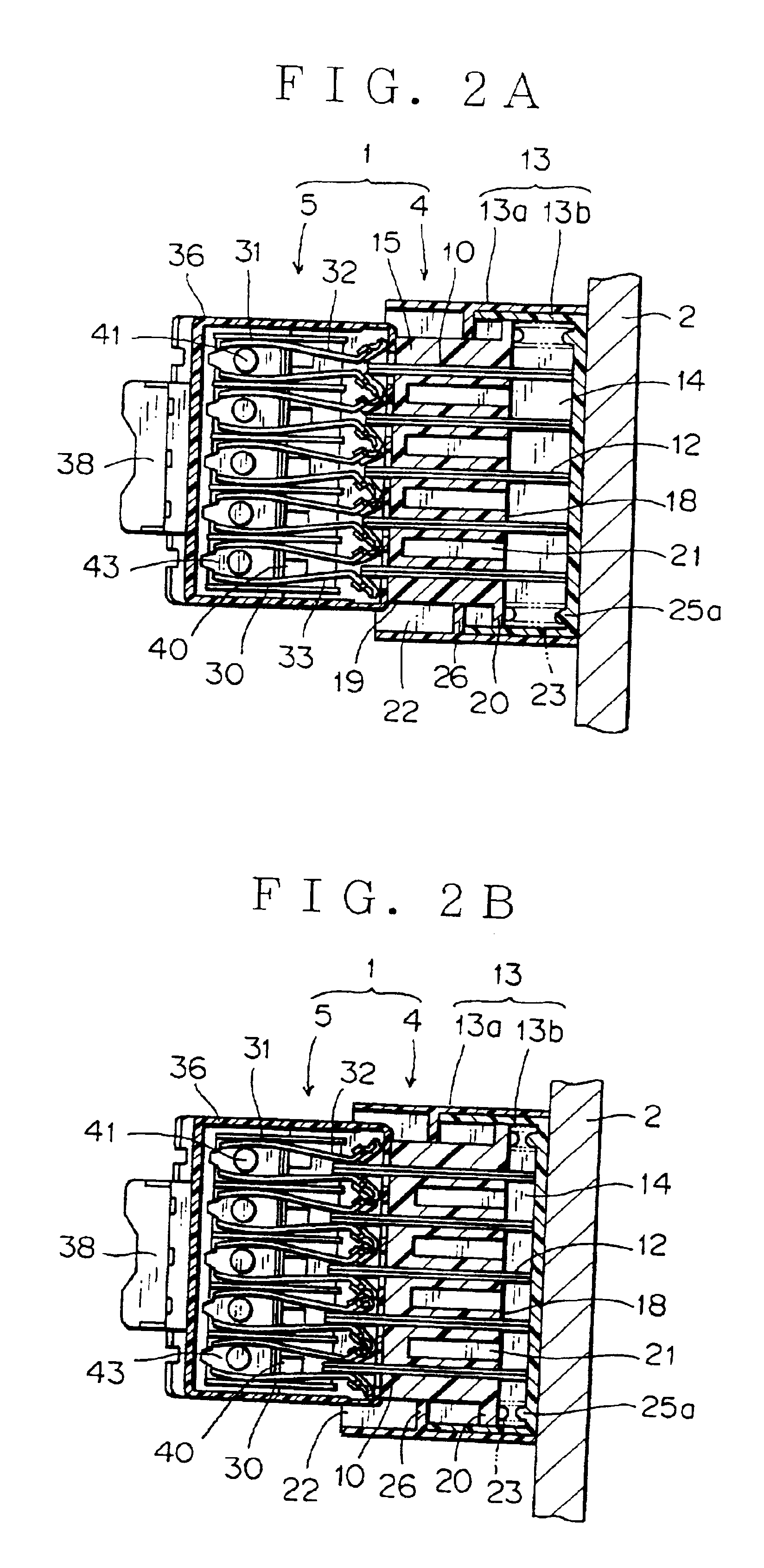

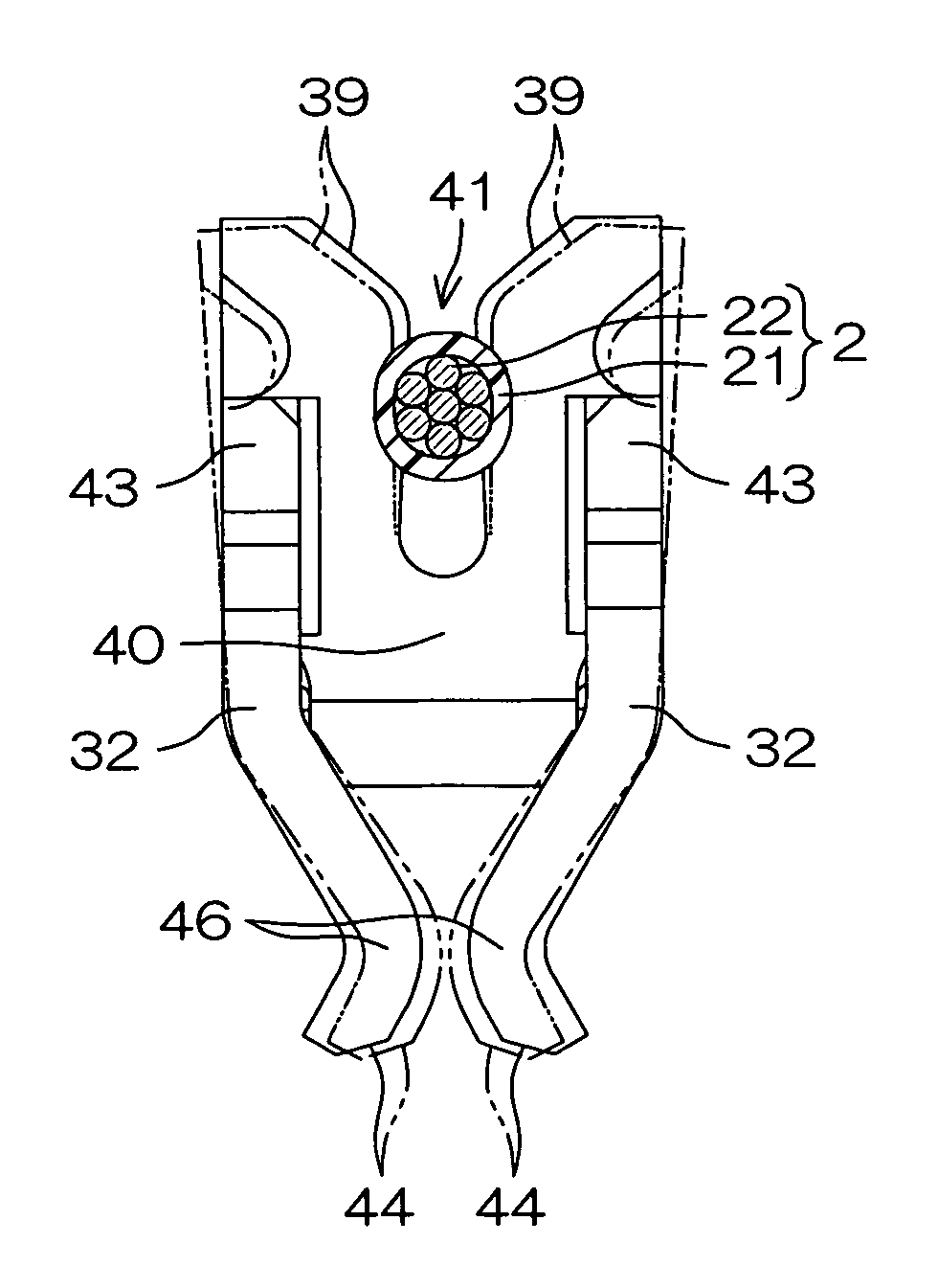

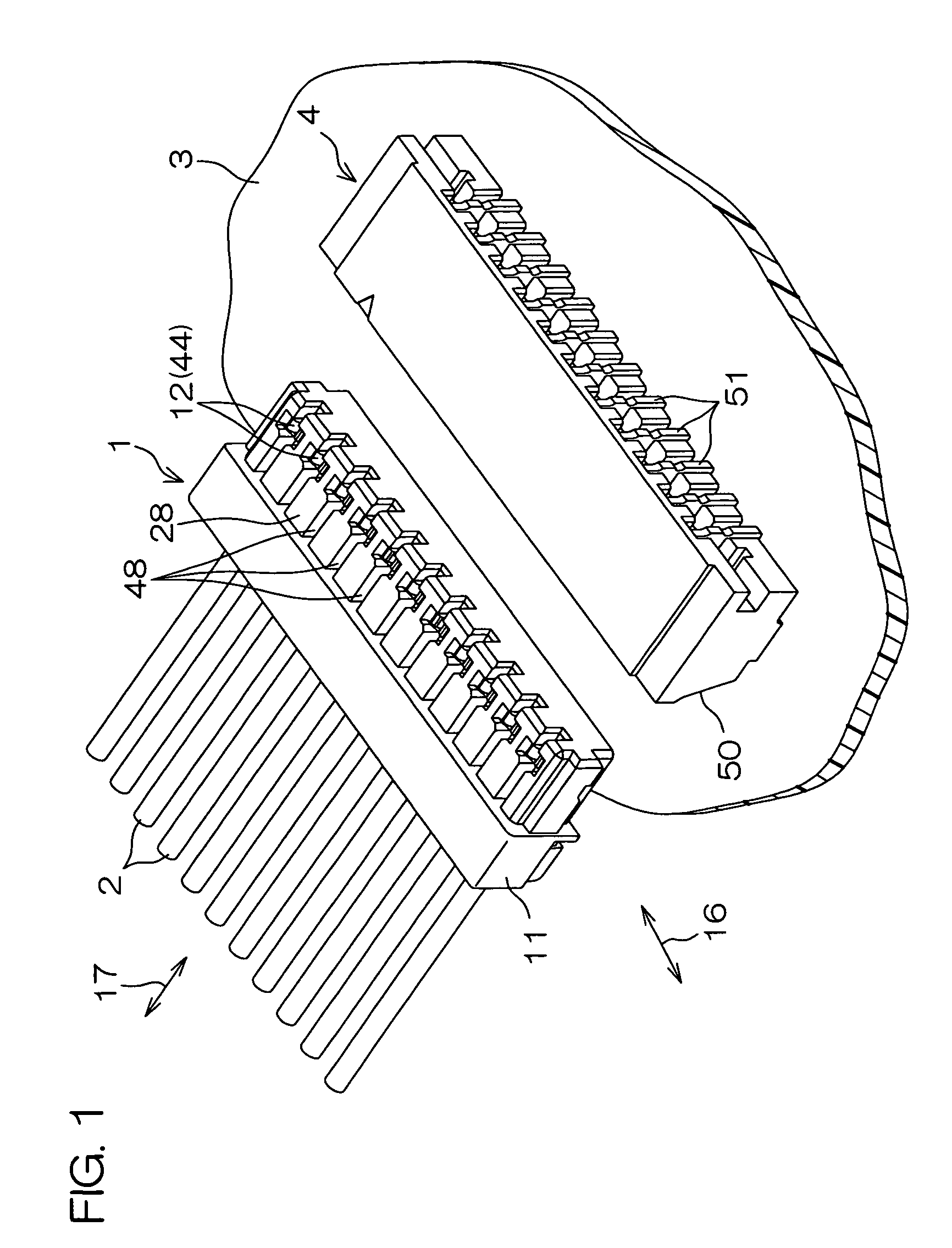

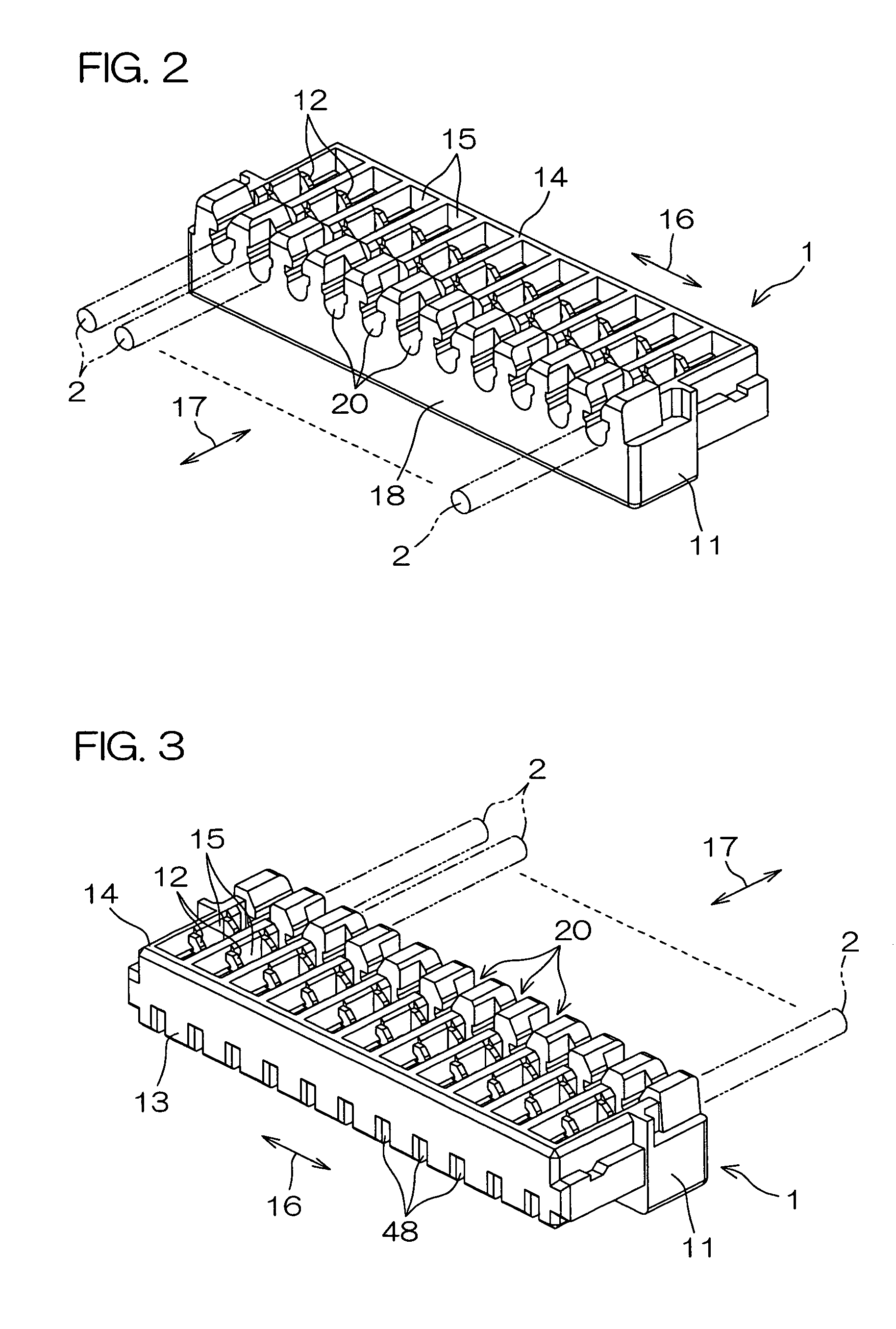

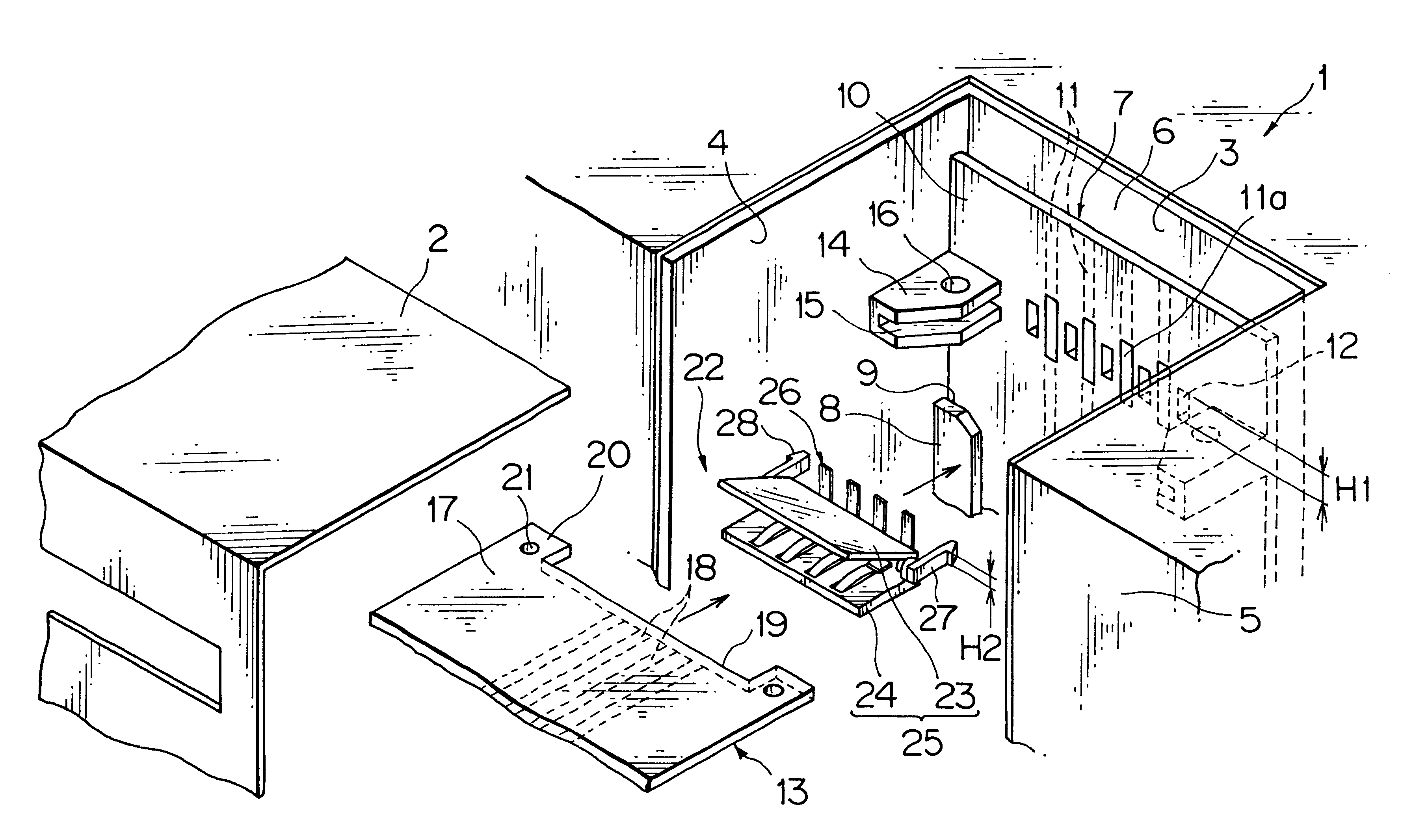

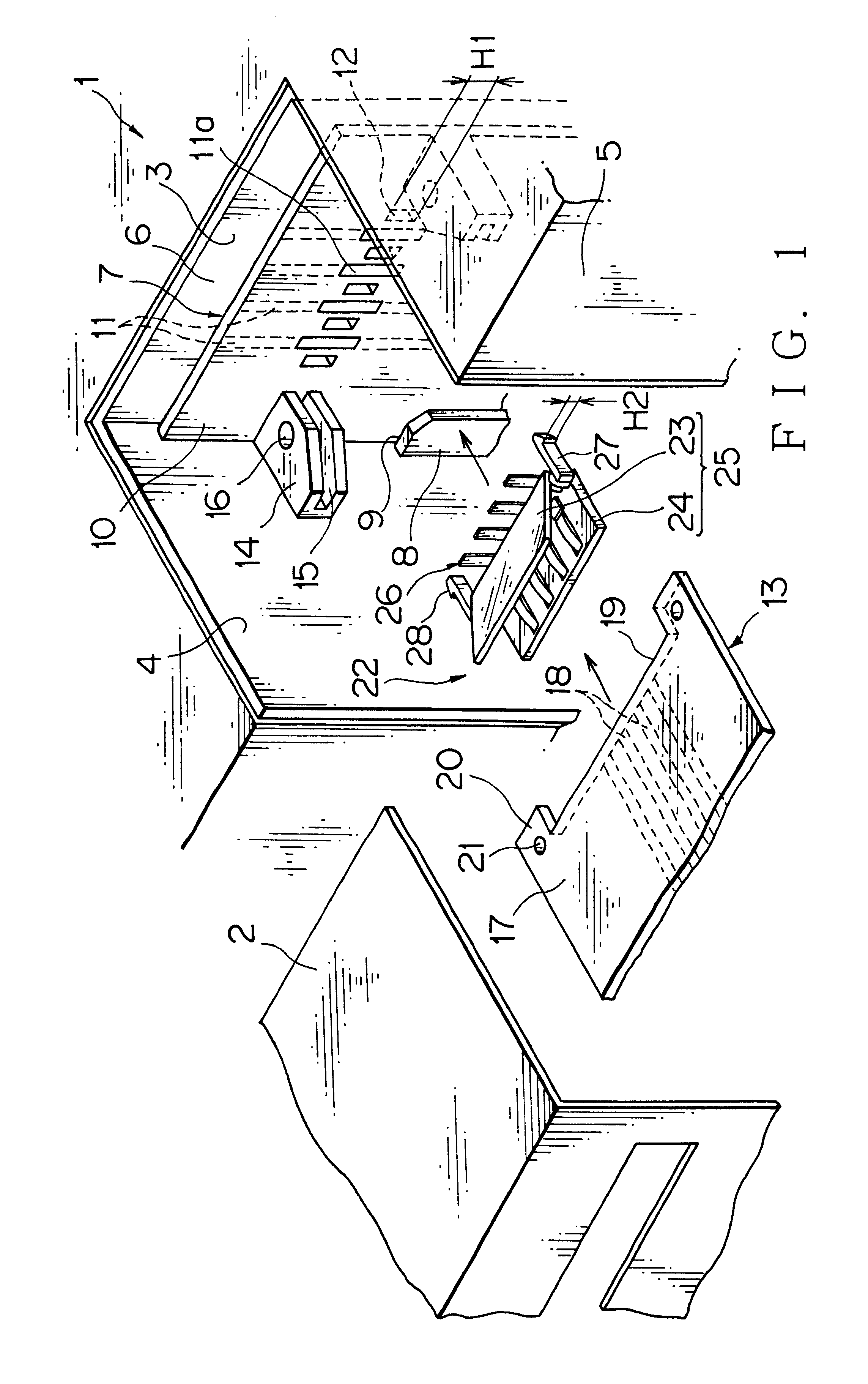

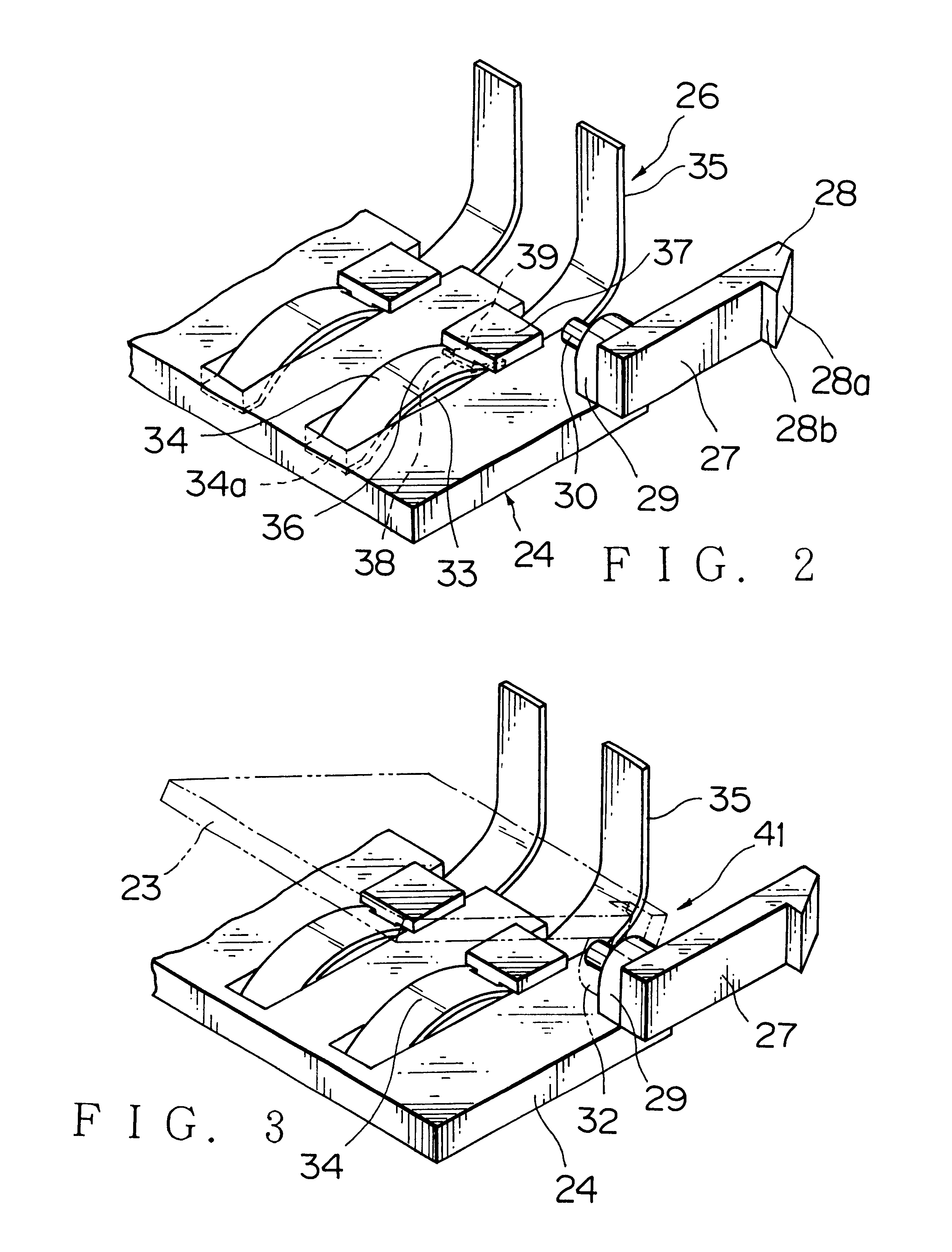

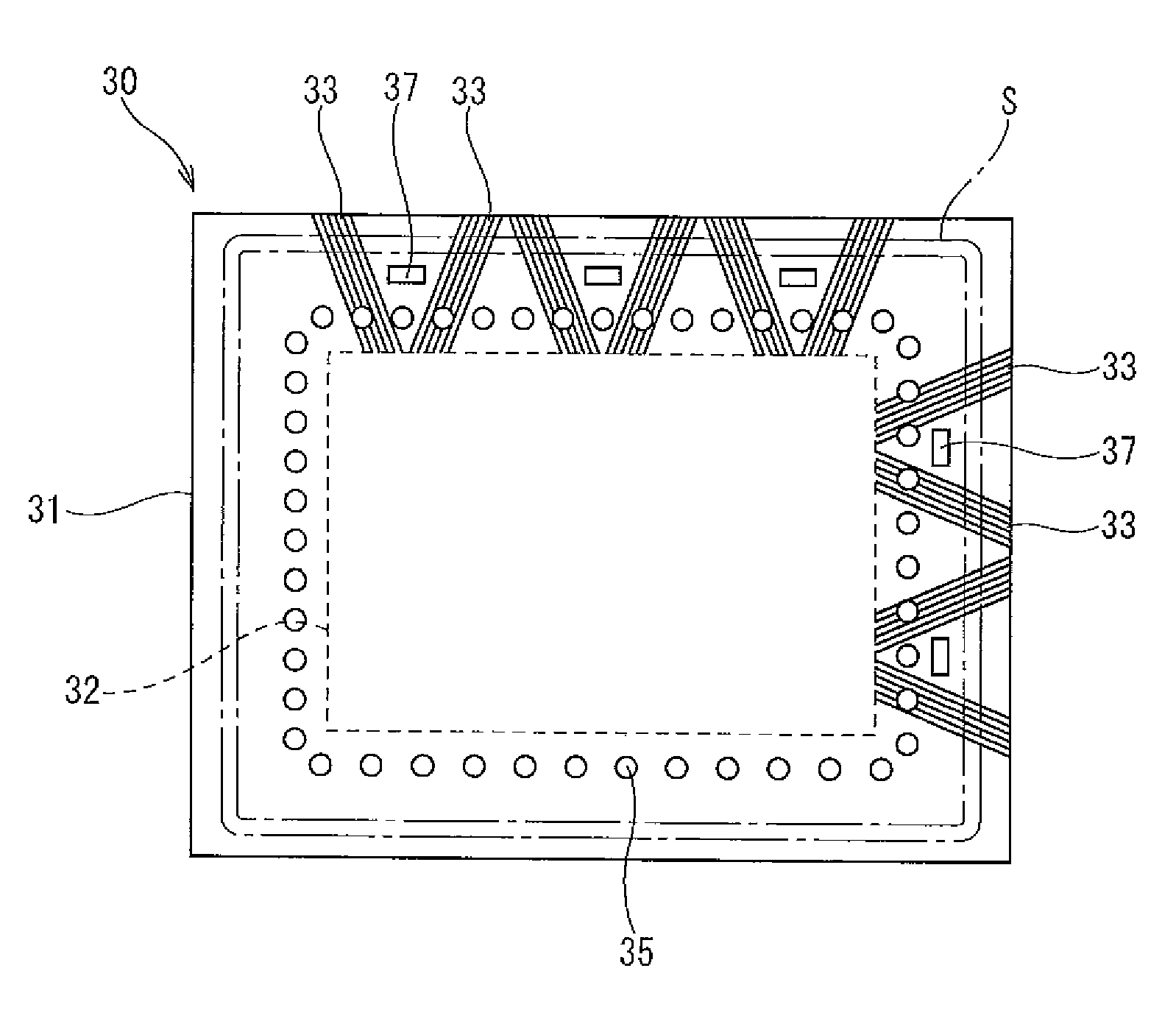

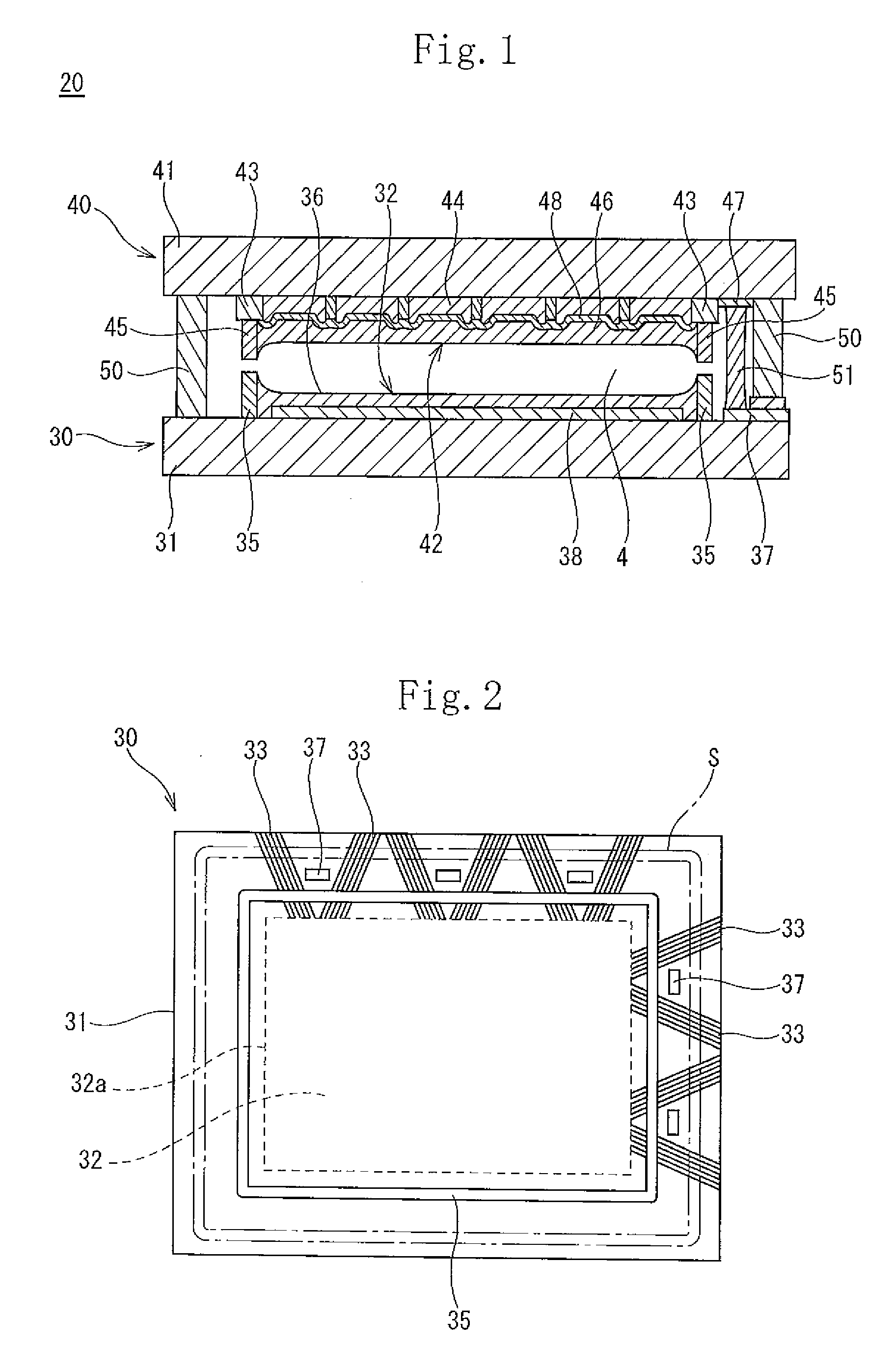

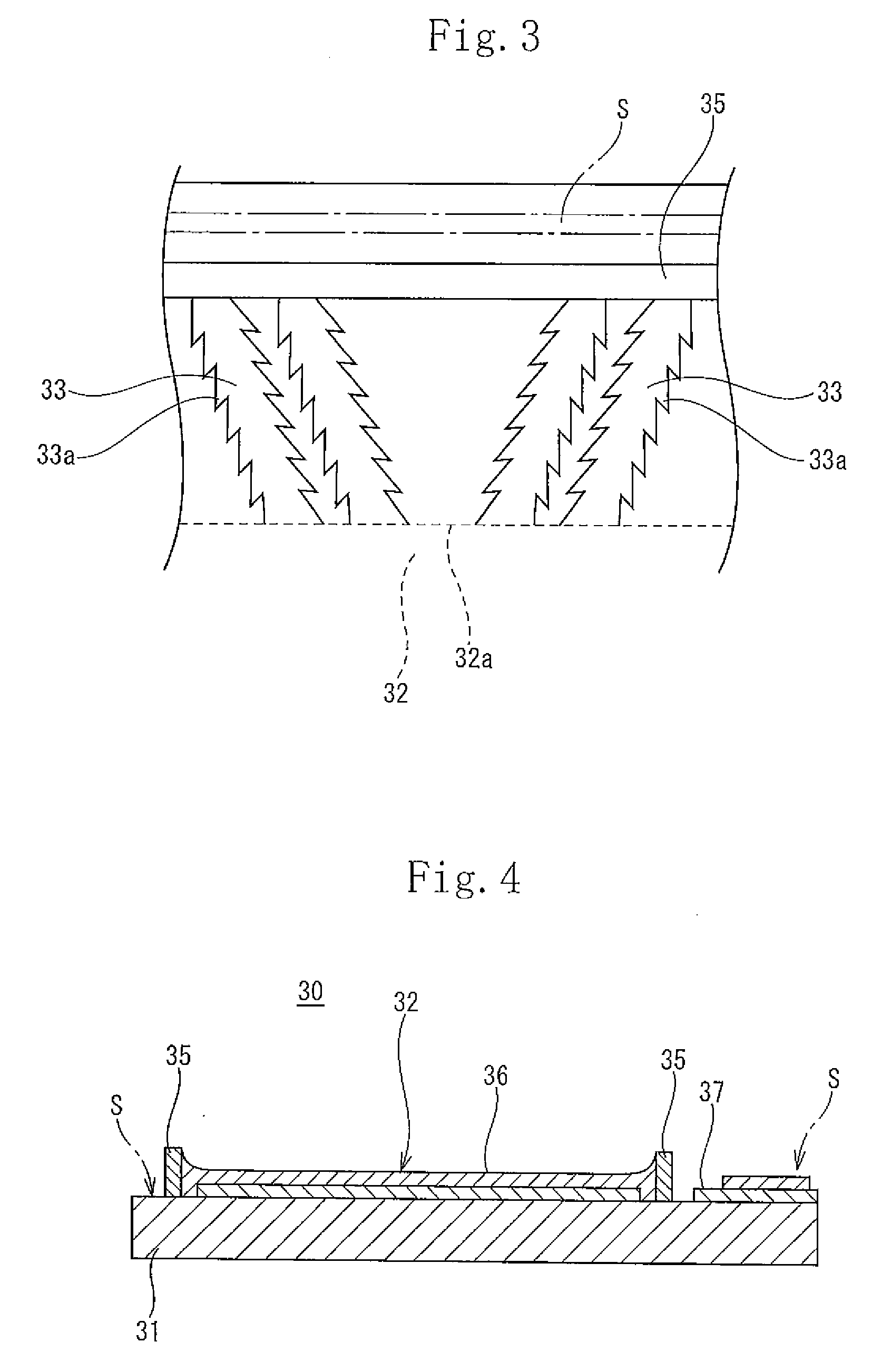

Electrical junction box having an inspection section of a slit width of a tuning fork-like terminal

InactiveUS20050032401A1Eliminate misjudgmentImprove electrical connection reliabilityLine/current collector detailsVehicle connectorsElectrical junctionTuning fork

A tuning fork-like terminal is accommodated in a terminal-containing section. The tuning fork-like terminal is provided on the central end with a slit adapted to receive a tab being connected. Clamping portions are projected from the opposed surfaces of the slit to pinch the tab between the clamping portions. A slit gage is inserted into a rectangular terminal hole formed in an end of the terminal-containing section to inspect a slit width between the clamping portions of the tuning fork-like terminal. A wide hole portion is formed in the rectangular terminal hole at the insertion position of the slit gage. The wide hole portion is formed by widening a length of a short side of the rectangular terminal hole. The central position of the slit in the tuning fork-like terminal and the central position of the slit gage coincide with each other, even if the tuning fork-like terminal is maximally shifted from the central position in the terminal-containing section, whereby the slit width can be precisely inspected to precisely inspect a slit width in a tuning fork-like terminal accommodated in a terminal-containing section of an electrical junction box.

Owner:SUMITOMO WIRING SYST LTD

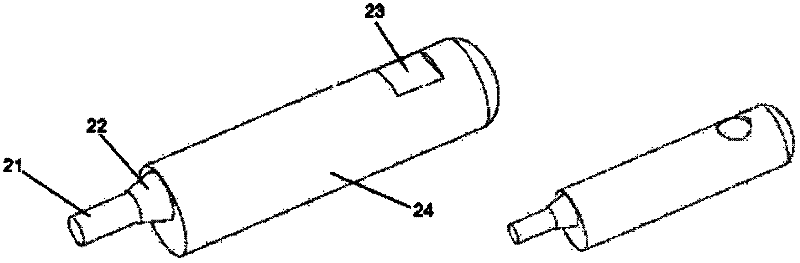

Micro optical probe of endoscope

ActiveCN102401995AImmune to environmental factorsAchieve high volumeSurgeryDiagnostic recording/measuringOptomechatronicsEndoscope

The invention discloses a micro optical probe of endoscope, which comprises an MEMS microscope, a circuit board, a self focusing optical assembly, a locating bottom plate and a housing; the micro optical probe of endoscope is characterized in that: the endoscope probe is designed by using integrated symmetrical structure, the MEMS microscope; the circuit board and the self focusing optical assembly are assembled on the locating bottom plate according to design requirements of optomechatronics to form a probe body, and a probe housing is formed by injection molding or casting and is tightly connected with the probe body. The housing opposite to the microscope surface of the MEMS microscope can be formed with an optical window, or the housing material is transparent to the used light. The probe housing is formed at a time by injection molding / casting technology, and this structure can protect the MEMS microscope from being influenced with environment factor and can bear a certain vibration impact and random shock; the sealed probe can work in various liquid environments; and large-batch and low-cost processing production of probes can be realized, and the aim of disposable probes will be fulfilled.

Owner:无锡微文半导体科技有限公司

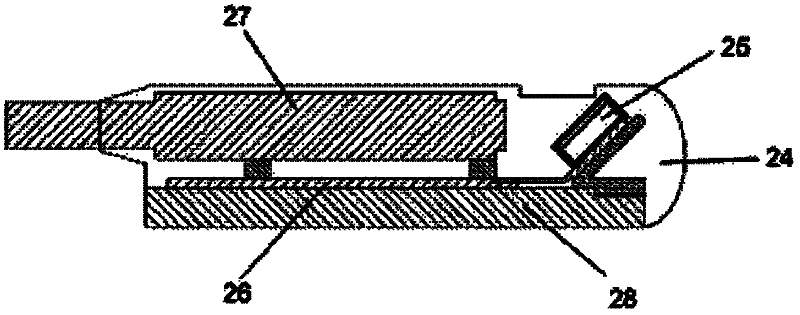

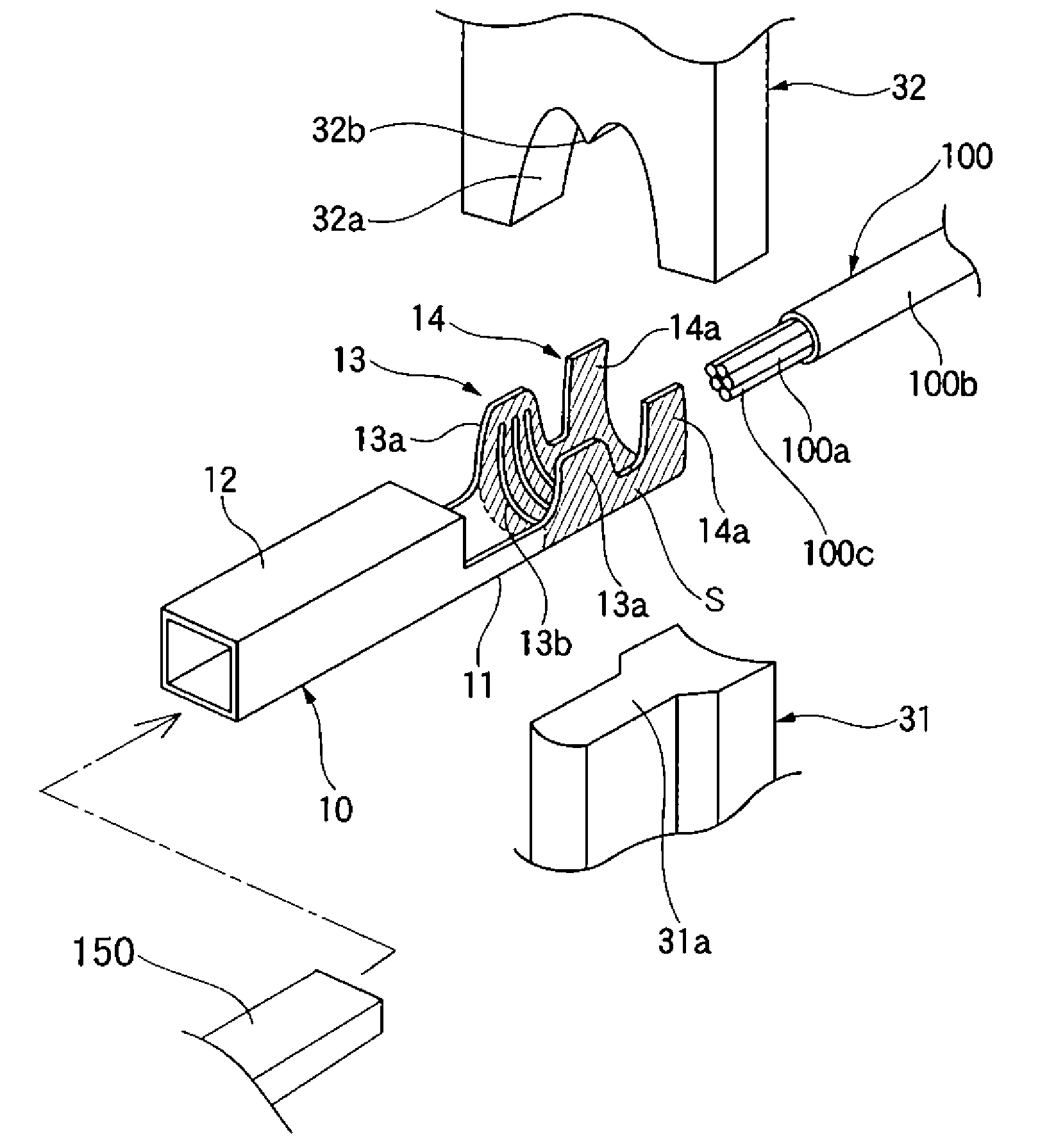

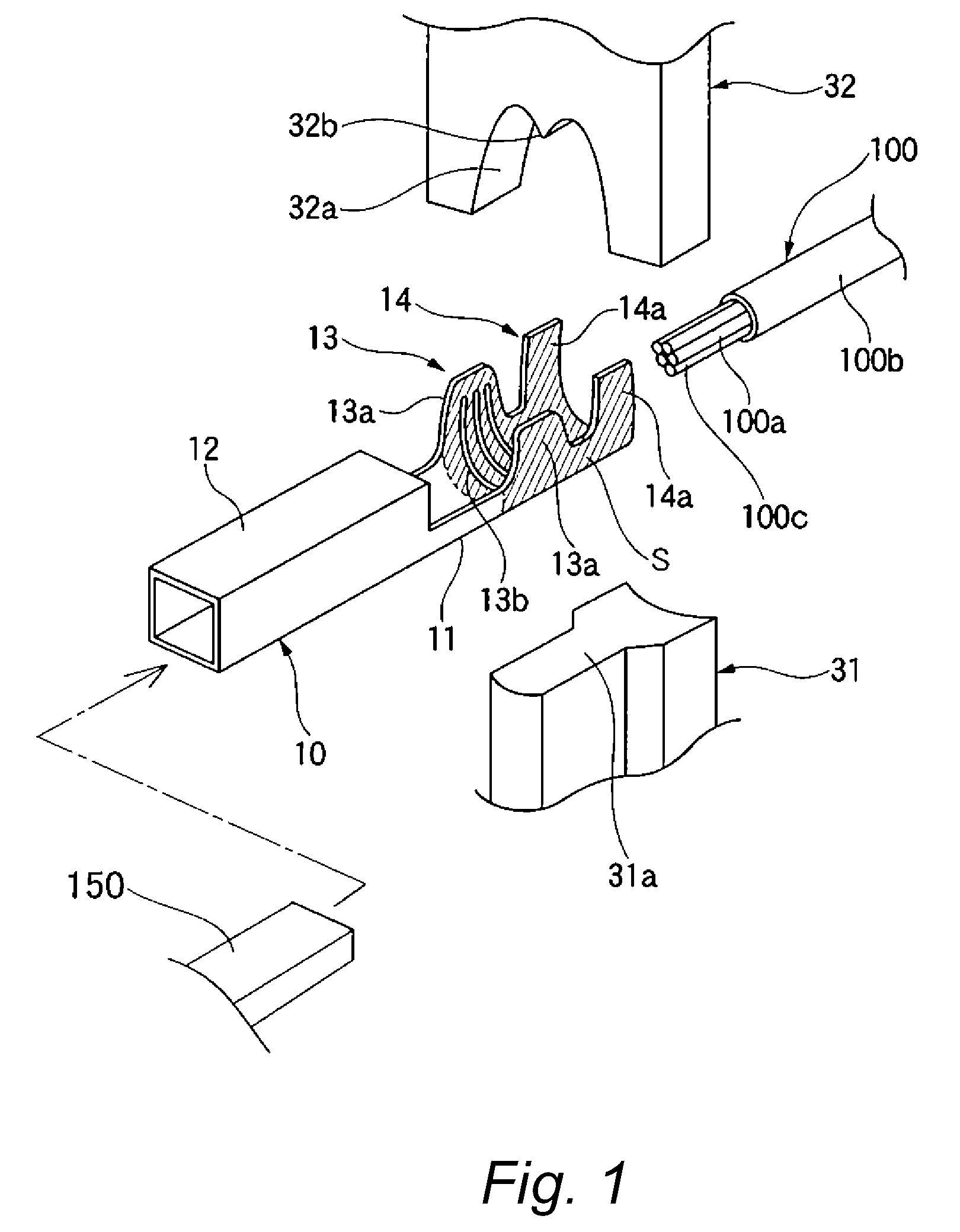

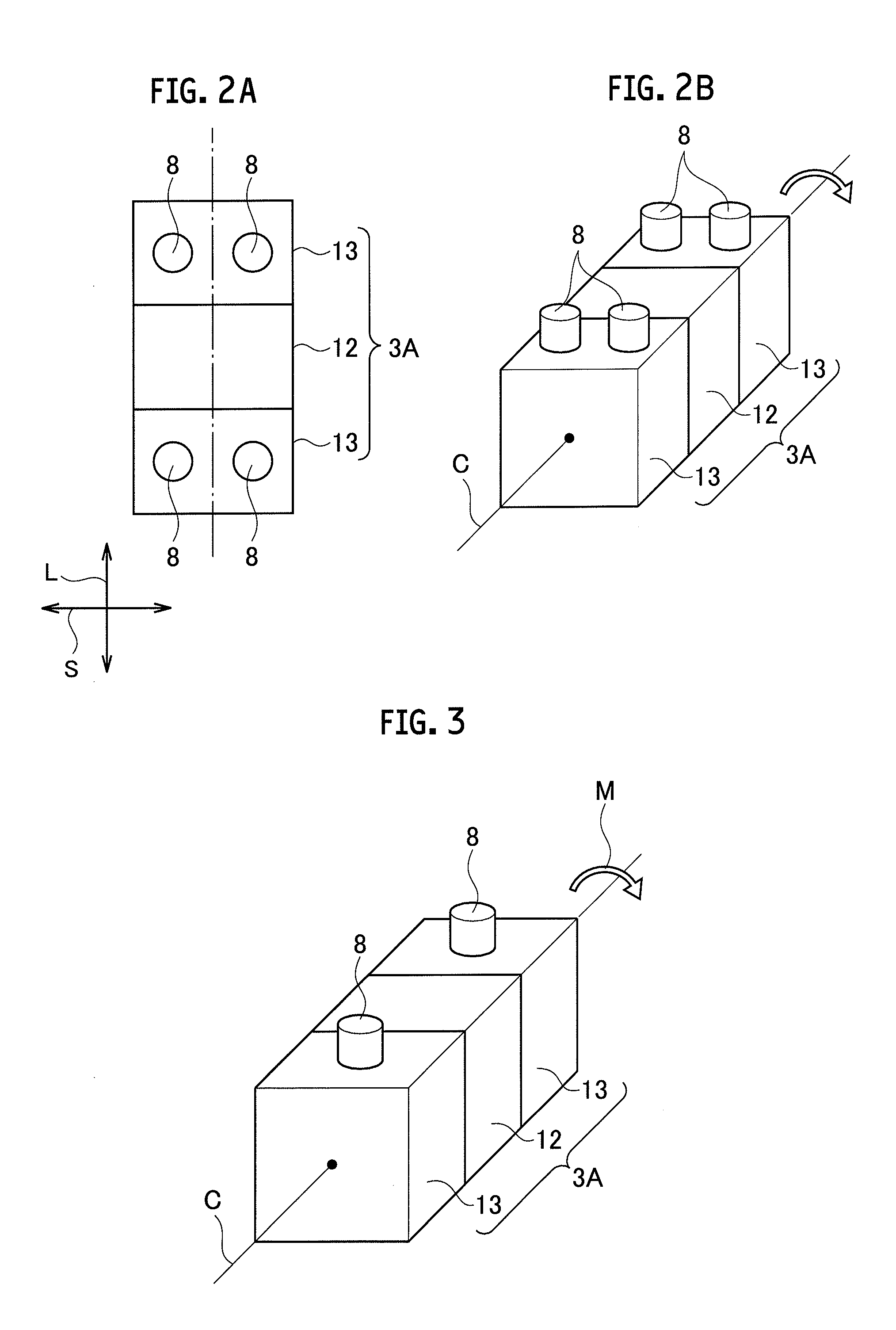

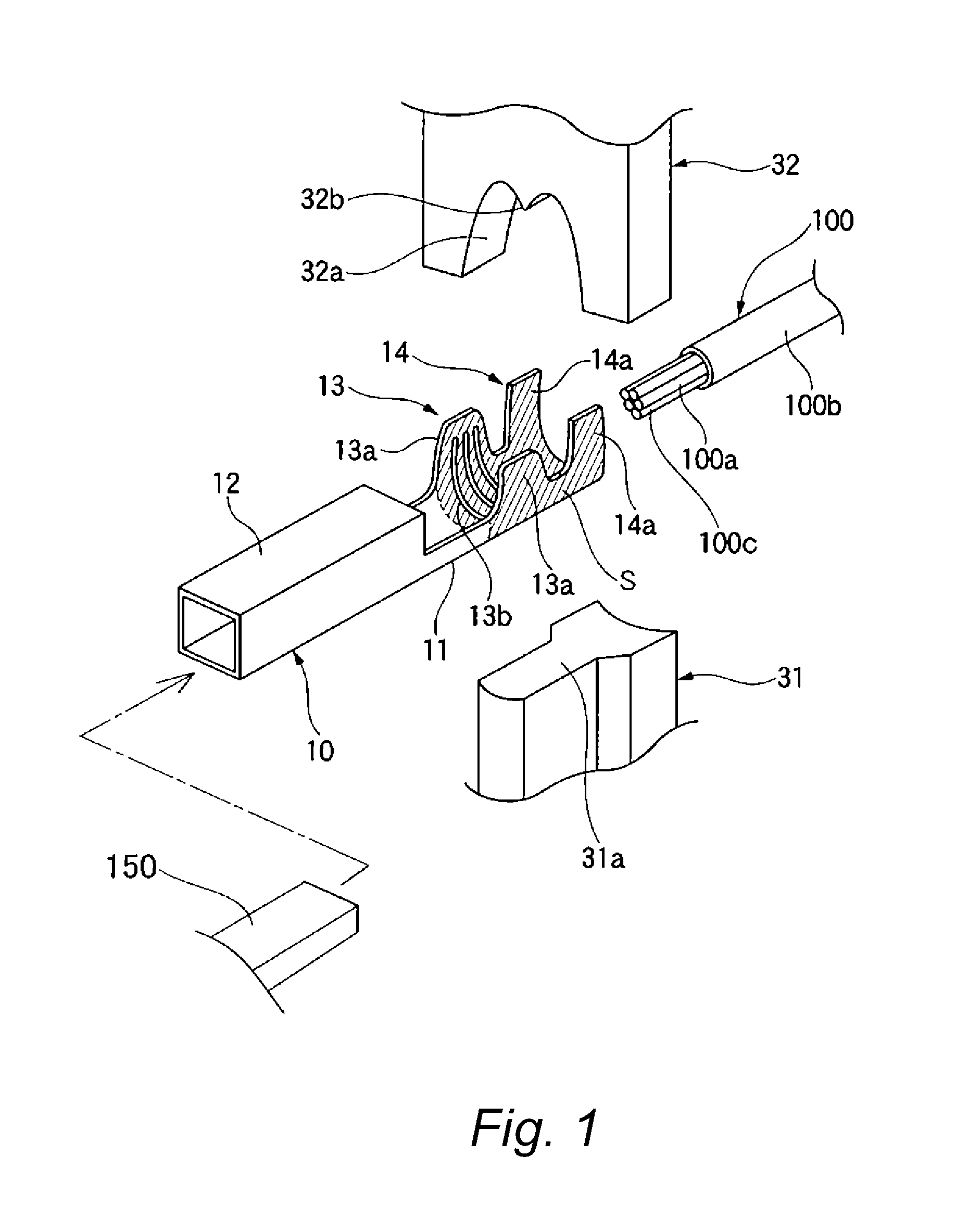

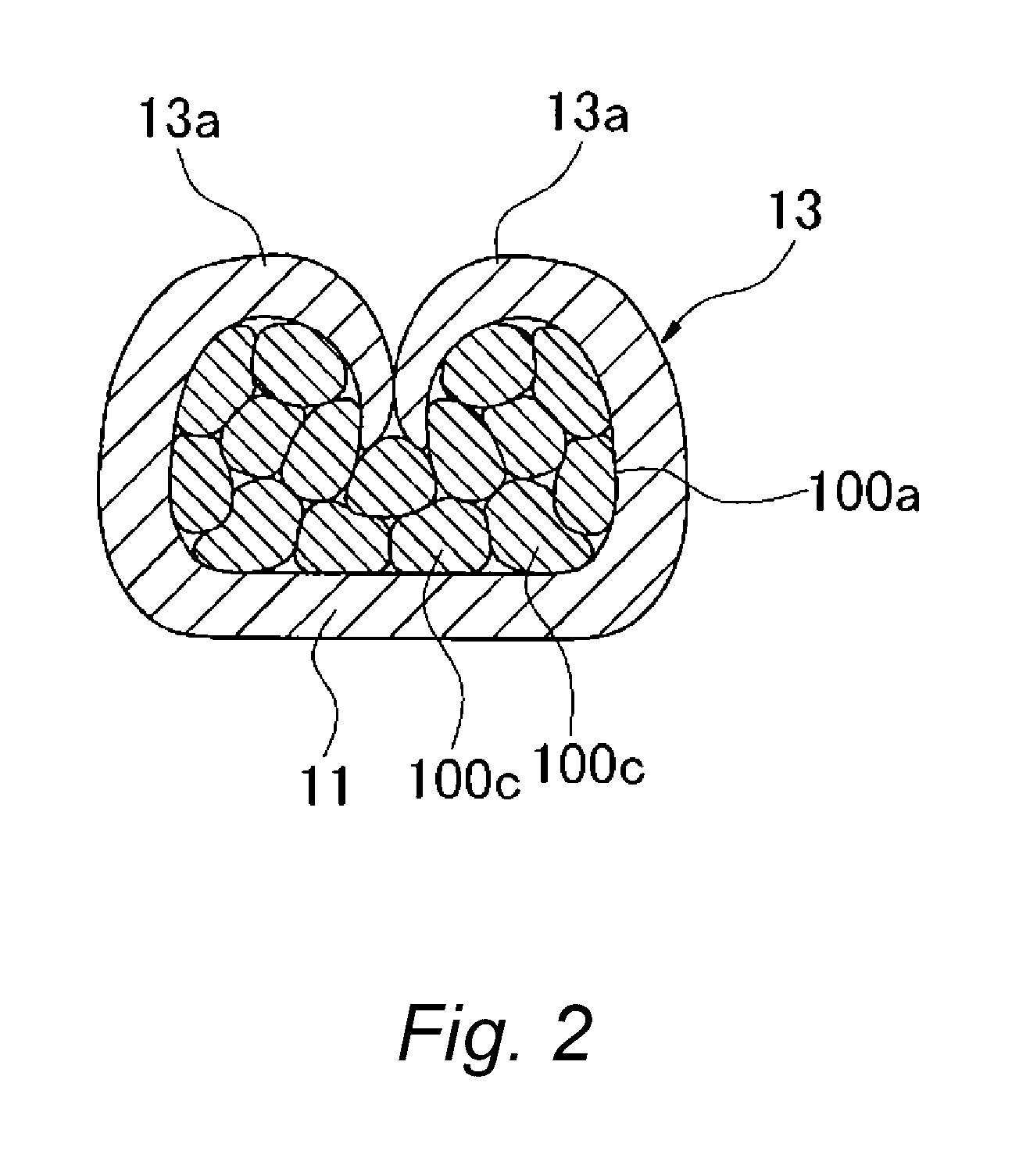

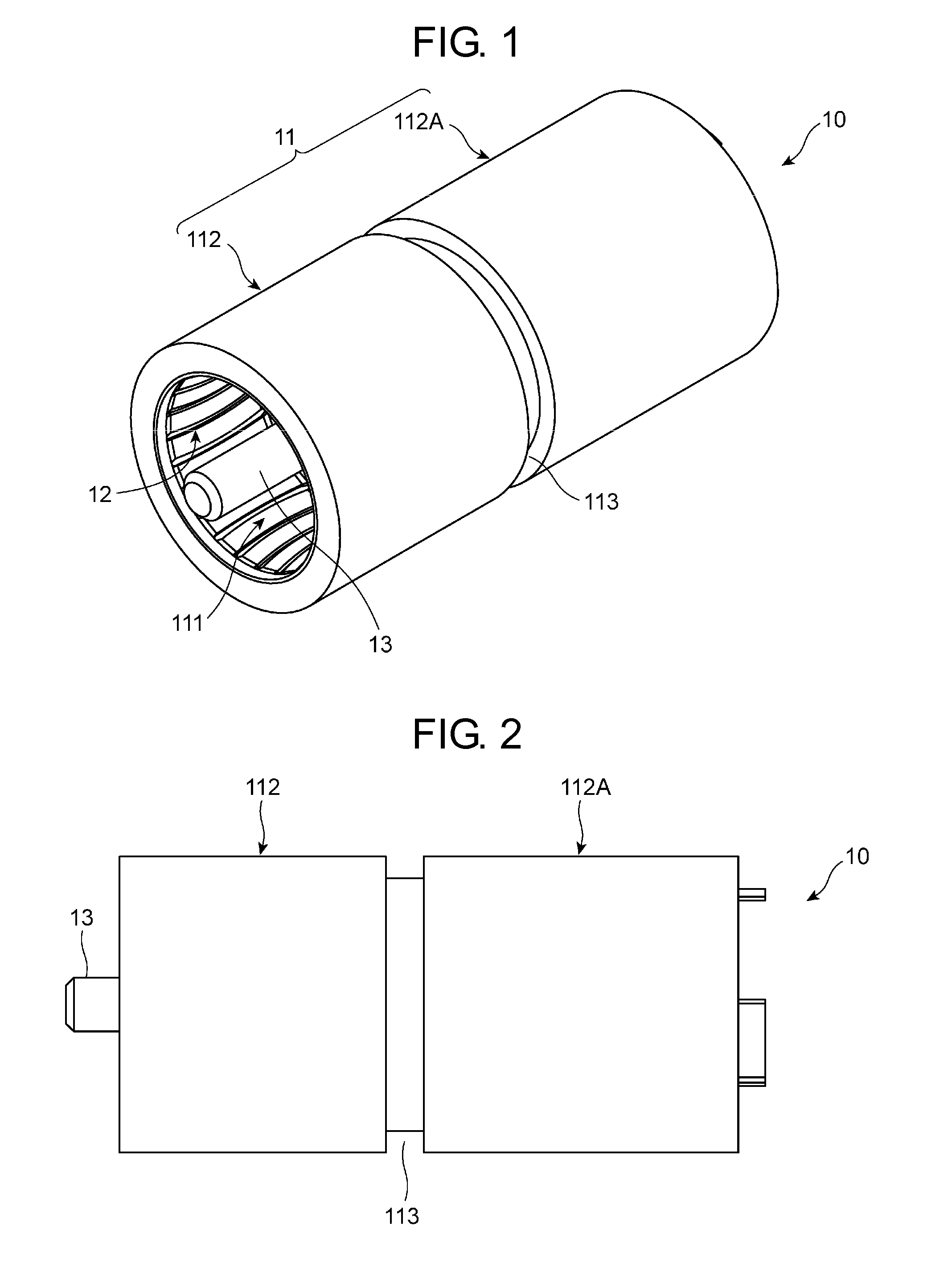

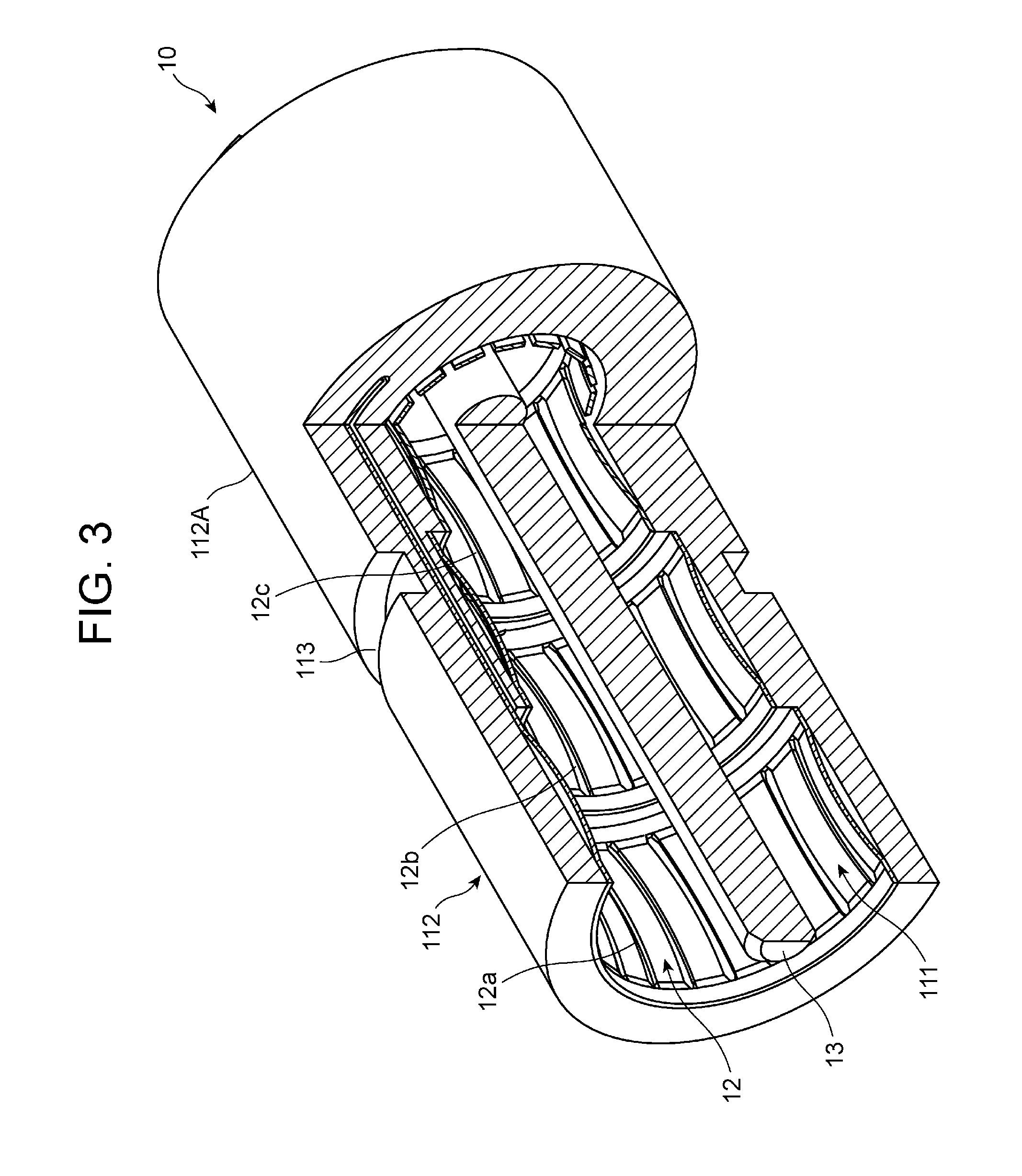

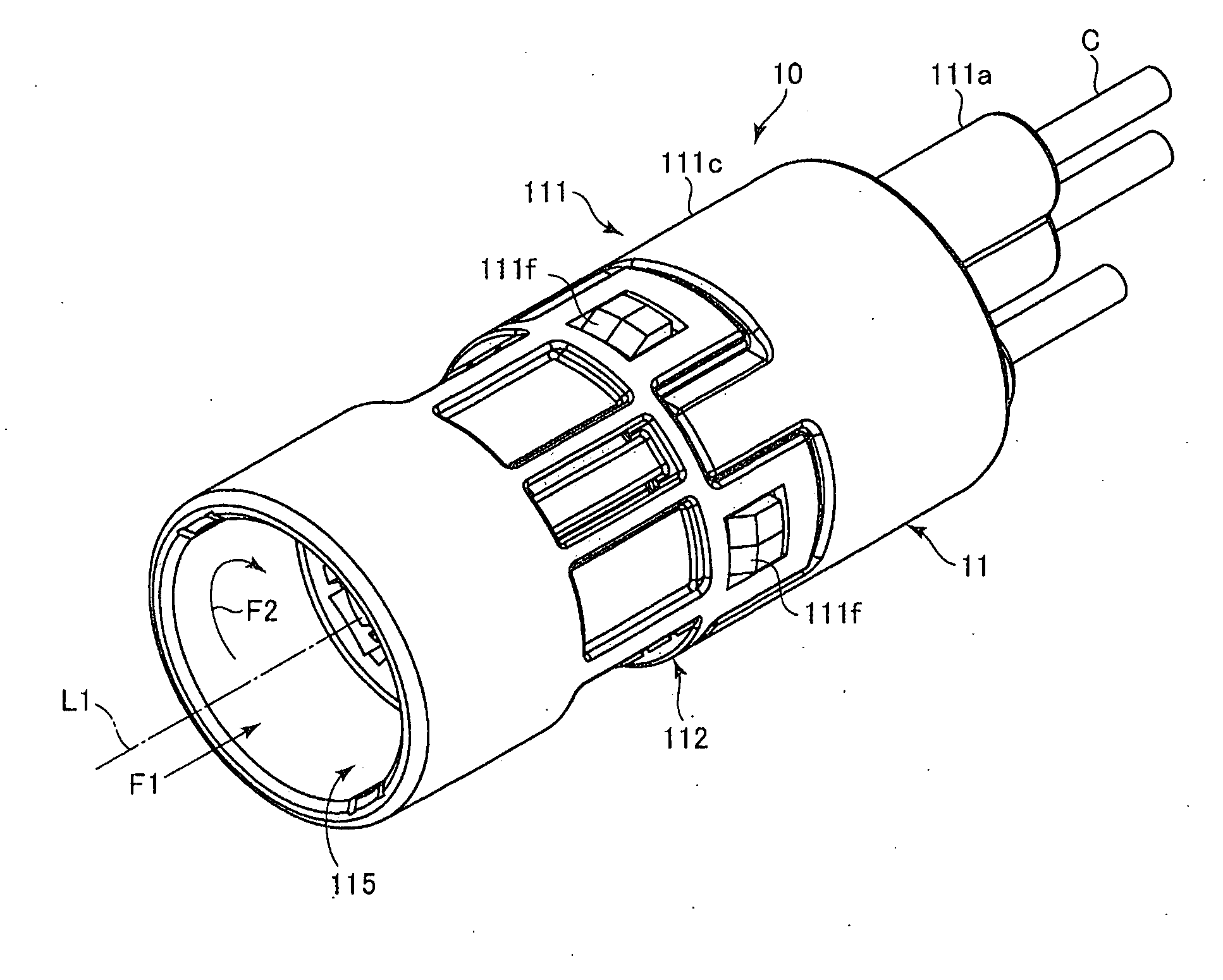

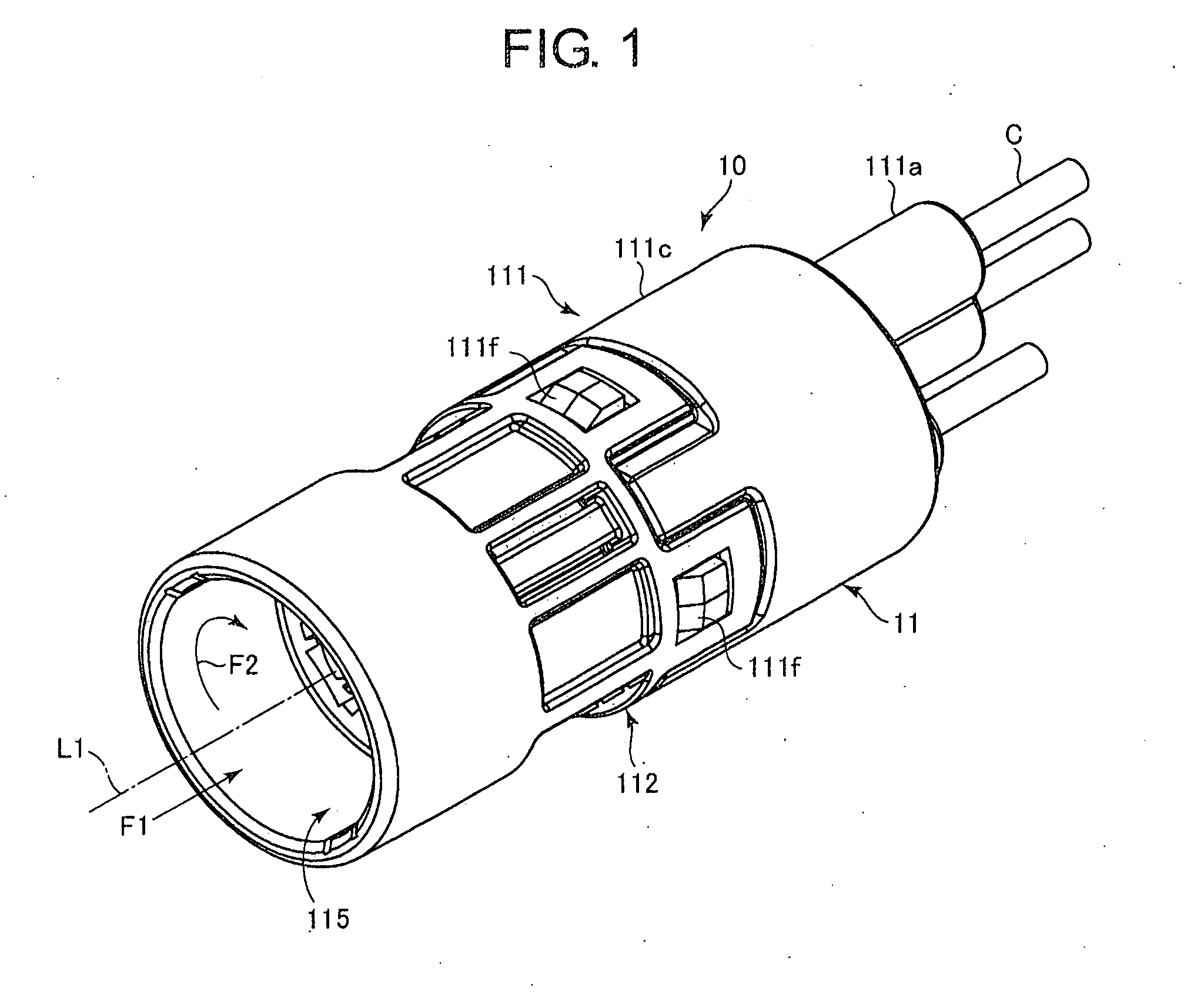

Method for crimping terminal to aluminum electric wire

ActiveUS8245396B2Improve electrical connection reliabilityCoupling device detailsCable junctionsElectricityElectrical conductor

In order to promote the adhesion of a crimp terminal (10) to an aluminum electric wire (100) by virtue of crimping to thereby realize an improvement in electric connecting performance, the thickness of tin plating applied to an inner surface of a conductor crimping portion (13) of the crimp terminal (10) is set to be in the range from 2.1 μm to 5.0 μm, and then, the conductor crimping portion (13) is crimped to a conductor (100a) of the aluminum electric wire (100).

Owner:YAZAKI CORP

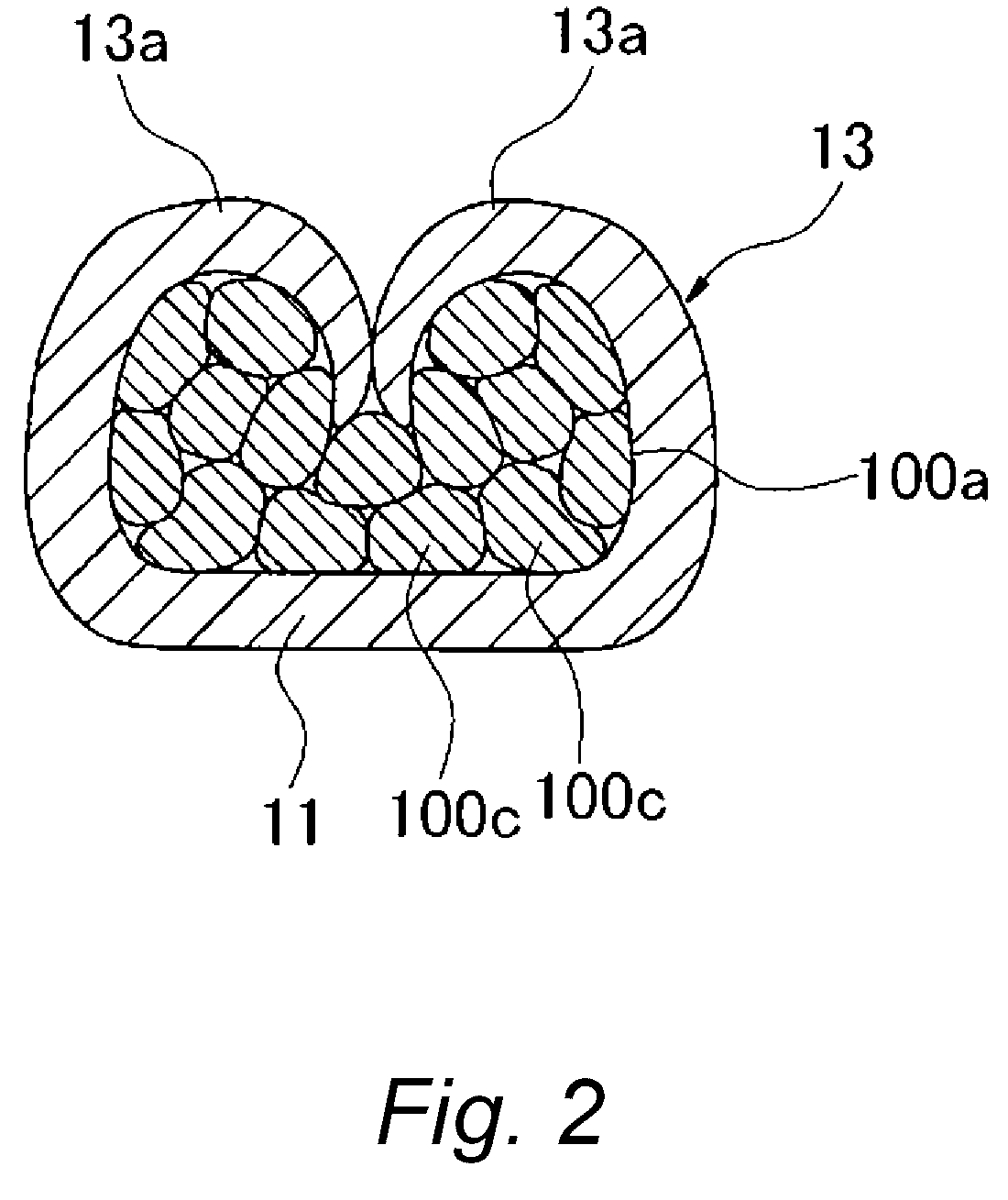

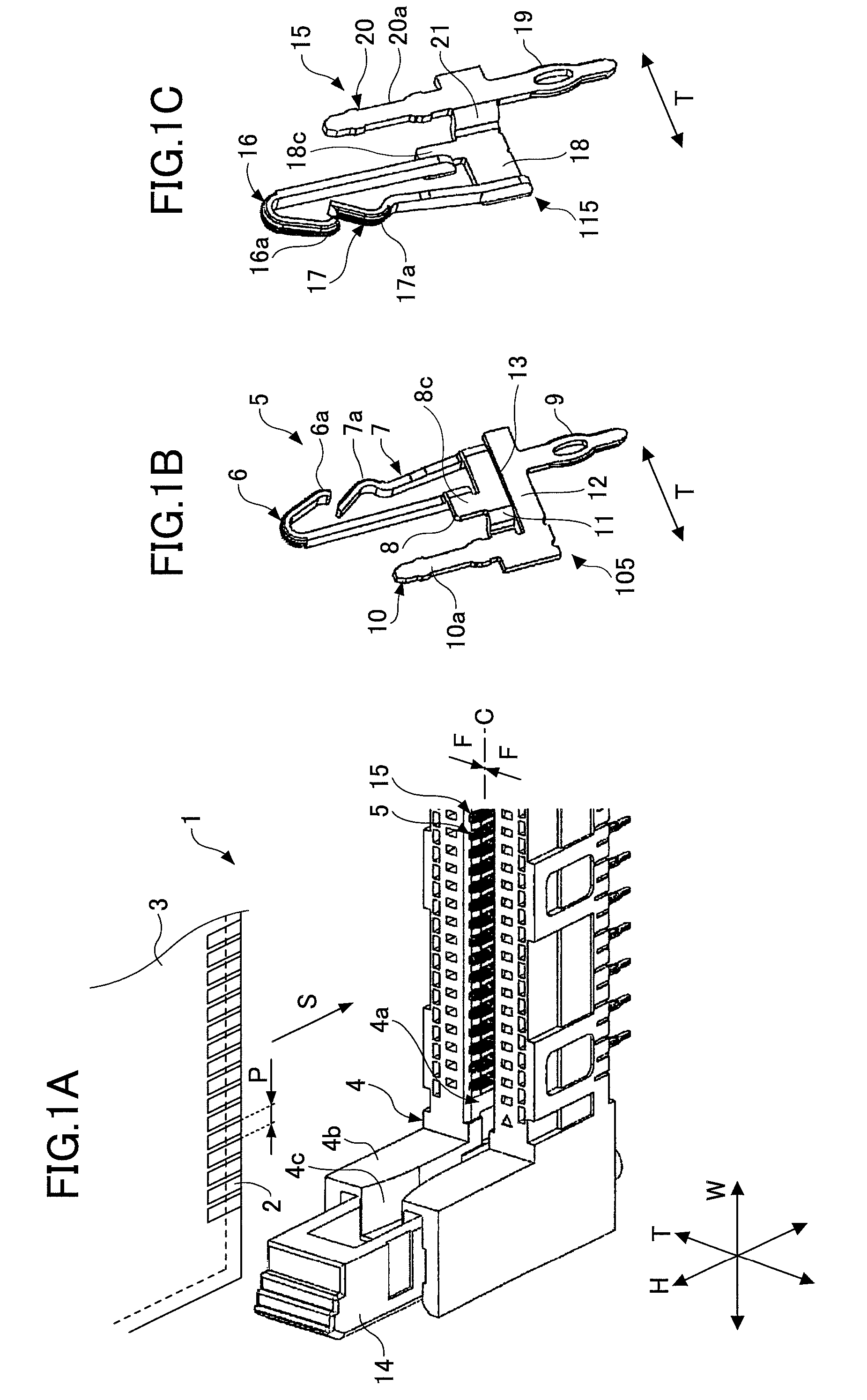

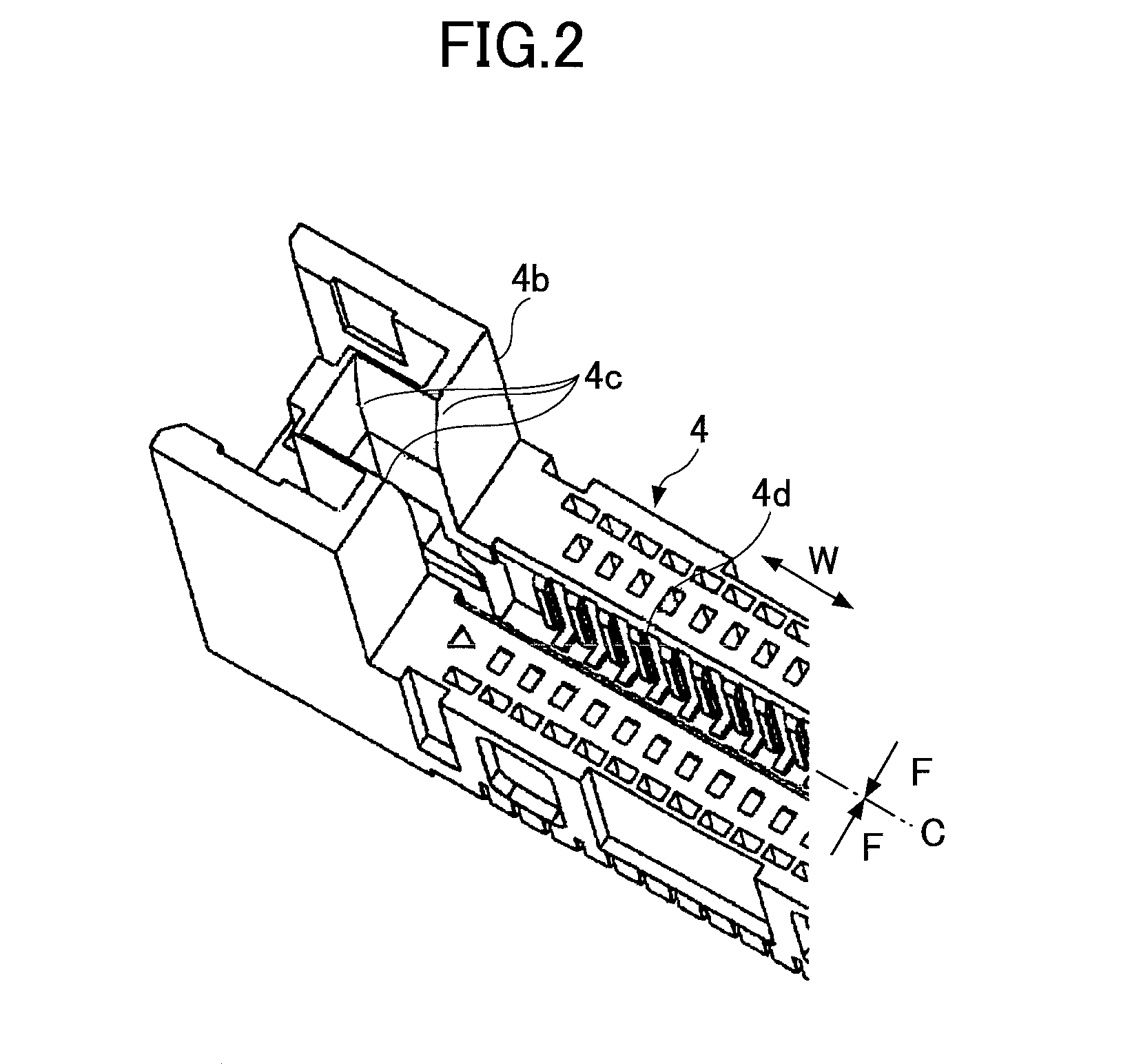

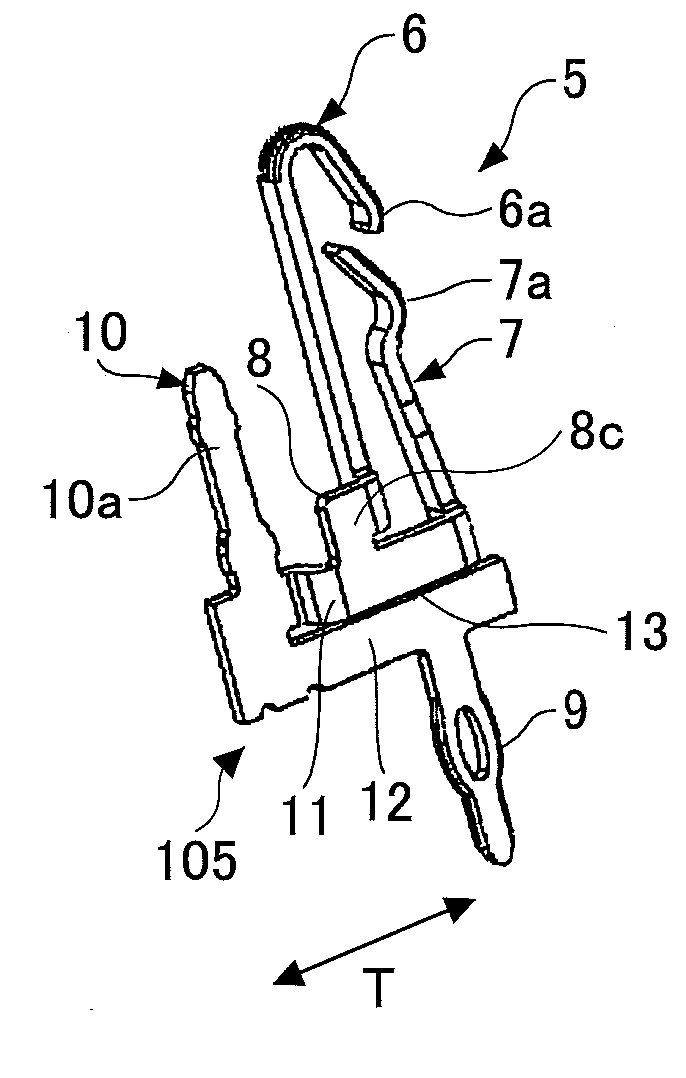

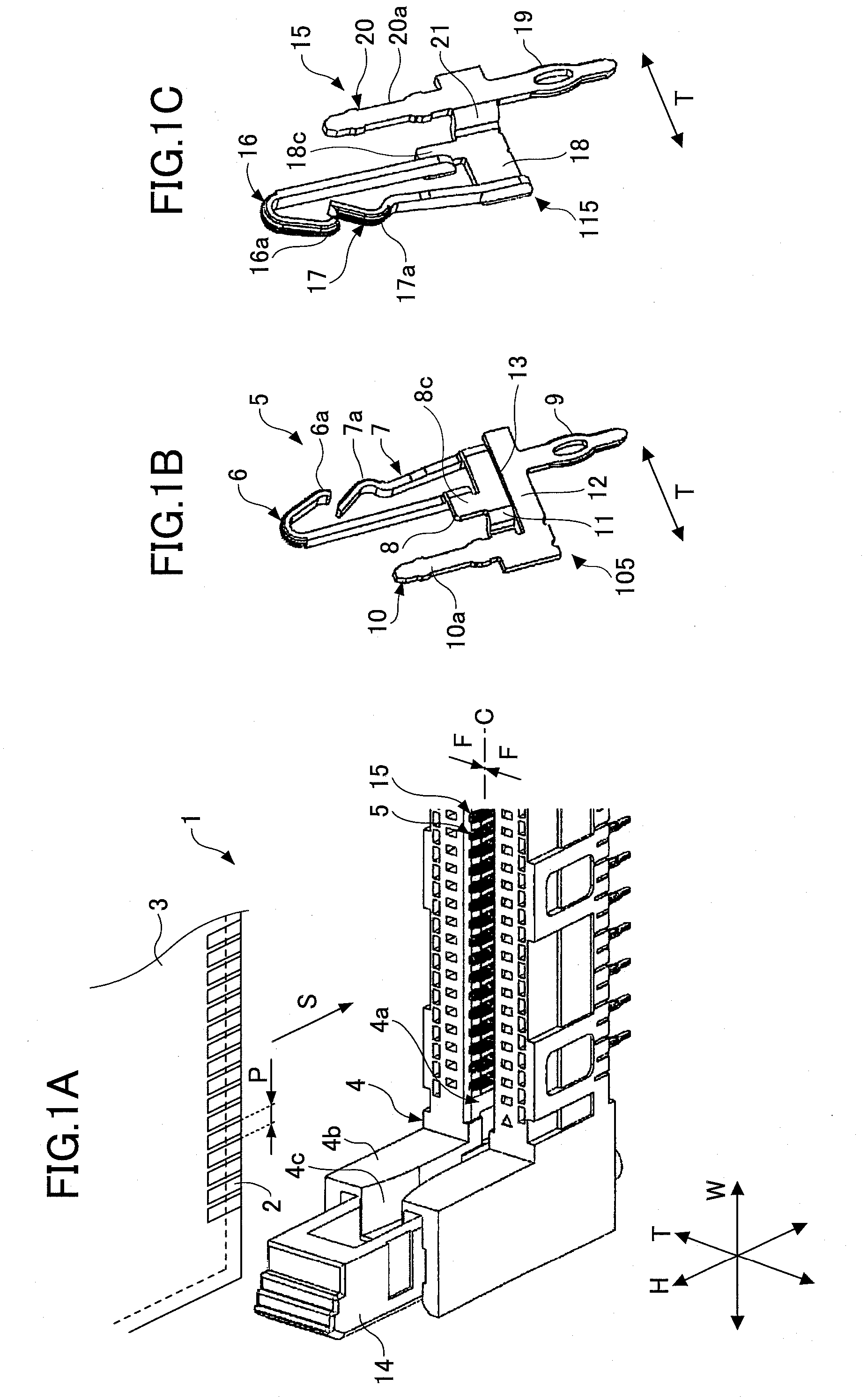

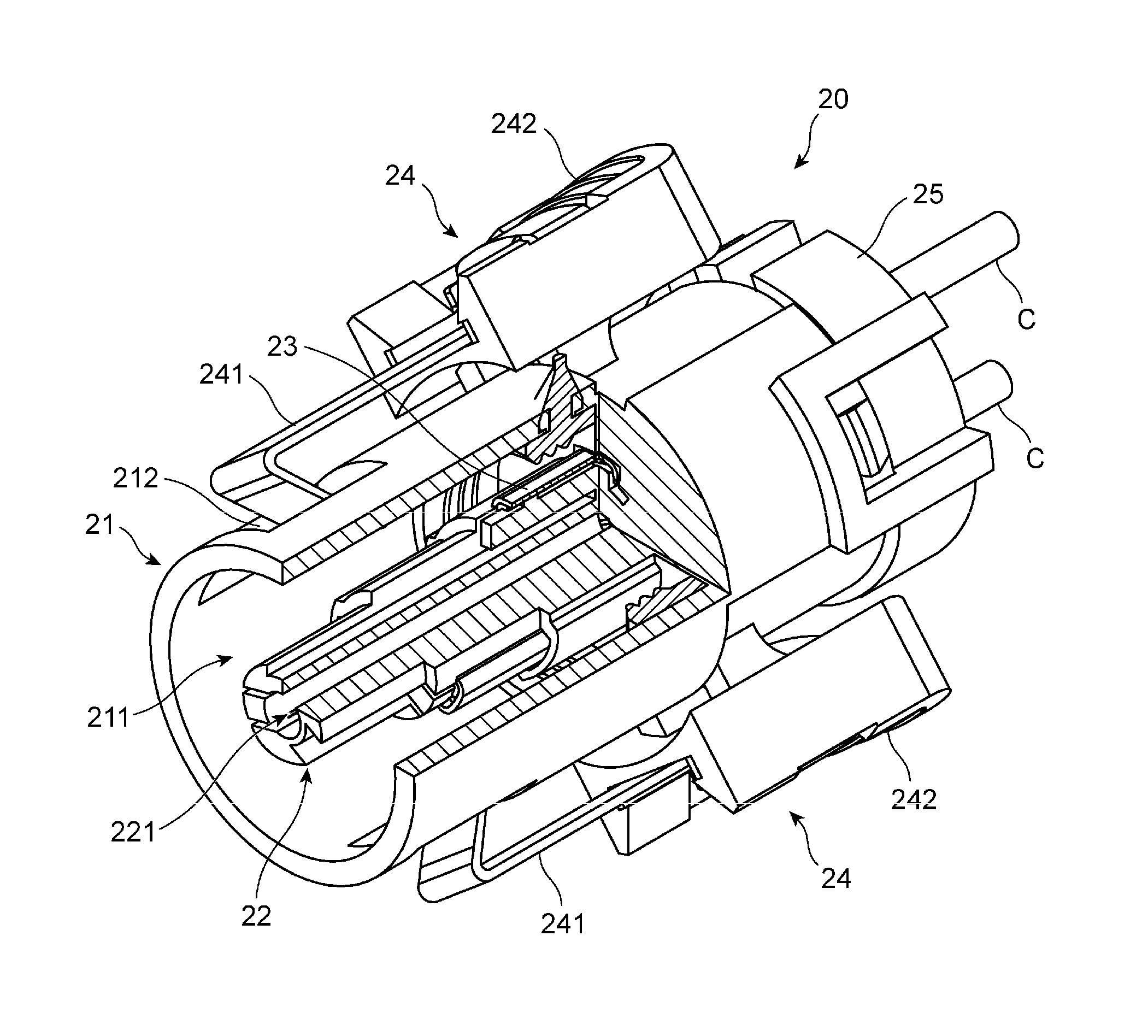

Connector to be electrically connected to connecting target and to substrate

InactiveUS8672713B2Improve electrical connection reliabilityCoupling device detailsTwo-part coupling devicesElectrical and Electronics engineeringEngineering

Owner:FUJITSU COMPONENENT LTD

Connector to be electrically connected to connecting target and to substrate

InactiveUS20120252275A1Improve electrical connection reliabilityCoupling device detailsTwo-part coupling devicesElectrical and Electronics engineering

Owner:FUJITSU COMPONENENT LTD

Thin-film transistor array, method of fabricating the same, and liquid crystal display device including the same

ActiveUS20100320471A1Improve electrical connection reliabilityReduce conductivitySolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A thin-film transistor array includes an electrically insulating substrate, a plurality of thin-film transistors arranged in a matrix on the substrate, and each including a channel, a source, and a drain each comprised of an oxide-semiconductor film, a pixel electrode integrally formed with the drain, a source signal line through which a source signal is transmitted to a group of thin-film transistors, a gate signal line through which a gate signal is transmitted to a group of thin-film transistors, a source terminal formed at an end of the source signal line, and a gate terminal formed at an end of the gate signal line. The source terminal and the gate terminal are formed in the same layer as a layer in which the channel is formed. The source terminal and the gate terminal have the same electric conductivity as that of the pixel electrode.

Owner:NEC LCD TECH CORP

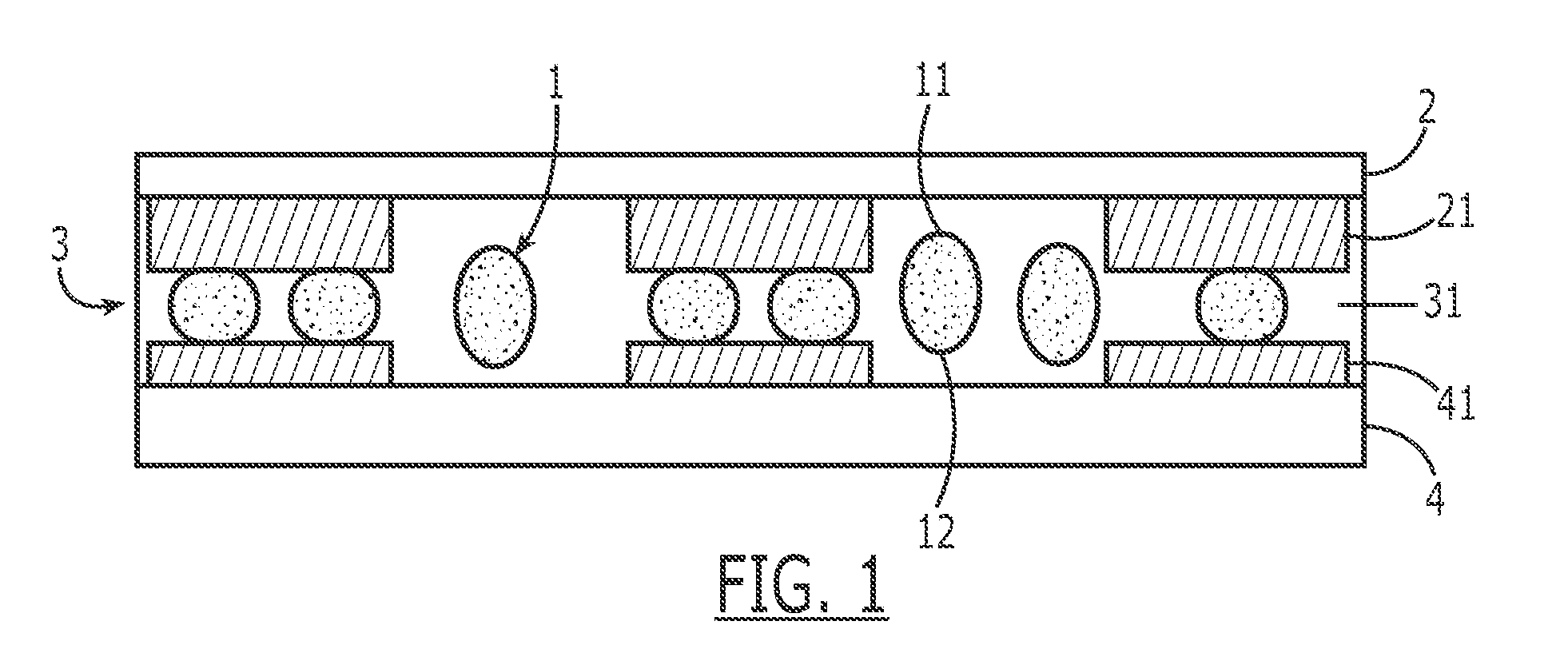

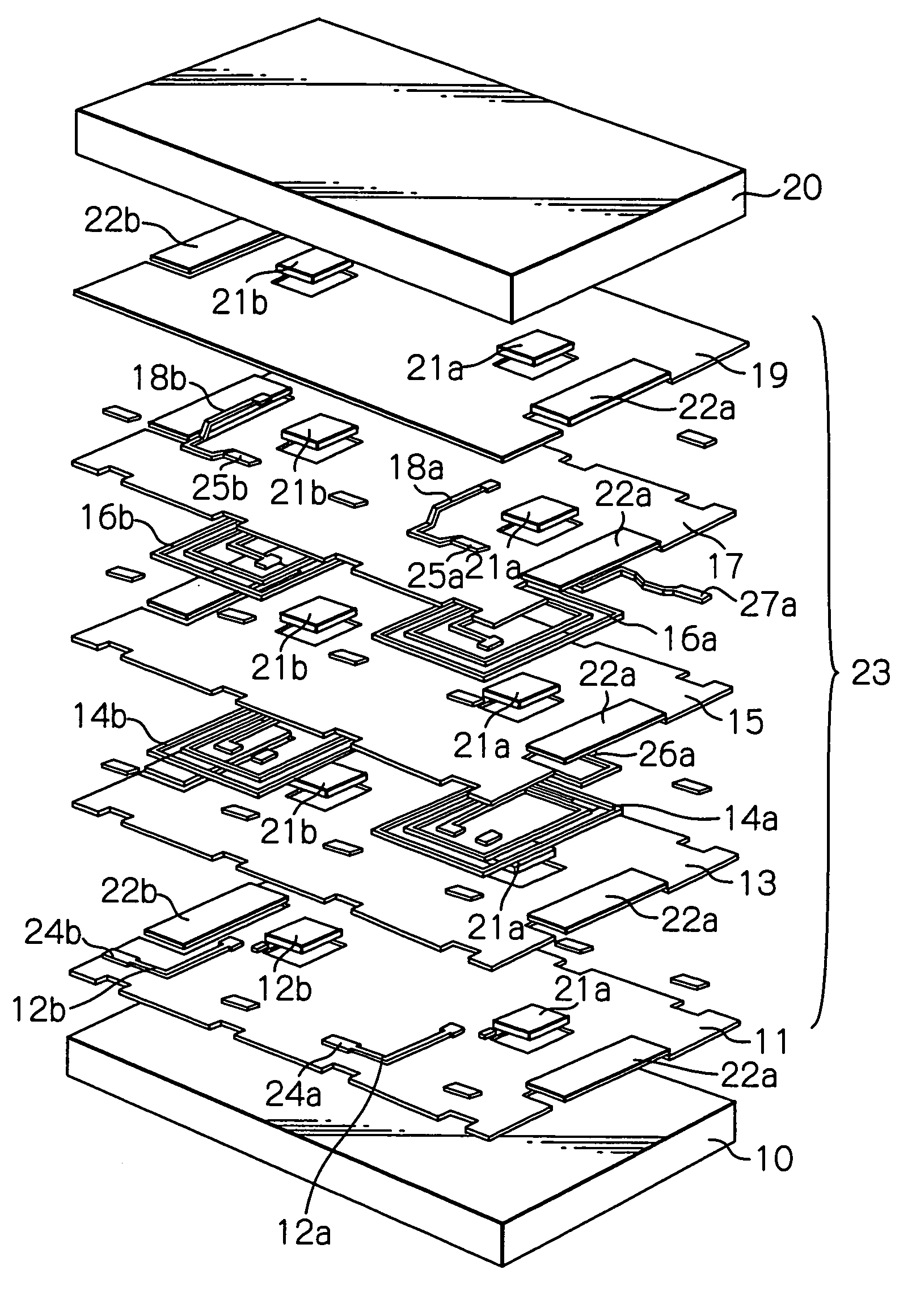

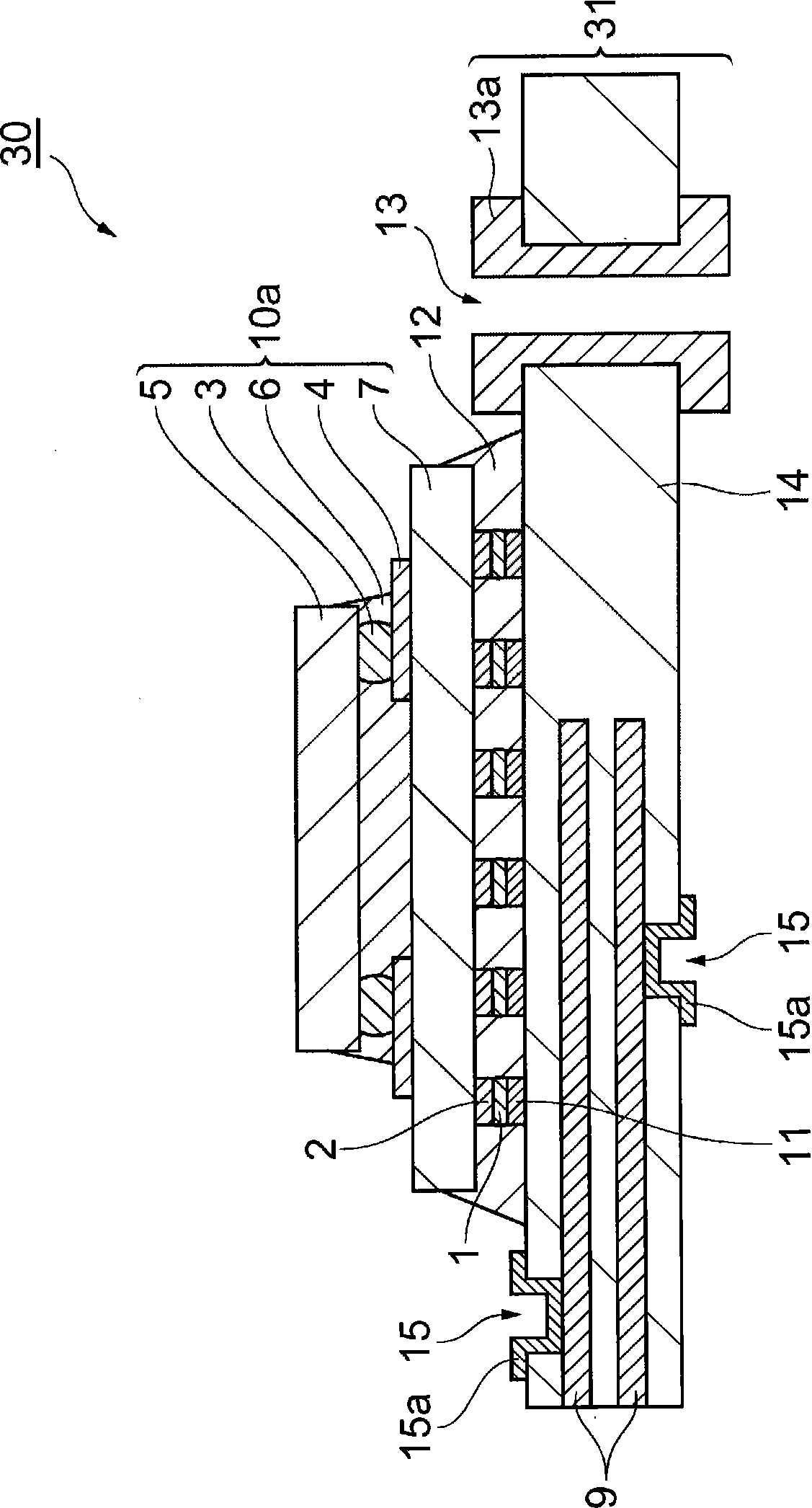

Laminated wiring board and manufacturing method for same

ActiveUS20130118791A1Improve electrical reliabilityAvoid displacementPrinted circuit assemblingPrinted electric component incorporationElectrical conductorElectronic component

A laminated wiring board, includes: a first substrate in which a conductor circuit is formed on one surface of an insulating layer and an adhesive layer is formed on an other surface of the insulating layer, and conductors are formed in via holes that pass through the insulating layer and the adhesive layer so that the conductor circuit is partially exposed therefrom; an electronic component electrically connected to the conductor circuit by allowing electrodes of the electronic component to be connected to the conductors; an embedding member arranged around the electronic components so that the electronic component is embedded therein; and a second substrate having an adhesive layer laminated to face the adhesive layer of the first substrate and sandwich the electronic component and the embedding member, wherein each of the electrodes of the electronic component is continuous with the conductor circuit through two or more of the conductors.

Owner:THE FUJIKURA CABLE WORKS LTD

Method for crimping terminal to aluminum electric wire

ActiveUS20110225820A1Improve electrical connection reliabilityCoupling device detailsConnection formation by deformationAluminiumEngineering

In order to promote the adhesion of a crimp terminal (10) to an aluminum electric wire (100) by virtue of crimping to thereby realize an improvement in electric connecting performance, the thickness of tin plating applied to an inner surface of a conductor crimping portion (13) of the crimp terminal (10) is set to be in the range from 2.1 μm to 5.0 μm, and then, the conductor crimping portion (13) is crimped to a conductor (100a) of the aluminum electric wire (100).

Owner:YAZAKI CORP

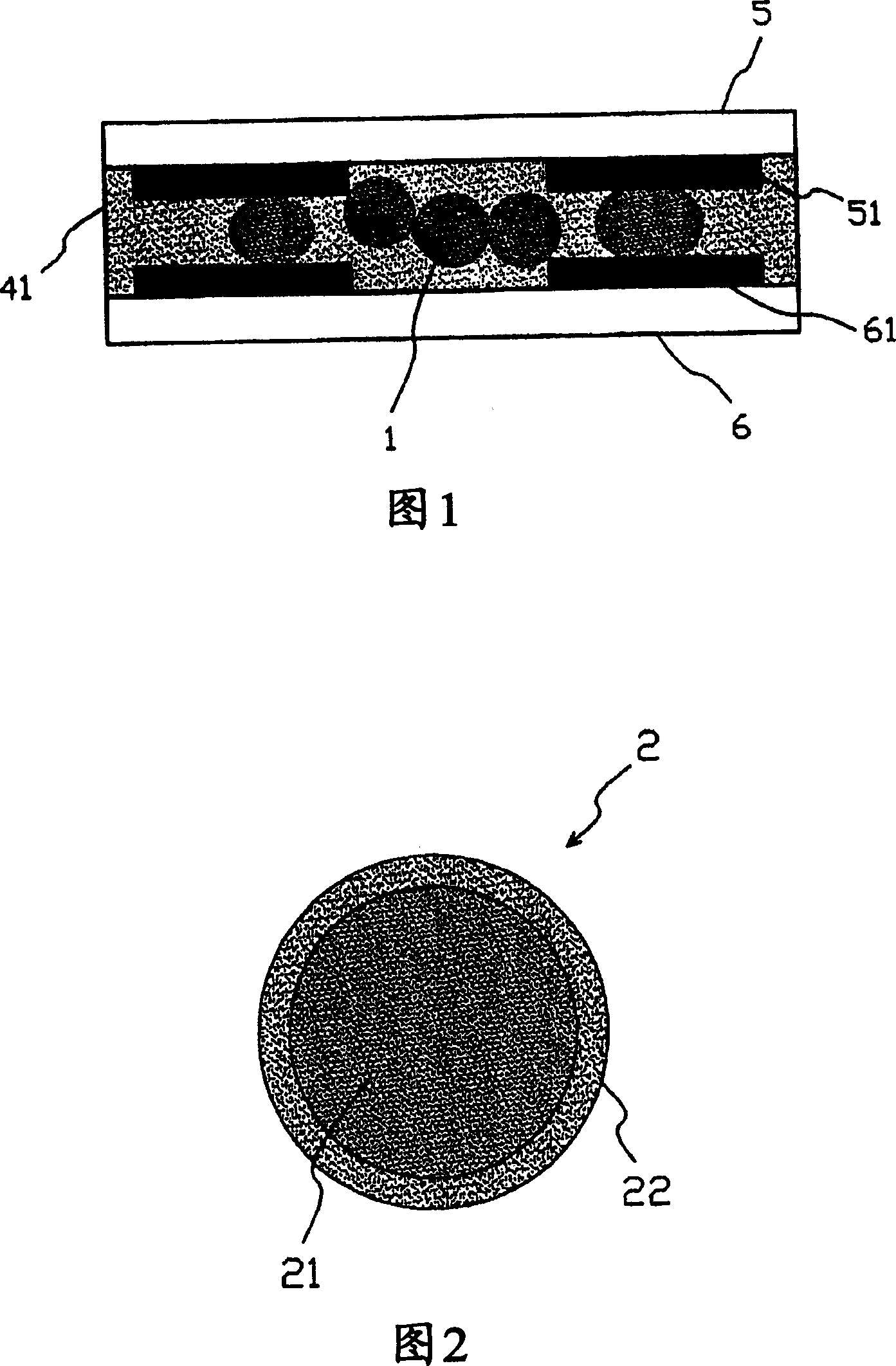

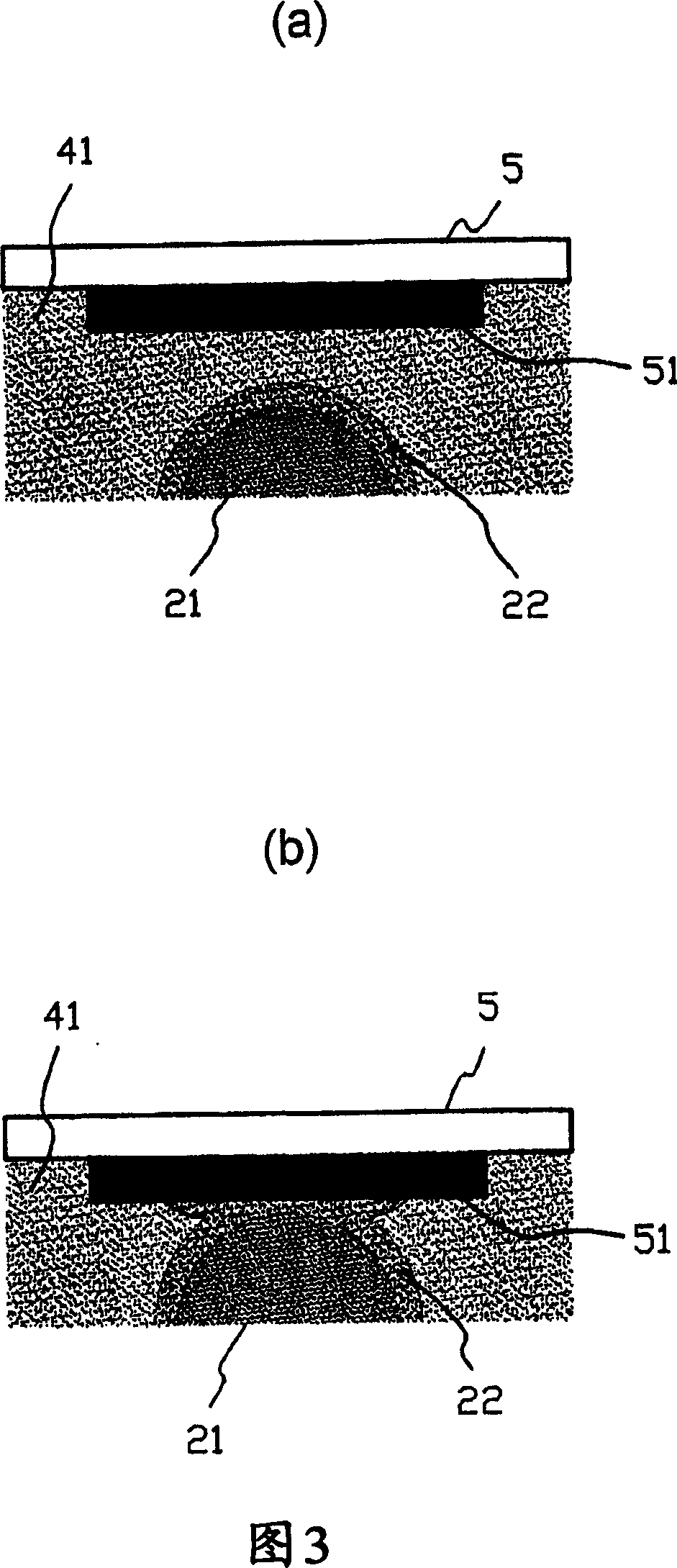

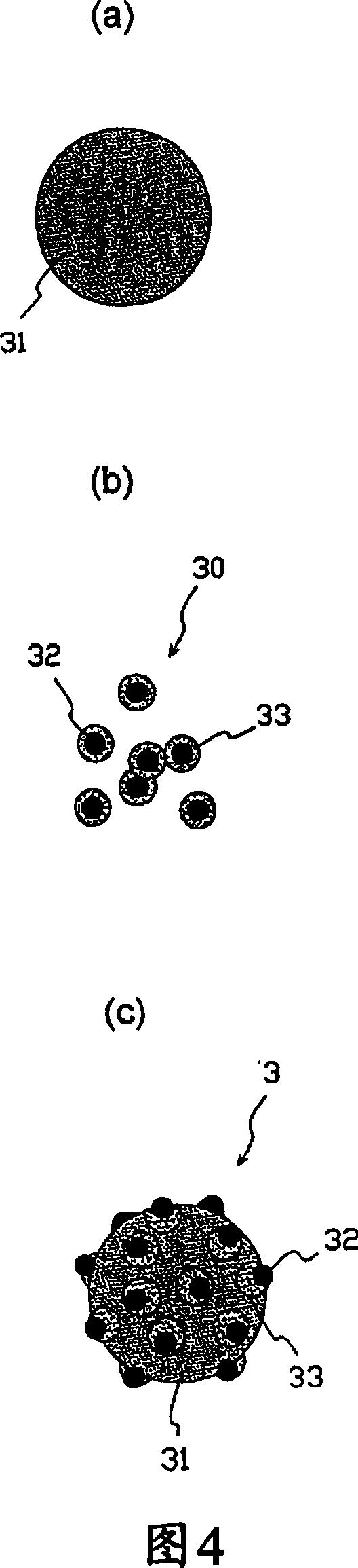

Polymer Particles, Conductive Particles, and an Anisotropic Conductive Packaging Materials Containing the Same

ActiveUS20070252112A1Improve conductivityIncrease contact areaLiquid surface applicatorsConductive materialAnisotropic conductive adhesiveOptoelectronics

Disclosed herein are anisotropic conductive particles contained in anisotropic conductive adhesive films which can be used in circuit board mounting applications. The conductive particles have a uniform shape, a narrow particle diameter distribution, and appropriate compressive de-formability and recoverability from deformation. In addition, the conductive particles exhibit enhanced conducting properties without being ruptured when interposed and compressed between connection substrates, thereby achieving a sufficient contact area between the particles and the connection substrates. Further disclosed are polymer-based particles used in the conductive particles.

Owner:KUKDO ADVANCED MATERIALS CO LTD

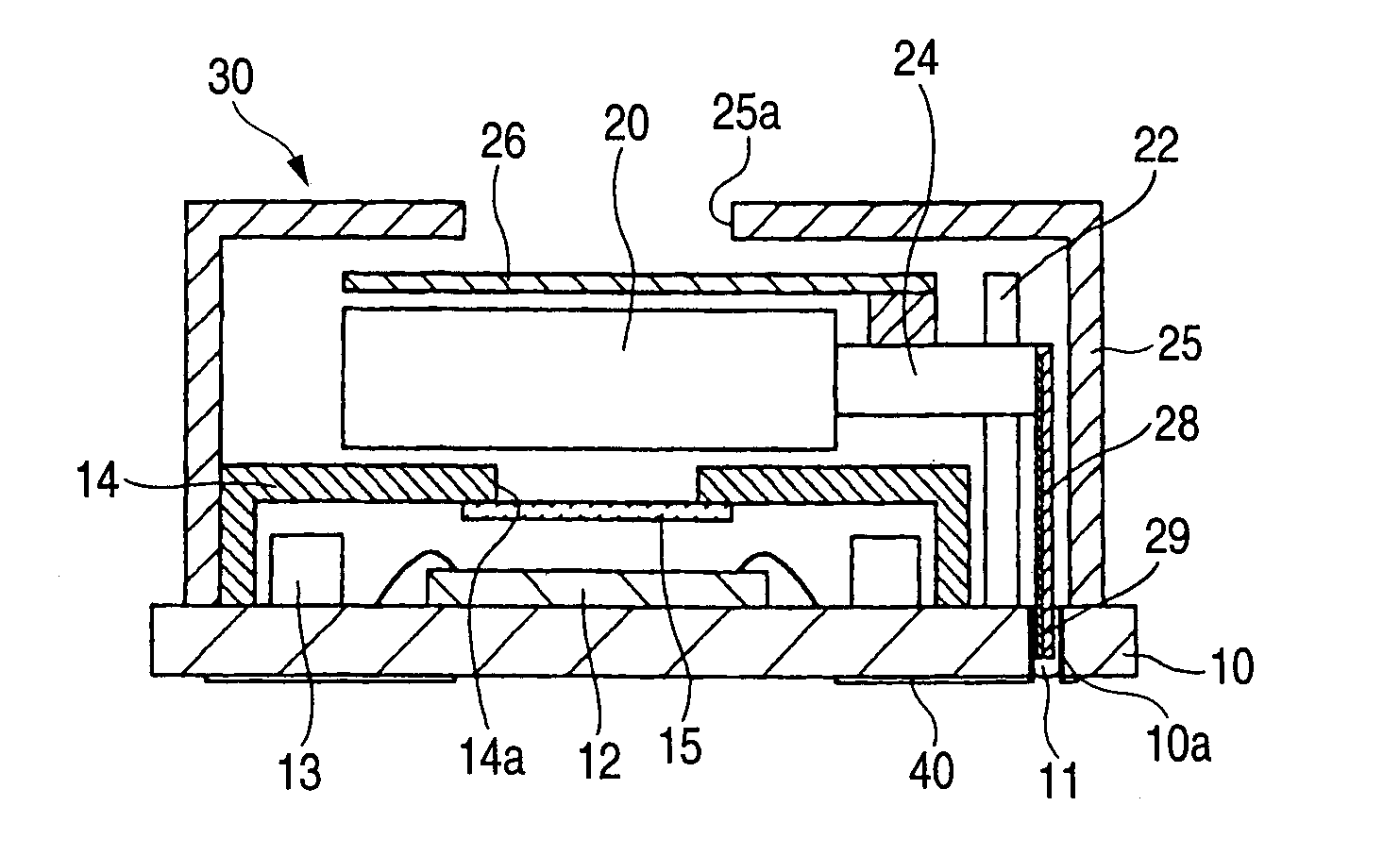

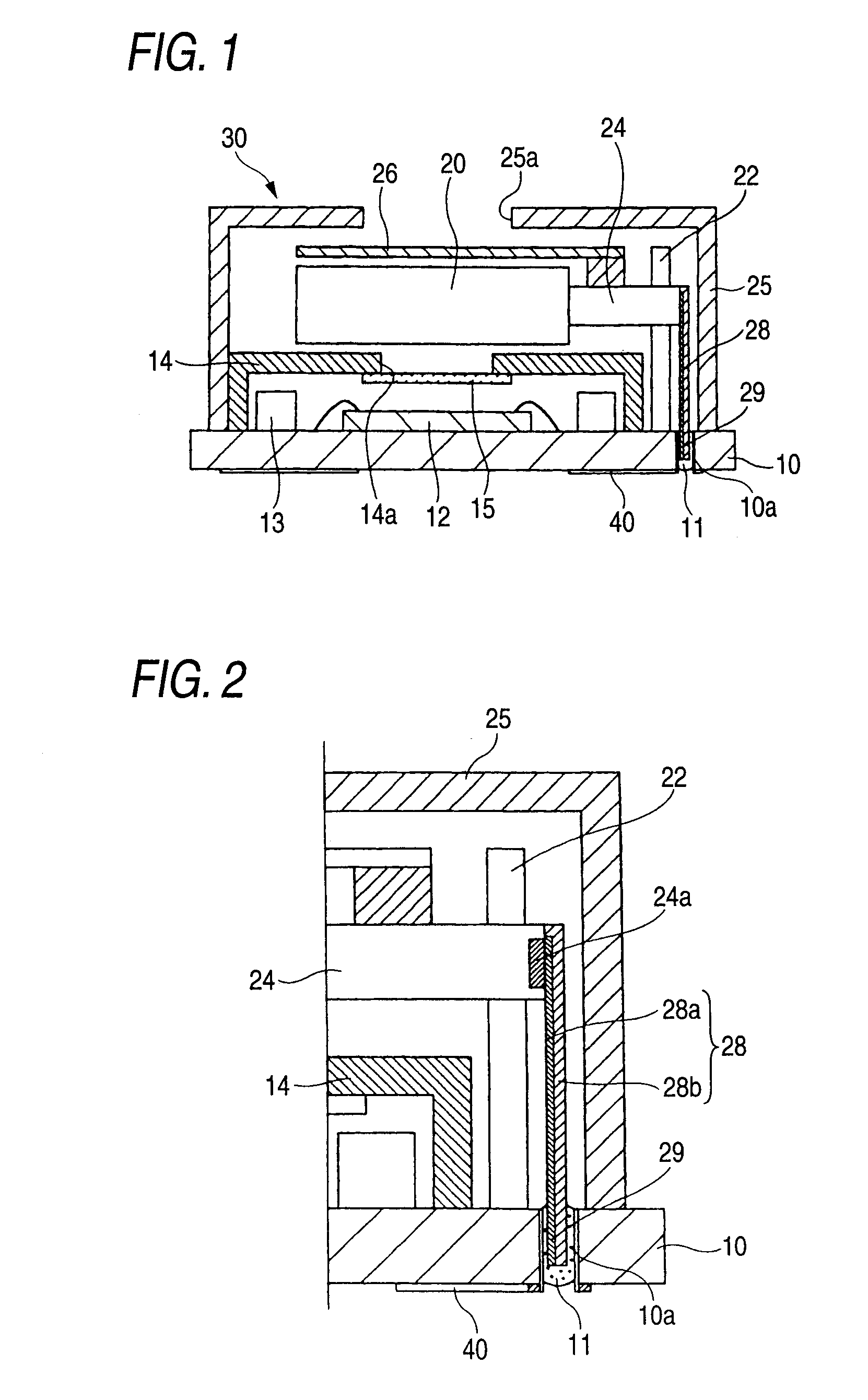

Battery fuse-containing box

ActiveUS6948982B2Improve reliabilityLimit in space utilizationCoupling device detailsCasings/cabinets/drawers detailsBattery terminalPolypropylene

A fuse-containing box is formed by placing a battery fuse and a bus bar connected to a terminal of the battery fuse on a supporting plate and by mounting a lower case and an upper case on the supporting plate. The fuse-containing box is mounted on an upper surface of a battery. A battery terminal to be fixedly fitted on a battery post projecting from the upper surface of the battery is fastened to the bus bar to electrically connect the battery fuse and the battery to each other. The lower case and the upper case are formed from a polypropylene-based resin. The supporting plate on which the battery fuse and the bus bar are mounted is formed from a heat-resistant nylon-based resin.

Owner:SUMITOMO WIRING SYST LTD

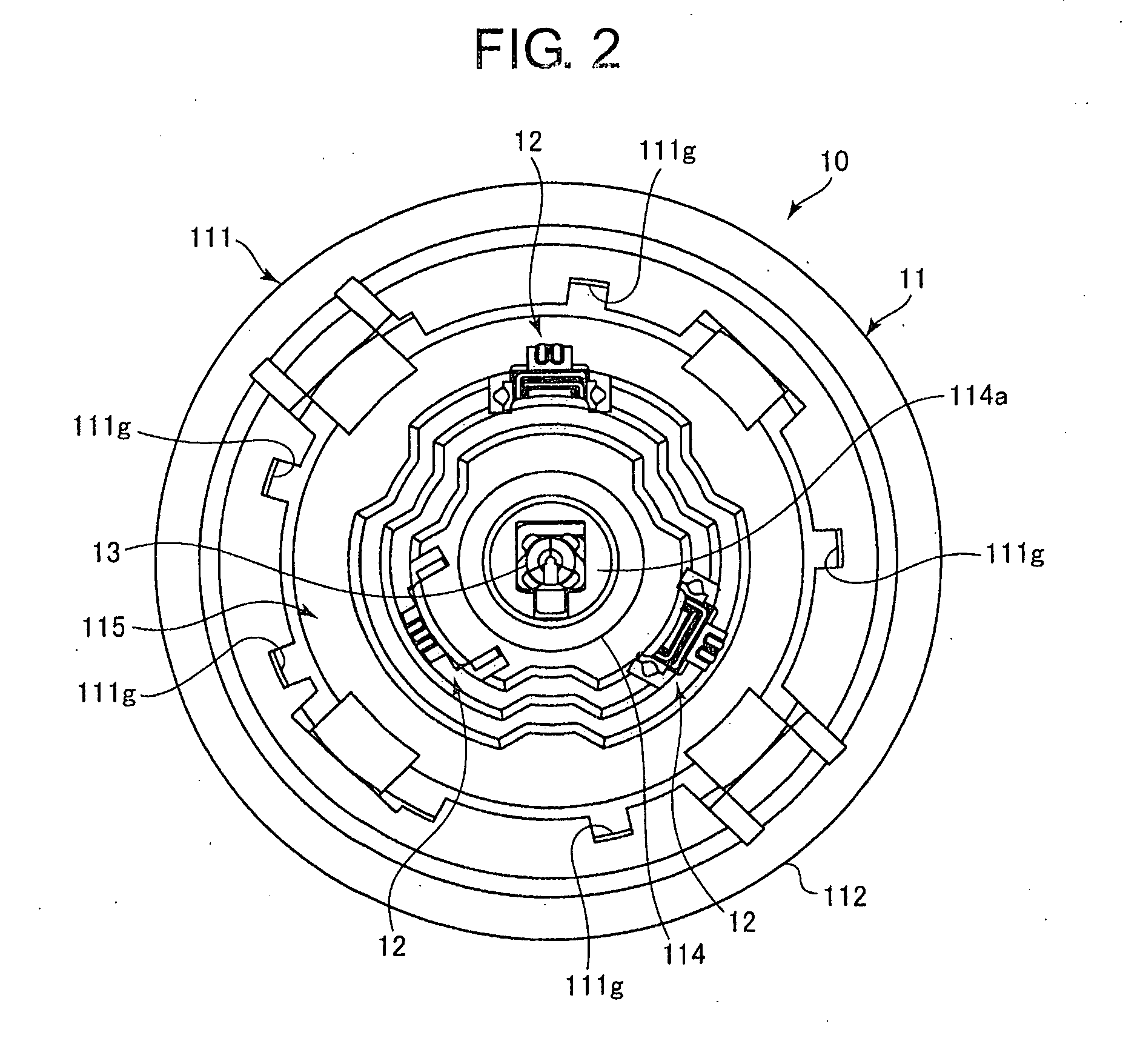

Camera module

InactiveUS20060239671A1Improve efficiencyEasy to implementTelevision system detailsProjector focusing arrangementCamera moduleComputer science

A camera module is provided wherein an image pickup device, a camera optical system and a driver, for aligning and focusing the camera optical system, are mounted on a board; wherein a connection terminal, to be electrically connected to the driver, is formed on a mounting face of the board; and wherein the connection terminal formed on the board is connected to the driver via a flexible wiring board.

Owner:SHINKO ELECTRIC IND CO LTD

Electric connector

InactiveUS20150099391A1Proof stress is improvedImprove electrical connection reliabilityIncorrect coupling preventionTwo-part coupling devicesMechanical engineeringContact plane

An electric connector includes a first housing including a guide shaft and a second housing including a guide hole into which the guide shaft is inserted, the guide shaft including a main body, and a projection radially projecting from the main body, the guide hole being formed at an inner surface thereof with a groove into which the projection is fit, the projection and the groove being formed such that a first imaginary line intersects with a second imaginary line, the first imaginary line being defined by extending a contact plane at which the projection and the groove make contact with each other when the first housing rotates relative to the second housing, towards a center of the main body, the second imaginary line being defined as a line bisecting a top surface of the projection and extending towards a center of the main body.

Owner:DAIICHI SEIKO CO LTD

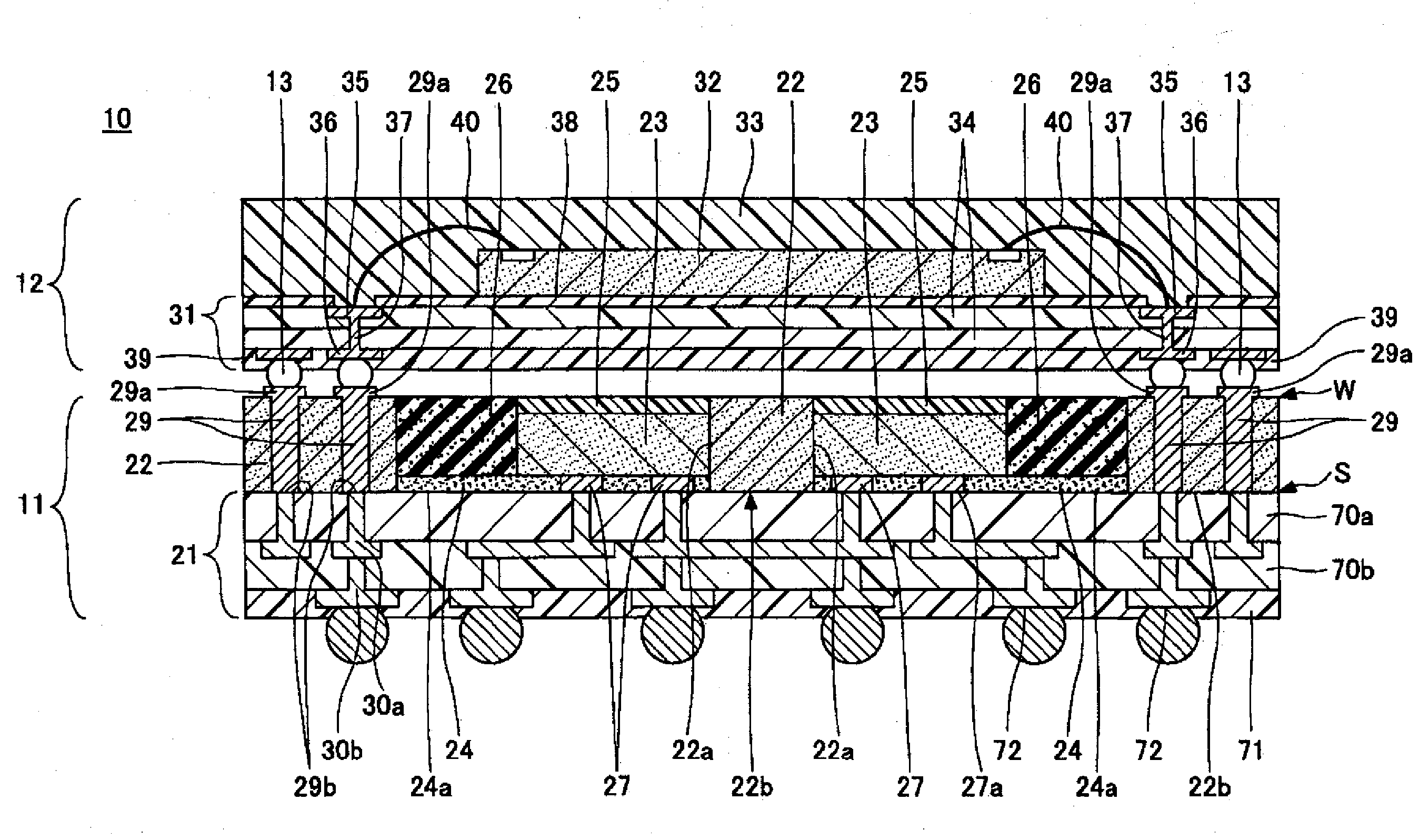

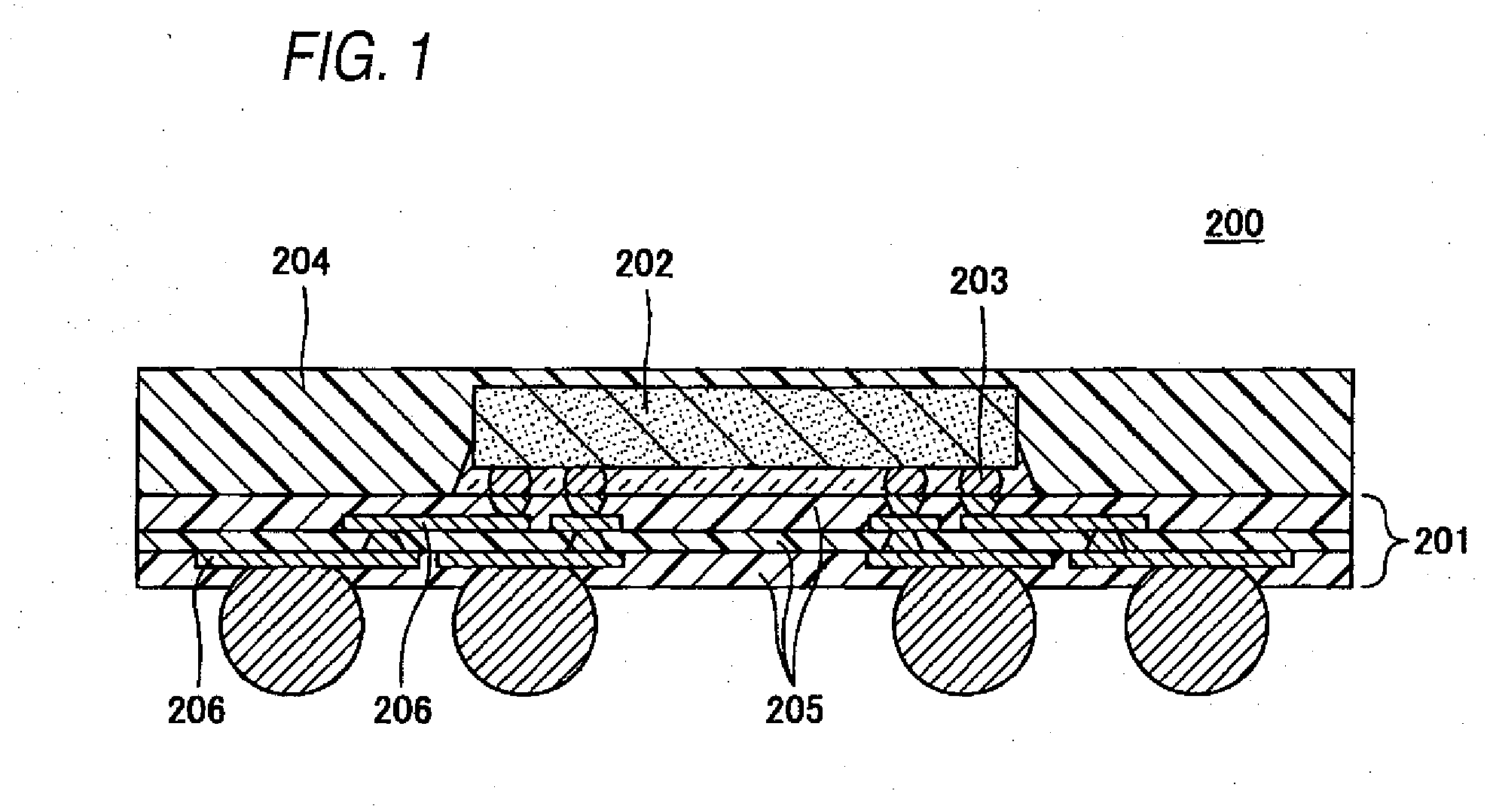

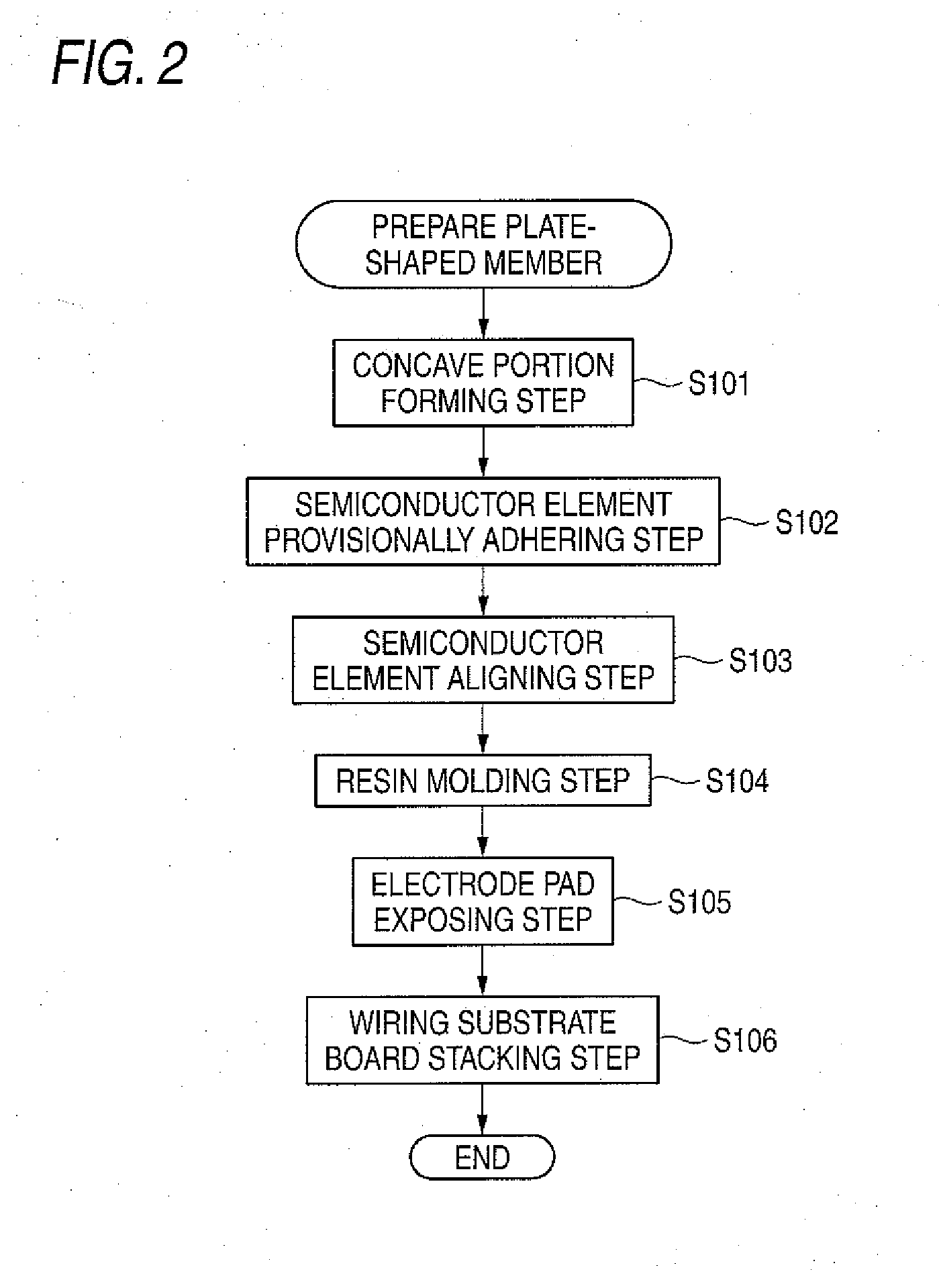

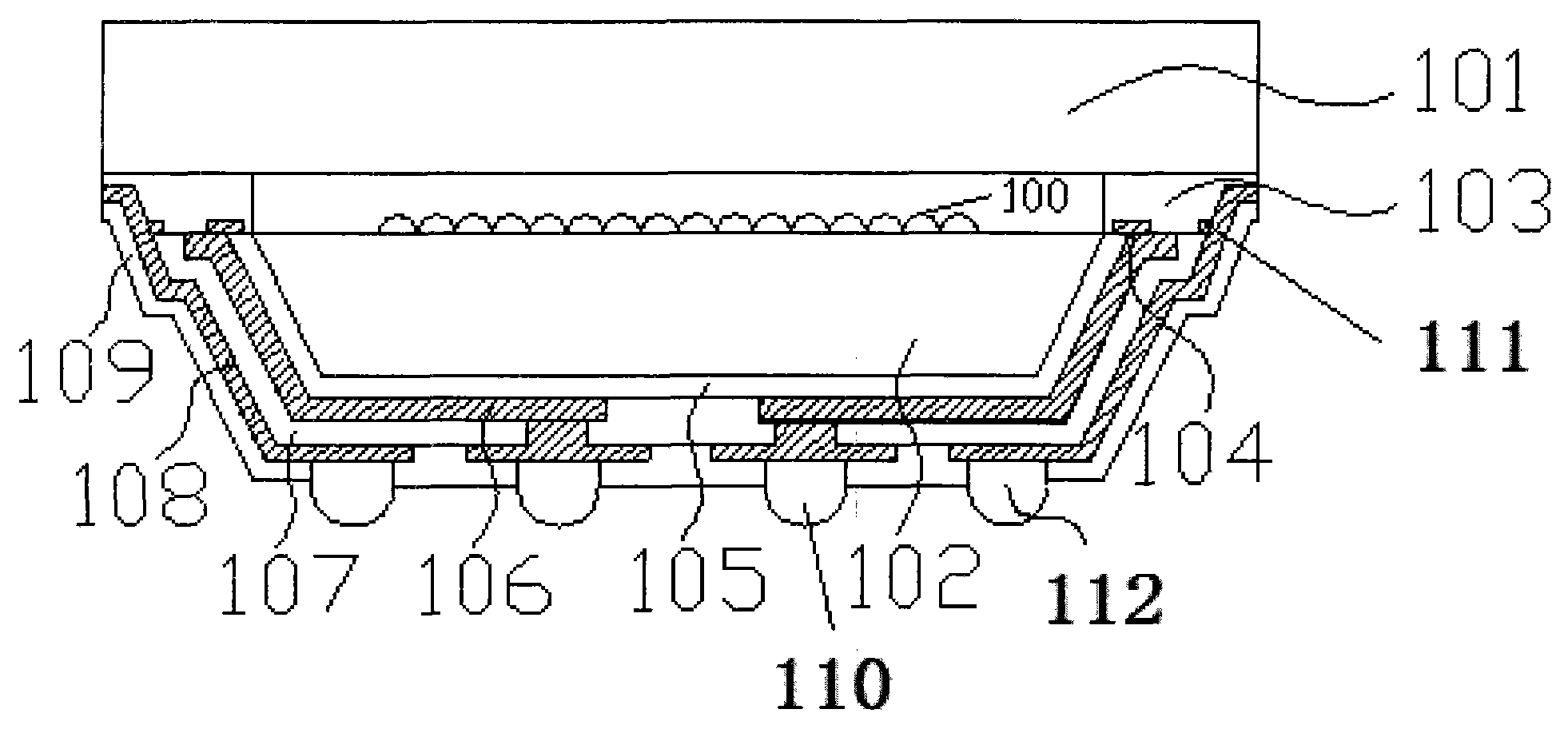

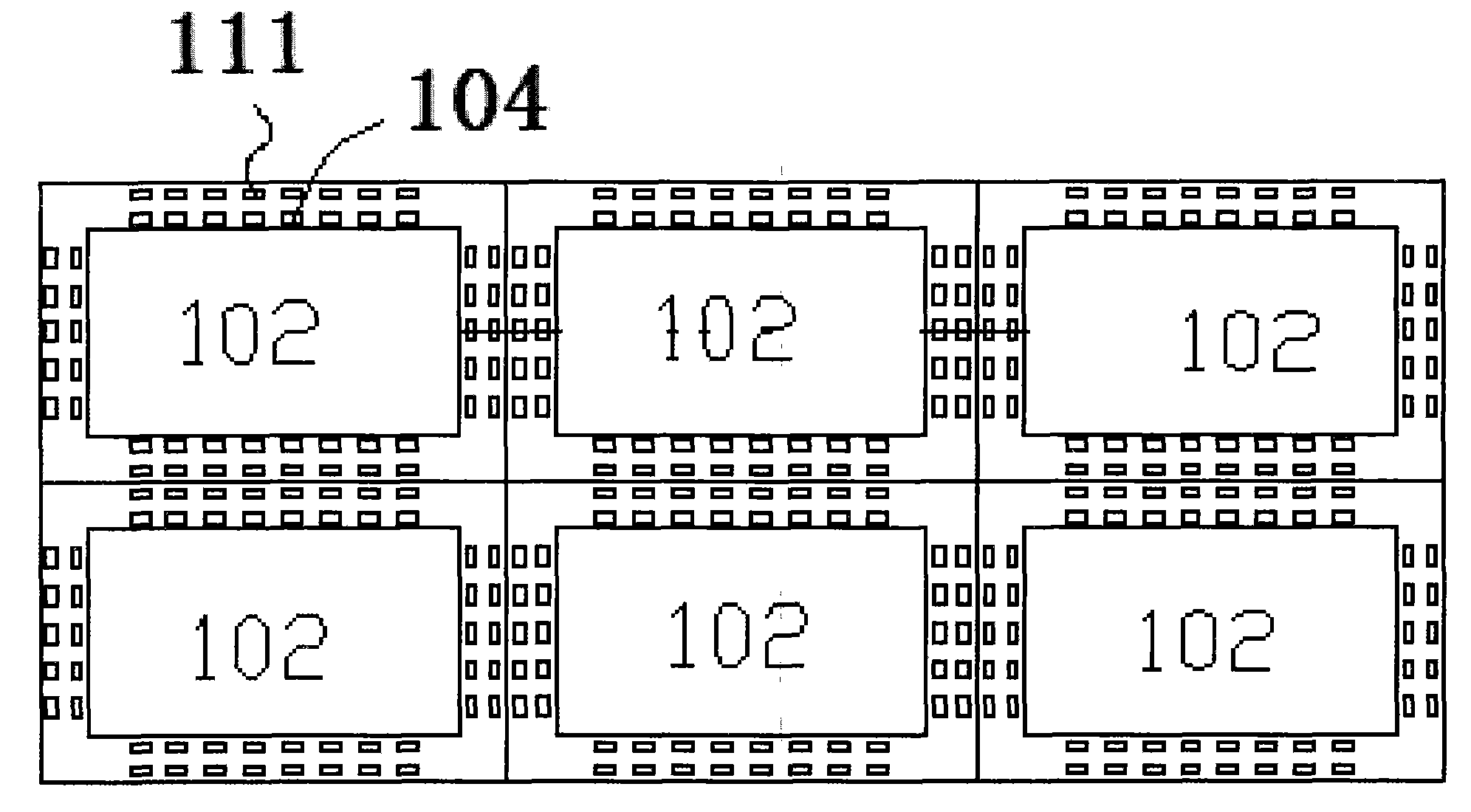

Manufacturing method of semiconductor device, semiconductor device, and electronic device

InactiveUS20100225001A1Improve electric connection reliabilityImprove electrical connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesGround planeEngineering

In a method for manufacturing a semiconductor device having a plate-shaped member, a semiconductor element, and a wiring board, the manufacturing method for the semiconductor device includes: a concave portion forming step (S101) of the plate-shaped member; a semiconductor element provisionally adhering step (S102) for provisionally adhering the semiconductor element to a portion located in the vicinity of a first corner portion of a concave portion; a semiconductor element aligning step (S103) for aligning the semiconductor element based upon thermal expansion of a semiconductor element depressing member; a resin molding step (S104) of the plate-shaped member; an electrode pad exposing step (S105) for exposing an electrode pad by grinding the plate-shaped member; and a wiring board stacking step (S106) for stacking layers by directly connecting the exposed electrode pad to the wiring layer on the ground plane of the plate-shaped member.

Owner:SHINKO ELECTRIC IND CO LTD

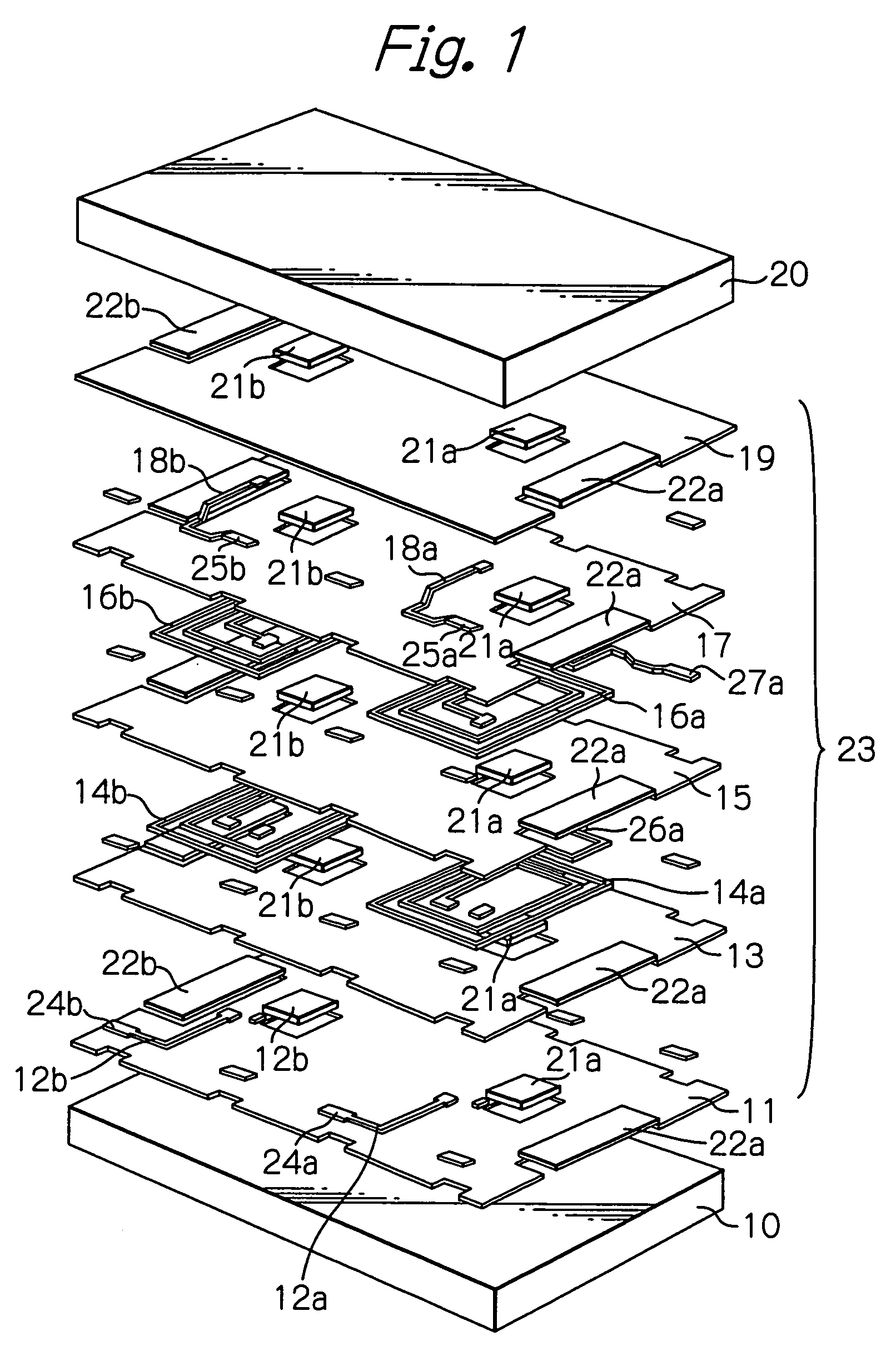

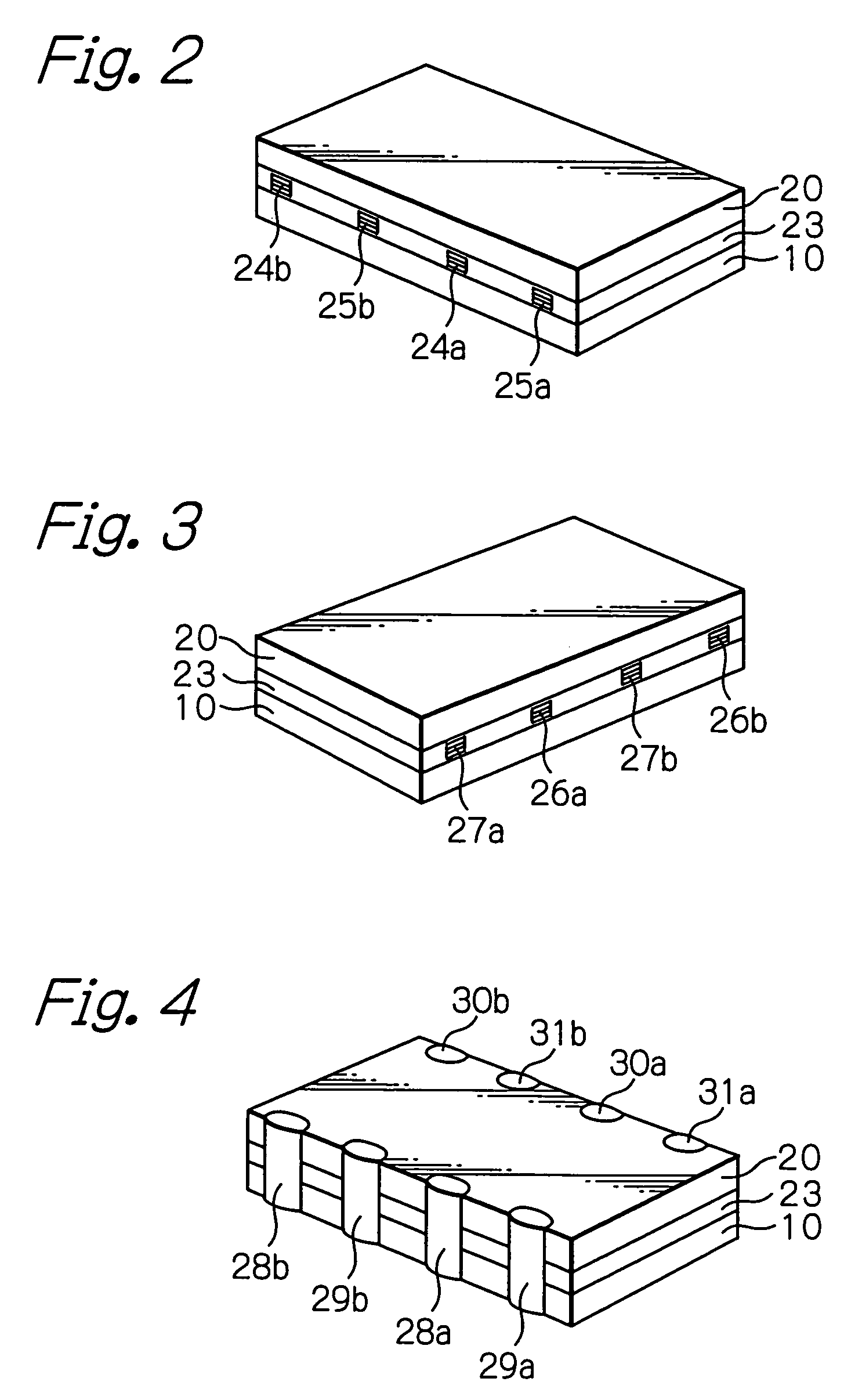

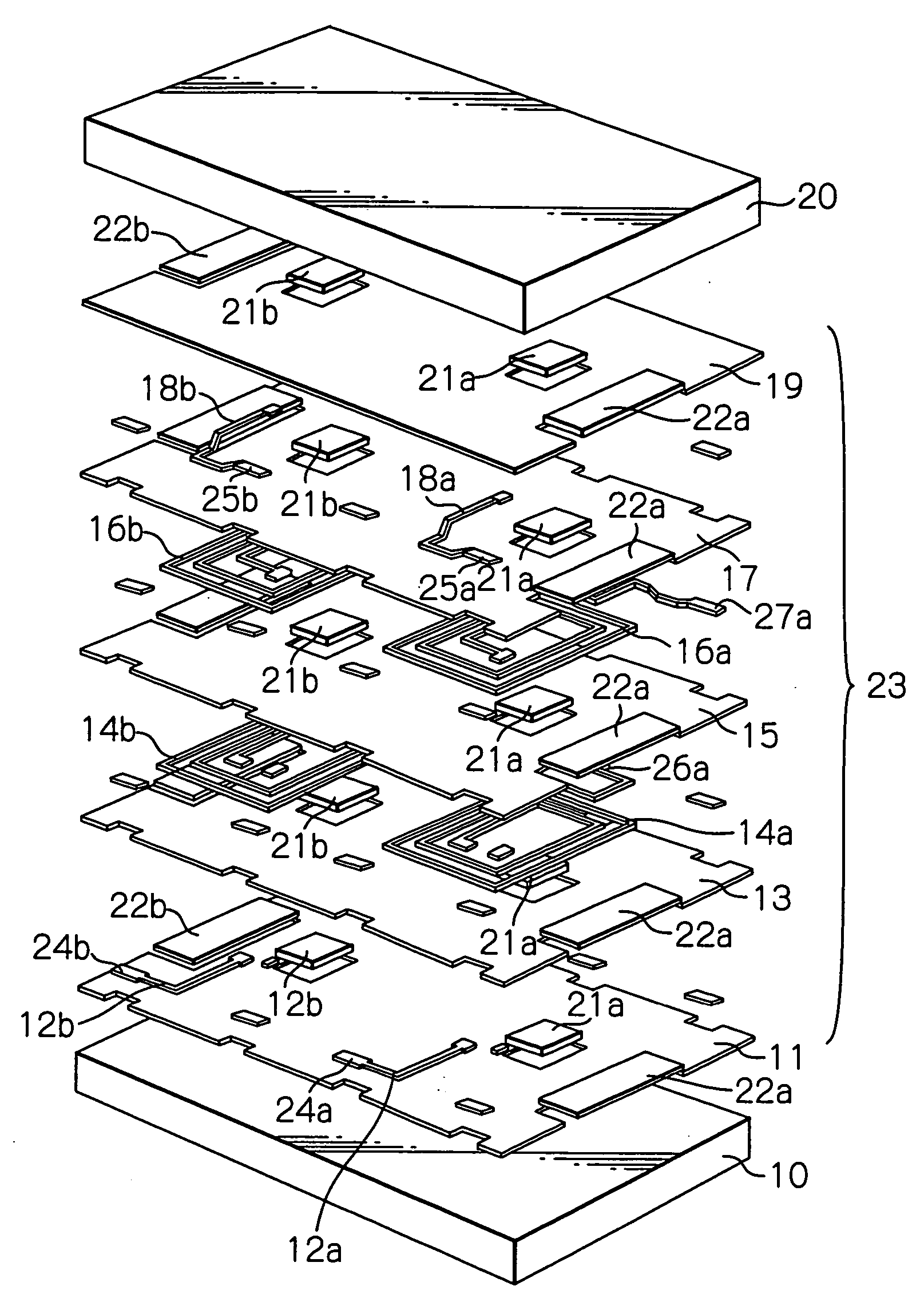

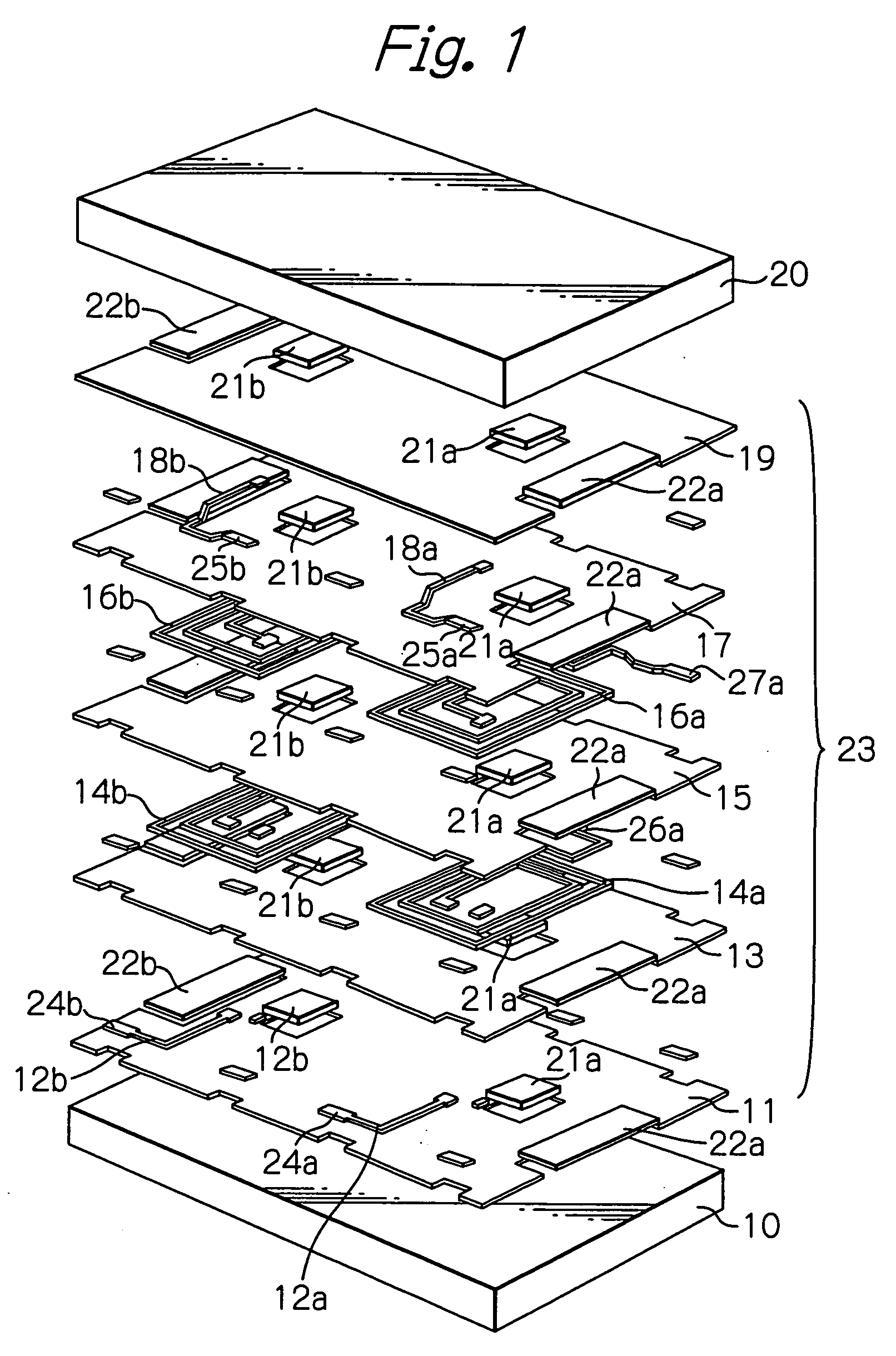

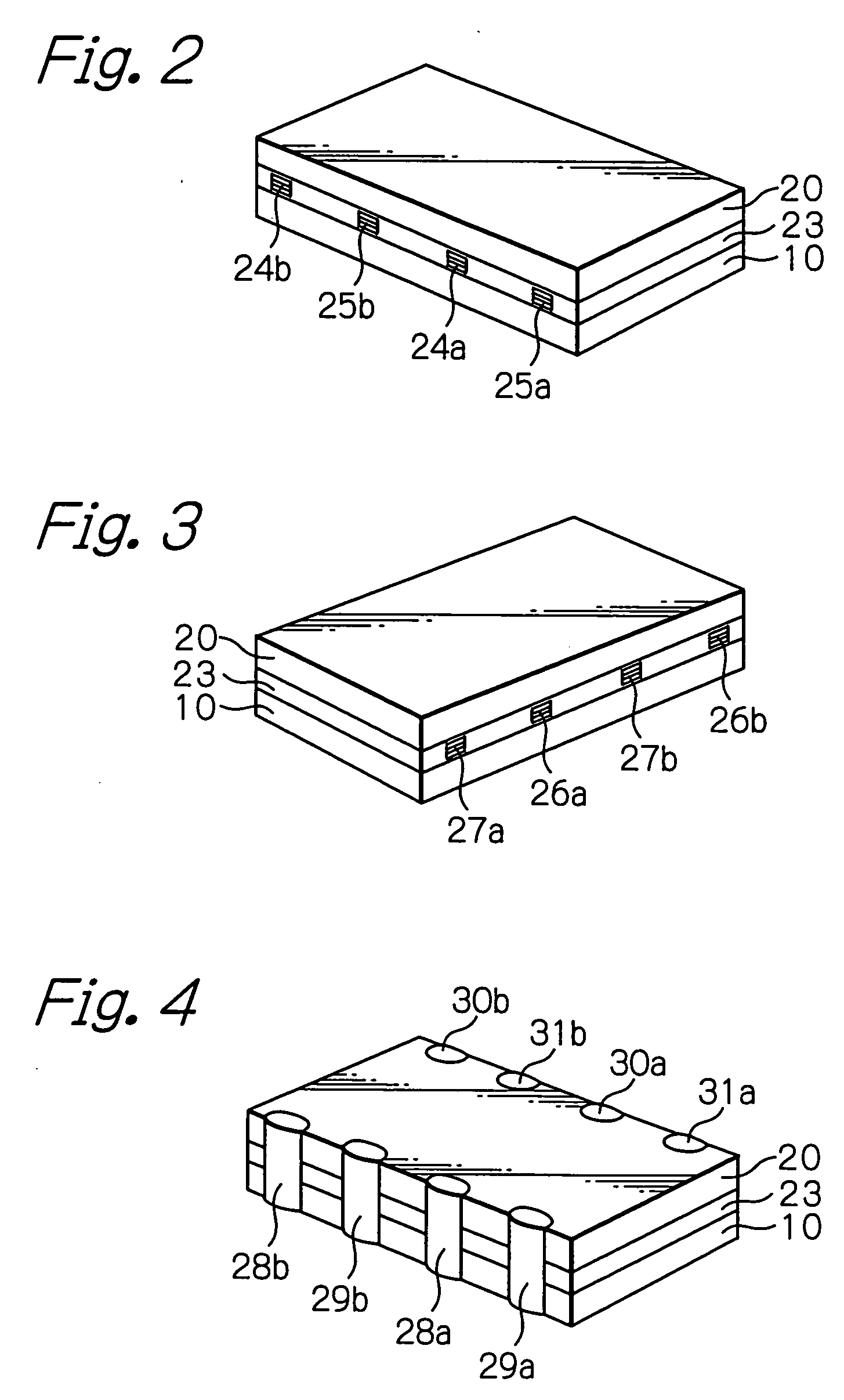

Thin-film common mode filter and thin-film common mode filter array

ActiveUS7023299B2Improve electrical connection reliabilityReliable electrical connectionMultiple-port networksTransformers/inductances coils/windings/connectionsLead ConductorEngineering

A thin-film common mode filter is provided, comprising: a pair of magnetic plates; upper / lower coil conductors formed between the magnetic plates, spirally wound in the magnetic plate surface direction, overlapped each other; upper / lower lead conductors one ends of which are connected electrically to one ends in centers of the upper / lower coil conductors, respectively, extended to external portions across these coil conductors; an upper / lower lead drawing terminals to which the other ends of the upper / lower lead conductors are connected, respectively; an upper / lower coil drawing terminals to which the other ends of the upper / lower coil conductors are connected, respectively; and each of the lower lead / coil drawing terminals and the upper coil / lead drawing terminals having a structure where at least two of conductor layers to be patterned into the upper / lower lead conductors and the upper / lower coil conductors are stacked, and brought into conduction with each other.

Owner:TDK CORPARATION

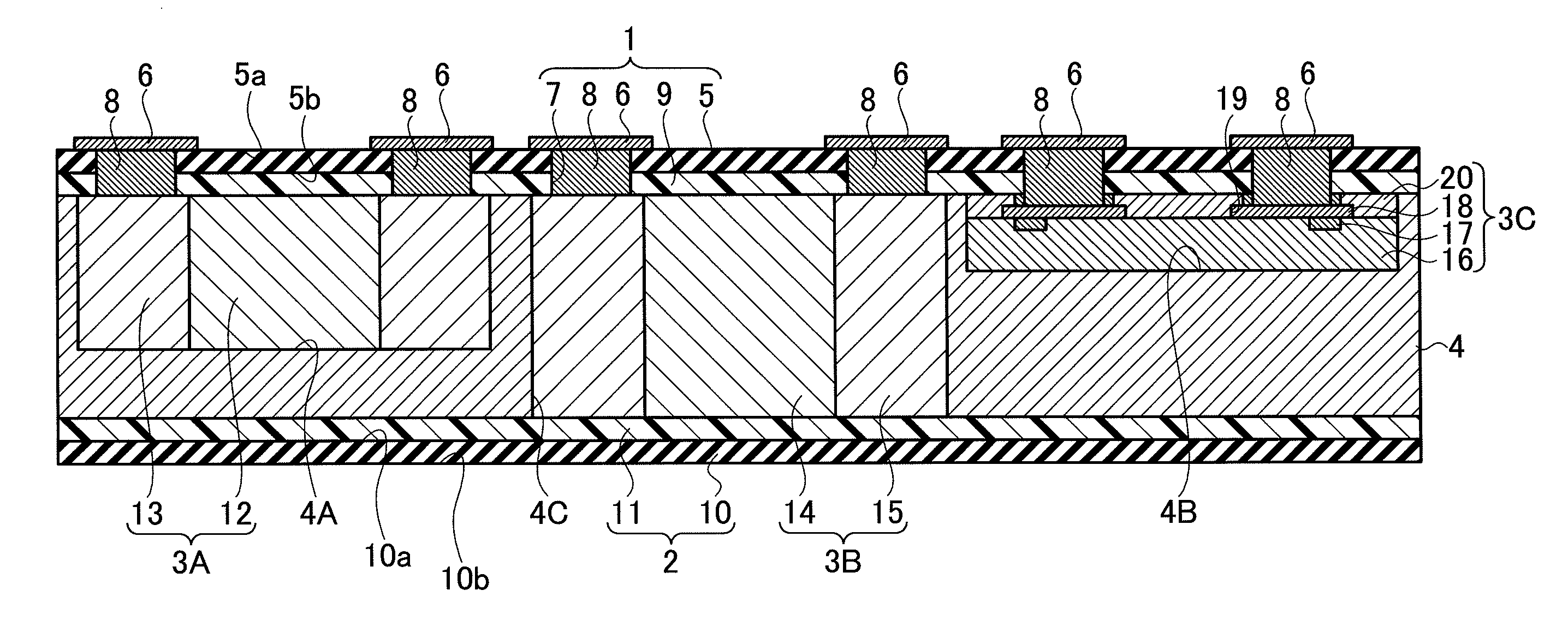

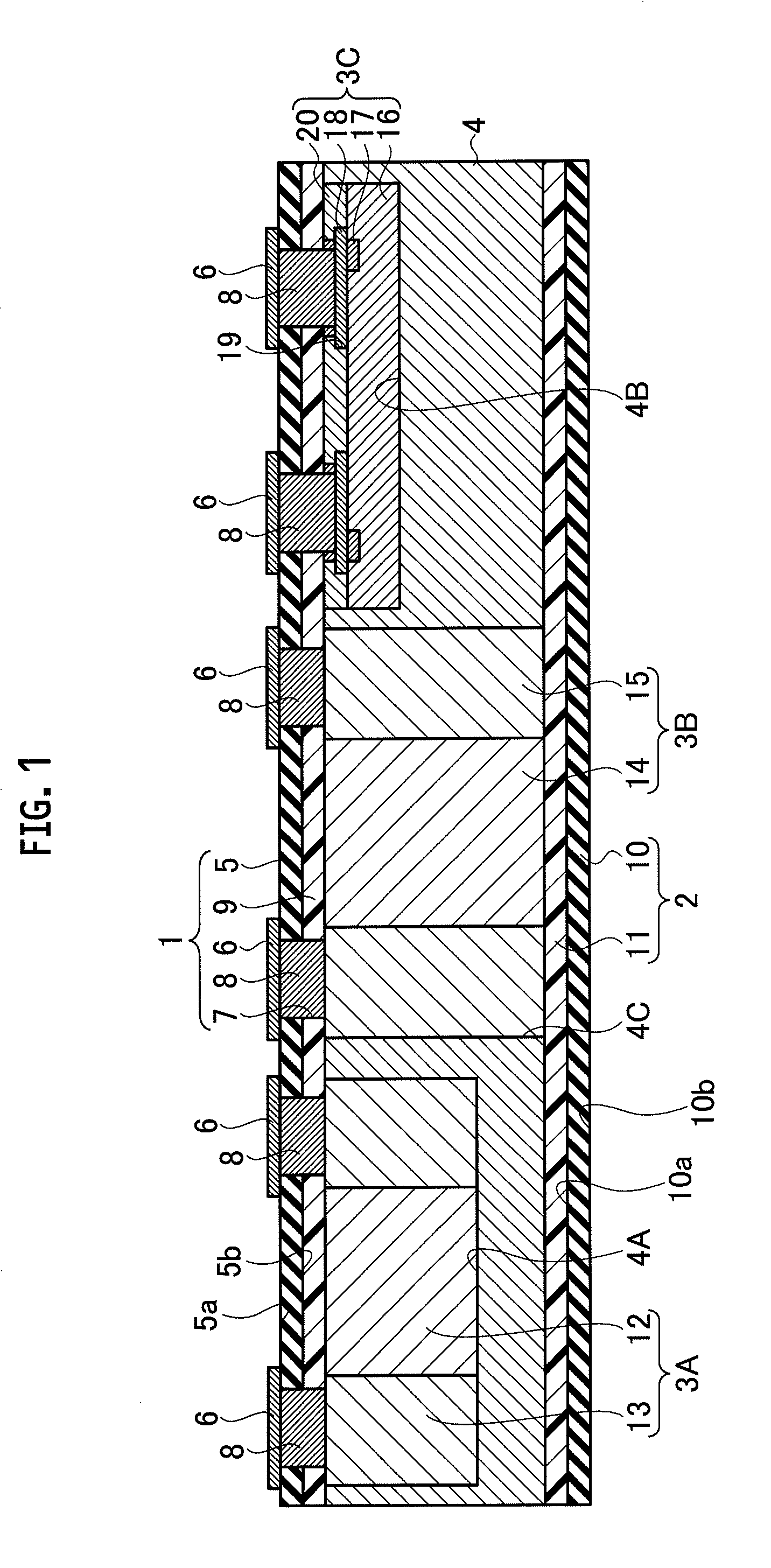

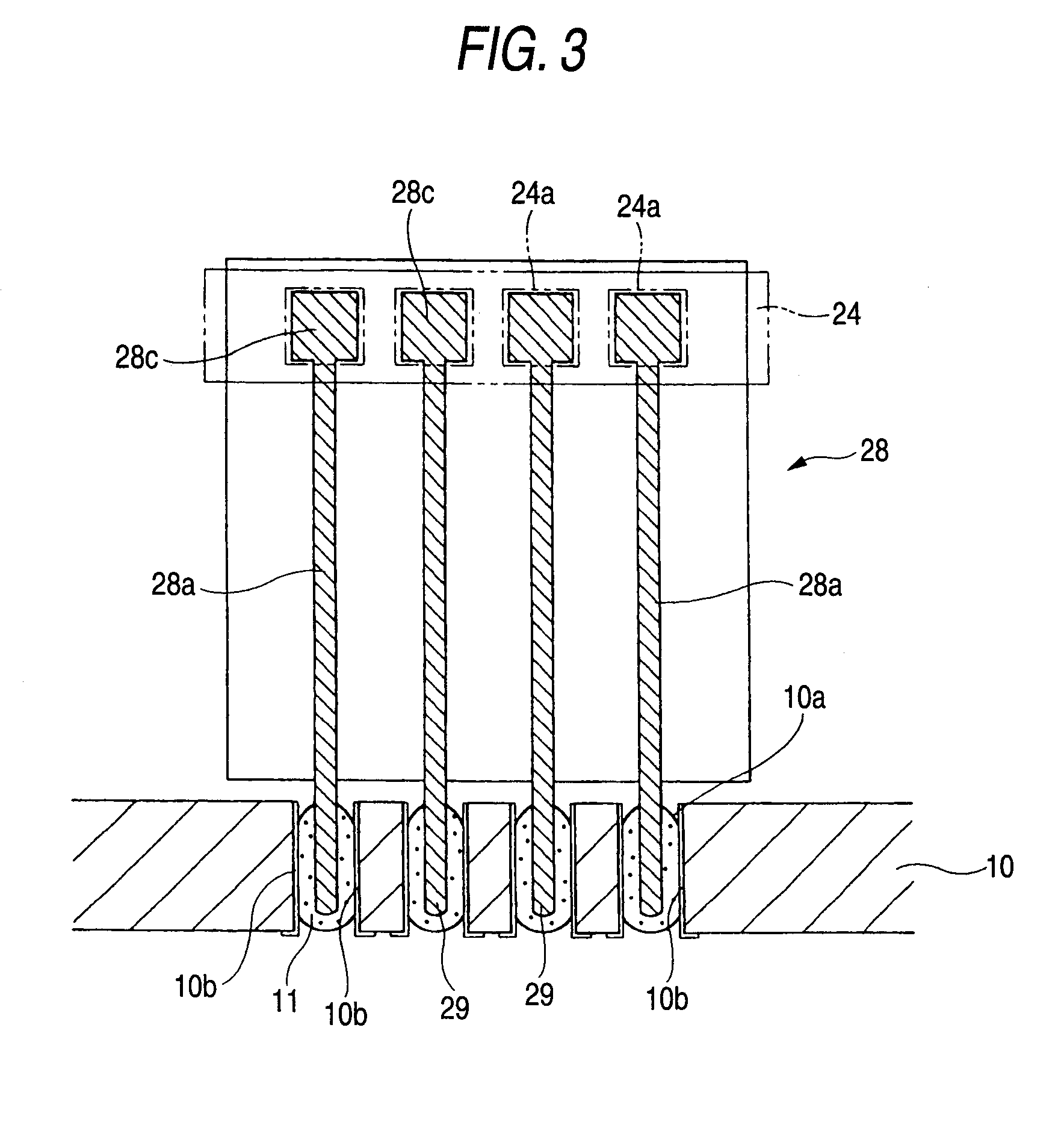

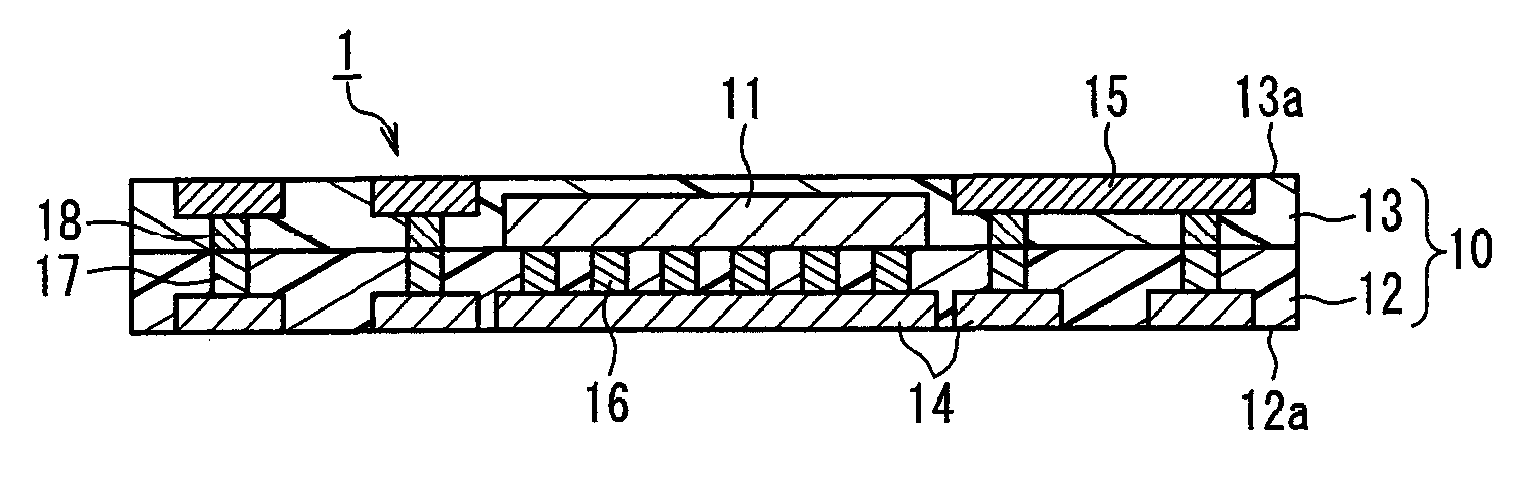

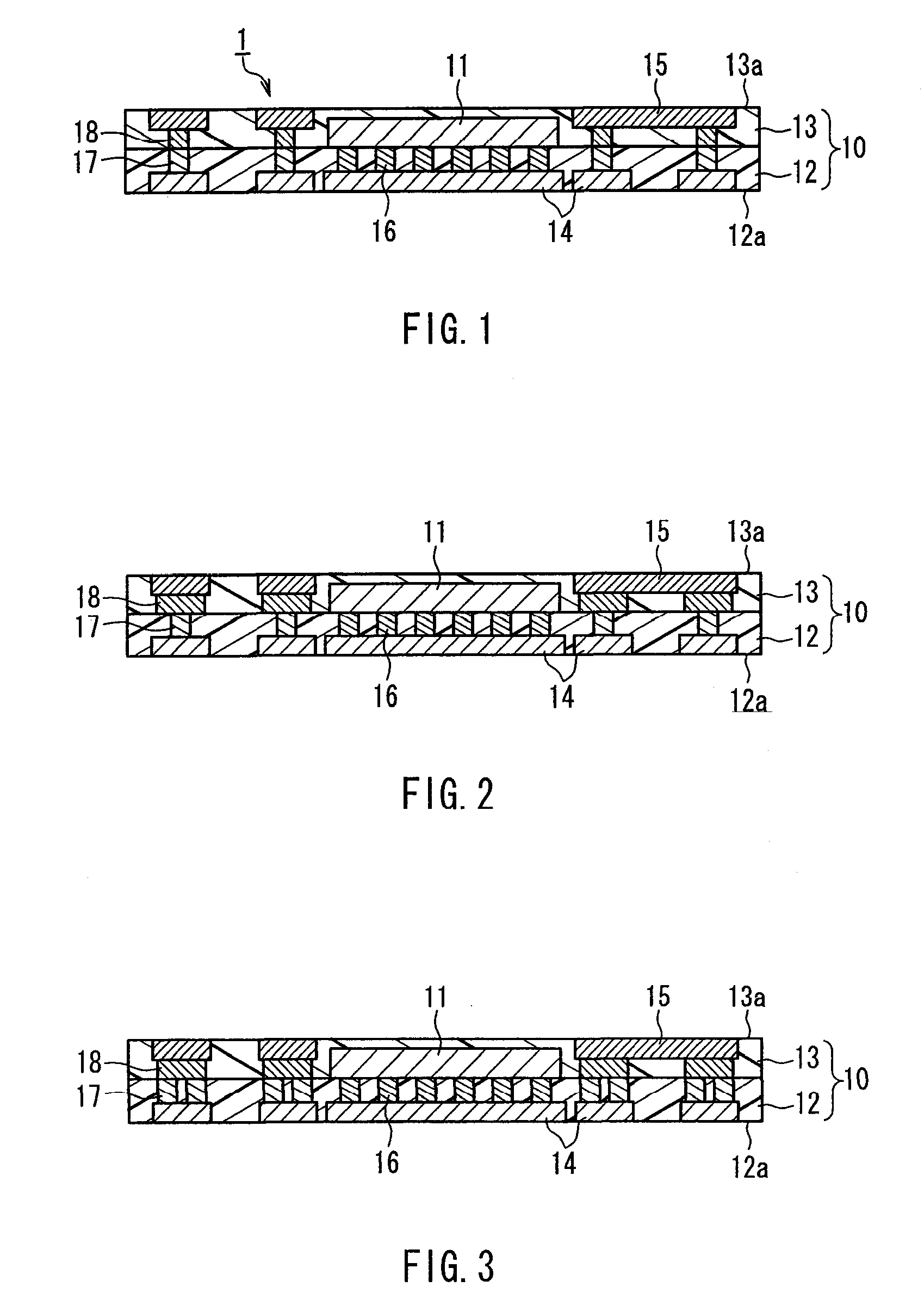

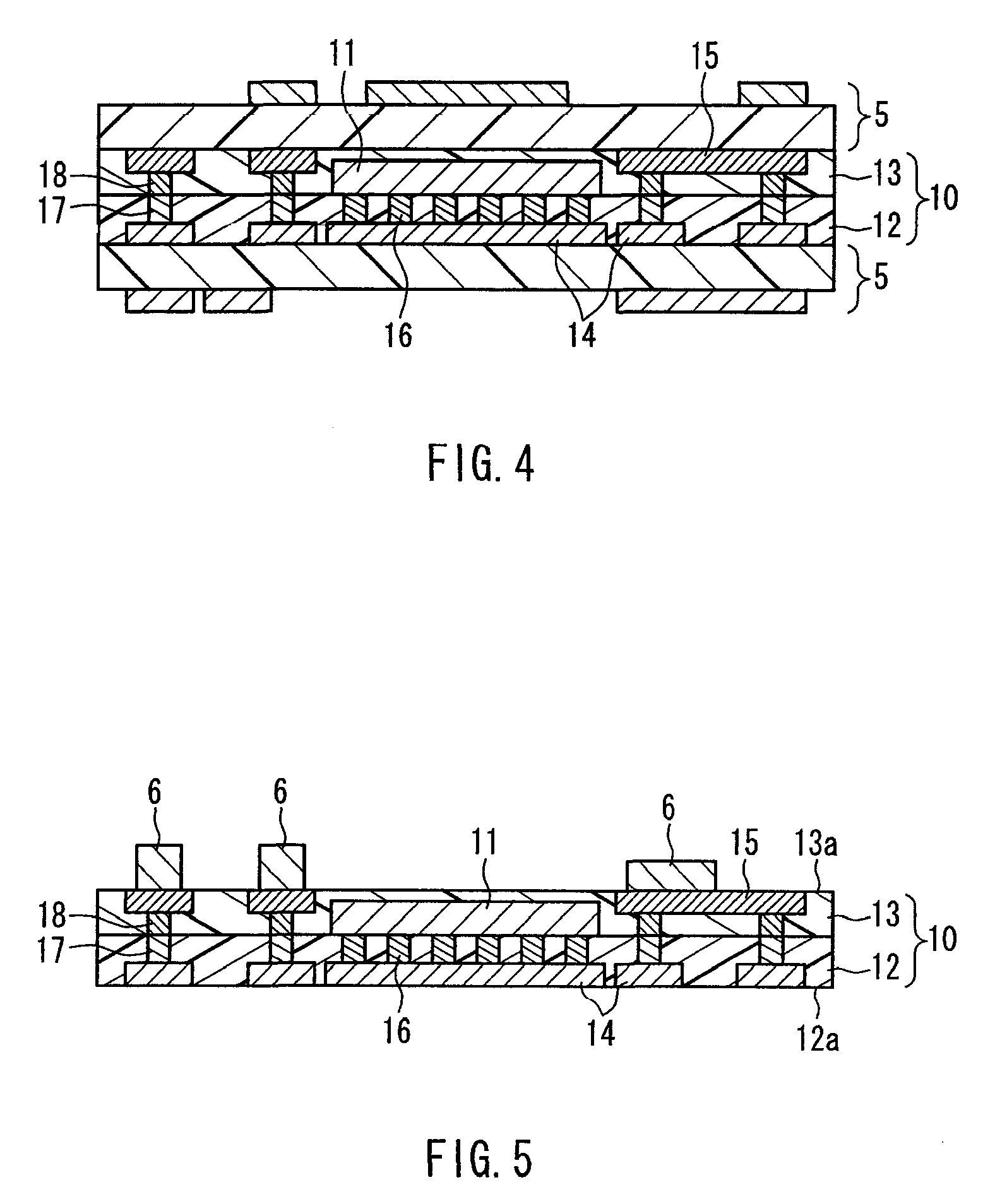

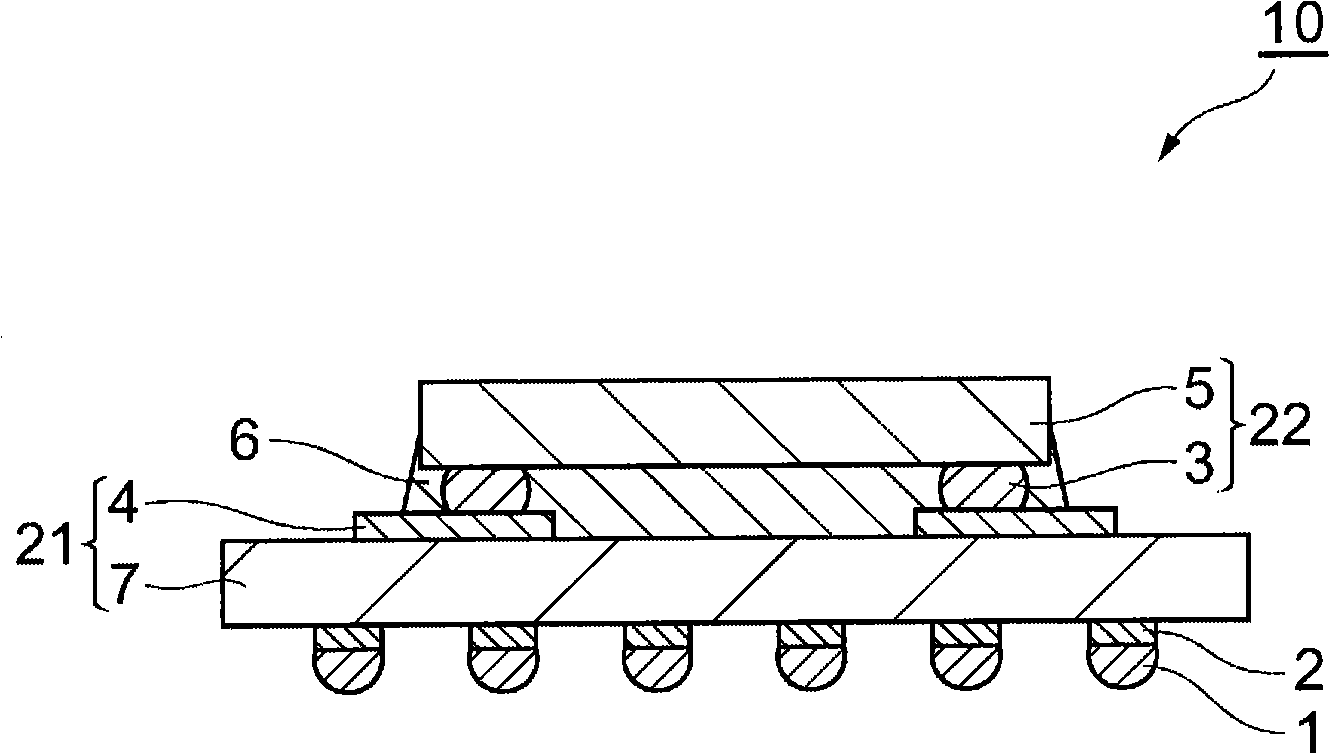

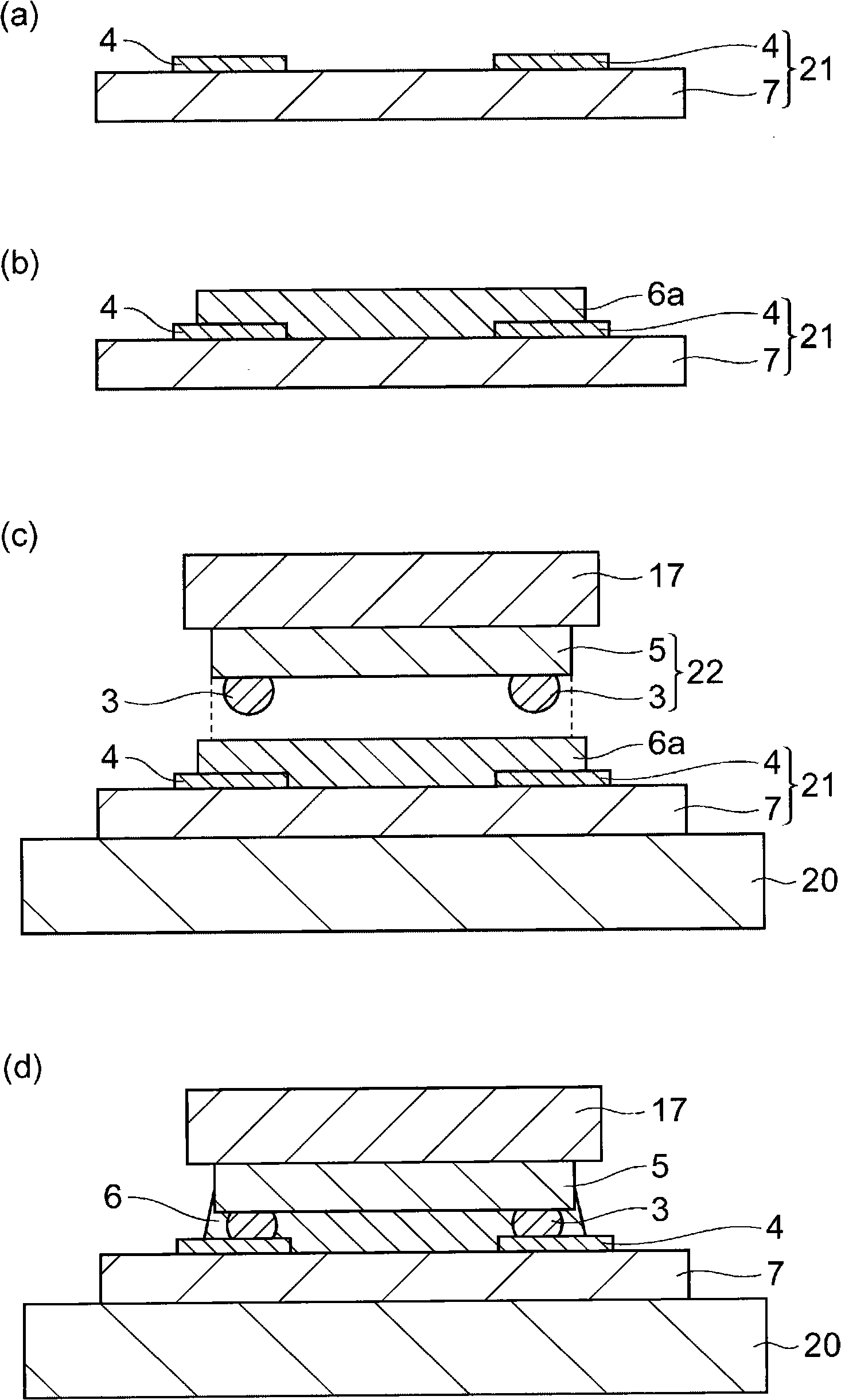

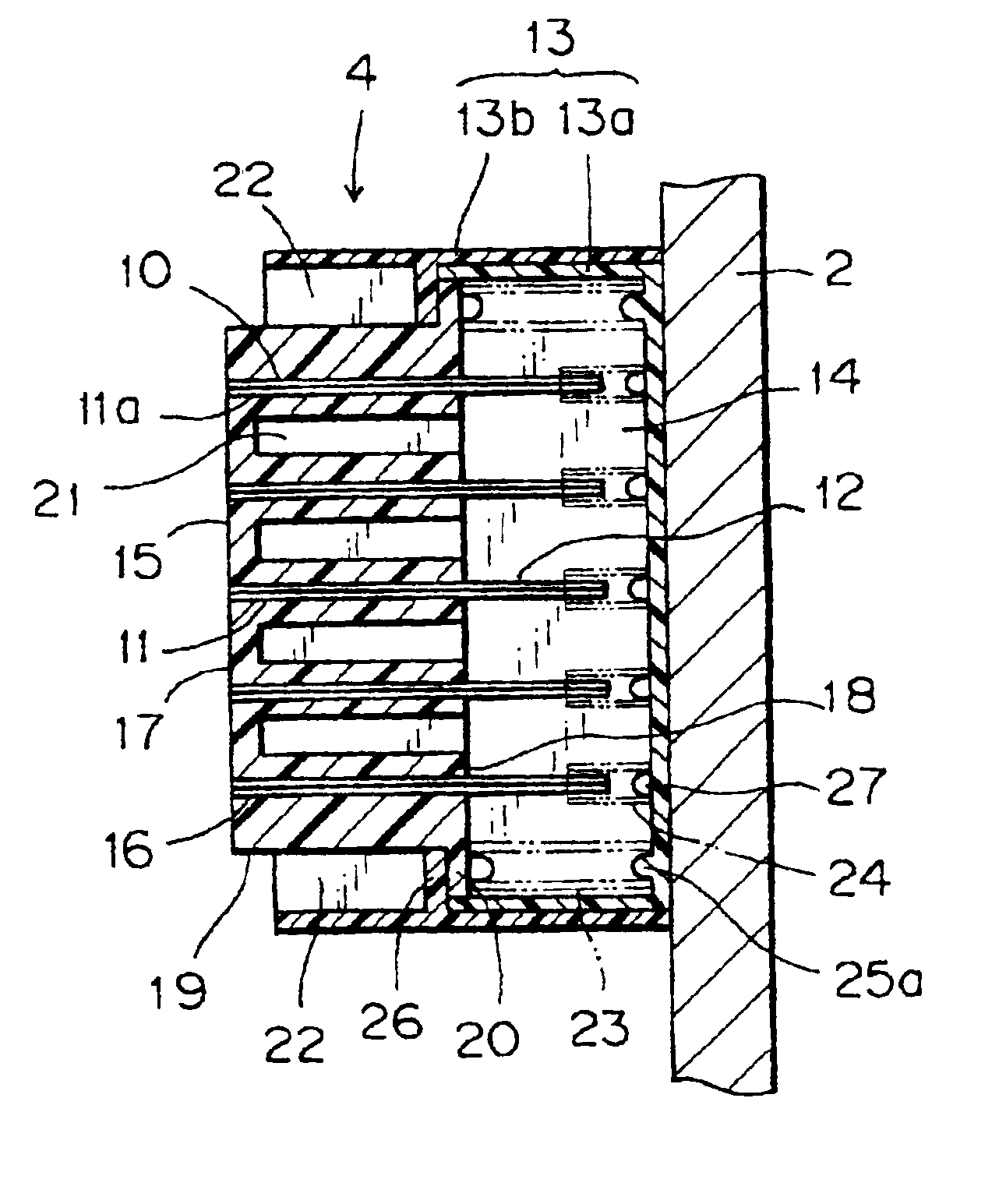

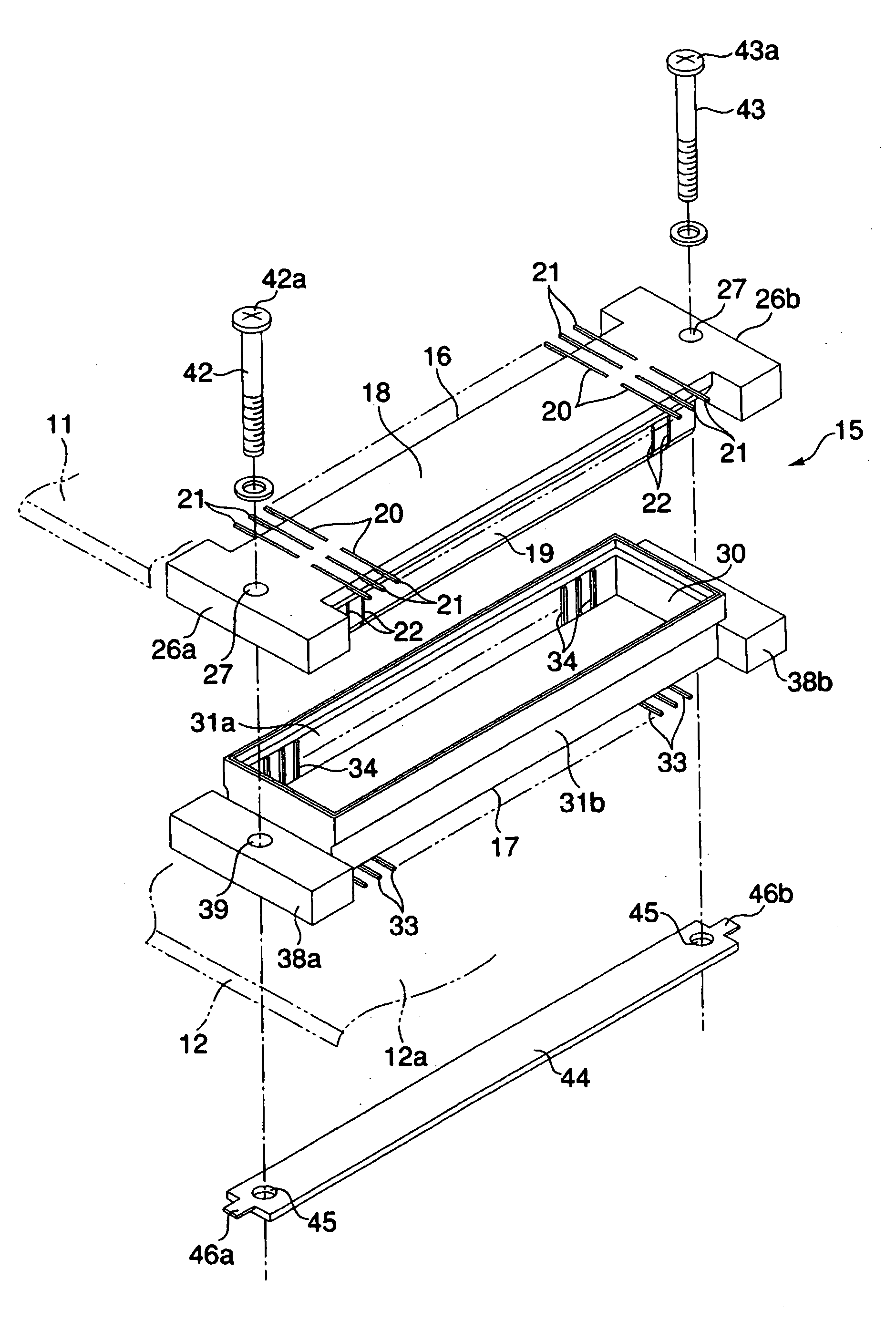

Module having built-in electronic component and method for manufacturing such module

InactiveUS20090115067A1Improve electrical connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesComputer moduleEngineering

An electronic component embedded module that can improve reliability of electric connection of inner vias, and a manufacturing method therefor are provided. A first electronic component (11) is embedded in a second electrical insulating layer (13) and connected electrically to a first wiring pattern (14) through first inner vias (16) that penetrate a first electrical insulating layer (12). The first wiring pattern (14) and a second wiring pattern (15) are connected electrically to each other through second inner vias (17) that penetrate the first electrical insulating layer (12) and third inner vias (18) that penetrate the second electrical insulating layer (13). The second inner vias (17) and the third inner vias (18) are arranged continuously.

Owner:PANASONIC CORP

Thin-film common mode filter and thin-film common mode filter array

ActiveUS20050116793A1Lowering of reliability in conductionReliable conductionMultiple-port networksTransformers/inductances coils/windings/connectionsLead ConductorMetallic Lead

A thin-film common mode filter is provided, comprising: a pair of magnetic plates; upper / lower coil conductors formed between the magnetic plates, spirally wound in the magnetic plate surface direction, overlapped each other; upper / lower lead conductors one ends of which are connected electrically to one ends in centers of the upper / lower coil conductors, respectively, extended to external portions across these coil conductors; an upper / lower lead drawing terminals to which the other ends of the upper / lower lead conductors are connected, respectively; an upper / lower coil drawing terminals to which the other ends of the upper / lower coil conductors are connected, respectively; and each of the lower lead / coil drawing terminals and the upper coil / lead drawing terminals having a structure where at least two of conductor layers to be patterned into the upper / lower lead conductors and the upper / lower coil conductors are stacked, and brought into conduction with each other.

Owner:TDK CORPARATION

Flux activator, adhesive resin composition, adhesive paste, adhesive film, semiconductor device fabrication method, and semiconductor device

InactiveCN101939379AEasy to ensure storage stabilityImprove electrical connection reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorSemiconductor device

Owner:HITACHI CHEM CO LTD

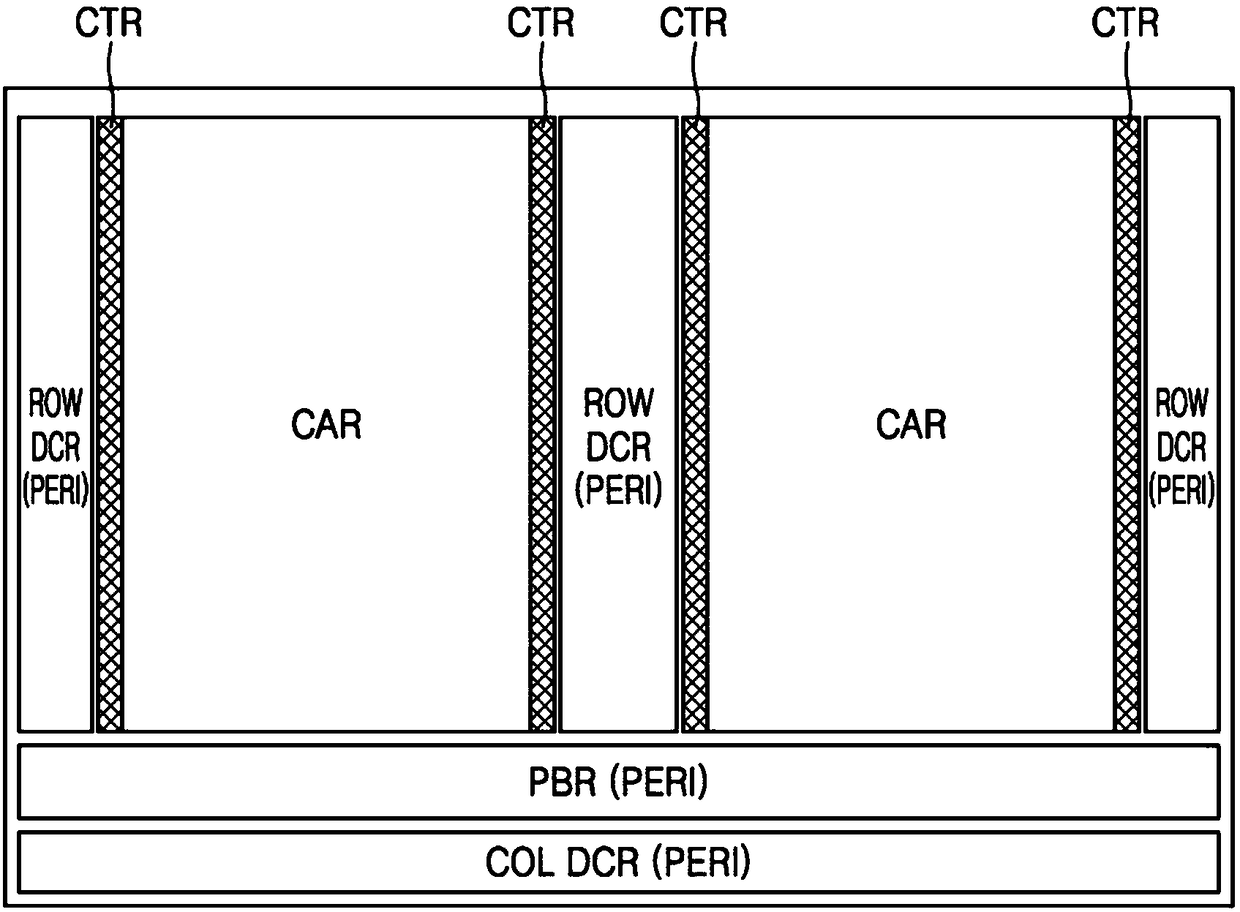

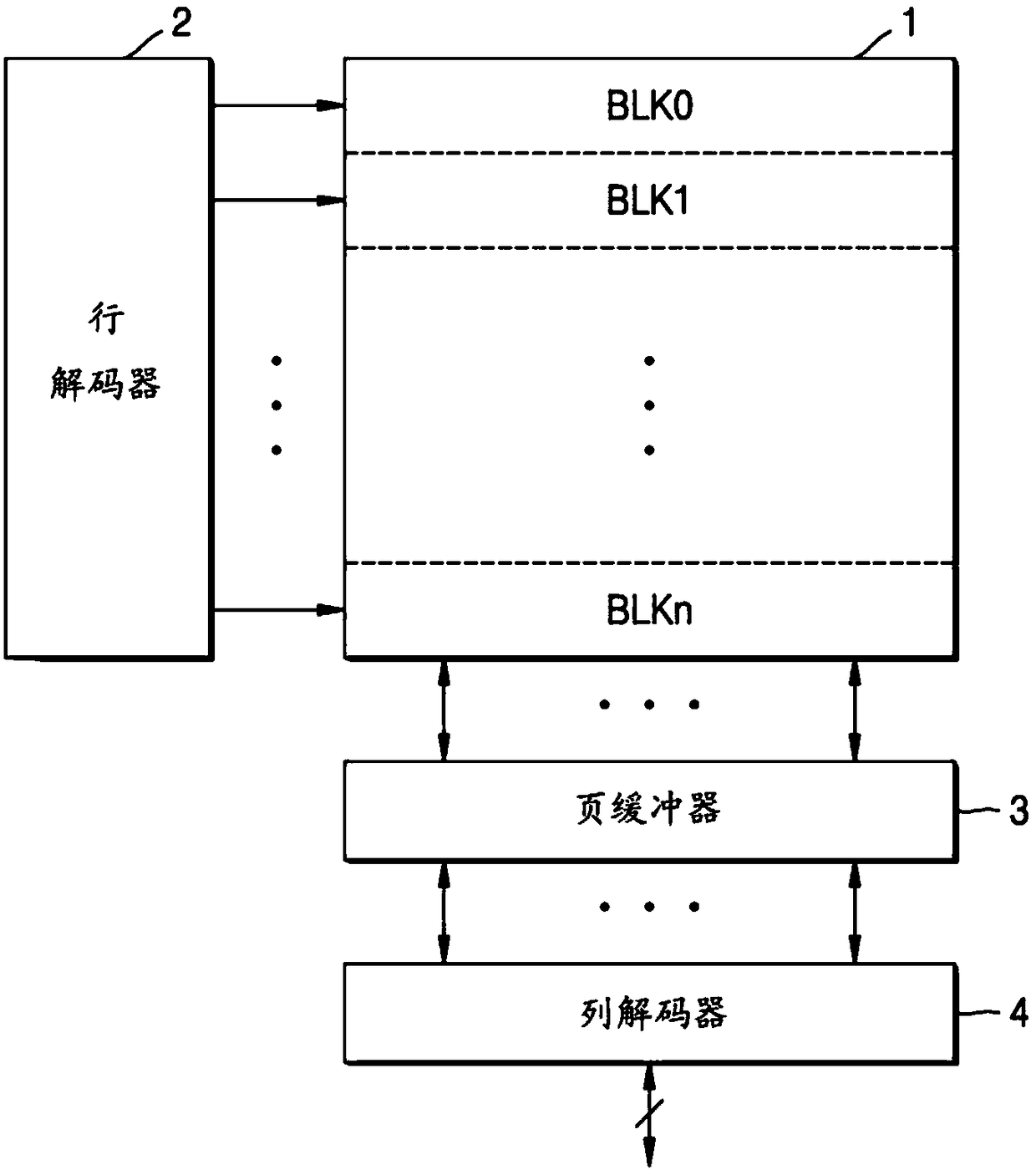

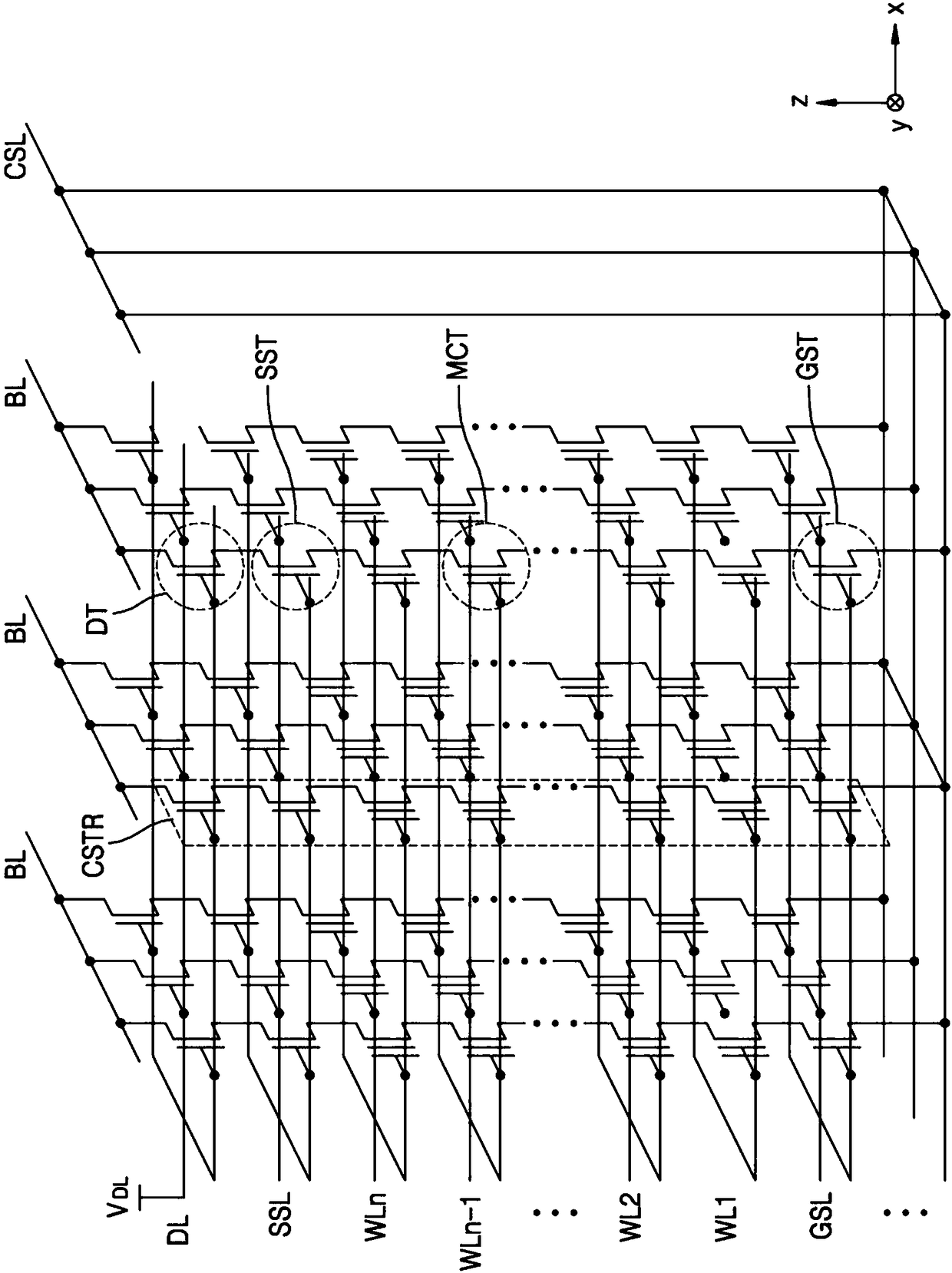

Three-dimensional semiconductor device

ActiveCN109309095AImprove electrical connection reliabilityWith structural stabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A three-dimensional semiconductor device includes: a substrate having a cell array region and a contact region; a stacked structure including a plurality of electrodes and a plurality of electrode isolation insulating layers, which are alternately stacked on the substrate in a vertical direction, and having a stepwise structure on the contact region; vertical structures penetrating the stacked structure in the cell array region, each of the vertical structures constituting a cell string; and word line contact plugs, each penetrating an uppermost electrode among the plurality of electrodes in aregion of each of tread portions of the stacked structure having the stepwise structure, being connected to another electrode under the penetrated uppermost electrode, and being electrically insulated from the penetrated uppermost electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

Power supply switch of motor vehicle

InactiveUS6837727B2Not to damageReliable contactVehicle connectorsIncorrect coupling preventionMobile vehiclePower switching

The switch includes a base body side connector and a movable body side connector for connecting electrical circuits provided in a base body side and a movable body side of a motor vehicle. One of the base body side connector and the movable body side connector has a receptacle terminal while the other has a pin tab terminal. The other connector has a terminal cover piece for receiving an electrical contact portion provided in a free end side of the pin tab terminal. The terminal cover piece is slidable in engagement and disengage directions of the terminals. The terminal cover piece is urged by a resilient member parallel to an extended direction of the pin tab terminal. The resilient member is positioned between a flange of the terminal cover piece and a bottom surface of a housing of the movable body side connector.

Owner:YAZAKI CORP

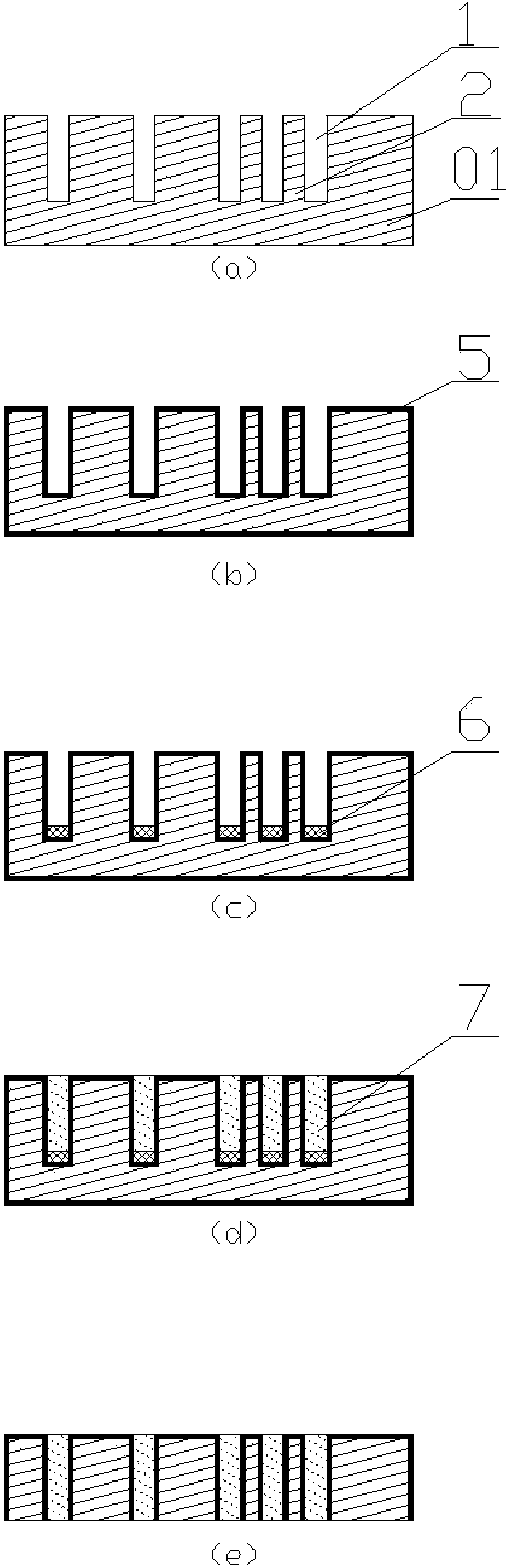

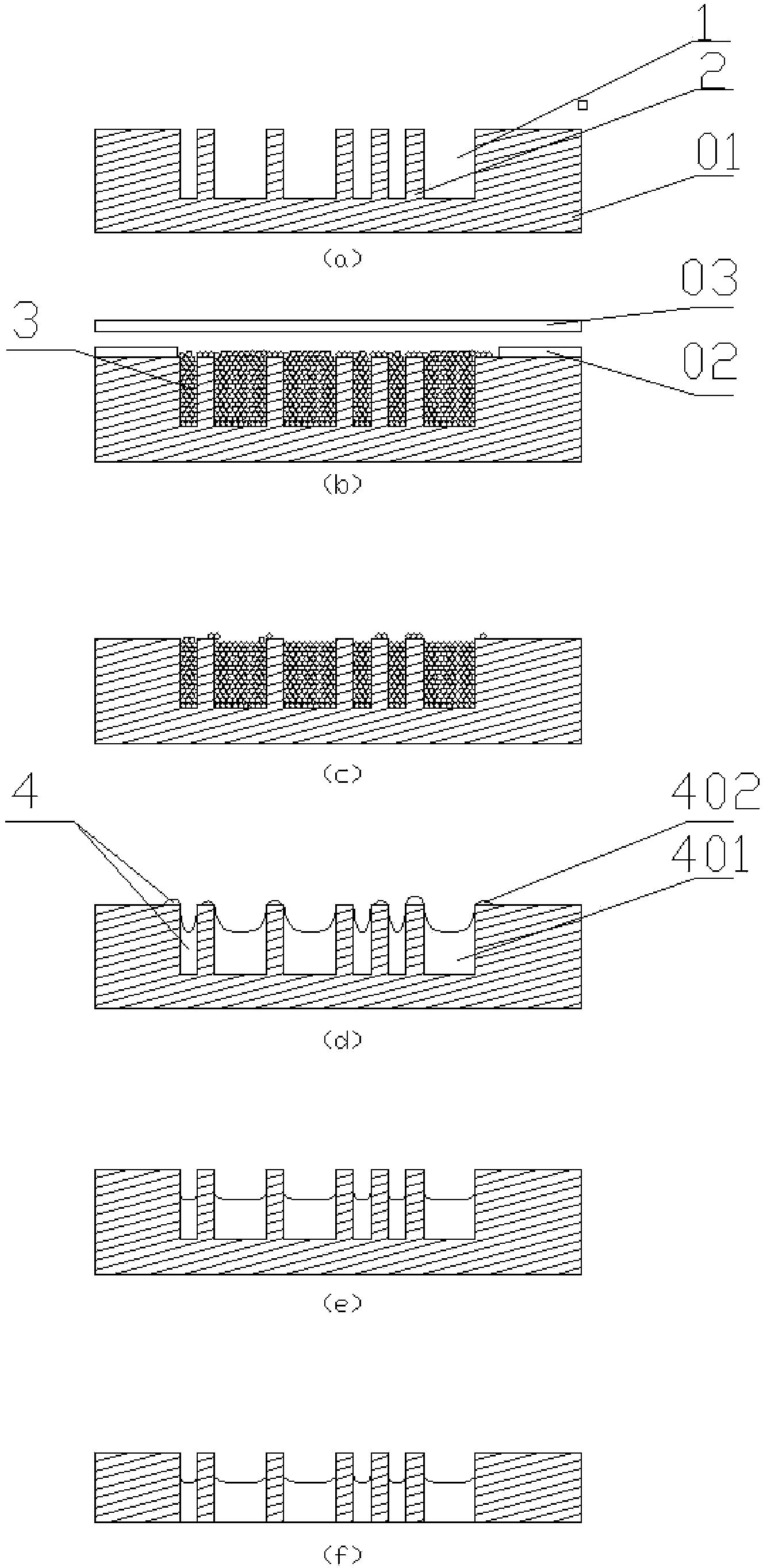

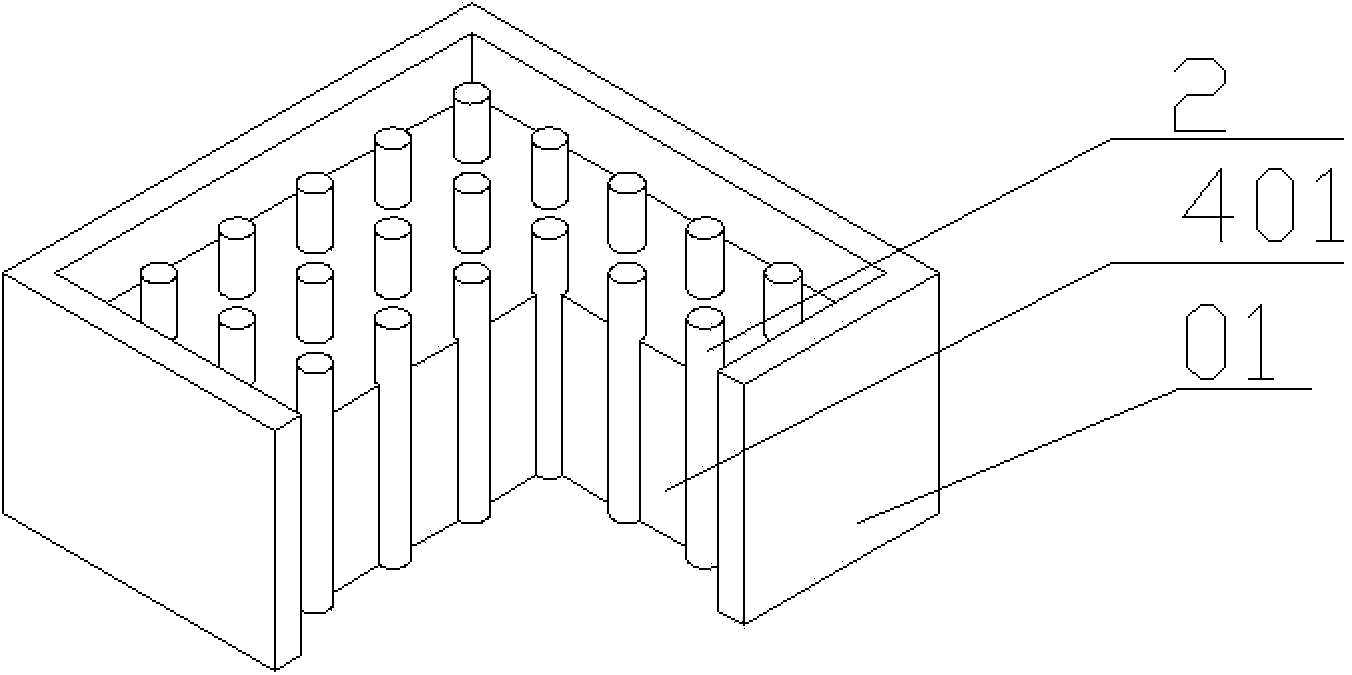

Method for manufacturing three-dimensional through hole interconnection structure based on molten glass skeleton

ActiveCN103413780AIncreased via densityImprove electrical connection reliabilitySemiconductor/solid-state device manufacturingScreen printingInterconnection

The invention discloses a method for manufacturing a three-dimensional through hole interconnection structure based on a molten glass skeleton, and relates to the interconnection technology of silicon through holes. Grooves are etched in a silicon layer, and silicon columns are formed. A screen printing plate with a pattern is made to align at the etched pattern of the silicon layer. Glass powder is arranged on the screen printing plate. The glass powder is extruded in the vertical direction to be filled into the grooves, and the screen printing plate is moved away. The glass powder on the surfaces of the tops of the silicon columns is removed. The silicon layer filled with the glass powder is heated and molten, no bubble exists inside the silicon layer, a molten glass structure is obtained after cooling, the silicon layer of the obtained molten glass structure is arranged in etching liquid, the remaining molten glass structure on the surfaces of the tops of the silicon columns is removed by the adoption of the wet etching technology, and the molten glass skeleton inside the grooves is obtained. By the adoption of the mechanical lapping mode, the lower portion of the silicon layer is machined in a thinned mode until the bottoms of the silicon columns are exposed out of the lower portion of the silicon layer, then, lapping damage is repaired by the adoption of the chemical mechanical polishing mode, and therefore the three-dimensional through hole interconnection structure based on the molten glass skeleton is obtained.

Owner:XIAMEN UNIV

Electric connector

InactiveUS9437972B2Improve electrical connection reliabilityCoupling device detailsTwo-part coupling devicesElectrical contacts

Owner:I PEX CO LTD

Insulation displacement contact and electric connector using the same

ActiveUS7056146B2Increasing resilient deformation rangeAvoid stress concentrationCoupling device connectionsContact member manufacturingEngineeringMechanical engineering

An insulation displacement contact includes a pair of insulation displacement blades and a pair of resilient contact pieces. The pair of insulation displacement blades are opposite to each other with their bases connected to each other such that there is formed, by their inner sides, a slot for receiving an insulated wire of which core wire portion is covered with an insulation. The pair of insulation displacement blades are arranged such that when the insulated wire is inserted into the slot, the insulation is cut and the core wire portion comes in press-contact with the insulation displacement blades. Each of the pair of resilient contact pieces is made of a plate member which is connected to the outer side of each insulation displacement blade, which extends toward the side opposite of the inlet of the slot up to a position exceeding the base of each insulation displacement blade, which has a contact portion for holding or nipping a mating contact at a position opposite of the slot inlet with respect to the base of each insulation displacement blade, and which has, between the connection portion connected to the outer side of each insulation displacement blade and the contact portion, a tapering portion of which width is gradually narrowed in the direction toward the contact portion.

Owner:JST MFG CO LTD

Electrical connecting module

InactiveUS20160172783A1The connection is tight and firmImprove electrical connection reliabilityIncorrect coupling preventionCouplings bases/casesElectrically conductiveElectrical and Electronics engineering

An electrical connecting module includes a first electrical connector, and a second electrical connector, both being coaxially fittable into each other. The first electrical connector includes a first housing, and a contact terminal housed in a terminal space formed in the first housing. The second electrical connector includes a second housing and a cylindrical terminal fixed in the second housing, the cylindrical terminal being fabricated by joining opposite ends of an electrically conductive sheet to each other in a manner such that the sheet defines a circular cross-section. The contact terminal includes an elastic contact piece contacting an inner surface of the cylindrical terminal. Each of the housings includes a positioning section for causing the elastic contact piece to contact the cylindrical terminal at the inner surface other than an area through which the opposite ends of the electrically conductive sheet are joined to each other.

Owner:DAIICHI SEIKO CO LTD

Connector and a connecting structure of circuit boards therewith

InactiveUS6497580B2Firmly connectedImprove connection workabilityRotary current collectorSecuring/insulating coupling contact membersEngineeringElectrical and Electronics engineering

Owner:YAZAKI CORP

Board for display device and display device

A substrate for a display having, on a surface thereof, a sealing compound disposed along a periphery of the substrate spaced at a predetermined interval from an outer edge of a display part to which an oriented film is applied; and a convex portion or / and a concave portion, for preventing the applied oriented film from spreading to the sealing compound, provided between the sealing compound and the outer edge of the display part. The convex portion has a configuration of a bank continuous or uncontinuous, whereas the concave portion is formed as a plurality of independent portions arranged side by side or dotted between the outer edge of the display part and the sealing compound.

Owner:SHARP KK

Insulated conductive particles and anisotropic conductive adhesive film containing the particles

ActiveCN1954393AEasy to break awayImprove electrical connection reliabilityPrinted circuit assemblingPrinted circuit aspectsAnisotropic conductive filmAnisotropic conductive adhesive

An insulated conductive particle for an anisotropic conductive film is disclosed. One embodiment of the particle includes a conductive particle and insulating fixative particles discontinuously fixed on the surface of the conductive particle. The insulating particles provides insulation with other adjacent insulated conductive particles, while the insulated conductive particle is electrically connected between electrodes with the insulating fixative particles being deviated from its position. The instant disclosure also provides a method for manufacturing the insulated conductive particle, an anisotropic conductive adhesive film containing the insulated conductive particles, and an electrically connected structure using the film.

Owner:KUKDO ADVANCED MATERIALS CO LTD

Connector and electronic apparatus having the same

InactiveUS20060057869A1Improve electrical connection reliabilityAvoid damageNutsCoupling device detailsEngineeringElectrical and Electronics engineering

Owner:KK TOSHIBA

Ultrathin semiconductor chip packaging structure and manufacturing process thereof

ActiveCN101789414AReduce package sizeReduce package thicknessSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The invention discloses an ultrathin semiconductor chip packaging structure, wherein double-layer leads are adopted for packaging a chip with a weld pad in double-row arrangement, and the two paths of leads do not mutually interfere, thereby further improving the reliability of electric connection; meanwhile, compared with the prior art, a single-side polymer is adopted for replacing the glass on the back surface of an original chip, a glass-silicon-polymer structure is adopted, the packaging thickness is further thinned, and the thickness can be reduced from the original 0.9mm to 0.5mm when in practical application, thereby greatly reducing the packaging volume of a semiconductor chip.

Owner:CHINA WAFER LEVEL CSP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com