Patents

Literature

54results about How to "Simplify layout process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

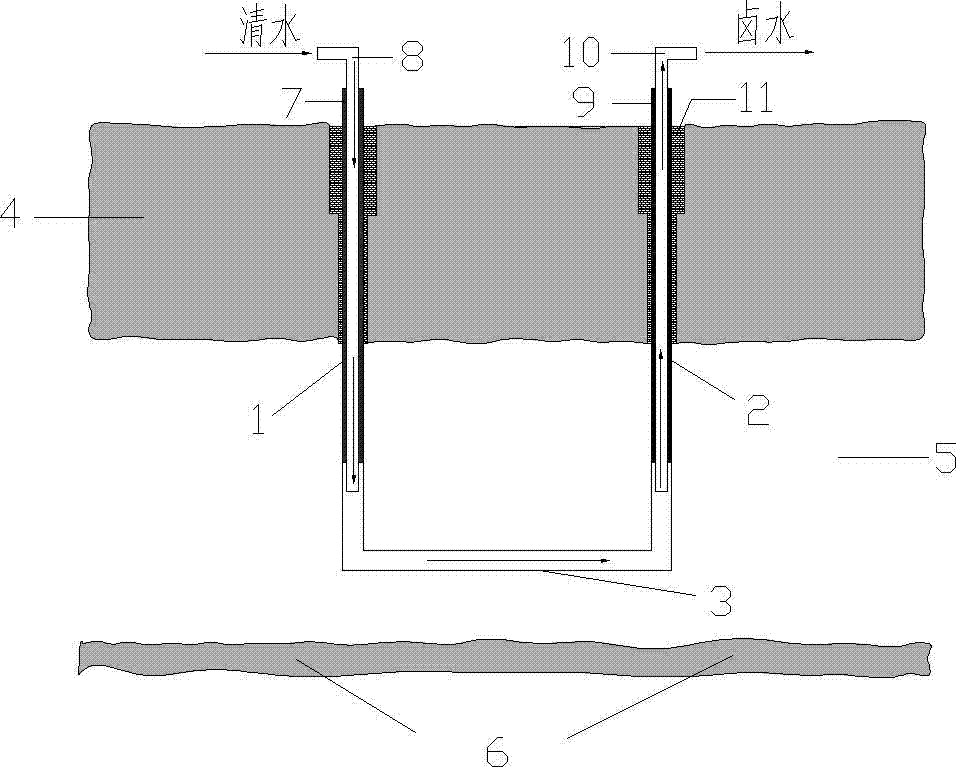

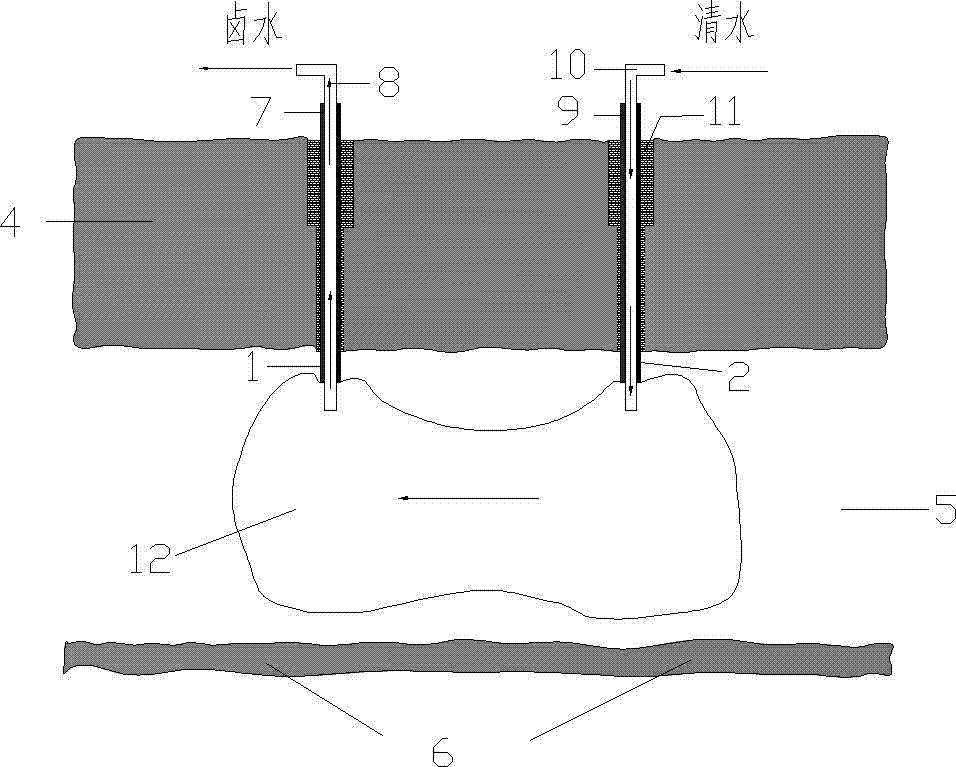

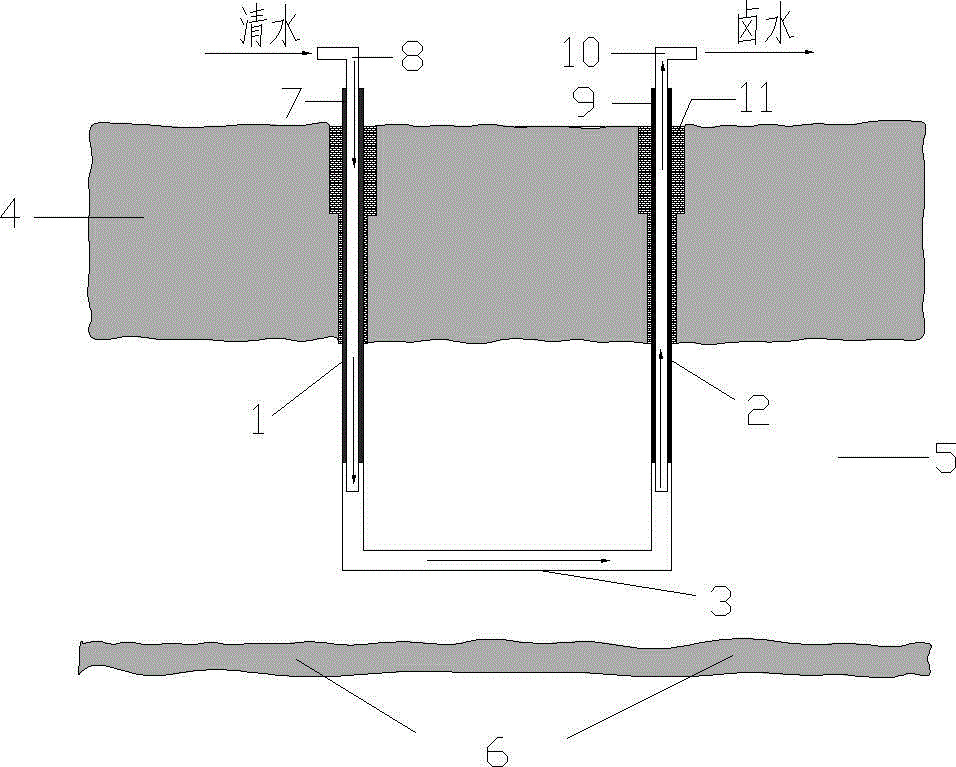

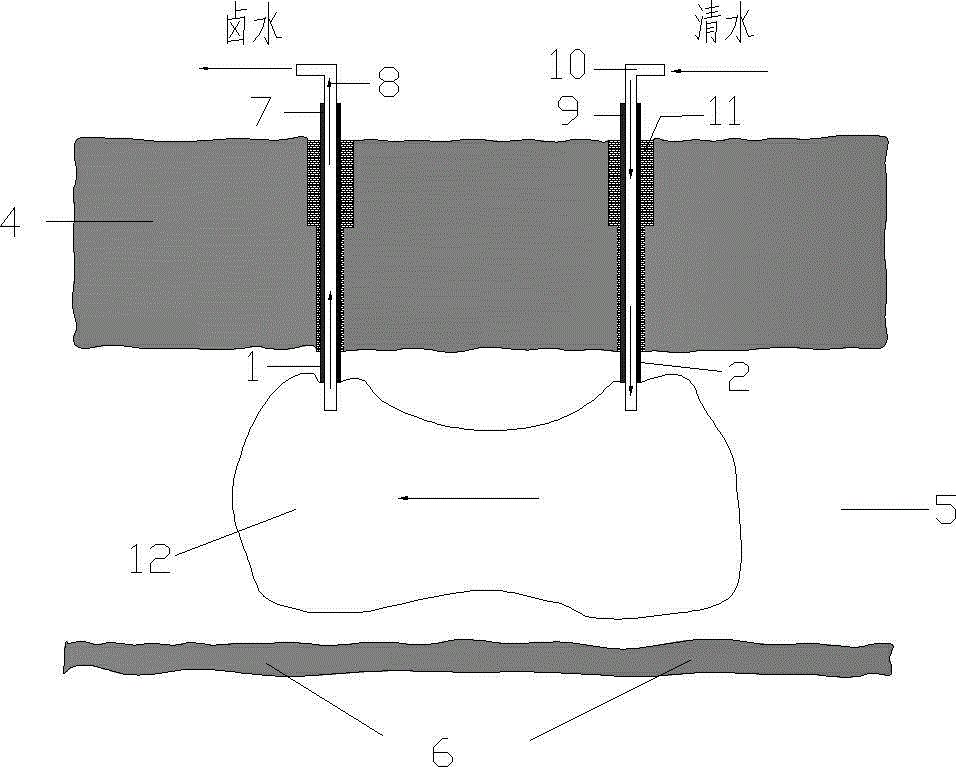

Double-vertical shaft horizontal butt joint salt cavern deposit construction method

The invention discloses a double-vertical shaft horizontal butt joint salt cavern deposit construction method. The method comprises the following steps of: (1) respectively constructing two vertical shafts on a salt rock ore layer; (2) constructing a horizontal well between the two vertical shafts; (3) respectively arranging a technical sleeve and an inner pipe in each vertical shaft; and (4) injecting clear water into one vertical shaft, discharging brine water from the other vertical shaft, exchanging the positions for water inflow and brine discharge after a period of time, and circulating in such a way till the shape of a cavity is similar to a horizontal calabash, thereby completing cavity construction. By utilizing the method, the construction speed of the salt rock cavern can be increased, a single-well casing arrangement process can be simplified, and the cavity construction cost can be reduced; and the concentration of the extracted brine water can be ensured on the premise of meeting the shape control of the cavity construction, and the brine water can be directly conveyed to a brine water treatment enterprise.

Owner:中国平煤神马集团联合盐化有限公司

Pretreatment technique for steel member hot spraying

InactiveCN101158013ALess investmentImprove processing efficiencyMolten spray coatingSuperimposed coating processThermal sprayingSurface cleaning

The invention discloses a pretreatment technique for the heat spraying for a steel part, belonging to the technique field of surface treatment. The process is as follows: surface cleaning-degreasing-derustin-sealing-surface coarsening-heat spraying. The invention has the advantages that the technique has simple requirements to the treatment of the parts, the distribution of the technique, and is easy to operate, good pretreatment quality, which warrants the quality of the heat spraying; besides, the technique requires little investment to the infrastructure, and has high treatment efficiency, low construction cost, and good economic benefit.

Owner:XUZHOU ZENITH COATING

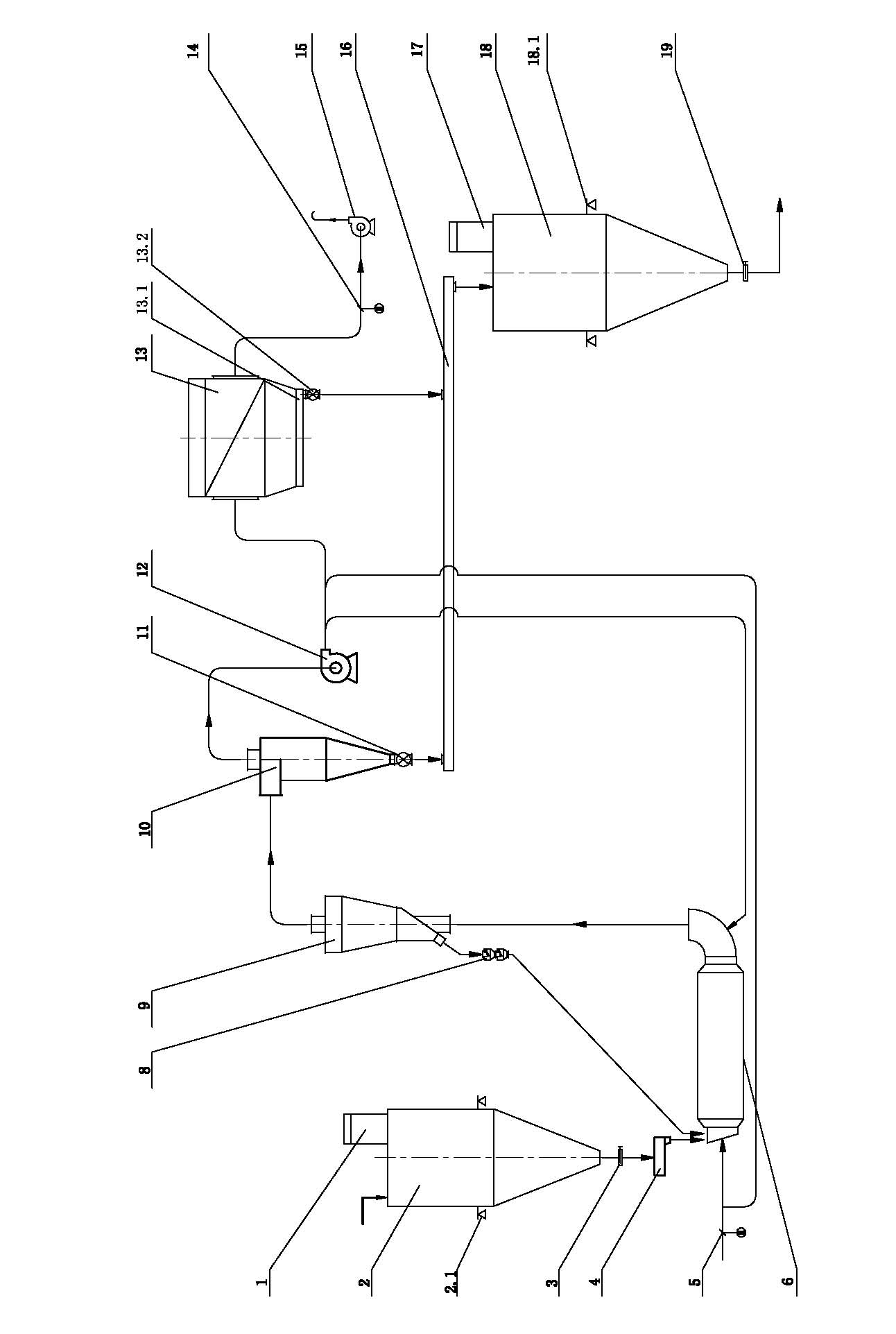

Process for preparing carbon forming powder

InactiveCN101972687AImprove dust carrying capacityReduce power consumptionGrain treatmentsProcess engineeringBall mill

The invention relates to a process for preparing carbon forming powder, in particular to a new process for preparing carbon forming powder by adopting an air swept type ball milling system. In the invention, equipment mainly comprises a raw material bin, an air swept type ball mill, a high-efficiency rotor type grader, a gas tank pulse bag type dust collector, a main exhaust fan and a finished powder bin. In the main work process of the invention, a raw material is fed and added to the air swept type ball mill through a feeder and is subjected to rough and fine powder grading through the high-efficiency rotor type grader, rough particles are returned to the ball mill for pulverizing once again, and fine particles enter the gas tank pulse bag type dust collector for collection. The invention has the technological performance advantages of high systemic force supply, low power consumption for unit product, high finished powder purity, and good uniformity and stability, and completely eliminates the phenomena of air leakage and ash flying in the traditional process because of the operation in a negative pressure state. The process is not only suitable for the optimization and technological improvement on the traditional process in the production process of the carbon forming powder, but also suitable for new projects of a carbon forming powder preparation system.

Owner:NANJING UNIV OF TECH

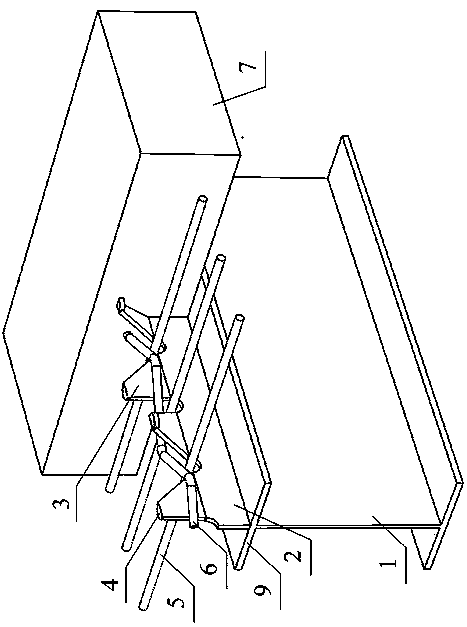

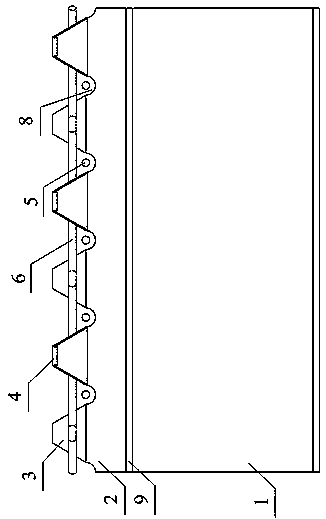

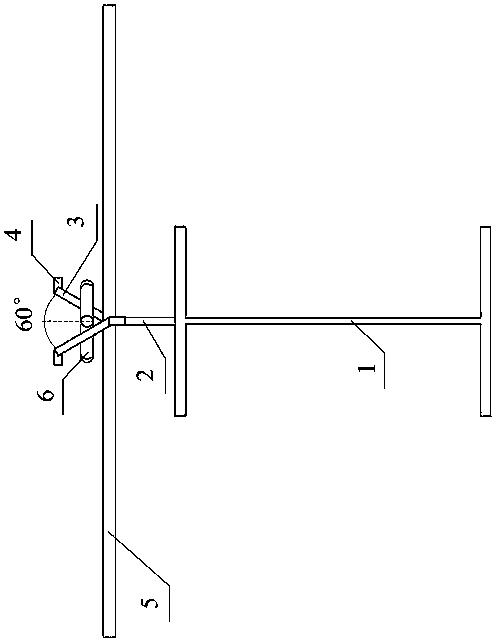

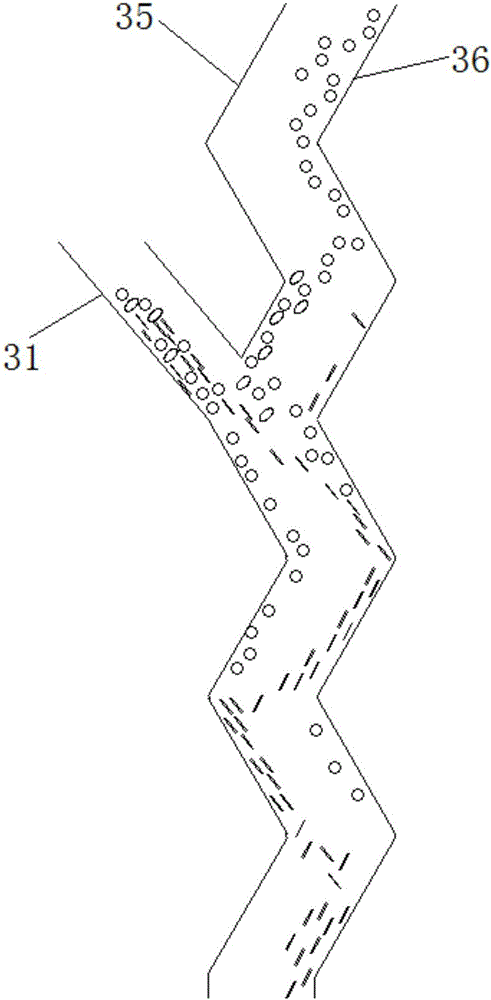

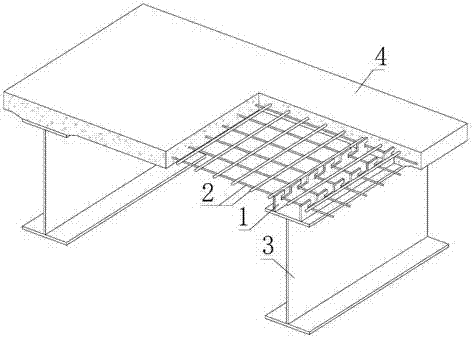

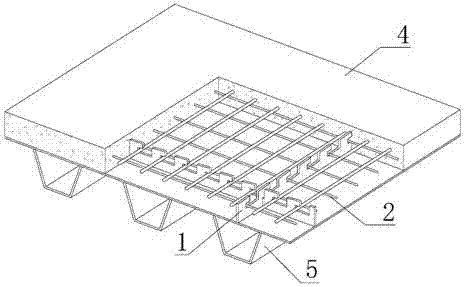

Structure of alternative folding flange type steel plate shear key and construction method thereof

ActiveCN107675609AGuaranteed utilizationNo wasteBridge structural detailsBridge erection/assemblyClassical mechanicsArchitectural engineering

Provided are a structure of an alternative folding flange type steel plate shear key and a construction method thereof. The steel plate shear key includes a ribbed plate which has semicircular holes,trapezoidal flange plates alternatively folding, and semicircular end plates. The semicircular hole is internally provided with a horizontal through rebar. A vertical bending rebar is arranged among the flange plates. An upper concrete panel is poured on a steel beam top plate, and the upper concrete panel completely covers the steel plate shear key. The construction method comprises the followingsteps: cutting and forming steel plates used in the shear key, alternatively folding the trapezoidal flange plates and the end plates, welding the ribbed plate integrally with the steel beam top plate, placing the horizontal through rebars and the vertical bending rebar, binding the structure using a reinforcing mesh, pouring the upper concrete panel and normally maintaining to set time, dismounting a formwork. The alternative folding flange type steel plate shear key is welded integrally with a steel beam, cooperative work of upper concrete and a lower steel beam is realized. The structure is advantaged by simple structure, convenient and fast construction, and little steel material waste, and is beneficial for popularization and application of a steel-concrete combined bridge.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

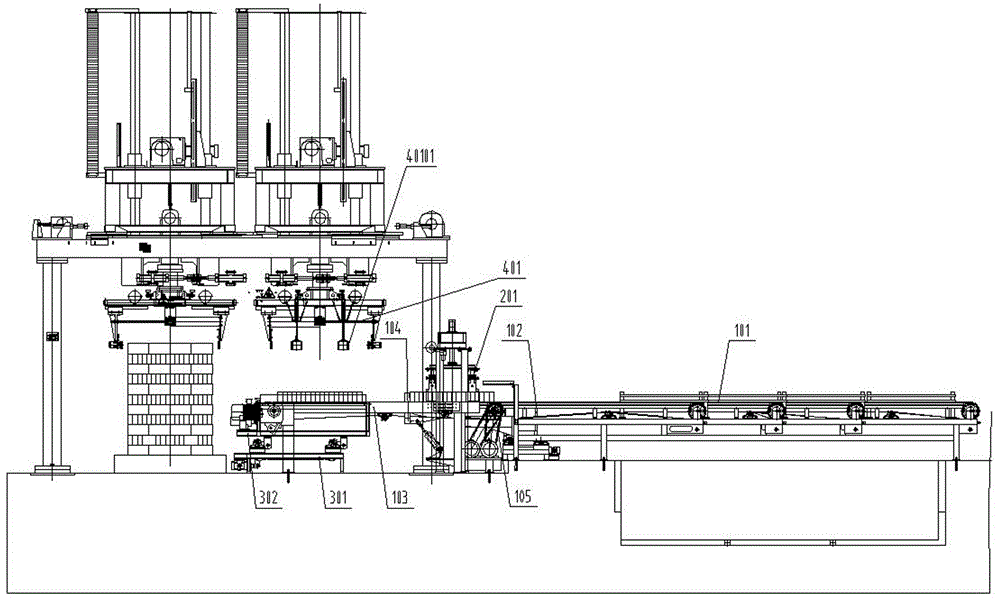

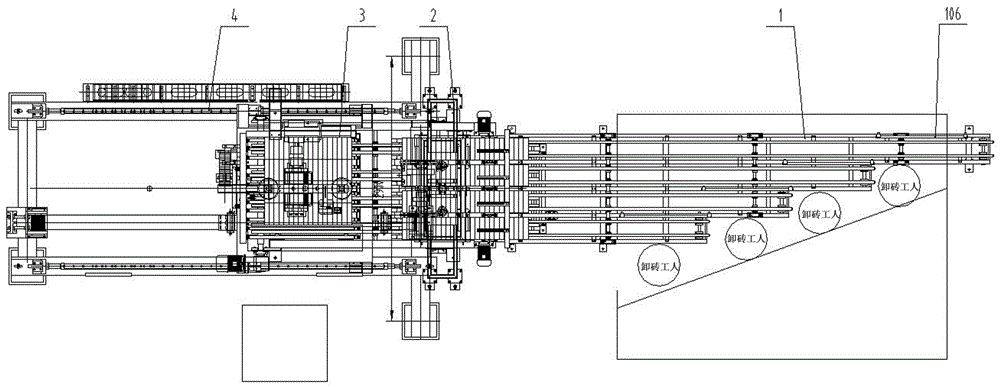

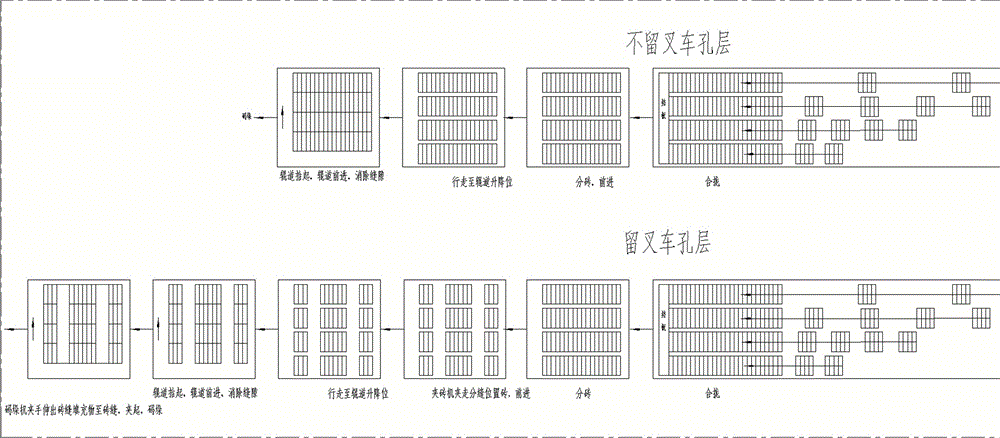

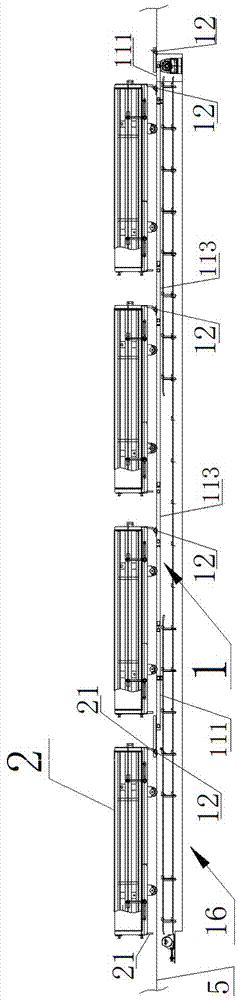

Semiautomatic brick unloading, grouping and stacking device and method for sintered bricks

PendingCN106743695AReduce equipment costsGood process stabilityStacking articlesDe-stacking articlesEngineeringBrick clamp

The invention relates to a semiautomatic brick unloading, grouping and stacking device and method for sintered bricks. A brick putting and grouping mechanism, a brick clamping machine, a lifting roller bed and a stacking machine are arranged, the bricks are unloaded on the brick putting and grouping mechanism through manual work, and semiautomatic brick unloading, grouping and stacking are achieved; and the equipment cost is low, and the beneficial effects that automatic grouping and packaging can be achieved are achieved. By means of the semiautomatic brick unloading, grouping and stacking method, the stability in the process is good, the technology layout is simple, the labor intensity is greatly improved, in addition, efficiency is high, safety is good, and very high application popularization value is achieved.

Owner:中建材(洛阳)节能科技有限公司

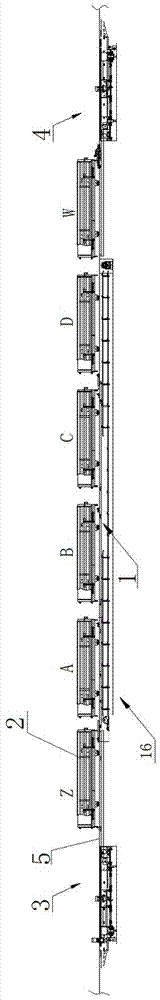

Die conveying system for aerated concrete block delaying curing stage and operating method

ActiveCN106976152AReduce energy consumptionGuarantee molding qualityAuxillary shaping apparatusMechanical conveyorsReciprocating motionEngineering

The invention relates to a die conveying system for an aerated concrete block delaying curing stage. The system comprises a multi-pushing drawing mechanism, the multi-pushing drawing mechanism comprises a plurality of drawing devices which can move in a reciprocation mode and are mutually connected linearly in a rigidity mode; the drawing devices move along a first rail, and each of the drawing devices is provided with an unidirectional turnover mechanism correspondingly; the unidirectional turnover mechanisms are matched with contacting baffles arranged on to-be-cured dies; second rails are arranged at two sides of the multi-pushing drawing mechanism, and the to-be-cured dies move along the second rails; and the unidirectional turnover mechanisms provide unidirectional thrust to the contacting baffles in the conveying direction of the to-be-cured dies, cross the contacting baffles when the drawing devices return and do not generate acting force to the contacting baffles. The die conveying system for the aerated concrete block delaying curing stage and an operating method can achieve the casted die conveying effects of being automatic, free of impacting, simple in process layout and low in energy consumption.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

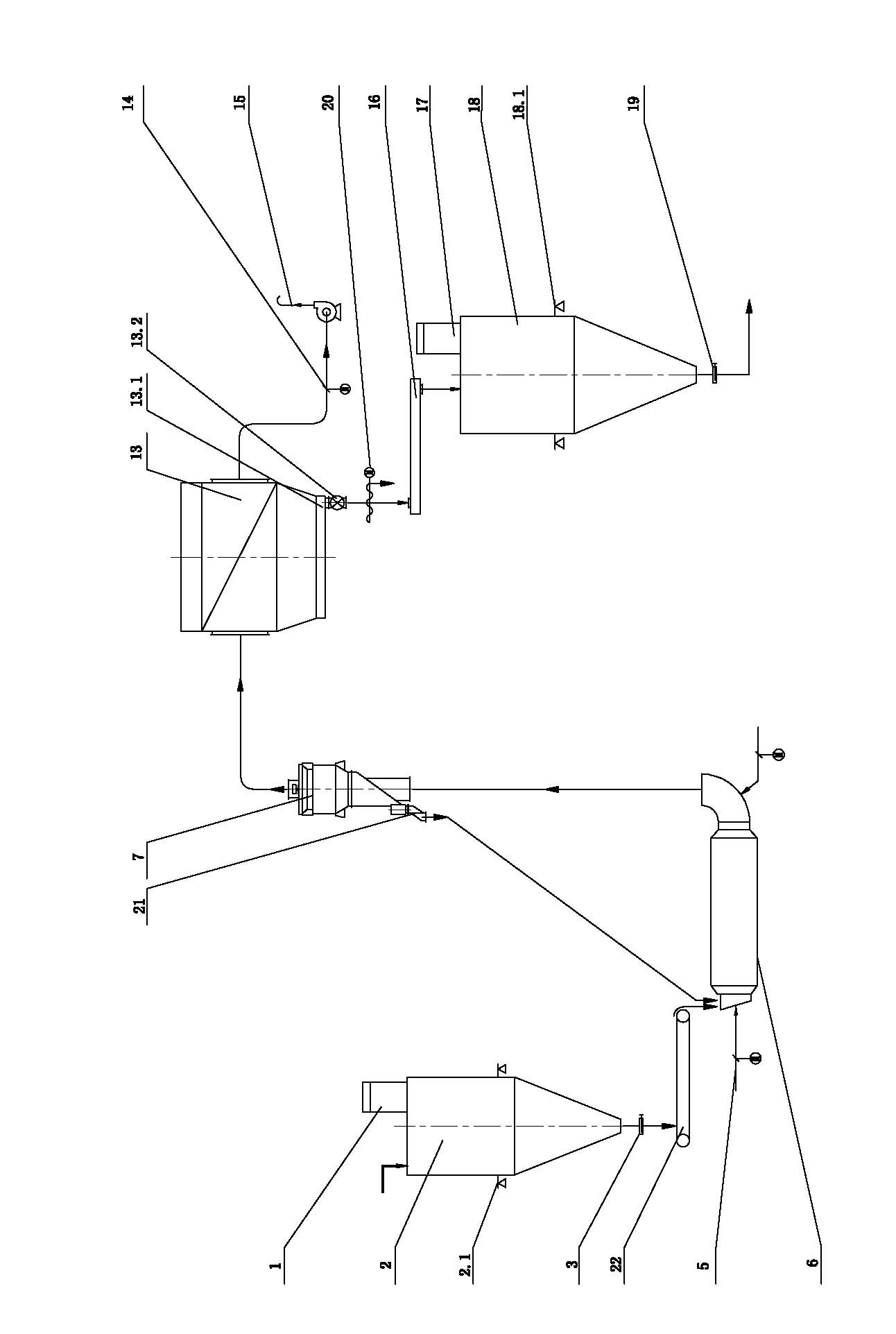

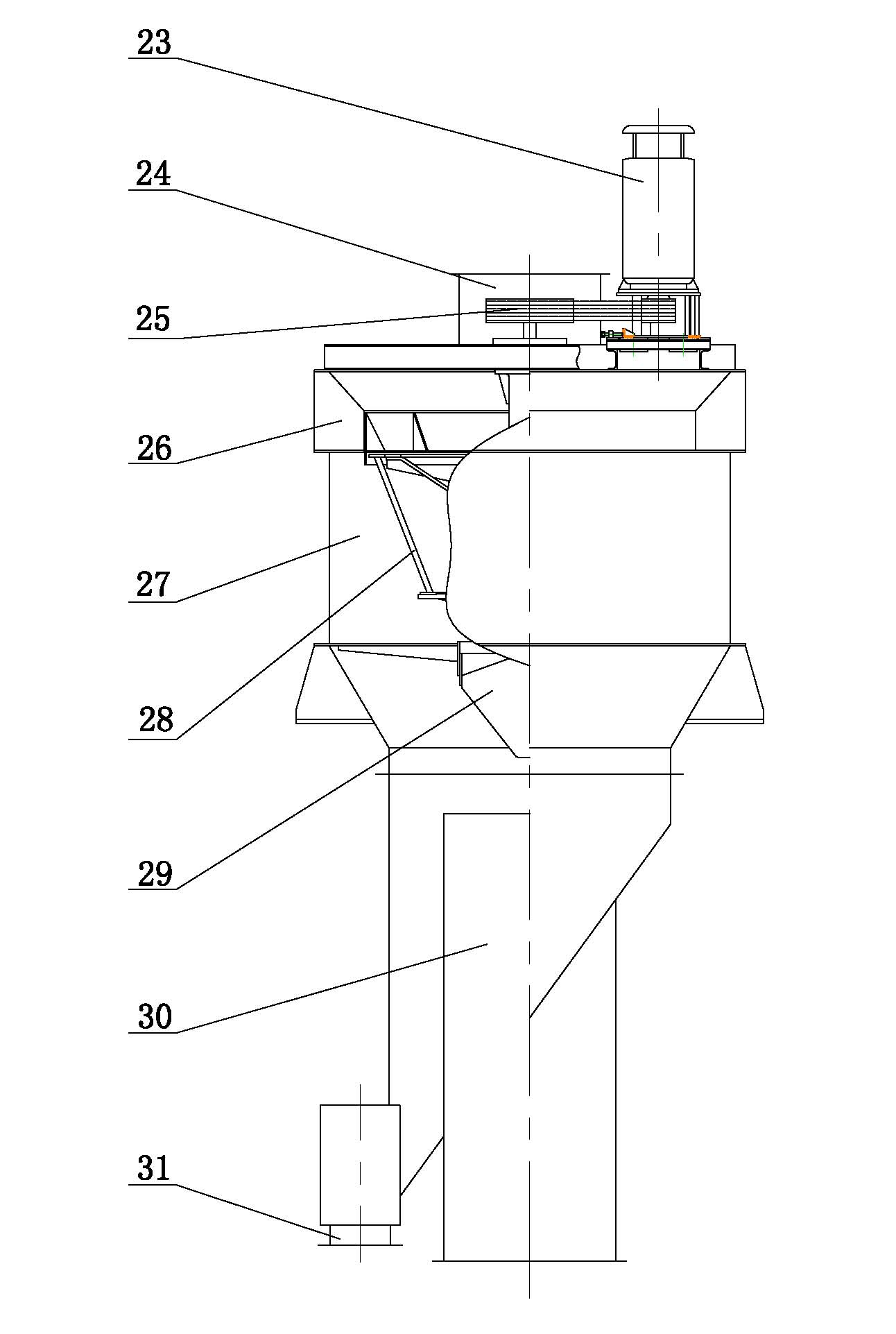

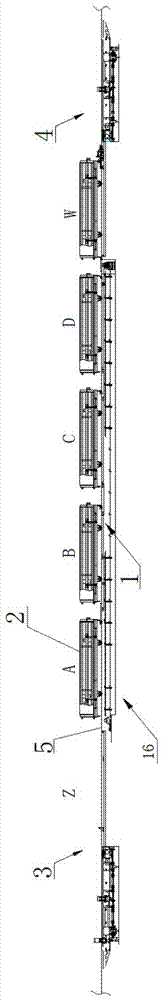

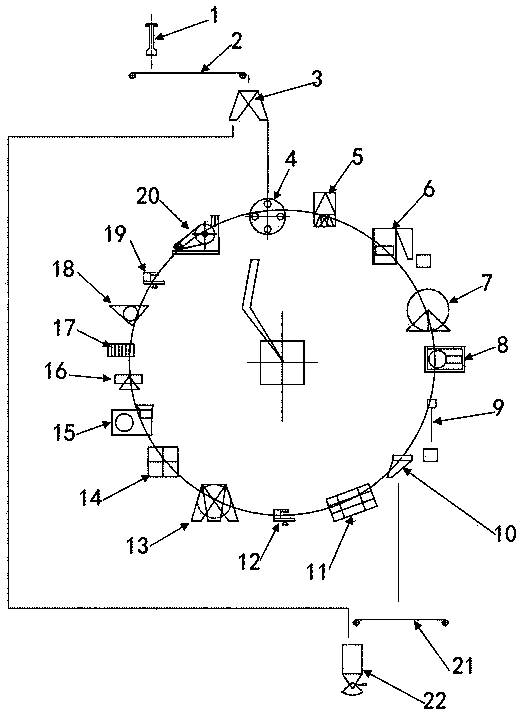

Temperature-controlled suspension roaster

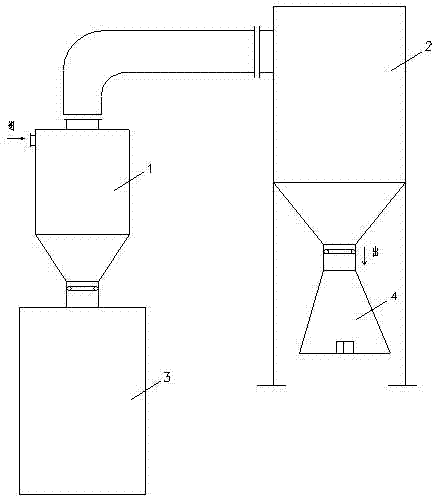

ActiveCN103193400AImprove decomposition efficiencyImprove cooling effectLime productionCycloneDecomposition

The invention relates to a temperature-controlled suspension roaster. The temperature-controlled suspension roaster comprises a cyclone separator, a preheating cyclone drum, a temperature-controlled roaster, a drier and a multistage cyclone cooler, wherein the cyclone separator is a two-stage cyclone separator which comprises a first-stage cyclone separator and a secondary cyclone separator, and the multistage cyclone cooler sequentially comprises a first-stage cooler, a middle-stage cooler and a final-stage cooler from the upstream to the upstream of the running path of material. The temperature-controlled suspension roaster has the advantages that the process arrangement is simple, the occupied land is small, and the operation and maintenance expenses are low; the roasting effect is good, the decomposition efficiency of magnesium carbonate is high, and magnesium oxide products with different purities can be obtained by changing calcination temperature; magnesite powder is dried and preheated by using discharged waste gas, the heat of high-temperature waste flue gas is fully recycled, and the heat efficiency of the roaster is improved; and the four-stage cyclone cooler has a good cooling effect and can be used for cooling a finished product magnesium oxide to be below 100 DEG C so that caloric content of magnesium oxide can be fully recovered for disintegrating magnesite and the energy consumption of the roaster can be reduced.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

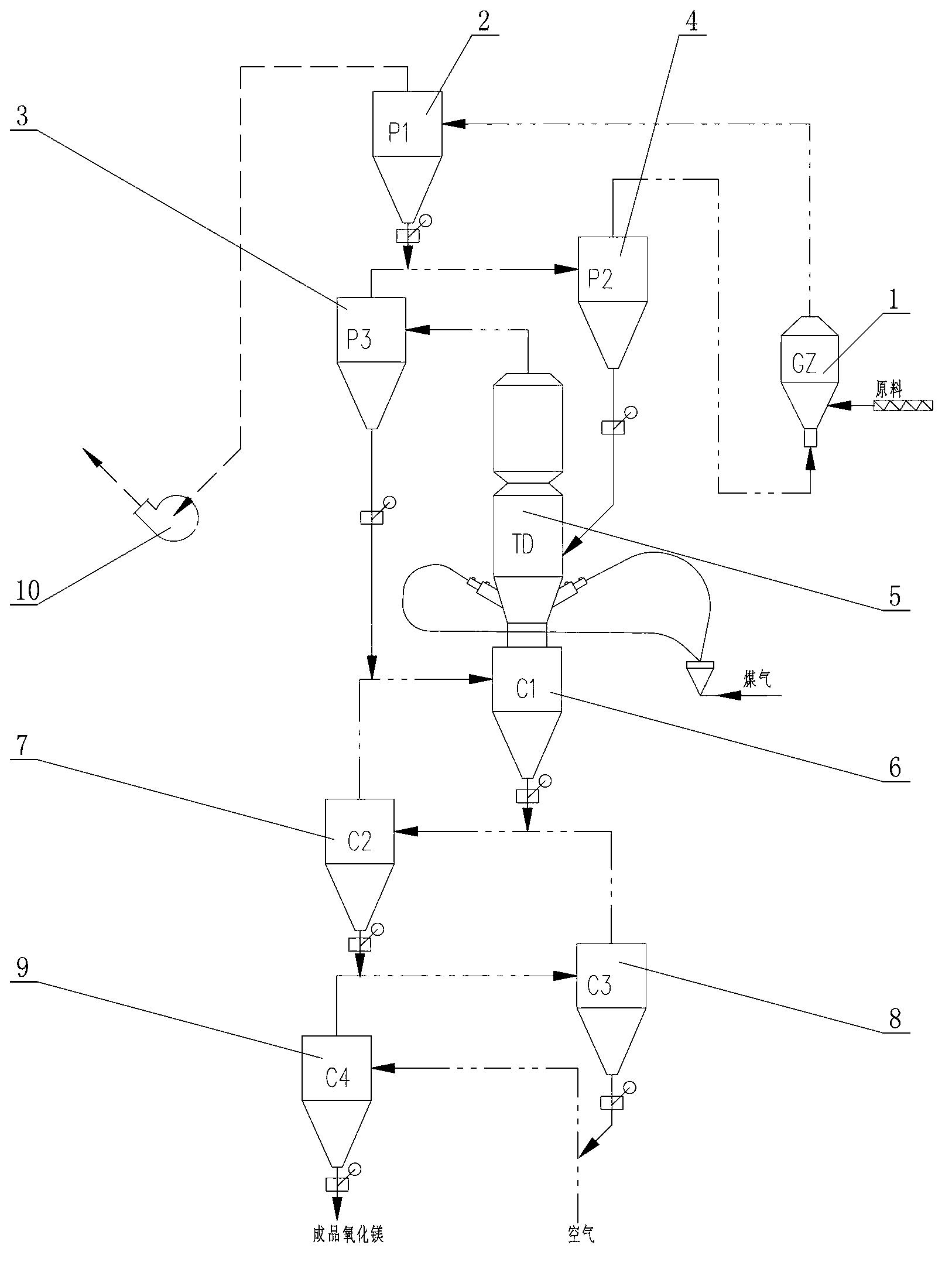

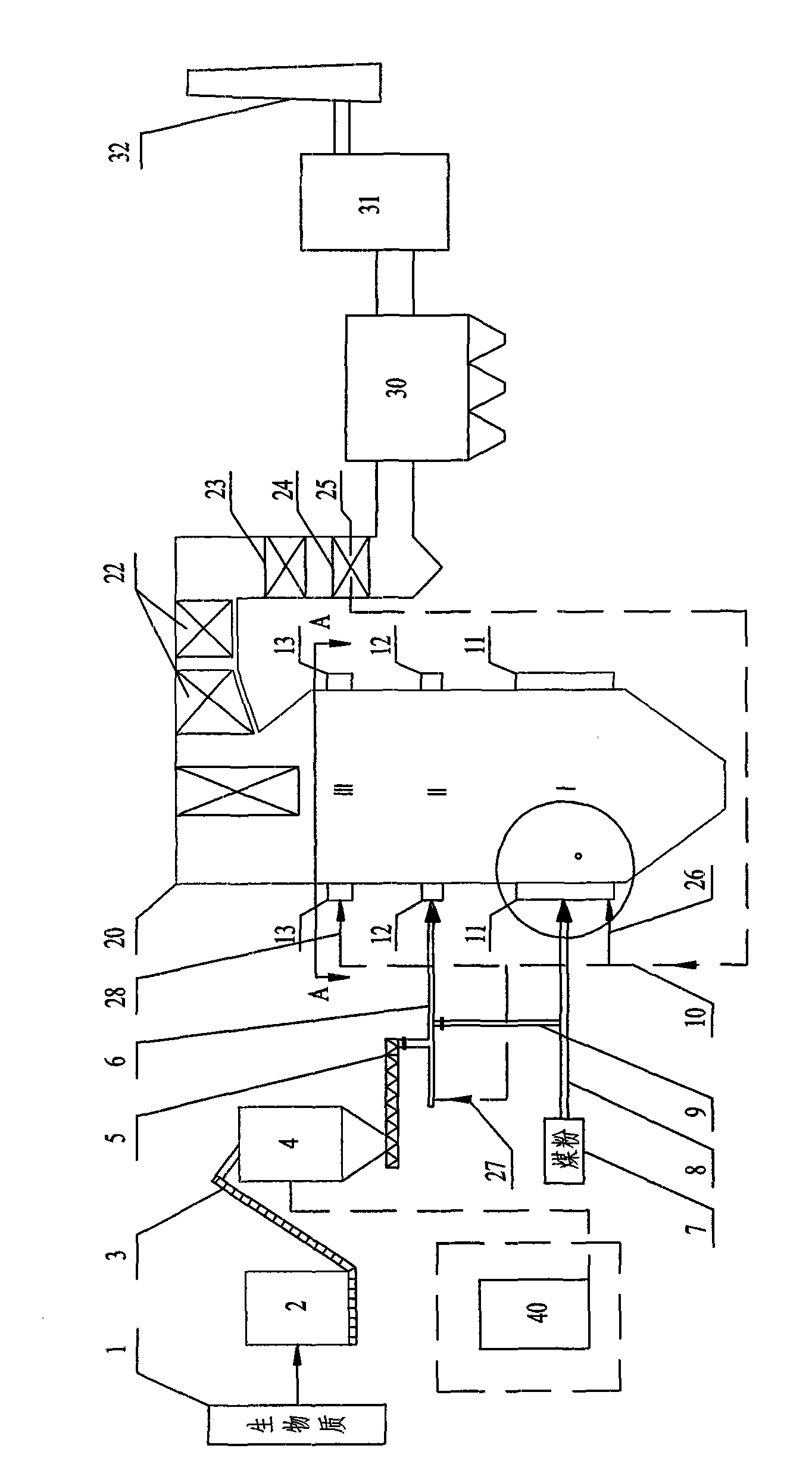

Waste gas waste heat recovery and purification process of coke oven gas heating system

InactiveCN110813006AImprove the heat quality of waste heat recoveryRealize desulfurization and denitrification purification treatmentCombination devicesCoke quenchingFlue gasExhaust fumes

The invention relates to a waste gas waste heat recovery and purification process of a coke oven gas heating system, and the method comprises the following steps: carrying out heat exchange cooling and dehydration treatment on coke oven waste flue gas generated in the coke oven heating process, and feeding into a dry quenching furnace for cooling high-temperature coke; allowing high-temperature waste flue gas discharged from the dry quenching furnace to enter a primary dust remover for dust removal, and meanwhile, spraying a desulfurizing agent into the primary dust remover to desulfurize thewaste flue gas; allowing the desulfurized high-temperature waste flue gas to enter a waste heat boiler for recovery of the heat of the high-temperature waste flue gas by the waste heat boiler, and controlling the outlet temperature of the waste flue gas by the waste heat boiler to allow the waste flue gas discharged after heat exchange to directly enter an SCR denitration device for denitration; and after heat exchange cooling and secondary dust removal are carried out on the denitrated waste flue gas, conveying one part of the denitrated waste flue gas to a chimney to be discharged, and conveying the other part of the denitrated waste flue gas to a waste flue gas pipeline on the upstream of the dry quenching furnace for recycling. According to the invention, the red coke waste heat and the coke oven waste flue gas waste heat are recycled, and meanwhile, the coke oven waste flue gas is purified, so that the flue gas emission meets the national standard, and the atmospheric pollution isreduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

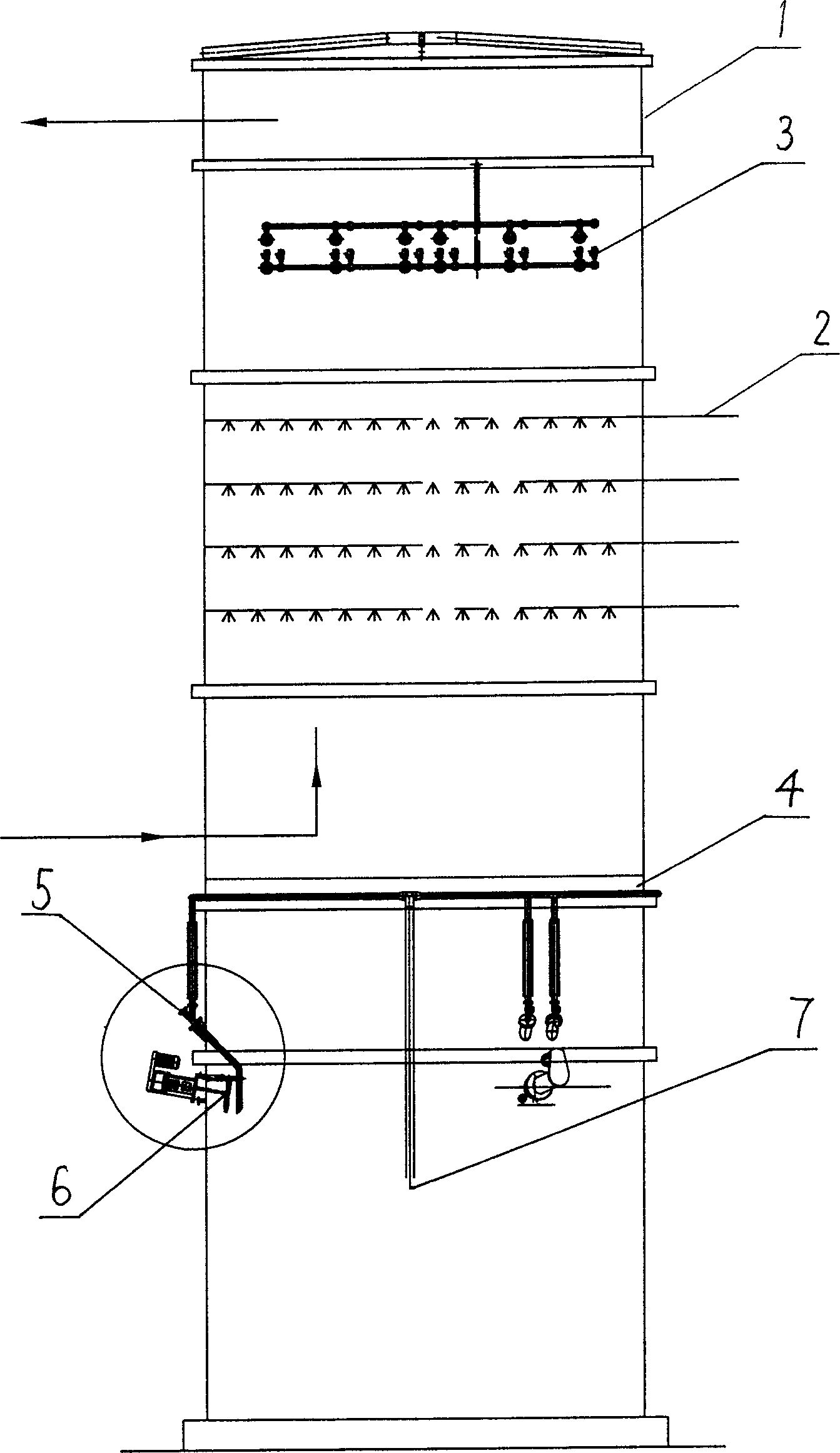

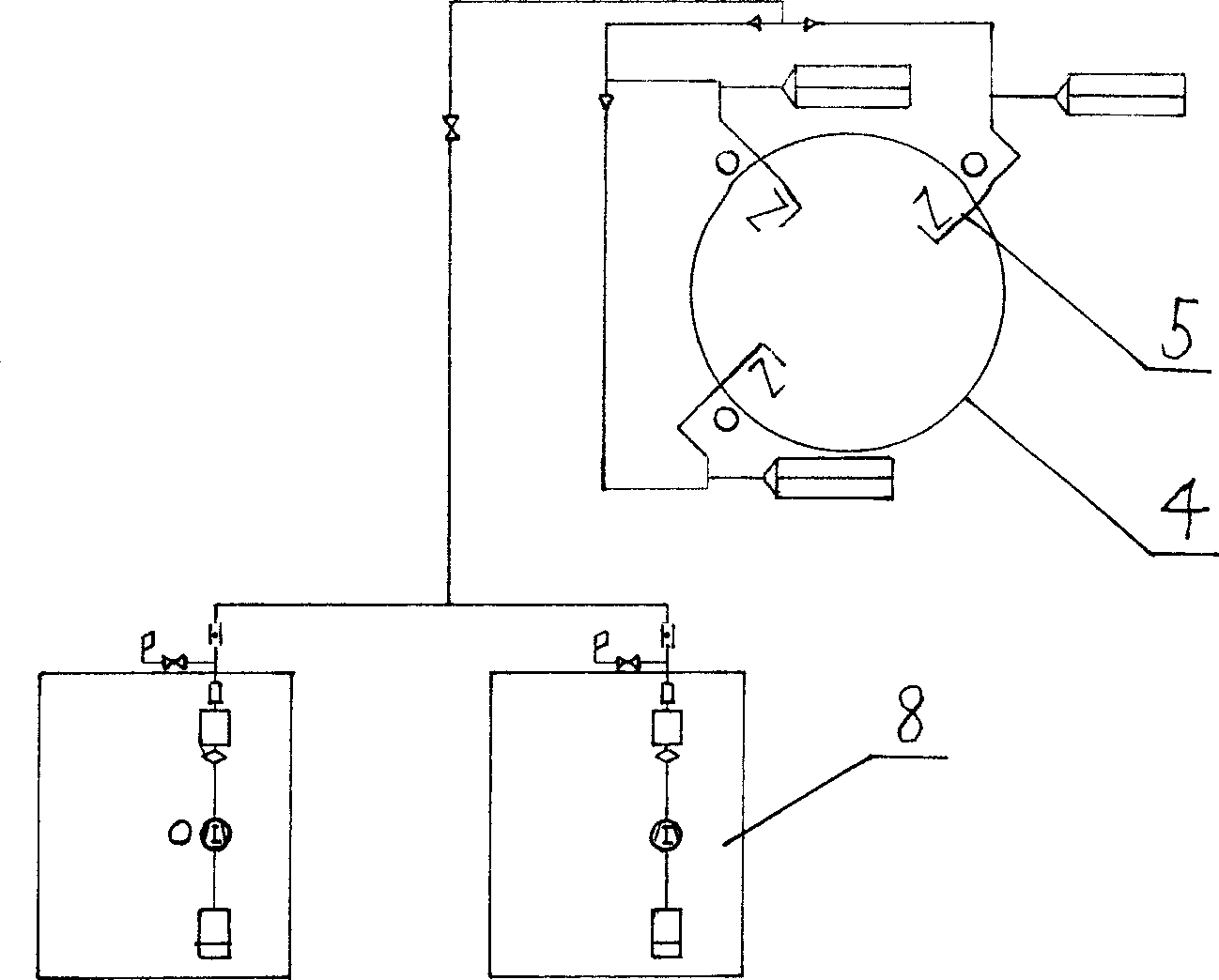

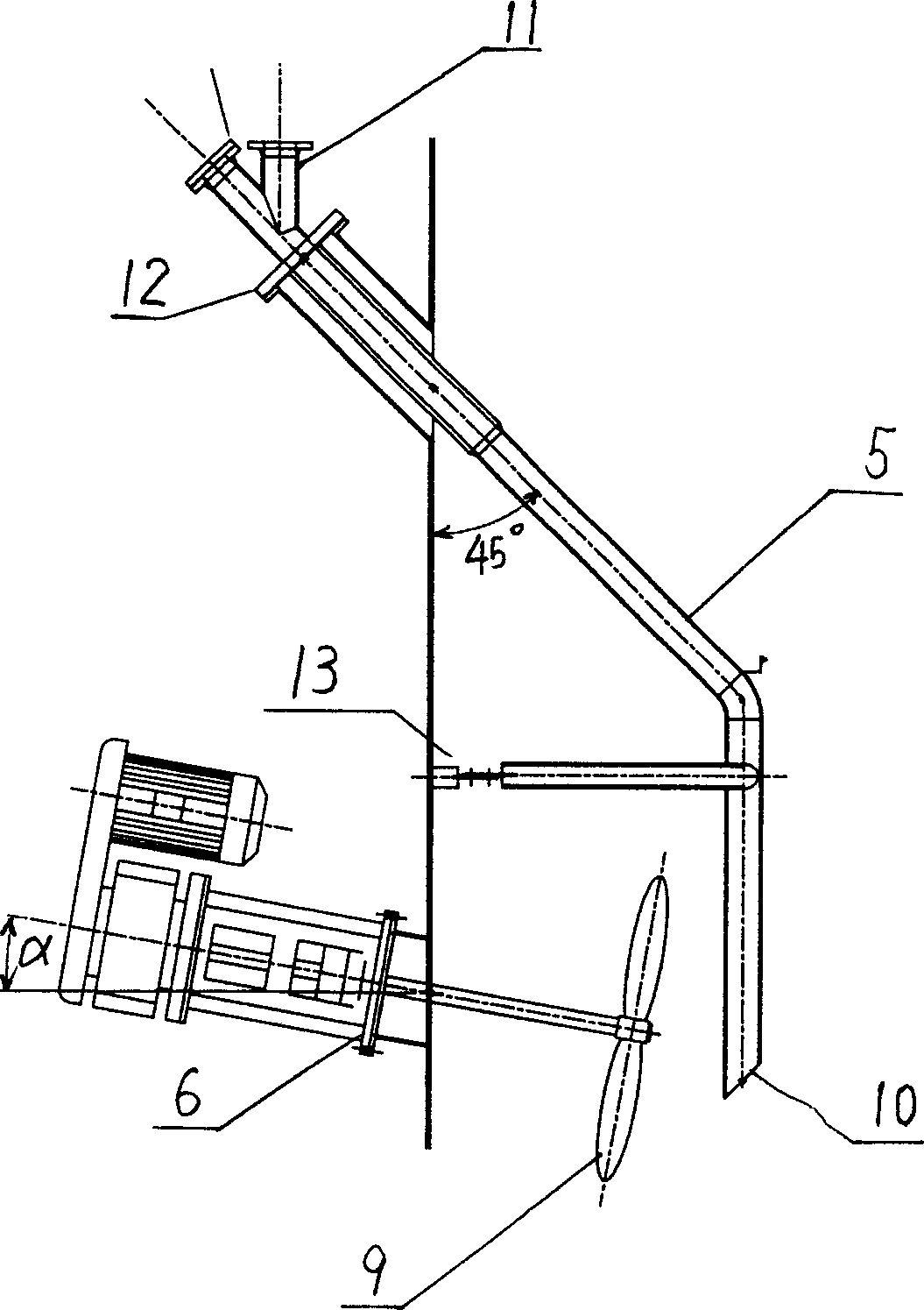

Forced oxidizing method and its device for smoke desulfurizing intermediate product-calcium sulfite

ActiveCN1587057AGuaranteed uptimeGuaranteed qualityCalcium/strontium/barium sulfatesDispersed particle separationEngineeringTower

The present invention provides forced oxidizing method and apparatus for calcium sulfite as the intermediate produce of desulfurizing fume. There are gypsum slurry pond in the bottom of the absorbing tower for desulfurizing reaction and storing slurry, oxidizing air generator outside the slurry pond and connected to two or three air spraying guns around the absorbing tower; air spraying guns inserted obliquely into the gypsum slurry to blow air into the slurry pond, and side stirrers between each of the air spraying gun outlets and the pond wall. The present invention has the advantages of simple and reasonable technological arrangement, low power consumption, full forced oxidation, etc.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Method for jointly controlling emission of NOx by utilizing multi-stage bias combustion and fuel reburning

ActiveCN101569829AEnhanced Heterogeneous Catalytic ReductionOvercome limitationsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlagEngineering

The invention belongs to the technical field of pulverized coal combustion, and discloses a method for jointly controlling the emission of NOx by utilizing multi-stage bias combustion and fuel reburning. The method comprises the steps: arranging a multi-stage bias burner containing 2 to 6 layers of bias burners in a multi-stage bias combustion area, sending 75 to 85 percent of fuel into the multi-stage bias combustion area, and generating flue gas containing the NOx during the combustion; spraying mixed reburning fuel of 15 to 25 percent of coal and biomass fuel into a mixed reburning area, forming a reburning reduction area, precipitating CHi and NHi active groups by the mixed reburning fuel in reducing atmosphere, and reacting the CHi and NHi active groups with the NOx generated in the multi-stage bias combustion area to be reduced into N2; and spraying the air into a burnout area, and completely combusting combustible substances which are not completely combusted. The method can efficiently control the emission of the NOx, ensure that the removal efficiency of the NOx is more than 80 percent, realize the combustion of high pulverized coal concentration, improve the performance of ignition and steady combustion, improve the adaptability of coal types, effectively prevent the slag bonding of water-cooled walls, and achieve the aims of improving boiler efficiency, saving energy and reducing consumption.

Owner:黄震

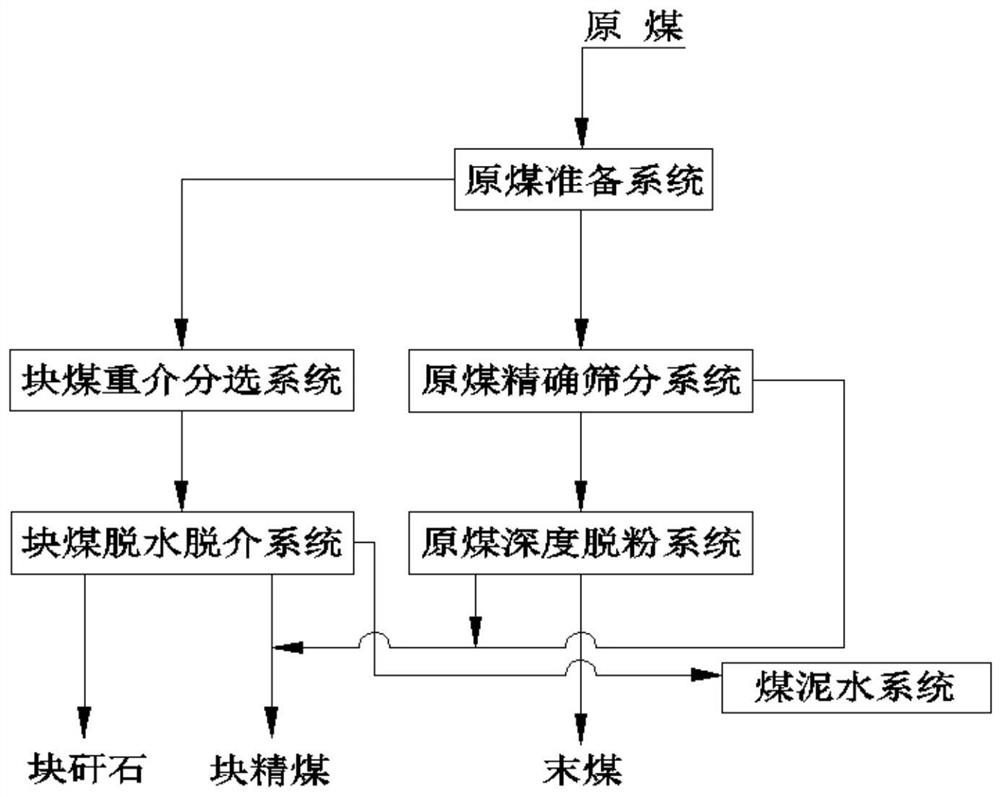

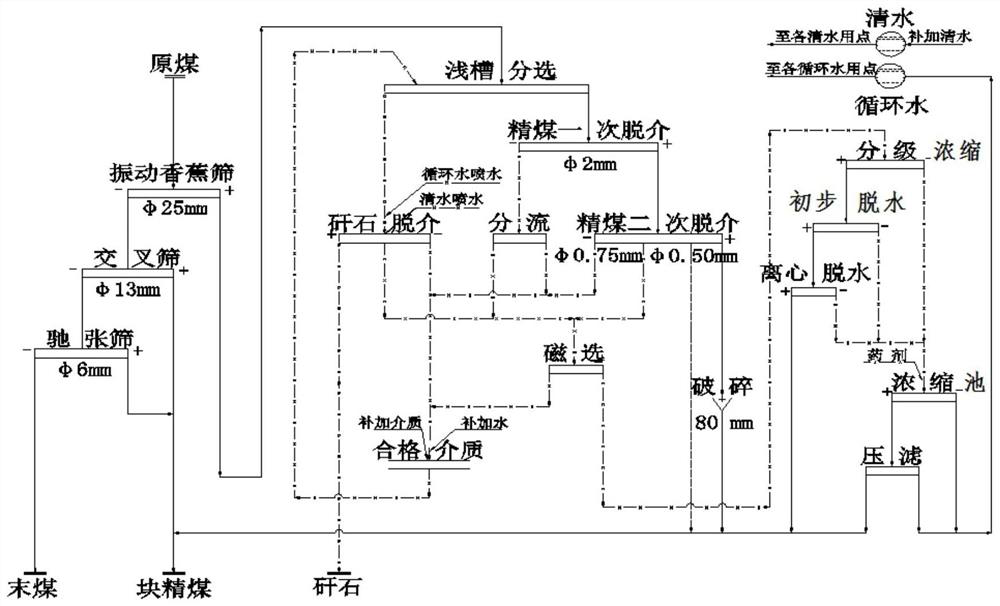

Classified washing process for thermal coal

InactiveCN112371325AQuality improvementSmall particle sizeSievingScreeningThermodynamicsWater treatment system

The invention discloses a classified washing process for thermal coal. The classified washing process comprises the following steps that raw coal is screened to raw coal with three particle sizes of being more than 25mm, between 25mm and 13mm and less than 13mm, all raw coal with the particle sizes of being more than 25mm enters into a lump coal dense medium separation system, the separated lump clean coal and lump gangue enter into a lump coal dehydration and medium removal system for treatment and then output separately, and screened water enters into a slime water treatment system; and allraw coal with the particle sizes between 25mm and 13mm is directly transferred to a lump clean coal belt, the raw coal with the particle sizes of being less than 13mm is subjected to deep screening and pulverized coal removal, the raw coal with the particle sizes of being more than 6mm is transferred to the lump clean coal belt to be output, and slack coal with the particle sizes of being less than 6mm enters a slack coal bunker to be output. The raw coal is classified and then enters different separation processes for separation, the characteristics of low separation lower limit and high separation precision of a dense-medium shallow-groove separator are combined, and the classified washing process is particularly suitable for thermal coal preparation plants with fragile coal quality andstrict requirements for product granularity, has the advantages of simple process arrangement and low production cost, improves the quality of clean coal, and also guarantees the yield of lump coal.

Owner:XINWEN MINING GROUP

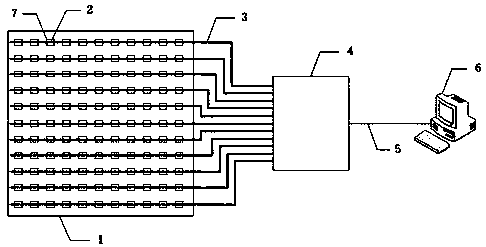

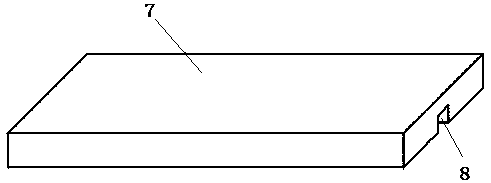

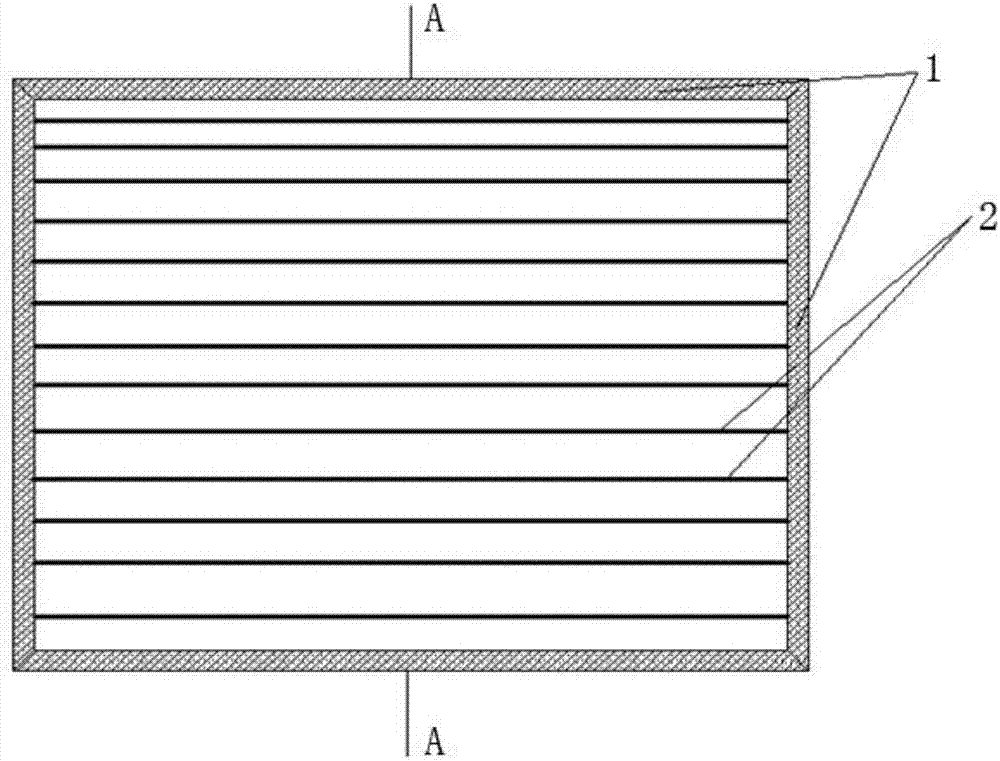

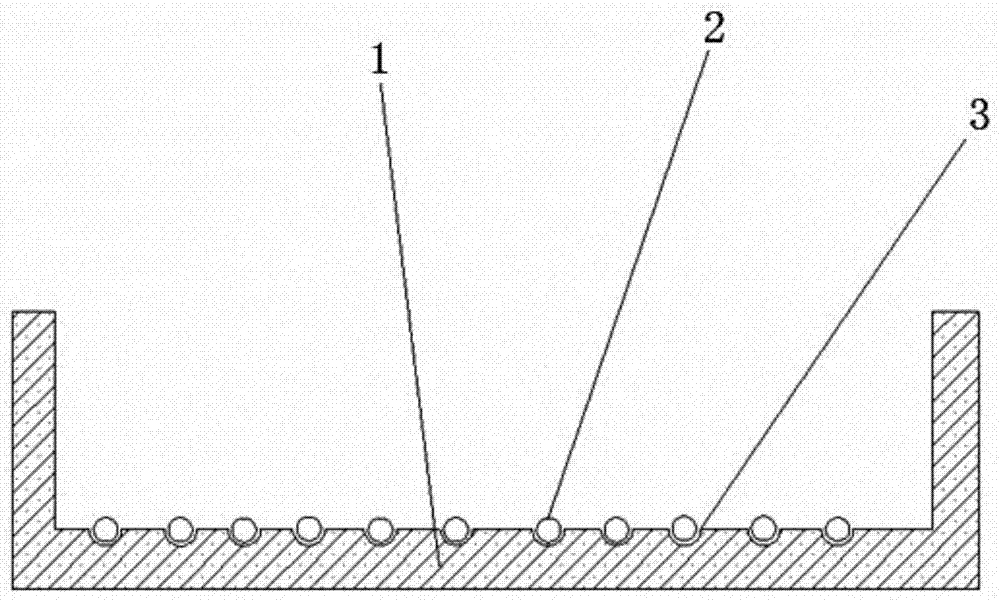

Wind tunnel test section bottom plate surface temperature uniformity testing device and testing method thereof

PendingCN110686798ANot affectedSimplify layout processThermometer detailsAerodynamic testingFiberInterference resistance

The invention provides a wind tunnel test section bottom plate surface temperature uniformity testing device and a testing method thereof. According to the scheme, the testing device comprises a bottom plate block, optical fibers, a fiber bragg grating signal demodulator and an upper computer; the number of the optical fibers is k, wherein k is a non-zero natural number; the k optical fibers are arranged on the bottom plate block in parallel; n fiber bragg gratings with different reflection center wavelengths are etched on each optical fiber, and the n fiber bragg gratings form a fiber bragg grating string, wherein n is a non-zero natural number; each optical fiber grating is packaged by a heat conduction substrate; all the fiber bragg grating strings are connected with the fiber bragg grating signal demodulator; and the fiber bragg grating signal demodulator is in data communication with an upper computer through a data line. According to the scheme, the temperature uniformity of thebottom plate surface of a wind tunnel test section can be accurately and effectively tested, the wiring is simple, the maintenance is convenient, the anti-interference capability is high, and the influence of the wind tunnel environment and gas flow is avoided.

Owner:中国空气动力研究与发展中心设备设计及测试技术研究所

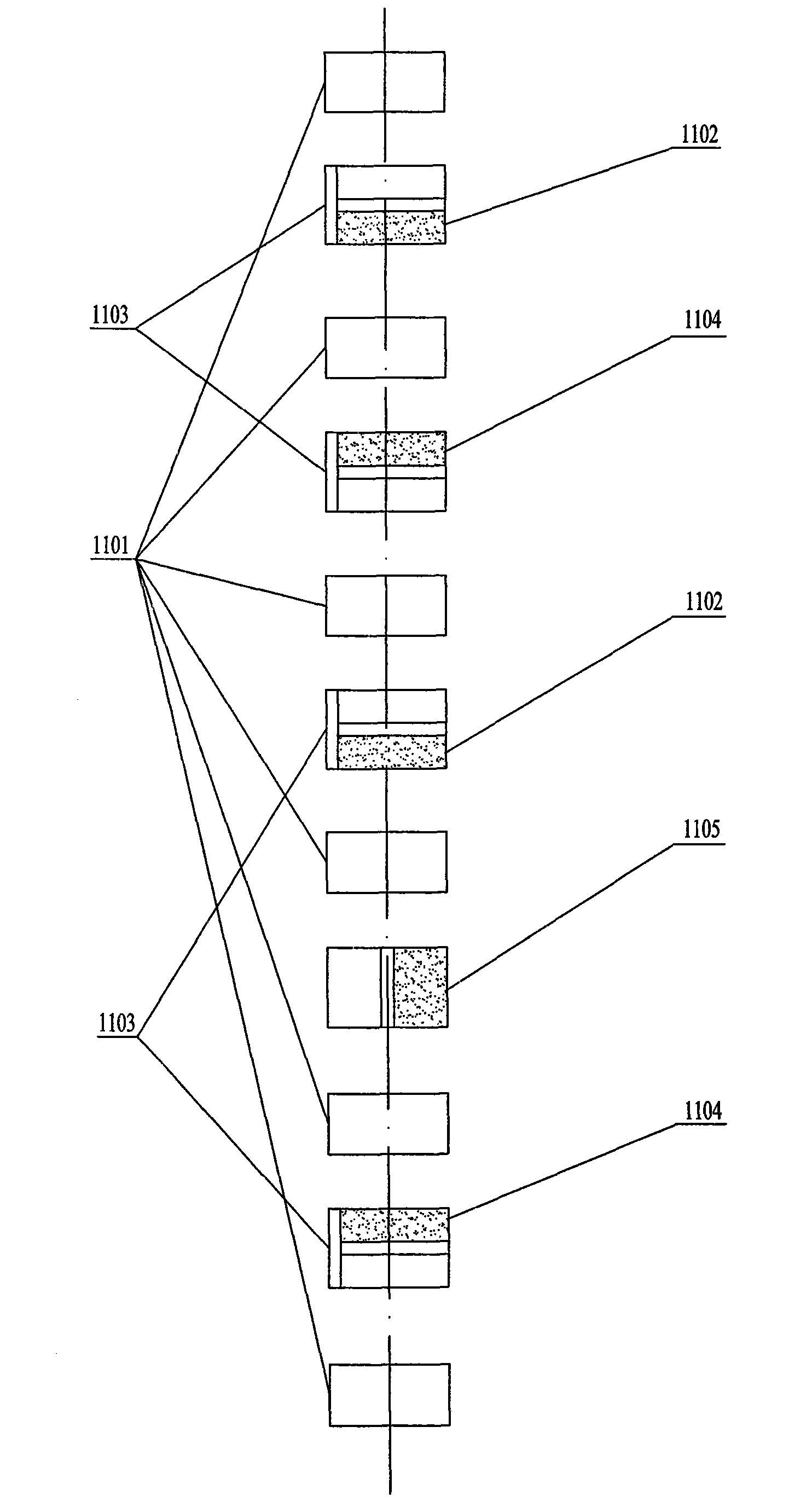

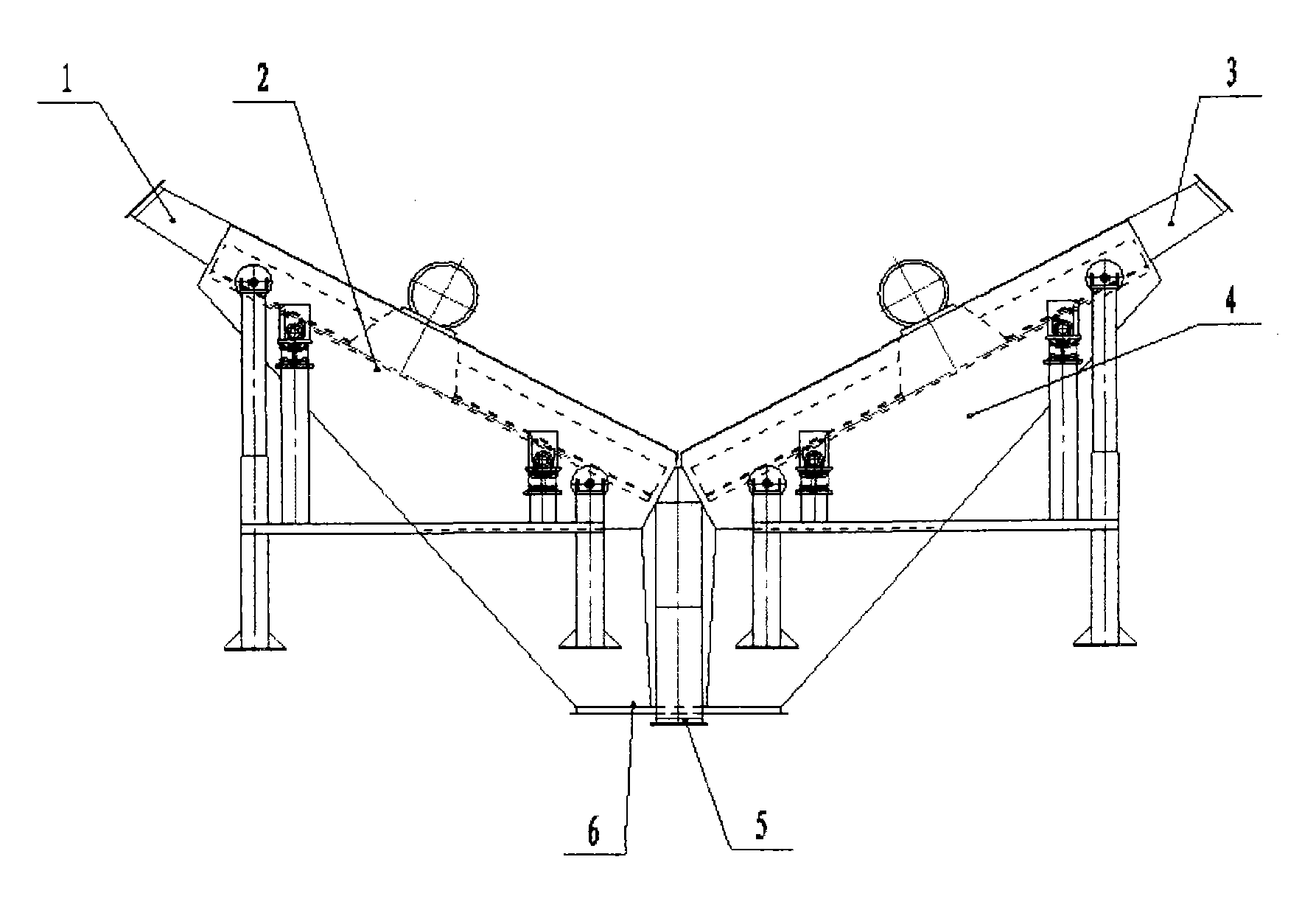

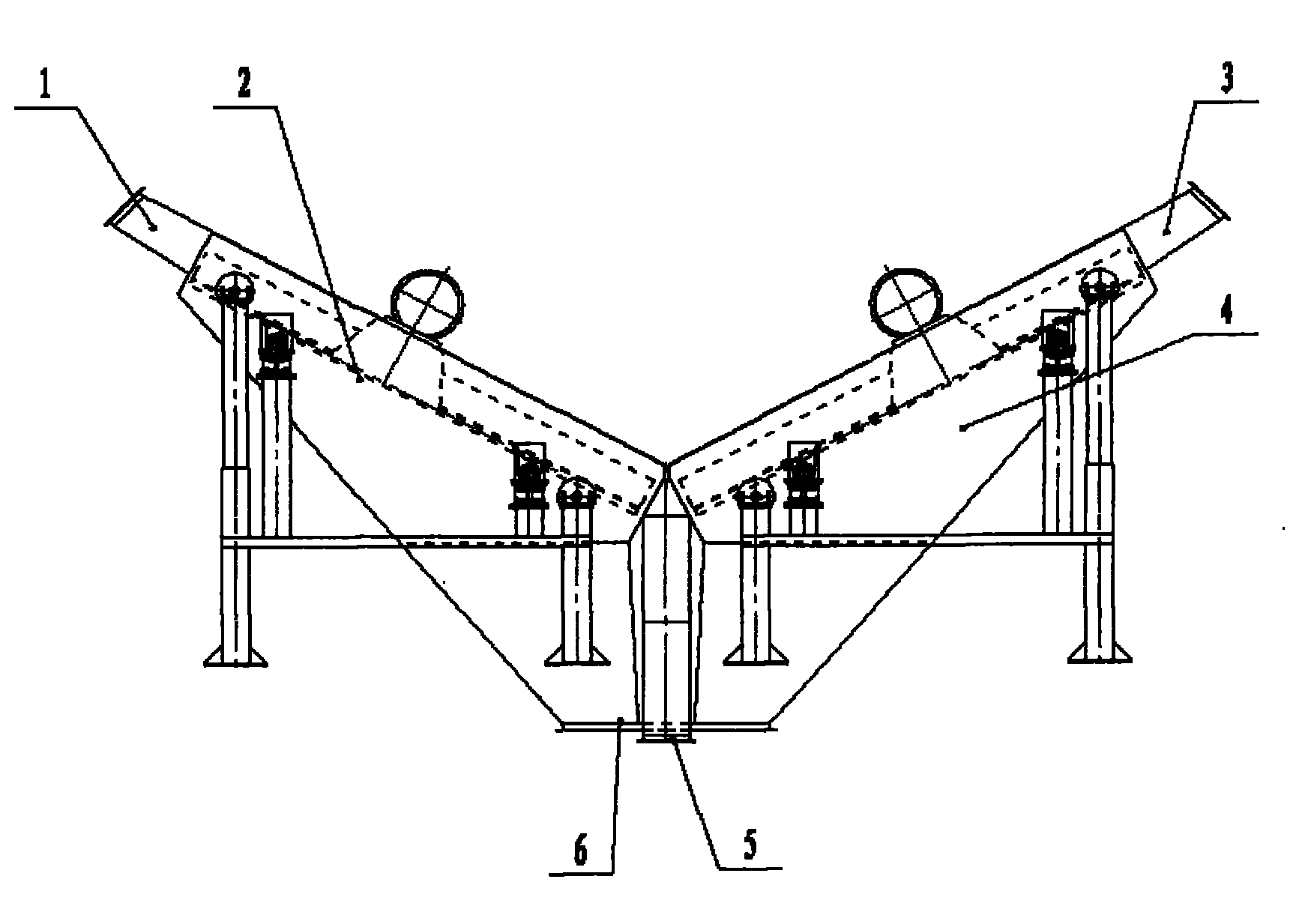

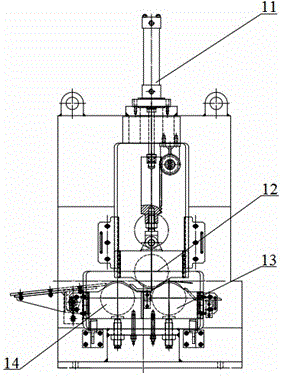

V-shaped self-flow vibration screen

InactiveCN102335654ASimplify layout processReduce purchasing costsSievingScreeningMaterial distributionBucket elevator

The invention discloses a V-shaped self-flow vibration screen. When the V-shaped self-flow vibration screen classifies a large number of materials, two self-flow vibration screens are integrated in a V shape, and two coarse material outlets and two fine material outlets are combined to one coarse material outlet and one fine material outlet. Materials are supplied to two material inlets of the V-shaped self-flow vibration screen by a bucket elevator and a three-way material distribution valve, are classified by the V-shaped self-flow vibration screen, and then flow into coarse and fine material outlets respectively and are discharged into next equipment. The V-shaped self-flow vibration screen is provided with only one coarse material outlet and one fine material outlet, and materials can be directly conveyed to next equipment by a chute, and conveying equipment is not needed. Due to the adoption of the V-shaped self-flow vibration screen, process set-up is easy, purchasing cost of equipment is reduced, and engineering building investment is reduced.

Owner:王华业

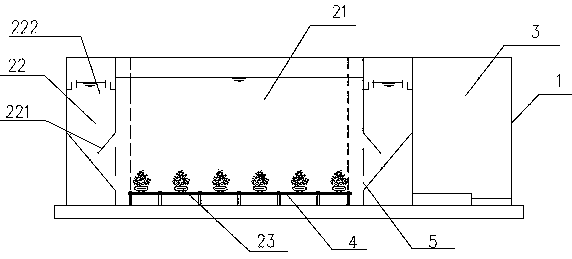

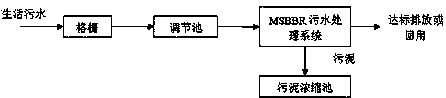

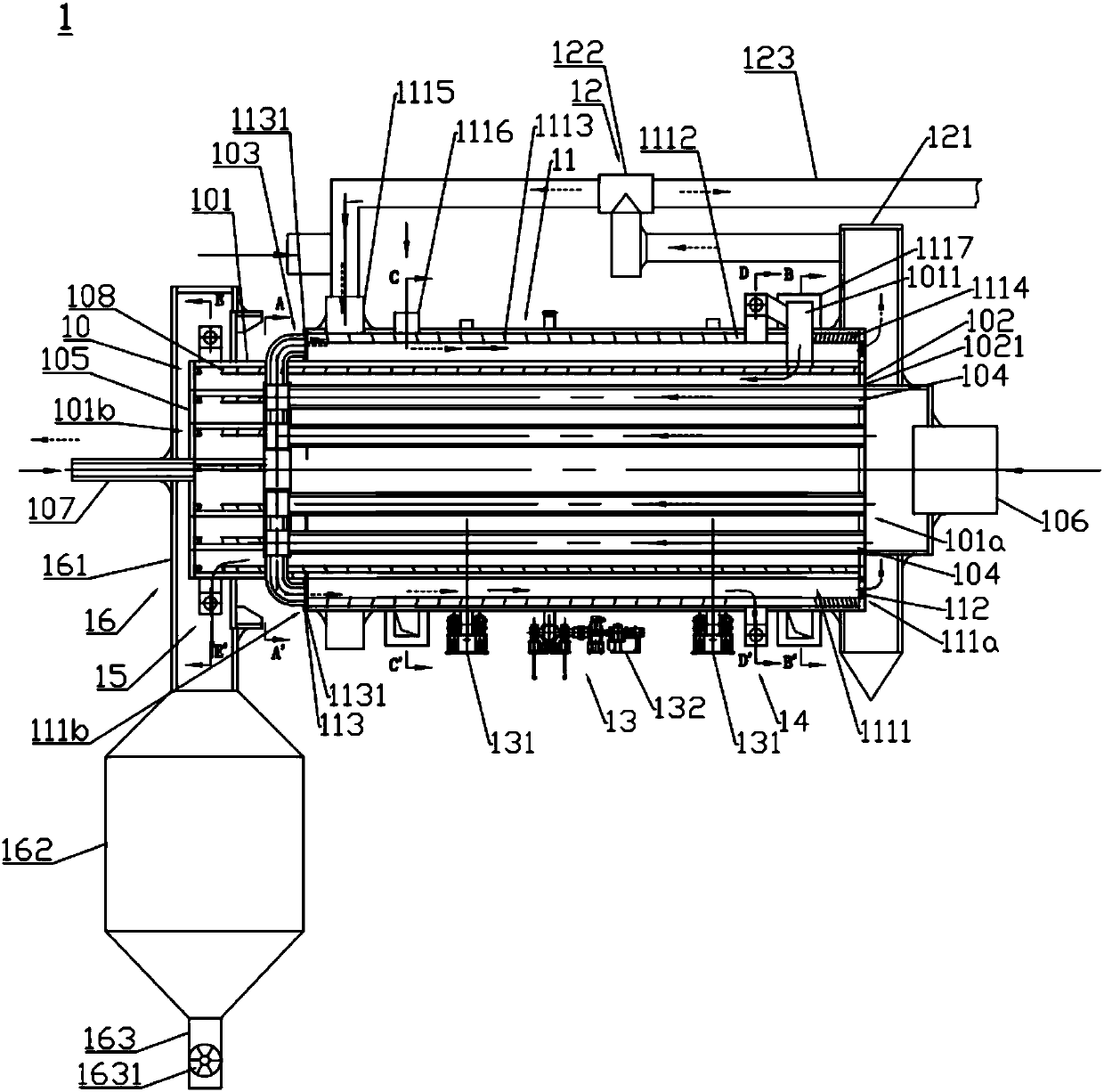

MSBBR wastewater treatment system and wastewater treatment process applying system

InactiveCN108751610APremium removalIncrease concentrationWater treatment parameter controlWater/sewage treatment by irradiationWater treatment systemSludge

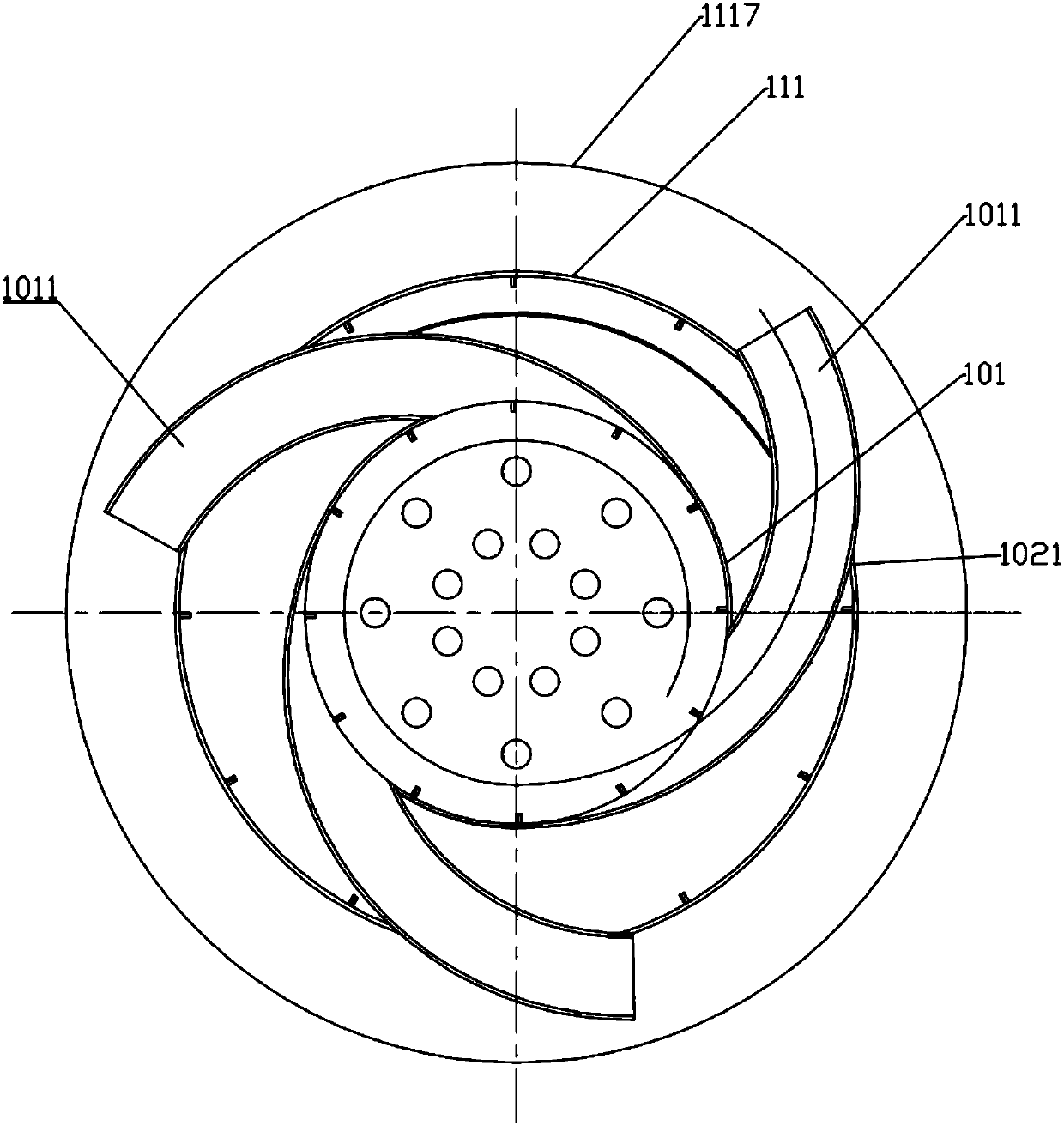

The invention discloses an MSBBR wastewater treatment system. The MSBBR wastewater treatment system comprises a pond body outer wall, a reaction zone and an equipment zone, wherein the reaction zone comprises a biological reaction zone and a settling zone; the biological reaction zone is arranged at the middle part of the pond body; the settling zone is arranged at the periphery of the biologicalreaction zone; the biological reaction zone is connected with the settling zone through a draining fine seam; an aeration device and a sludge collecting pipeline are arranged at the bottom of the biological reaction zone. Besides, the invention also discloses a wastewater treatment process applying the MSBBR wastewater treatment system. The MSBBR wastewater treatment system disclosed by the invention has the advantages of stable system / technology, high-quality effluent, few constructs, land conservation, low investment cost, low energy consumption, low operation cost and the like.

Owner:四川美源环能科技有限责任公司

Low-rank coal drying and pyrolysis integral quality improvement processing process equipment

ActiveCN107663460ALower working temperatureReduce heat lossIndirect heating destructive distillationSpecial form destructive distillationProcess equipmentEngineering

The invention relates to low-rank coal drying and pyrolysis integral quality improvement processing process equipment, which comprises a pyrolysis device, a drying device, a circulation fan flow division device, a support rotating device, an annular material guide airlock device, an annular discharging airlock device and a discharging device, wherein the pyrolysis device is arranged in the dryingdevice; the circulation fan flow division device is arranged in the drying device; the support rotating device is arranged at the bottom of the drying device and is opposite to the circulation fan flow division device; the annular material guide airlock device is arranged at one end of the drying device and communicates with the pyrolysis device; the annular discharging airlock device is arrangedat one end of the pyrolysis device, and is opposite to the annular material guide airlock device; the discharging device is arranged at the annular discharging airlock device. The pyrolysis device ofthe low-rank coal drying and pyrolysis integral quality improvement processing process equipment and the drying device are combined into a whole; the process arrangement is simplified; the process cost is reduced.

Owner:JIANGSU PENGFEI GROUP

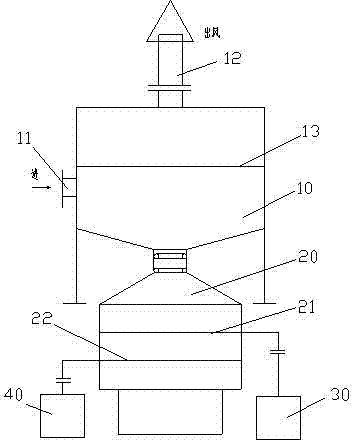

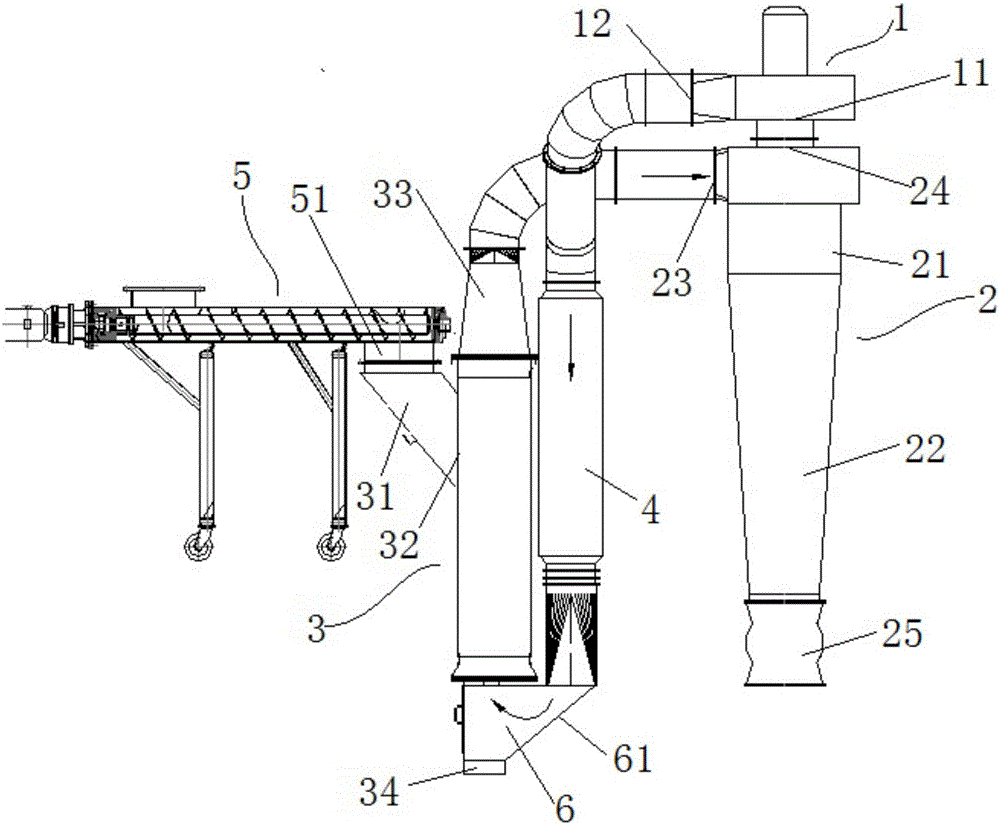

Integral dust removing and separating device

InactiveCN103752516ARealize the needs of processing technologySimplify layout processSievingGas current separationBiochemical engineeringSmall footprint

The invention discloses an integral dust removing and separating device. The separating device comprises a receiving sharer, a powder sieve, a charging bucket and a powder bucket, wherein the side part of the receiving sharer is provided with a feeding inlet; material dust-containing air current is fed from the feeding inlet of the receiving sharer; the top of the receiving sharer is provided with an air outlet pipeline; scattered air separated from dust is exhausted from the air outlet pipeline; the powder sieve is arranged on the lower part of the receiving sharer, and is a rotary vibration sieve; a first filter screen and a second filter screen are arranged at a certain interval in sequence in the powder sieve; the pore diameter of the first filter screen is larger than that of the second filter screen, so that materials and dust can be separated; the charging bucket is communicated with the first filter screen, and is used for collecting finished materials; the powder bucket is communicated with the second filter screen, and is used for collecting dust. The integral dust removing and separating device provided by the invention has simple processing set-up and small floor area; a product is treated at one time after sieving, can be weighed directly, and is convenient for metering; a general flow can be completed by one operator, and the running cost is low.

Owner:LIANYUNGANG ZHONGYI AVIATION MATERIALS

Construction method of double-shaft horizontal docking salt cavern storage

The invention discloses a double-vertical shaft horizontal butt joint salt cavern deposit construction method. The method comprises the following steps of: (1) respectively constructing two vertical shafts on a salt rock ore layer; (2) constructing a horizontal well between the two vertical shafts; (3) respectively arranging a technical sleeve and an inner pipe in each vertical shaft; and (4) injecting clear water into one vertical shaft, discharging brine water from the other vertical shaft, exchanging the positions for water inflow and brine discharge after a period of time, and circulating in such a way till the shape of a cavity is similar to a horizontal calabash, thereby completing cavity construction. By utilizing the method, the construction speed of the salt rock cavern can be increased, a single-well casing arrangement process can be simplified, and the cavity construction cost can be reduced; and the concentration of the extracted brine water can be ensured on the premise of meeting the shape control of the cavity construction, and the brine water can be directly conveyed to a brine water treatment enterprise.

Owner:中国平煤神马集团联合盐化有限公司

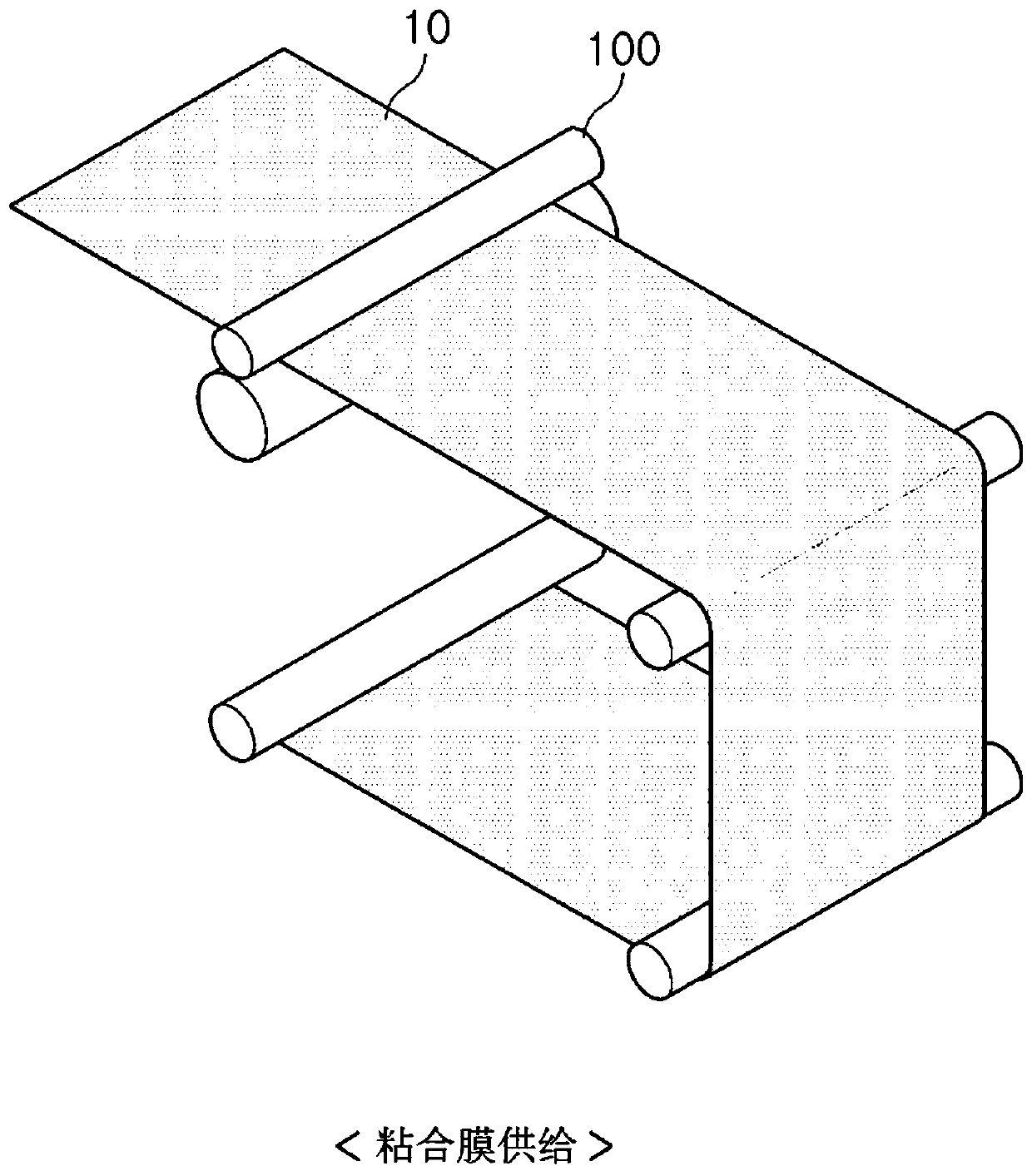

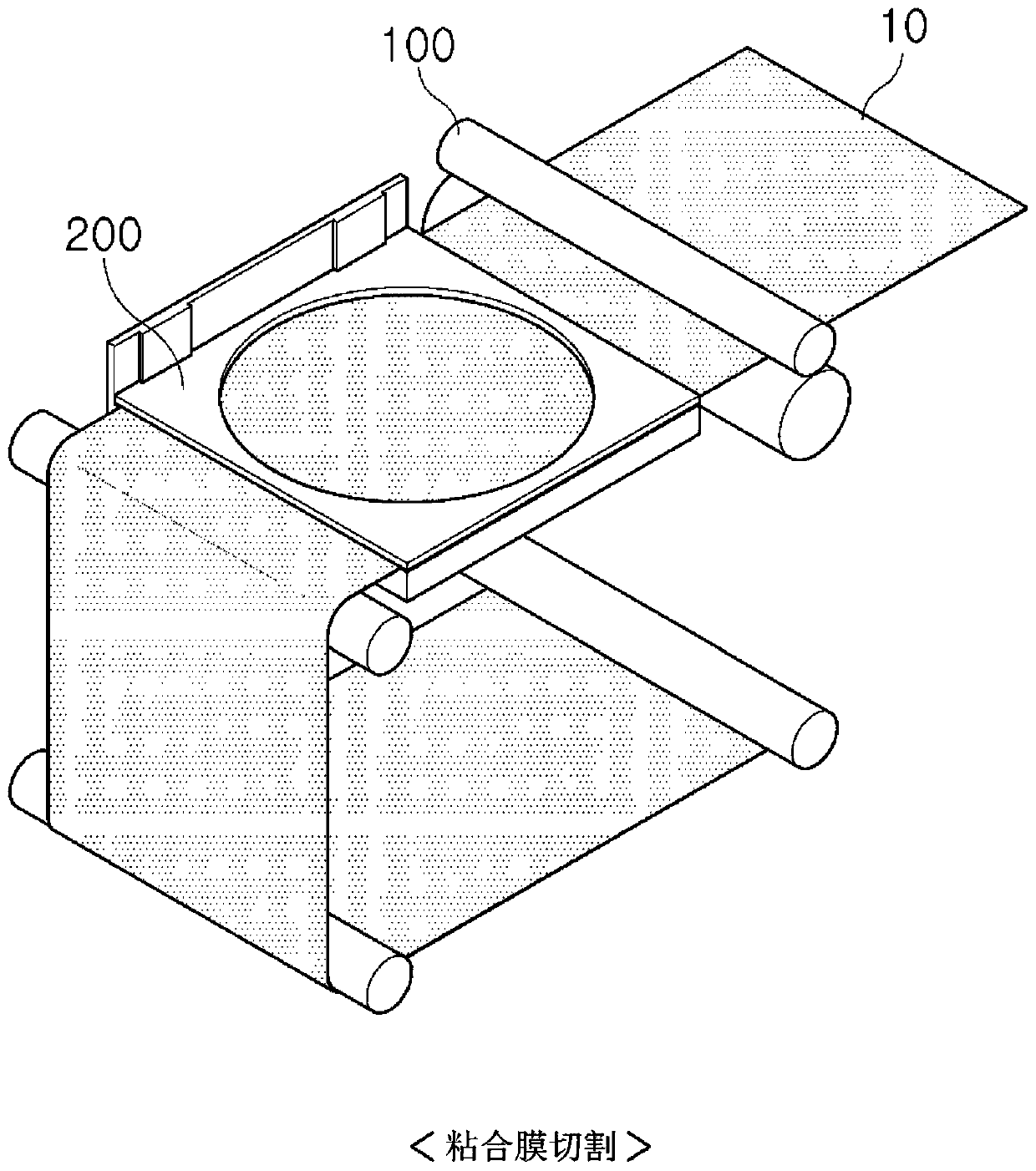

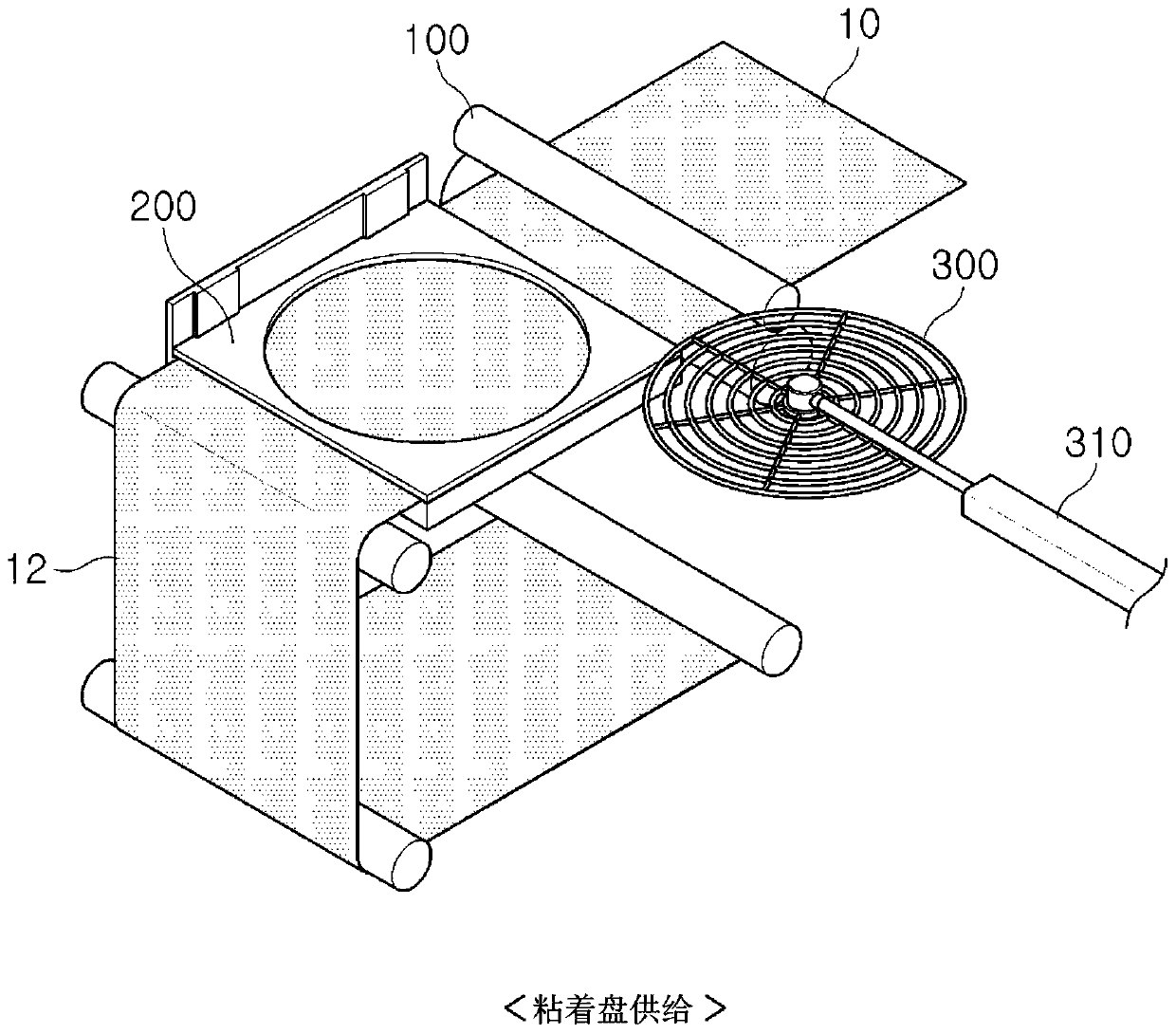

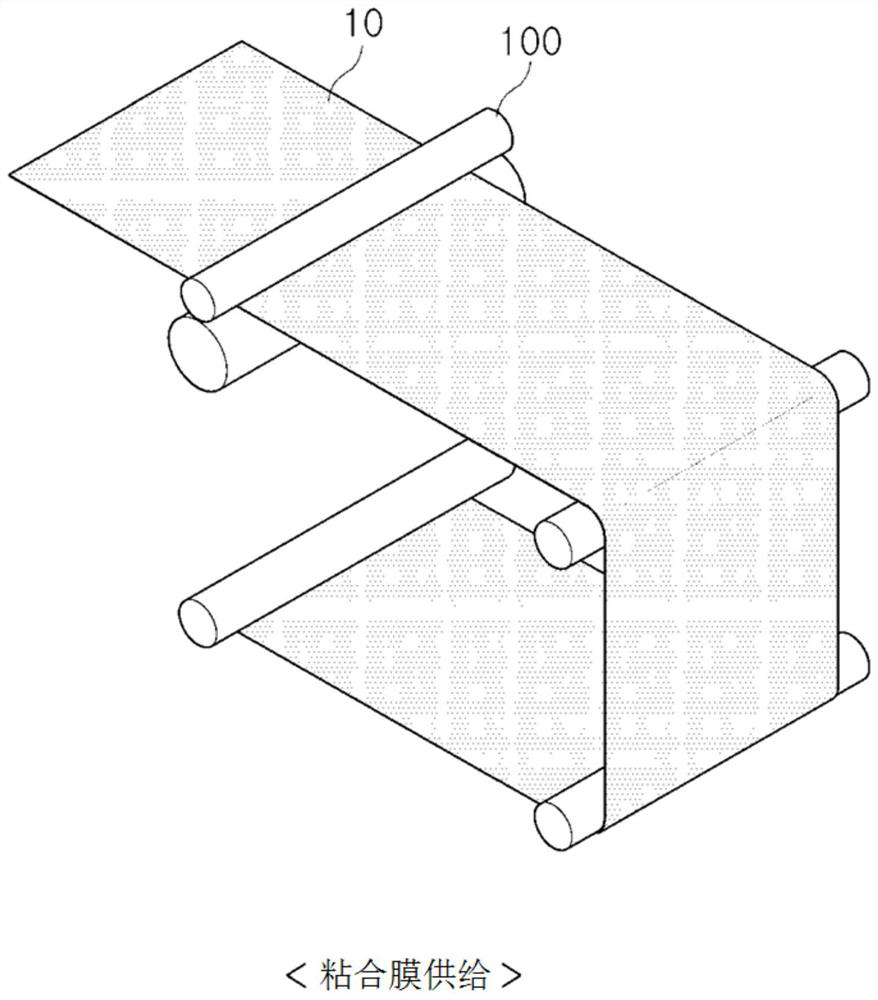

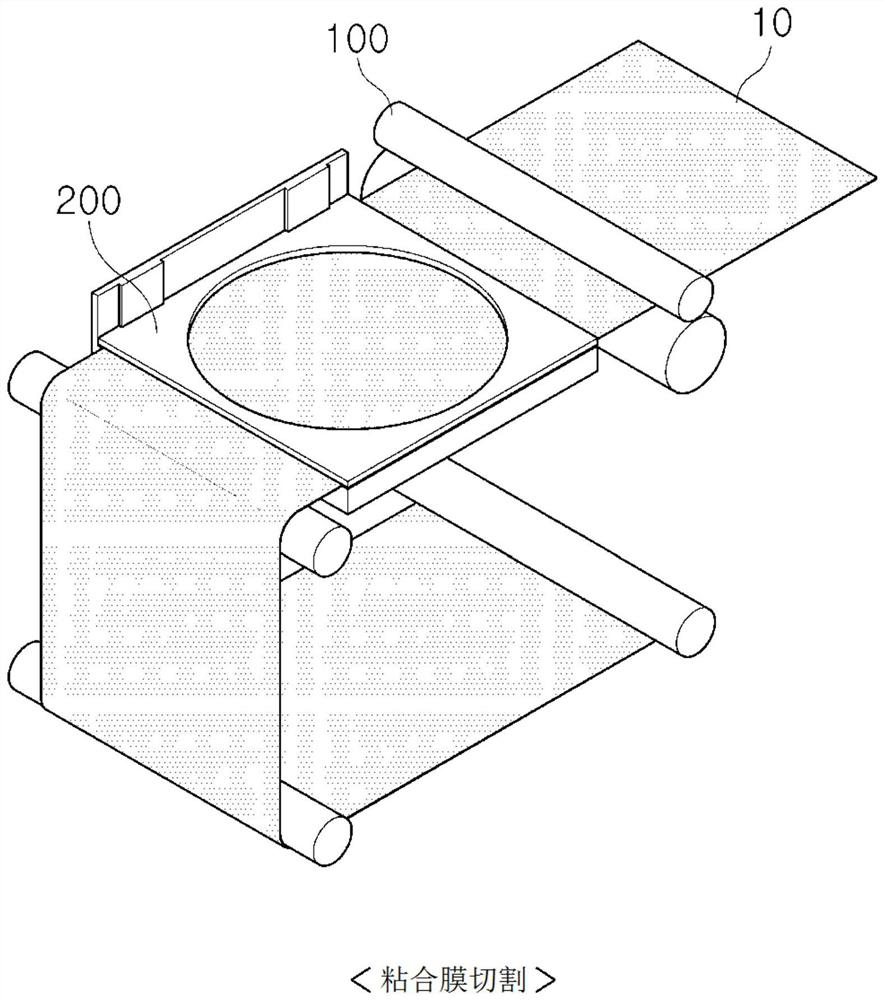

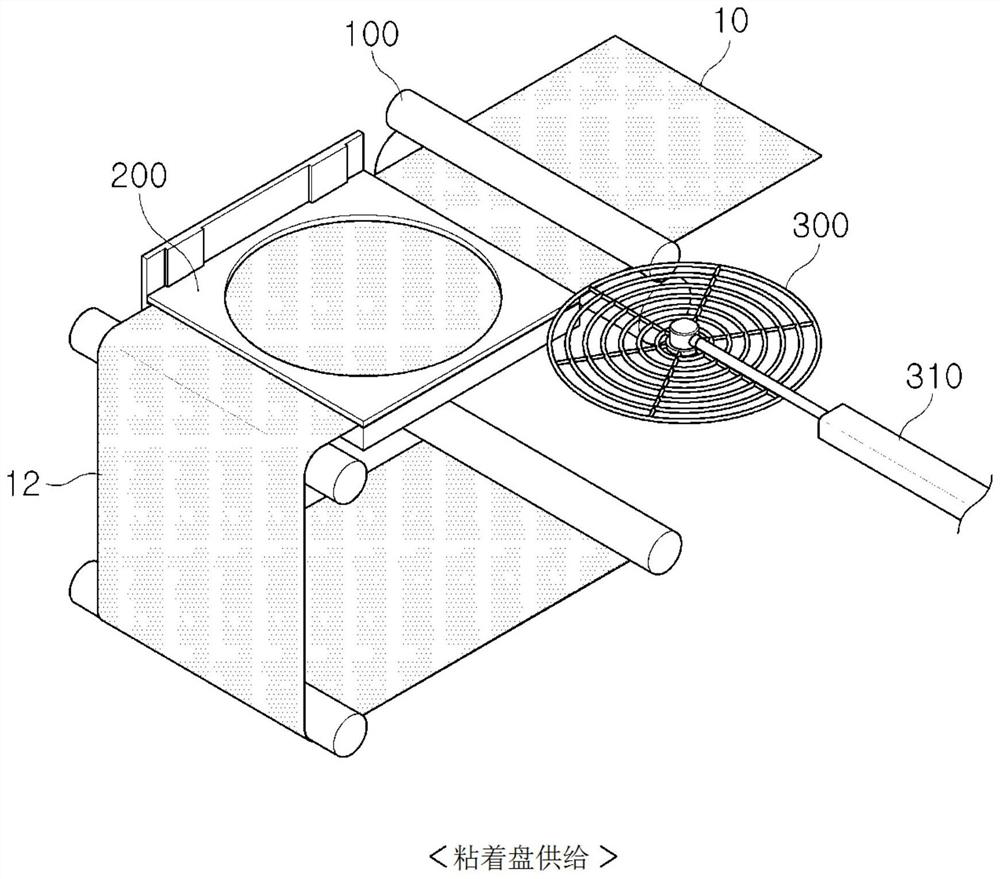

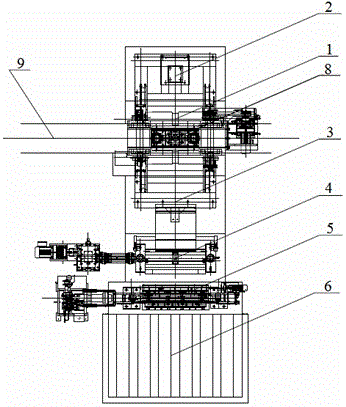

TSV vacuum laminating method, apparatus, and bonding system using same

ActiveCN111180367ALaminated highImprove qualityFinal product manufactureSolid-state devicesWaferingMechanical engineering

The present invention relates to a method for performing a laminating process for a TSV process. A technical point of the laminating method for the TSV process is to provide a vacuum laminating methodfor the TSV process, which includes: an adhesive film supplying step of supplying an adhesive film by using a transfer roller; an adhesive film cutting step of cutting the adhesive film into a predetermined shape by using a cutter; a primary protective film peeling step of bonding the adhesive film cut in the predetermined shape to a lower portion of an adhesive chuck to peel a primary protectivefilm formed on a lower portion of the adhesive film; an adhesive chuck separation step in which the adhesive chuck is separated from the adhesive film after the adhesive film, where the primary protective film is peeled off, is transferred to a vacuum laminator by the adhesive chuck and seated on the top of a carrier wafer; a vacuum laminating step of laminating the carrier wafer and the adhesivefilm seated on the top of the carrier wafer; and a secondary protective film peeling step of peeling a second protective film formed on the top of the adhesive film. Accordingly, the adhesive film and the carrier wafer are laminated in a vacuum state, thereby minimizing dusts and particles, so that high quality laminating is implemented.

Owner:AP SYST INC

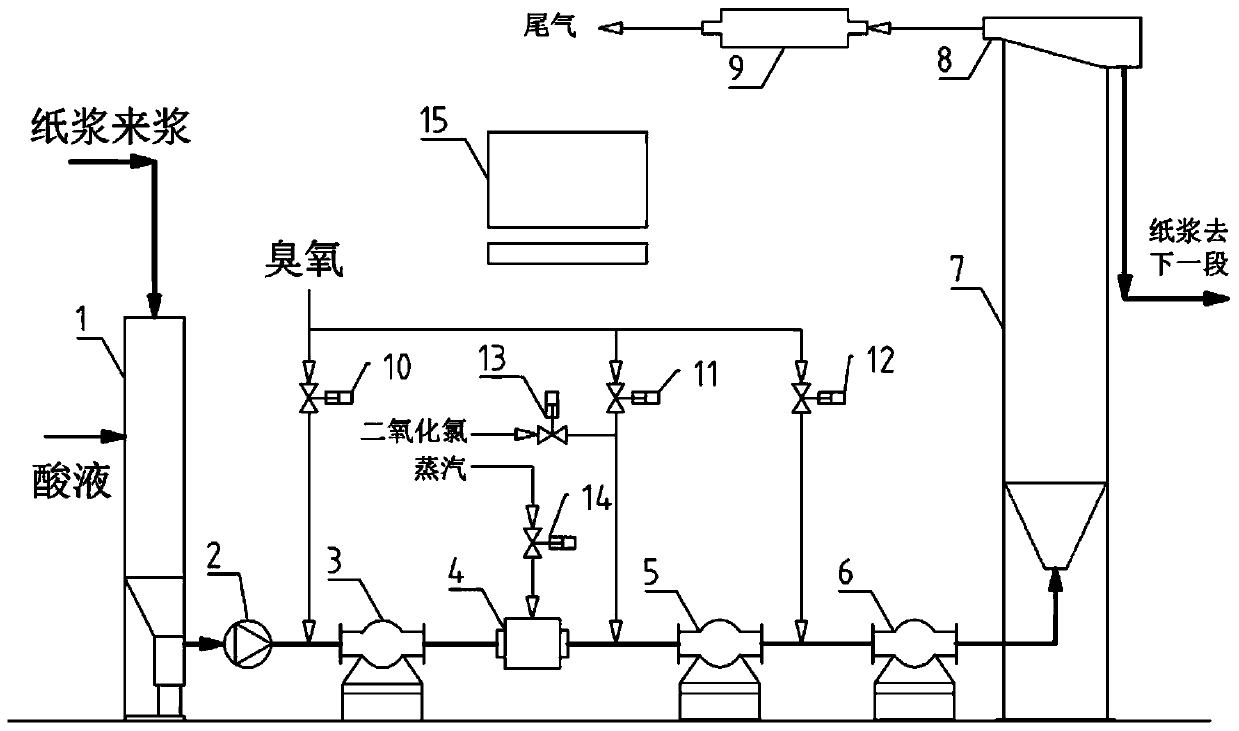

Method and device for efficiently bleaching medium-concentration paper pulp through cooperation of ozone and chlorine dioxide

InactiveCN110656527AReduce pollution loadSynergistic Efficient BleachingPulp bleachingPulp bleachingOrganic chloride compound

Owner:SOUTH CHINA UNIV OF TECH

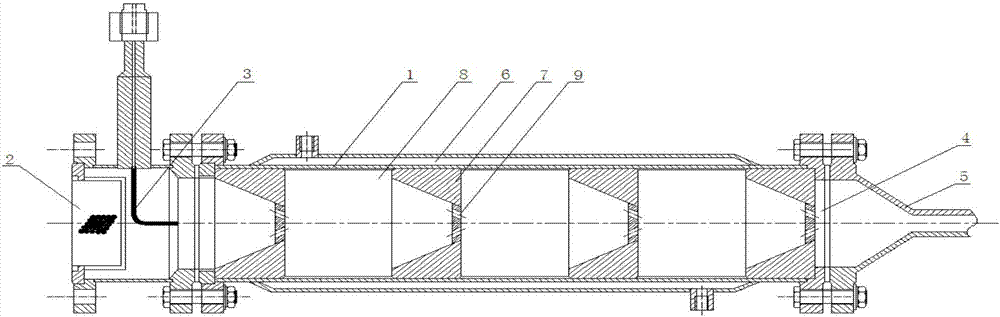

Method and device for static sensitization of emulsion explosives

InactiveCN107382638AEasy workshop layoutSimple structureExplosive working-up apparatusSensitizationEngineering

The invention provides a method and device for static sensitization of emulsion explosives. According to the invention, a tubular sensitizing pipe with an interlayer is arranged; the front end of the tubular sensitizing pipe is connected with an emulsifying matrix and sensitizer conveying pipe; the rear end of the tubular sensitizing pipe is connected with an explosive injecting pipe of a charging machine and with a certain length; the interior of the tubular sensitizing pipe is provided with, according to a certain sequence, 2 to 6 cone-type sensitization cups with holes and 1 to 5 mixers; and under the conditions of production capacity of 2-8 t / h, a temperature of 50-70 DEG C, a pressure of 0.8-1.5 MPa and co-action of foaming agents A and B, the emulsifying matrix is continuously mixed and sensitized so as to form a stable emulsion explosive.

Owner:FUJIAN CIVILIAN BLASTING CHEM

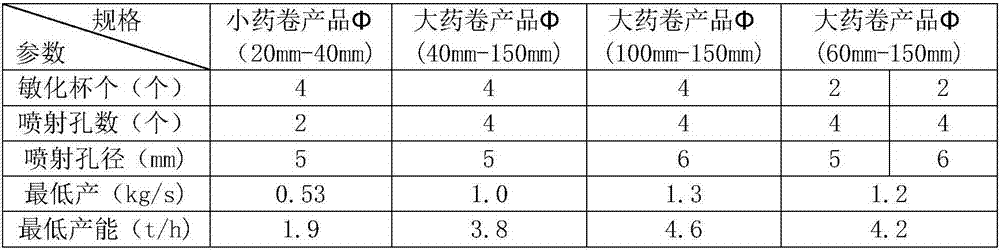

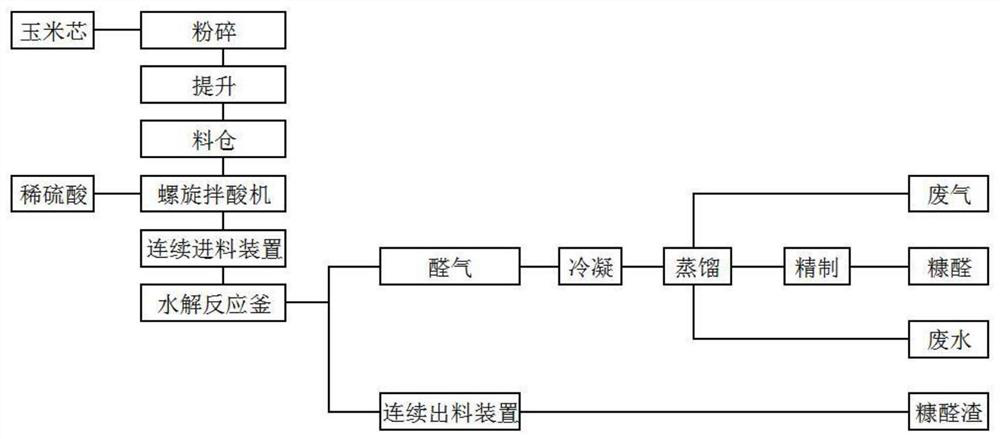

Hydrolysis kettle continuous material feeding and discharging production process in gas-phase furfural production

InactiveCN113372309AIncrease volumeReduce in quantityOrganic chemistryChemical/physical/physico-chemical processesProcess engineeringFurfural

The invention discloses a hydrolysis kettle continuous material feeding and discharging production process in gas-phase furfural production, and belongs to the technical field of furfural production. The invention aims at the problems that 95% of the existing furfural production industry adopts a sulfuric acid catalysis method, the generated furfural is removed by steam stripping, and the hydrolysis process is intermittent, and the root reason is that the feeding and discharging of a hydrolysis kettle are intermittent. The invention relates to the production process for realizing continuous and stable feeding and discharging of materials in a hydrolysis kettle by using a device capable of blocking pressurized steam and continuously feeding and discharging the materials. Due to continuous feeding and discharging of the hydrolysis kettle, three independent processes of loading, reacting and unloading of the hydrolysis kettle can be omitted, so that loading, reacting and unloading of the hydrolysis kettle are carried out at the same time, and the production period is greatly shortened.

Owner:镇江市昌达机械有限公司

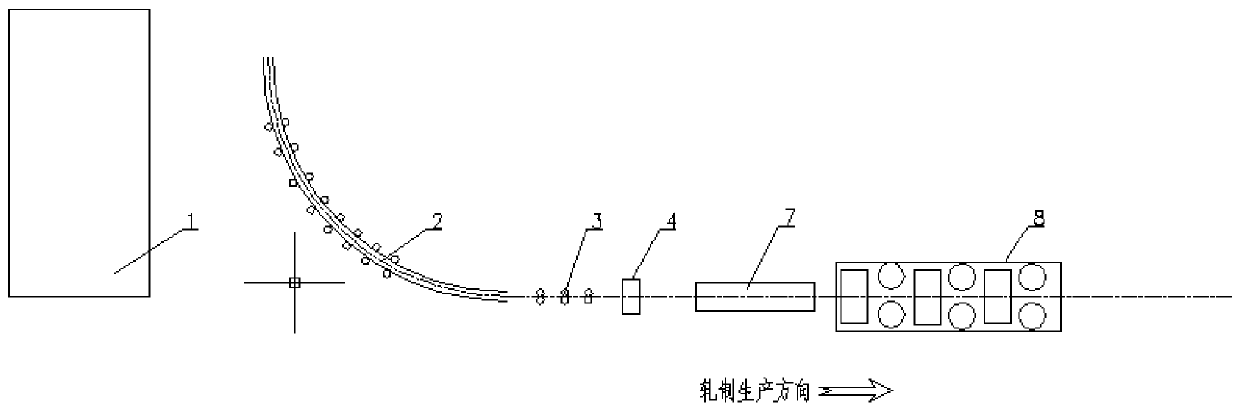

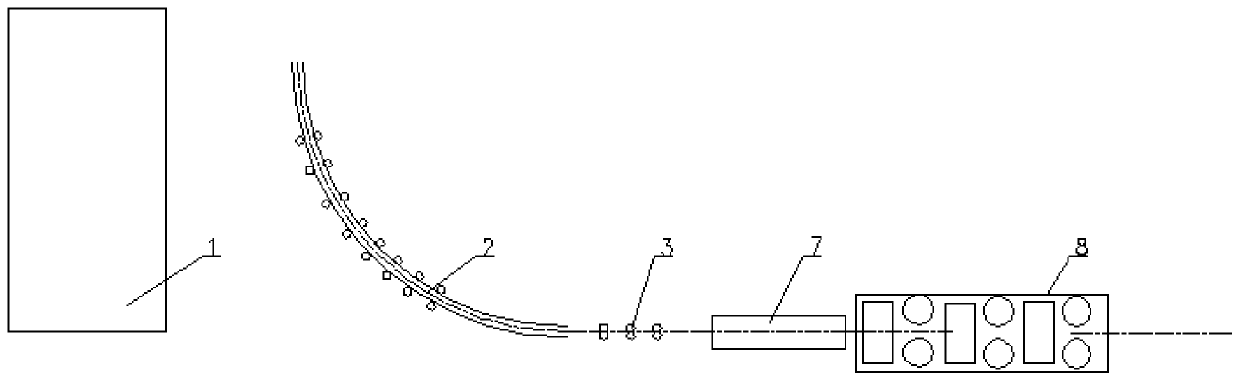

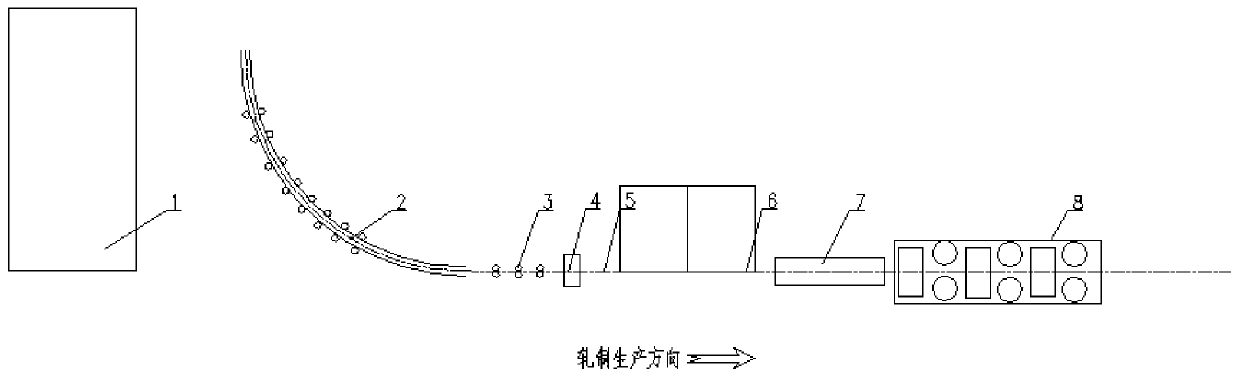

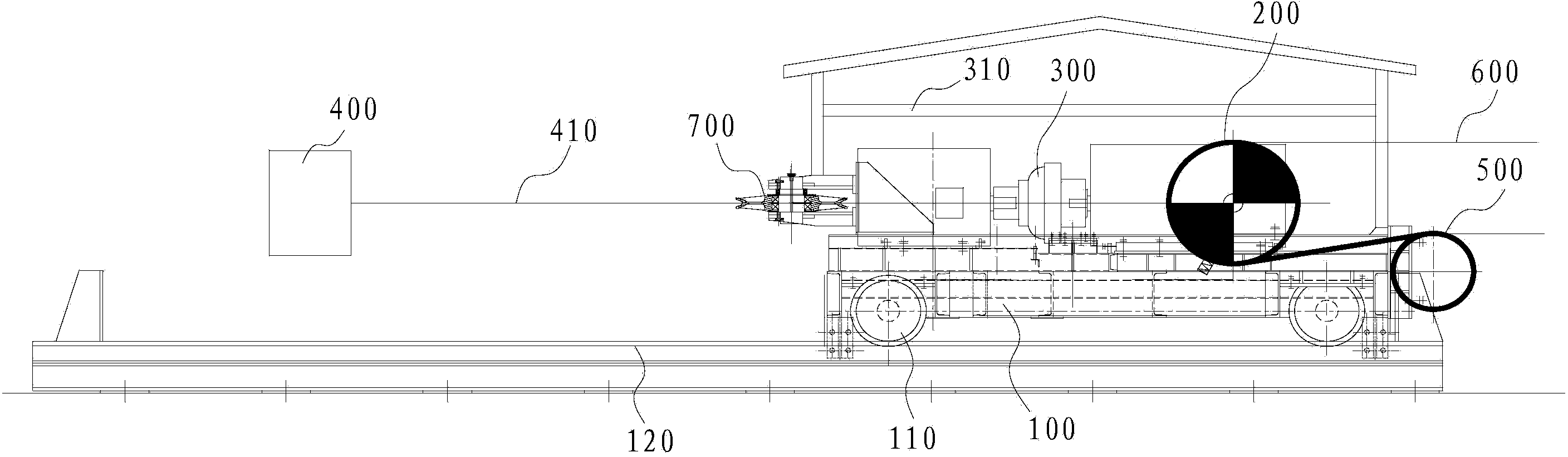

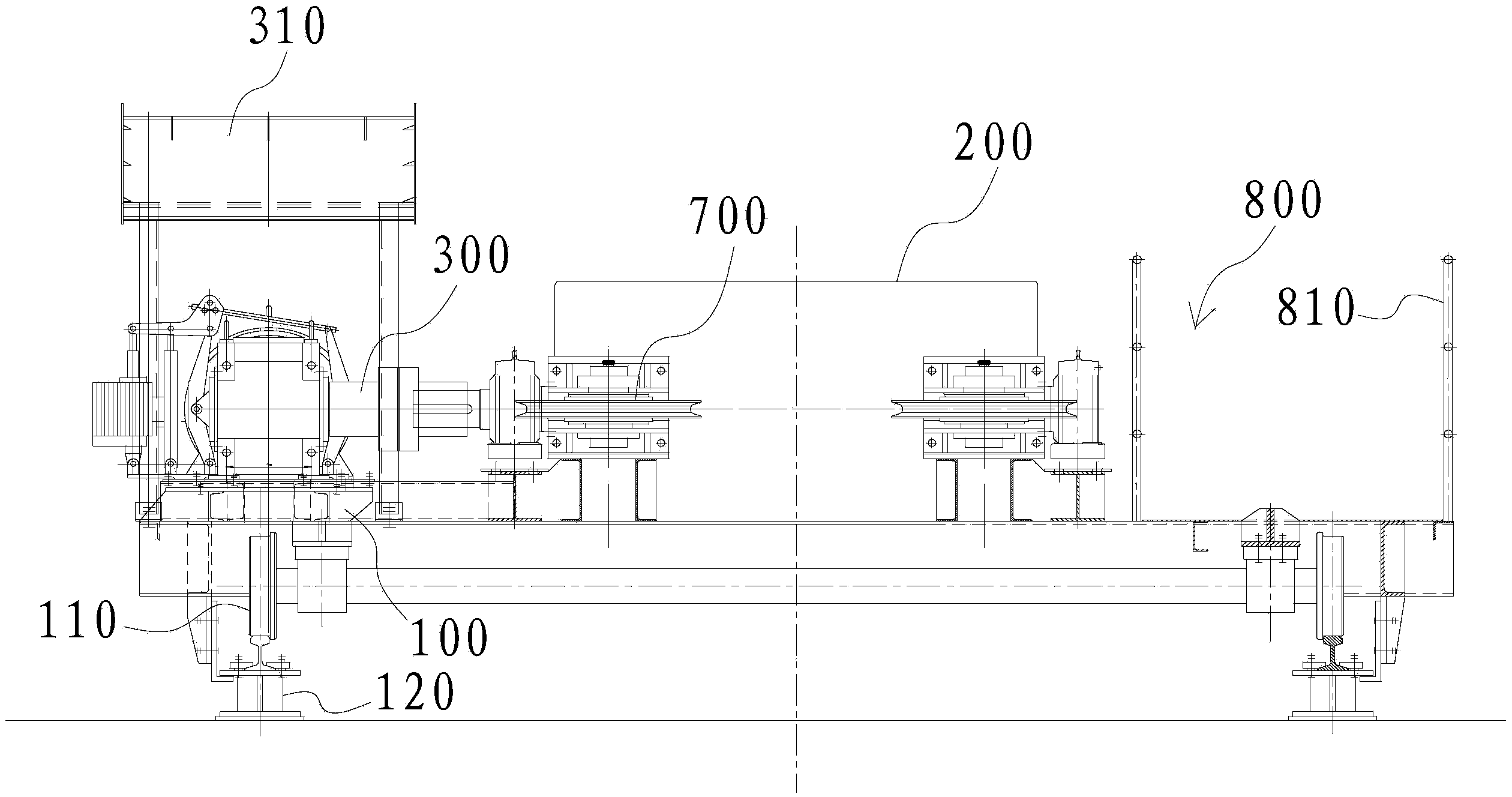

Long log direct-rolling casting blank thermal insulation device, production line and method

PendingCN111438188AReduce carbon emissionsImprove direct rolling rateWork heating devicesMetal rolling arrangementsThermal insulationElectric heating

The invention discloses a long log direct-rolling casting blank thermal insulation device, a production line and a method and belongs to the technical field of steel metallurgical industrial long logdirect rolling. The casting blank thermal insulation device comprises a steel pushing mechanism, a cantilever roller bed, an electric heating device and a stepping beam structure which are arranged ona box, and the stepping beam structure comprises a movable beam and a fixed beam. The casting blank thermal insulation production line comprises a steel furnace, a continuous casting machine, a withdrawal and straightening machine, a dividing shear, a parallel flow roller bed, the casting blank thermal insulation device, an electromagnetic induction heat supplementing device and a rolling line. According to the production line, by arranging the casting blank thermal insulation device behind the continuous casting parallel flow roller bed, when a continuous casting blank cannot be produced dueto a short-time fault of the rolling line, the continuous casting blank enters the casting blank thermal insulation device for thermal insulation, and after the fault is handled, the continuous casting blank in the casting blank thermal insulation device discharges steel through the stepping beam structure in the casting blank thermal insulation device and is rolled after heat supplementing by electric induction. In the whole production process, except for a small quantity of head and tail blanks, no continuous casting blank gets off, and therefore the direct rolling rate and yield of the long log direct-rolling production line are increased.

Owner:CISDI ENG CO LTD +1

Material sorting system

InactiveCN106584708AEfficient separationSolve the unscrewable problemPlastic recyclingEngineeringCentrifugal force

The invention discloses a material sorting system, and relates to the technical field of waste treatment. The material sorting system comprises a centrifugal fan, a cyclone separator and an airflow chamber. The airflow chamber comprises a feeding port, a first discharging port and a second discharging port. The first discharging port is located above the second discharging port. The feeding port is formed between the first discharging port and the second discharging port. A second air inlet of the cyclone separator is connected with the first discharging port. A second air outlet of the cyclone separator is connected with a first air inlet of the centrifugal fan. A first air outlet of the centrifugal fan is connected with the second discharging port end of the airflow chamber. The centrifugal fan is arranged above the cyclone separator. By means of the material sorting system, repeated material sorting can be achieved, the material sorting rate can be increased, the purity of materials obtained after sorting can be improved, and waste recycling is achieved.

Owner:HUNAN VARY TECH

Organic polymer luminescent concrete and preparation method thereof

InactiveCN107574769AIncrease profitLow costCeramic shaping apparatusTraffic signalsSurface layerUltraviolet

The invention discloses organic polymer luminescent concrete and further discloses a preparation method of the organic polymer luminescent concrete. The organic polymer luminescent concrete comprisesa concrete plate, transparent side luminescent materials and light sources. The transparent side luminescent materials are embedded in the surface layer of the concrete plate, at least one ends of allthe transparent side luminescent materials are located at the edge of the concrete plate, and the ends, located at the edge of the concrete plate, of the transparent side luminescent materials are equipped with the light sources; the transparent side luminescent materials are arranged on the surface of the concrete, and the advantages that the utilization rate of the transparent side luminescentmaterials is high, and the cost is low are achieved; according to the organic polymer luminescent concrete and the preparation method thereof, the luminescence principle adopts the principle of side surface luminescence of the transparent side luminescent materials, the light source arrangement technology is simple, and industrialization popularization is facilitated; the application range is wide; and additionally the organic polymer luminescent concrete is electrically neutral, contains no heat, and is free of ultraviolet rays and maintenance, capable of achieving color changing, high in strength, good in weathering-resistant property, long in service life and suitable for aspects such as building decoration and pavement or park guidance.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Bulk material sampling and sample preparation system

InactiveCN108535049ALower the altitudeLess investmentWithdrawing sample devicesPreparing sample for investigationPhysical performance testingControl system

The invention relates to a sampling system and in particular relates to a bulk material sampling and sample preparation system. The invention provides an automatic bulk material sampling and sample preparation system which is used for preparing a chemical analysis sample, a physical performance sample, a metallurgy performance sample and the like online through bulk materials, and can realize functions including online granularity distribution determination, sample moisture detection, physical performance testing and the like; the bulk material sampling and sample preparation system comprisesa sample preparation device and a mechanical arm; a granularity composition analysis device, a moisture measurement device, an analysis sample preparation device, a sample storage device and a washingdevice are arranged around the mechanical arm; the bulk material sampling and sample preparation system further comprises a control system; the sample preparation device, the mechanical arm, the granularity composition analysis device, the moisture measurement device, the analysis sample preparation device, the sample storage device and the washing device are connected with the control system; the mechanical arm is controlled by the control system to convey the bulk materials to each device in sequence and a full-automatic sample preparation system is applicable to industries including an iron and steel metallurgy industry, an ore terminal industry, an electric industry, an exploration industry and the like.

Owner:青岛海亿特机电科技发展有限公司

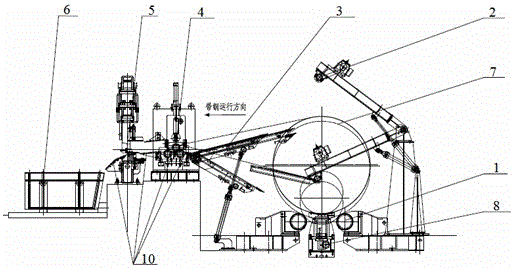

Tensioning car of belt conveyor

InactiveCN103662660ARealize the function of stacking and retrievingLow costConveyorsVehicle frameInverse operation

The invention discloses a tensioning car of a belt conveyor. The tensioning car of the belt conveyor comprises a tensioning car frame, a tensioning driving roll, at least one driving device and a tensioning device, wherein the tensioning driving roll is arranged at the front end of the tensioning car frame through bearings; a rubber belt of the belt conveyor is arranged on the tensioning driving roll in a surrounding mode; the driving device is arranged on the tensioning car frame and used for driving the tensioning driving roll to rotate; the tensioning device is arranged outside the tensioning car frame, is connected with the tensioning car frame through a steel wire rope and tensions the tensioning car frame. The tensioning car of the belt conveyor has the advantages that the tensioning car frame is tensioned through the tensioning device, the driving device on the tensioning car frame drives the tensioning driving roll to drive the rubber belt, and therefore materials can be stacked in an inverse operation mode, the equipment cost is saved, and the tensioning car of the belt conveyor is compact and stable in structure, simple and reasonable in process layout, full in function and practical in tensioning and driving function, and can be widely used for belt conveyors of large bulk-material stacking plants such as power plants, steel mills, ports, wharfs and coal yards.

Owner:HENGYANG CONVEYING MACHINERY

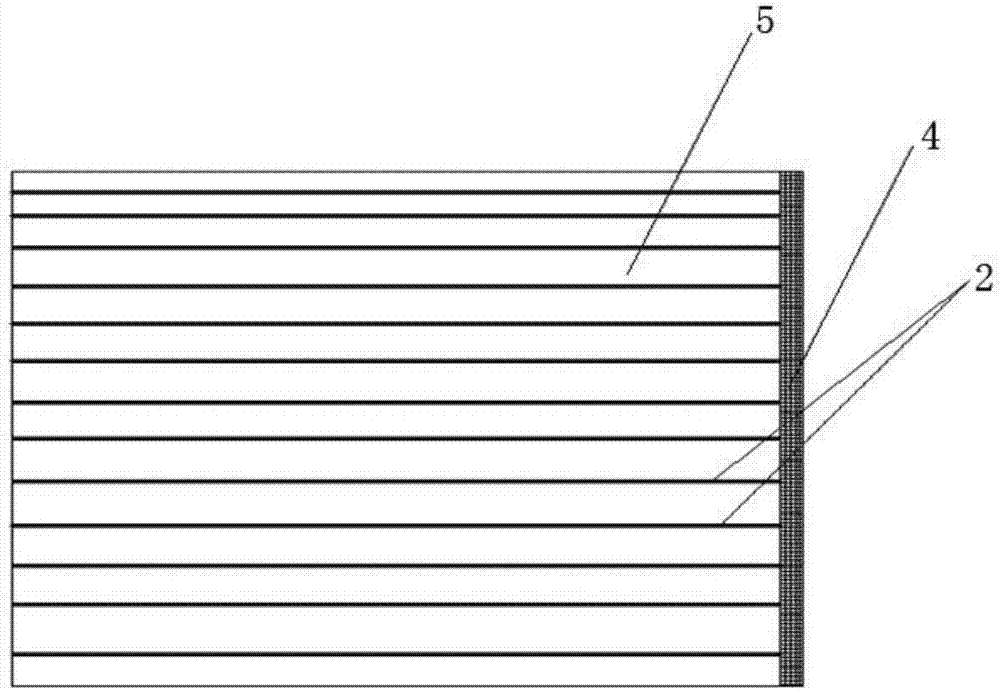

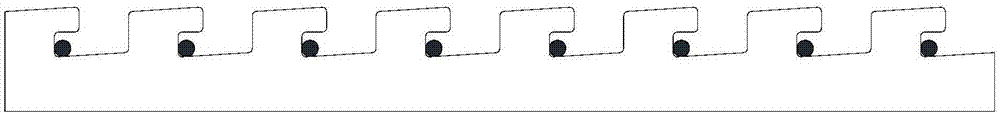

Perforated plate connector with shoe-shaped slotted holes, steel beam and method

InactiveCN105887660BSimplify layout processLow costBridge structural detailsBridge erection/assemblyBridge deckClassical mechanics

The invention discloses a perforated plate connecting piece with boot-shaped slots. The perforated plate connecting piece is characterized in that one side of each shear connecting piece has a flat outline, protruded connectors are repeatedly arrayed on the other side of each shear connecting piece, and boot-shaped recessed slots are repeatedly formed in the other side of each shear connecting piece; the shapes of the protruded connectors are consistent with those of the recessed slots after the protruded connectors rotate by 180-degree angles, and the sizes of the protruded connectors are consistent with those of the recessed slots after the protruded connectors rotate by the 180-degree angles; the protruded connectors and the recessed slots of the two connecting pieces with identical sizes can be exactly butted to one another in an embedded manner and can be spliced to form a complete slab after one of the connecting pieces rotates by 180-degree angles. The invention further discloses a steel beam with the perforated plate shear connecting piece with the boot-shaped slots, an orthotropic steel plate provided with the perforated plate shear connecting piece with the boot-shaped slots, a method for machining the perforated plate connecting piece, a method for connecting the perforated plate connecting piece with a concrete bridge deck slab and a construction method for applying the perforated plate connecting piece to composite beams. The perorated plate connecting piece, the steel beam, the orthotropic steel plate, the methods and the construction method have the advantages that perforated plates are high in shear strength and good in fatigue resistance, processes for arranging reinforcing steel bars can be simplified, accordingly, the construction efficiency can be greatly improved, the manufacturing and mounting costs can be saved, and the engineering cost can be lowered.

Owner:TONGJI UNIV

Vacuum lamination method and device for tsv process and bonding system using same

ActiveCN107009717BLaminated highImprove qualityFinal product manufactureSolid-state devicesPolymer scienceWafering

The present invention relates to a laminating method for TSV process, comprising: an adhesive film supplying step of supplying the adhesive film with a transfer roller; an adhesive film cutting step of cutting the adhesive film into a prescribed shape with a cutter; the first The step of peeling the protective film, sticking the adhesive film cut into the prescribed shape to the lower part of the adhesive disc, and peeling the first protective film formed on the lower part of the adhesive film; the step of separating the adhesive disc, the first protective film After the peeled adhesive film is transferred to a vacuum laminator through the adhesive tray and placed on the carrier wafer, the adhesive tray is separated from the adhesive film; the vacuum lamination step, for placement on the carrier wafer laminating the adhesive film and the carrier wafer; and a second protective film peeling step of peeling the second protective film formed on the upper part of the adhesive film. Thereby, the adhesive film and the carrier wafer are laminated in a vacuum state to minimize generation of dust and particles, and high-quality lamination can be realized.

Owner:AP SYST INC

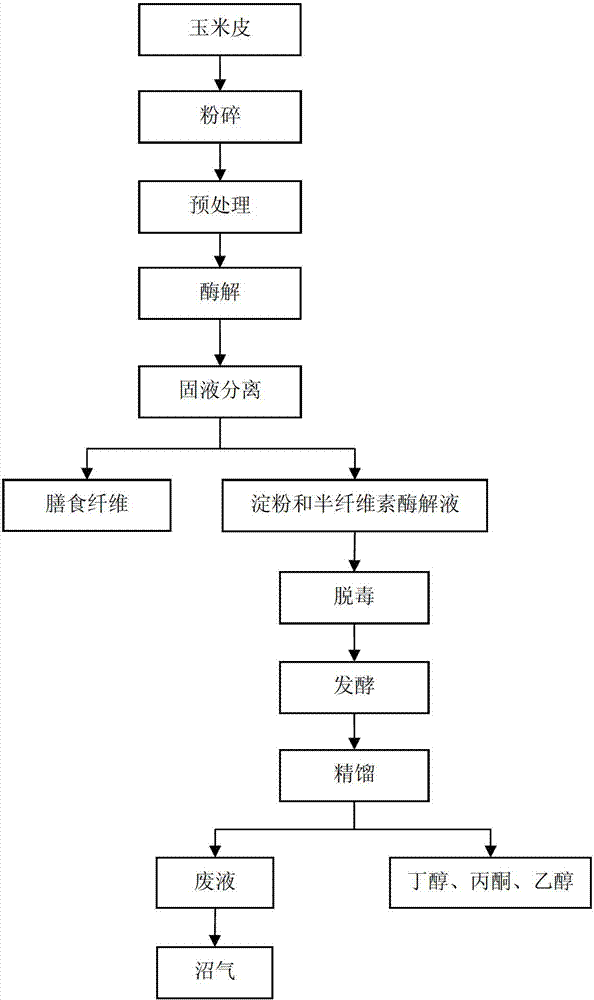

Method for fermenting butanol and co-producing dietary fiber by corn bran

The invention relates to the field of biological energy, and in particular relates to a method for fermenting butanol and co-producing dietary fiber by corn bran, which comprises the following concrete steps of: 1) pre-processing; 2) enzymatically hydrolyzing; 3) implementing solid-liquid separation, to obtain dietary fiber and enzymatic hydrolysate; 4) detoxifying the enzymatic hydrolysate; 5) refilling a nitrogen source into the detoxified enzymatic hydrolysate to prepare a fermenting culture medium; fermenting and breeding butanol by the sterilized fermenting culture medium under an anaerobic condition to produce a strain, so as to obtain a fermented product; and 6) rectifying the fermented product and collecting the butanol. According to the method for fermenting the butanol and co-producing the dietary fiber by the corn bran, measures are adjusted to local conditions, and the corn bran which is a byproduct of processing the corn is adopted as a raw material to ferment the butanol, so not only the waste is utilized to bring about benefit for environmental protection but the product additional value is improved for deep processing of the corn; and a way of improving the economic benefit is provided for the enterprises.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Strip head treatment device for skin pass unit and method of use thereof

The invention relates to a band steel heat treatment device for a temper mill. The device is arranged on an inlet side of a steel coil channel of the temper mill, and comprises a compression roller, a pair of carrier rollers, an uncoiler, a band steel molding device, a hydraulic shearing device and a waste box, which are sequentially arranged along the direction vertical to the steel coil channel, wherein the pair of carrier rollers is symmetrically arranged along the steel coil channel; the band steel molding device comprises a band steel pinch roll; the compression roller, the pair of carrier rollers and the band steel pinch roll all can rotate positively and reversely; and an up uncoiling manner is adopted as the steel coil uncoiling manner. The invention further relates to an application method of the band steel heat treatment device. The band steel heat treatment device is arranged on the inlet side of the steel coil channel of the temper mill, so that technological arrangement is simple; a channel does not need to be additionally formed; the civil engineering and equipment investment are effectively saved; the band steel heat treatment device is adjacent to the temper mill, so that a plurality of middle procedures are reduced; the operation of an operator is convenient; the labor amount of the operator is effectively reduced; the band steel heat treatment efficiency is relatively high; the transportation cost and the time cost are reduced; and the production benefits are improved.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com