Bus bar, printed circuit board (PCB) and surface mounting method of bus bar

A PCB circuit board and PCB board technology, which is applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, root rods/rods/wires/strip conductors, etc., can solve the problem of unsatisfactory effects and increased Problems such as tooling cost and affecting the heat conduction effect of bus bars can prevent poor contact from affecting heat conduction and improve life and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

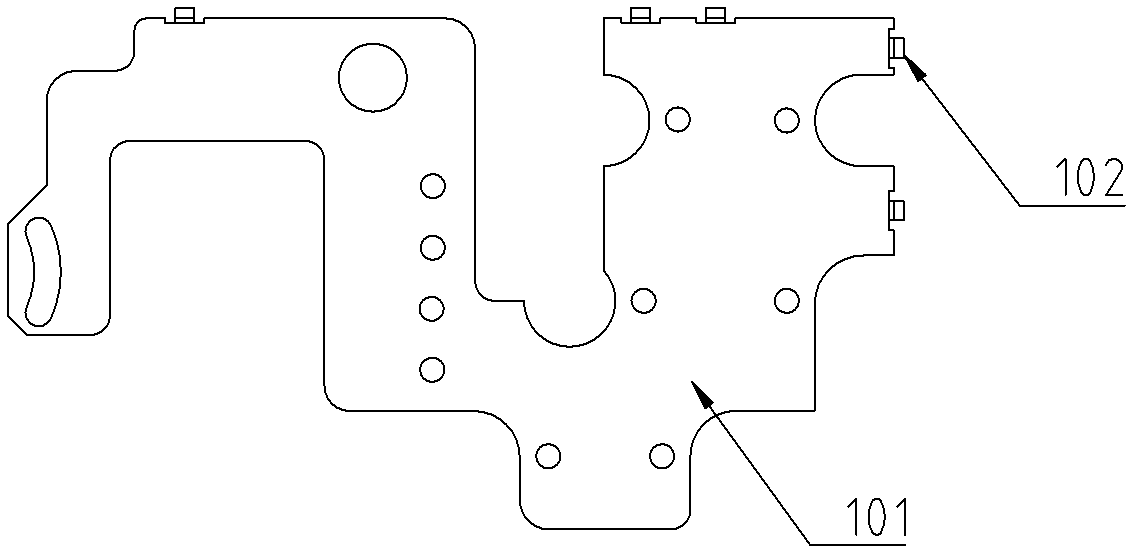

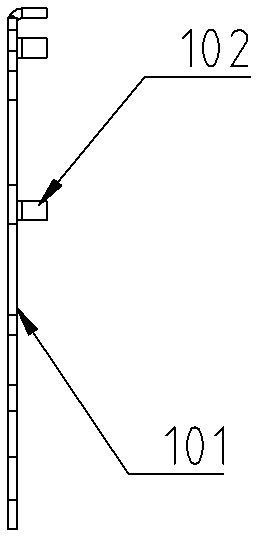

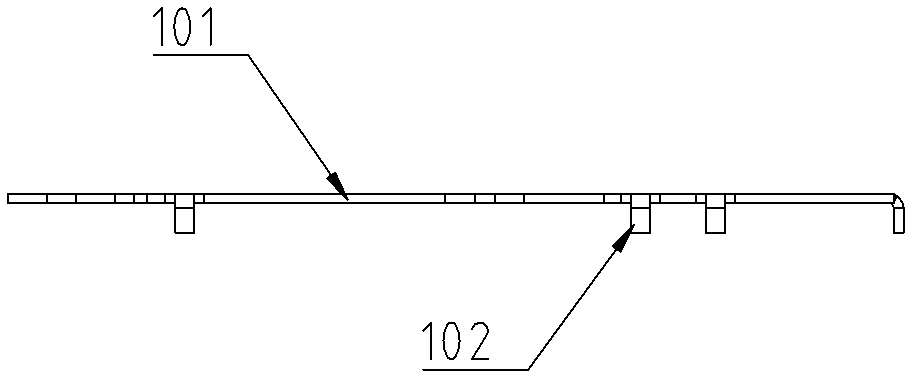

[0035] The structure of the bus bar in Embodiment 1 of the present invention is as follows Figure 1 to Figure 4 As shown, it includes a board body 101 and five positioning feet 102 . The five positioning feet 102 are located on the edge of the board body 101 , formed by extending and bending the edge of the board body 101 , and the five positioning feet 102 are perpendicular to the board body 101 .

[0036] The structure of the bus bar in embodiment 2 of the present invention is as follows Figure 5 to Figure 7 As shown, the three positioning pins 102 are positioning pins, and the plate body 101 is provided with the same number of pin holes as the positioning pins 102, and the positioning pins 102 are fixed in the pin holes through interference, and the three positioning pins 102 are perpendicular to the plate body 101.

[0037] The structure of the PCB circuit board of embodiment 3 of the present invention is as Figure 5 to Figure 7 As shown, including the bus bar 1 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com