External closed cylinder viscous shear damper for stay cables

An external, stay-cable technology, applied in shock absorbers, shock absorbers, liquid shock absorbers, etc., can solve the problem of affecting the performance and service life of the damper, reducing the out-of-plane vibration damping effect of the damper, and the deviation of the damper. Central location and other issues, to achieve the effect of strong applicability to the external environment, low manufacturing and maintenance costs, and avoiding stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

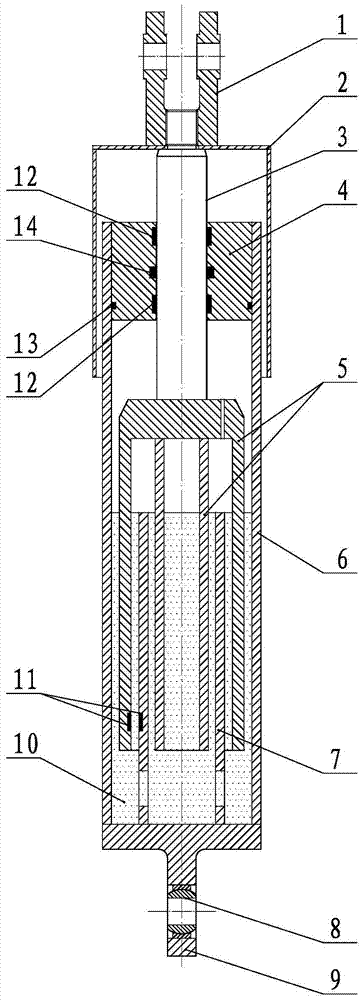

[0027] Such as figure 1 As shown, the present invention mainly includes an inner insertion tube 5 and an outer damping cylinder 6, the inner lower part of the outer damping cylinder 6 is provided with an inner damping cylinder 7, and an inner insertion tube capable of moving up and down is provided between the outer damping cylinder 6 and the inner damping cylinder 7. 5. The outer damping cylinder 6 is filled with damping fluid 10, and the damping fluid 10 is filled in the gap between the outer damping cylinder 6, the inner damping cylinder 7 and the inner insertion tube 5. The damping fluid 10 is a polymer damping fluid.

[0028] The inner cannula 5 can adopt a single-tube structure or a multi-tube structure as required.

[0029] The upper end of the outer damping cylinder 6 is sealingly connected to the guide cover 4, the upper end of the inner tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com