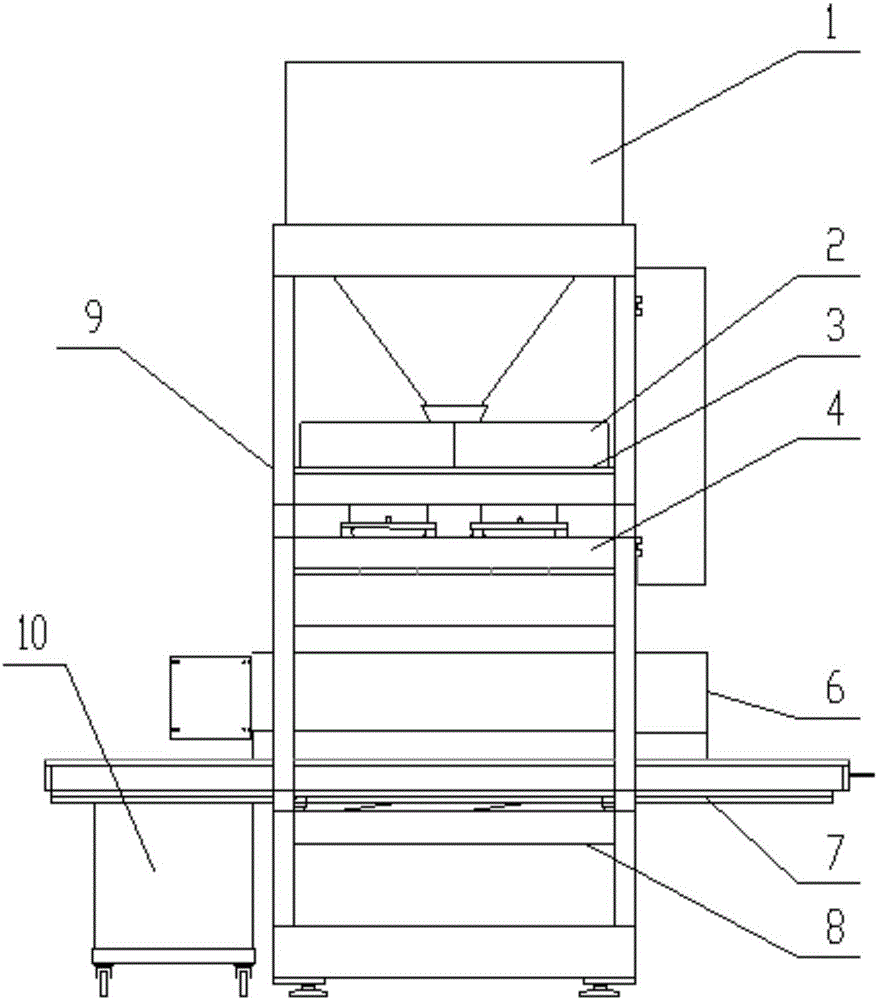

Refractory brick raw material weighing and transporting system

A transportation system and refractory brick technology, which is applied in the field of refractory brick raw material weighing and transportation system, can solve the problems of large performance differences of refractory bricks, inconsistent pressing density of refractory bricks, and inability to accurately control weight, etc., to achieve accurate control and avoid pressing density inconsistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

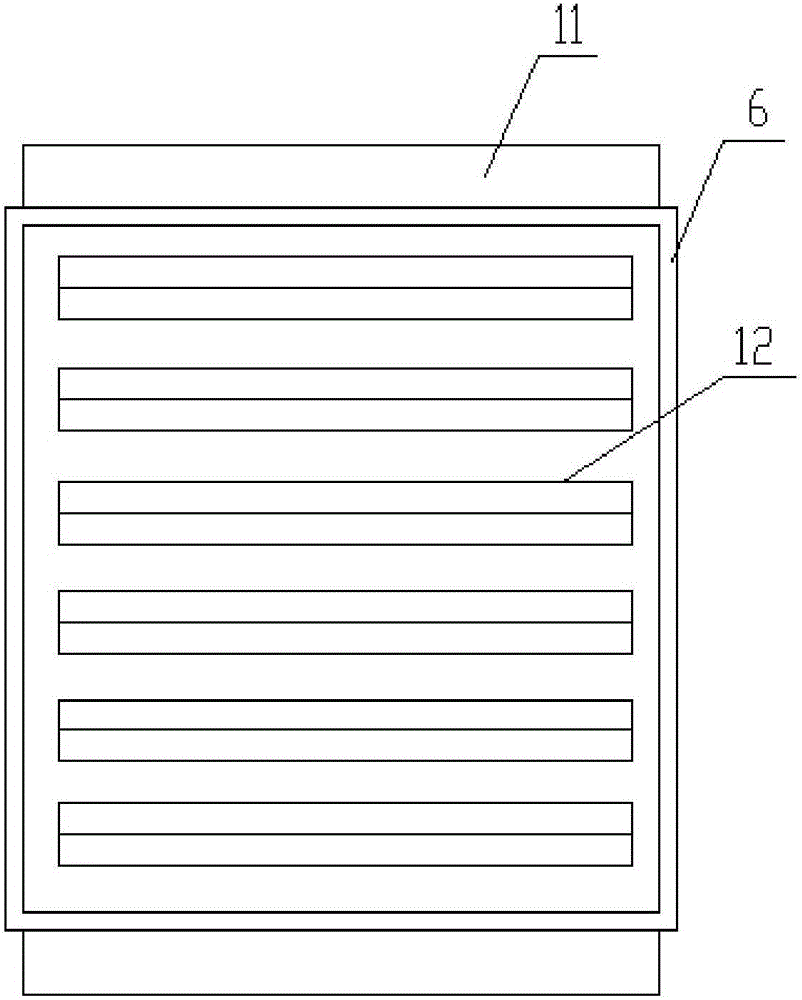

[0045] The refractory brick raw material weighing and transportation system provided in the embodiment of the present application solves or partially solves the inability to accurately control the weight of the material entering the mold of the press in the prior art, resulting in large differences in the performance of refractory bricks, and the accumulation of materials causing compression For the technical problem of unqualified refractory bricks, the feeding bin with the first feeding conduit and the first screw rod is installed, and the weighing bin with the first cavity and the second cavity is set under the feeding bin, and the delivery bin is set on the slide On the rail, and at the bottom of the conveying bin, a number of fixed gates with a triangular longitudinal section and a movable gate that can slide relative to the fixed gates are set to realize accurate control of the weight of the materials entering the mold of the press. It is automatic, and at the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com