Use of carbon-supported transitional metal carbides catalyst in hydrazine decomposition reaction

A transition metal, supported catalyst technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of no patents and literature reports, etc. The effect of reducing the preparation cost, large specific surface area, and high hydrazine decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

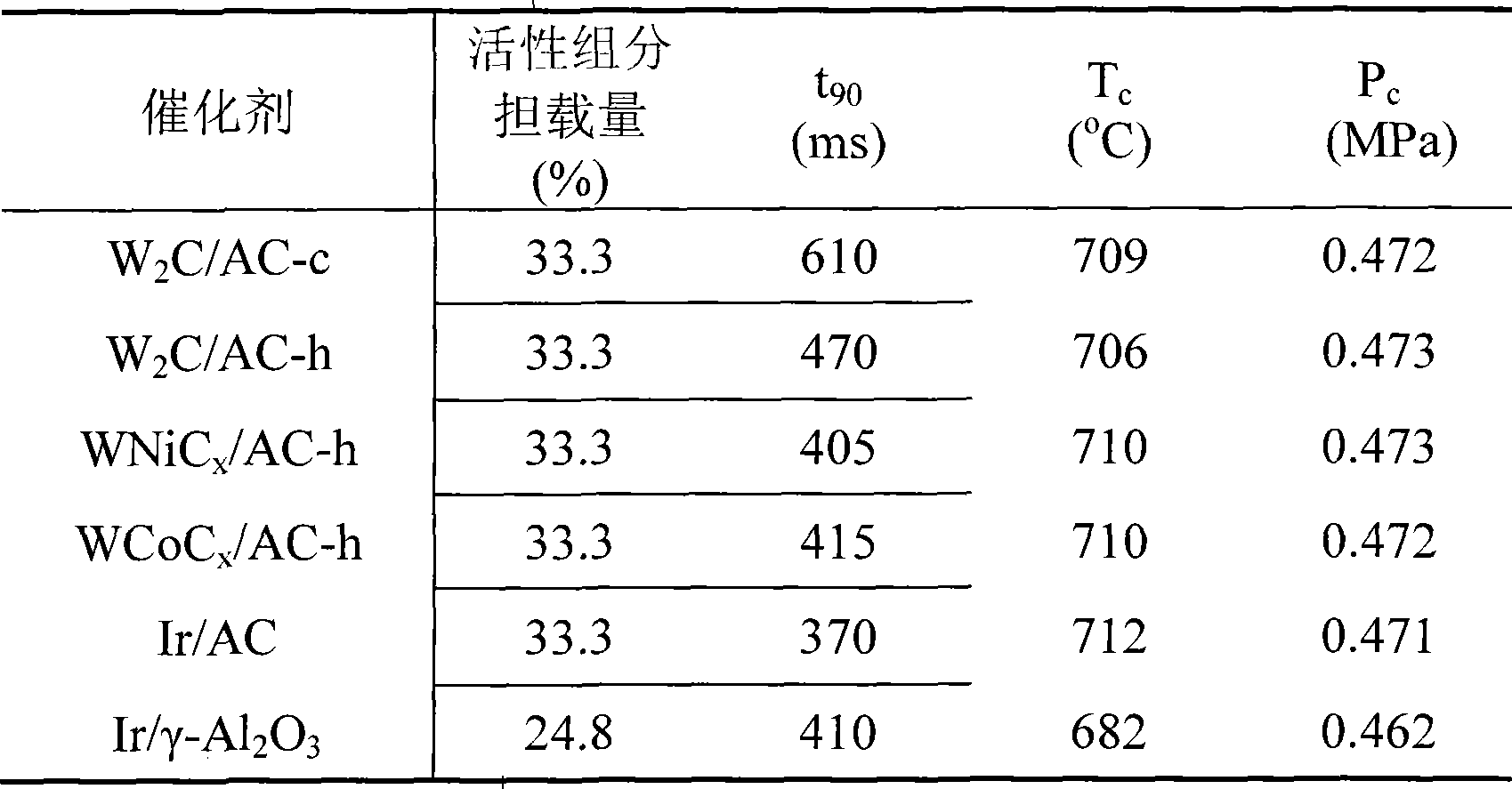

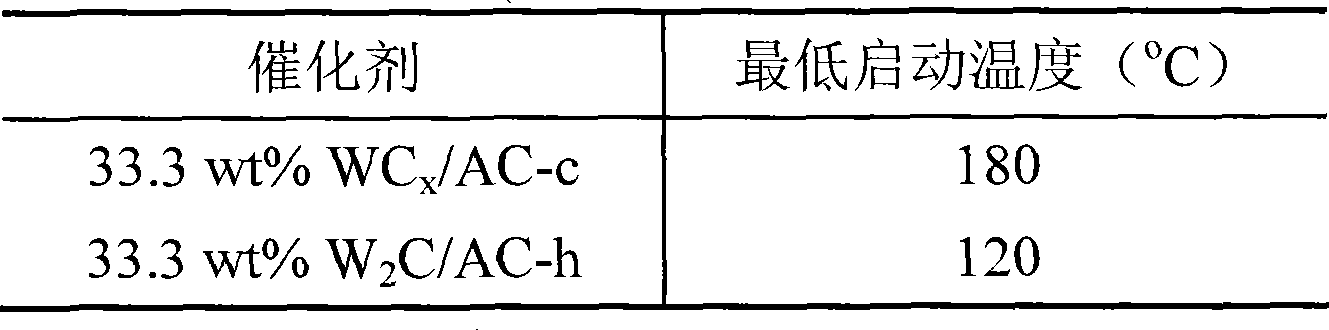

[0019] WC x Preparation of / AC-c catalyst

[0020] Weigh 0.31g, 1.38g, and 2.44g of ammonium metatungstate and dissolve them in 3.0ml of deionized water, impregnate equal volumes of the resulting clear solutions onto 2.0g of activated carbon (AC) carriers, dry at room temperature for 12 hours, and then Dry in an oven at 120°C for 12 hours, and bake at 500°C for 4 hours in a nitrogen atmosphere to obtain WO 3 / AC precursor. WO 3 / AC precursor, in the mixed gas of methane and hydrogen (25% methane content), temperature programming reaction, from room temperature to 450 °C at a rate of 10 °C / min, and then to 850 °C at a rate of 1 °C / min , after being kept at this temperature for 2 hours, cooled to room temperature, the catalyst is marked as WC x / AC-c, the mass loadings of the active components of the prepared catalysts were: 10wt%, 33.3wt%, 55wt%.

Embodiment 2

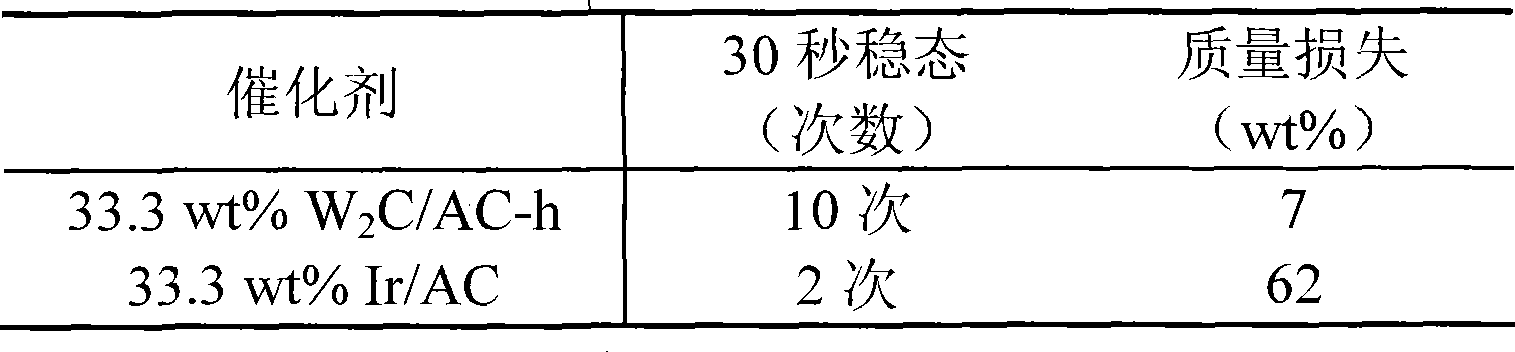

[0022] W 2 Preparation of C / AC-h catalyst

[0023] The catalyst preparation method is the same as in Example 1, except that the mixed gas of methane and hydrogen in the temperature-programmed reaction process is replaced with pure hydrogen. The catalyst is labeled W 2 C / AC-h, the mass loading of active components is 10wt%, 33.3wt%, 55wt%.

Embodiment 3

[0025] wxya x Preparation of / AC-h catalyst

[0026] Weigh 1.04g ammonium metatungstate and 1.19g nickel nitrate dissolved in 3.0ml deionized water to form a mixed solution (the molar ratio of tungsten and nickel is 1:1), impregnate the obtained clear solution into 2.0g activated carbon ( AC) on the carrier, dried at room temperature for 12 hours, then dried in an oven at 120°C for 12 hours, and calcined at 500°C for 4 hours in a nitrogen atmosphere to obtain WNiO 4 / AC precursor. WNiO 4 / AC precursor, temperature programmed reaction in hydrogen, rising from room temperature to 450°C at a rate of 10°C / min, and then rising to 850°C at a rate of 1°C / min, after keeping at this temperature for 2 hours, Cool to room temperature. The catalyst is labeled WNiC x / AC-h (33.3 wt% active ingredient).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com