Patents

Literature

38results about How to "Reduce downside resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

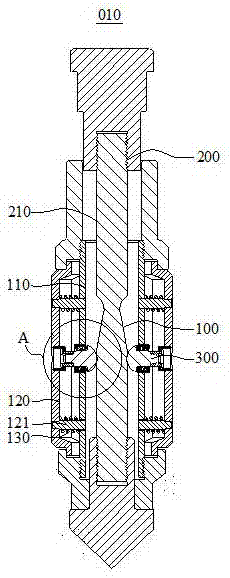

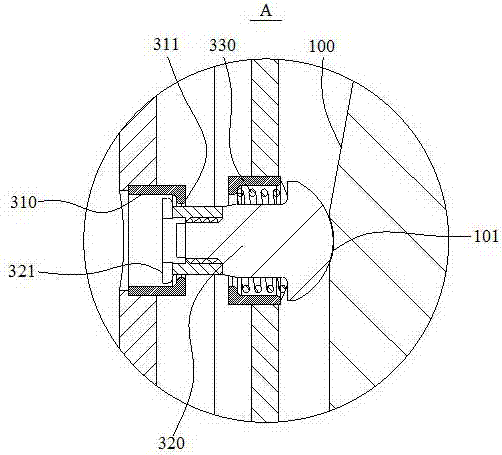

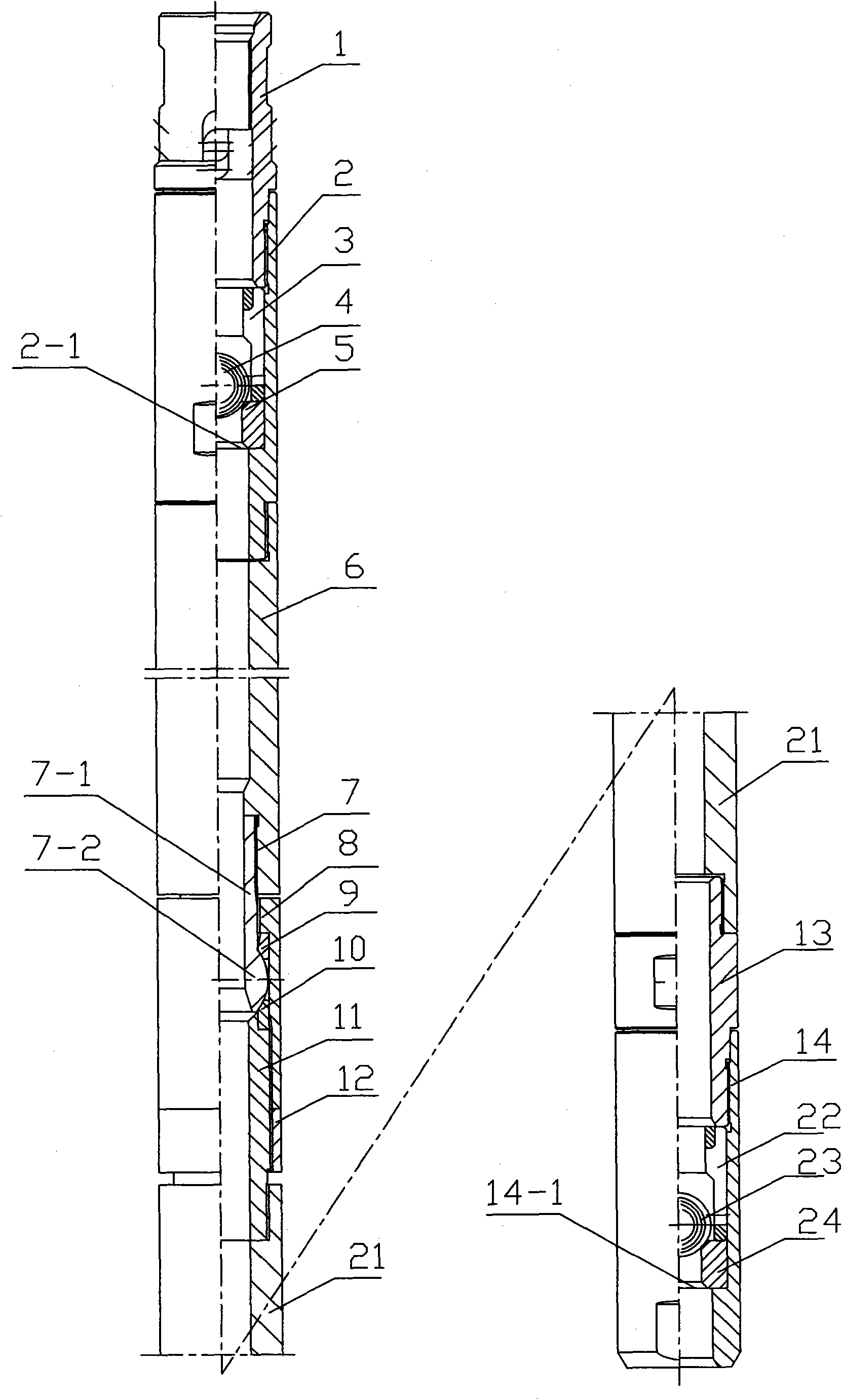

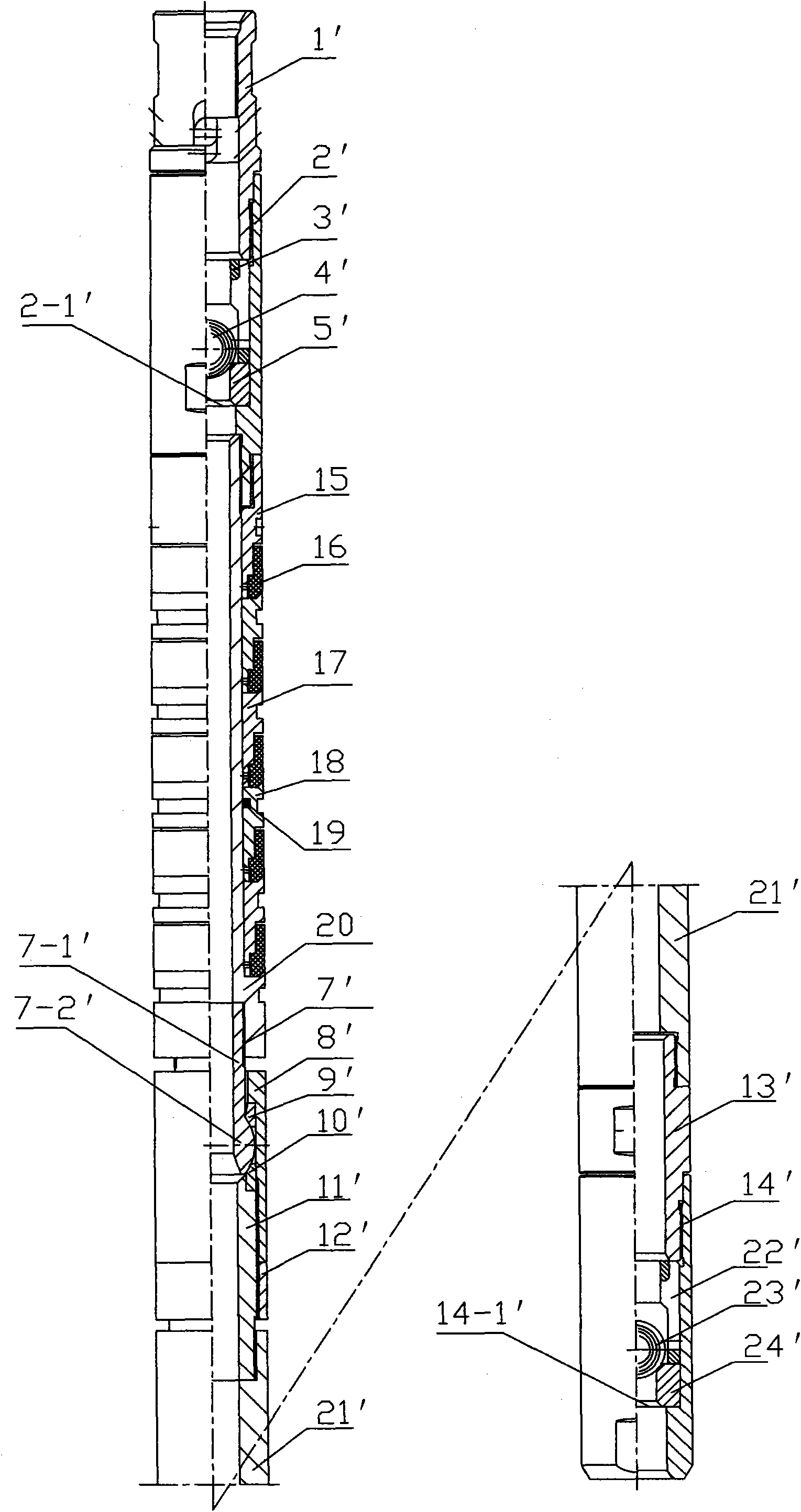

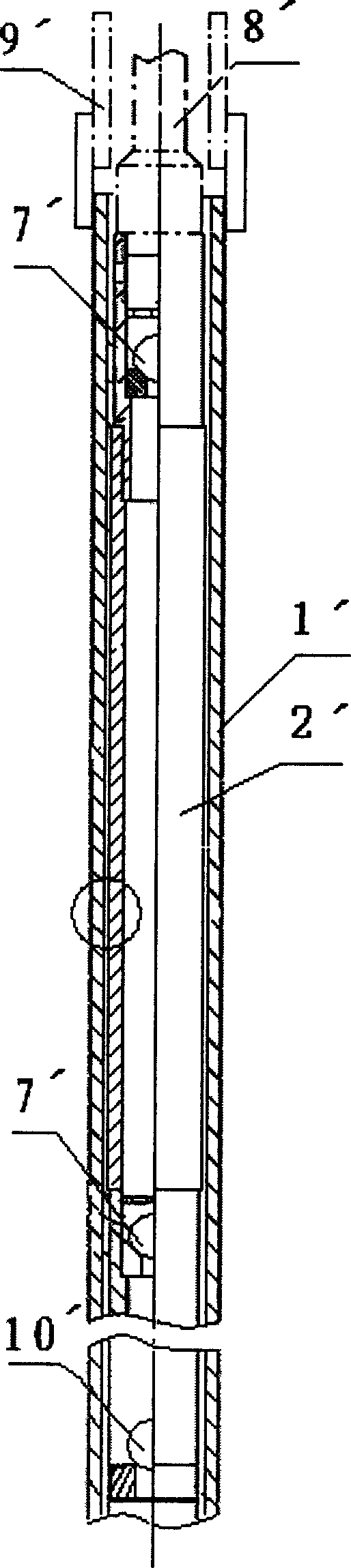

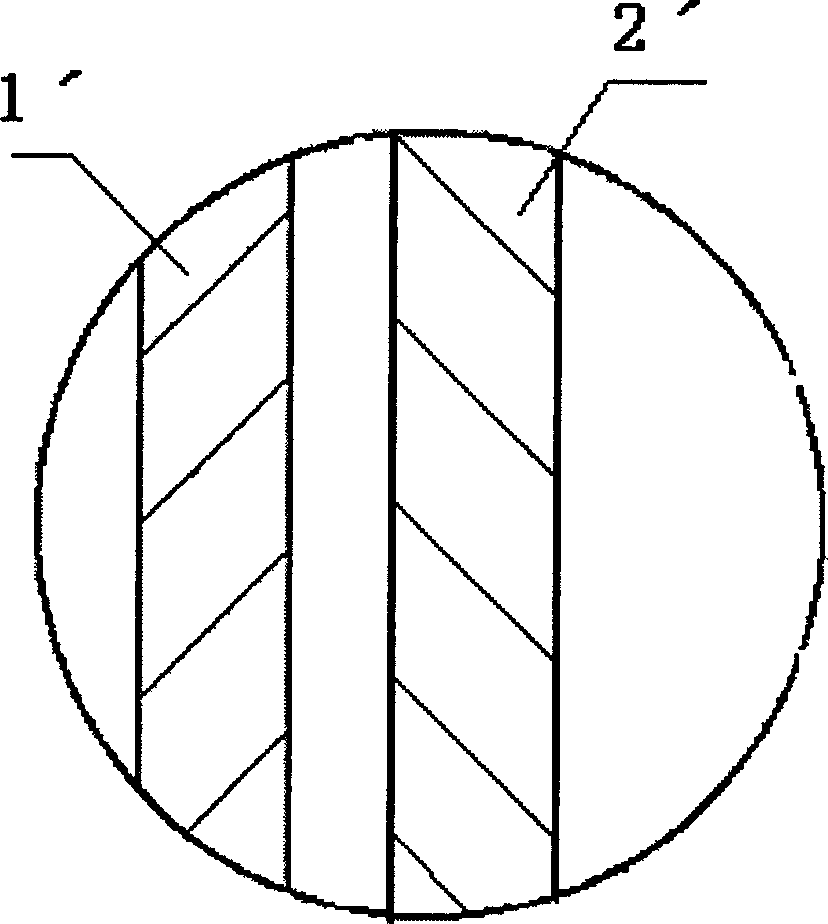

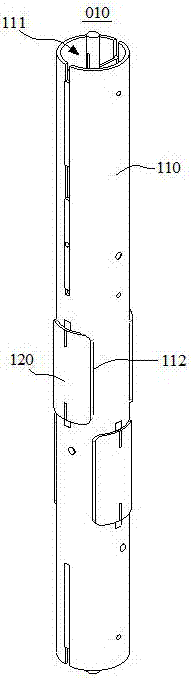

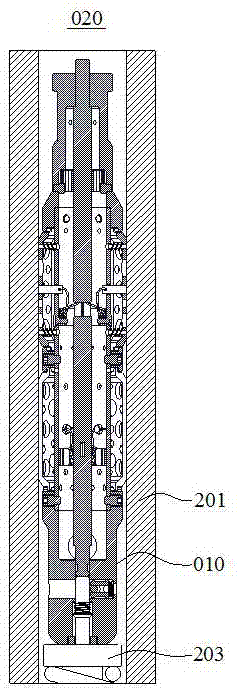

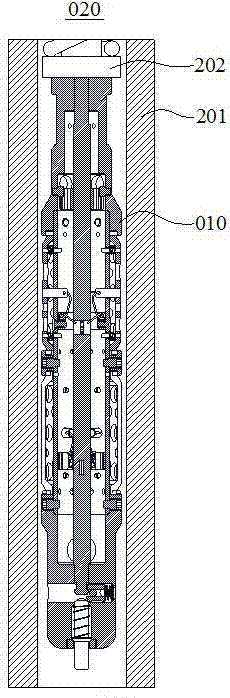

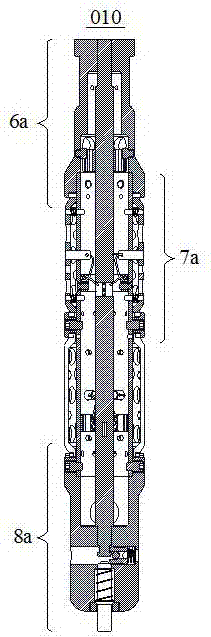

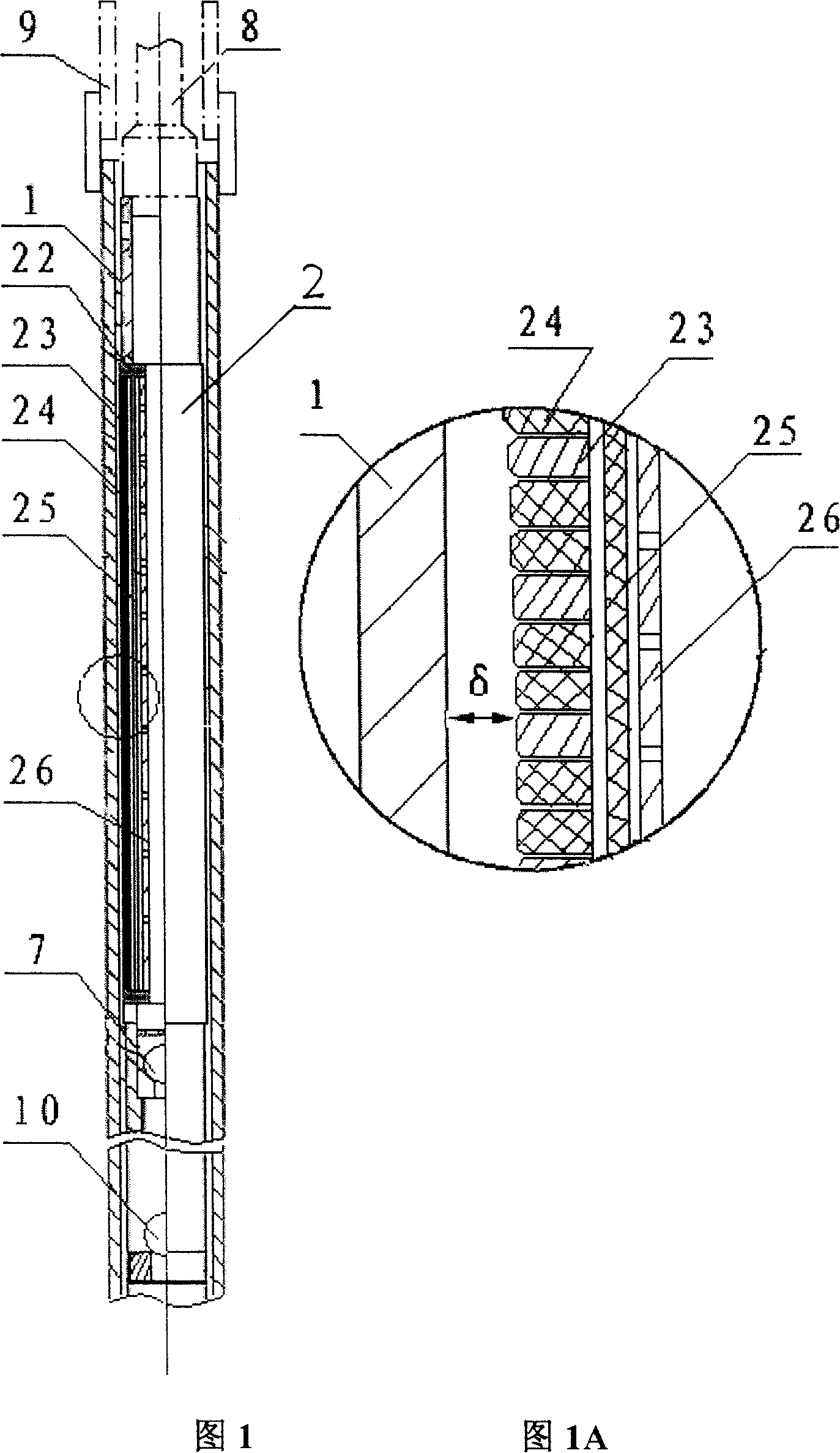

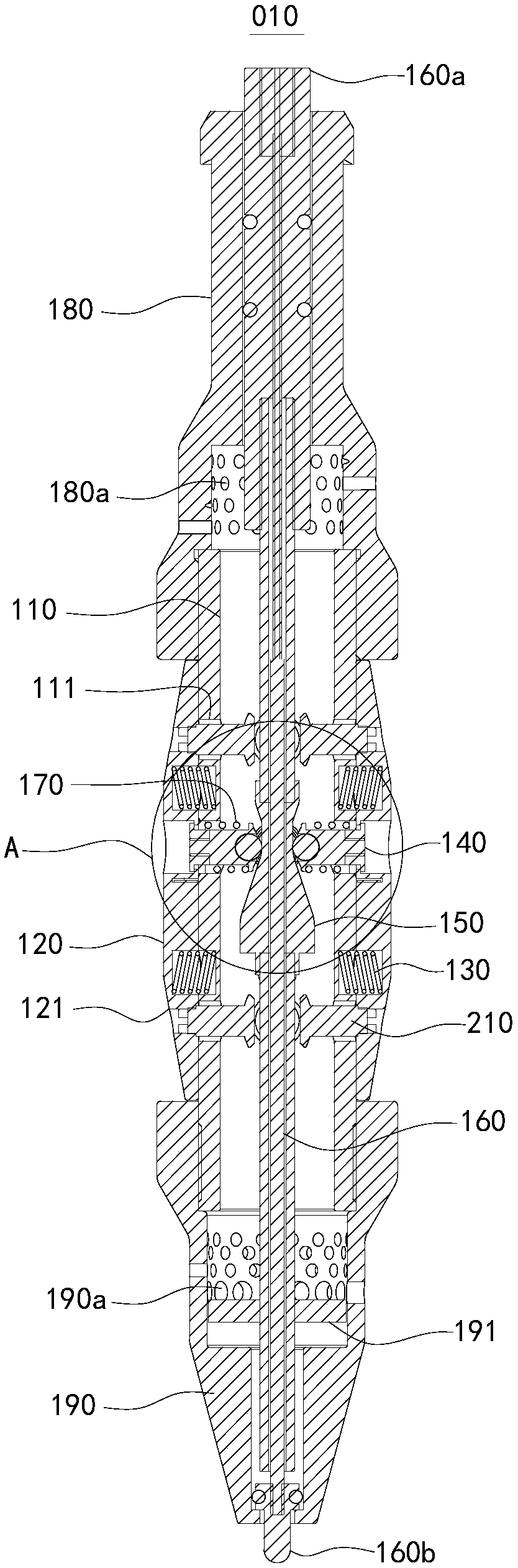

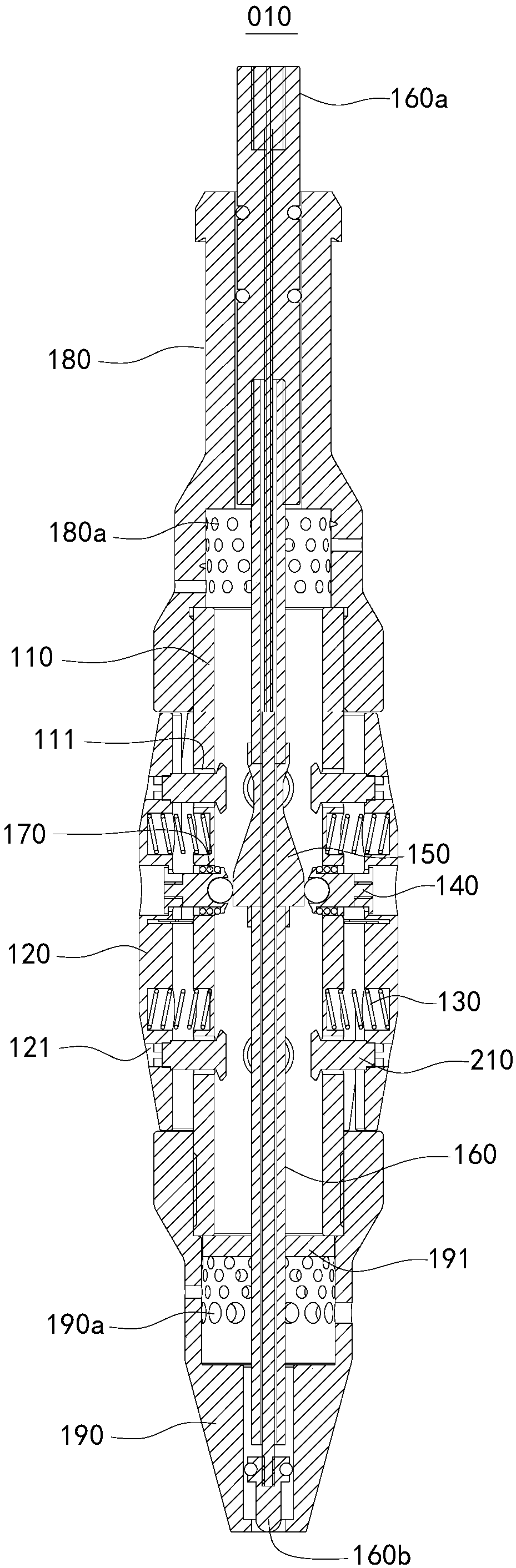

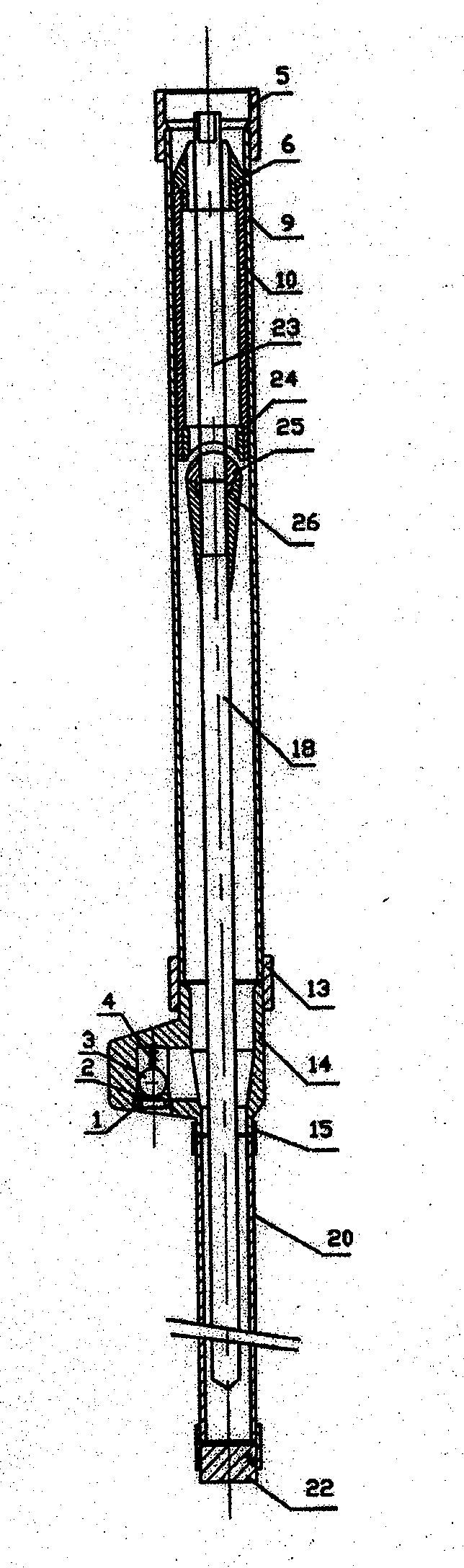

Fluid separating device, shaft structure and method for producing petroleum or natural gas

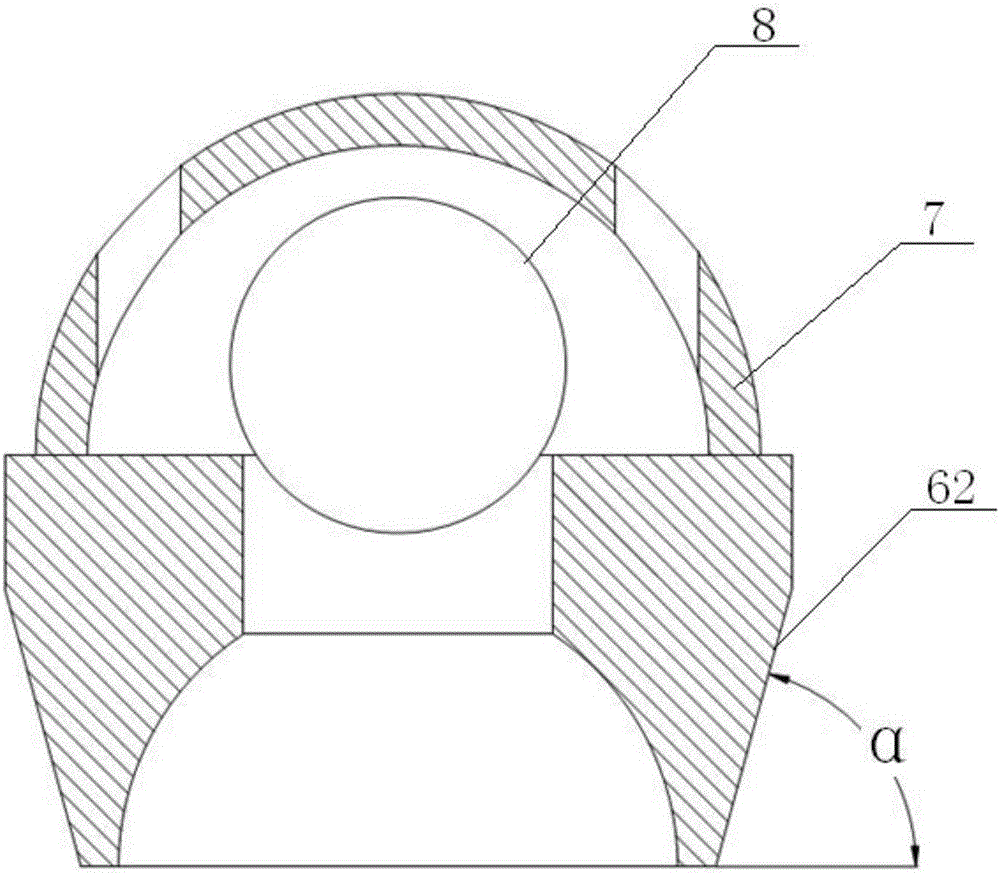

ActiveCN107313739AReduce downside resistanceEliminate frictionFluid removalSealing/packingElastic componentEngineering

Owner:CHENGDU BISON TECH CO LTD

Method for soft reduction through bulging

The invention discloses a method for soft reduction through bulging, which is suitable for the end of a solidification stage of a casting blank. The method comprises the following steps of: controlling bulging which is generated on the surface of a shell of the casting blank and does not have any internal defect, and applying certain reduction to the bulging by using upper and lower rollers of a straightening machine to make molten steel in a thick area in the casting blank reasonably distributed in a certain space, so that segregation severity is reduced, intermediate porosity and shrinkage of the casting blank are reduced, and the internal quality of the casting blank is improved.

Owner:上海亚新连铸技术工程有限公司 +1

Flexible combined oil pump plunger piston

ActiveCN101825083AAvoid enteringPlay the role of scraping sandPositive displacement pump componentsLiquid fuel engine componentsEngineeringFriction force

The invention provides a flexible combined oil pump plunger piston, which relates to the technical field of mechanical petroleum mining, in particular to a plunger piston used in an oil pump. The flexible combined oil pump plunger piston comprises an upstream movable valve, wherein the lower end of the upstream movable valve is sequentially connected with at least two sections of small-section sealing bodies, two adjacent sections of small-section sealing bodies are connected through a flexible connector, and the lower end of the small-section sealing body at the lowest end is connected with an upstream movable valve. After the adoption of the flexible connection between all small-section sealing bodies, the mutual rotation, eccentricity regulation and bending (at a small angle) of the small-section sealing bodies can be realized. The invention solves the problems of long rigidity matching surface of the plunger piston and a pump tube, great down operation resistance, severe camber wear of the pump tube and the plunger piston and the like, reduces the friction force formed during the down operation of the plunger piston, improves the sealing reliability of the plunger piston during the up operation, and simultaneously prolongs the effective sealing period.

Owner:CHINA PETROLEUM & CHEM CORP +1

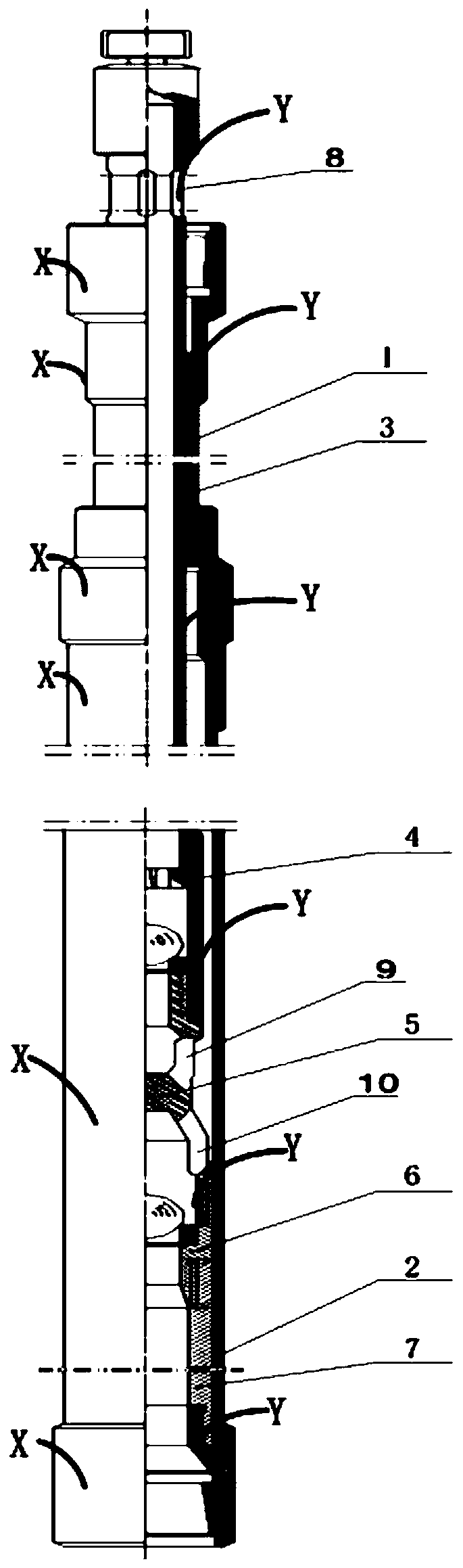

Packer for formation testing and method for performing formation testing by adopting packer

ActiveCN111911110APrevent pre-settingGood for walkingWell/borehole valve arrangementsSealing/packingUpper jointEngineering

The invention relates to a packer for formation testing and a method for performing formation testing by adopting the packer. The packer comprises an upper joint, wherein a conical female thread is formed in the upper end of the upper joint, a core pipe extending downwards is screwed in an internal thread in the lower end of the upper joint, and the lower end of the core pipe is inserted into an upper port of a lower joint and is sealed through an O-shaped ring; a conical male thread is formed in the lower end of the lower joint; and a bypass mechanism capable of communicating upper liquid flow and lower liquid flow of the packer is arranged on the periphery of the core pipe and below the upper joint, a setting mechanism is arranged below the bypass mechanism, a shear pin mechanism is arranged below the setting mechanism, and a transposition mechanism for controlling bypass and setting is arranged below the shear pin mechanism. During well descending, the bypass is opened to communicate upper and lower annuluses, after in place, the core pipe is rotated, the bypass is closed, setting is performed, stratum fluid enters a string, then the bypass is opened, unsetting is performed, andthe string is lifted. In the drilling process, it is ensured that the straddle packer cannot be set in advance, so that packer rubber sleeves are effectively protected, and the straddle test successrate is practically increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

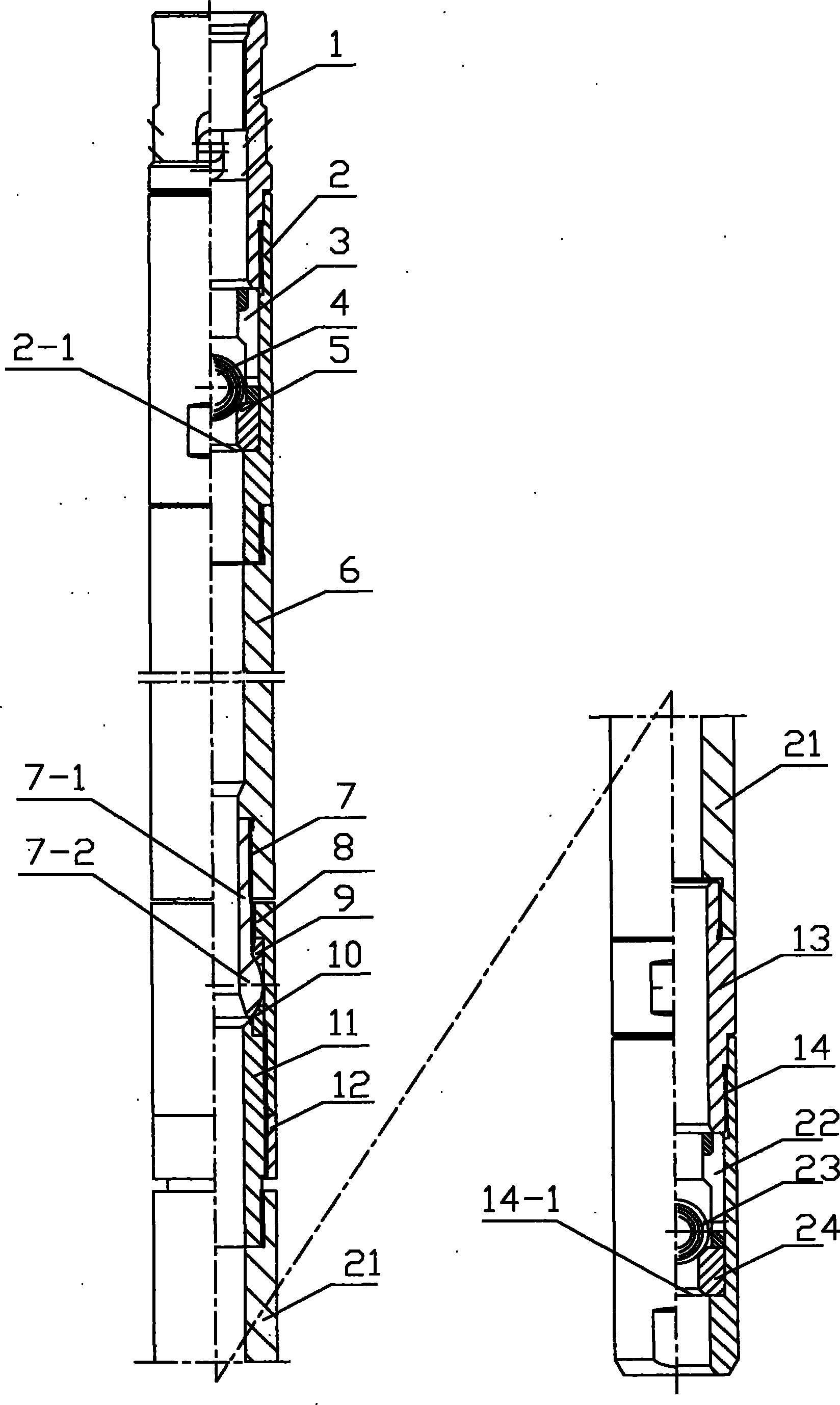

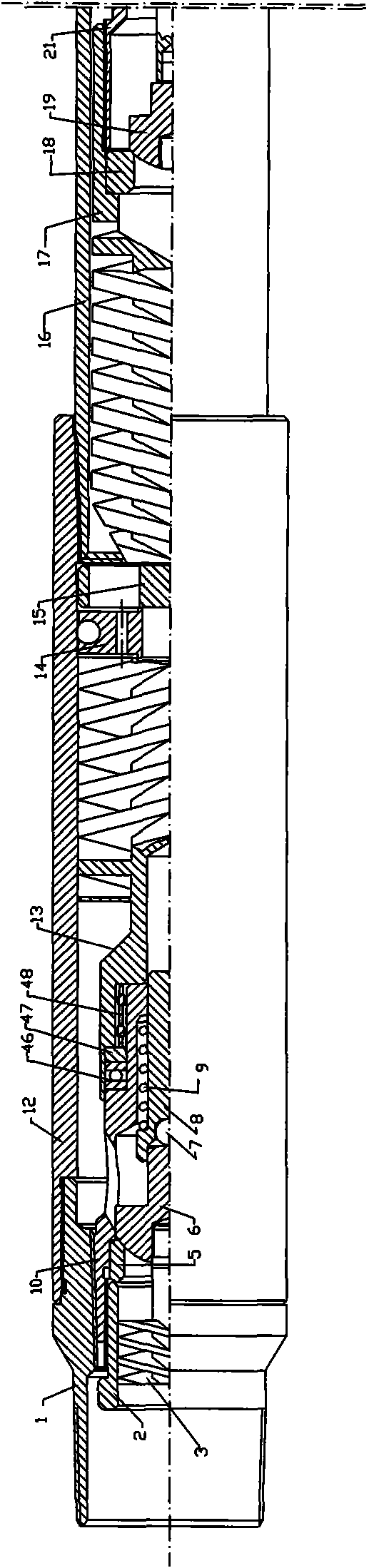

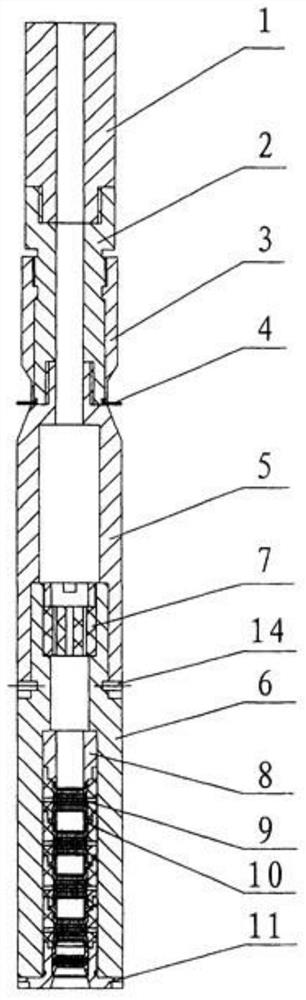

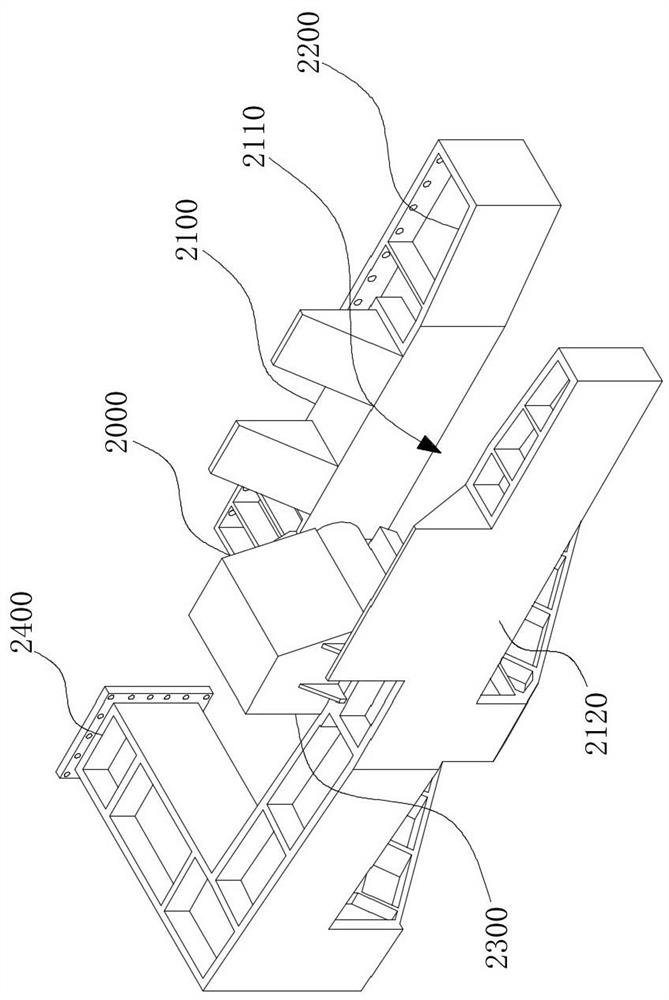

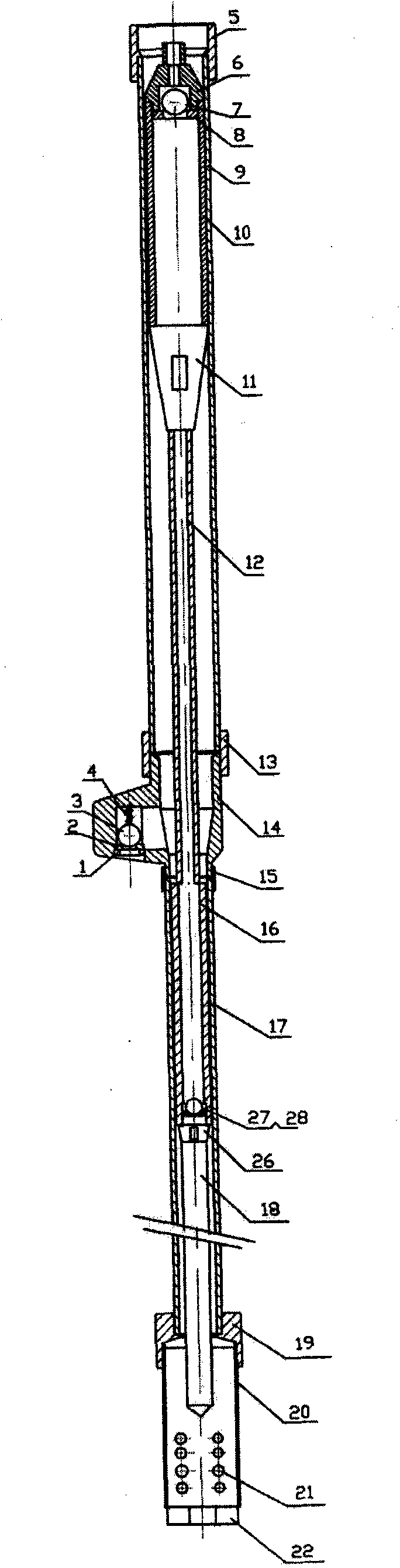

Multi-section centering self-rotating reducer oil pipe pump

InactiveCN101858332AAvoid deformationReduce downside resistancePositive displacement pump componentsFlexible member pumpsEngineeringUpper joint

The invention relates to a multi-section centering self-rotating reducer oil pipe pump. An integral oil pump is used as a center pump cylinder. The pump cylinder is provided with an upper joint and a lower joint. A plunger assembly is installed in the pump cylinder and is formed by a reducer plunger unit. The reducer plunger unit at least comprises two stages. The reducer plunger unit of each stage is provided with a self-propelled reducing mechanism and a self-rotating pushing mechanism. The self-propelled reducing mechanism and the self-rotating pushing mechanism are sheathed on the frame of the reducer plunger unit of the corresponding stage. A connecting bearing capable of automatically centering is arranged between two adjacent reducer plunger units. An upper thruster is arranged at the upper end of the plunger assembly. The upper thruster with bolted with a rotator. An anti-collision mechanism is installed at the upper end of the rotator and comprises an anti-collision bar, an anti-collision bar joint and an anti-collision block. A sand scraping cup is sheathed on the external side of the anti-collision bar joint. A sand retainer is sheathed on the external side of the upperend of the anti-collision block. An anti-sand-burying rotating half-ball standing valve assembly is arranged at the lower end of the plunger assembly.

Owner:姚尔强 +1

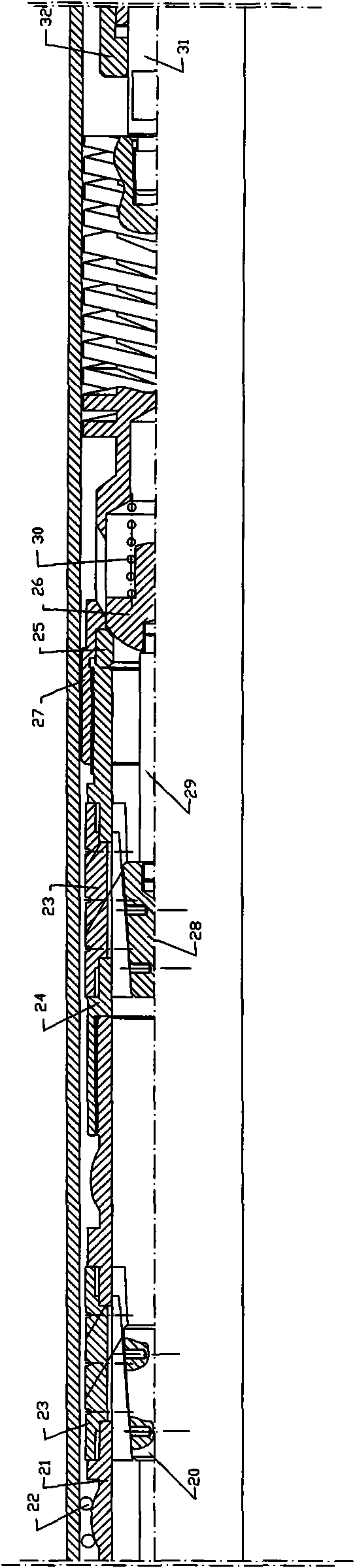

Hydraulic self-sealed plunger oil-well pump

InactiveCN1892031AImprove pump efficiencyReduce gapPositive displacement pump componentsFlexible member pumpsElastomerEngineering

The invention provides a hydraulic self-sealing plunger oil pump, for thoroughly solving the friction problem between sucker rod and oil pipe, comprising plunger, pump barrel and traveling valve, where central rod sieve tube of the plunger is jacketed with a seal elastomer layer, the seal elastomer is jacketed with rigid metal ring and elastic seal ring. In the up-stroke course of the oil pump, the high pressure in the plunger acts through the seal elastomer onto the wearable elastic seal ring to reduce clearance between the seal ring and the pump barrel, strengthening seal and reducing leakage; in the down-stroke course, the pressures at two ends of the plunger are the same, the wearable seal ring contracts, increasing the clearance and reducing down-going resistance of the plunger. And the seal ring structure of the invention is applied to all hydraulic-plunger or multi-plunger pumps, having advantages of reducing the leakage of pump, raising volume of pump and efficiency of pump, etc.

Owner:DAQING OILFIELD CO LTD

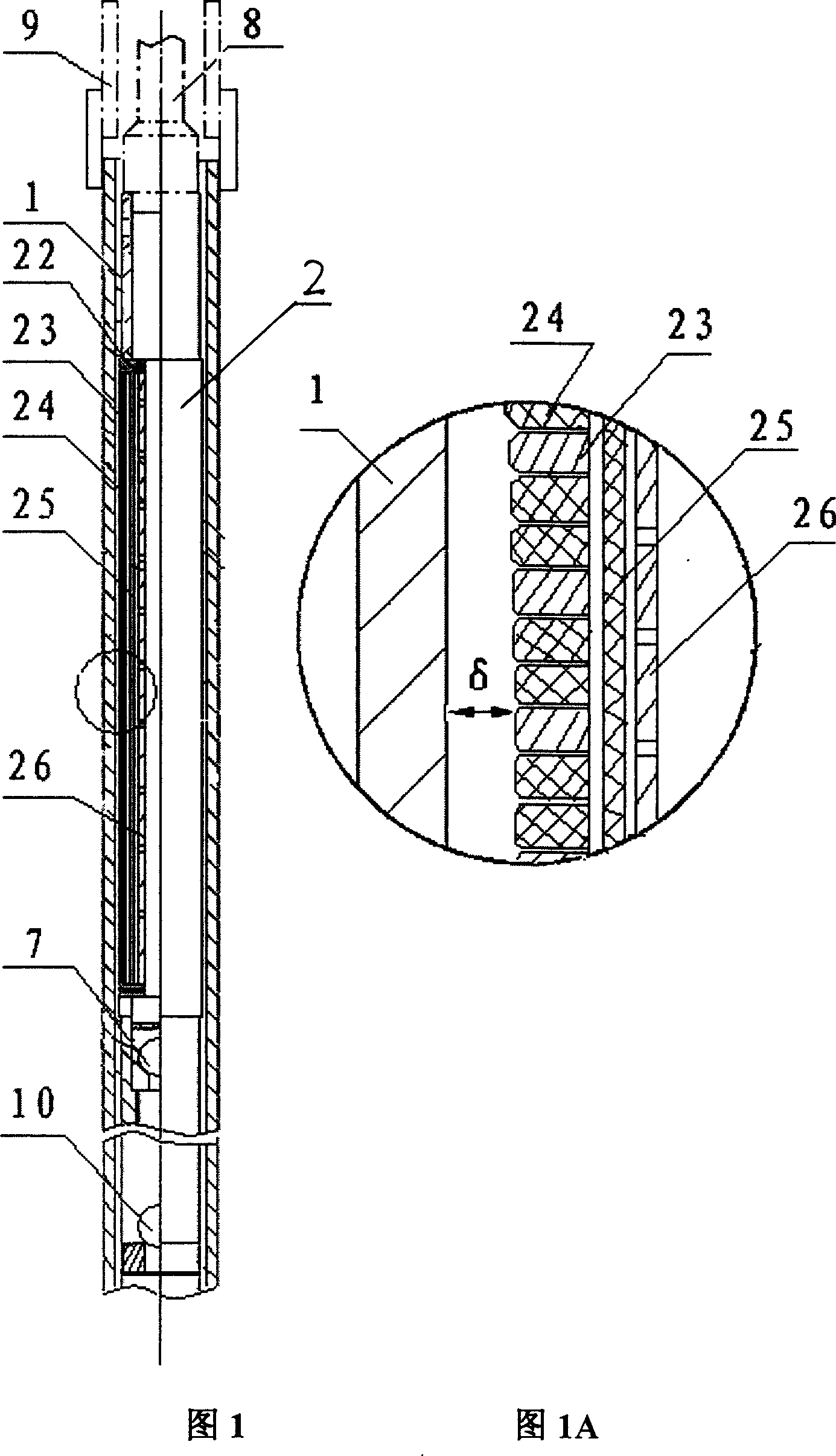

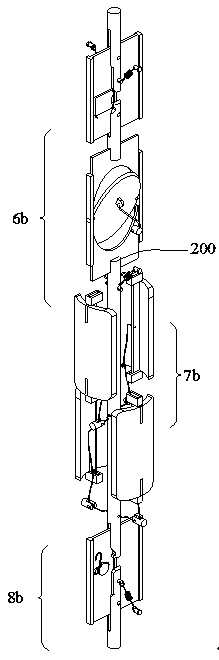

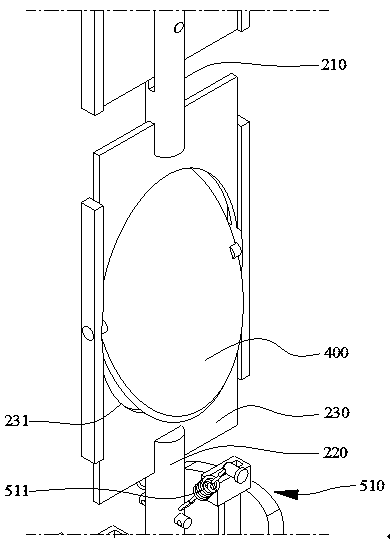

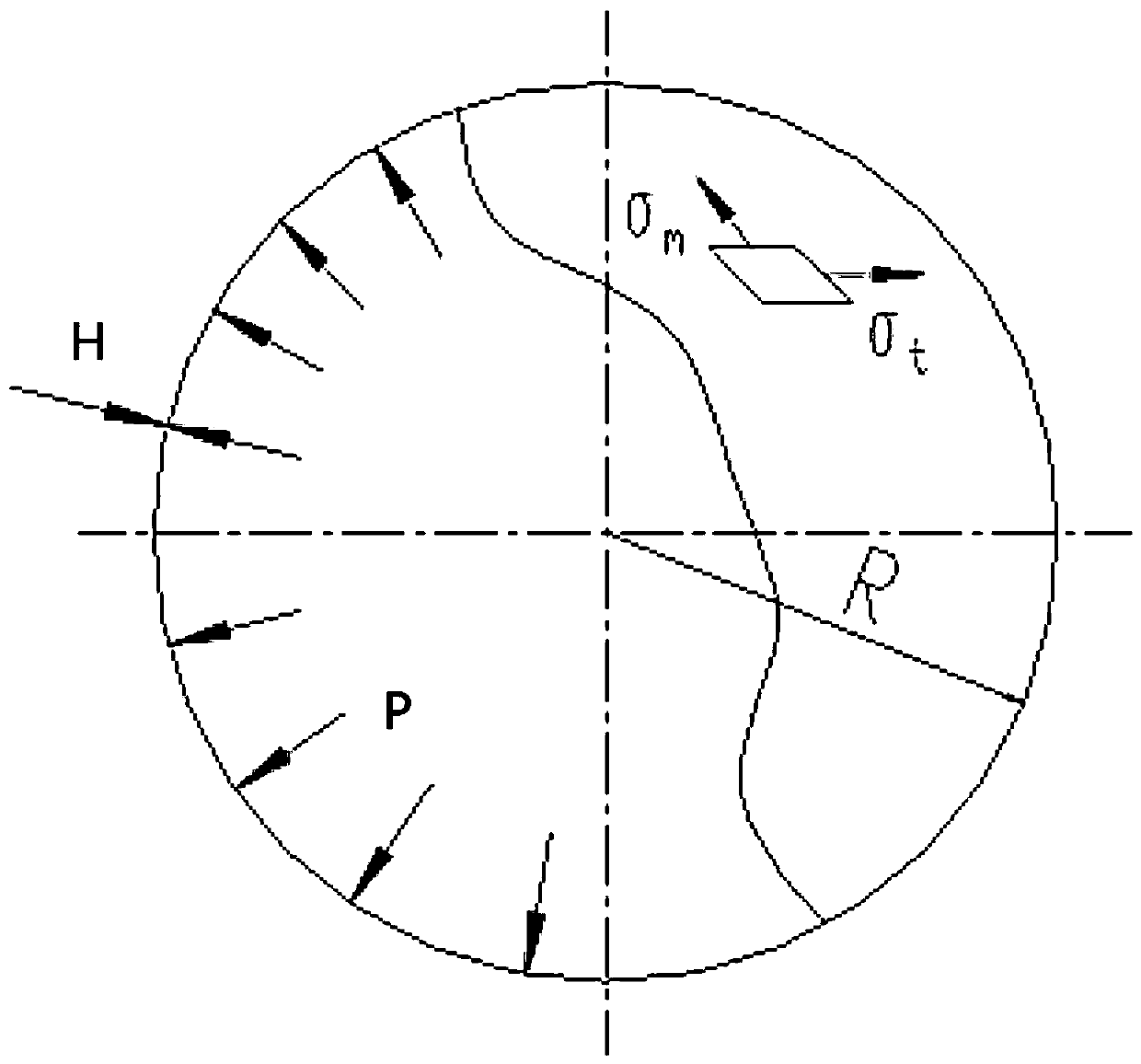

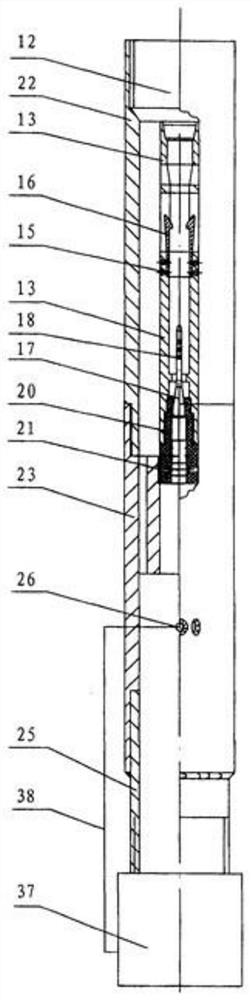

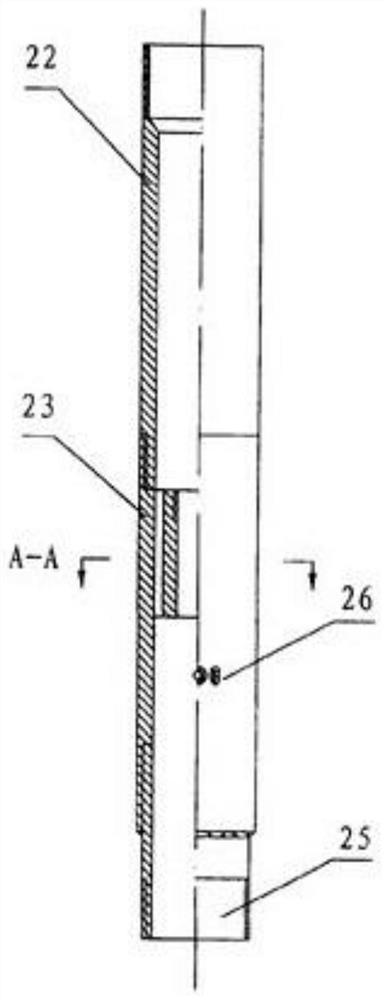

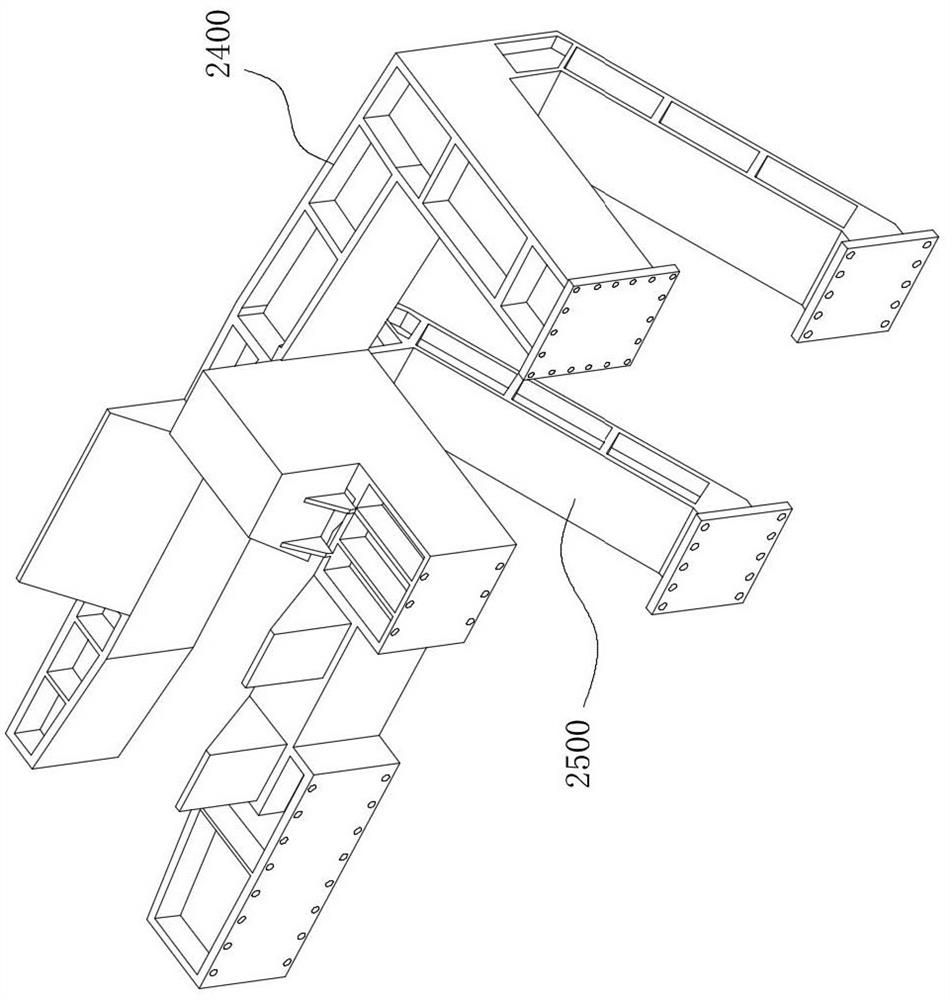

Fluid separating device, shaft structure and petroleum or natural gas producing method

ActiveCN107503712AReduce downside resistanceReduce the stress areaFluid removalWell/borehole valve arrangementsHIT deviceMethods of production

The invention relates to the technical field of oil and gas production, and discloses a fluid separating device, a shaft structure and a petroleum or natural gas producing method. By means of the fluid separating device and the shaft structure, the requirement for the hitting force of the fluid separating device and a lower hitting device is lowered, a mandrel can be switched between an opened position and a closed position only with small hitting force between the fluid separating device and the lower hitting device, and the reliability of the fluid separating device and the shaft structure in working is improved. By means of the method, the exit of a shaft is opened when the fluid separating device goes down, petroleum or natural gas can still be sprayed out of the shaft when the fluid separating device goes down, the continuous production of petroleum or natural gas is achieved, and production efficiency is greatly improved.

Owner:成都百胜野牛科技有限公司

Fluid separating device, shaft structure and method for producing petroleum or natural gas

ActiveCN107313738AReduce downside resistanceReduce impact forceFluid removalSealing/packingThermodynamicsProcess engineering

The invention relates to the technical field of oil and gas exploitation, and discloses a fluid separating device, a shaft structure and a method for producing petroleum or natural gas. The fluid separating device, the shaft structure and the method have the advantages that requirements on impact force of a mandrel and a lower impact device can be lowered by the fluid separating device and the shaft structure, the mandrel can be changed from contraction locations to expansion locations only by the aid of low impact force between the mandrel and the lower impact device, and the reliability of the fluid separating device and the shaft structure during work can be improved; the method for producing the petroleum or the natural gas can be continuously implemented without shutting down wells, accordingly, the petroleum or the natural gas can be continuously produced, and the production efficiency can be greatly improved.

Owner:成都百胜野牛科技有限公司

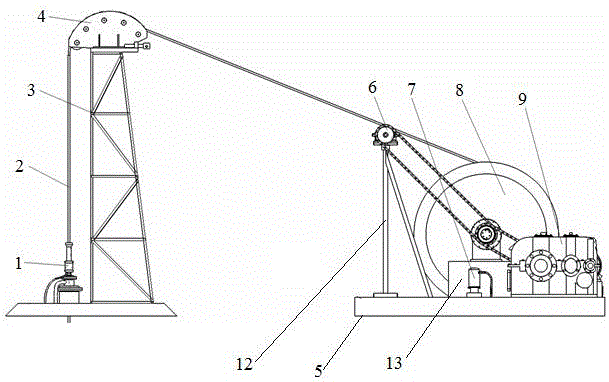

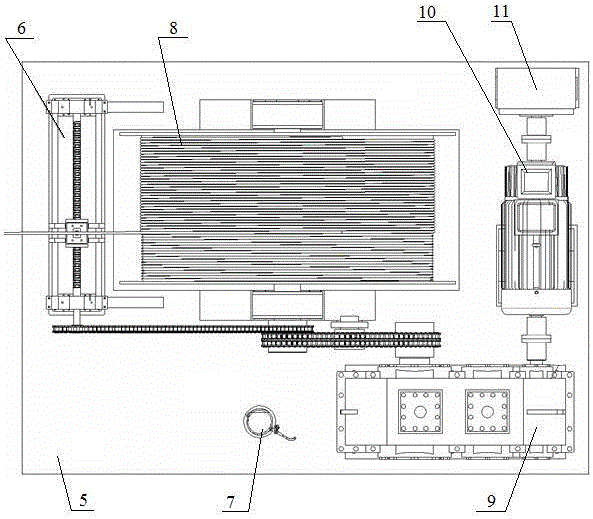

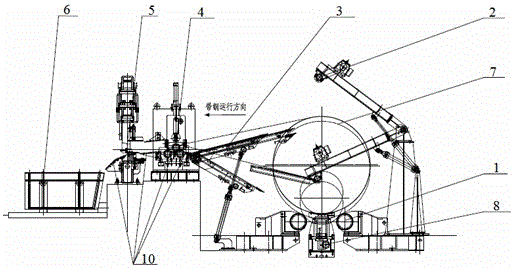

Numerical control winding pumping unit with sealed steel wire rope

InactiveCN106761571AReduce contact stressUniform stress distributionFluid removalNumerical controlEngineering

The invention relates to a numerical control winding pumping unit with a sealed steel wire rope. A magnetic powder brake of the numerical control winding pumping unit for the sealed steel wire rope is connected to a motor, a rolling cylinder is fixed onto a cylinder seat, a reduction gearbox output shaft is connected with a rotating shaft of the rolling cylinder through a first chain inclined upwards, and an encoder is mounted on the reduction gearbox output shaft; the sealed steel wire rope is wound on the rolling cylinder, the sealed steel wire rope enters an oil well after passing through a rope guider, a guide mechanism and a well mouth sealing device in sequence, the other end of the sealed steel wire rope is connected with an underground oil extractor, a pressure sensor is fixedly arranged at the upper end of the oil extractor, and the lower end of the oil extractor is connected to a weighing rod; the rope guider is mounted on a rope guiding support, the rotating shaft of the rolling cylinder is connected with a one-way reciprocating lead screw of the rope guider through a second chain inclined upwards, and the sealed steel wire rope is rightly tangential to a rope guiding wheel of the roper guider; and the guide mechanism comprises a plurality of continuous fixed pulleys. The sealed steel wire rope is used, the sealing property reaches up to more than 90%, and a pneumatic swabbing seal box is also matched with the sealed steel wire rope, so that a well mouth is good in sealing property, and the service life of the steel wire rope is long.

Owner:NORTHEAST GASOLINEEUM UNIV

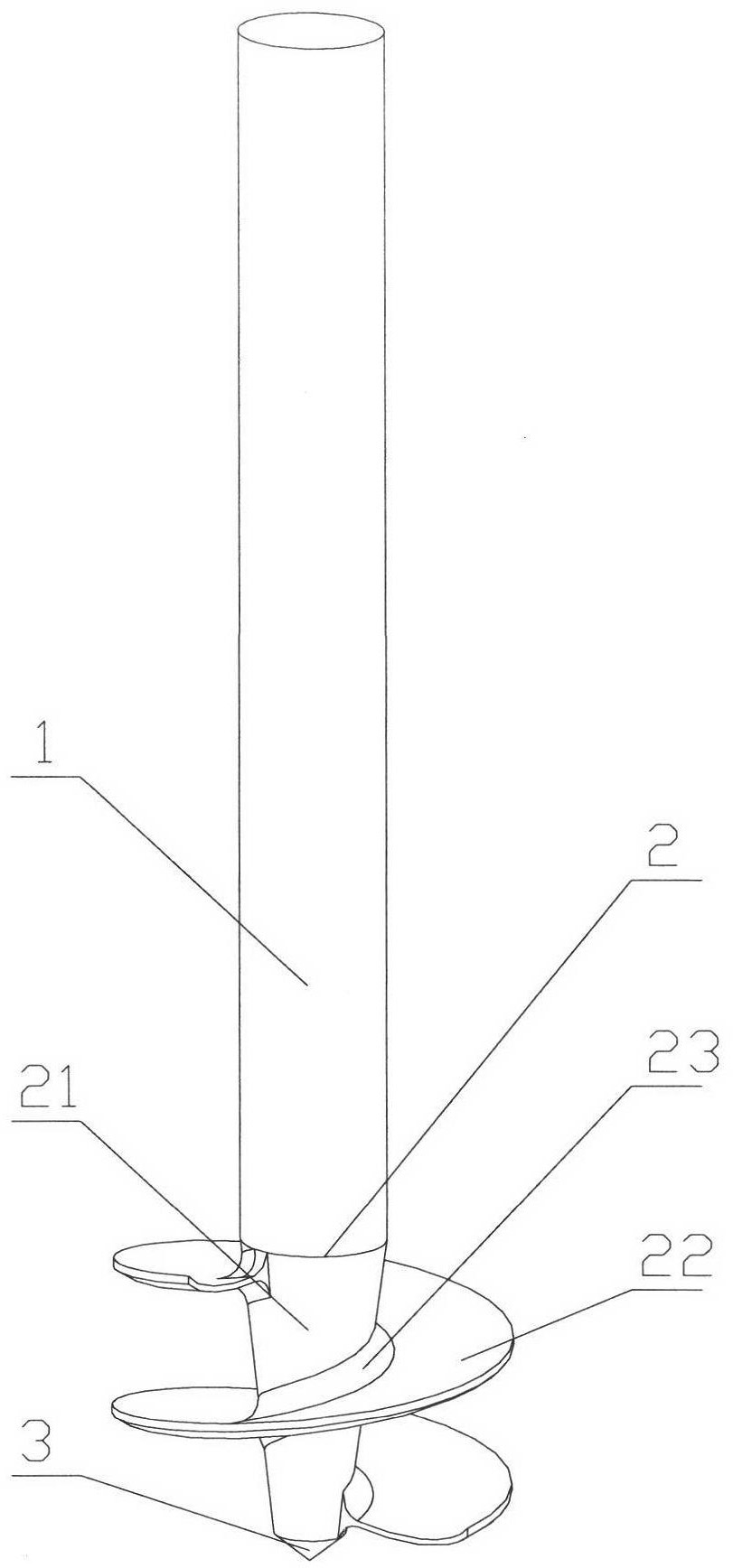

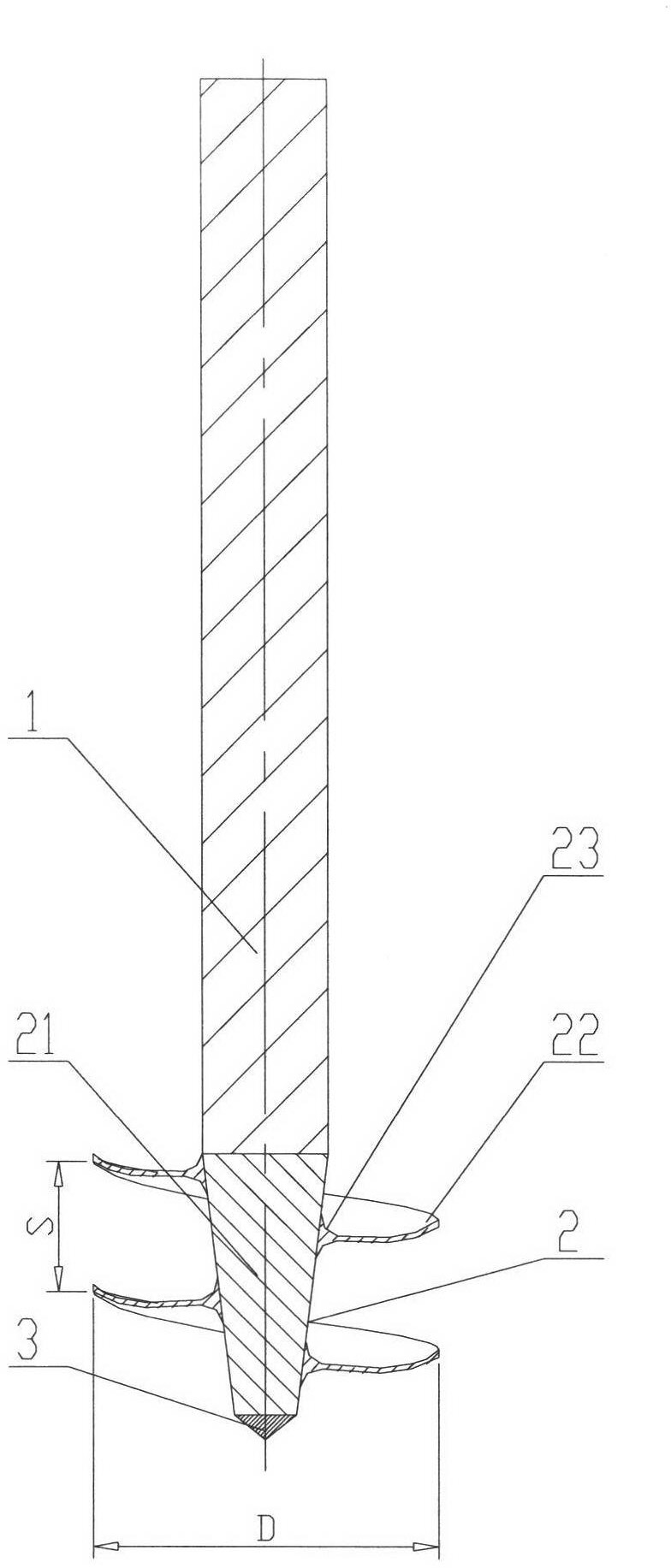

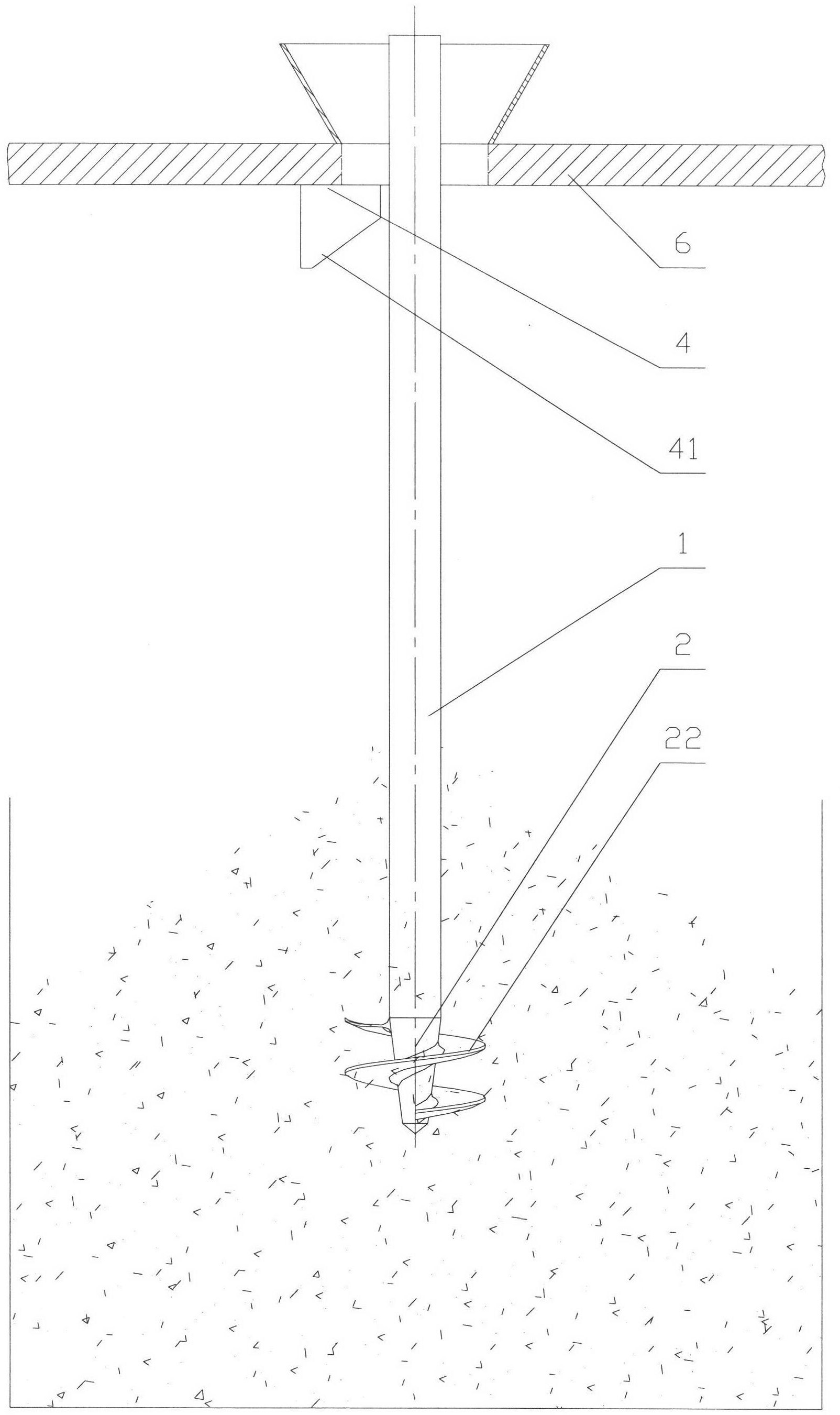

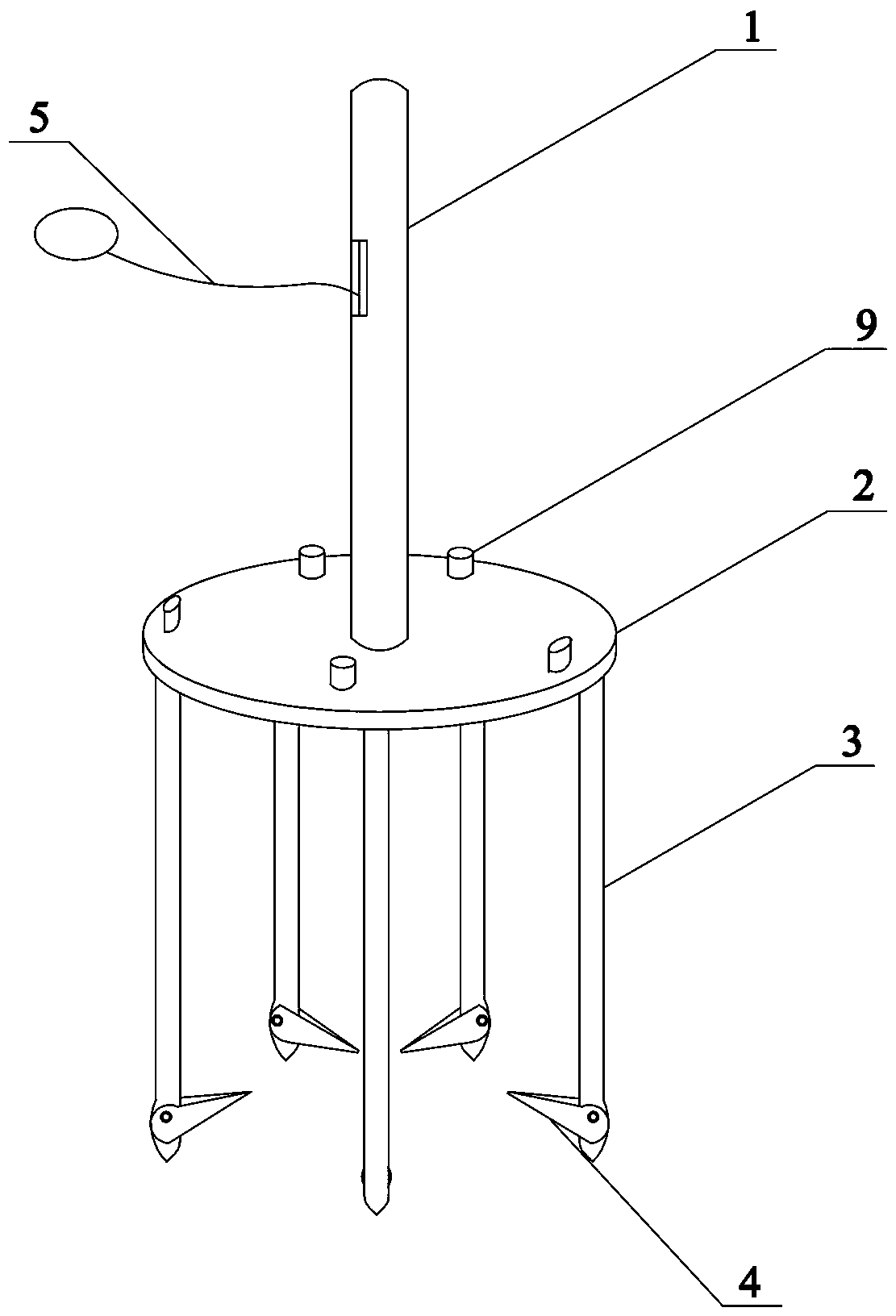

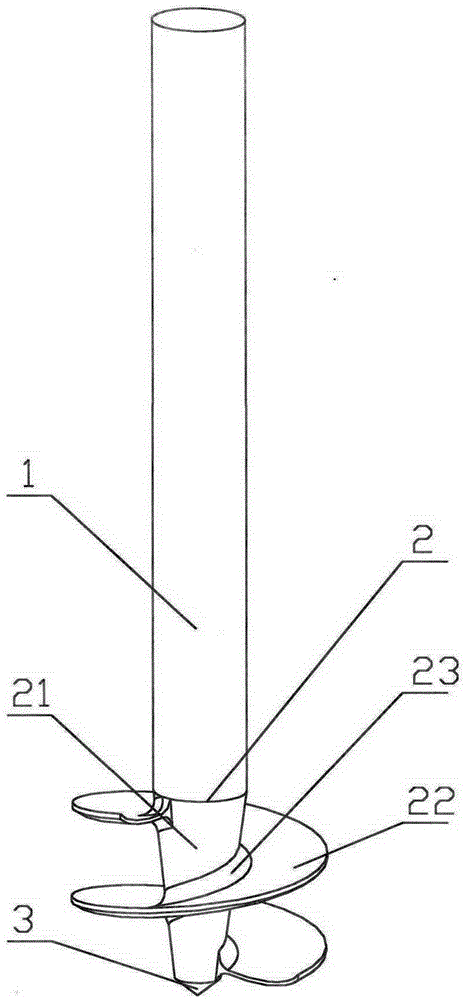

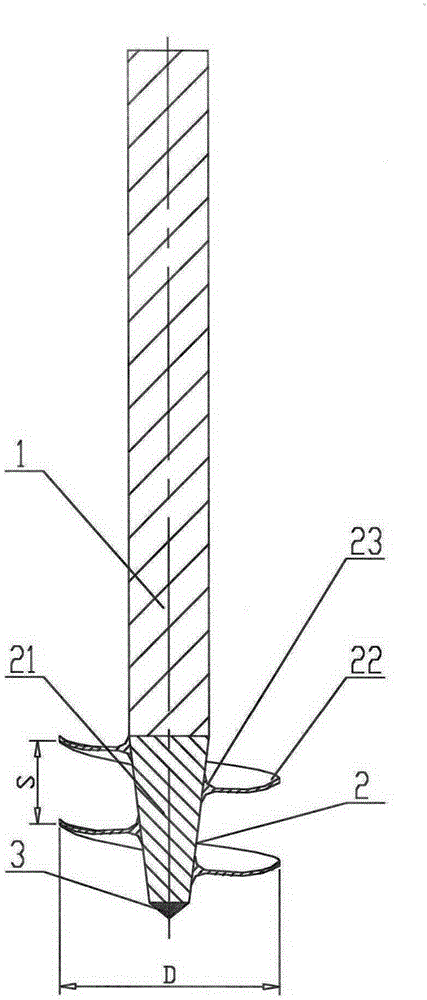

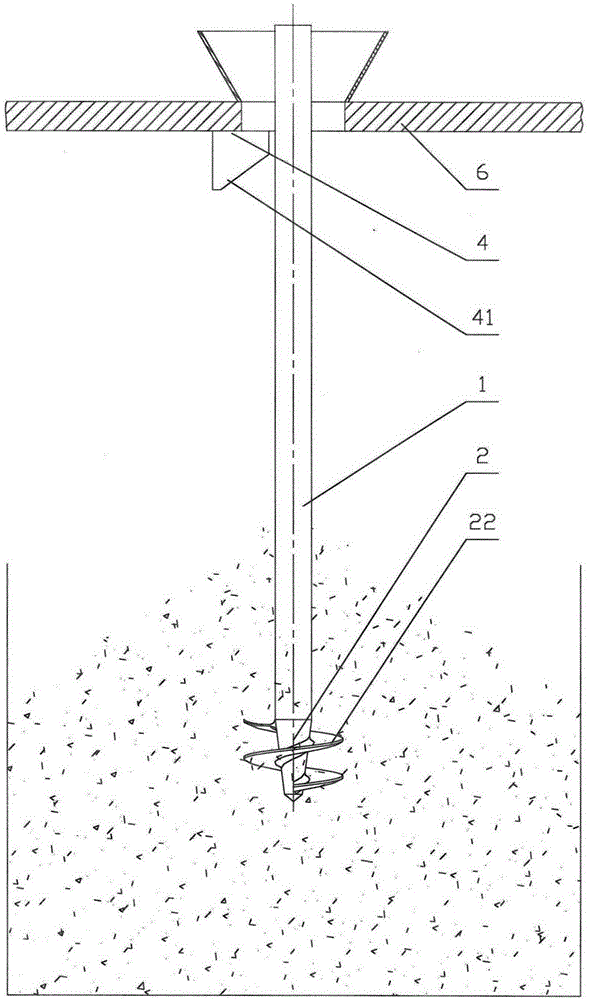

Spiral screwing type sampler and sampling device

ActiveCN102564803AReduce downside resistanceReduced Power RequirementsWithdrawing sample devicesFailure rateSpiral blade

The invention provides a spiral screwing type sampler. The spiral screwing type sampler comprises an upper sampling rod and a lower spiral lifer; the spiral lifer comprises a spiral central spindle and a spiral blade wound outside the spiral central spindle; and the upper surface of the spiral blade for loading sampled materials extends in a shape of sunken circular arc surface along the radial direction of the spiral lifter. Compared with the prior art, the spiral screwing type sampler and the sampling device have the advantages of greatly reducing failure rate, along with simple structure, low downgoing resistance, high sampling speed, high reliability, convenience in equipment maintenance, and high working efficiency and the like.

Owner:长沙通发高新技术开发有限公司

Anti-drag sand-proof rod oil well pump

ActiveCN104847636AReduce downside resistanceAchieve sealingPositive displacement pump componentsFlexible member pumpsRubber ringEngineering

The invention relates to an anti-drag sand-proof rod oil well pump. The outer periphery of the upper portion of a plunger is provided with a groove matched with a rubber ring, sealing of a gap between the plunger and a pump barrel is realized, and the problem that sand is prone to getting into the gap between the plunger and the pump barrel to result in sand jamming when the pump stops operating in well shut-in period and the plunger is at upper or lower dead points is solved. Owing to the rubber ring structure, rigid contact between the plunger and the pump barrel is modified into flexible contact, and downgoing resistance of the plunger is reduced by increase of contact area and the gap between the plunger and the pump barrel. By the aid of an inverted frustum conical structure at a plunger discharge valve and an internal streamline flow passage, downgoing resistance of the plunger can be reduced to enable underground fluid to flow out of a pump cavity more easily. Owing to the streamline flow passage in the lower half portion of a suction valve, resistance of well fluid flowing through the suction valve can be reduced.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

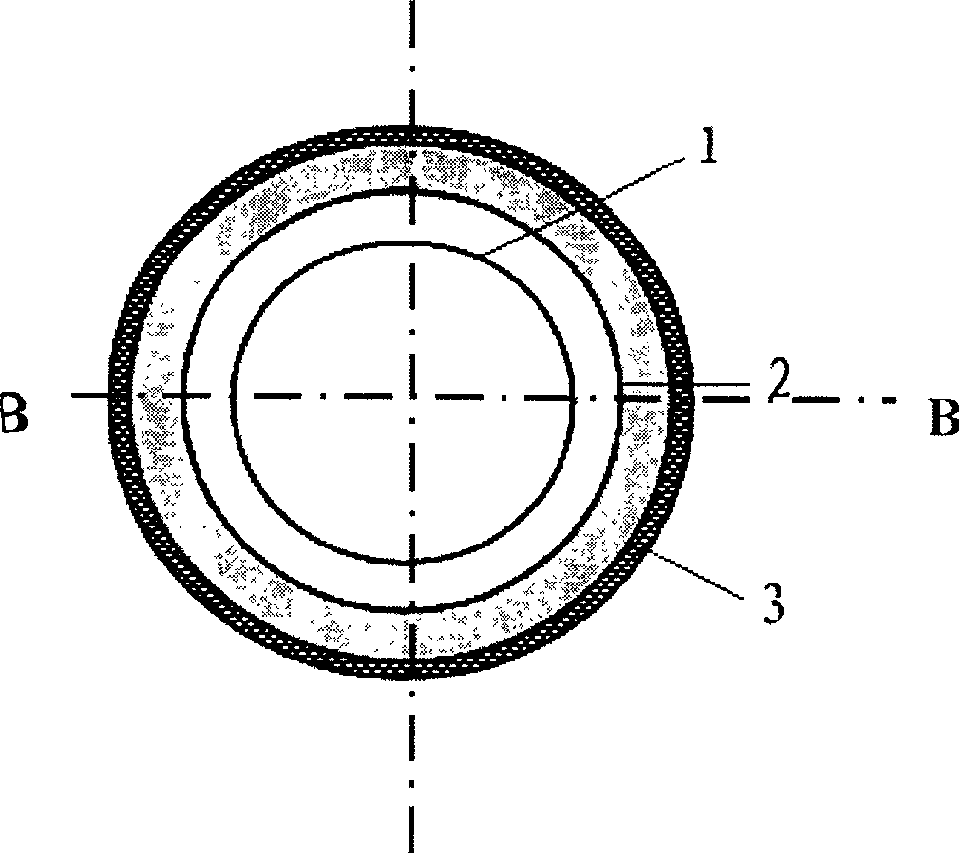

Hydraulic self-sealed plunger oil-well pump

InactiveCN100385120CImprove pump efficiencyReduce gapPositive displacement pump componentsFlexible member pumpsElastomerHigh pressure

The invention provides a hydraulic self-sealing plunger oil pump, for thoroughly solving the friction problem between sucker rod and oil pipe, comprising plunger, pump barrel and traveling valve, where central rod sieve tube of the plunger is jacketed with a seal elastomer layer, the seal elastomer is jacketed with rigid metal ring and elastic seal ring. In the up-stroke course of the oil pump, the high pressure in the plunger acts through the seal elastomer onto the wearable elastic seal ring to reduce clearance between the seal ring and the pump barrel, strengthening seal and reducing leakage; in the down-stroke course, the pressures at two ends of the plunger are the same, the wearable seal ring contracts, increasing the clearance and reducing down-going resistance of the plunger. And the seal ring structure of the invention is applied to all hydraulic-plunger or multi-plunger pumps, having advantages of reducing the leakage of pump, raising volume of pump and efficiency of pump, etc.

Owner:DAQING OILFIELD CO LTD

Anticorrosive wear-resistant graphene coated pipe

PendingCN111804547AExcellent self-lubricating wear resistanceGood lubrication and wear resistanceFireproof paintsPretreated surfacesAlkyl dimethyl benzyl ammonium chlorideGraphene

The invention relates to the technical field of pipelines, in particular to an anticorrosive wear-resistant graphene coated pipe. The anticorrosive wear-resistant graphene coated pipe is prepared by the following processing steps that graphene, fluororesin, molybdenum disulfide, a solid lubricant, an amphiphilic compound, dodecyl dimethyl benzyl ammonium chloride, oleic acid hydroxyethyl imidazoline, a flame retardant, a solvent, tungsten oxide and an auxiliary agent are mixed and stirred; then heating dispersion treatment is carried out for later use; the outer surface of the pipe body to becoated and sprayed is cleaned up, the surface of the pipe body is roughly polished, and then the outer side of the polished pipe body is sprayed with a spraying agent; and the sprayed pipe body is subjected to high-temperature dissolving and sintering. According to the graphene coated pipe, the graphene coated pipe has the extremely high wear-resisting characteristic, through UMT mechanical performance and friction tests, the self-lubricating wear-resisting performance of the coating is excellent, and under the effects of the coating thickness being 50 microns and the force being 13 MPa, the coating is resistant to stainless steel ball friction for more than 200 thousand times and is not abraded through; and from the aspect of wear-resisting property comparison, the coating can ensure thata base material can work for a long time under the wear working condition.

Owner:大庆市盛日石油技术开发有限公司

Self-sealed compensated beam-pumping stabilizer

InactiveCN1896453AAct as a centralizerPlay a role in pumpingDrilling rodsFluid removalScrew threadSucker rod

This invention discloses a kind of compensated oil pumping centering guide device that is isolated itself. When centering guiding the sucker rod, this invention can compensate and pump oil isolating itself. After clamping baffle ring between the boss of sucker rod and the jointing hook connecting the external screw thread, the centering guiding cover is added. The crescent shaped leather package is nested on the baffle ring. The high anti-friction coating and centering guiding cover at the edge of leather package is used to centering guide and prevent sucker rod abrasion.

Owner:DAQING OILFIELD CO LTD

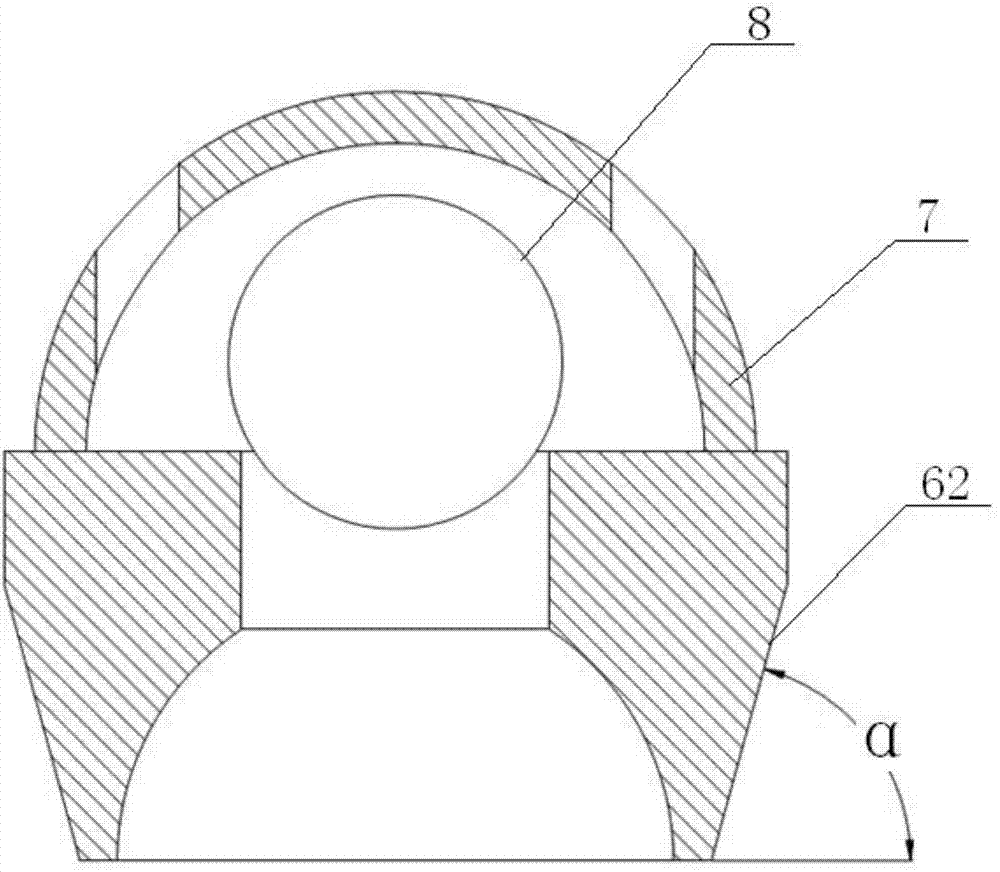

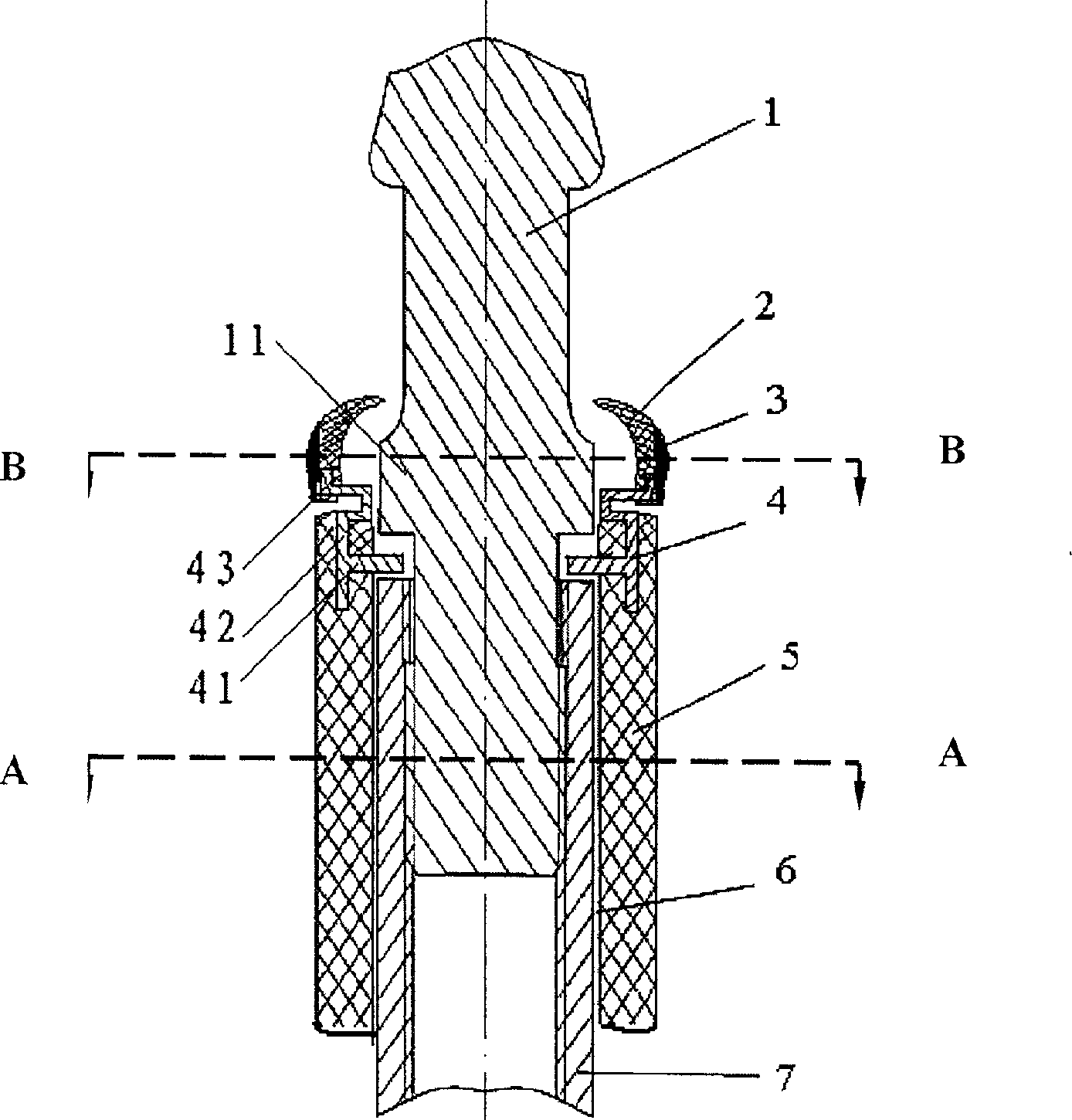

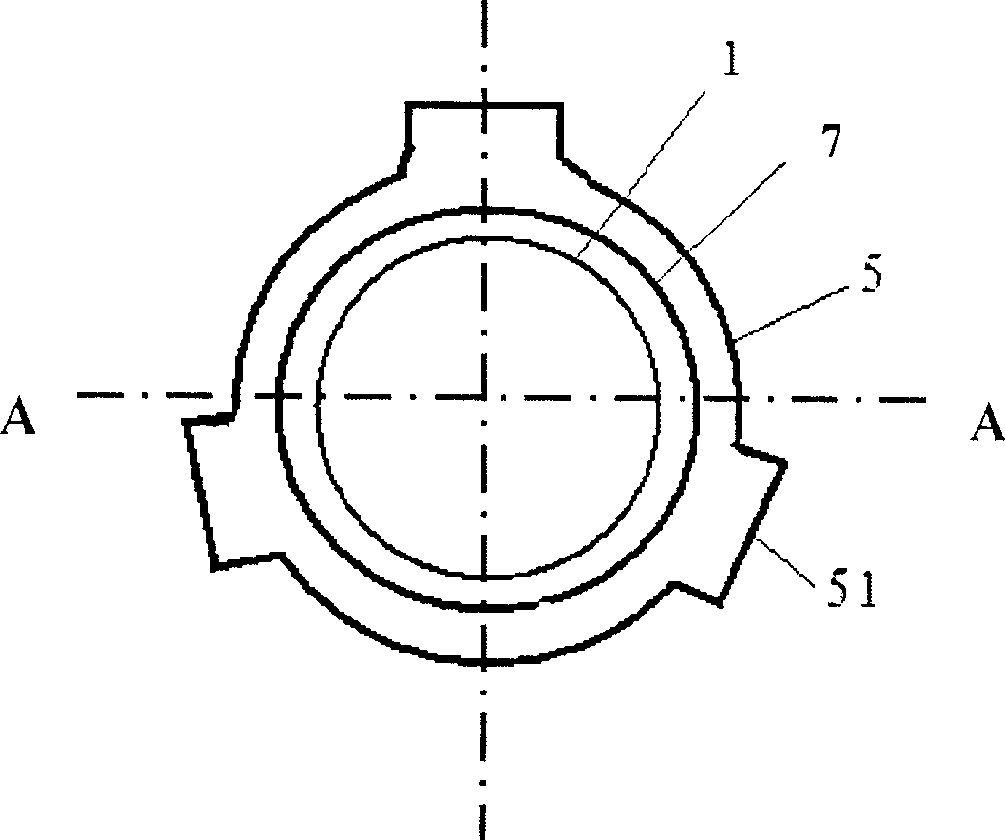

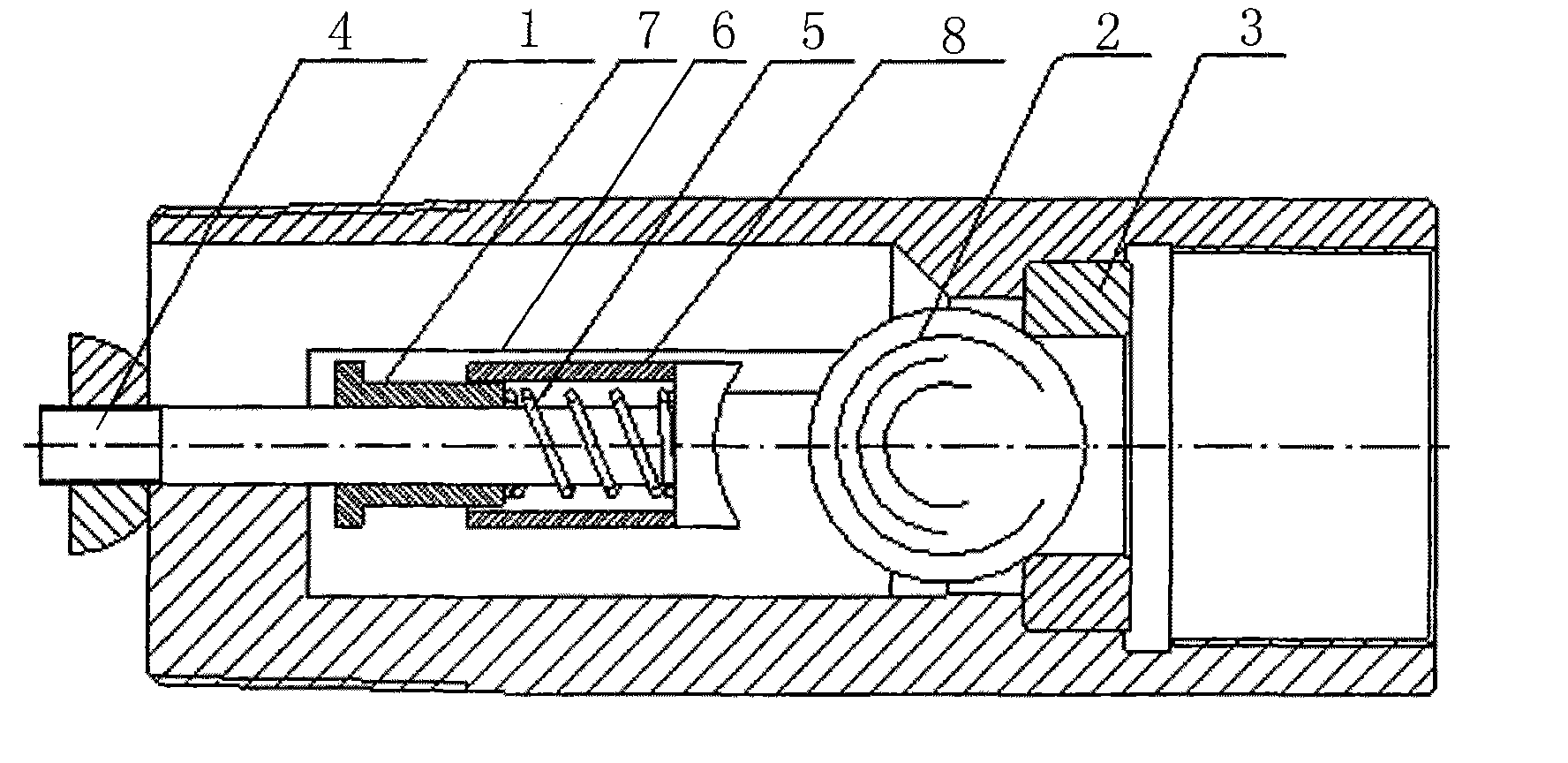

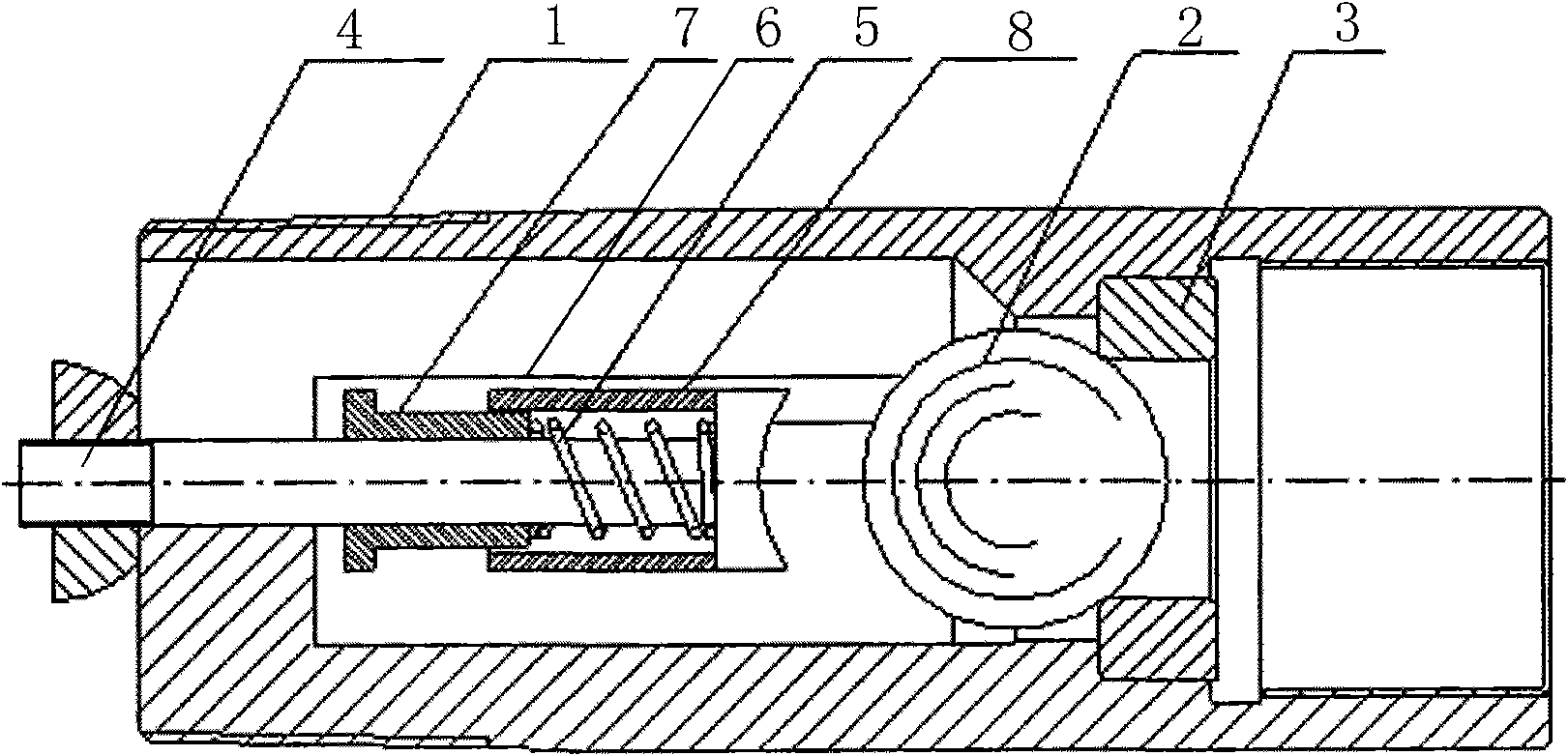

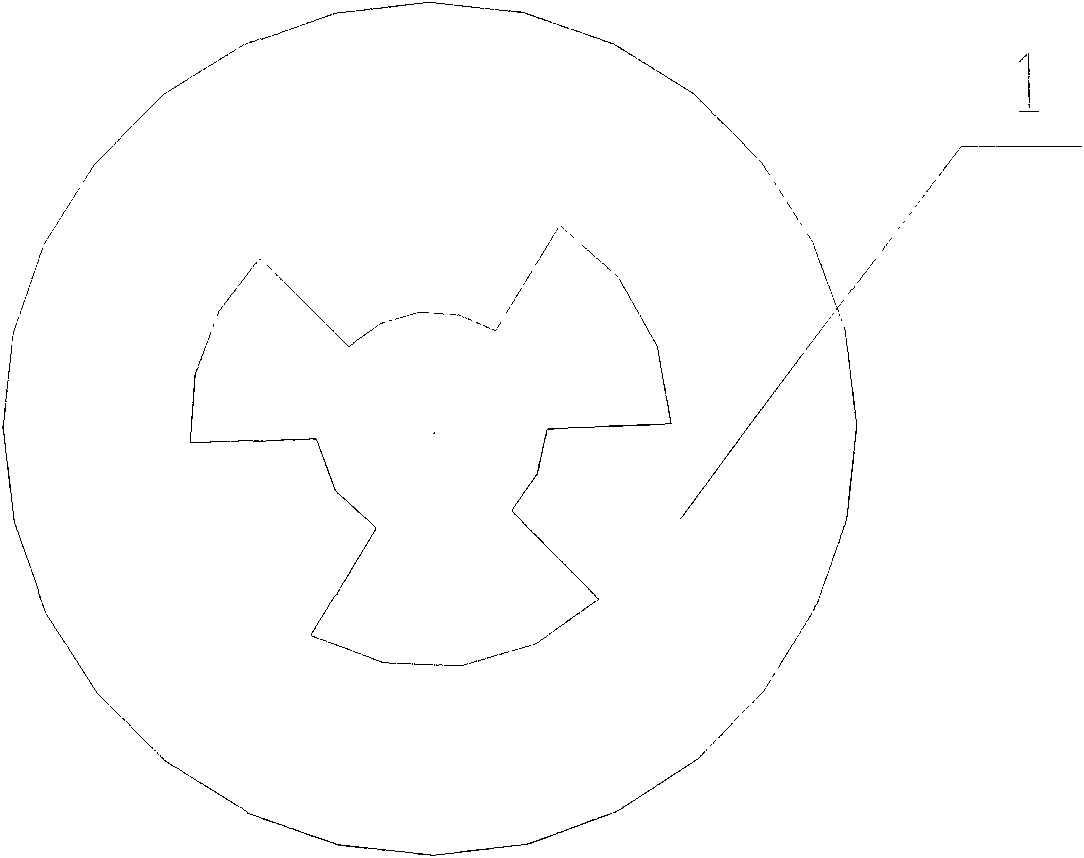

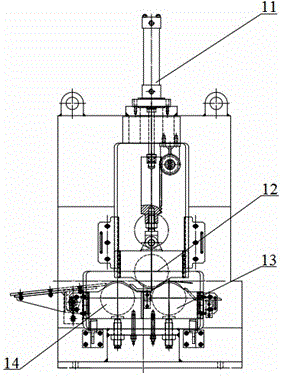

Ball valve motion track positioning control type oil-well pump valve assembly

InactiveCN101813084AClose fastAvoid damagePositive displacement pump componentsLiquid fuel engine componentsEngineeringPosition control

The invention relates to a ball valve motion track positioning control type oil-well pump valve assembly, which comprises a valve housing (1) and a valve ball (2), wherein a valve seat (3) is arranged in the valve housing (1); the valve ball (2) is positioned above the valve seat (3); a power valve (4) is arranged in the top center of an inner cavity of the valve housing (1); the lower end surface of the power valve (4) is a semicircle spherical surface and corresponds to the valve ball (2); the power valve (4) and the valve housing (1) can relatively slide; and an elastic part (5) for resetting the power valve (4) is arranged on the power valve (4). The positioning control mechanism prolongs the service life of the valve assembly, keeps a large flow channel to reduce feed liquid flow resistance, accelerates the closing speed of the ball valve to reduce the leakage and improves the pump efficiency.

Owner:李光献 +1

Fluid separation device, shaft structure and method of producing oil or natural gas

ActiveCN107503712BReduce downside resistanceReduce the stress areaFluid removalWell/borehole valve arrangementsThermodynamicsPetroleum oil

The invention relates to the technical field of oil and gas exploitation, and discloses a fluid separation device, a shaft structure and an oil or natural gas production method. The fluid separation device and the shaft structure reduce the requirements for the impact force between the fluid separation device and the lower impact device, and only need a small collision force between the fluid separation device and the lower impact device to complete the mandrel from the open position to the closed position. The conversion between positions improves the working reliability of the fluid separation device and the shaft structure. In the production method of oil or natural gas, the outlet of the well is opened when the fluid separation device goes down, so that when the fluid separation device goes down, the oil or natural gas can still be ejected from the well, realizing continuous production of oil or natural gas, and greatly improving production. efficiency.

Owner:成都百胜野牛科技有限公司

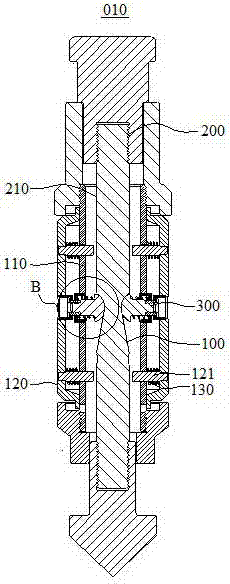

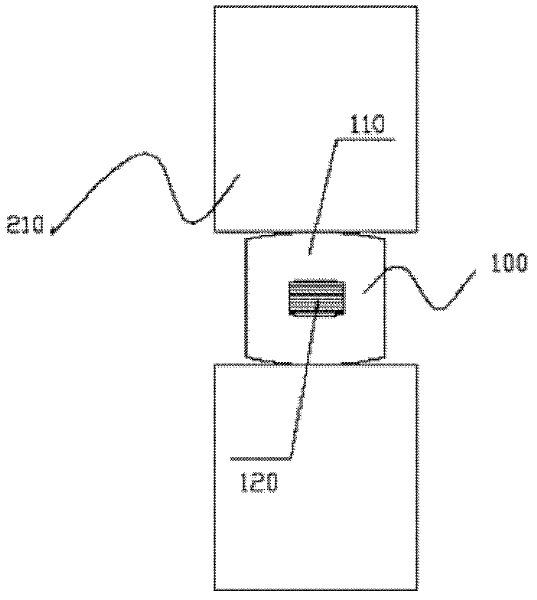

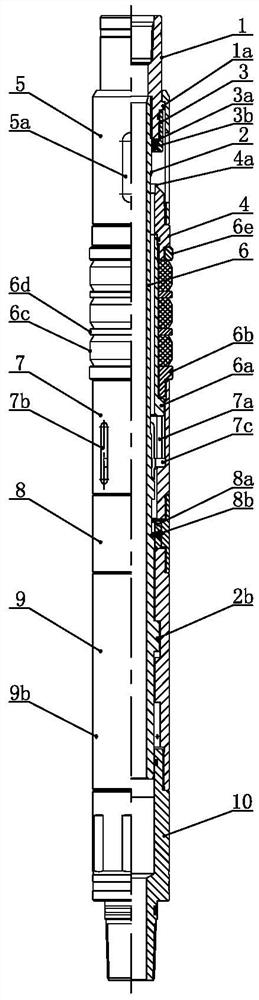

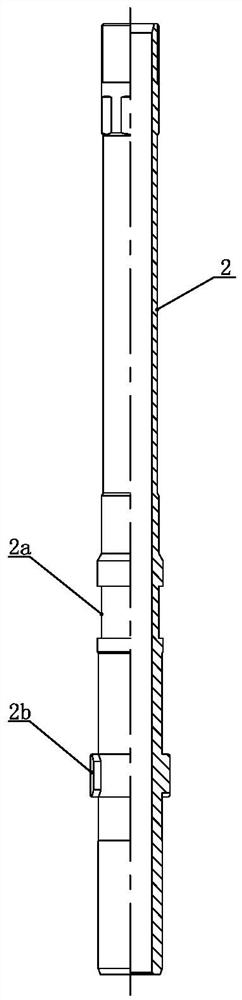

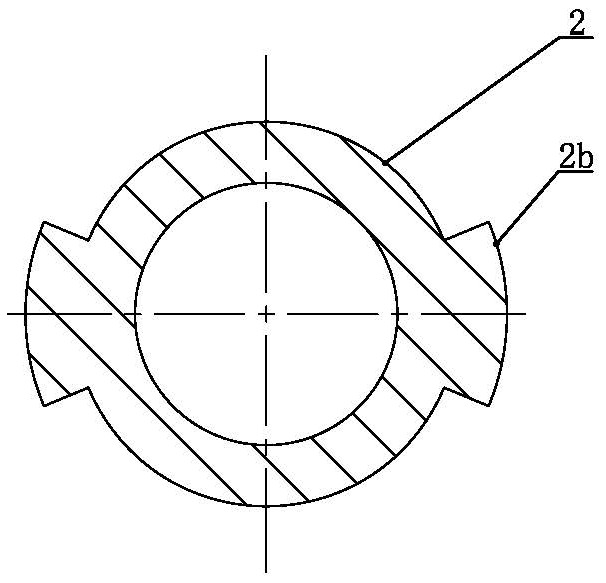

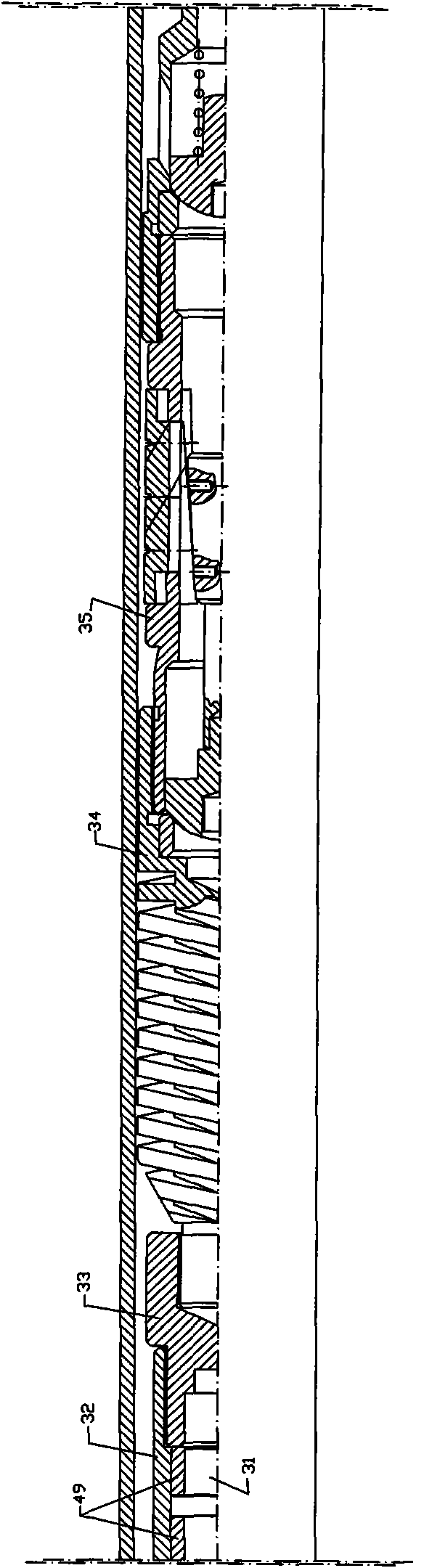

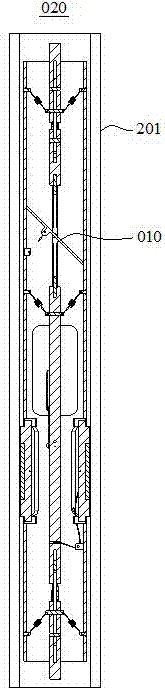

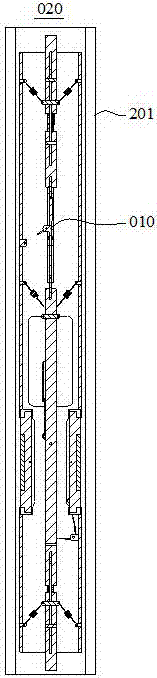

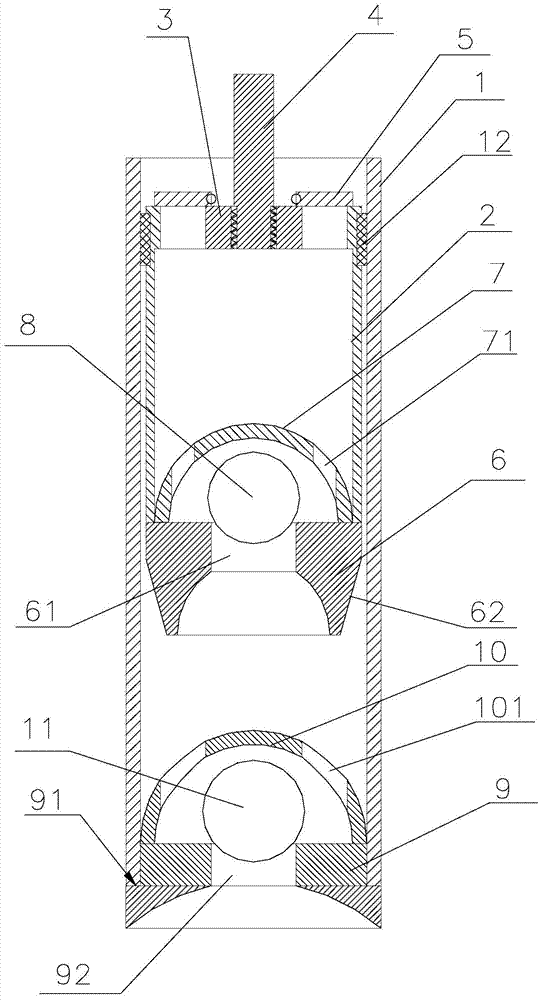

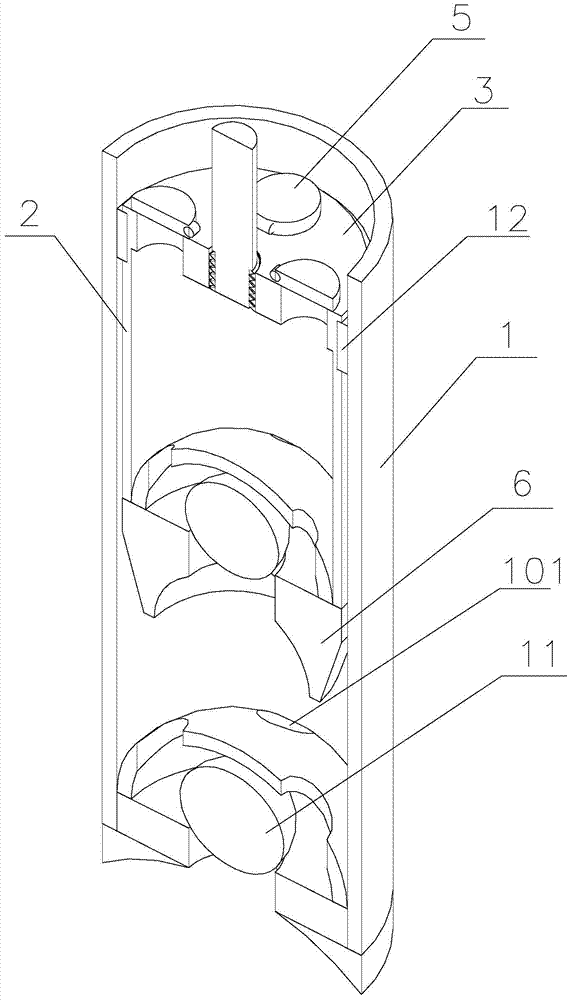

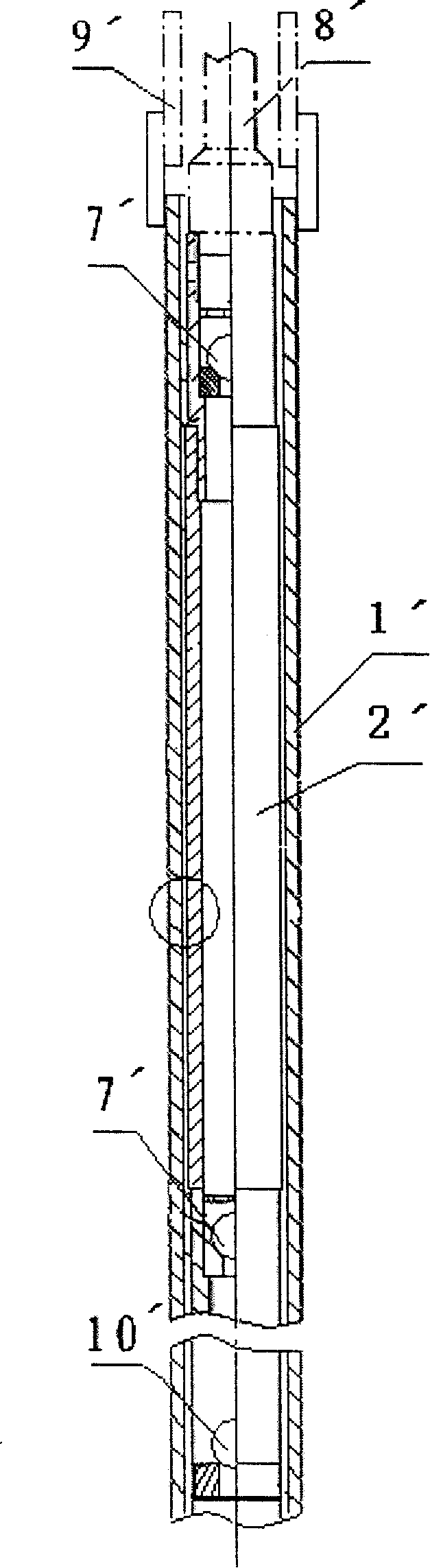

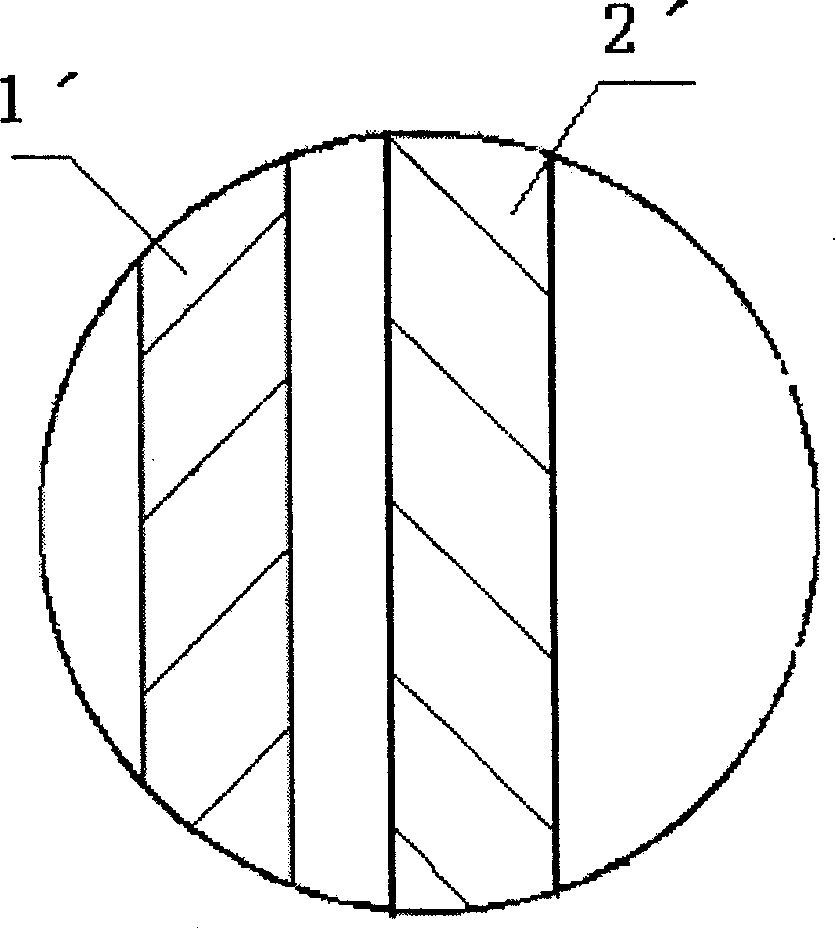

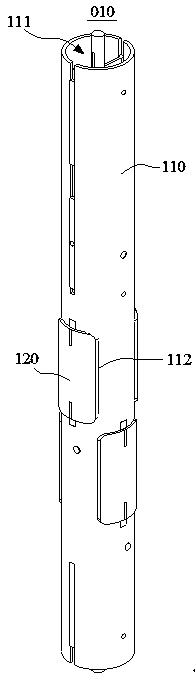

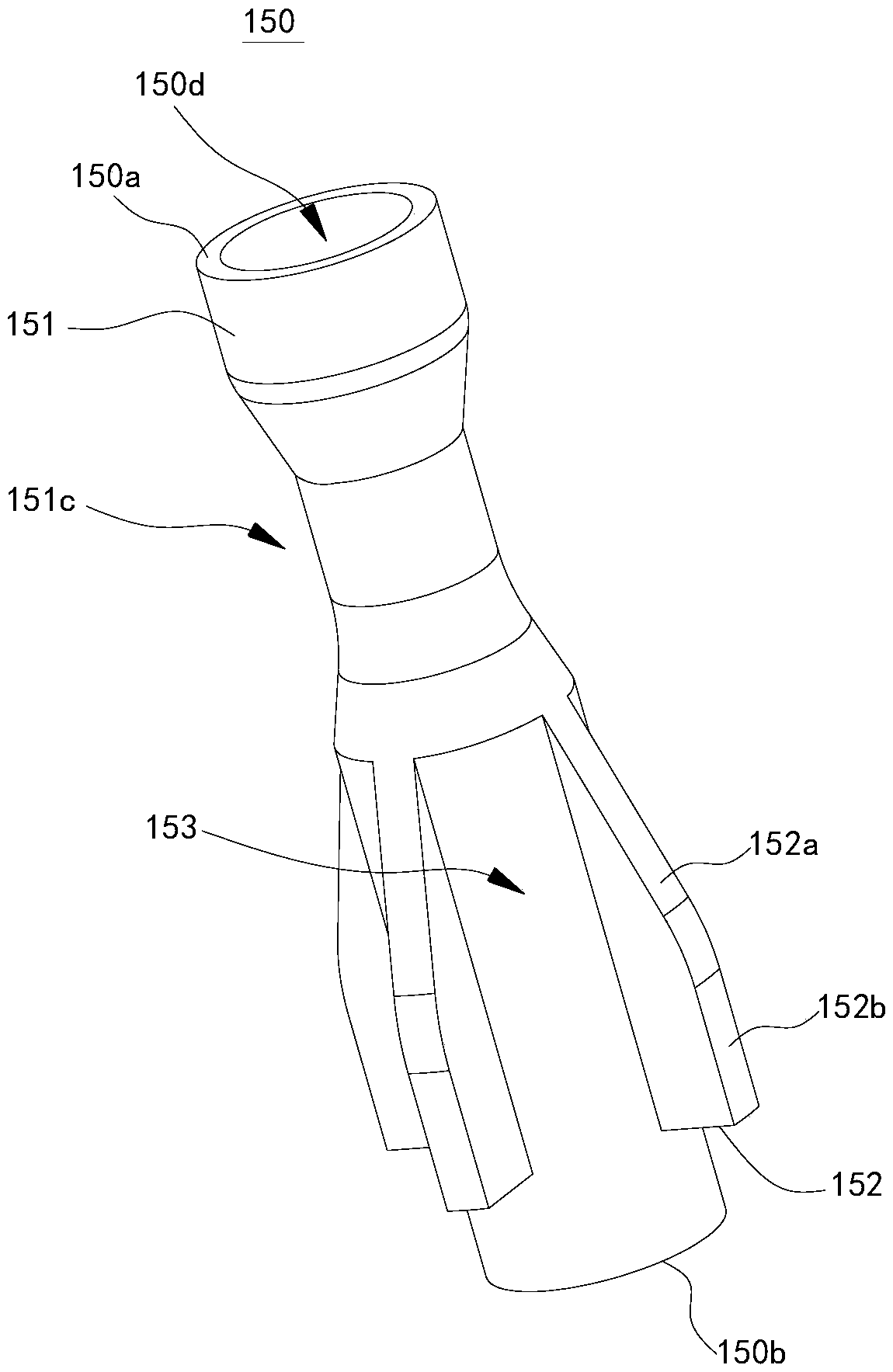

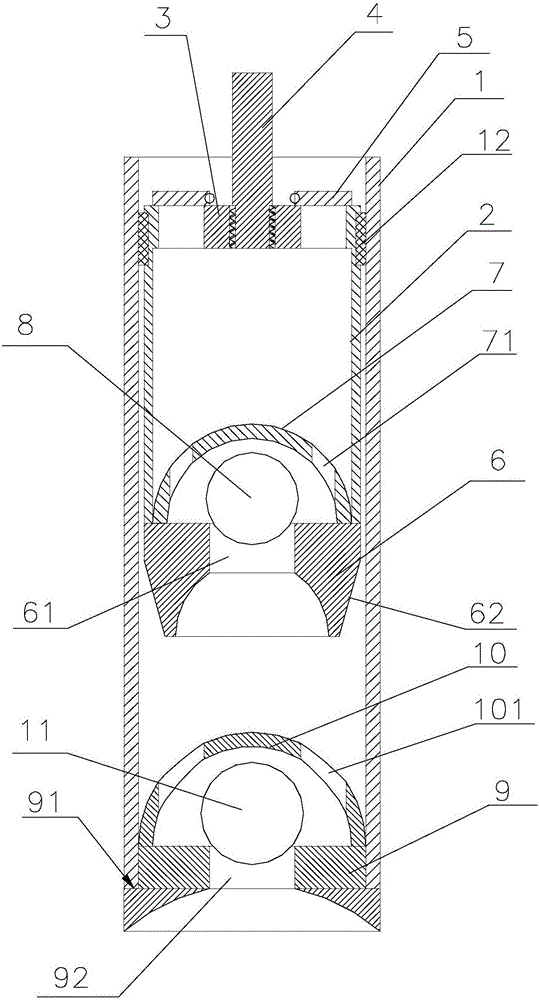

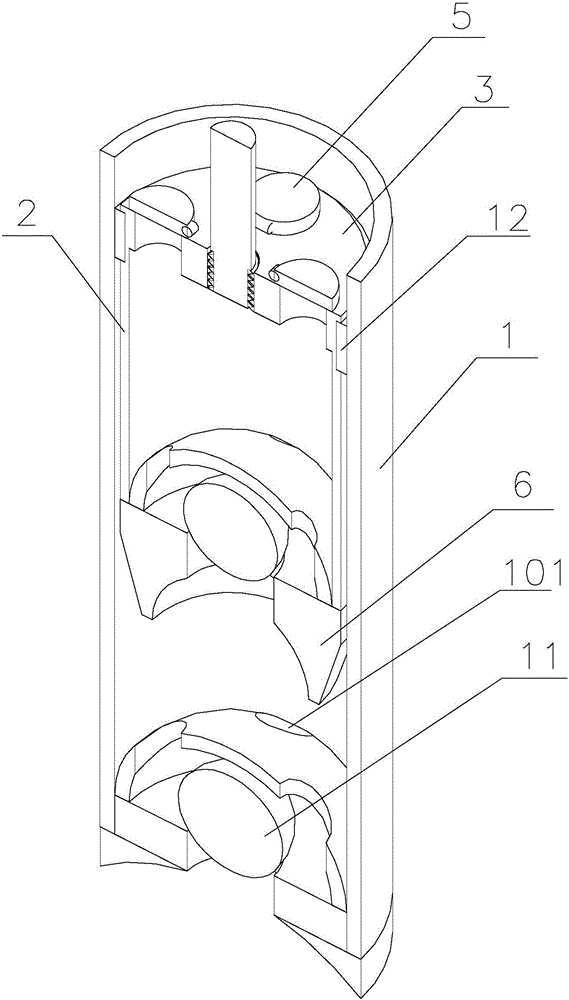

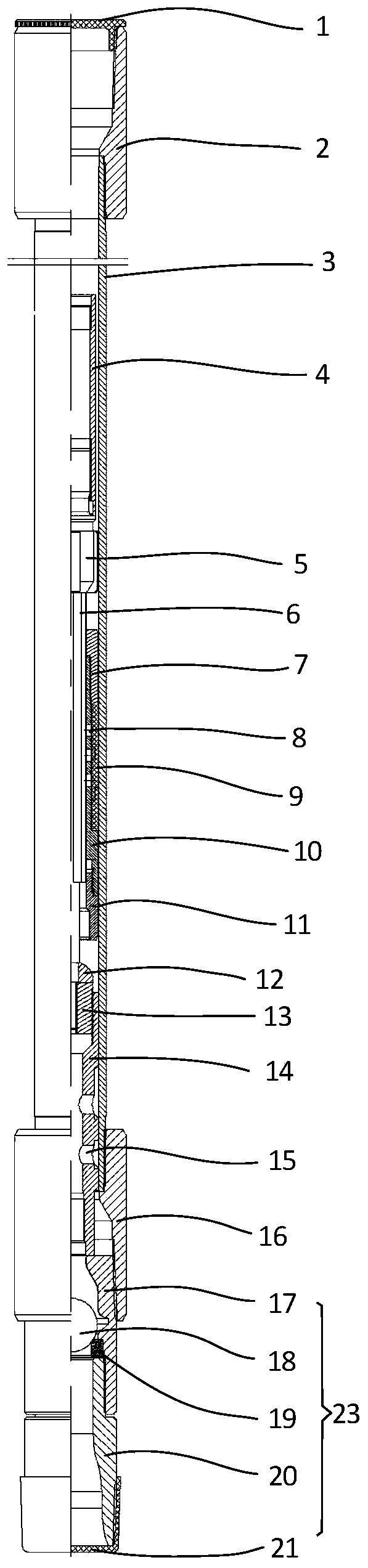

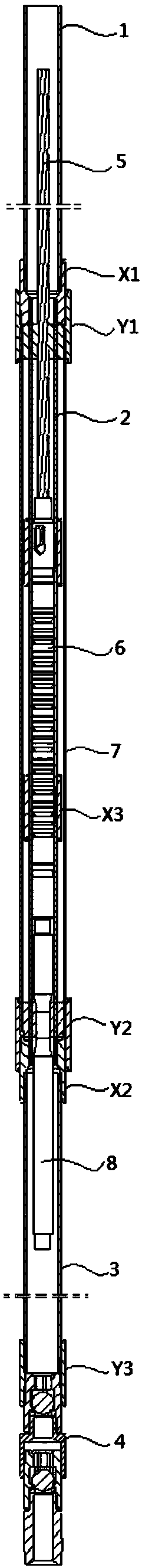

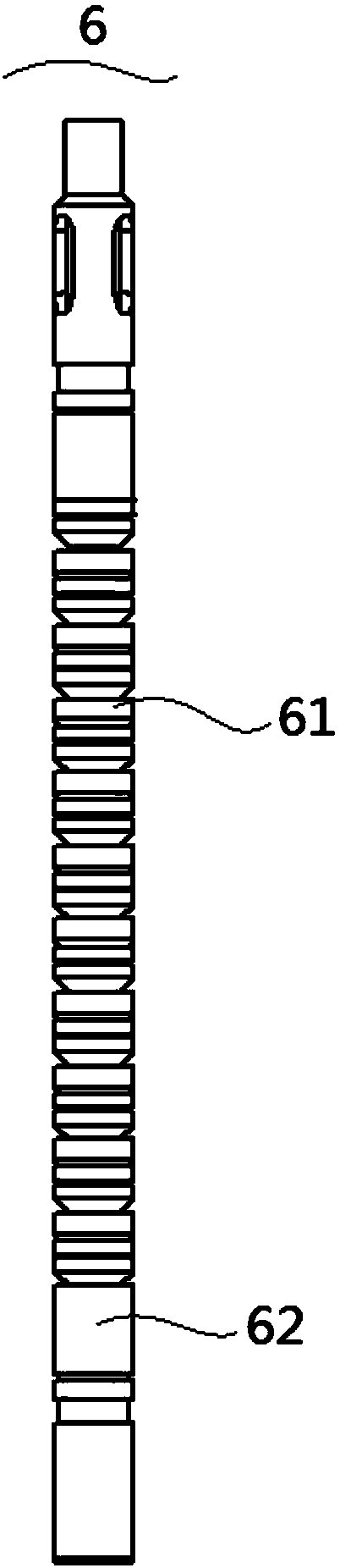

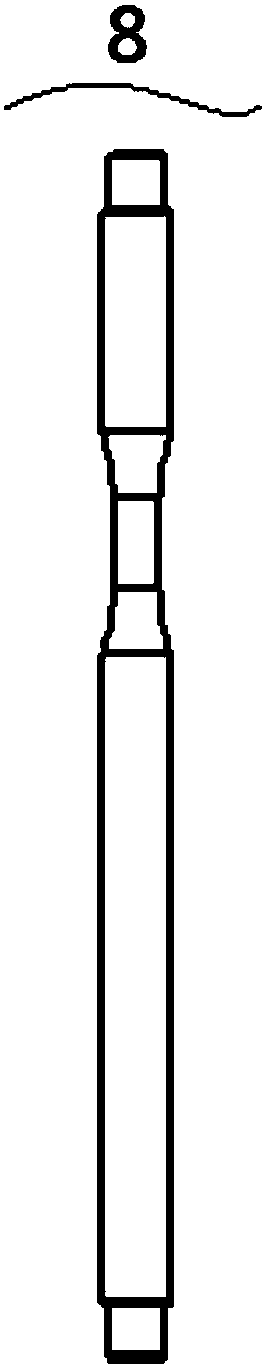

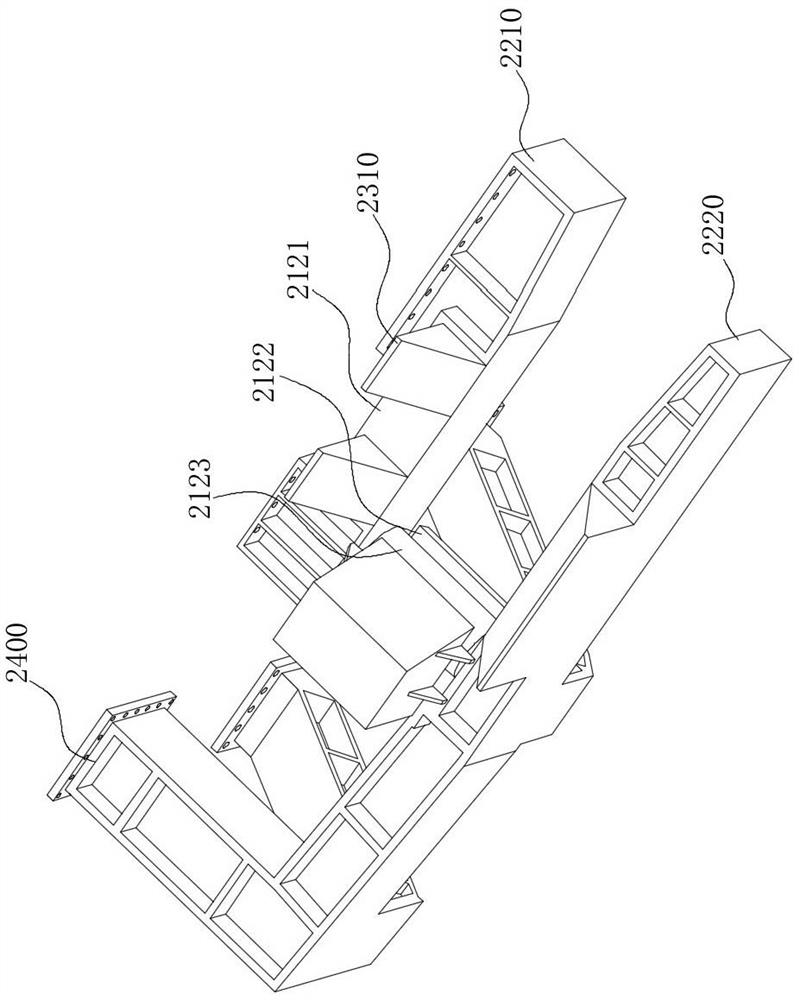

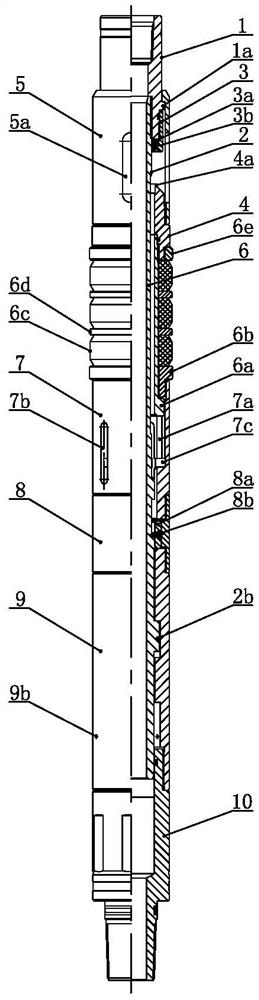

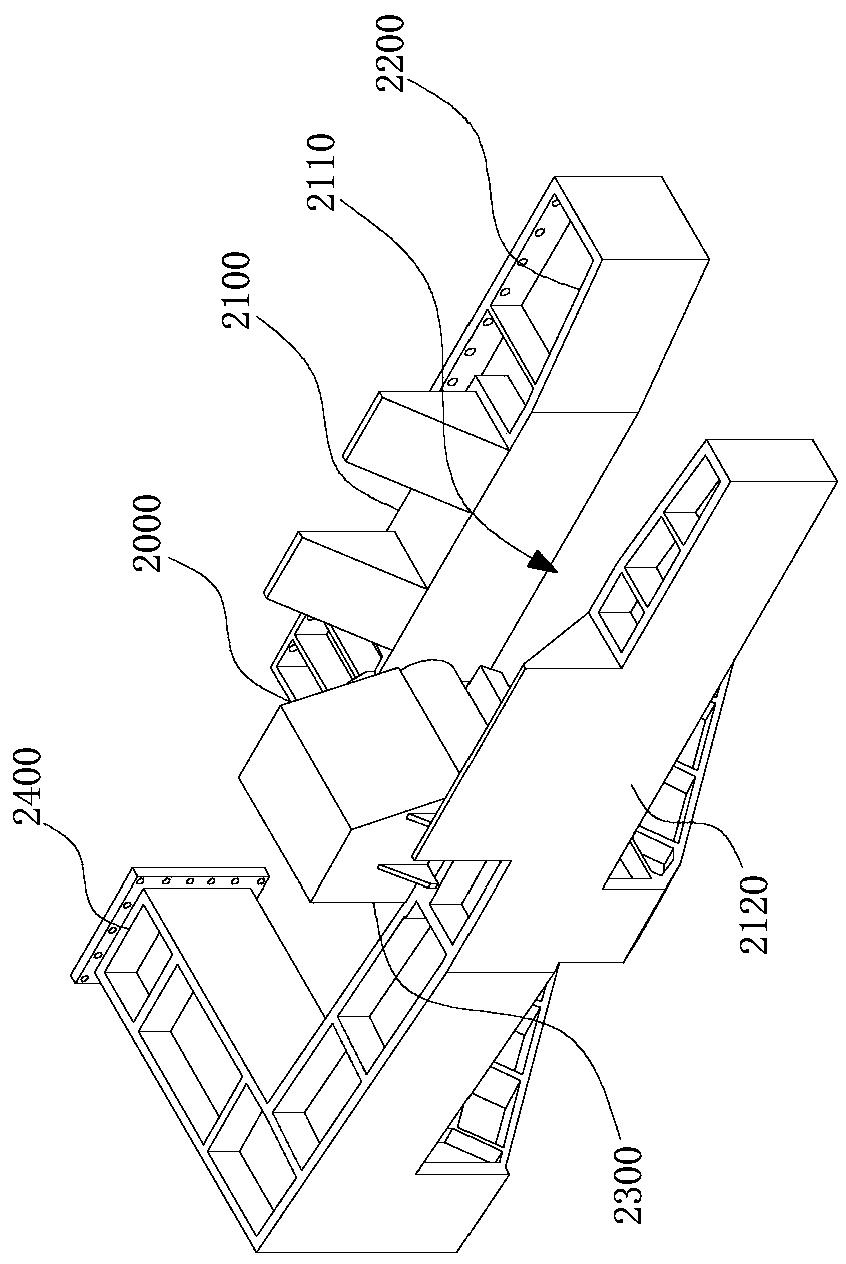

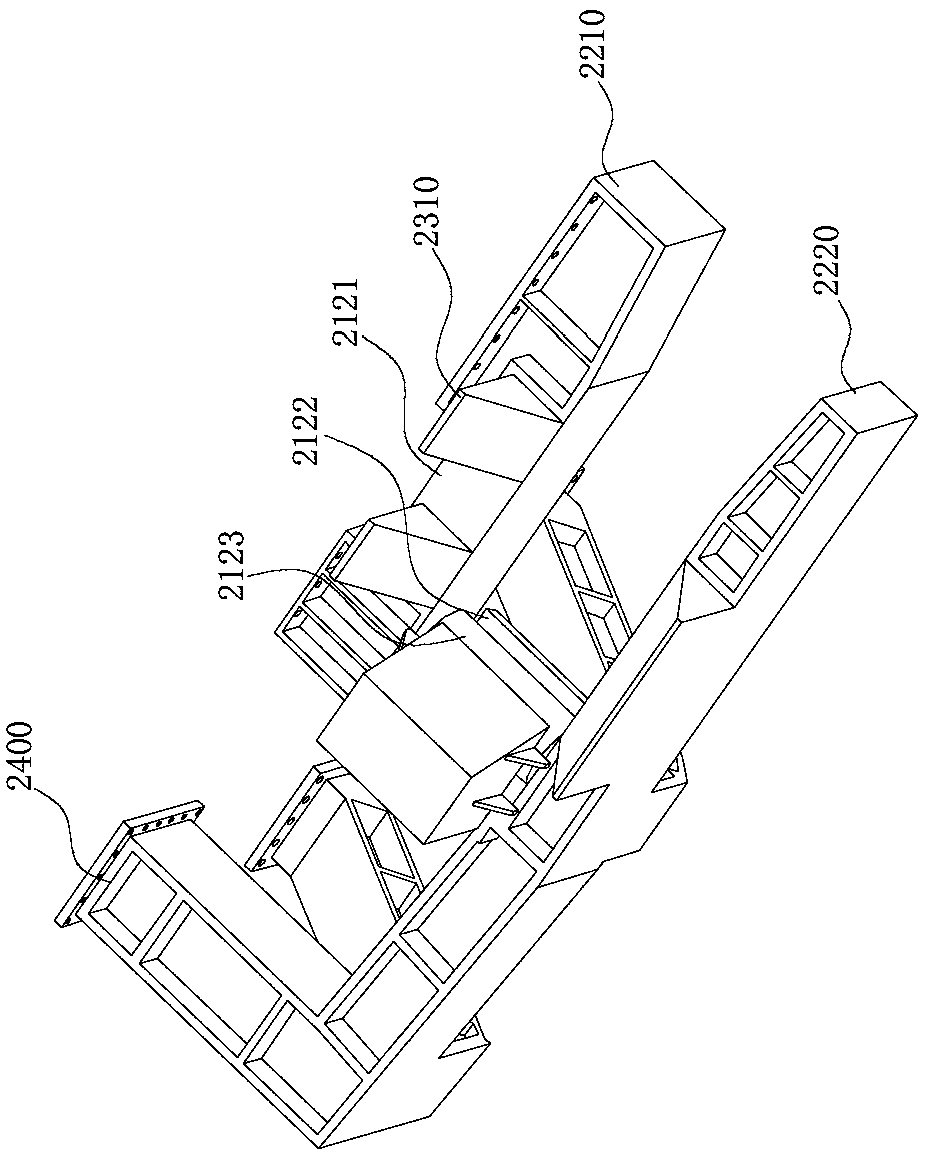

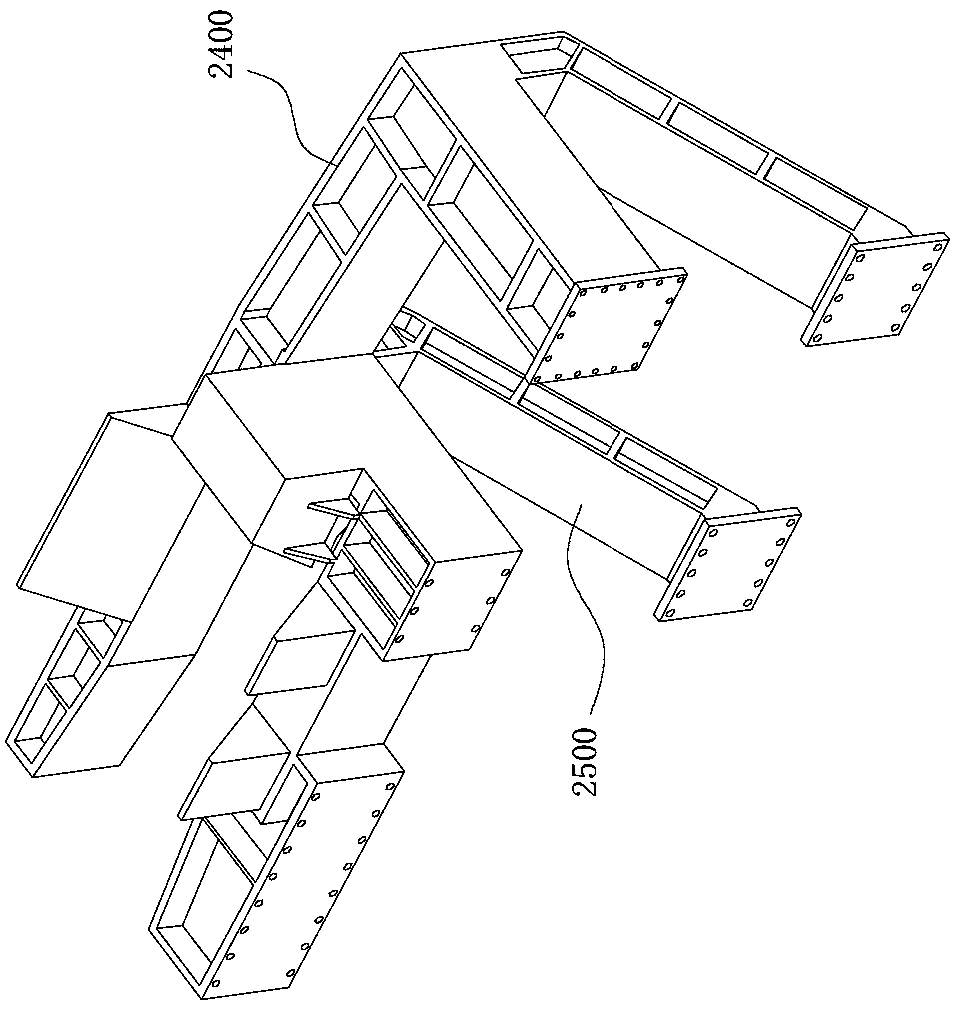

Position control part and plunger

PendingCN109630386AFast downlinkReduce downside resistancePositive displacement pump componentsFlexible member pumpsRadial positionPosition control

The invention relates to the technical field of natural gas and oil exploitation, and discloses a position control part and a plunger. When the plunger provided by the embodiment of the invention needs to move downwards, the position control part moves from the expanded position to the retracted position, so that the sealing spacers retract inwards to the position close to the inner position in radial direction, at this moment the maximum outer diameter of the plunger is smaller than the inner diameter of an oil-gas well shaft, friction between the packers and the inner wall of the well shaftis eliminated, a space for fluid to pass through is formed between the plunger and the inner wall of the well shaft, so that downward resistance of the plunger is greatly reduced. In addition, the position control part controls the radial positions of the sealing spacers through position control surfaces on fins, so that flow spaces allowing fluid to pass through can be formed between adjacent fins. When the plunger allows the fluid to pass through a core tube when moving downwards, flow area of the core tube can be increased due to the existence of the flow spaces, so that downward resistanceof the plunger is reduced to a greater extent, and the plunger can move downwards to the bottom of the well more rapidly.

Owner:成都百胜野牛科技有限公司

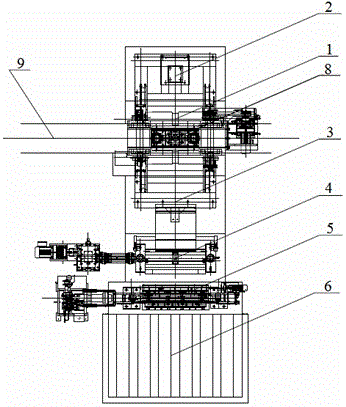

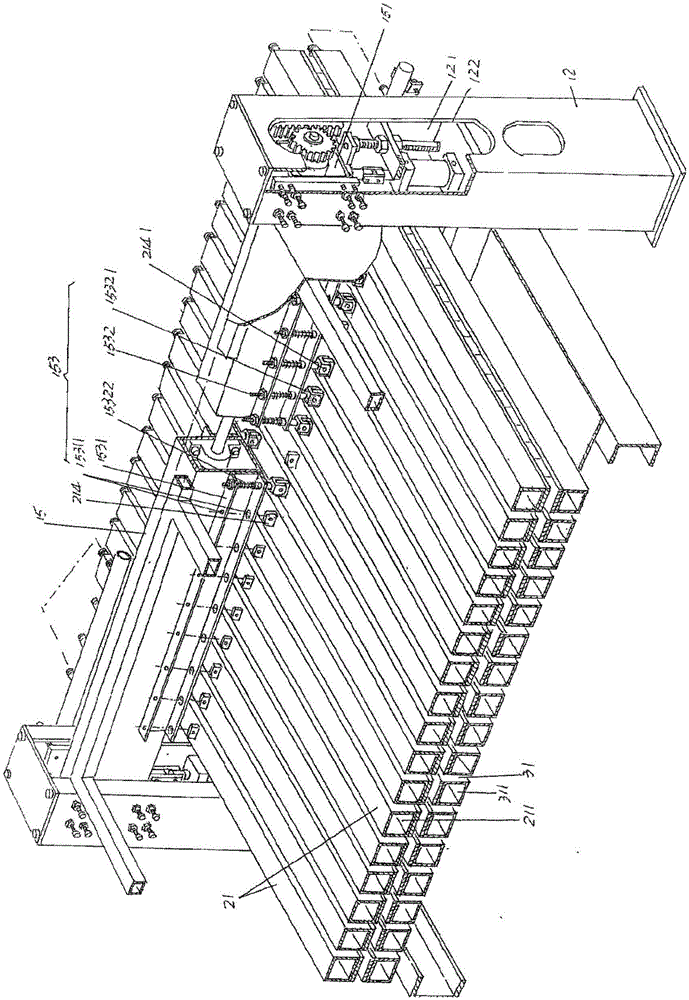

Strip head treatment device for skin pass unit and method of use thereof

The invention relates to a band steel heat treatment device for a temper mill. The device is arranged on an inlet side of a steel coil channel of the temper mill, and comprises a compression roller, a pair of carrier rollers, an uncoiler, a band steel molding device, a hydraulic shearing device and a waste box, which are sequentially arranged along the direction vertical to the steel coil channel, wherein the pair of carrier rollers is symmetrically arranged along the steel coil channel; the band steel molding device comprises a band steel pinch roll; the compression roller, the pair of carrier rollers and the band steel pinch roll all can rotate positively and reversely; and an up uncoiling manner is adopted as the steel coil uncoiling manner. The invention further relates to an application method of the band steel heat treatment device. The band steel heat treatment device is arranged on the inlet side of the steel coil channel of the temper mill, so that technological arrangement is simple; a channel does not need to be additionally formed; the civil engineering and equipment investment are effectively saved; the band steel heat treatment device is adjacent to the temper mill, so that a plurality of middle procedures are reduced; the operation of an operator is convenient; the labor amount of the operator is effectively reduced; the band steel heat treatment efficiency is relatively high; the transportation cost and the time cost are reduced; and the production benefits are improved.

Owner:WISDRI ENG & RES INC LTD

A drag-reducing and sand-preventing rod well pump

ActiveCN104847636BReduce downside resistanceAchieve sealingPositive displacement pump componentsFlexible member pumpsRubber ringEngineering

The invention relates to an anti-drag sand-proof rod oil well pump. The outer periphery of the upper portion of a plunger is provided with a groove matched with a rubber ring, sealing of a gap between the plunger and a pump barrel is realized, and the problem that sand is prone to getting into the gap between the plunger and the pump barrel to result in sand jamming when the pump stops operating in well shut-in period and the plunger is at upper or lower dead points is solved. Owing to the rubber ring structure, rigid contact between the plunger and the pump barrel is modified into flexible contact, and downgoing resistance of the plunger is reduced by increase of contact area and the gap between the plunger and the pump barrel. By the aid of an inverted frustum conical structure at a plunger discharge valve and an internal streamline flow passage, downgoing resistance of the plunger can be reduced to enable underground fluid to flow out of a pump cavity more easily. Owing to the streamline flow passage in the lower half portion of a suction valve, resistance of well fluid flowing through the suction valve can be reduced.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Oil well pump

InactiveCN111365217AGuaranteed uptimeReduce downside resistancePositive displacement pump componentsFlexible member pumpsEngineeringPumpjack

The invention discloses an oil well pump. The oil well pump includes a pump cylinder, a plunger assembly arranged in the pump cylinder, a central rod and a fixed valve assembly located below a travelling valve element, wherein the plunger assembly includes a plunger cylinder and an expansion sleeve sleeving outside the plunger cylinder, a radial through hole is formed in the cylinder wall of theplunger cylinder, the through hole is opposite to the expansion sleeve in the radial direction, a travelling valve seat is arranged at the lower end of the plunger cylinder, the plunger assembly sleeve the central rod, and a travelling valve element matched with the travelling valve seat is arranged at the lower end of the central rod; when the central rod drives the plunger assembly to move upwards, the travelling valve element is connected with the travelling valve seat, and the expansion sleeve is enlarged by the hydraulic pressure through the through hole to be fitted with the inner wall of the pump cylinder in a sealing mode; when the central rod drives the plunger assembly to move downwards, the travelling valve element is separated from the travelling valve seat, the expansion sleeve is reset to have an interval gap between the expansion sleeve and the pump cylinder.

Owner:PETROCHINA CO LTD

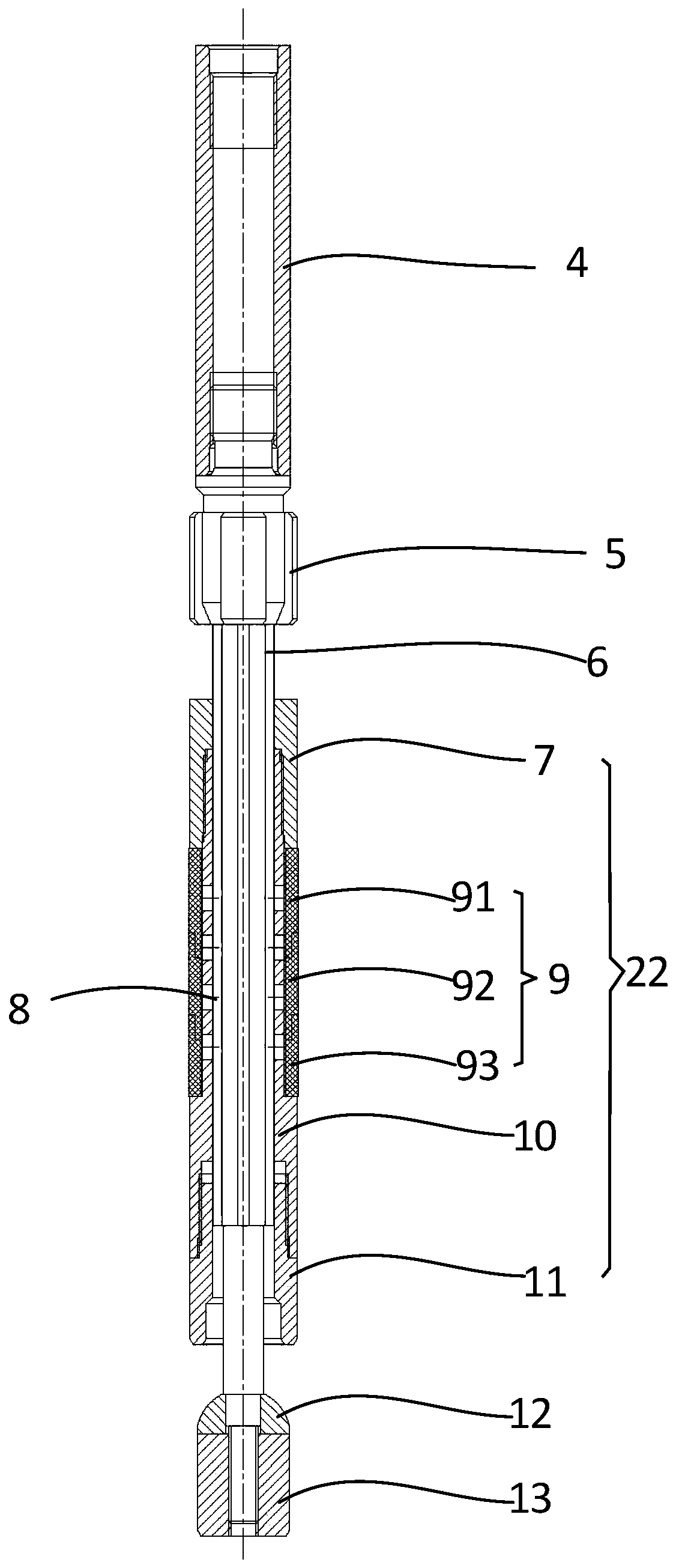

Oil-submersible cable butt joint device used in oil pipe and oil-submersible cable butt joint splitting method

PendingCN113690833AAvoid damageReduce manufacturing costCable junctionsApparatus for joining/termination cablesStructural engineeringElectric cables

The invention discloses an oil-submersible cable butt joint device used in an oil pipe and an oil-submersible cable butt joint splitting method. The oil-submersible cable butt joint device used in the oil pipe comprises a cable upper connector and a cable lower connector. The cable upper connector comprises a weight bar, a female connector, a snap ring lock sleeve, a snap ring, a female connecting cylinder, a female body, a packing ring and a power connection ring. Three packing rings and three power connection rings are arranged in the female head body, and the three packing rings and the three power connection rings are distributed alternately. The cable lower connector comprises a cable passing oil pipe nipple, a female head locking body, a lock hook, a male head assembly, conducting rings and a fixed base; the number of the conducting rings is three, and the three conducting rings are distributed at intervals in an insulating mode in the vertical direction. The cable upper connector is inserted into the female head locking body of the cable lower connector, so that the locking hook clamps the clamping ring, and the three power connection rings are in one-to-one correspondence contact with the three conductive rings. Damage to the cable is reduced, the operation cost is reduced, and the pump inspection operation efficiency is improved.

Owner:LIAONING HAIDISHENG MECHANICAL

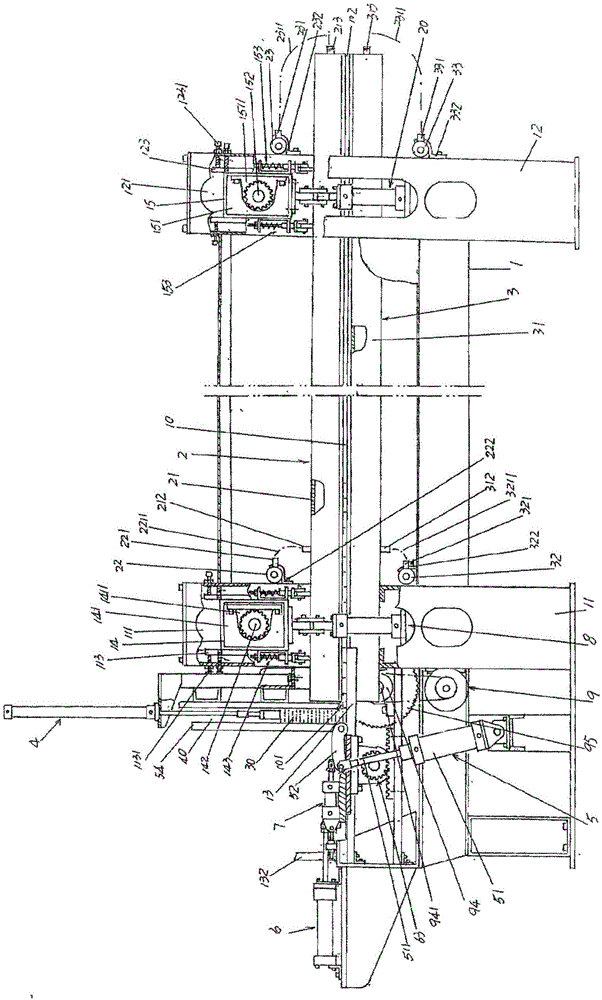

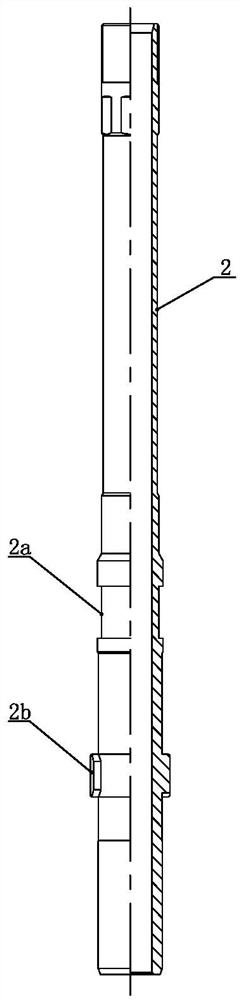

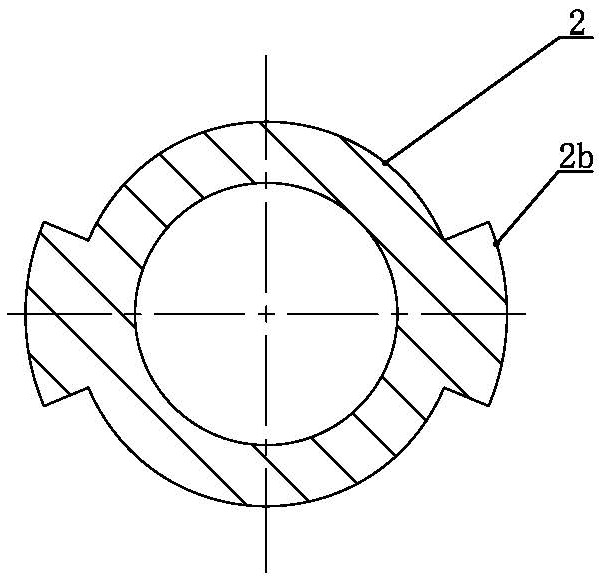

Matched technical pipe column for cable-type pumping unit

InactiveCN110206494AReduce downside resistanceReduce wearDrilling rodsFluid removalWellheadOil production

The invention discloses a matched technical pipe column for a cable-type pumping unit, and belongs to the technical field of oilfield oil production equipment. The matched technical pipe column comprises a first oil pipe, a plurality of oil-well pump cylinders, a second oil pipe, a valve, a steel wire rope and a plunger, wherein the first oil pipe, the oil-well pump cylinders, the second oil pipeand the valve are sequentially connected downwards from a wellhead, the steel wire rope penetrates through the first oil pipe to enter the oil-well pump cylinders, and the plunger is connected with the lower end of the steel wire rope; the plunger comprises a plurality of leather cups sequentially arranged from top to bottom, and lips of the leather cups are upward; when the plunger moves upwards,the edges of the lips of the leather cups can make close contact with the inner walls of the oil-well pump cylinders; and when the plunger moves downwards, gaps can be formed between the edges of thelips of the leather cups and the inner walls of the oil-well pump cylinders. The plunger in the pipe column adopts a soft-sealing plunger, the sealing effect can be ensured, the plunger can be further prevented from being abraded, and the service life of the plunger is prolonged.

Owner:PETROCHINA CO LTD

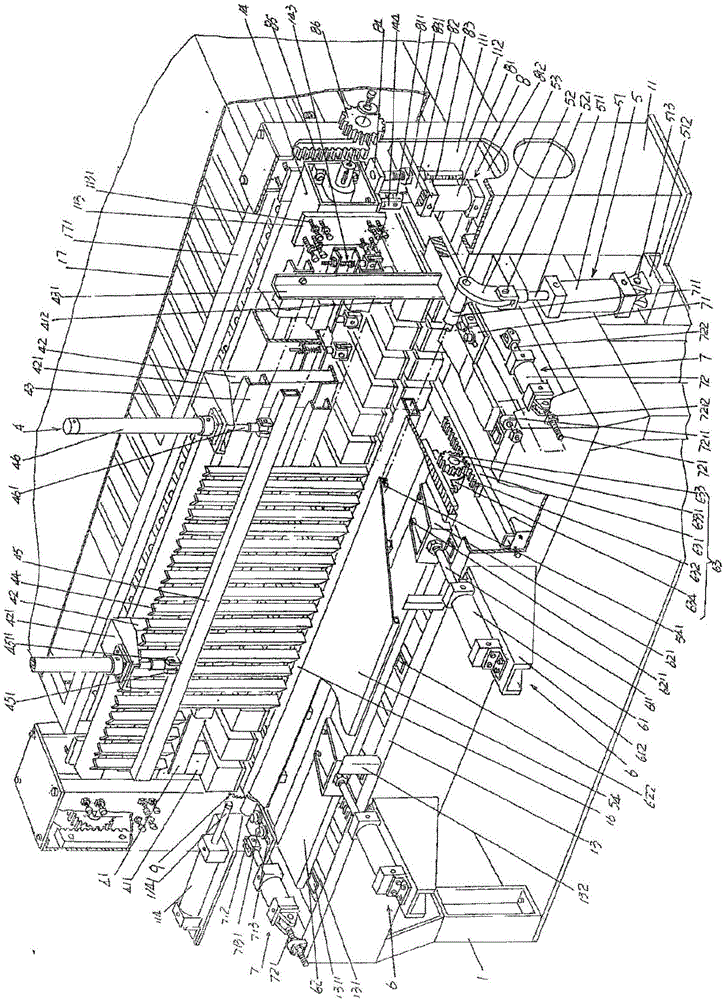

Automatic plate jointing machine with material pressing function

ActiveCN106272752AIncrease exerciseLow movement resistanceOther plywood/veneer working apparatusPlywood pressesWood processorWood machining

Owner:江西木之宝家具有限公司

Underground floater cleaning grass fisher

ActiveCN107700590AReduce downside resistanceAchieve cleaning effectGeneral water supply conservationDrinking water installationCircular discAnimal science

Owner:李宁

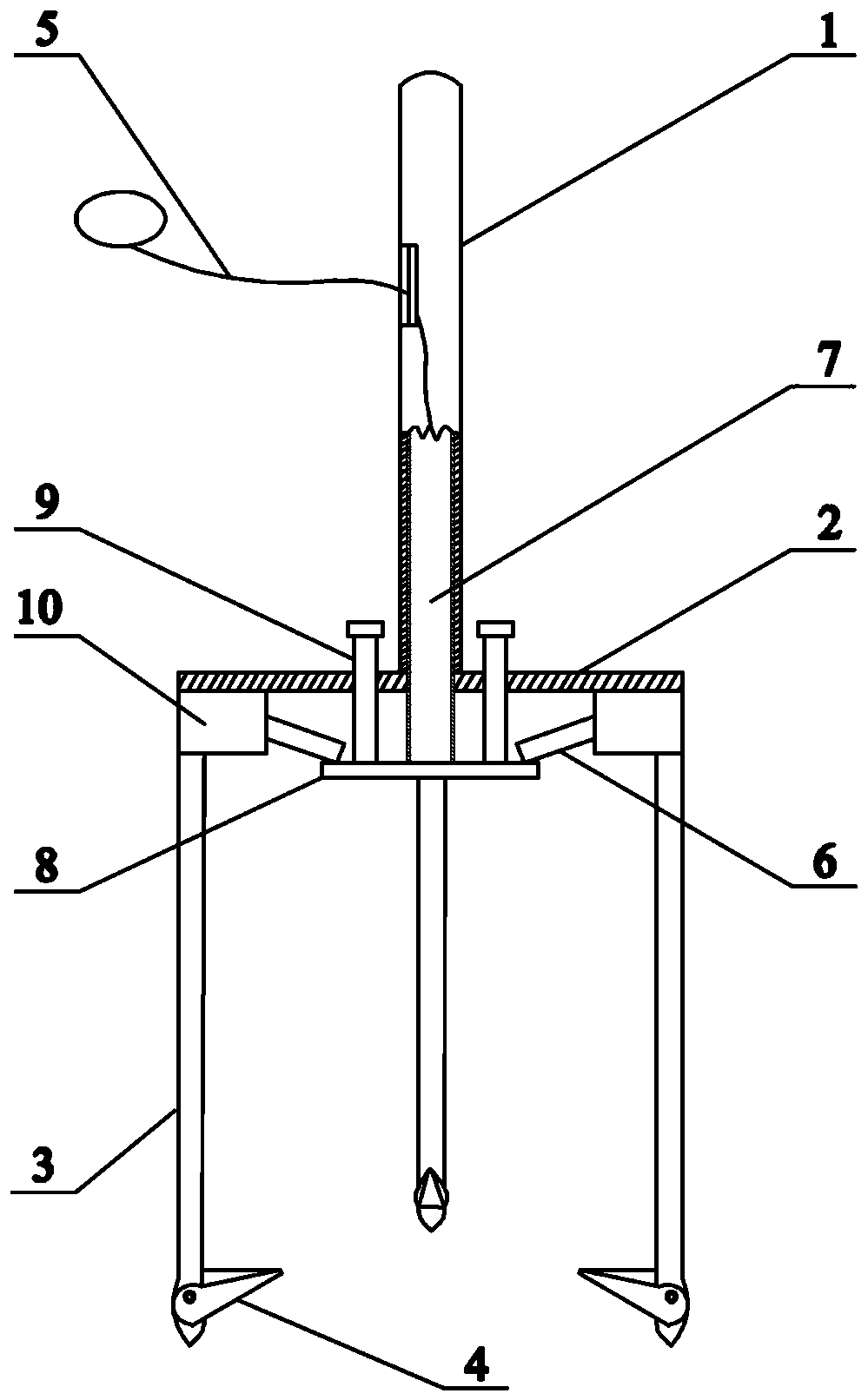

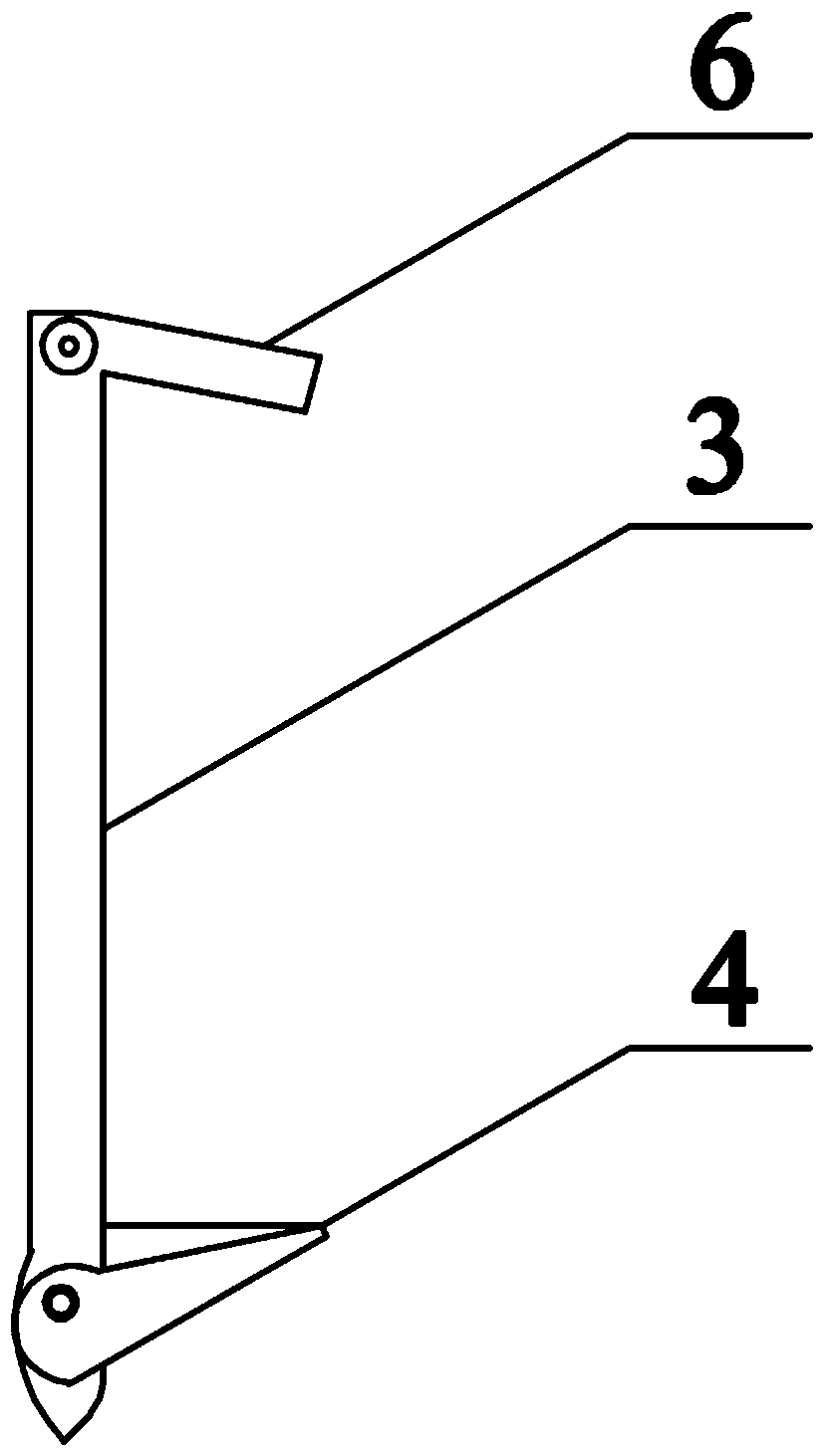

A guide device for a pile driver

ActiveCN110185038BSolve easy deviationSolve the problem of collapseBulkheads/pilesArchitectural engineeringStructural engineering

The invention relates to a guide device for a pile driver. The guide device is installed on the pile driver. The guide device is provided with a pile body press-in guide part and / or a pile body arrangement guide part. The pile body press-in guide part is used for During pile driving, the prefabricated pile body forms a sliding guide cooperation in the preset downward direction of the pile driver, so that the pile body of the prefabricated pile can be pressed into the ground along the preset downward direction of the pile driver, and the pile body is arranged and guided The part is used to form a limited fit with the previous precast pile along the preset arrangement track of each prefabricated pile, so that the precast pile body can be matched with each prefabricated pile according to the preset layout after being pressed into the ground. The arrangement trajectory of the present invention is arranged in a linear manner. The structure of the present invention is stable and the layout is reasonable. It realizes the function of guiding the prefabricated piles in the preset pressing direction, and can realize the linear arrangement of the prefabricated piles according to the preset arrangement trajectory. The function meets the requirements of use.

Owner:安徽恒坤建筑科技有限公司

Oil extraction method of weight adding under pump and oil well pump with weight adding under pump

InactiveCN101949277BReduce eccentric wearReduce mutual wearFlexible member pumpsFluid removalFill factorInlet valve

The invention discloses an oil extraction method of weight adding under a pump and an oil well pump with weight adding under the pump, used in pumping units and oil pumped wells in the petroleum industry. In the oil extraction method of weight adding under the pump, a weight adding bar is connected under an oil well pump plunger assembly to reduce the bend and the deformation of a pumping rod string. The oil well pump with weight adding under the pump comprises a pump cylinder assembly, the plunger assembly and an auxiliary mechanism under the pump. The plunger assembly is provided with a liquid outlet valve and a liquid inlet pump, an upper plunger and a lower plunger are connected with a connection bar through a plunger lower joint to connect the weight adding bar under the plunger assembly. The method uses the liquid inlet valve with an offset structure outside the pump while adding weight under the pump, thereby lightening the eccentric wear of pipes and bars and reducing the stroke loss. Due to the weight adding bar arranged under the pump, the pumping rod is kept in the straightening state all the time under the action of gravity, thereby lightening the mutual abrasion of the pipes and the bars. The weight adding under the pump can reduce the elastic bending and deformation of the pumping bar string, thereby reducing the stroke loss and enhancing the filling factor of the oil well pump.

Owner:CHINA PETROLEUM & CHEM CORP +1

Formation test packer and method for formation test using same

ActiveCN111911110BPrevent pre-settingEasy to walkWell/borehole valve arrangementsSealing/packingUpper jointEngineering

The invention relates to a packer for formation testing and a method for using the same for formation testing. The packer includes an upper joint, the upper end of the upper joint is provided with a tapered female thread, and the inner thread at the lower end of the upper joint is screwed with a downward Extended core tube, the lower end of the core tube is plugged into the upper port of the lower joint and sealed by an O-ring, the lower end of the lower joint is provided with a tapered male thread; the outer circumference of the core tube and the lower part of the upper joint are provided with a communication seal The bypass mechanism for the upper and lower liquid flow of the spacer, the setting mechanism is arranged under the bypass mechanism, the shear pin mechanism is arranged under the setting mechanism, and the transposition mechanism for controlling bypass and setting is arranged under the shear pin mechanism. When going downhole, the bypass is opened to connect the upper and lower annulus; when in place, the core pipe is rotated, the bypass is closed and set, the formation fluid enters the pipe string, and then the bypass is opened and unsealed, and the pipe string is lifted. The invention ensures that the straddling packer will not be set in advance during the drilling process, thereby effectively protecting the packer rubber cylinder and effectively improving the success rate of the straddling test.

Owner:CHINA PETROLEUM & CHEM CORP +1

A tube type thickening pump

ActiveCN107781130BNot easy to pile upReduce leakagePositive displacement pump componentsFlexible member pumpsEngineeringPressure feedback

The invention discloses a tubular viscous oil pump, and belongs to the field of oil pumps. The tubular viscous oil pump comprises a pump cylinder module assembly, and a plunger module assembly positioned in a pump cylinder module; the pump cylinder module assembly comprises an upper pump cylinder, and a lower pump cylinder connected with the upper pump cylinder; and the plunger module assembly comprises an upper plunger, a liquid draining valve, a liquid feeding and draining short section, a liquid feeding valve and a lower plunger serially connected in sequence. The tubular viscous oil pump is characterized in that the inner diameter of the upper pump cylinder is smaller than the inner diameter of the lower pump cylinder; the length of the upper pump cylinder is smaller than the length ofthe lower pump cylinder; the outer diameter of the upper plunger is smaller than the outer diameter of the lower plunger; the length of the upper plunger is smaller than the length of the lower plunger; and through vacuum negative-pressure feedback force formed by the pump cavity, the pressure to the plungers by rod posts is burdened, the descending resistance is reduced, and the bending and theeccentric wear of the rod posts are prevented.

Owner:PETROCHINA CO LTD

Screw-in sampler and sampling device

ActiveCN102564803BReduce downside resistanceReduced Power RequirementsWithdrawing sample devicesFailure rateSpiral blade

Owner:长沙通发高新技术开发有限公司

Guide device for pile driver

ActiveCN110185038ASolve easy deviationSolve the problem of collapseBulkheads/pilesEngineeringStructural engineering

The invention relates to a guide device for a pile driver. The guide device is arranged on the pile driver and provided with a pile body press-in guide part and / or a pile body distribution guide part,wherein the pile body press-in guide part is used for forming sliding guide fit with a pile body of a prefabricated pile in the preset press-down direction of the pile driver during piling so that the pile body of the prefabricated pile can be pressed underground in the preset press-down direction of the pile driver, and the pile body distribution guide part is used for forming limiting fit withthe previously driven prefabricated pile along the preset distribution track of the prefabricated piles so that after the pile body of the prefabricated pile is pressed underground, the pile body of the prefabricated pile and the driven prefabricated piles can be distributed sequentially along the preset distribution track. The guide device is stable in structure and reasonable in layout, can guide the prefabricated piles in the preset press-down direction, and can be used for sequentially distributing the prefabricated piles according to the preset distribution track, so that the use requirements are met.

Owner:安徽恒坤建筑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com