Classified washing process for thermal coal

A thermal coal and process technology, which is applied in the field of thermal coal grading and washing process, can solve the problems of reducing the economic benefit of the enterprise, poor dehydration effect of coal slime, and reduced calorific value, achieving significant economic and social benefits, and simplifying the treatment of coal slime water. system, the effect of reducing production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the features, objectives and advantages of the present invention, a thermal coal classification, washing and sorting process of the present invention will be further described in detail below through specific embodiments.

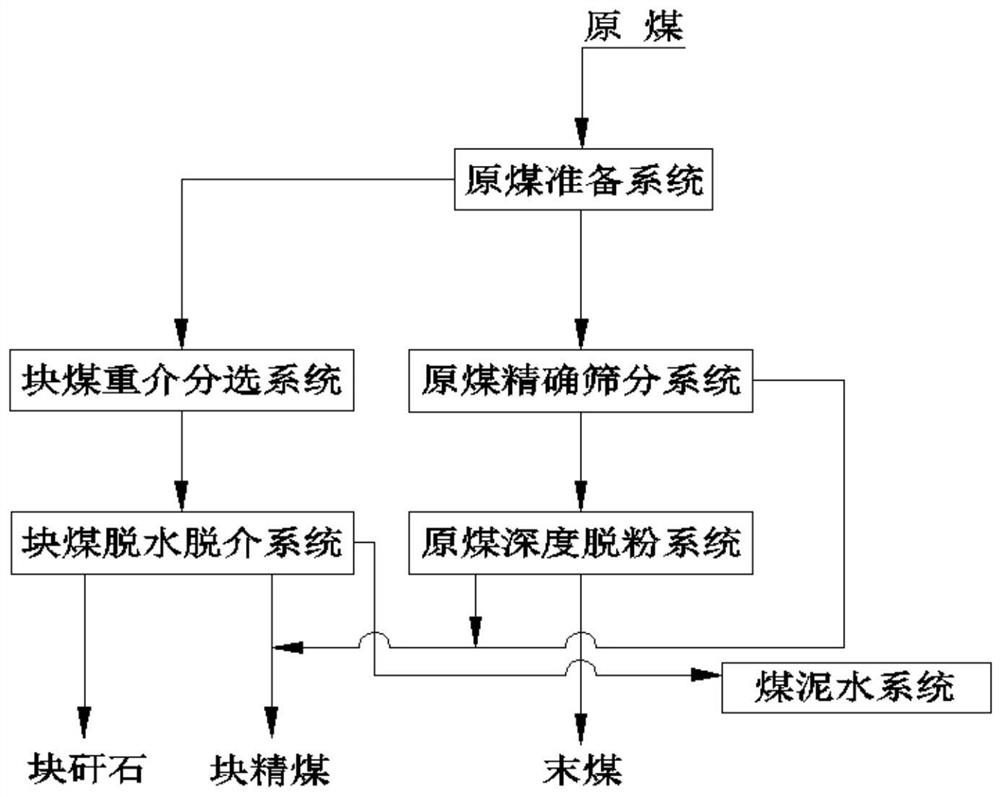

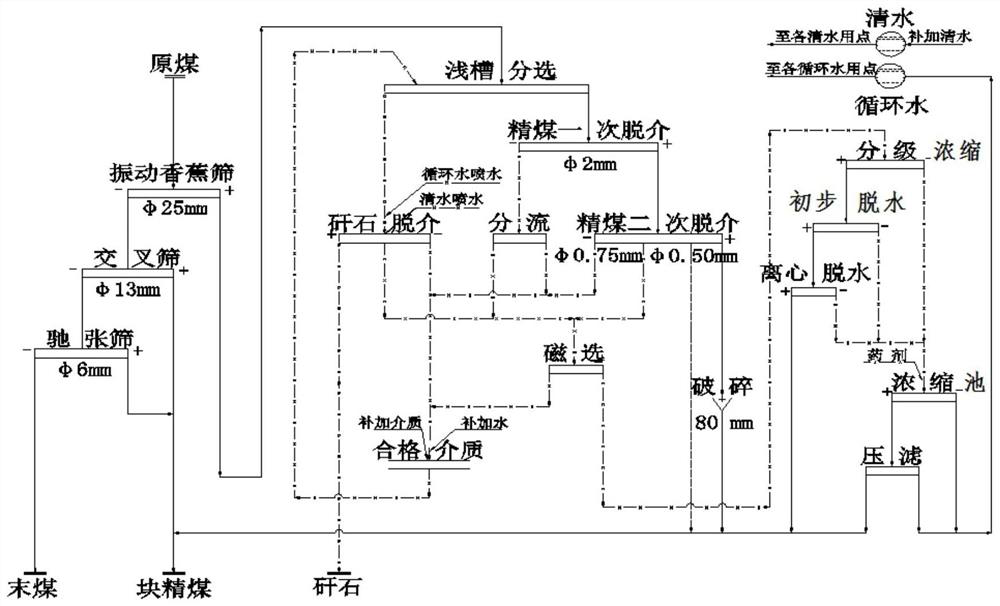

[0021] refer to Figure 1-2 , the specific implementation of the so-called thermal coal classification washing process of the present invention is as follows:

[0022] The raw coal enters the raw coal preparation system and the raw coal precision screening system through the washing belt, and is successively screened through the 25mm mesh grading sieve and the 13mm sieve mesh grading sieve to separate the raw coal with three particle sizes of >25mm, 25-13mm and 25mm enters the lump coal dense medium separation system, and the lump clean coal and lump gangue separated by the dense medium shallow groove separator enter the lump coal dehydration and medium separation system for treatment and output respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com