TSV vacuum laminating method, apparatus, and bonding system using same

A vacuum layer and vacuum technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of complex lamination, bonding and debonding processes, difficulty in maintenance, management and repair, and complex and large-scale devices and other problems, to achieve the effect of suppressing voids, saving maintenance and management costs, and simplifying process layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention relates to a lamination process of a through-silicon via (Through Silicon Via, hereinafter referred to as "TSV") process for improving the integration degree of semiconductor elements.

[0037] In particular, an adhesive film capable of efficiently laminating an adhesive film to a carrier wafer for maintaining the strength of a device wafer relates to a vacuum lamination for high-quality vacuum lamination capable of suppressing generation of dust and particles.

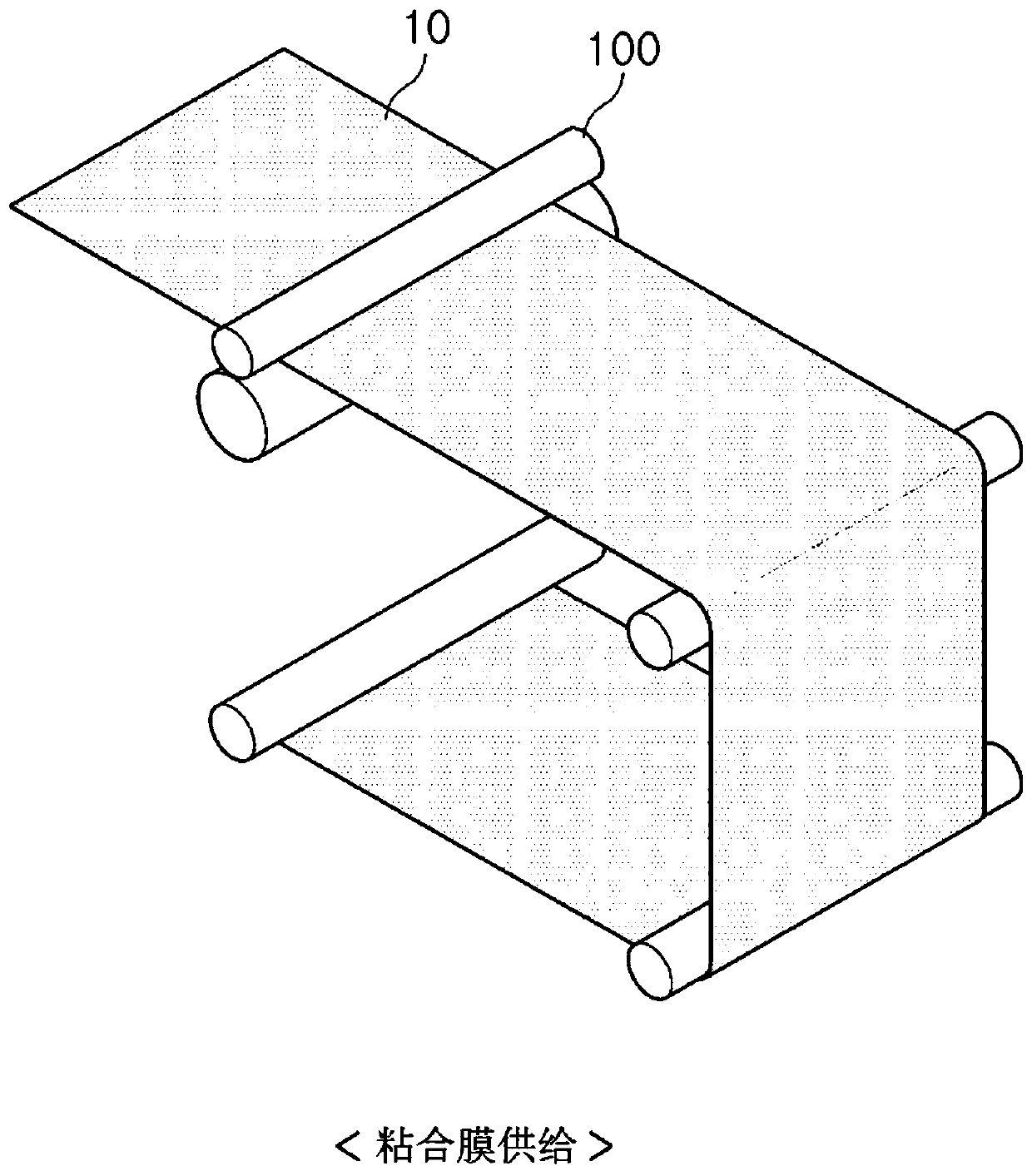

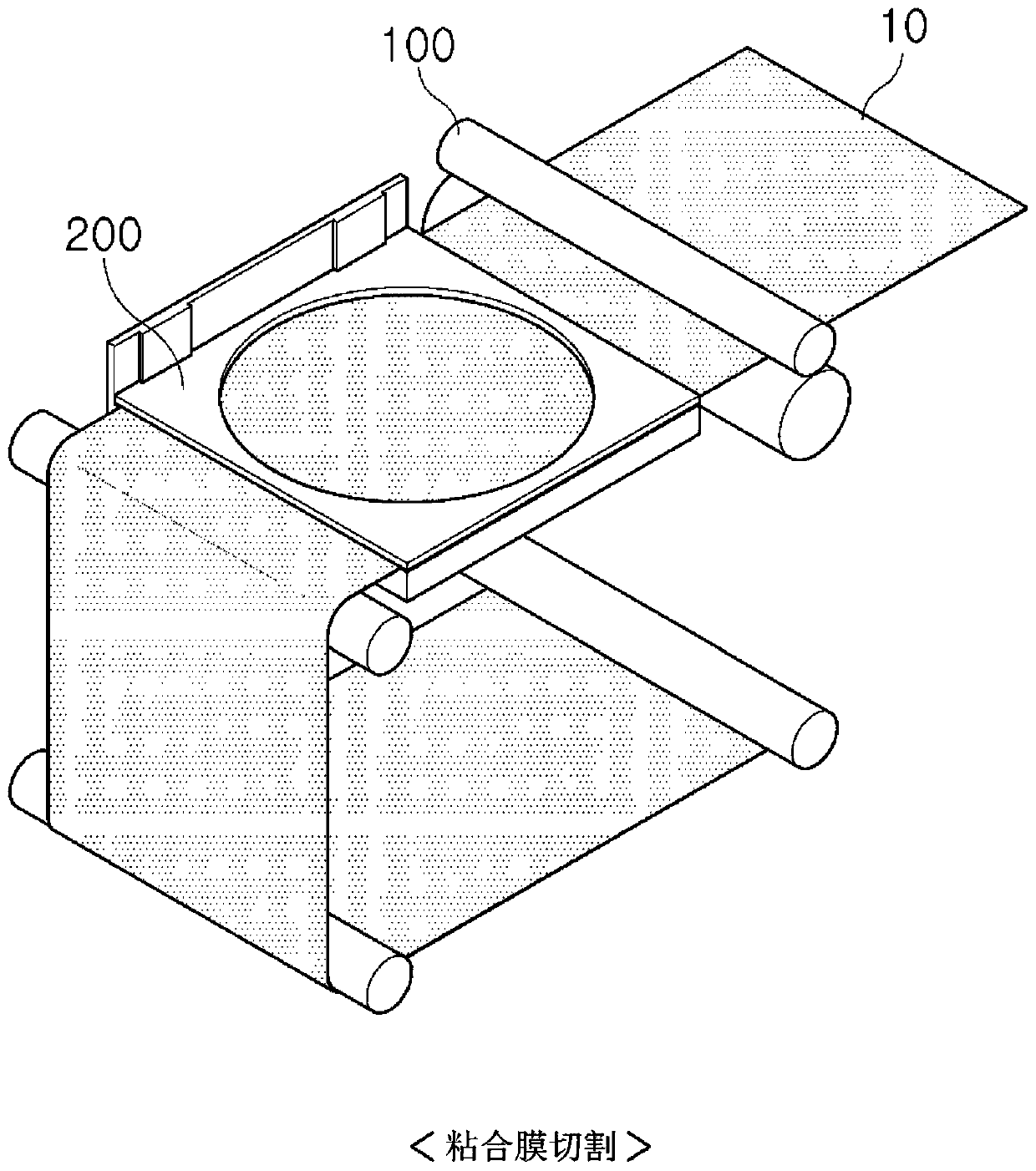

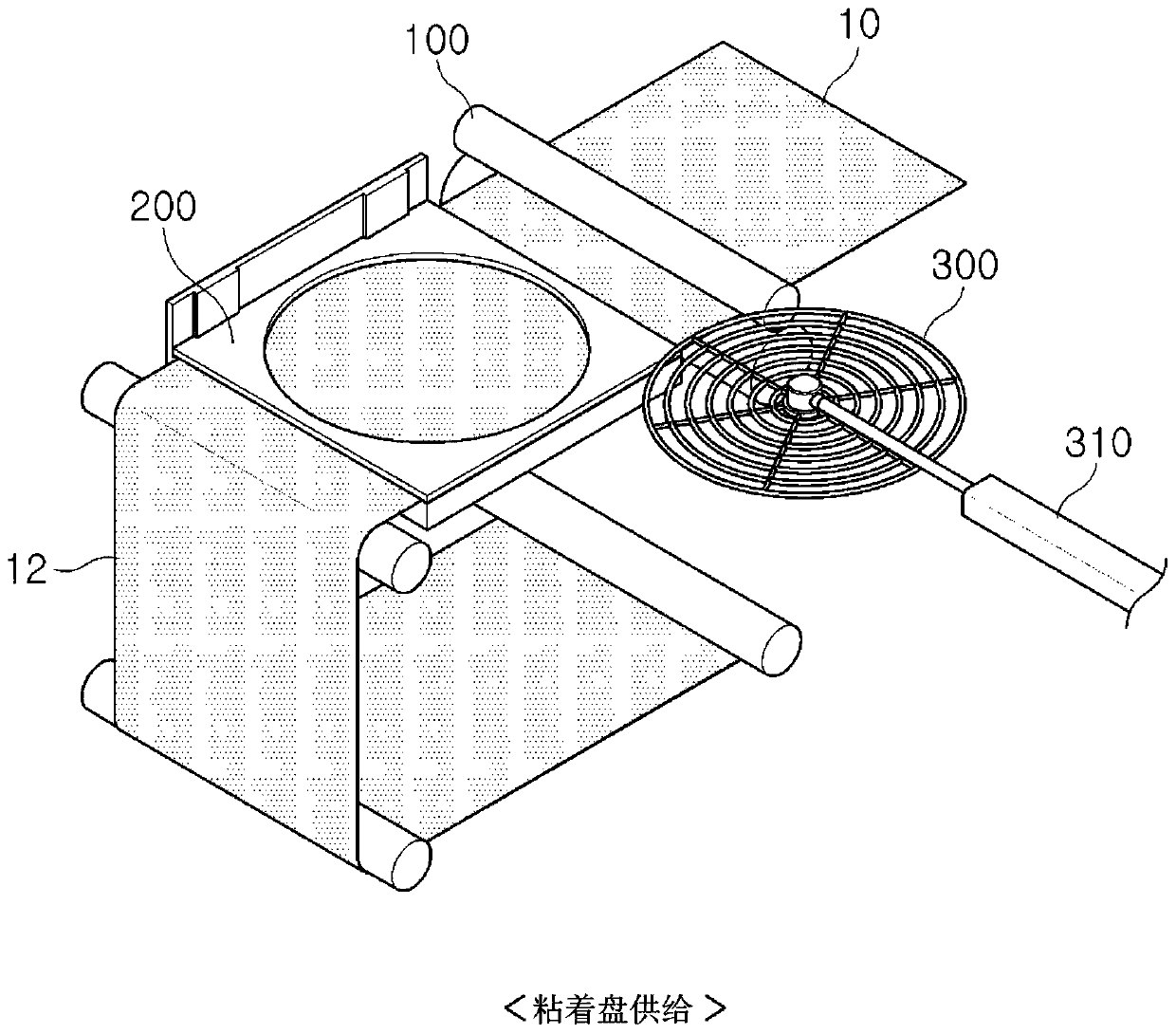

[0038] Figure 1 to Figure 8 is a schematic diagram of the vacuum lamination process sequence and the main parts of the device according to the present invention, Figure 9 to Figure 11 is a diagram illustrating an example of a bonding system according to vacuum lamination in the present invention.

[0039] As shown in the figure, in the present invention, the adhesive film 10 and the carrier wafer 20 are laminated in a vacuum state, so generation of dust and particles can be minimized, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com