Bulk material sampling and sample preparation system

A bulk material and sample preparation technology, applied in the field of sampling systems, can solve problems affecting the authenticity and accuracy of test samples, and achieve the effect of increasing the difficulty of maintenance, flexible equipment use, and speeding up the turnaround time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

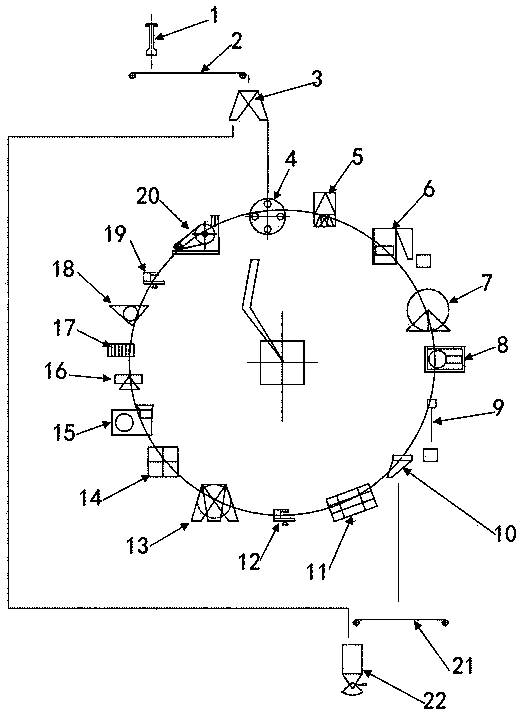

[0039]A bulk material sampling and preparation system, which includes a sample preparation device, a manipulator 24, a particle size composition analysis device, a moisture measurement device, an analysis sample preparation device, a sample storage device and a cleaning device are arranged around the manipulator, and it also includes a control system. The device, manipulator, particle size composition analysis device, moisture measuring device, analytical sample preparation device, sample storage device and cleaning device are all connected to the control system, and the control system controls the manipulator 24 to send bulk materials to each device in turn. The sample preparation device includes a sampling machine, a shrinking machine 13 , a belt conveyor 2 , and a crusher 20 , wherein the shrinking machine 13 and the crusher 20 are arranged around a manipulator 24 . The particle size composition analysis device includes a particle size screening machine 18, a screen storage ...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that in this embodiment, the packaging machine and the coding and reading machine are set together as a packaging coding and reading machine 6, which also includes a rotation speed strength testing machine 7, a coke granulator 8 .

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1 is that the moisture measuring device of this embodiment is provided with a separate moisture weighing balance and cleaning device 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com