Oil-submersible cable butt joint device used in oil pipe and oil-submersible cable butt joint splitting method

A technology of submersible cable and docking device, applied in cable installation device, cable joint, cable installation and other directions, can solve problems such as damage, reduce production costs, reduce operating costs, and improve pump inspection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

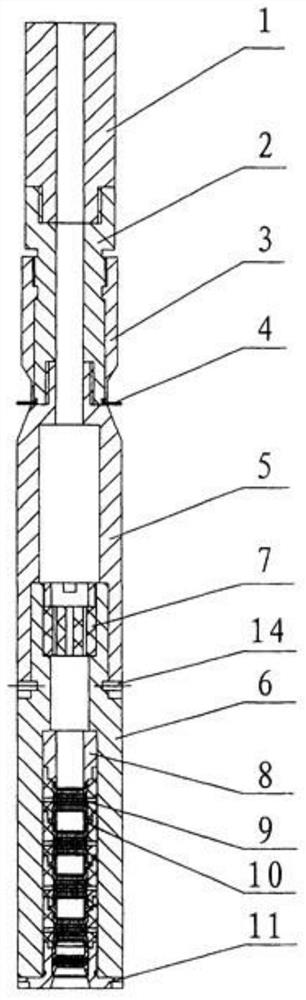

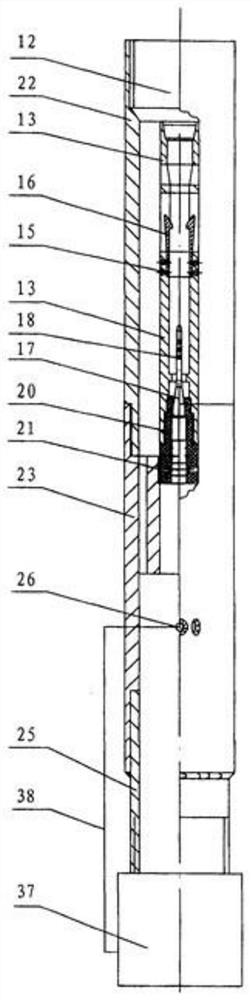

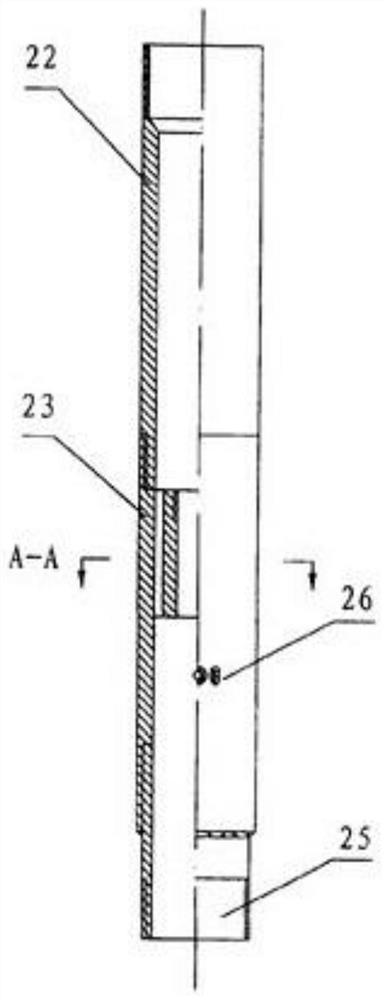

[0036] This embodiment provides a submersible cable docking device used in oil pipes, which includes a cable upper connector 39 and a cable lower connector 40 . Such as figure 1As shown, the cable upper connector 39 includes a weighted rod 1, a female connector 2, a snap ring lock sleeve 3, a snap ring 4, a female connector cylinder 5, a female body 6, a packing ring 9 and an electrical connection ring 10 . The weighting rod 1, the female connecting body 2, the female connecting cylinder 5 and the female body 6 are respectively provided with an inner cavity through up and down, and the weighting rod 1, the female connecting body 2, the female connecting cylinder 5 and the female The bodies 6 are connected in sequence, so that the weighting rod 1 , the female connecting body 2 , the female connecting cylinder 5 and the inner cavity of the female body 6 communicate with each other. Specifically, one end of the weighting rod 1 has a pin thread so as to be threadedly connected t...

Embodiment 2

[0044] Embodiment 2 provides a method for docking and splitting submersible cables in downhole pressurized tubing, which is applied to the docking device for submersible cables in tubing in Embodiment 1, including the following steps:

[0045] S1: Install the lower end cable 38 in the cable lower connector 40, the upper end of the lower end cable 38 extends from the cable hole 26 into the inner cavity of the connection sleeve 29 or the inner cavity of the fixed body 23, passes through the male head assembly 17, and finally the lower end cable 38 is electrically connected with three conductive rings 18;

[0046] S2: The lower joint 25 of the short joint 12 of the cable oil pipe is electrically connected to the upper joint 22 of the oil pipe of the electric submersible pump unit 37, the lower end of the lower end cable 38 is electrically connected to the electric submersible pump unit 37, and the cables fixed together are connected under the The body 40 and the submersible elect...

Embodiment 3

[0052] Embodiment 3 provides a method for connecting and splitting submersible cables in downhole atmospheric pressure tubing. Embodiment 3 is mostly the same as Embodiment 2. A valve, when the oil pipe is lowered, the well fluid is kept under the valve. After the docking, the pump is powered on, and the valve is opened by the pressure generated by the oil well pump to start production. The purpose of normal pressure docking is mainly to ensure the success of docking. Butting under normal pressure can reduce the impact of impurities on the surface of the male connector during docking, reduce the downward resistance of the cable, and improve the success rate of docking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com