Fluid separating device, shaft structure and method for producing petroleum or natural gas

一种分隔装置、流体的技术,应用在开采流体、土方钻采、密封/封隔等方向,能够解决流体分隔装置无法下行回到井底、下行速度缓慢等问题,达到提高使用寿命、降低下行阻力、连续生产的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

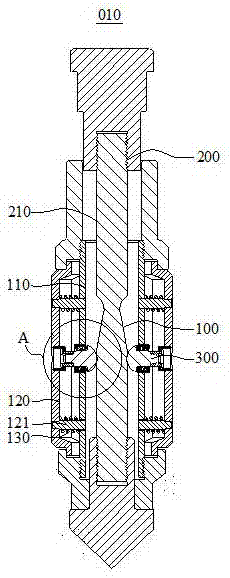

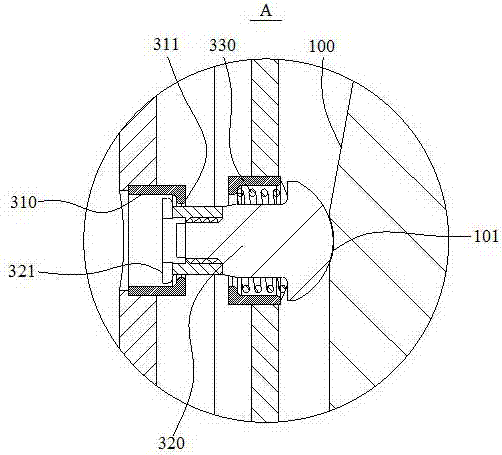

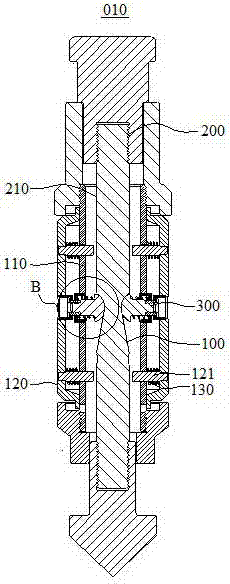

[0058] Please refer to Figure 1-Figure 4 . figure 1 A schematic structural diagram of the fluid separation device 010 in an expanded state provided for this embodiment. figure 2 for figure 1 Enlarged view of A. image 3 A schematic structural diagram of the fluid separation device 010 in a contracted state provided for this embodiment. Figure 4 for image 3 Enlarged view of B.

[0059] In this embodiment, the fluid separation device 010 includes a cylinder 110 , a partition 120 , a first elastic member 130 , a first guiding device 200 and a second guiding device 300 . A plurality of partitions 120 are arranged around the barrel 110 . The first elastic member 130 is disposed between the separator 120 and the cylinder body 110 , and the first elastic member 130 exerts a radially outward elastic force on the separator 120 so that the first separator 120 can radially rotate relative to the cylinder body 110 . outside sports. The first guide device 200 is axially threade...

Embodiment 2

[0068] Please refer to Figure 7-Figure 10 . Figure 7 A schematic structural diagram of the fluid separation device 010 in an expanded state provided for this embodiment. Figure 8 for Figure 7 Enlarged view of C. Figure 9 A schematic structural diagram of the fluid separation device 010 in a contracted state provided for this embodiment. Figure 10 for Figure 9 Enlarged view of D.

[0069] In this embodiment, the fluid separation device 010 includes a cylinder 110 , a partition 120 , a first elastic member 130 , a first guiding device 200 and a second guiding device 300 . A plurality of partitions 120 are arranged around the barrel 110 . The first elastic member 130 is disposed between the separator 120 and the cylinder body 110 , and the first elastic member 130 exerts a radially outward elastic force on the separator 120 so that the first separator 120 can radially rotate relative to the cylinder body 110 . outside sports. The first guide device 200 is axially t...

Embodiment 3

[0077] Please refer to Figure 13-Figure 16 . Figure 13 A schematic structural diagram of the fluid separation device 010 in an expanded state provided for this embodiment. Figure 14 for Figure 13 Enlarged view of E. Figure 15 A schematic structural diagram of the fluid separation device 010 in a contracted state provided for this embodiment. Figure 16 for Figure 15 Enlarged view of F.

[0078] In this embodiment, the fluid separation device 010 includes a cylinder 110 , a partition 120 , a first elastic member 130 , a first guiding device 200 and a second guiding device 300 . A plurality of partitions 120 are arranged around the barrel 110 . The first elastic member 130 is disposed between the separator 120 and the cylinder body 110 , and the first elastic member 130 exerts a radially outward elastic force on the separator 120 so that the first separator 120 can radially rotate relative to the cylinder body 110 . outside sports. The first guide device 200 is axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com