Inorganic insulating mortar with wide-range adjustable thermal conduction coefficient and its preparation method

A technology of inorganic thermal insulation mortar and thermal conductivity, which is applied in the field of building energy saving and building materials, can solve the problems of easy segregation and stratification of inorganic thermal insulation mortar in storage and transportation, large performance fluctuation, poor stability, etc., and achieves easy control of product quality and good construction performance. Excellent, thick application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

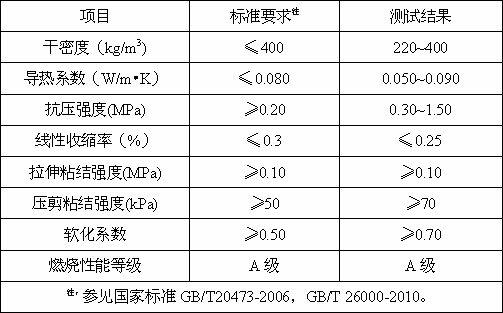

[0029] Example 1: Inorganic thermal insulation mortar with a thermal conductivity of 0.050~0.060W / m.K, its components and proportions (percentage by weight) are: cement: 38.4%, fly ash: 5.8%, slaked lime: 5.8%, vitrified microbeads : 48.1%, PP fiber: 0.18%, redispersible latex powder: 1.055%, cellulose ether: 0.58%, starch ether: 0.07%, air-entraining agent: 0.015%. The performance results obtained from the sampling test at the construction site are shown in Table 2.

[0030] Table 2 Performance Test Results of Inorganic Thermal Insulation Mortar in Example 1

[0031] project performance results Dry apparent density (kg / m 3 ) 235 Thermal conductivity (W / m·K) 0.057 Compressive strength (MPa) 0.32 Linear shrinkage (%) 0.23 Tensile bond strength (MPa) 0.12 Compressive shear bond strength (kPa) 75 Softening coefficient 0.73

Embodiment 2

[0032] Example 2: Inorganic thermal insulation mortar with a thermal conductivity of 0.060~0.070W / m.K, its components and proportions (percentage by weight) are: cement: 41.5%, fly ash: 9.6%, slaked lime: 5.2%, vitrified microbeads : 42.14%, PP fiber: 0.16%, redispersible latex powder: 0.95%, cellulose ether: 0.38%, starch ether: 0.06%, air-entraining agent: 0.012%. The performance results obtained from the sampling test at the construction site are shown in Table 3.

[0033] Table 3 Performance Test Results of Inorganic Thermal Insulation Mortar of Example 2

[0034] project performance results Dry apparent density (kg / m 3 ) 255 Thermal conductivity (W / m·K) 0.065 Compressive strength (MPa) 0.47 Linear shrinkage (%) 0.21 Tensile bond strength (MPa) 0.13 Compressive shear bond strength (kPa) 79 Softening coefficient 0.74

Embodiment 3

[0035] Example 3: Inorganic thermal insulation mortar with a thermal conductivity of 0.070~0.080W / m.K, its components and proportions (percentage by weight) are: cement: 42.6%, fly ash: 8.6%, slaked lime: 7.2%, vitrified microbeads : 40.26%, PP fiber: 0.124%, redispersible latex powder: 0.78%, cellulose ether: 0.38%, starch ether: 0.048%, air-entraining agent: 0.008%. The performance results obtained from the sampling test at the construction site are shown in Table 4.

[0036] Table 4 The performance test results of the inorganic thermal insulation mortar of Example 3

[0037] project performance results Dry apparent density (kg / m 3 ) 293 Thermal conductivity (W / m·K) 0.076 Compressive strength (MPa) 0.61 Linear shrinkage (%) 0.22 Tensile bond strength (MPa) 0.15 Compressive shear bond strength (kPa) 102 Softening coefficient 0.76

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com