Water-absorbing resin and process for producing same

a technology of water-absorbing resin and process, which is applied in the direction of chemistry apparatus and processes, bandages, wood layered products, etc., can solve the problems of unpleasant slimy feeling, lack of water-soluble content in the aspect, and inability to achieve satisfactory absorbing properties, small amount of water-soluble content, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

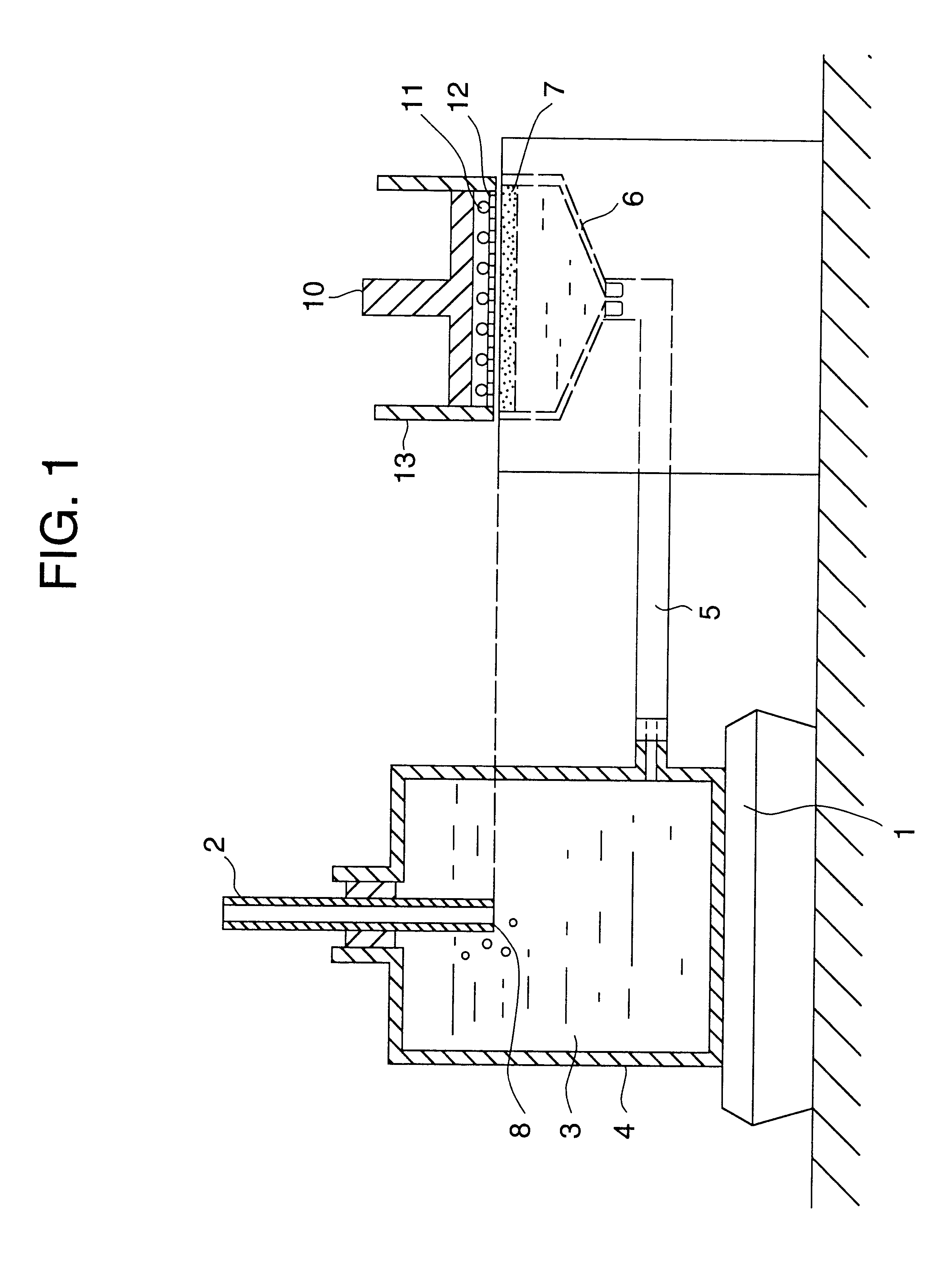

A jacketed 13-liter-content stainless steel double-arm kneader equipped with two sigma-type blades having a rotating diameter of 120 mm was charged with 6,538 g of an aqueous solution (D) containing 2,168 g of a monomer component (A) composed of 35 mol% of acrylic acid and 65 mol% of sodium acrylate; 24.5 g of polyethylene glycol diacrylate (an average molecular weight: 478) as a compound (B); 13.1 g of ethylene glycol diglycidyl ether as a compound (C) and 4,332.4 g of deionized water. The resulting aqueous solution (D) was degassed and the reaction system was replaced with a nitrogen gas.

Water at 20.degree. C. was passed through the jacket to control the temperature of the vessel. 12.56 g of a 10 wt% aqueous solution of 2,2-azobis-2-amidinopropane dihydrochloride, 0.88 g of a 1 wt% aqueous solution of L-ascorbic acid, 12.56 g of a 10 wt% aqueous solution of sodium persulfate, and 5.6 g of a 0.35 wt% aqueous solution of hydrogen peroxide as initiators were added to the reaction sys...

example 2

A water-absorbing resin was obtained in the same manner as in Example 1 except for changing the amount of ethylene glycol diglycidyl ether in Example 1 to 21.8 g. The properties of the resulting water-absorbing resin are shown in Table 1.

example 3

A water-absorbing resin was obtained in the same manner as in Example 1 except for changing the amount of ethylene glycol diglycidyl ether in Example 1 to 4.4 g. The properties of the resulting water-absorbing resin are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com