Guide device for pile driver

A technology of guide and guard device and pile driver, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., and can solve problems such as inconsistency, omission, and large difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

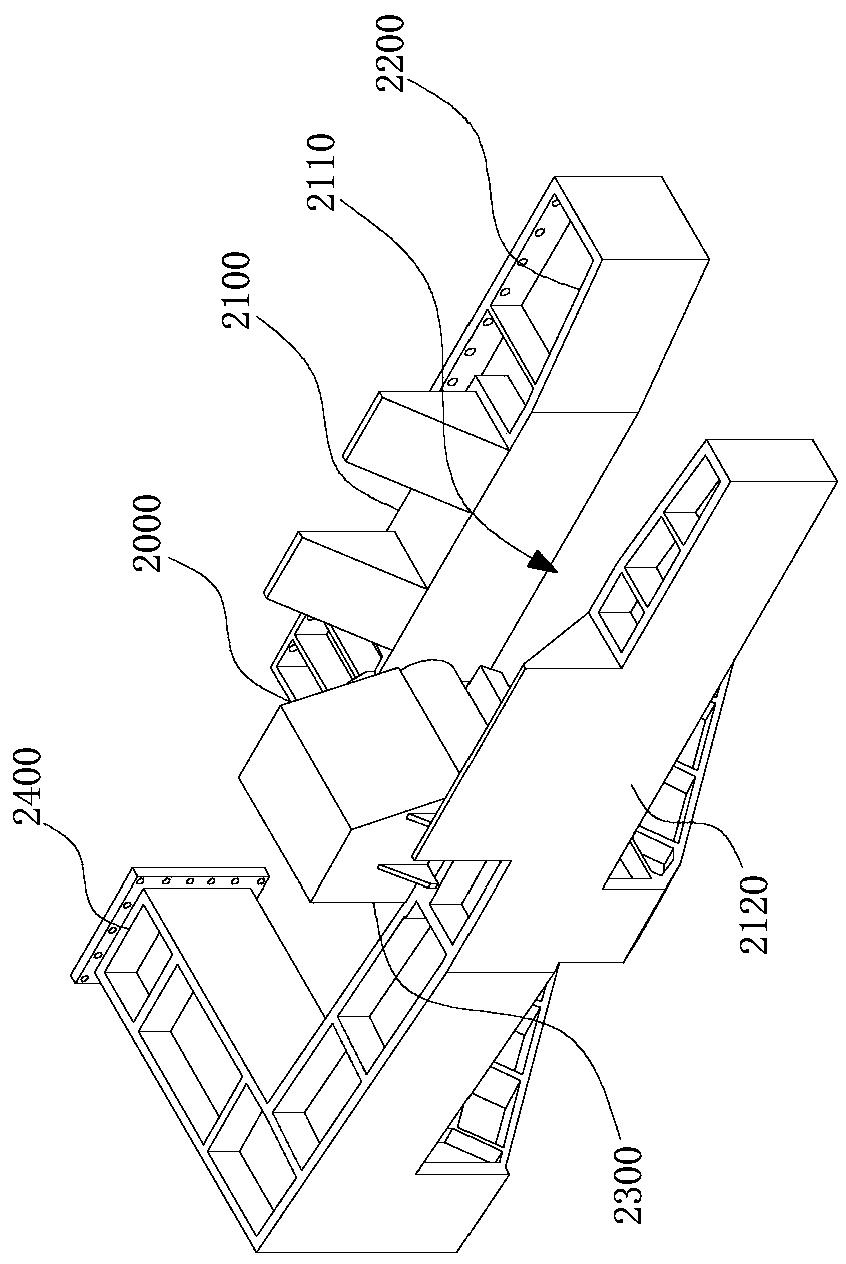

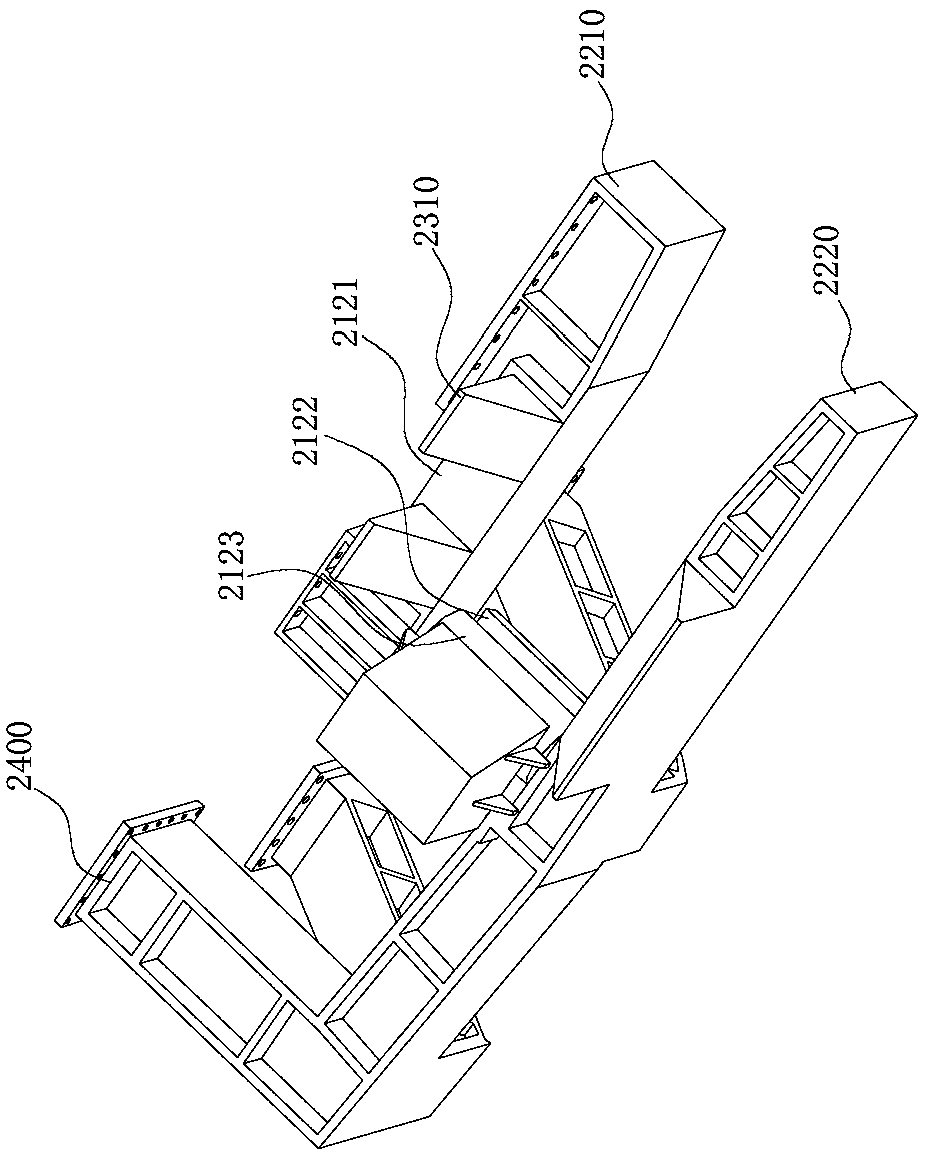

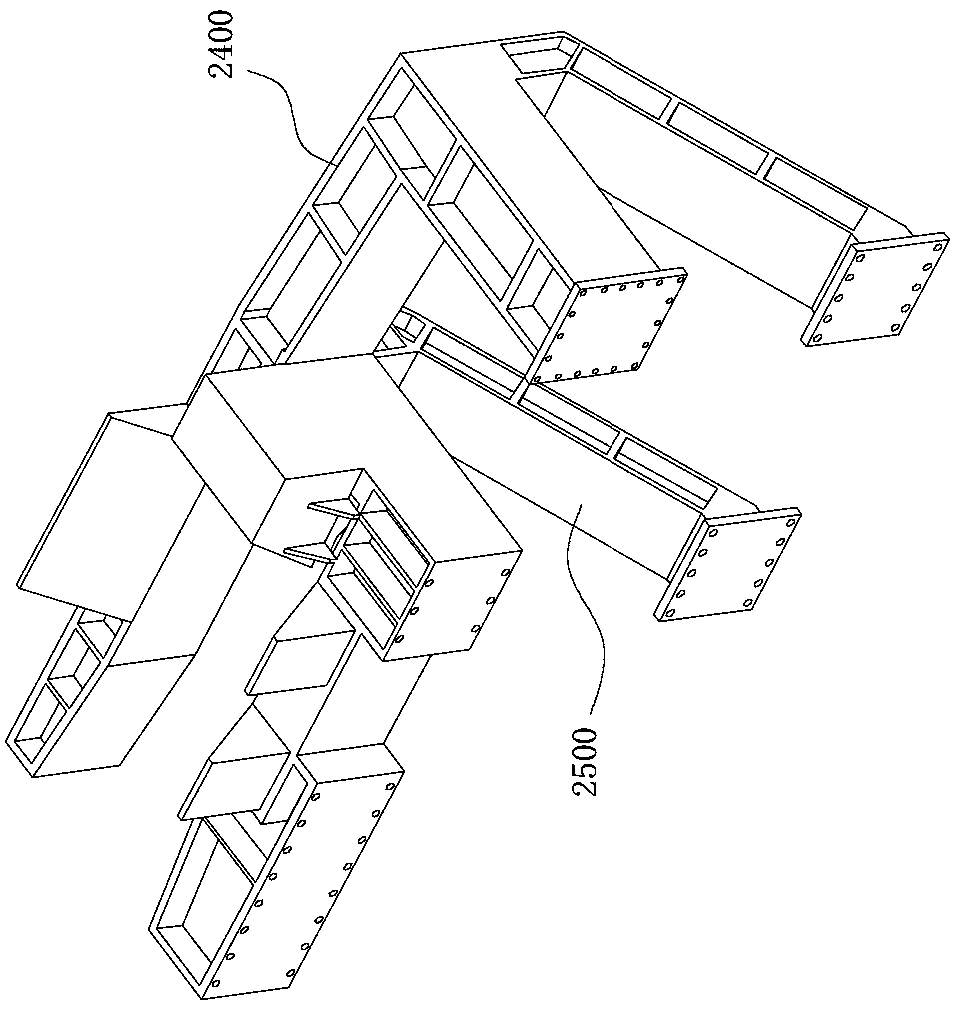

[0038] refer to Figure 1-5In the implementation of the present invention, a guide device for pile drivers is proposed. The guide device 2000 is installed on the pile driver 1000, and the guide device 2000 is provided with a pile body pressing guide part 2100 and / or a pile body arrangement guide Part 2200, the pile body press-in guide part 2100 is used to form sliding guide cooperation with the pile body of the prefabricated pile 3000 in the pressing direction preset by the pile driver 1000 during pile driving, so that the pile body of the prefabricated pile 3000 can move along the direction of the pile driver 1000 The preset downward pressure direction is pressed into the ground, and the pile arrangement guide part 2200 is used to form a limited fit with the previous precast pile 3000 along the preset arrangement track of each prefabricated pile 3000, so that the prefabricated pile After the 3000 pile bodies are pressed into the ground, they can be arranged in a sequential ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com