Patents

Literature

139results about How to "Small difference in performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Data processing method and apparatus

ActiveCN103825669ASmall difference in performanceCode conversionChannel coding adaptationCoding blockParallel computing

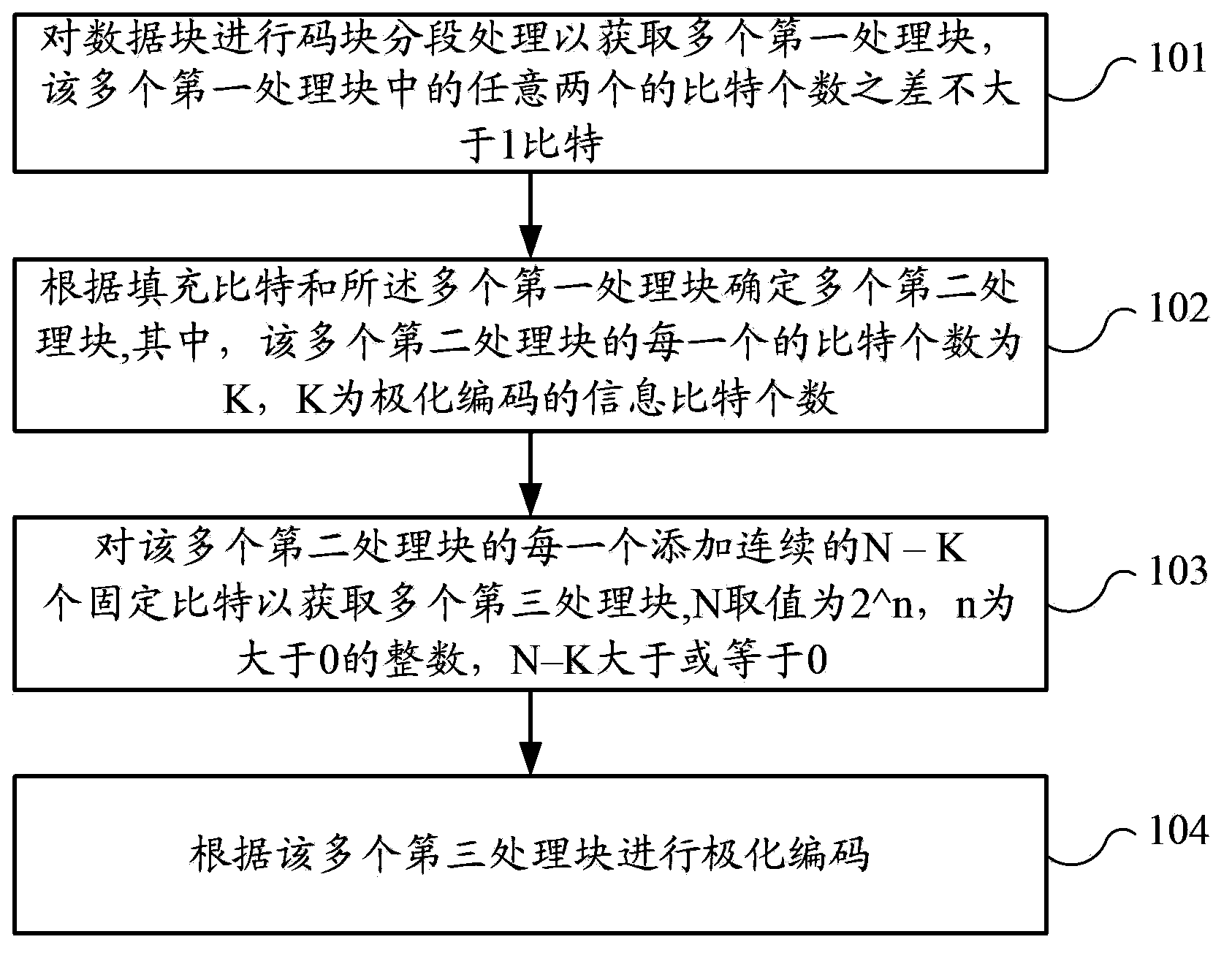

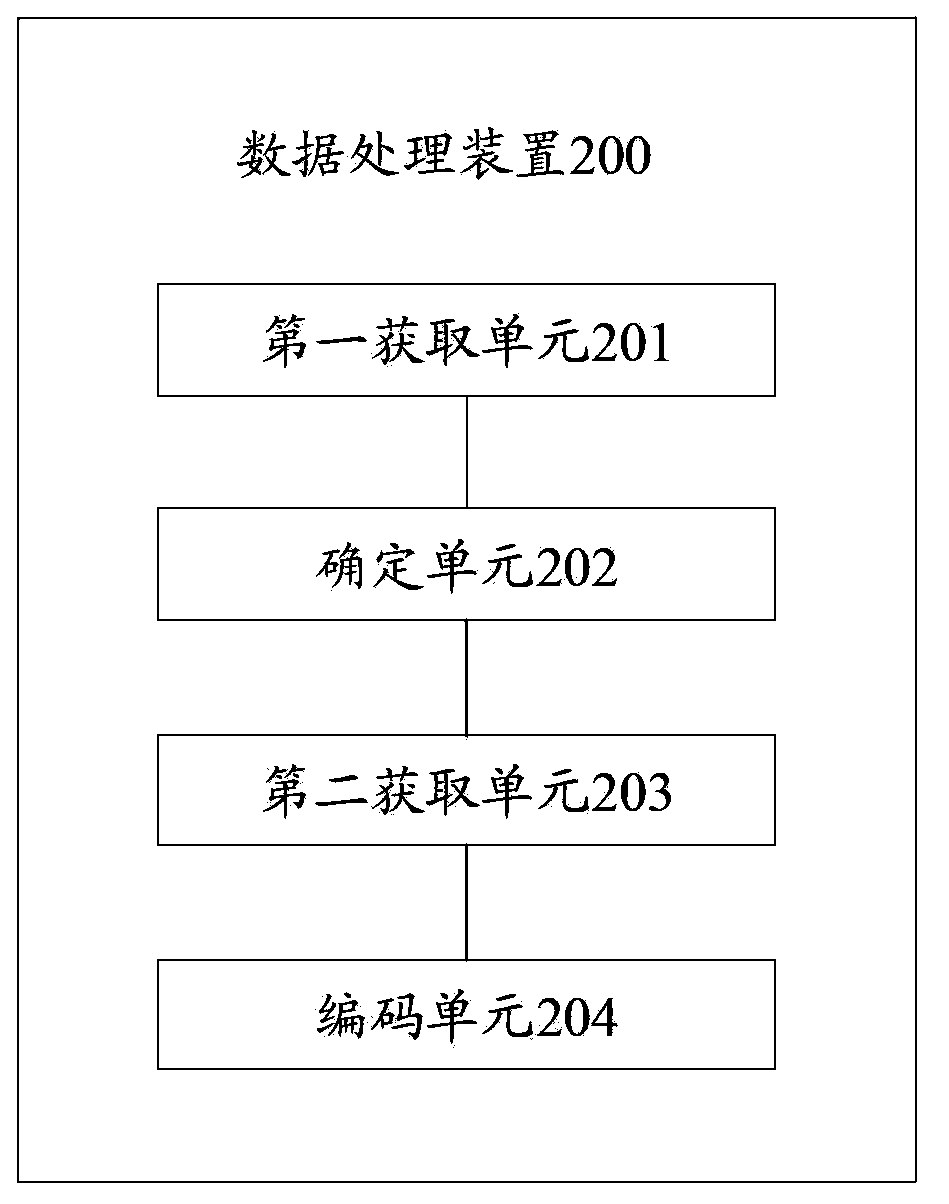

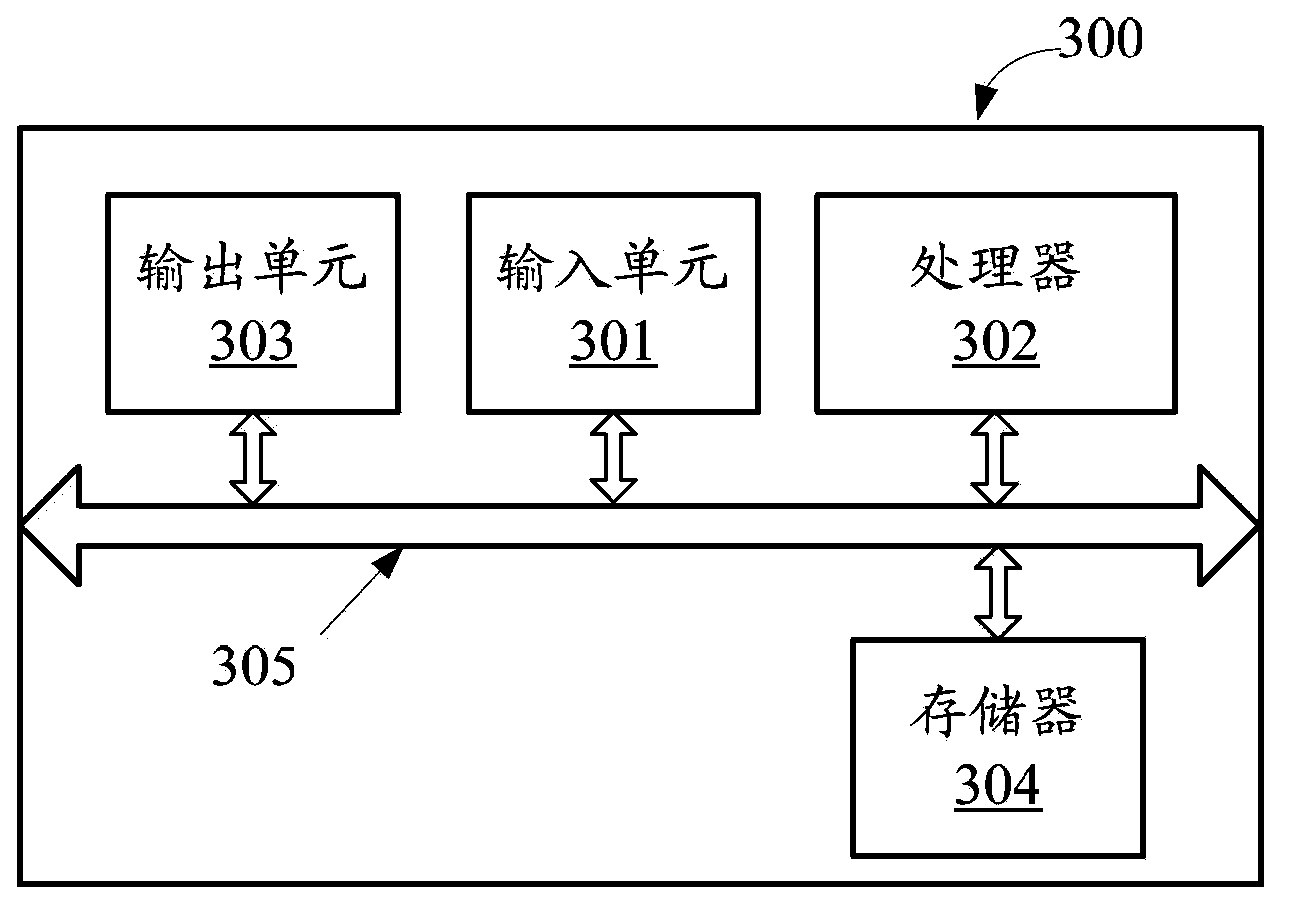

The embodiments of the invention provide a data processing method and apparatus. The method comprises: performing code block segment processing on a data block so as to obtain multiple first processing blocks, the difference of the bit numbers of any two of the multiple first processing blocks being not greater than one bit; according to a filling bit and the multiple first processing blocks, determining multiple second processing blocks, the value of the filling bit being a preset value; adding continuous N-K fixation bits for each of the multiple second processing blocks so as to obtain multiple third processing blocks, the values of the fixation bits being preset values, and (N-K)>=0; and according to the multiple third processing blocks, performing polar coding. In the embodiments of the invention, the data blocks are segmented as uniformly as possible and are subjected to filling bit processing and fixation bit processing so as to perform the polar coding and reduce performance differences among code blocks.

Owner:HUAWEI TECH CO LTD

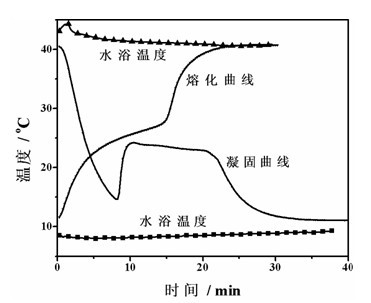

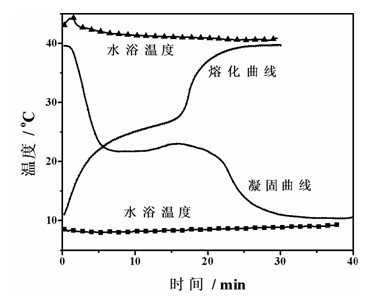

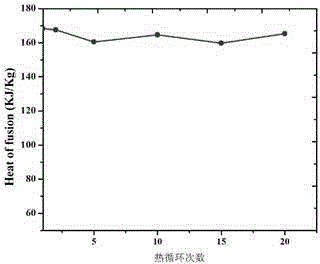

Inorganic phase-change material and preparation method thereof

InactiveCN102660231ALatent heat of fusion without decaySimple methodHeat-exchange elementsDisodium phosphateHydrogen phosphate

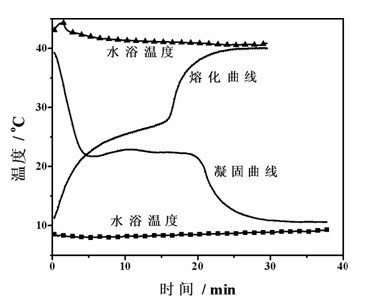

The invention discloses an inorganic phase-change material and a preparation method thereof. The inorganic phase-change material comprises at least one of a thickening agent and a water-retaining agent, and main thermit, nucleating agent, pH regulator, heat conducting agent, and water, wherein the main thermit is eutectic salt of sodium sulfate decahydrate and sodium hydrogen phosphate docecahydrate. The preparation method comprises the following steps: adding the main thermit in water, stirring in 40-45 DEG C water bath until completely fusing, adding the nucleating agent, the pH regulator, and the heat conducting agent and fully stirring to completely dissolve the nucleating agent and the pH regulator and uniformly disperse the heat conducting agent, then adding at least one of the thickening agent and the water-retaining agent and stirring to uniformly disperse the thickening agent or completely expanse the water-retaining agent, so as to obtain the inorganic phase-change material. The inorganic phase-change material of the invention has the characteristics of noninflammability and no toxicity, the phase change temperature is 21-27 DEG C, the latent heat of phase change is 214 kJ / kg, and the inorganic phase-change material has no attenuation of performance after 1000 weeks of the solidification-fusing cycle.

Owner:WUHAN UNIV

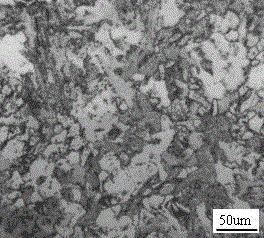

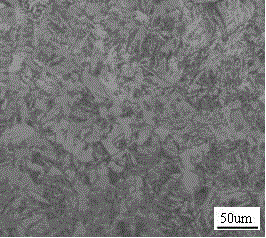

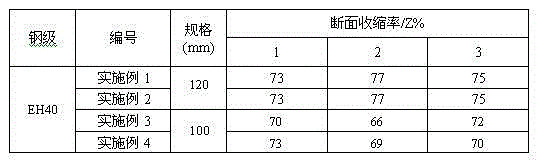

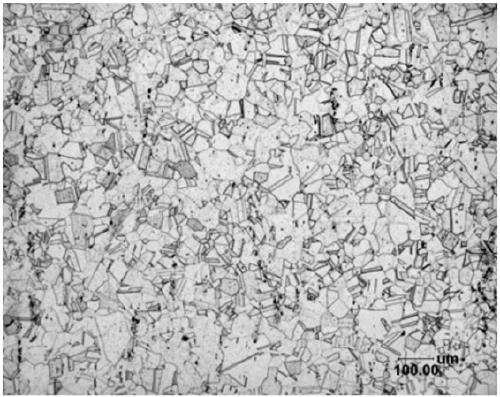

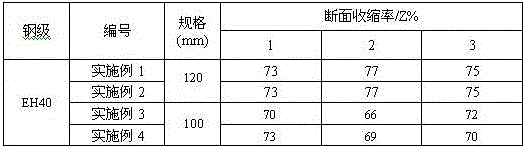

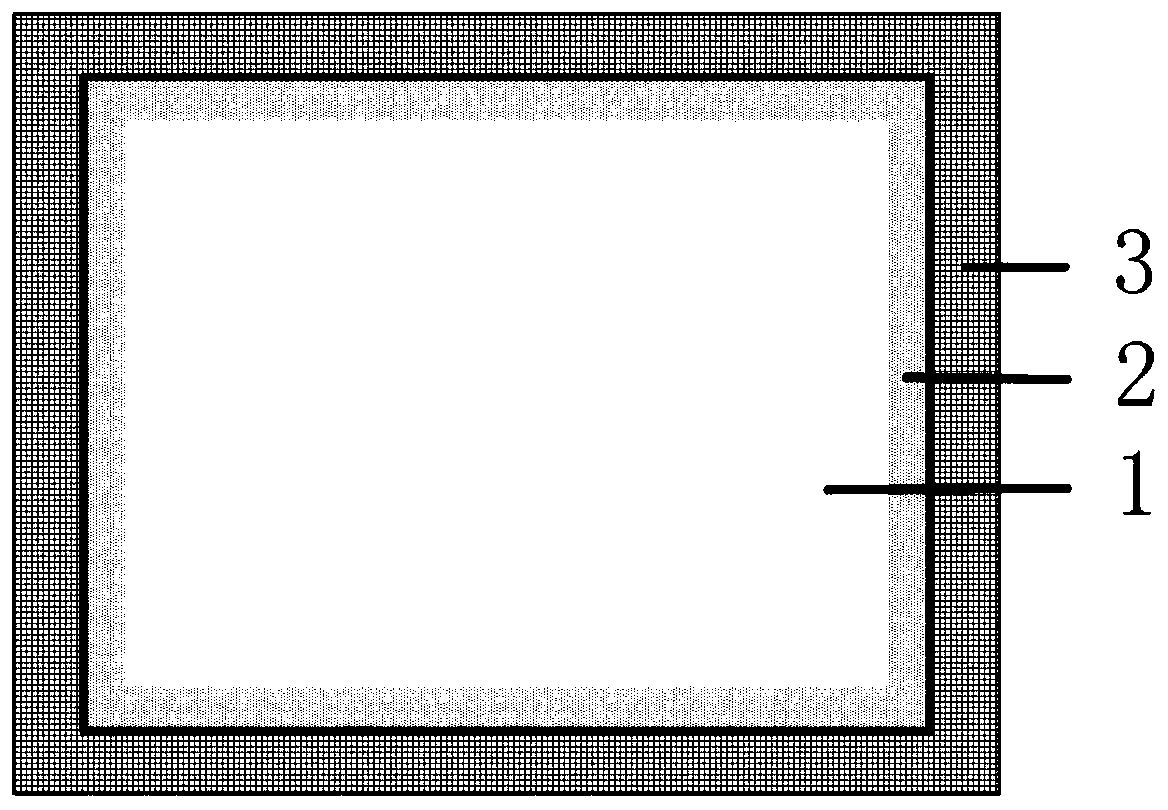

Extra-thick tempering EH40 steel for ocean engineering and preparation method thereof

The invention relates to extra-thick tempering EH40 steel for ocean engineering. A steel plate comprises the following chemical components by weight percent: 0.12 to 0.15 percent of C, 0.15 to 0.50 percent of Si, 1.30 to 1.60 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.0050 percent of S, 0.020 to 0.050 percent of Nb, 0.020 to 0.050 percent of V, 0.008 to 0.020 percent of Ti, 0.15 to 0.40 percent of Ni, 0.10 to 0.20 percent of Cr, and balance of Fe and unavoidable impurity elements. The manufacturing process of the steel plate comprises the steps of smelting, casting, reheating, rolling and tempering. The tempering process is used for substituting the normalizing process to produce a low-scaling-ratio extra-thick plate, so that the adverse effect caused by the center segregation can be avoided.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

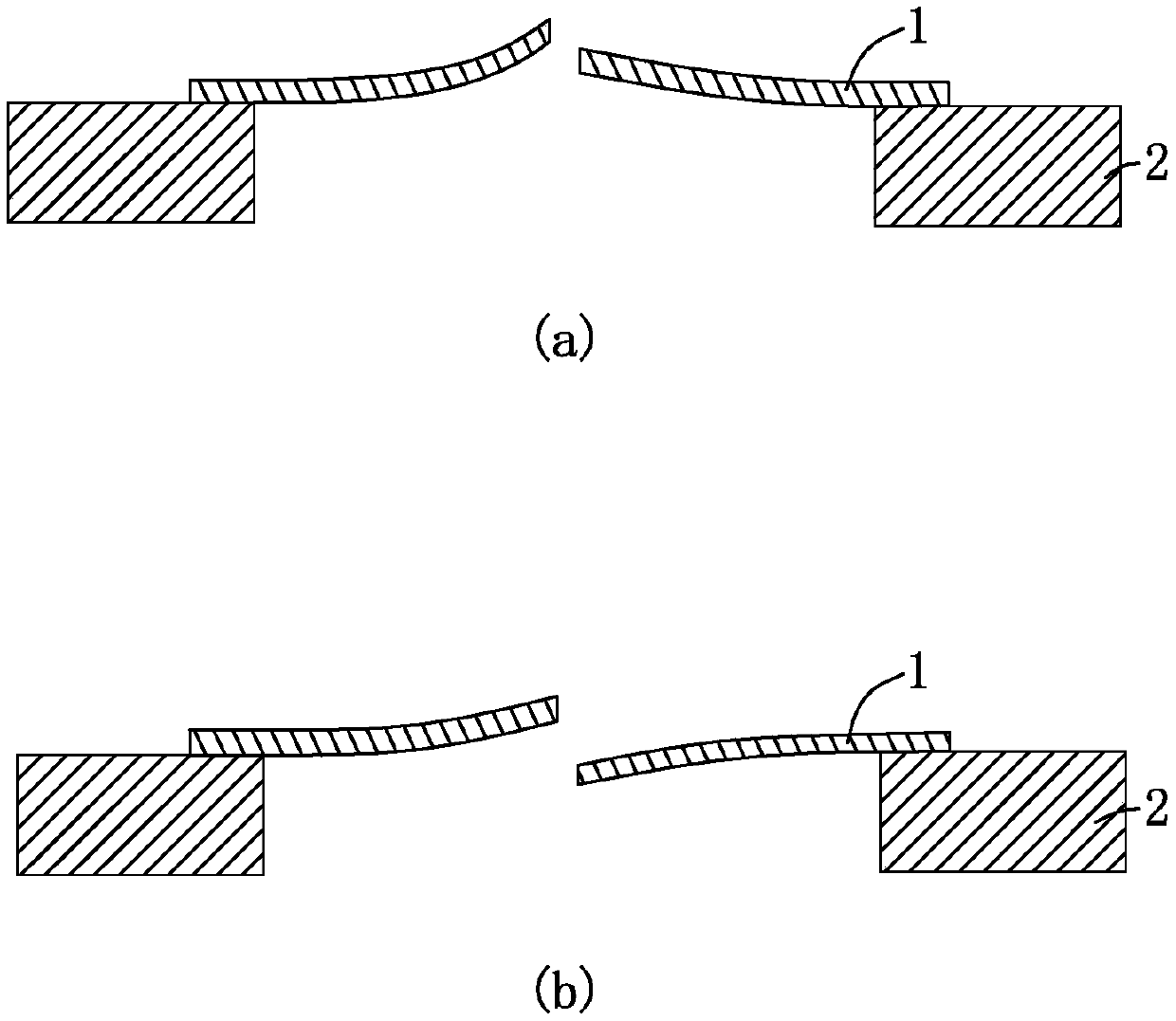

Metal-reinforced plastic composite material part and its molding method

InactiveCN102825860AImprove performanceImprove mechanical propertiesSynthetic resin layered productsMetal layered productsFiberMetal

The invention discloses a metal-reinforced plastic composite material part and its molding method. The part is obtained through bonding a metal plate, a fiber and a heat-conductive filler reinforced plastic layer directly or by means of a bonding layer to realize the organic combination of respective advantages of the metal and the reinforced plastic. The molding method comprises a step that the metal plate and the plastic layer are pre-molded and then bonded together or a step that the metal plate is pre-molded and then is injected or coated with the plastic layer, so the molding process has the advantages of high efficiency, economy, good technological economy and easy large-scale industrial implementation.

Owner:CHONGQING UNIV

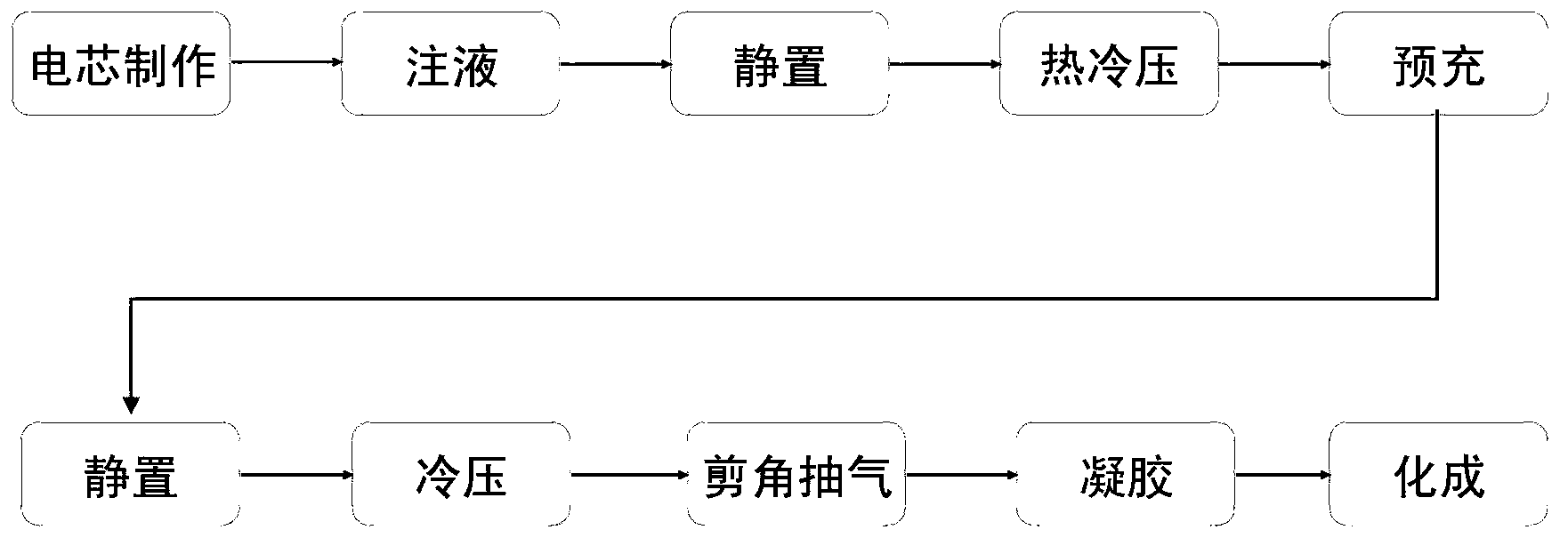

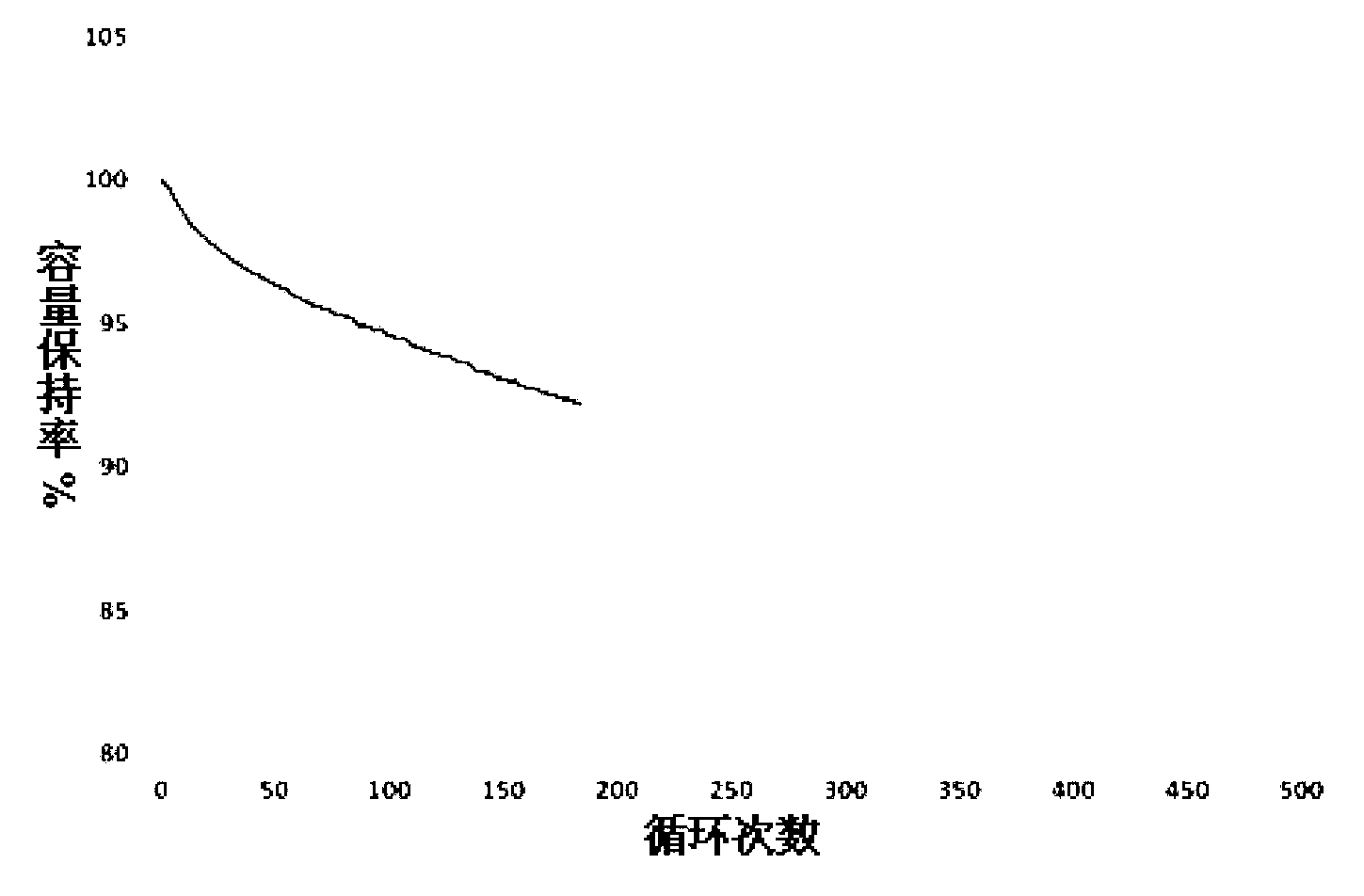

Method for preparing gel diaphragm cell by in-situ polymerization and prepared battery

ActiveCN103258977ASmall difference in performanceConducive to consistencySecondary cellsCell component detailsChemistryIn situ polymerization

The invention discloses a method for preparing a gel diaphragm cell by in-situ polymerization and a prepared battery. The method comprises the following steps of: adding a special initiator and a monomer, which are needed for a polymerization reaction, into an organic solvent electrolyte for dissolving lithium salts to prepare a polymer electrolyte; and then manufacturing a gel cell. According to the conditions of the polymerization reaction of the polymer electrolyte, due to a designed polymerization process technology, the polymer electrolyte and a polymer diaphragm gradually form a gel diaphragm in the gel battery so as to manufacture the cell with good diaphragm gel effect, good interface effect of an electrolyte electrode and consistent electric performance.

Owner:CENT SOUTH UNIV +1

High-strength cold-roll-forming structural steel and method for producing same

InactiveCN1970811AInhibition of segregationFast solidificationTemperature control deviceMetal rolling arrangementsMolten steelHeating furnace

The invention discloses a high-strength cool-bent moulding structural steel and manufacturing method, which comprises the following parts: 0.03-0.12% C,0.08-0.50% Si,1.20-1.95% Mn,not more than 0.02% P,not more than 0.006% S, 0.05%-0.15% Mo,0.005-0.055% Als,0.03-0.07% Nb,0.08-0.15% Ti,0.01-0.05% V ,0.0008-0.004% Ca and Fe and inevitable impurity with Ceq not more than 0.42%. The making method is characterized by the following: controlling the fusing point of smolten steel over 15-30 deg.c; casting continuously; setting drawing speed of casting bland at 1.5-4.0m / min and blank thickness between 100 and 200mm; heating in the furnace directly; setting the even heating temperature at 1100-1250 deg.c, fine-rolling temperature at 940-1070 deg.c and outlet temperature at 840-920 deg.c; freezing rapidly after 0-7s; setting the coiling temperature at 500-610 deg.c with yielding strength of steel board over 700Mpa and drawing-proof strength between 750 and 950Mpa and extending rate over 17%.

Owner:ANGANG STEEL CO LTD

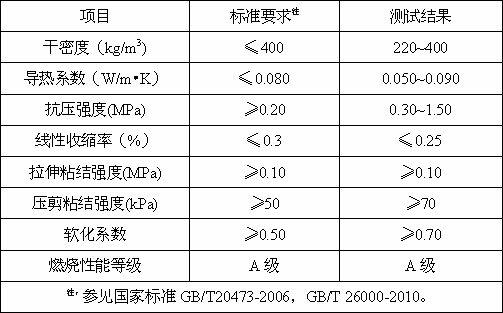

Inorganic insulating mortar with wide-range adjustable thermal conduction coefficient and its preparation method

The invention relates to inorganic insulating mortar for building energy conservation and its preparation method. The inorganic insulating mortar comprises the following components by weight: 35%-50% of ordinary portland cement, 5%-10% of fly ash, 5%-10% of hydrated lime, 35%-50% of vitrified micro-beads, 0.1%-0.2% of PP (polypropylene) fiber, 0.5%-1.2% of redispersible emulsion powder, 0.2%-0.6% of cellulose ether, 0.03%-0.07% of starch ether, and 0%-0.02% of an air-entraining agent. The thermal conduction coefficient of the inorganic insulating mortar can be adjusted within the grade range of 0.050W / m.K to 0.090W / m.K according to needs. The inorganic insulating mortar of the invention is monocomponent dry-mixed mortar uniformly mixed by lightweight aggregate and powder materials, and not only solves the problems of poor transportation storage stability and easy segregation in this kind of products, but also has the characteristics of excellent construction performance, bonding property, high strength, incombustibility and fire prevention, thermal insulation performance, hollowing and cracking avoidance, as well as low economic cost, etc.

Owner:TONGJI UNIV

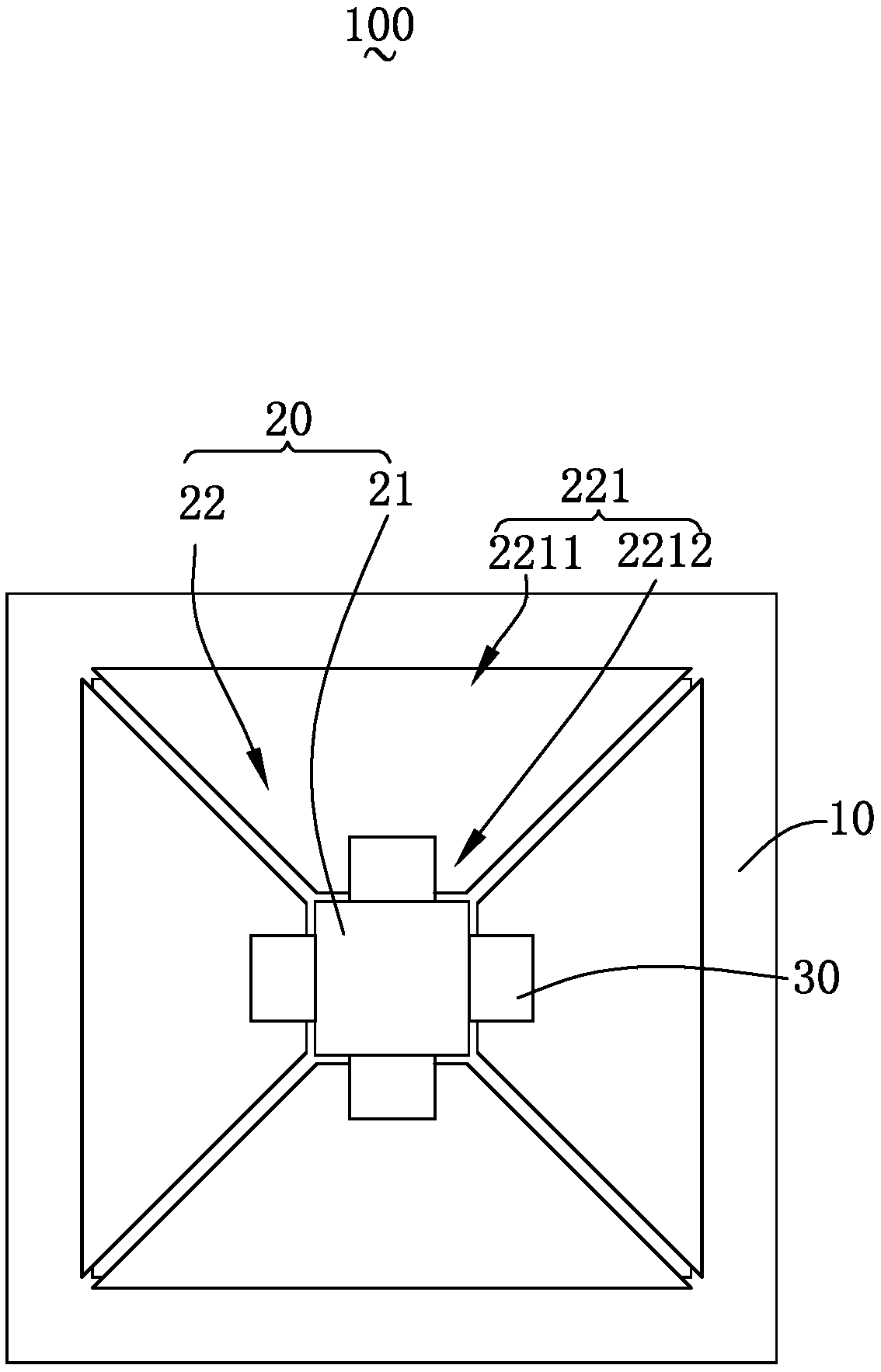

Piezoelectric microphone

ActiveCN109587613AEasy to useImprove uniformityPiezoelectric/electrostrictive microphonesMicrophonesMobile endPiezoelectric cantilever

The invention provides a piezoelectric microphone, which comprises a base with a back cavity and a piezoelectric cantilever beam diaphragm fixed on the base, wherein the piezoelectric cantilever beamdiaphragm comprises a first diaphragm located in the center and suspended above the back cavity and a second diaphragm fixed on the base and surrounding the first diaphragm; and the second diaphragm comprises a fixing end fixed at one side of the base and a mobile end close to one side of the first diaphragm and suspended above the back cavity. The piezoelectric microphone also comprises an elastic telescopic piece connecting the first diaphragm and the mobile end. Compared with a related technology, the piezoelectric microphone provided in the invention has better performance.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

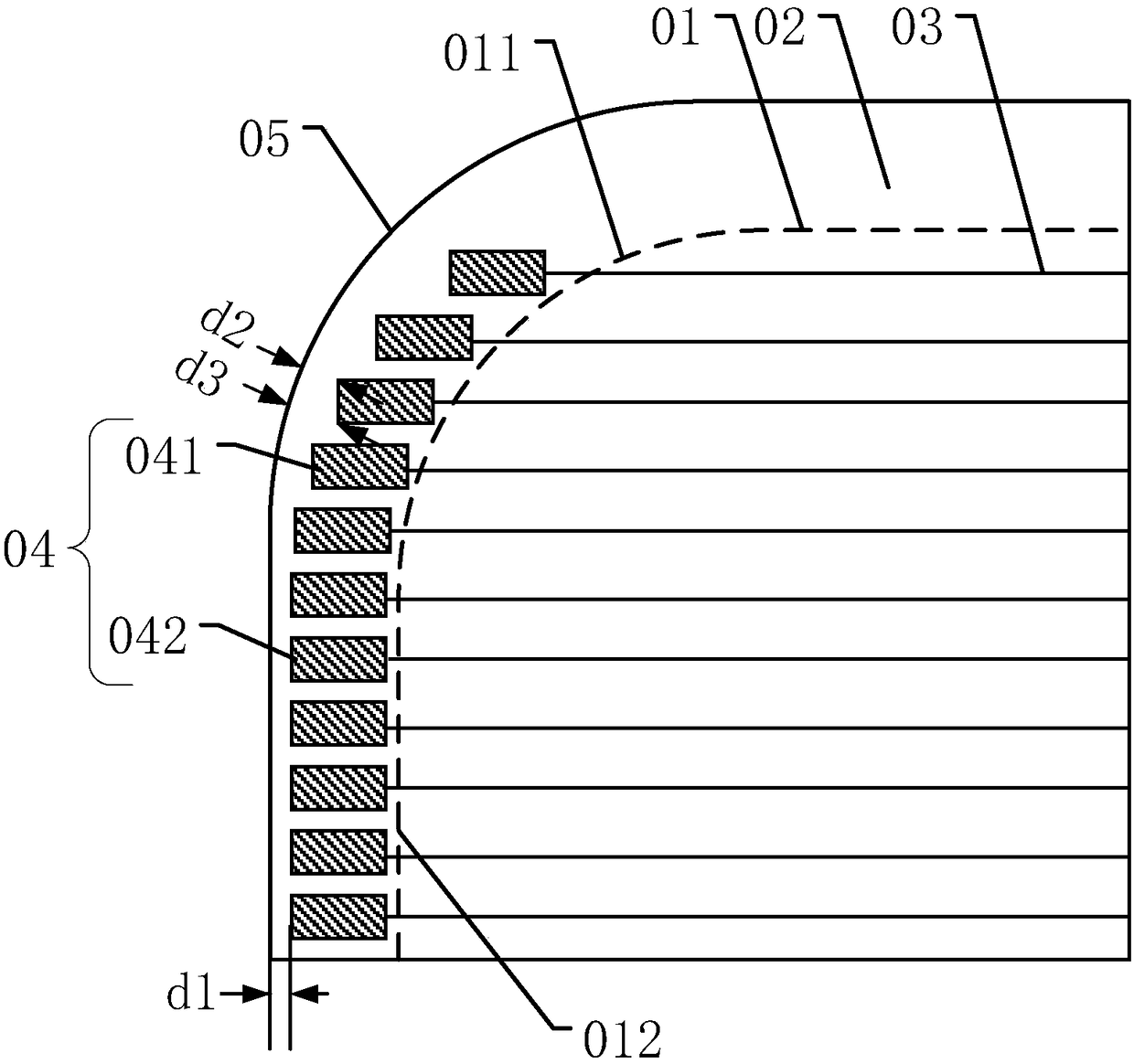

Array substrate, display panel and display device

ActiveCN108573682AReduce the amount of changeSmall difference in performanceStatic indicating devicesSolid-state devicesData linesDisplay device

The invention discloses an array substrate, a display panel and a display device and belongs to the display technology field. A display area and a non-display area are included. The display area comprises a plurality of gate lines which are extended along a first direction and a plurality of data lines which are extended along a second direction. The array substrate comprises at least one segmentof special-shaped edge. The non-display area comprises a plurality of shifting registers. The shifting registers comprise a plurality of transistors. The plurality of transistors comprise sensitive transistors and non-sensitive transistors. The plurality of shifting registers comprise at least one first shifting register. The first shifting register is adjacent to the special-shaped edge. In the first shifting register, the channel direction of at least one sensitive transistor is parallel to the first direction or the second direction, and the channel direction of at least one non-sensitive transistor is intersected with the first direction and the second direction. Compared with the prior art, the uniformity of the thickness of the array substrate corresponding to a part of the non-display area where the first shifting register is located can be improved, and display quality is increased.

Owner:SHANGHAI AVIC OPTOELECTRONICS

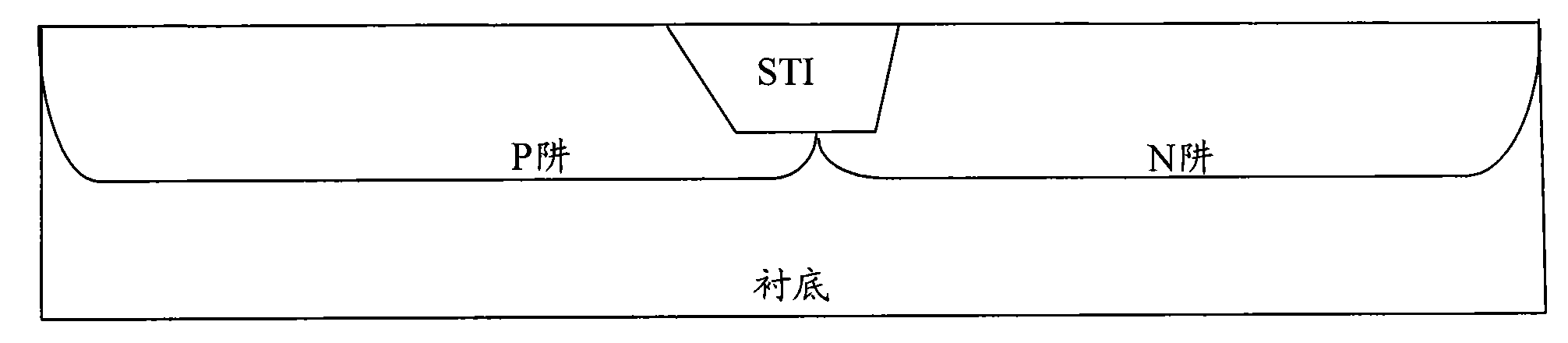

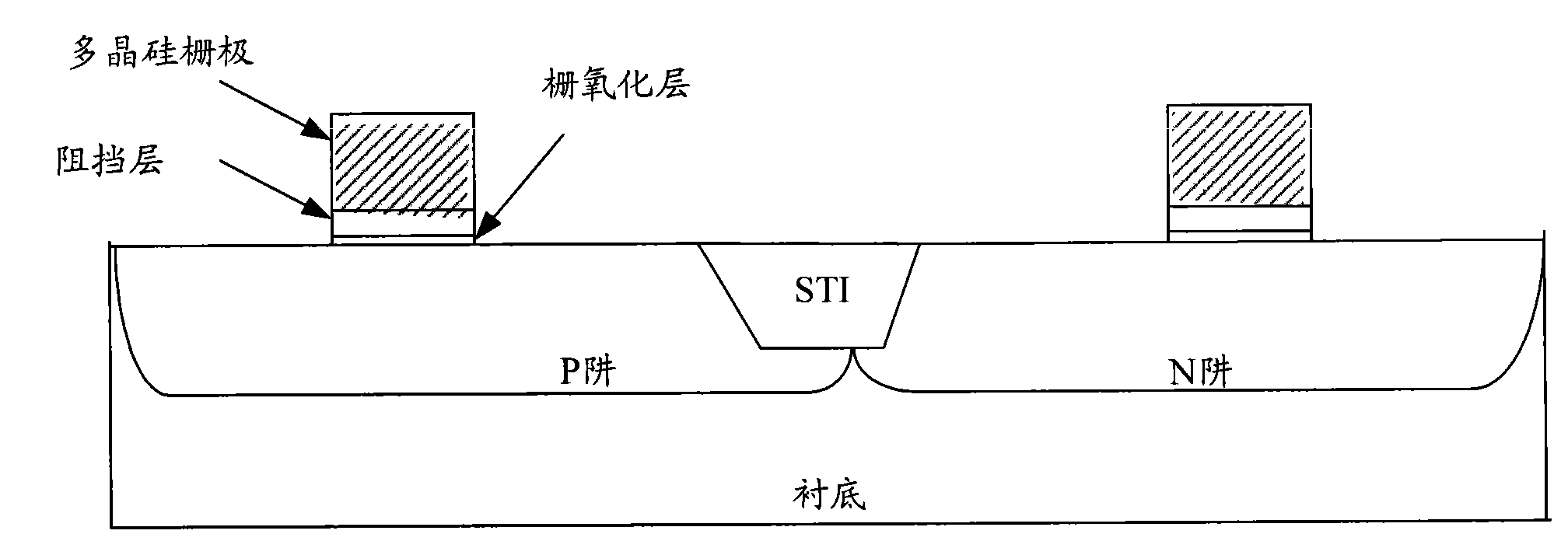

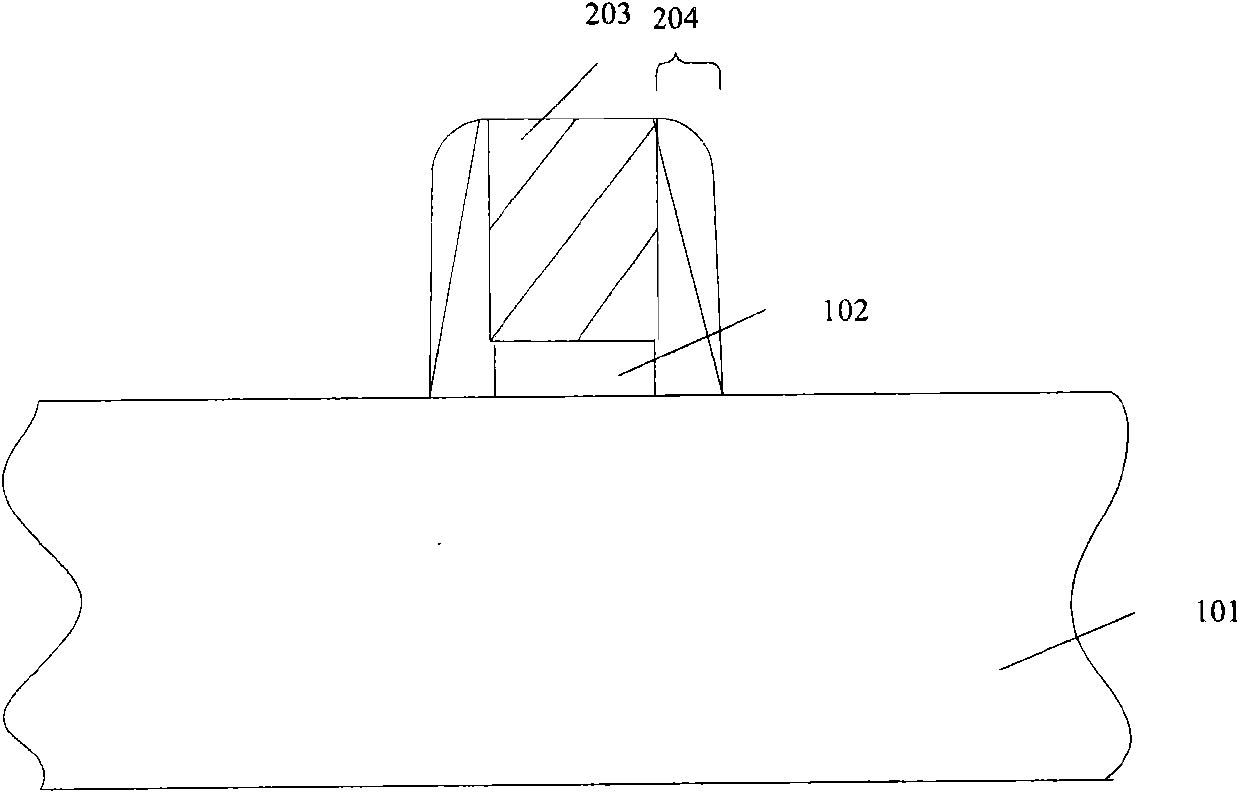

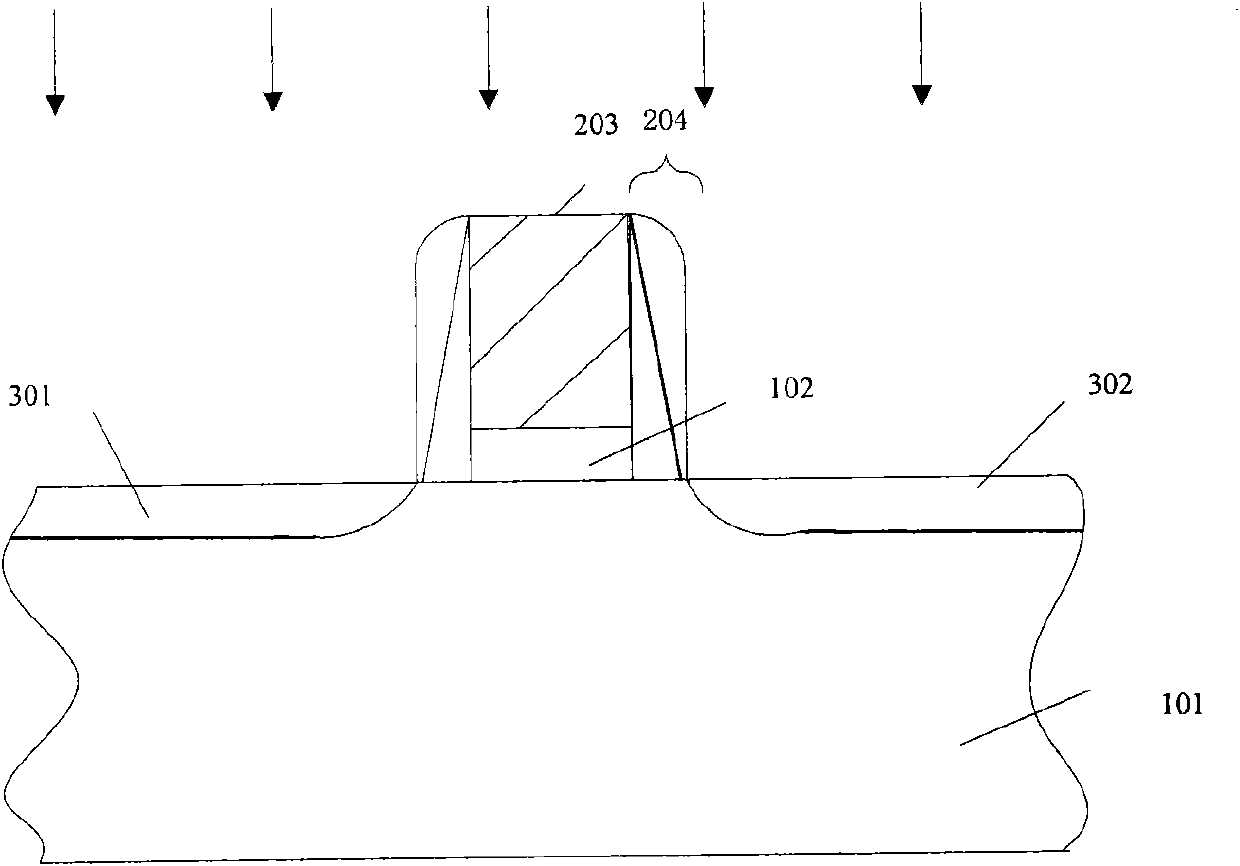

Method for manufacturing semiconductor device

InactiveCN102097382AImprove performanceSmall difference in performanceSemiconductor/solid-state device manufacturingSemiconductor devicesNitrideSemiconductor

The invention discloses a method for manufacturing a semiconductor device, which comprises the following steps of: forming a shallow trench isolation region for isolating an active region in a substrate; forming a high dielectric constant grid oxide layer, a titanium nitride blocking layer and a temporary polycrystalline silicon grid, sequentially positioned on the substrate, of an N-type metal oxide semiconductor (NMOS) tube and a P-type metal oxide semiconductor (PMOS) tube in the active region respectively; and then forming auxiliary side wall layers on two sides of the temporary polycrystalline silicon grids of the NMOS tube and the PMOS tube. The method can improve the performance of the semiconductor device and reduce the performance difference between the semiconductor devices at the same time.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

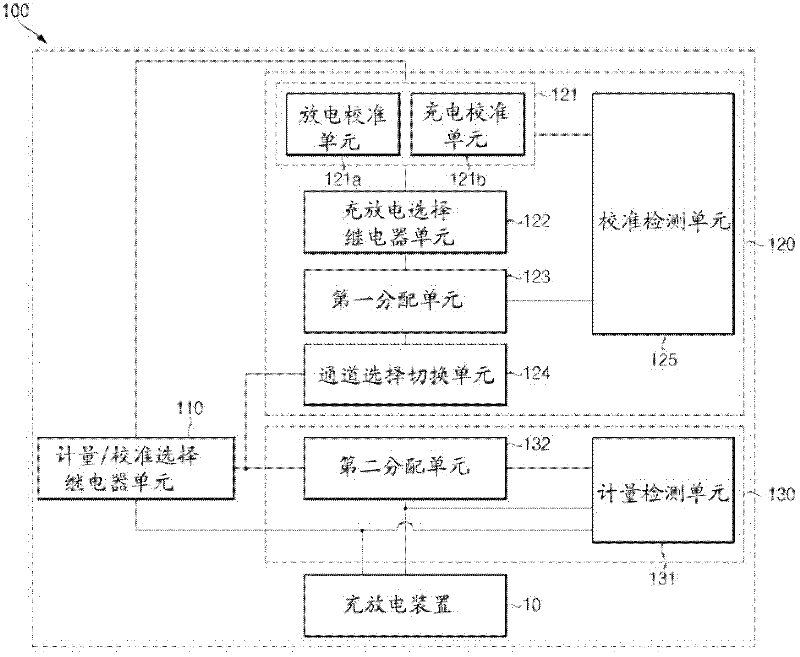

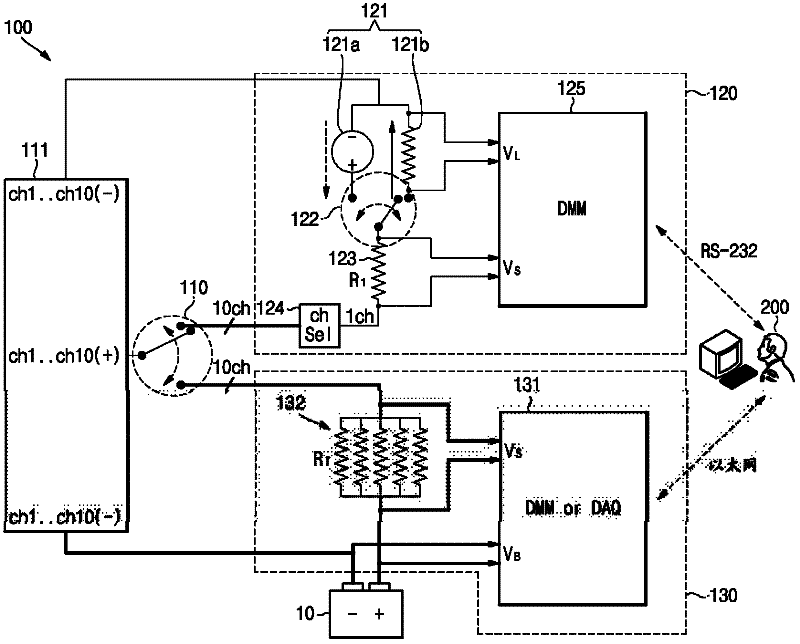

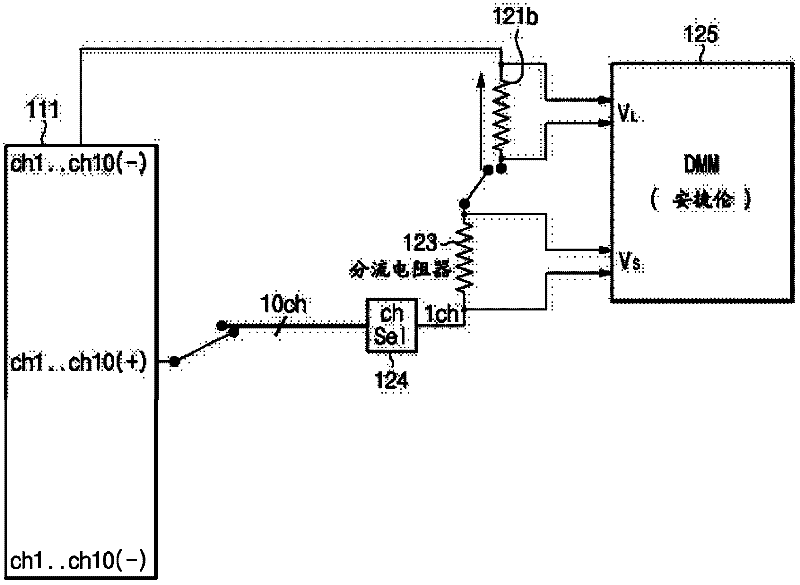

System for charging-discharging device of secondary battery

ActiveCN102638071AEasy CalibrationSimplify the calibration processDigital variable displayBatteries circuit arrangementsEngineeringCharge discharge

The present invention provides a system for charging-discharging device of a secondary battery, which comprises the following components: a charging / discharging device, a calibrating unit and a metering unit, thereby easily executing calibration operation of the charging / discharging device without individual battery tray. In one embodiment, the system comprises the following components: the calibrating unit which is used for calibrating charging / discharging function of the charging / discharging device, the metering unit which is used for measuring charging / discharging function of the charging / discharging device, and a metering / calibrating selection relay unit which is provided between the calibrating unit and the metering unit and switches calibration operation of the calibrating unit or metering operation of the metering unit.

Owner:SAMSUNG SDI CO LTD

Extra thick quenched and tempered steel plate for ocean platform tooth bar and production method thereof

The invention which belongs to the technical field of steel concretely discloses an extra thick quenched and tempered steel plate for an ocean platform tooth bar and a production method thereof. The extra thick quenched and tempered steel plate for the ocean platform tooth bar comprises the following components, by weight, 0.14-0.18% of C, 0.15-0.35% of Si, 0.95-1.30% of Mn, equal to or less than0.015% of P, equal to or less than 0.005% of S, 2.35-2.55% of Ni, 0.35-0.55% of Cr, 0.40-0.60% of Mo, 0.020-0.050% of Nb, 0.010-0.030% of Ti, 0.020-0.045% of total Al, and the balance Fe and inevitable impurities, and the thickness of the steel plate reaches 177.8mm. The extra thick quenched and tempered steel plate for the ocean platform tooth bar, which is prepared through carrying out steps ofsmelting by an electric furnace, steel ingot casting by a die, TMCP rolling, fully enclosed quenching and tempering by a well type heating furnace, and the like, has the advantages of high yield strength, good elongation, excellent Z-directional performance, good low temperature impact toughness, good layered tearing resistance, and low production cost.

Owner:WUYANG IRON & STEEL +1

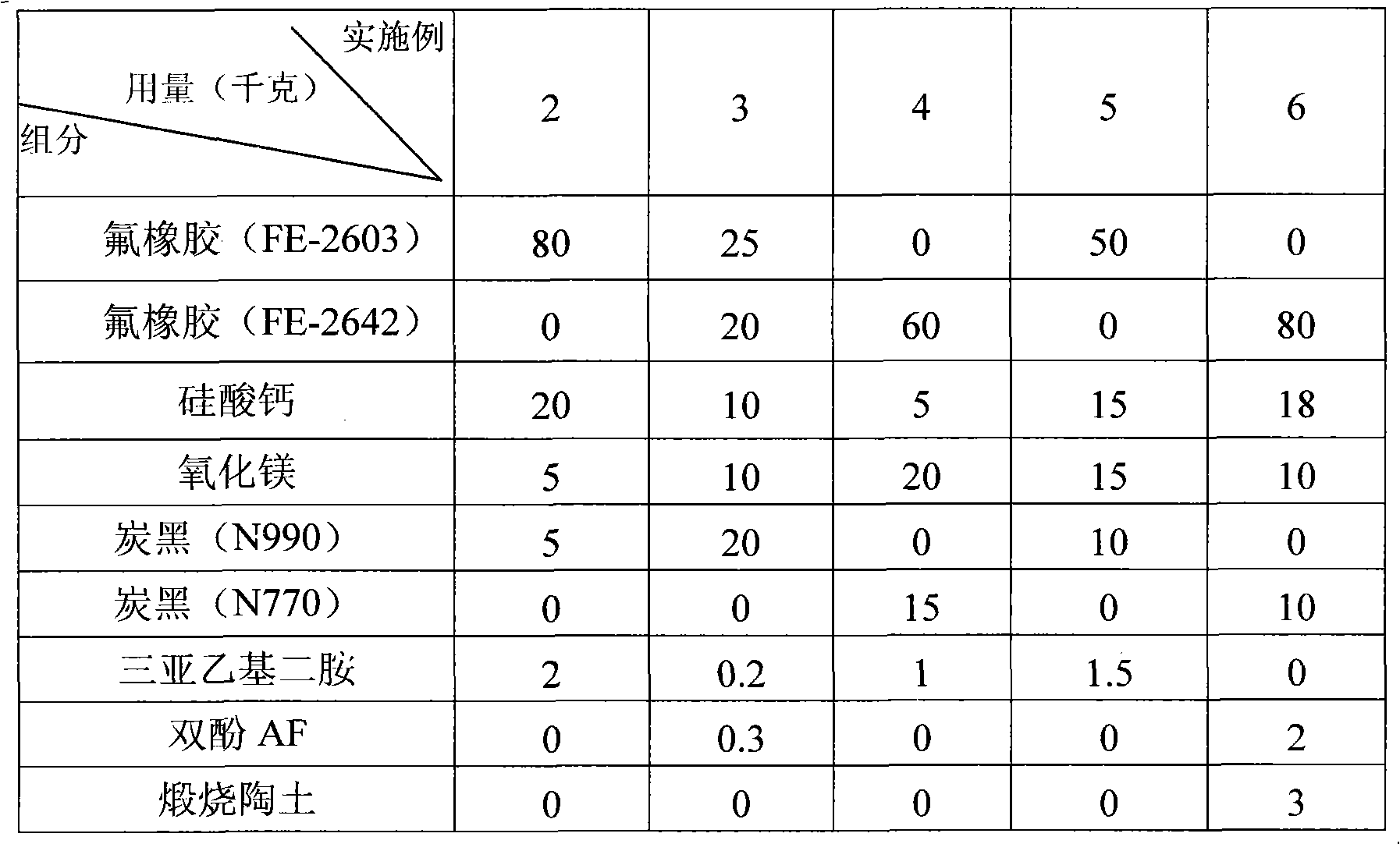

Fluoride rubber and plastic sealing material and preparation method thereof

ActiveCN101838430AHigh temperature resistantOil resistantOther chemical processesCalcium silicateCross-link

The invention discloses a fluoride rubber and plastic sealing material with good performance and low cost, and a preparation method of the rubber. The sealing material comprises the following raw materials in part by weight: 40-80 parts of fluorous rubber, 5-20 parts of calcium silicate, 5-20 parts of carbon black, 5-20 parts of magnesium oxide and 0.5-2 parts of cross-linking agent. The method comprises the steps of arranging the fluorous rubber in an internal mixer at the temperature of 150-160 DEG C with the plasticating time of 4min-10min, adding the carbon black, 1 / 3 of the magnesium oxide and 1 / 3 of the calcium silicate with the plasticating time of 6min-8min, then adding the rest magnesium oxide and calcium silicate, plasticating, stopping, overturning the warehouse to output the materials for spare use, arranging the materials in an open mill, adding the cross-linking agent at the temperature less than or equal to 65 DEG C, thinly introducing four times after material feed, packing with a triangular bag five times, and feeding plates.

Owner:河北鑫科新材料科技有限公司

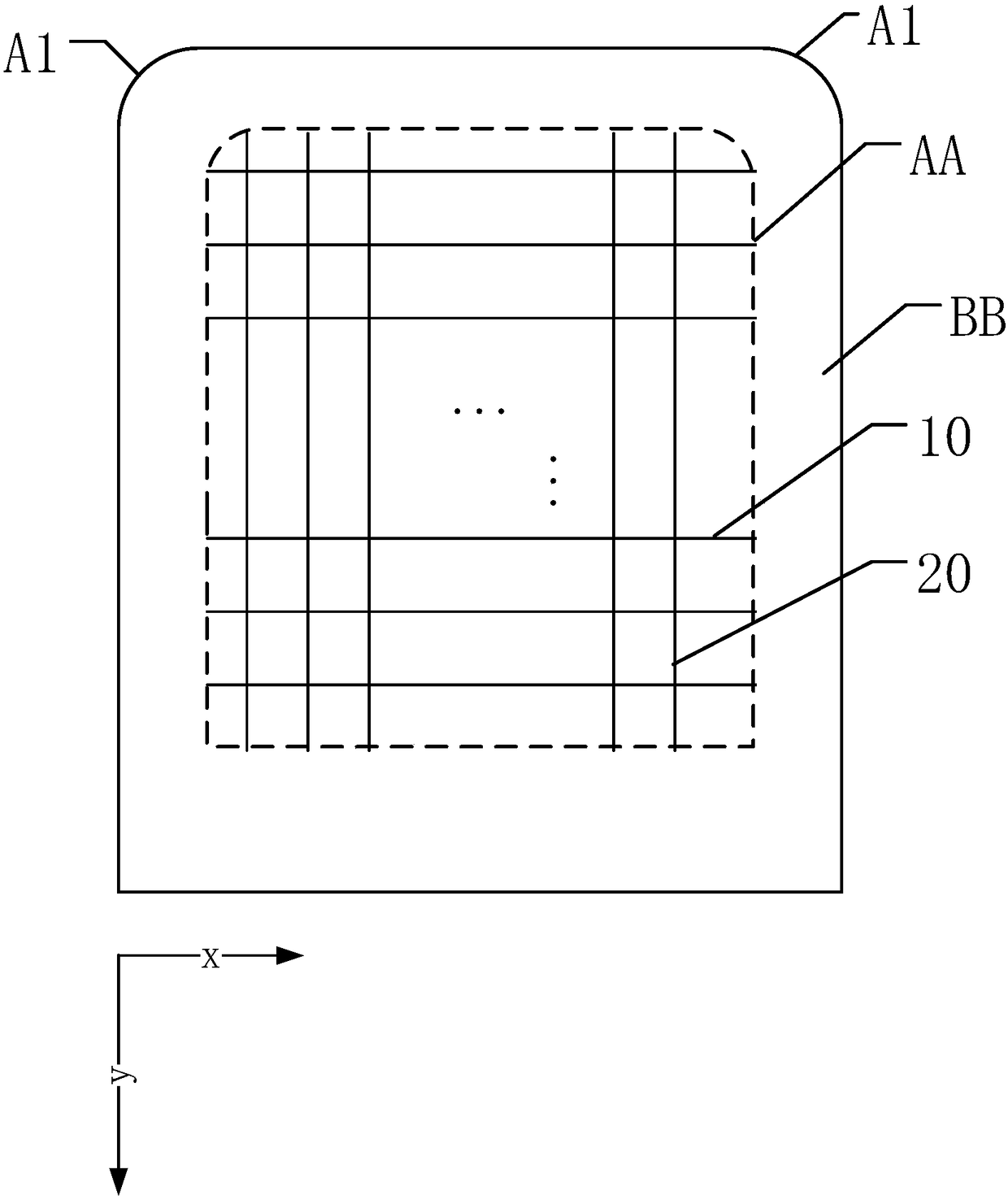

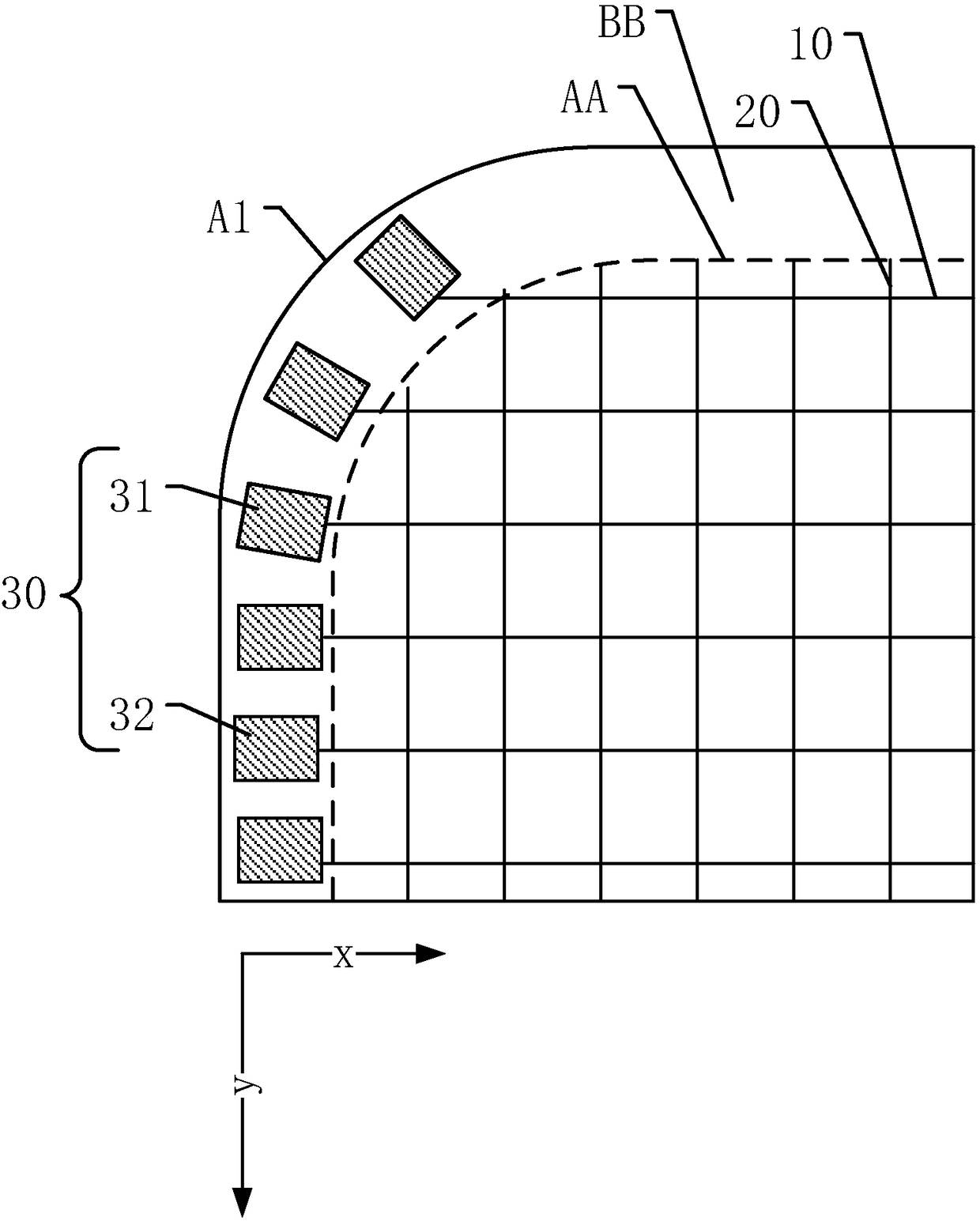

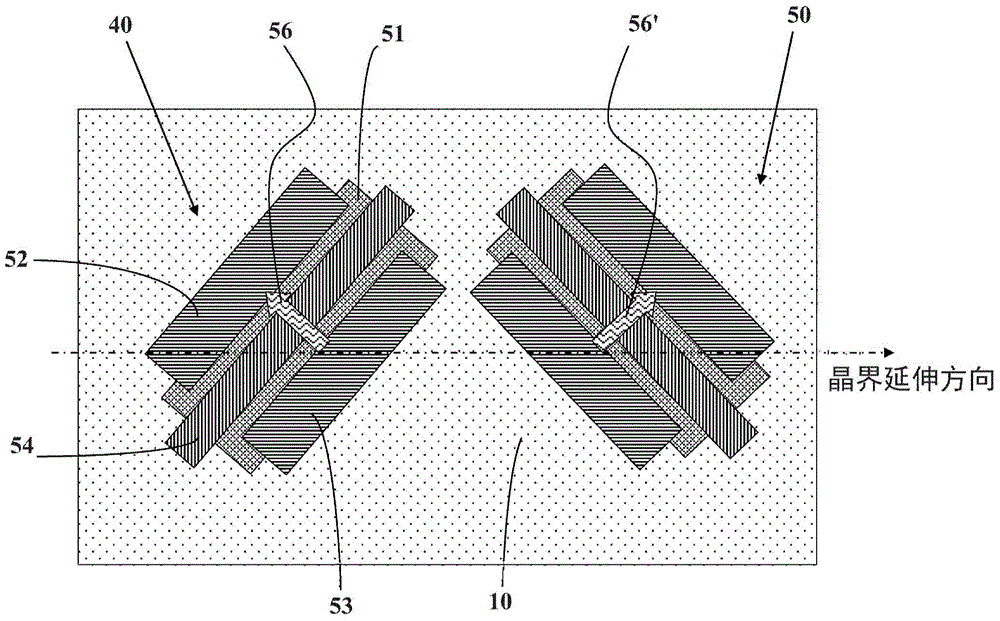

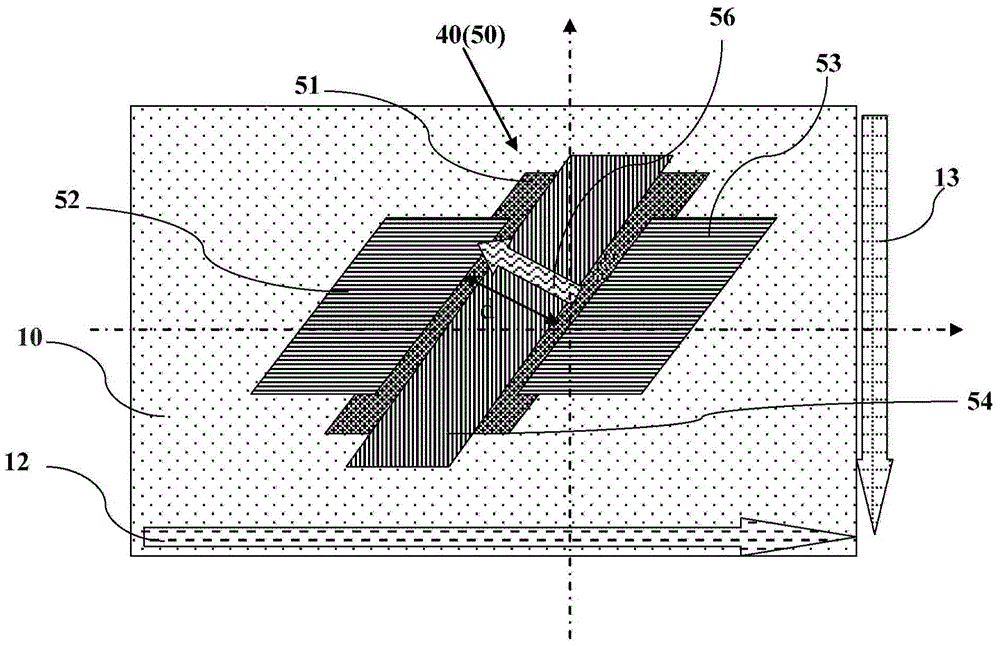

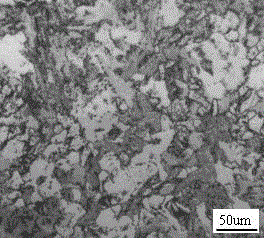

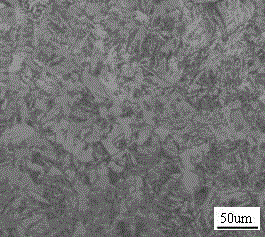

Array substrate, manufacturing method of array substrate and display device

ActiveCN104465673ASmall difference in performanceThe difference in the effect of reducing electron mobilityTransistorSolid-state devicesPower flowDisplay device

The invention discloses an array substrate, a manufacturing method of the array substrate and a display device. The array substrate comprises a substrate body, a poly-Si thin film and multiple thin film transistors. The poly-Si thin film comprises multiple crystal boundaries extending in the same direction. The multiple thin film transistors comprise at least one thin film transistor with the channel current direction as the first direction and at least one thin film transistor with the channel current direction as the second direction. The first direction and the second direction are different. Each thin film transistor comprises a grid electrode, an active layer, a source electrode and a drain electrode, wherein the active layer is composed of the poly-Si thin film. The included angle between the first direction and the crystal boundary extending direction and the included angle between the second direction and the crystal boundary extending direction are not equal to 90 degrees. By reducing difference of influence of the crystal boundaries on the electronic mobility of the thin film transistors with the channel current in the first direction and the thin film transistors with the channel current in the second direction, performance difference of the two kinds of thin film transistors is reduced.

Owner:BOE TECH GRP CO LTD +1

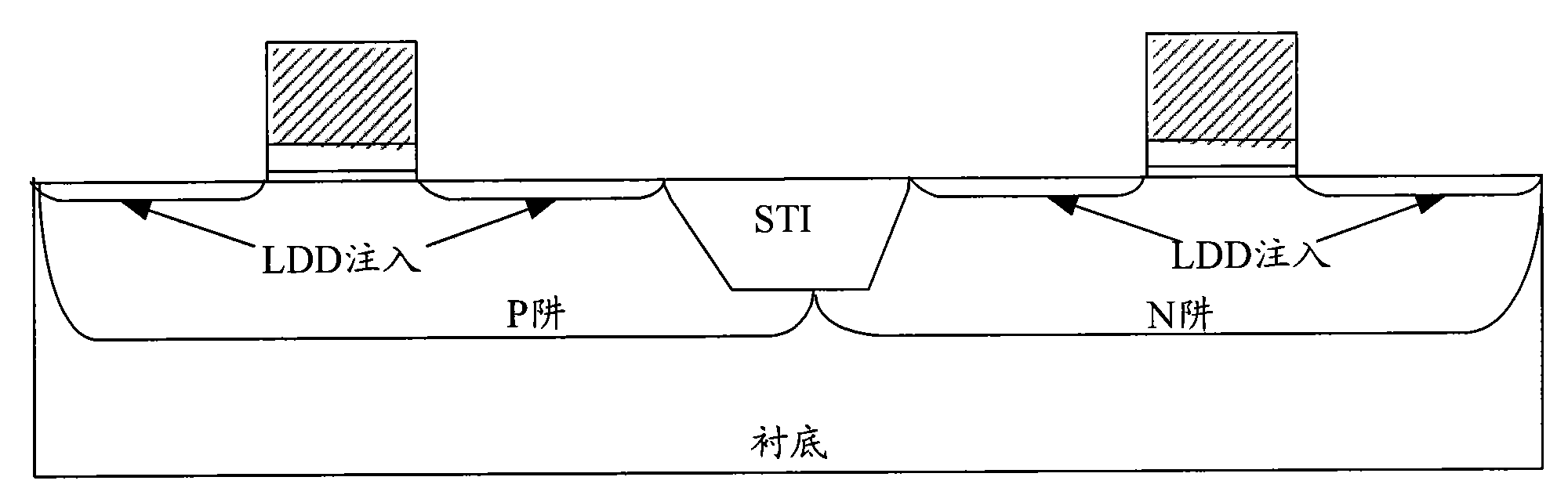

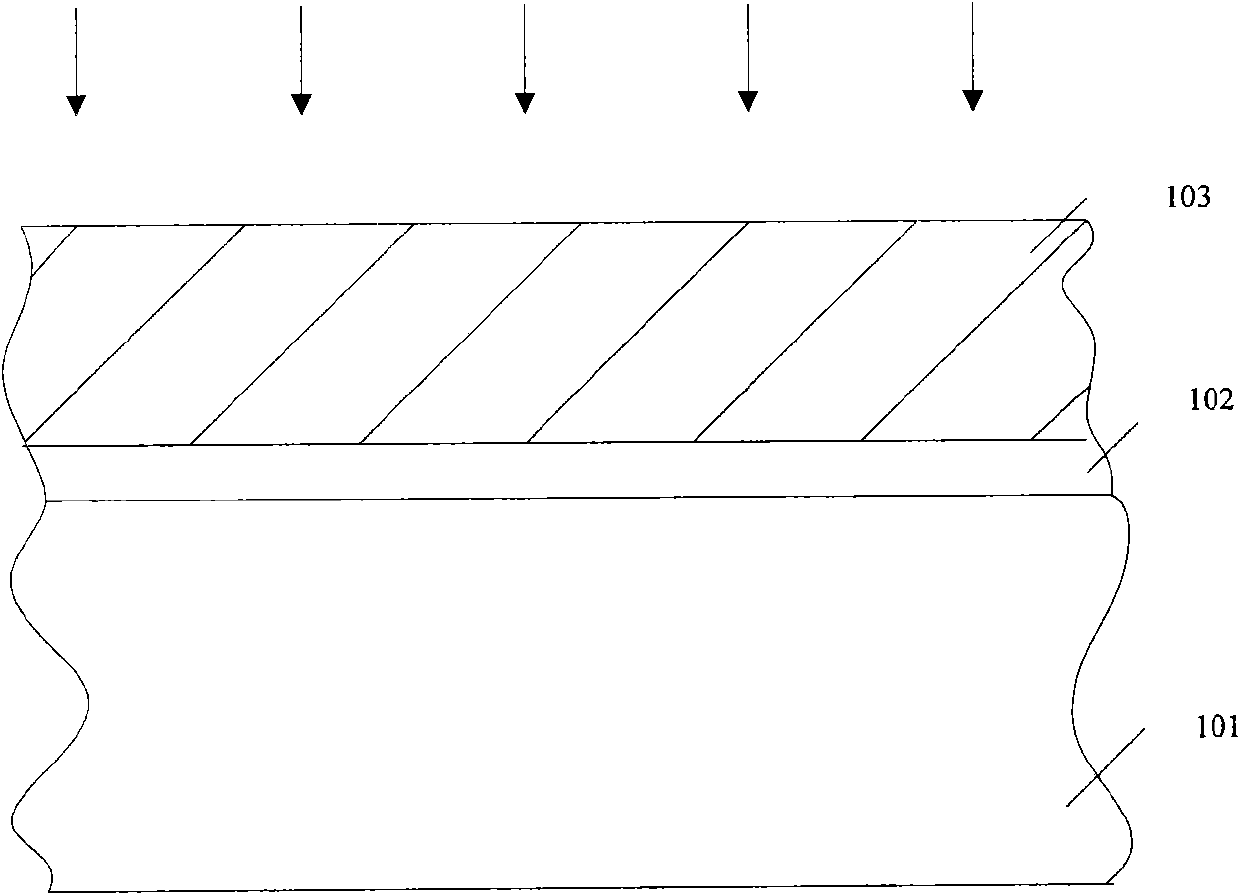

Doping method

ActiveCN102024703ASmall difference in performanceSemiconductor/solid-state device manufacturingIon beamSemiconductor

The invention discloses a doping method. The method comprises the following steps of: forming a grid electrode structure on a semiconductor substrate; forming side wall layers on the two sides of the grid electrode structure; adjusting an angle of an ion beam and keeping a fixed included angle between the ion beam and the vertical direction of the surface of the substrate; lightly or heavily doping the substrates on the two sides of a grid electrode by using half the preset ion injection dosage; turning a wafer for 180 degrees in the horizontal direction; and lightly or heavily doping the substrates on the two sides of the grid electrode by using half the preset ion injection dosage to form a lightly doped drain electrode and a lightly doped source electrode or drain electrode and source electrode. By the method, the performance difference of a semiconductor device can be reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Solidifing agent of modified like epoxy resins by alcyl amine

The invention is an alicyclic amine modified epoxy resin hardener, using aminomethyl cyclopentamine as material for modification. Its characteristic: it is synthesized of epoxy resin active diluting agents like aminomethyl cyclopentamine, alkyl alcohol glycidyl ether / organic acid glycidic ester, etc, and / or small molecular weight epoxy resin, and other raw materials. The hardener has moderate active hydrogen equivalent, low viscosity, and hardens at normal temperature, and the hardening course has the characters of low heat release, no toxic and excitive volatile, being uneasy to absorb moisture and blush, good compatibility with the epoxy resin, condensate with light colors and even colorless, etc, and it is an environmental protection hardener. It shows very good performance as used in self-leveling coating and ordinary floor coating, electronic sealing material, handicraft decoration, etc.

Owner:DALIAN UNIV OF TECH

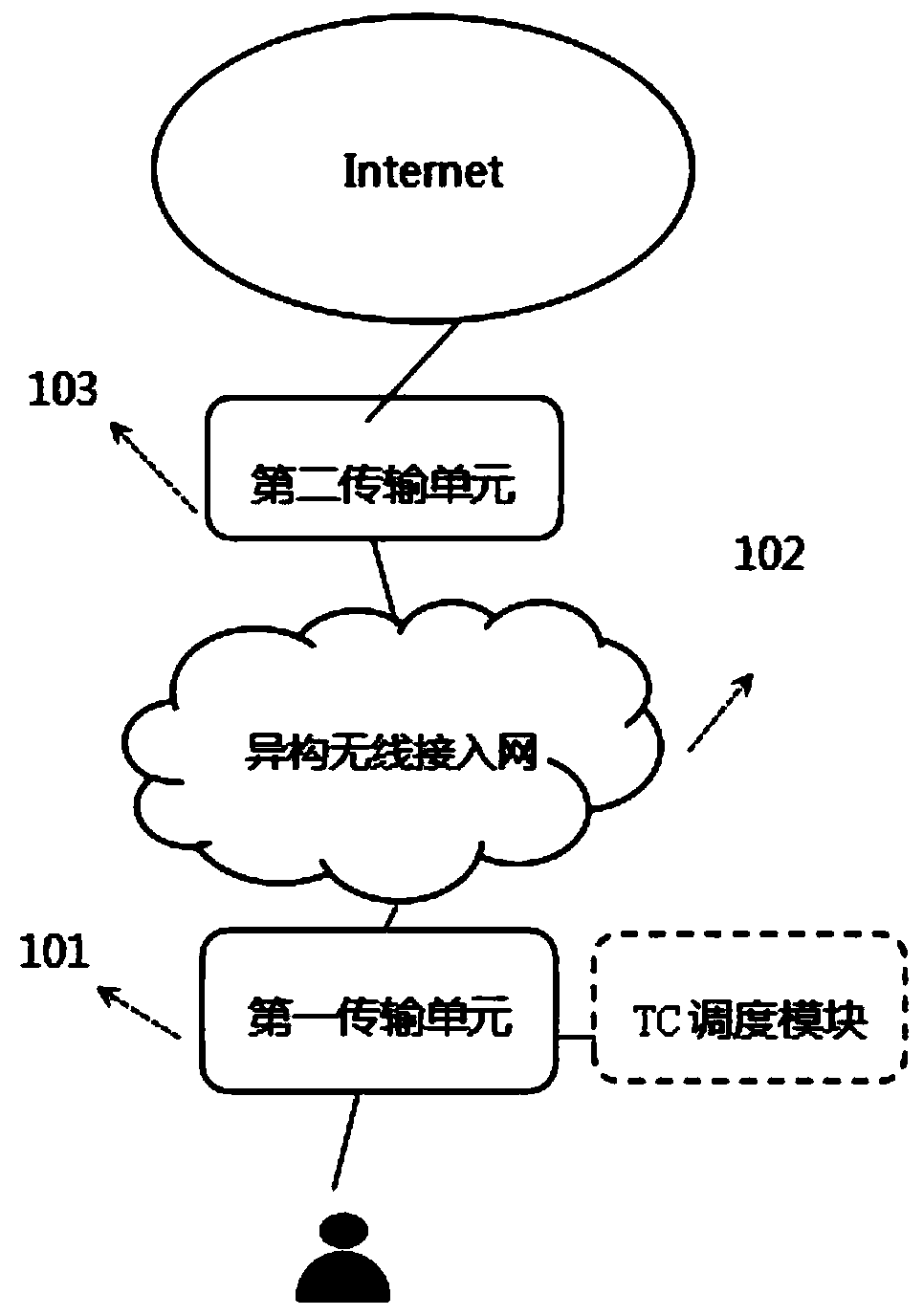

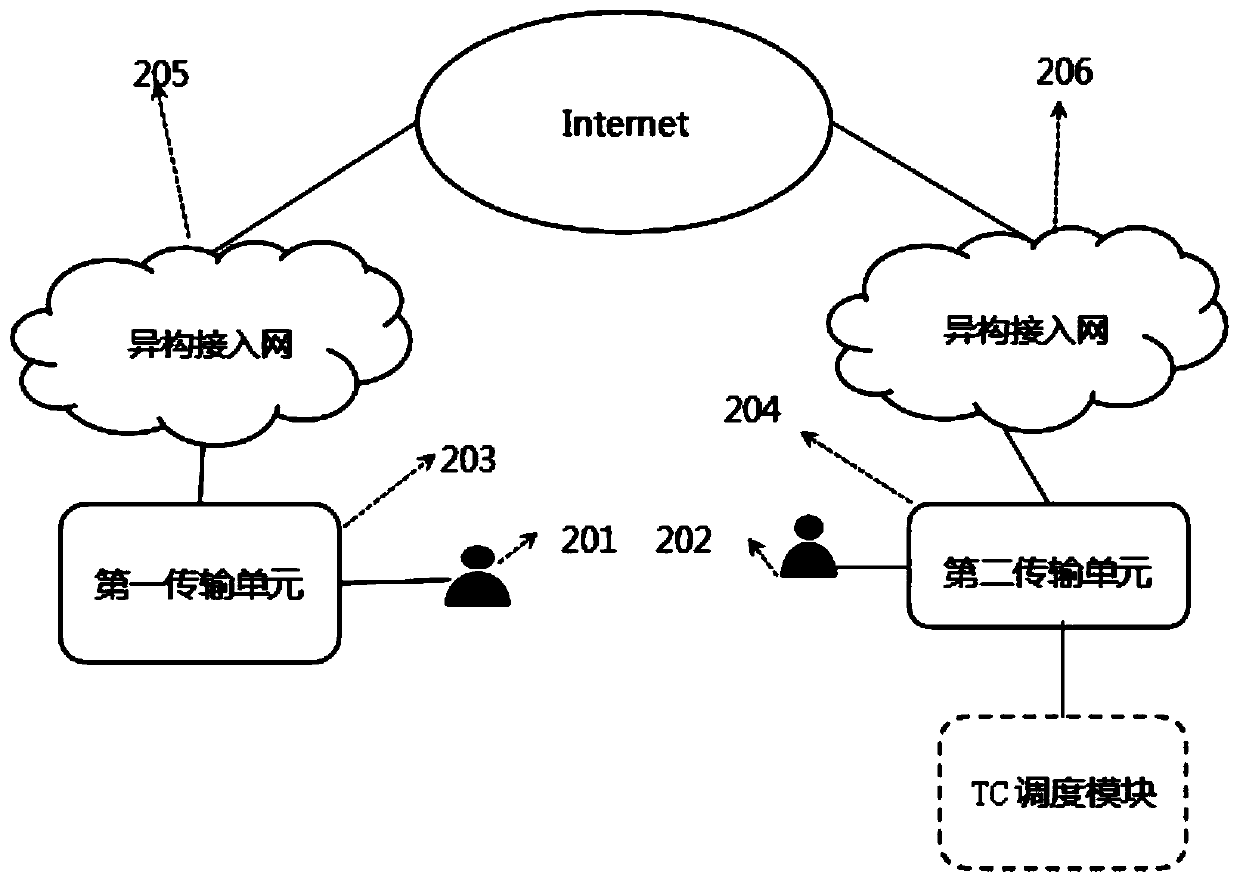

Multi-path cross-protocol transmission data packet scheduling method and system

ActiveCN110662256AImprove throughputImprove congestionNetwork traffic/resource managementConnection managementTransmission protocolData pack

The invention provides a multi-path cross-protocol transmission data packet scheduling method and system, and belongs to the technical field of communication. A first transmission unit is used as an intermediate device of a sending end. Asecond transmission unit is used as an intermediate device of a receiving end, and the first transmission unit and the second transmission unit are both configured with physical interfaces and transmission protocols for forwarding packets; after the transmission unit senses reachable information of the opposite end, a plurality of end-to-end links bound with the physical interface attributes are established; and the second transmission unit is configured with a virtual network loop or a physical port corresponding to the link, senses the time delay, the throughput and the congestion state of the link in real time, and adjusts the sending rate of the link, so that the customizable time delay of packet forwarding and the alignment of the sending rate arerealized. According to the invention, the performance difference between concurrent links is reduced, the disorder of data packets is reduced, the congestion of a cache region of a receiving end canbe prevented, and the overall throughput of a multi-path cross-protocol transmission system and the disorder of control data are improved on the premise of ensuring the safety.

Owner:BEIJING JIAOTONG UNIV

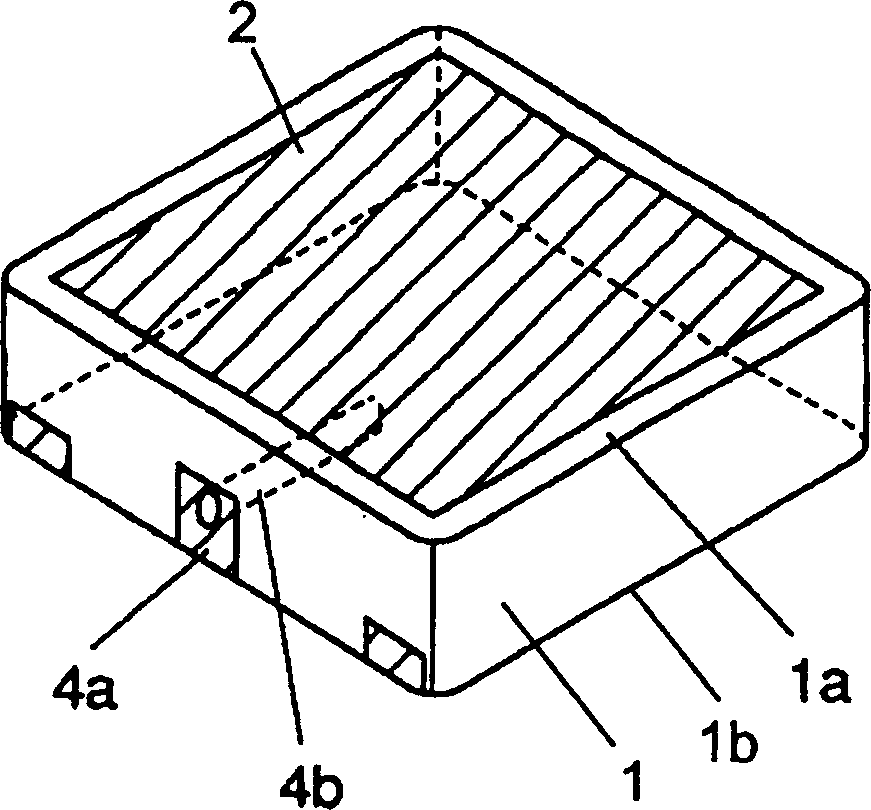

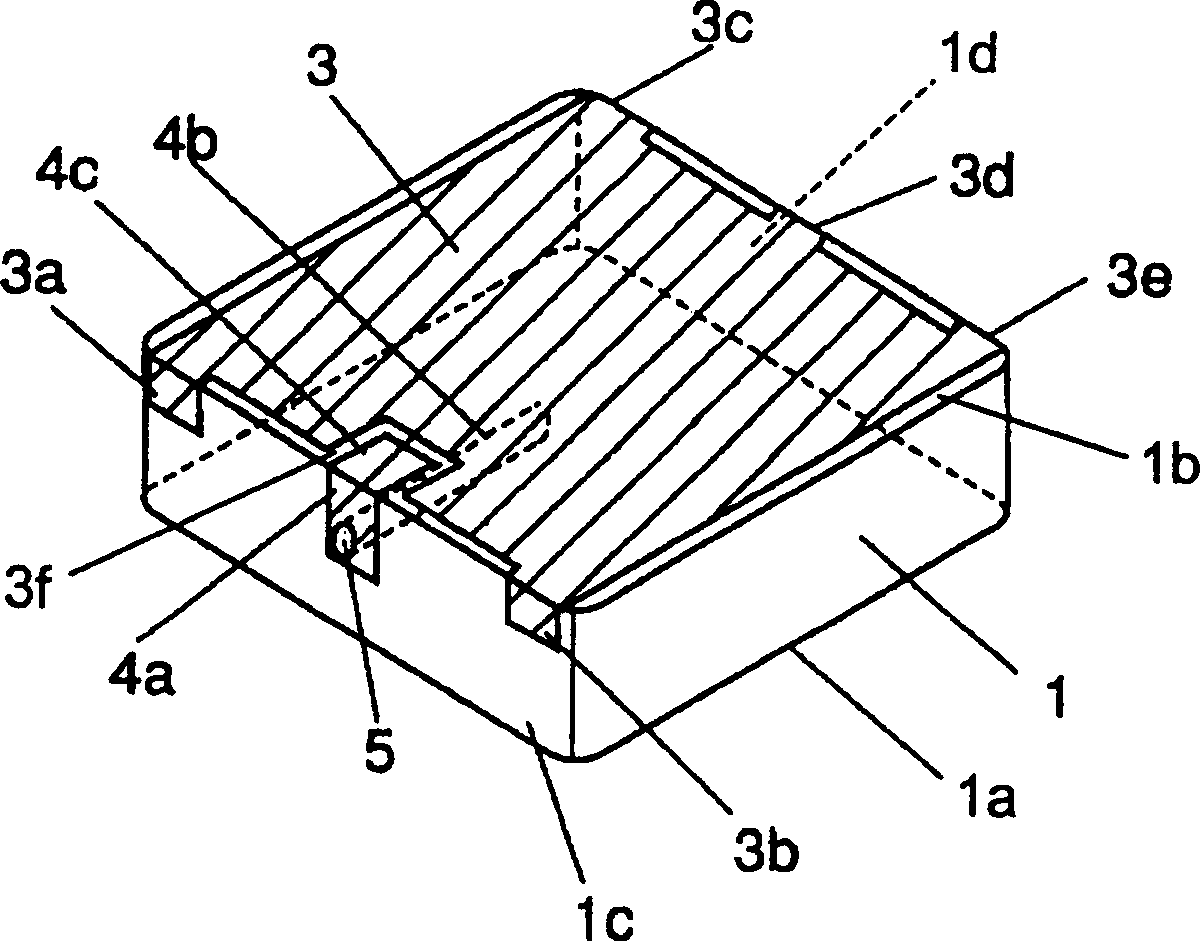

Surface mounting antenna, and mobile communication device using such antnena

InactiveCN1383344ASmall difference in performanceIncrease productivityAntenna supports/mountingsRadiating elements structural formsSurface mountingEngineering

The invention discloses a surface mount antenna and a mobile communication device using the antenna. The radiation electrode is provided on the first main surface of the substrate. The ground electrode is provided on the second main surface of the substrate. The first feeding electrode is provided on at least a part of the side surface and the second main surface of the substrate. The second feeding electrode is formed on the inner wall surface of the hole provided in parallel to the first and second main surfaces. The first feeding electrode and the ground electrode are kept in a non-contact state. The first feeding electrode is electrically connected to the second feeding electrode. A mobile communication device using such a surface-mounted antenna can be miniaturized, has little variation in performance, and has high production efficiency and reliability.

Owner:PANASONIC CORP

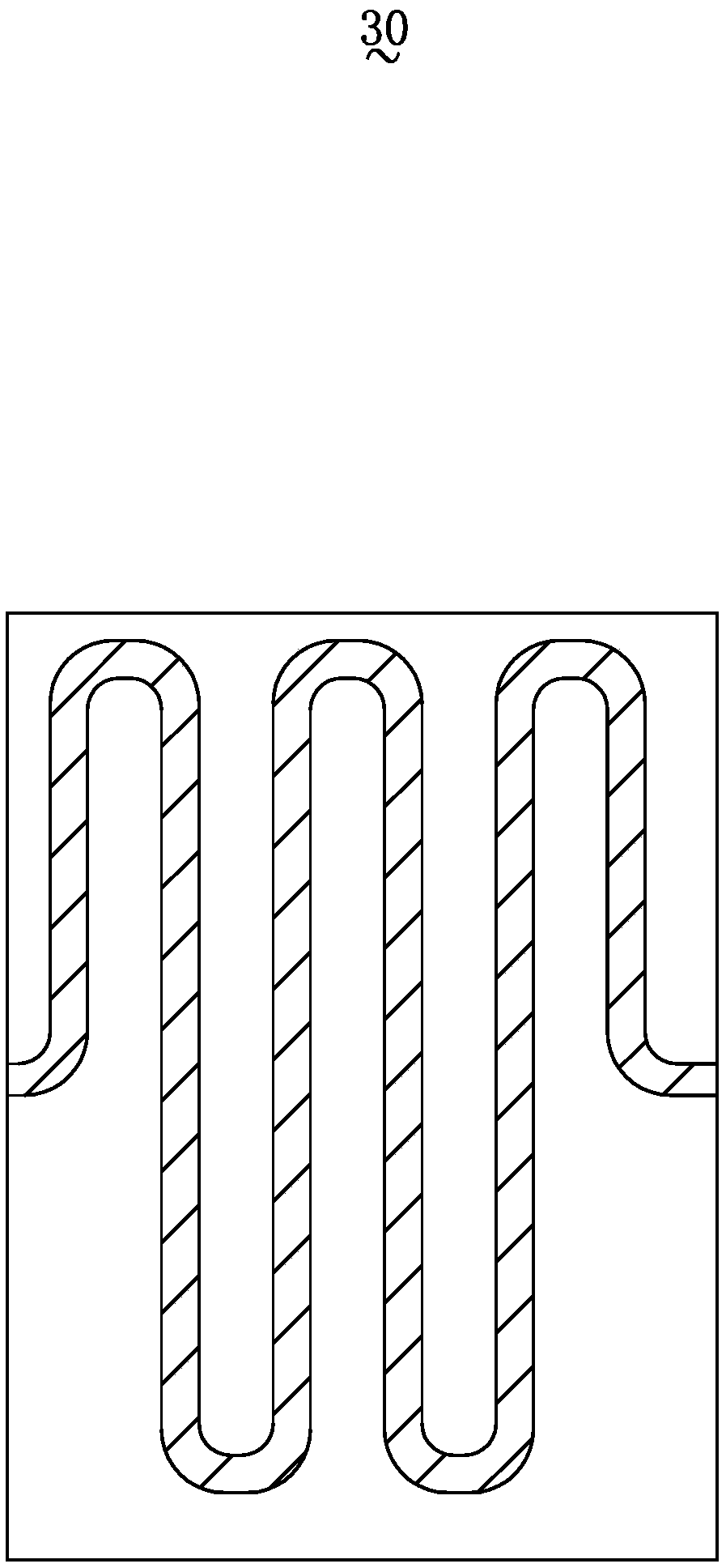

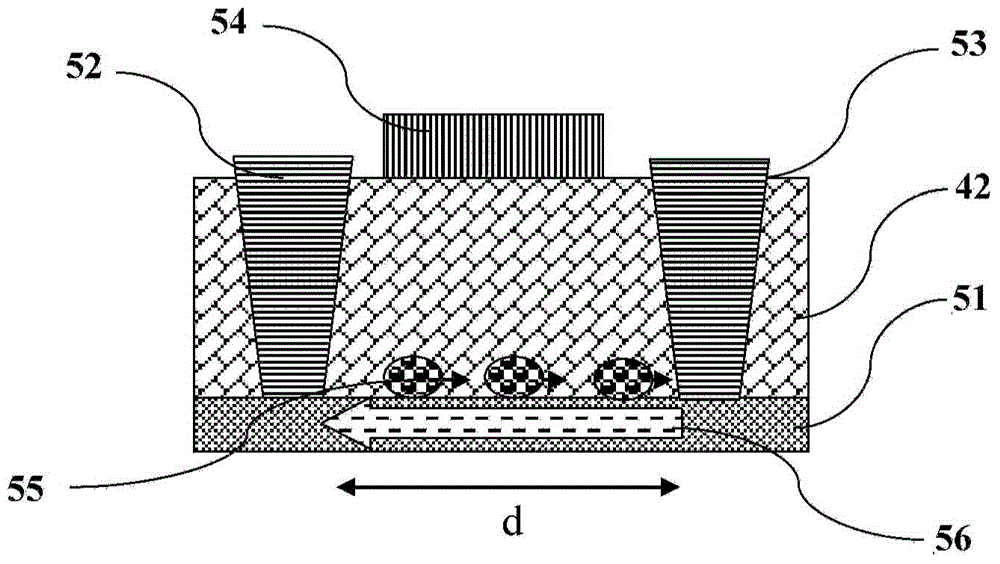

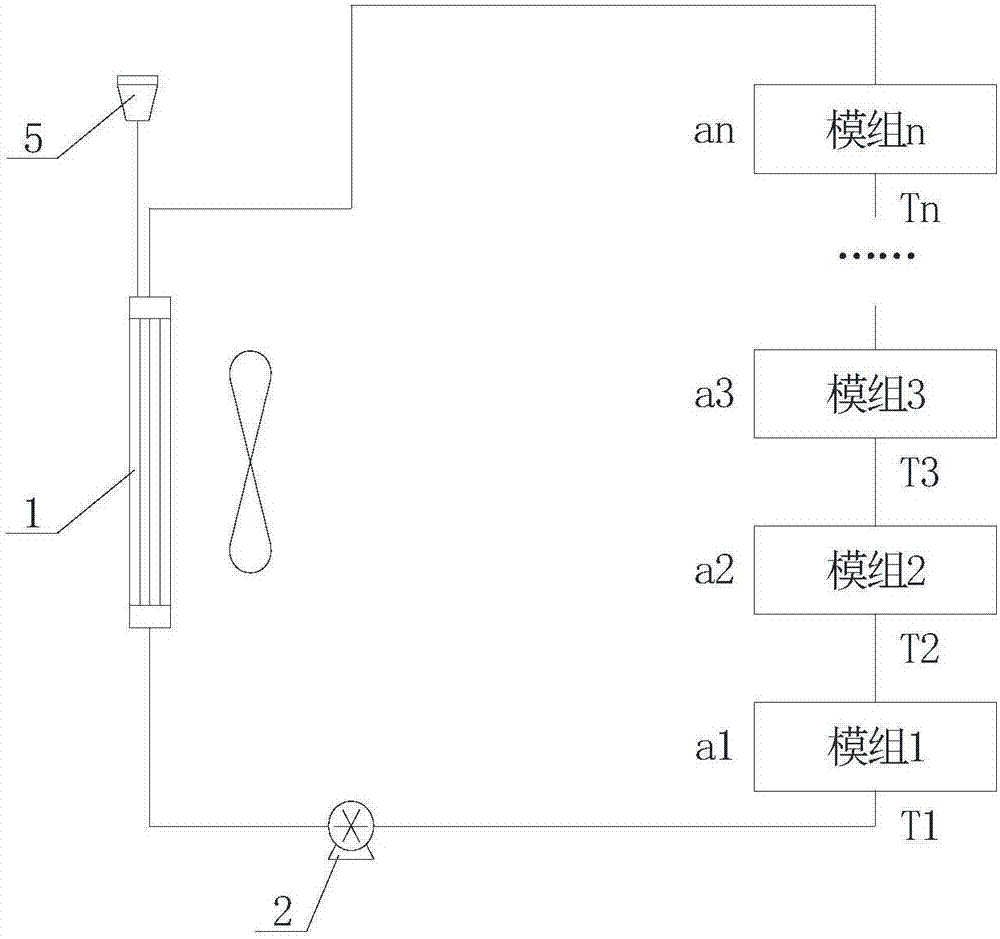

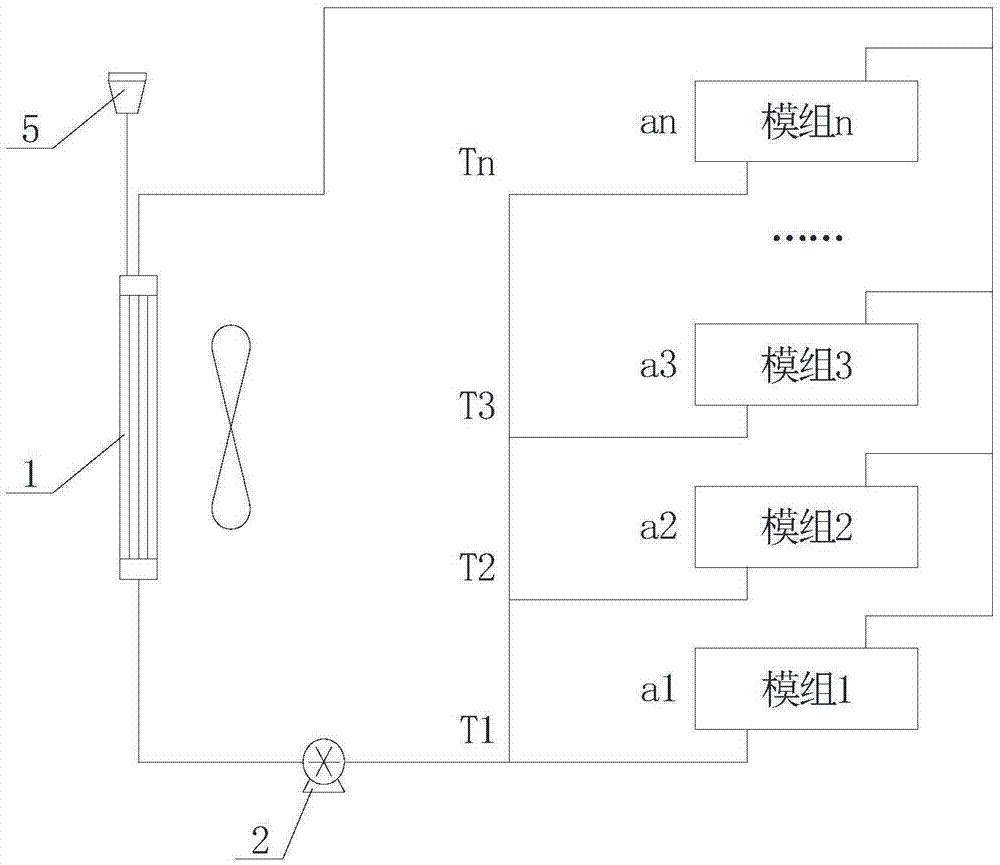

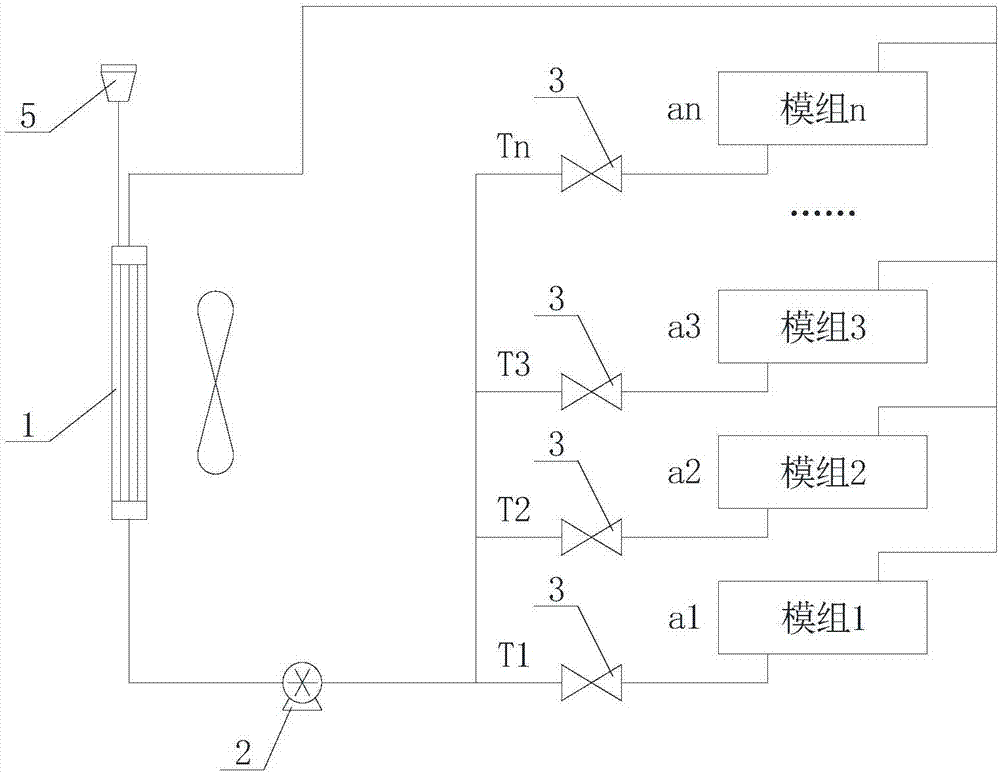

Flow sharing device and method of battery energy storage liquid cooling system

ActiveCN107403975AExtended service lifeSmall difference in performanceSecondary cellsCell component detailsElectrical batteryLiquid cooling system

The invention discloses a flow sharing device of a battery energy storage liquid cooling system, and solves the technical problems of non-ideal temperature equalization effect of the battery liquid cooling system in the prior art. The flow sharing device of the battery energy storage liquid cooling system comprises a plurality of groups of battery modules in parallel; each group of battery module is connected with the liquid cooling system and is provided with a cooling liquid input opening; a throttling pipe is arranged in the input opening; throttling holes are formed in the throttling pipe; the pressure of cooling liquid entering the input openings is regulated to be equal through the throttling pipe. The flow sharing device has the advantages that the liquid cooling system can more uniformly distribute cooling liquid flow among battery sub packs or modules, so that the battery system can be enabled to work at a more consistent environment temperature; the performance difference of the modules is reduced; the service life of the battery is prolonged.

Owner:JING JIN ELECTRIC TECH CO LTD

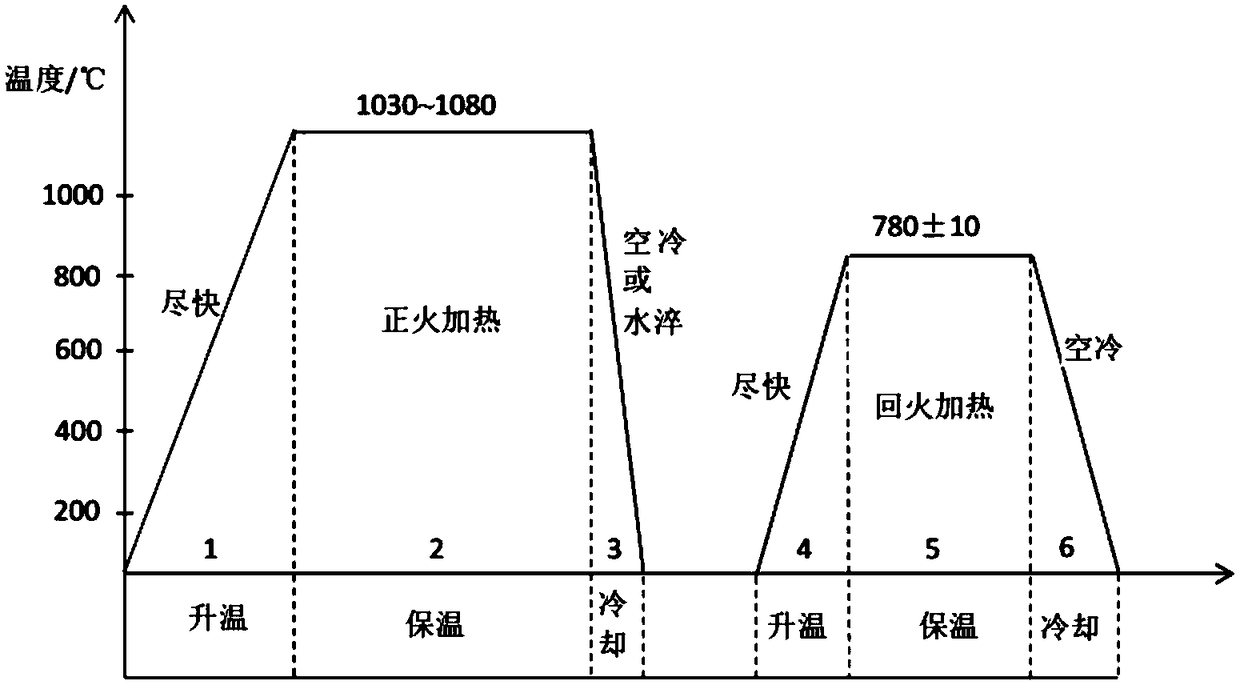

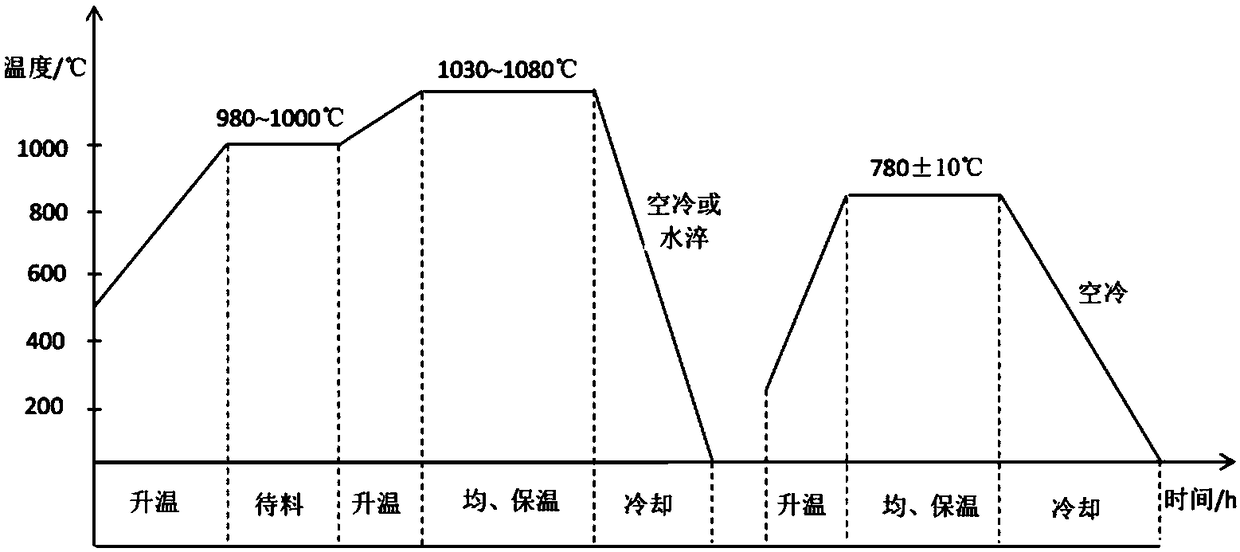

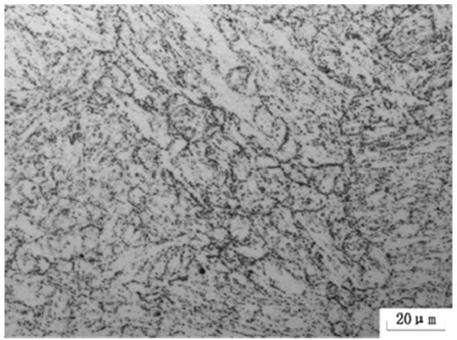

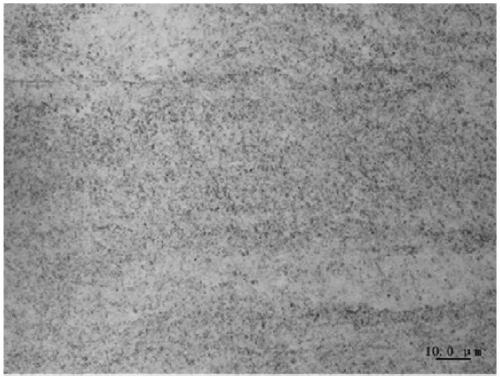

Method for improving radial structure and performance uniformity of G115 steel large-caliber thick-wall pipe

ActiveCN108950148AImprove radial temperature fieldImprove uniformityFurnace typesHeat treatment furnacesQuenchingCaliber

The invention discloses a method for improving radial structure and performance uniformity of a G115 steel large-caliber thick-wall pipe, and belongs to the technical field of steel materials. The process comprises the following steps of a normalizing system and a tempering system, wherein the normalizing system is characterized in that a tube blank subjected to hot-extrusion is adopted, chargingis carried out by using the temperature of 400-600 DEG C, warming is carried out with the heating speed of 100-120 DEG C / h until the temperature reaches 980-1000 DEG C, the hardening time is 0.5-1 min / mm, then warming is carried out with the heating speed of 130-150 DEG C until the temperature reaches 1030-1080 DEG C, then hardening is carried out, the hardening time is 0.5-0.8 min / mm, heat preservation is carried out for 1-3 hours after hardening, and air cooling or water quenching is carried out to the room temperature; and the tempering system is characterized in that charging is carried out by using the temperature less than or equal to 600 DEG C, warming is carried out with the heating speed of 120-150 DEG C / h until the tempering temperature reaches 780 + / - 10 DEG C, the time of heatpreservation is 3-5 hours, and air cooling is carried out to the room temperature. The method has the advantages that the radial temperature field of the thick-wall pipe is improved, moreover, the grain of the thick-wall pipe is not prone to coarsening, so that the radial structure and performance uniformity of the thick-wall pipe is greatly improved.

Owner:CENT IRON & STEEL RES INST

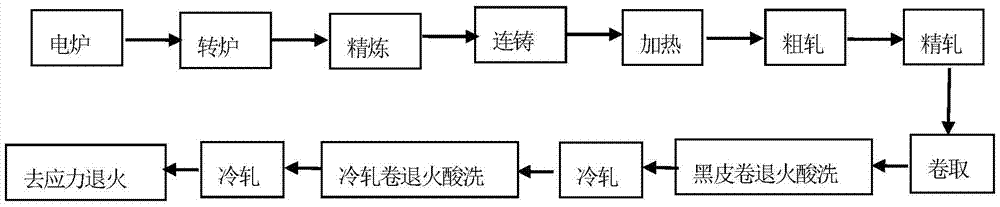

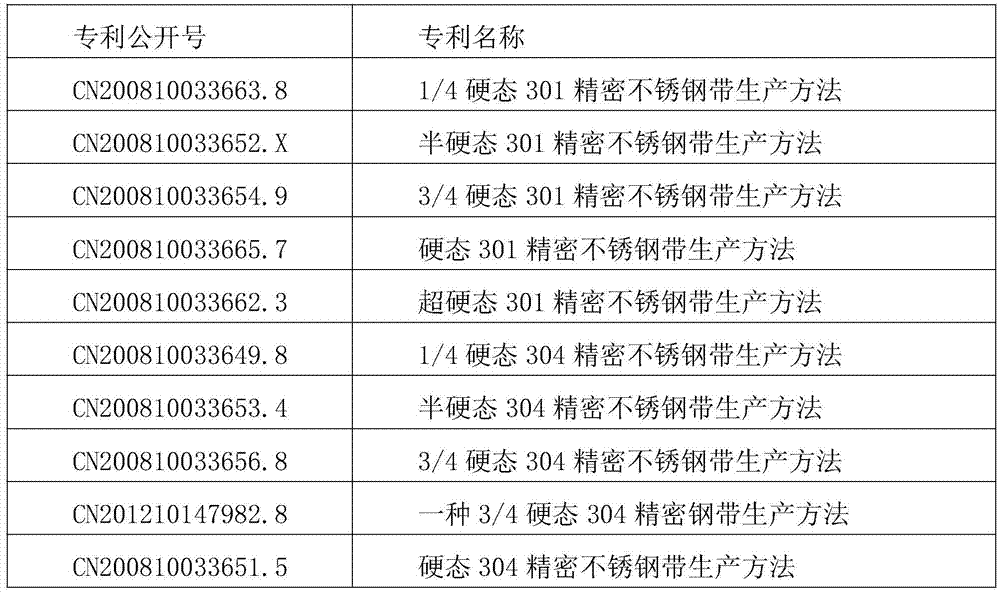

Hard austenitic stainless steel for conveyor and manufacturing method and application thereof

The invention provides a hard austenitic stainless steel for a conveyor and a manufacturing method and application thereof. The chemical compositions of the austenitic stainless steel comprises, by mass, 0.07%-0.10% of C, 1.0% or the less of Si, 2.0% or the less of Mn, 16.5%-17.5% of Cr, 6.5%-7.0% of Ni, 0.02%-0.04% of N, 0.4%-0.6% of V, 0.040% or the less of P, 0.01% or the less of S and the balance Fe and inevitable impurities. On the basis of the chemical compositions of common 301 stainless steel, a small quantity of V is added, the proportion of alloy components is optimized, and especially it is guaranteed that Nieq is 18.9-21, so that the fluctuation range of performance after same quenching-tempering and cold rolling process is reduced; and the total reduction ratio of quenching-tempering and cold rolling is reduced, the reduction ratio of single pass of cold rolling is reduced, and the condition is provided for improving of plate cut.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

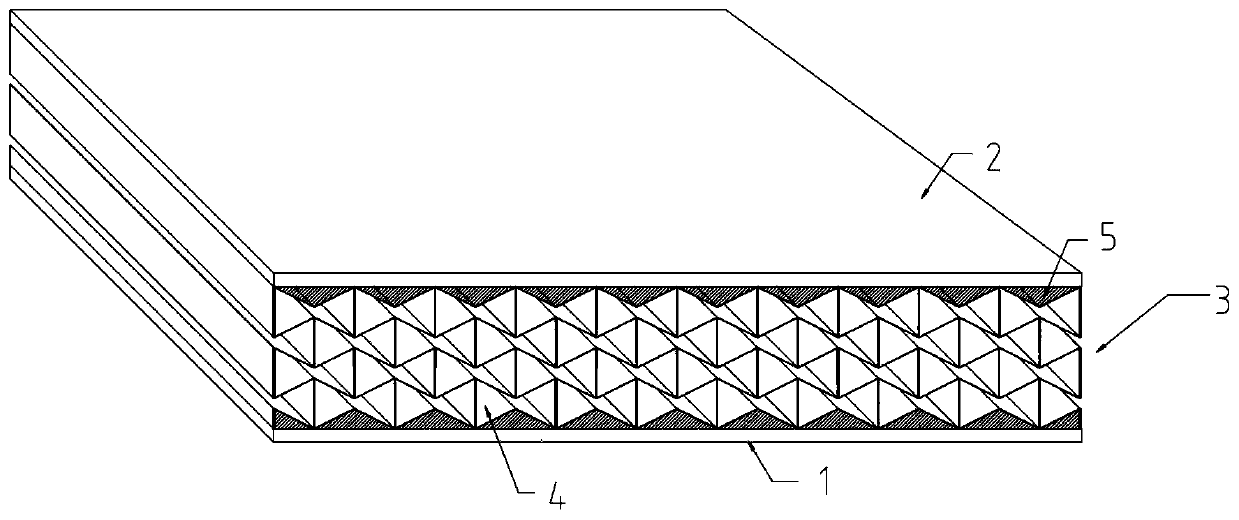

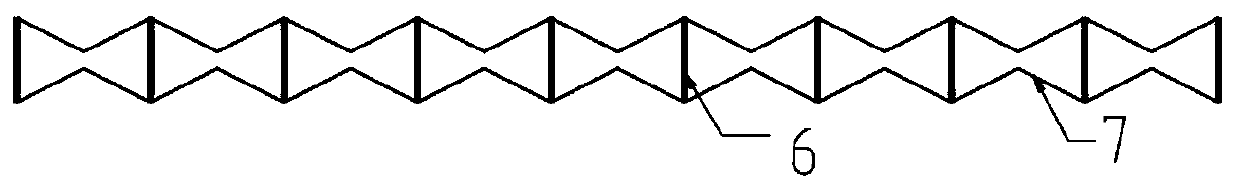

Sound insulation and noise reduction composite material and preparation method thereof

ActiveCN111114020AImprove sound insulation and noise reduction performanceHigh shear modulusLamination ancillary operationsSynthetic resin layered productsLoad resistanceSi substrate

The invention relates to the field of material science, and in particular, relates to a sound insulation and noise reduction composite material and a preparation method thereof. The sound insulation and noise reduction composite material comprises a base plate, a top plate and a sandwich layer located between the base plate and the top plate, wherein the sandwich layer is provided with a negativePoisson's ratio unit; the negative Poisson's ratio unit is mainly formed by alternately stacking and bonding a first negative Poisson's ratio unit and a second negative Poisson's ratio unit made of two different materials and having concave hexagonal structures. The sound insulation composite material has the negative Poisson's ratio unit, the sound insulation and noise reduction performance of the material can be improved, meanwhile, the shear modulus, the fracture resistance, the resilience toughness and the load resistance of the material are improved, and the application range of the material is greatly expanded.

Owner:上海众汇泡沫铝材有限公司

Distillation learning method and device, computer equipment and storage medium

PendingCN111898735AAchieve knowledge transferImproving Distillation LearningNeural architecturesNeural learning methodsNetwork onNetwork output

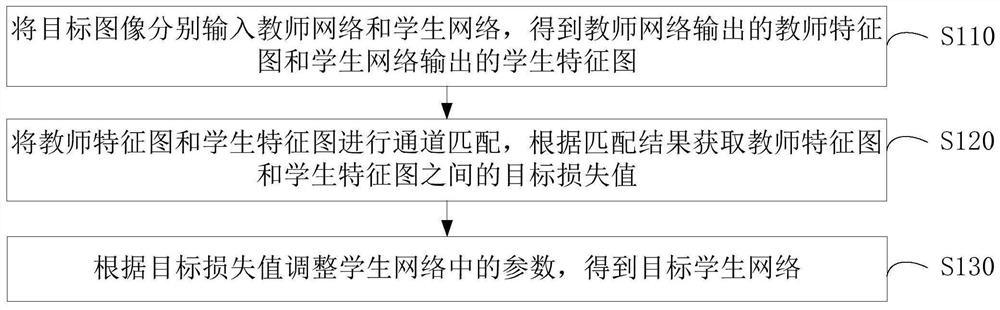

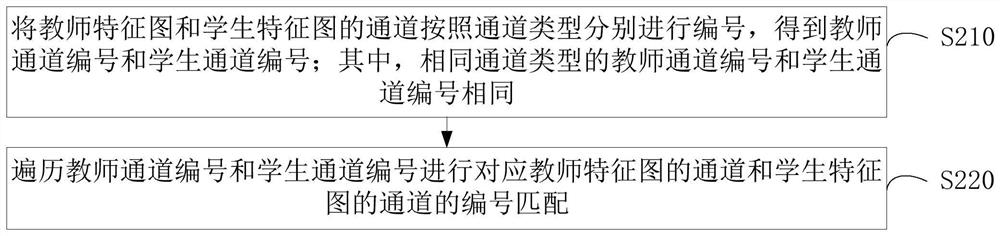

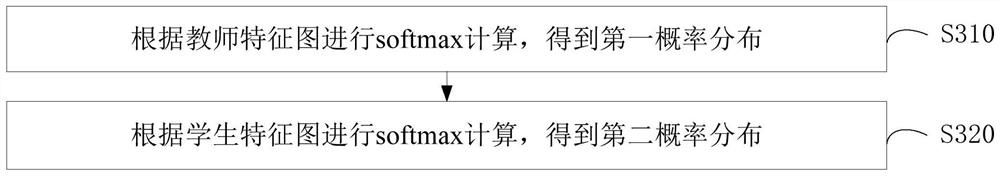

The invention relates to a distillation learning method and device, computer equipment and a storage medium. The method comprises the following steps: respectively inputting a target image into a teacher network and a student network to obtain a teacher feature map output by the teacher network and a student feature map output by the student network; performing channel matching on the teacher feature map and the student feature map, and obtaining a target loss value between the teacher feature map and the student feature map according to a matching result; and adjusting parameters in the student network according to the target loss value to obtain a target student network. By adopting the method, the distillation learning effect of the student network on the teacher network can be improved, and the performance difference between the student network and the teacher network is reduced.

Owner:上海眼控科技股份有限公司

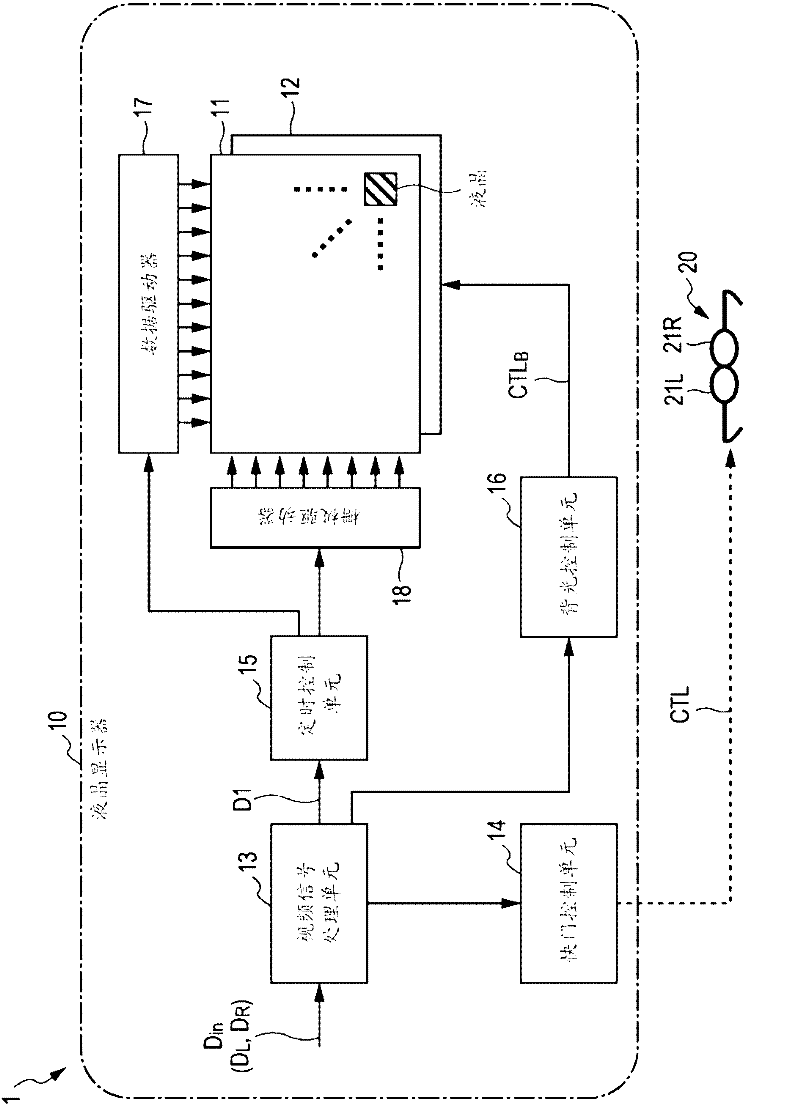

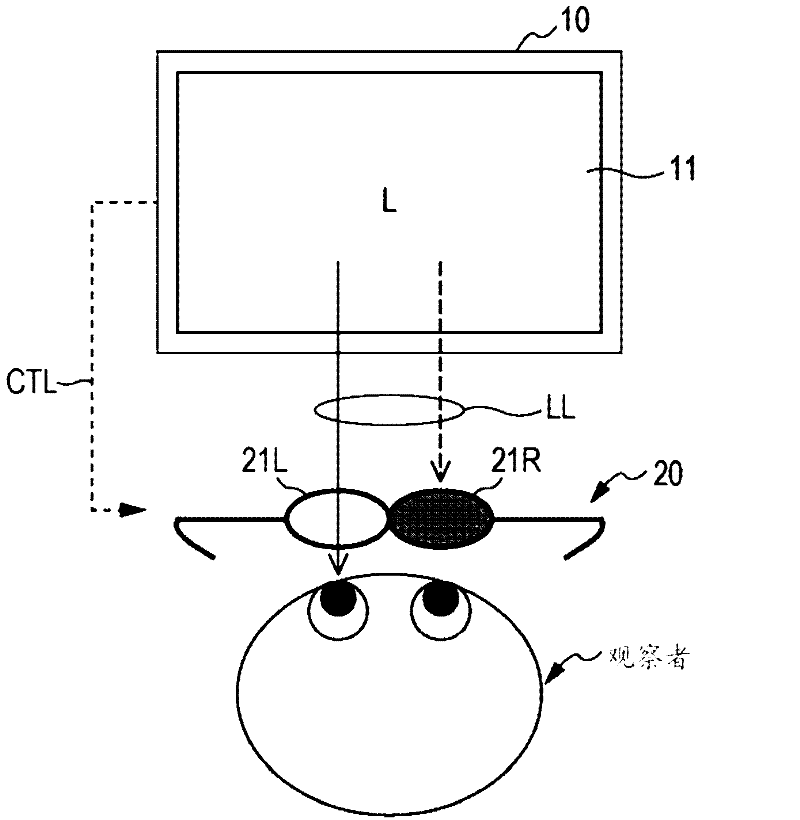

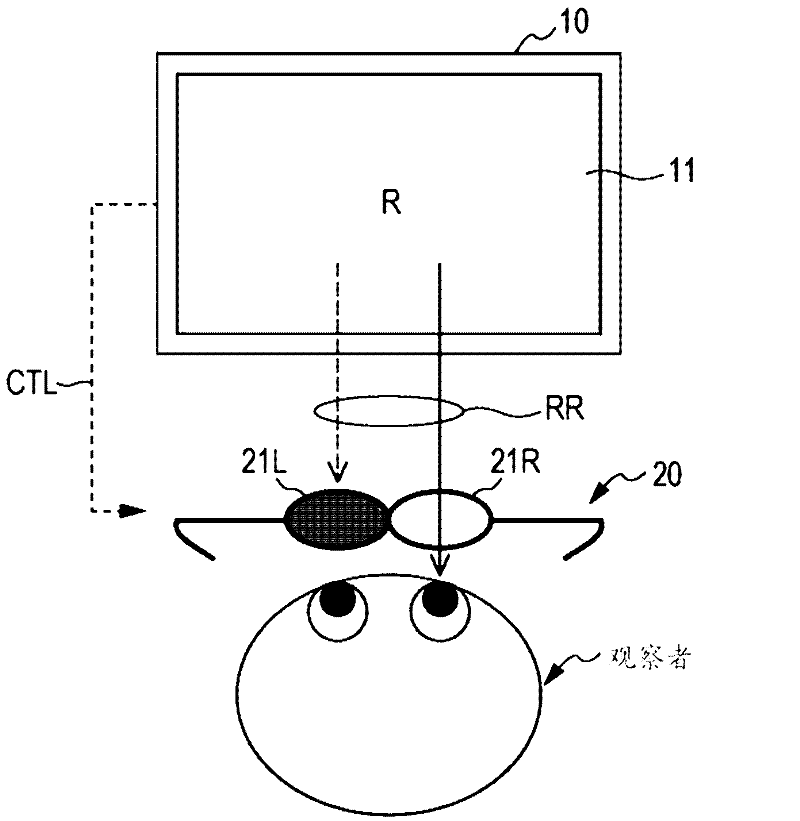

Video signal processing device, video signal processing method, and computer program

InactiveCN102263969AReduce processingReduce harmful effectsStatic indicating devicesSteroscopic systemsStereoscopic videoHistogram

A video signal processing device, a video signal processing method, and a computer program. The video signal processing device comprises: a histogram detection unit, which detects the histogram of the brightness distribution of any one of the left-eye video signal and the right-eye video signal in the input stereoscopic video signal; the gamma curve calculation unit, based on the histogram detection The histogram detected by the unit calculates a gamma curve; and a gamma curve output unit corrects the left eye video signal and the right eye video signal based on the gamma curve calculated by the gamma curve calculation unit.

Owner:SONY CORP

Calcium chloride hexahydrate phase change energy storage material and preparation method therefor

InactiveCN105086947AAdjustable phase change temperatureReduce subcoolingHeat-exchange elementsCalcium Chloride HexahydratePhase change

The invention relates to a low-temperature phase change energy storage material, particularly an energy storage material comprising CaCl2.6H2O and a preparation method therefor. The energy storage material is shinyleaf yellowhorn shell loaded salt hydrate CaCl2.6H2O which is prepared by mixing shinyleaf yellowhorn shells with salt hydrate, wherein CaCl2.6H2O exists in the shinyleaf yellowhorn shells in form of dispersed minute particles. The energy storage material provided by the invention has the advantages that the CaCl2.6H2O energy storage material has the characteristics of regulated phase change temperature, high thermal cycling stability, low degree of supercooling and the like, is good in chemical stability, non-toxic, green, environmental-friendly, safe, incombustible and great in density, and the cost of the container is lowered. Moreover, the preparation method is simple.

Owner:NORTHEAST NORMAL UNIVERSITY

High-strength nitrogen-containing economical austenite stainless steel and manufacturing method thereof

The invention relates to a high-strength nitrogen-containing economical austenite stainless steel and a manufacturing method thereof. The chemical components of the stainless steel, by weight, of 0.05-0.15% of C, 0.3-1% of Si, 8.5-11.0% of Mn, 14.0-16.0% of Cr, 1.0-2.5% of Ni, 0.10-0.25% of N, less than 0.08% of P, less than 0.01% of S, 0.5-2.0% of Cu, 0.1-0.5% of Mo, and the balance Fe and inevitable impurities, wherein Md <30 / 50> is greater than or equal to 20 DEG C. In the manufacturing process of the high-strength nitrogen-containing economical austenite stainless steel, through cold rolling twice and flexible annealing, crystal grains are refined through production and inversion of deformation martensites, and finally, the crystal grains of which the dimension is smaller than 500nm are obtained, so that the intensity of materials is greatly improved; and the obtained high-strength nitrogen-containing economical austenite stainless steel has the following specific properties that the yield strength is greater than or equal to 650MPa, the tensile strength is greater than or equal to 1000MPa, and the elongation rate is greater than or equal to 35%, and the high-strength nitrogen-containing economical austenite stainless steel is suitable for preparation of high-strength fine-specification precision strip steels.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

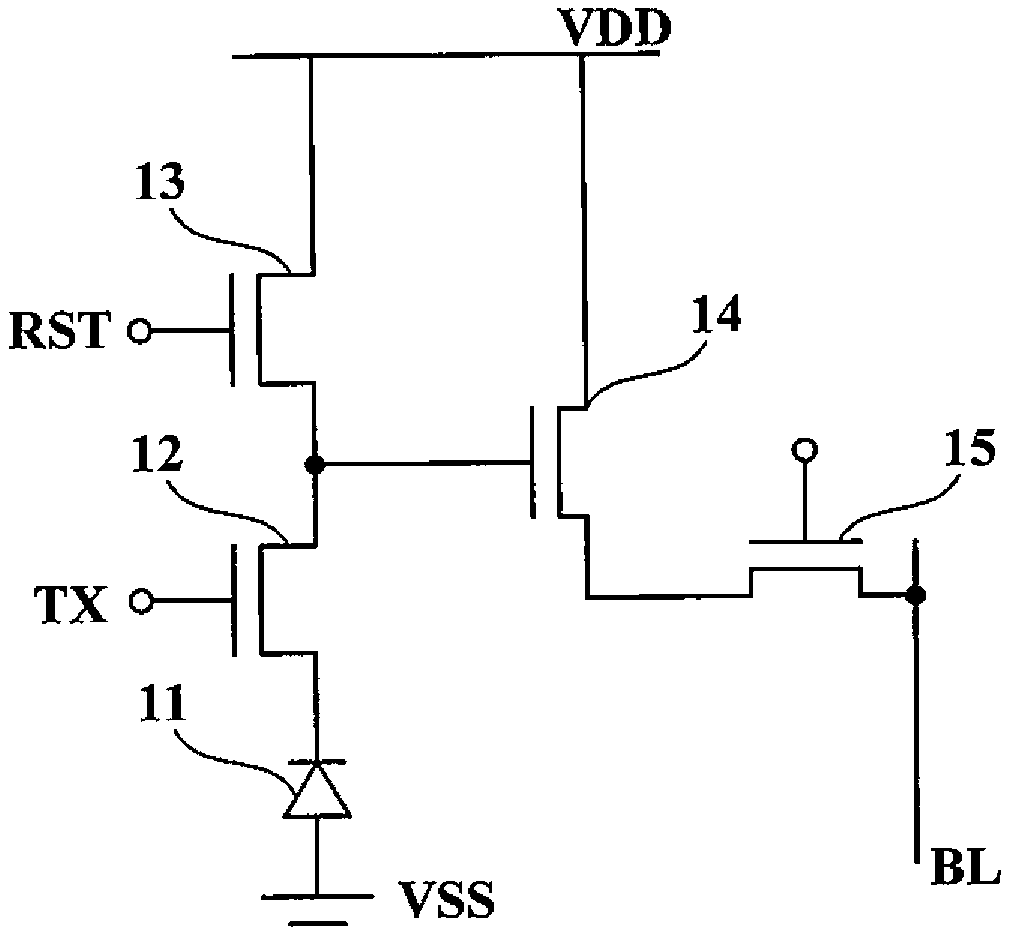

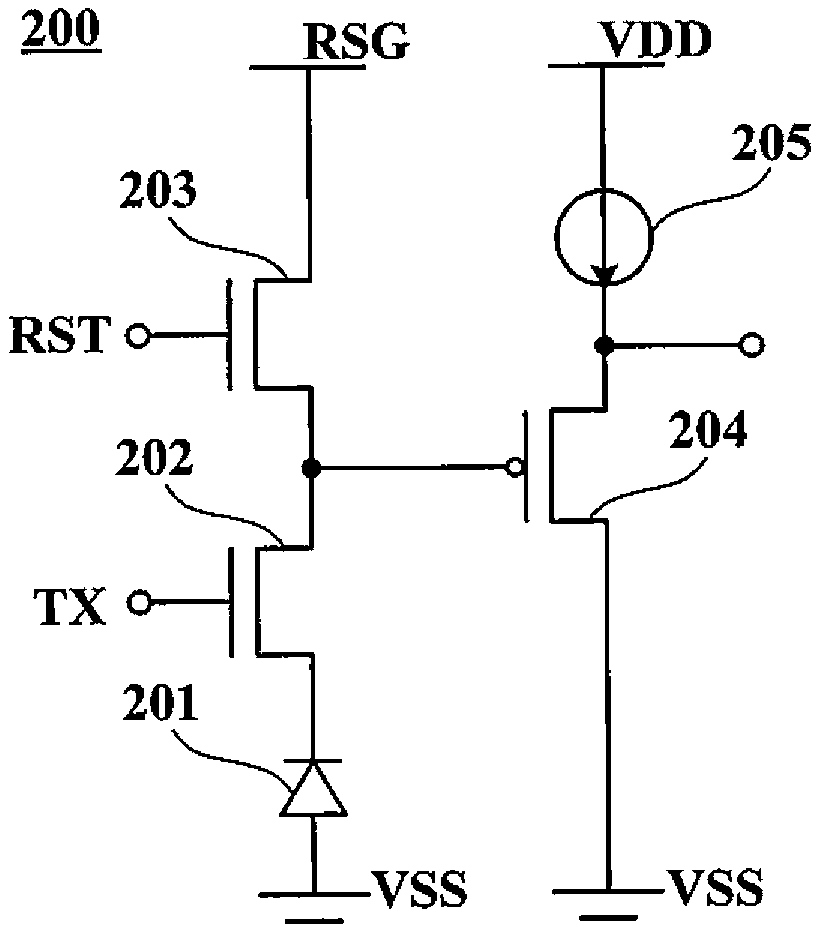

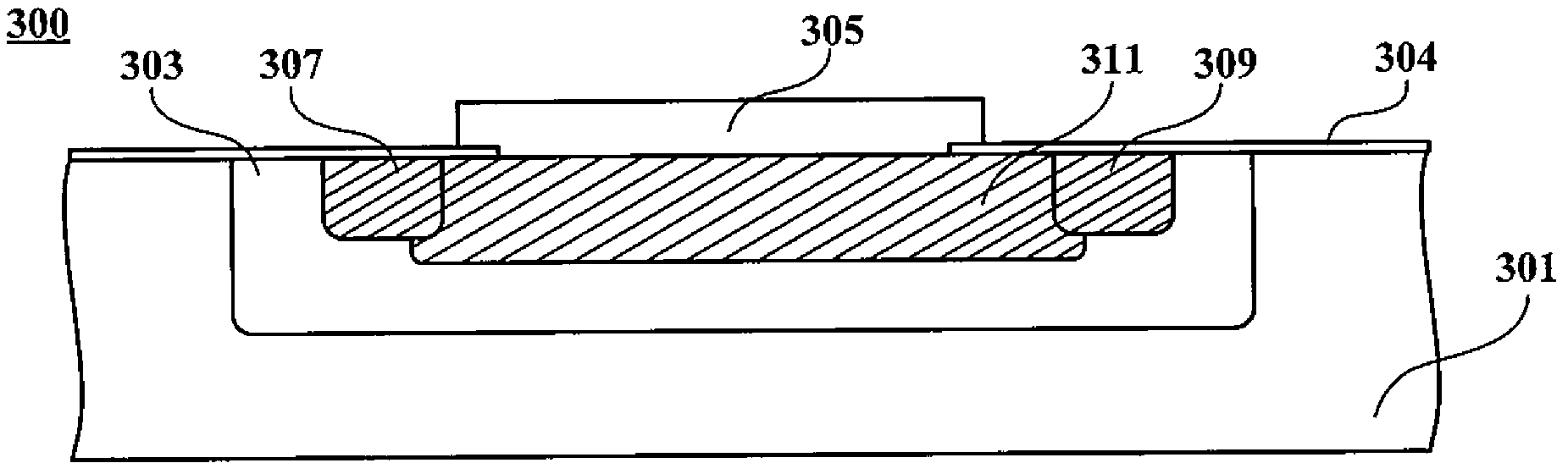

Image sensor and manufacturing method of transistor

ActiveCN102709302AImprove image qualityImprove reliabilityTransistorSemiconductor/solid-state device manufacturingOptoelectronicsField-effect transistor

The invention discloses an image sensor and a manufacturing method of a transistor. The image sensor comprises a pixel array. One or a plurality of pixel units of the pixel array respectively comprise one source following transistor. Each source following transistor is a junction type field effect transistor and comprises a first conduction type substrate, a second conduction type well, a second conduction type deposition doped layer, a first conduction type source region, a first conduction type drain region and a first conduction type doped layer, wherein the second conduction type well is positioned in the first conduction type substrate; the second conduction type deposition doped layer is positioned outside the surface of the first conduction type substrate and at least part of the second conduction type deposition doped layer is positioned on the second conduction type well; the first conduction type source region is positioned in the second conduction type well; the first conduction type drain region is positioned in the first conduction type substrate and / or the second conduction type well; at least part of the first conduction type doped layer is positioned between the second conduction type well and the second conduction type deposition doped layer so as to ensure the first conduction type source region to be electrically connected with the first conduction type drain region; and PN nodes are respectively formed between the first conduction type doped layer and the second conduction type well and between the first conduction type doped layer and the second conduction type deposition doped layer.

Owner:GALAXYCORE SHANGHAI

A kind of extra-thick quenched and tempered marine engineering eh40 steel and its preparation method

The invention relates to extra-thick tempering EH40 steel for ocean engineering. A steel plate comprises the following chemical components by weight percent: 0.12 to 0.15 percent of C, 0.15 to 0.50 percent of Si, 1.30 to 1.60 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.0050 percent of S, 0.020 to 0.050 percent of Nb, 0.020 to 0.050 percent of V, 0.008 to 0.020 percent of Ti, 0.15 to 0.40 percent of Ni, 0.10 to 0.20 percent of Cr, and balance of Fe and unavoidable impurity elements. The manufacturing process of the steel plate comprises the steps of smelting, casting, reheating, rolling and tempering. The tempering process is used for substituting the normalizing process to produce a low-scaling-ratio extra-thick plate, so that the adverse effect caused by the center segregation can be avoided.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Preparation method of wear-resistant hydraulic pump part

ActiveCN110616401AGood physical and mechanical propertiesIncrease coefficient of frictionVacuum evaporation coatingSputtering coatingCarbide coatingWear resistant

The invention belongs to the technical field of hydraulic pump manufacturing, and particularly relates to a preparation method of a wear-resistant hydraulic pump part. A carbide coating, a PVD methodand a carburizing technology are combined, a carburizing diffusion layer is prepared between the carbide coating and a part substrate through an ion sputtering method, namely, the surface of the partis subjected to a surface carburizing treatment by the ion sputtering method, and then a composite method of ion plating and magnetron sputtering is used for depositing a HfCrMoC carbide coating withcomponents in gradient change. The preparation method can slow the physical property difference between the carbide coating and the base material of the hydraulic pump part, improve the surface hardness and support effect of the base material, has high surface hardness and core toughness, and has a smooth surface and high wearing resistance; the adhesion between the coating and the substrate can be enhanced by 100% or more, the surface hardness of the invention is increased by two times or more, the surface treatment time is reduced by 80% or more, the service life of the hydraulic pump is doubled or more, and the maintenance and care cost of the hydraulic pump is reduced by 50% or more.

Owner:JINING ANTAI MINING EQUIP MFG CO LTD

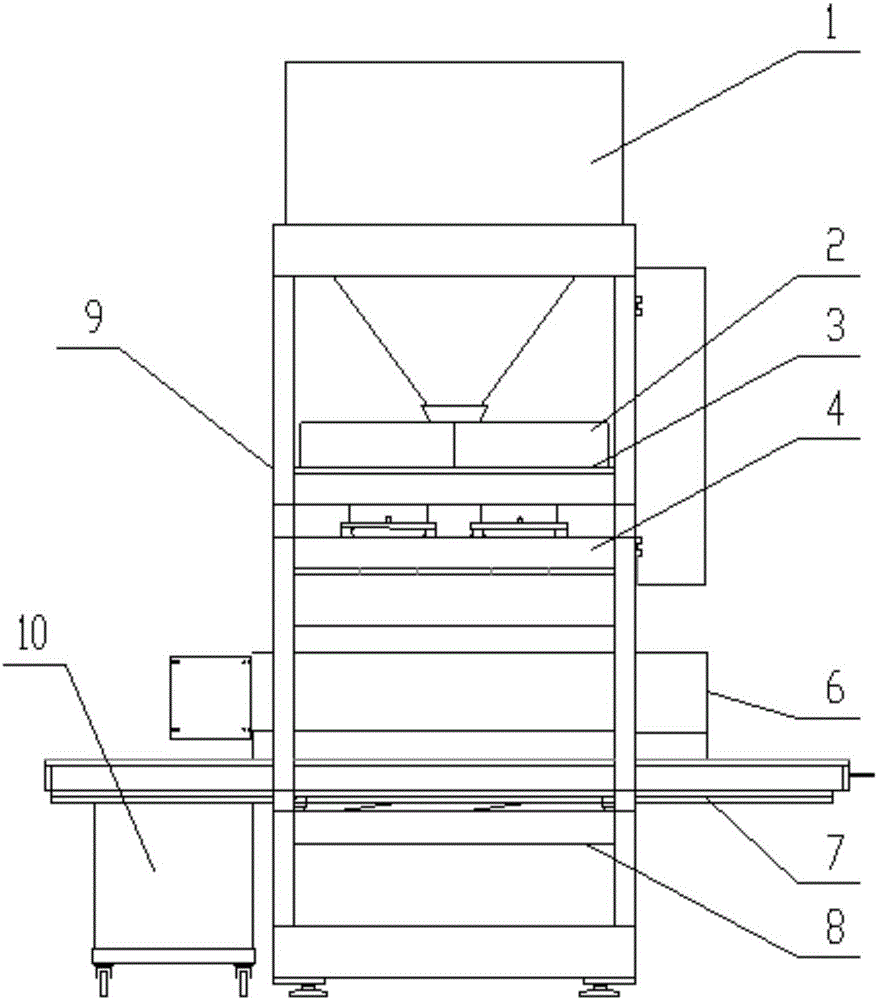

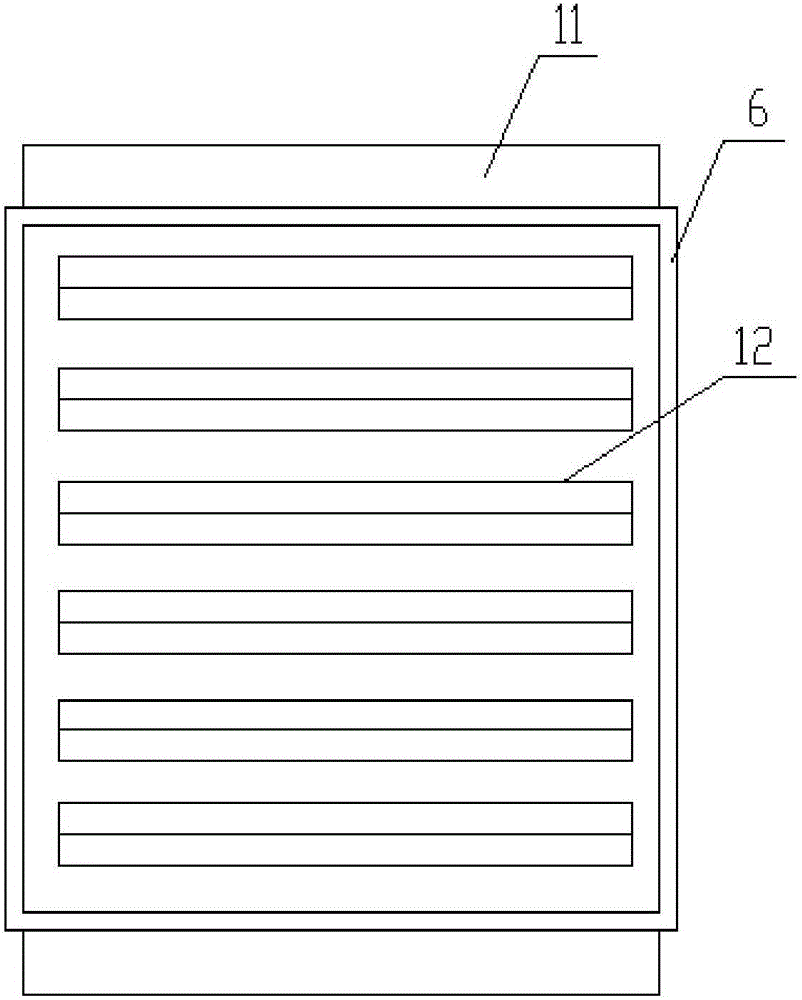

Refractory brick raw material weighing and transporting system

ActiveCN105035781AFor precise controlAvoid pressing density inconsistenciesLoading/unloadingEngineeringMechanical engineering

Owner:武汉吉森智能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com