Long log direct-rolling casting blank thermal insulation device, production line and method

A thermal insulation device and production line technology, applied in the direction of metal rolling, metal rolling, workpiece heating devices, etc., can solve the problems of continuous casting slab waste, large investment, and infeasibility, and achieve continuous casting slab head and tail The effect of small temperature difference between core and surface, low investment and operation cost, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

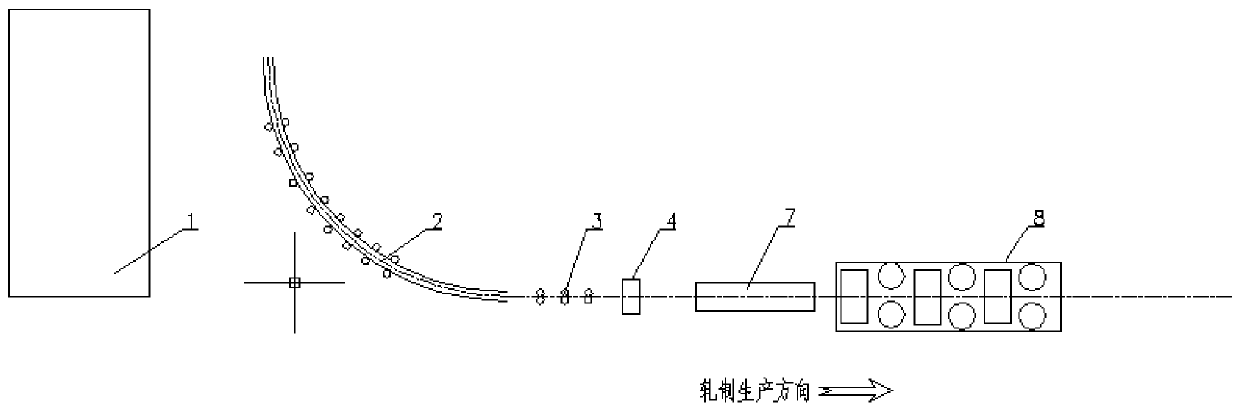

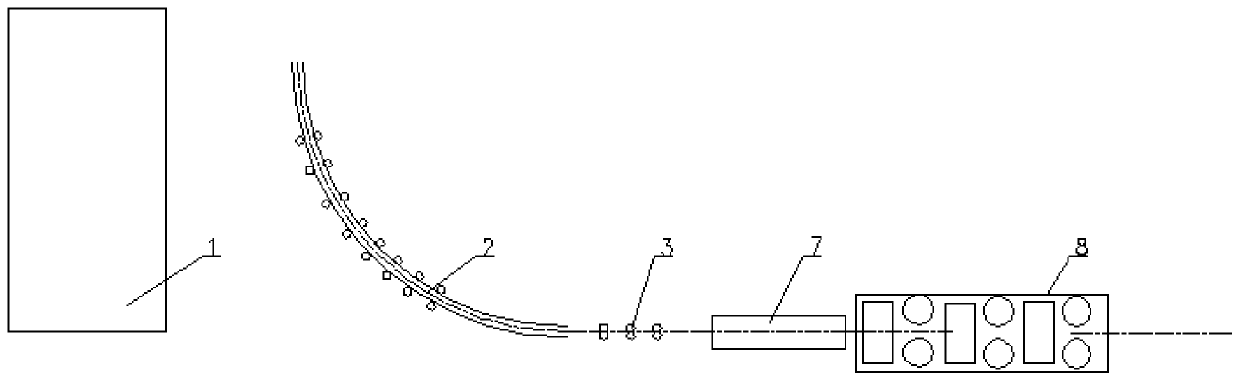

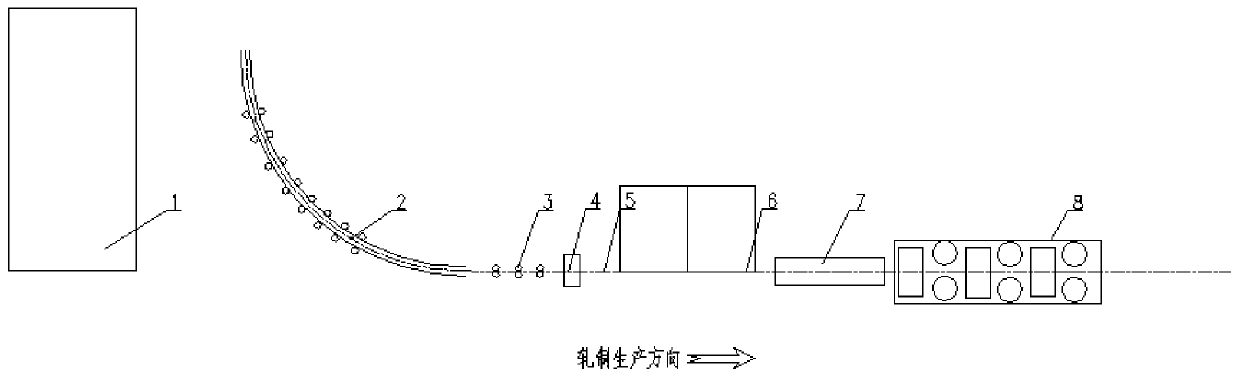

[0050] The production process sequence according to the present invention includes: continuous casting by continuous casting machine, cutting to length of continuous casting slab, parallel flow of continuous casting slab, thermal insulation and buffering of slab heat preservation device, supplementary heat by electromagnetic induction, rolling by rolling mill, cooling and collection. to combine Figure 7 As shown, the process is as follows:

[0051] (1) High-speed continuous casting: High-speed continuous casting technology is used for sequential multi-strand continuous casting. The cross-sectional size of the continuous casting slab is 165mm×165mm, the continuous casting speed is 3.6m / min, the number of continuous casting strands is five strands, and the hourly output is 230t / h;

[0052] (2) Continuous casting slab cutting to length: After being cooled by the secondary cooling section of the continuous casting segment and stretched and straightened by the tension leveler, t...

Embodiment 2

[0059] The production process sequence according to the present invention includes: continuous casting by continuous casting machine, cutting to length of continuous casting slab, parallel flow of continuous casting slab, thermal insulation and buffering of slab heat preservation device, supplementary heat by electromagnetic induction, rolling by rolling mill, cooling and collection. to combine Figure 7 As shown, the process is as follows:

[0060] (1) High-speed continuous casting: High-speed continuous casting technology is used for sequential multi-strand continuous casting. The cross-sectional size of the continuous casting slab is 165mm×165mm, the continuous casting speed is 3.6m / min, the number of continuous casting strands is five strands, and the hourly output is 230t / h;

[0061] (2) Continuous casting slab cutting to length: After being cooled by the secondary cooling section of the continuous casting segment and stretched and straightened by the tension leveler, t...

Embodiment 3

[0069] The production process sequence according to the present invention includes: continuous casting by continuous casting machine, cutting to length of continuous casting slab, parallel flow of continuous casting slab, thermal insulation and buffering of slab heat preservation device, supplementary heat by electromagnetic induction, rolling by rolling mill, cooling and collection. to combine Figure 7 As shown, the process is as follows:

[0070] (1) High-speed continuous casting: High-speed continuous casting technology is used for sequential multi-strand continuous casting. The cross-sectional size of the continuous casting slab is 165mm×165mm, the continuous casting speed is 3.6m / min, the number of continuous casting strands is five strands, and the hourly output is 230t / h;

[0071] (2) Continuous casting slab cutting to length: After being cooled by the secondary cooling section of the continuous casting segment and stretched and straightened by the tension leveler, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com