Organic polymer luminescent concrete and preparation method thereof

A concrete and polymer technology, applied in the field of organic polymer luminescent concrete and its preparation, can solve the problems of limited application range, low utilization rate of optical fibers, high price, etc., and achieves simple light source arrangement process, wide application range and weather resistance performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

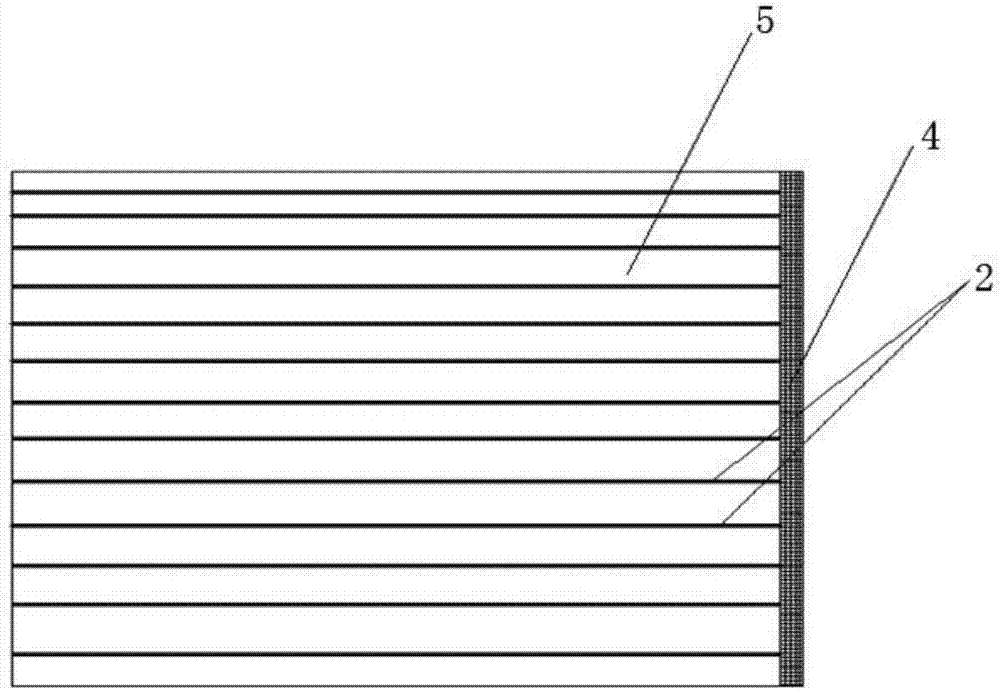

[0038] as attached image 3 As shown, an organic polymer luminescent concrete includes a concrete slab 5, a transparent side luminescent material 2 and a light source 4, the transparent side luminescent material 2 is embedded in the surface layer of the concrete slab 5, and each transparent side luminous material 2. At least one end is located at the edge of the concrete slab 5, and a light source is provided at the end of the transparent side luminescent material 2 at the edge of the concrete slab 5. attached image 3 In the organic polymer luminescent concrete shown, the transparent side luminescent material 2 is embedded in the surface of the concrete slab in parallel, and the light source provided at the edge of the transparent side luminescent material and the concrete slab is a strip light source 4 .

[0039] A method for preparing organic polymer light-emitting concrete, comprising the steps of:

[0040] 1) Material preparation:

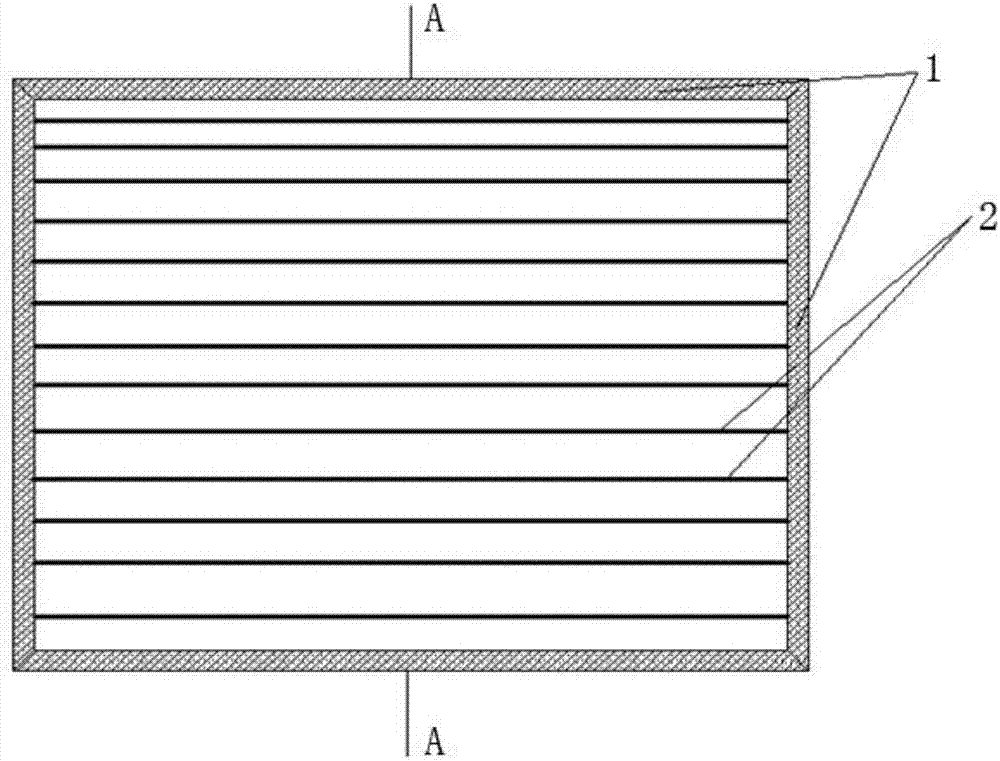

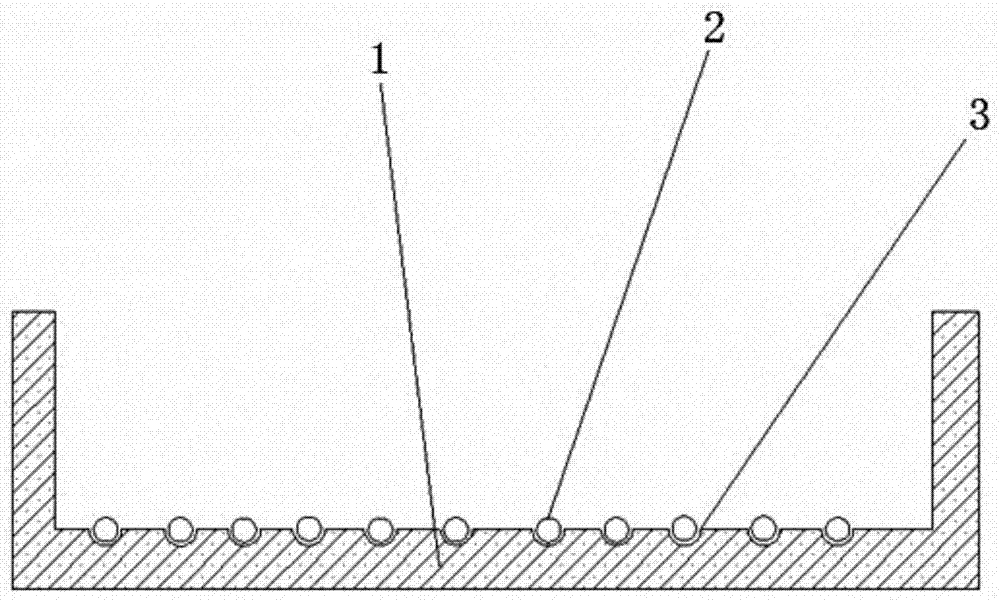

[0041] as attached figure 1 , 2 As...

Embodiment 2

[0058] as attached Figure 4 As shown, an organic polymer luminous concrete includes a concrete slab 5, a flexible transparent side luminous material 6 and a point light source 7, the flexible transparent side luminous material 6 is embedded in the surface layer of the concrete slab 5, and the flexible transparent side At least one end of the luminescent material 6 is located at the edge of the concrete slab 5 , and a point light source 7 is provided at the end of the flexible transparent luminescent material 6 at the edge of the concrete slab 5 .

[0059] Different from Example 1, in Example 2, the luminescent material used is flexible transparent side luminescent material 6, which forms a pattern on the surface of the concrete slab 5, and the shape of the pattern can be set according to actual needs.

[0060] Correspondingly, in Embodiment 2, the light source used is a point light source 7, which is located at the end of the edge of the flexible transparent side luminescent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com