Clamping device for processing roller

A clamping device and plate roller technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high technical requirements for employees and inconvenient adjustment, and achieve the effect of convenient loading and unloading of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

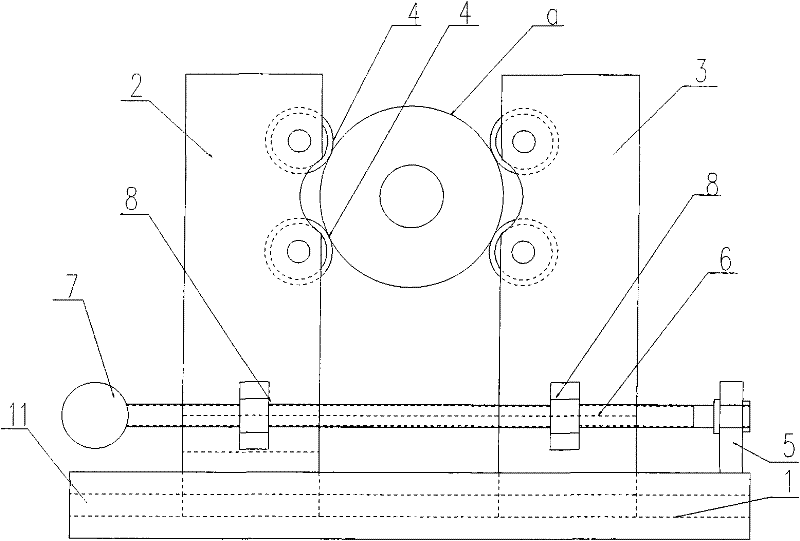

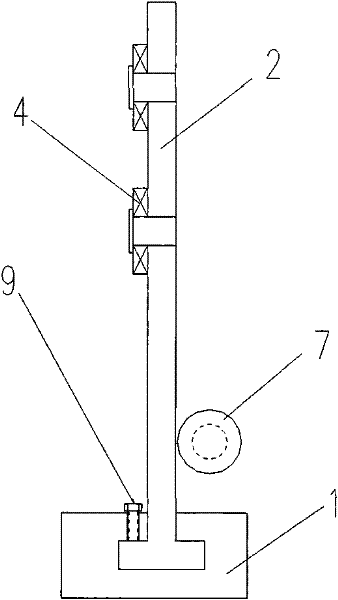

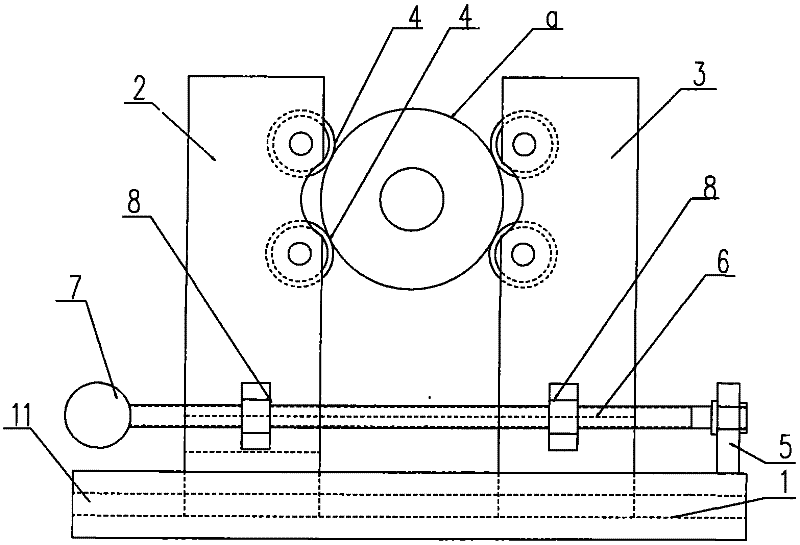

[0018] see figure 1 , figure 2 , the present invention is used for the clamping device of plate roll processing, comprises base 1, left moving vertical board 2, right moving vertical board 3, four rollers 4, by bracket 5, screw mandrel 6, hand wheel 7 and two nuts 8 Composed screw drive mechanism and two locking screws 9.

[0019] A chute 11 extending left and right is provided in the base 1 .

[0020] The left mobile vertical plate 2 and the right mobile vertical plate 3 are respectively installed on the left and right sides of the base and can move left and right along the chute 11.

[0021] Four rollers 4 are symmetrically installed on the opposite sides of the left mobile vertical plate 2 and the right mobile vertical plate 3, and the center formed by the four rollers is consistent with the center of the lathe. Four rollers among the present invention adopt the same size bearing.

[0022] The bracket 5 is fixed on the right end of the base 1.

[0023] Two nuts 8 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com