Patents

Literature

61results about How to "Guaranteed refinement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

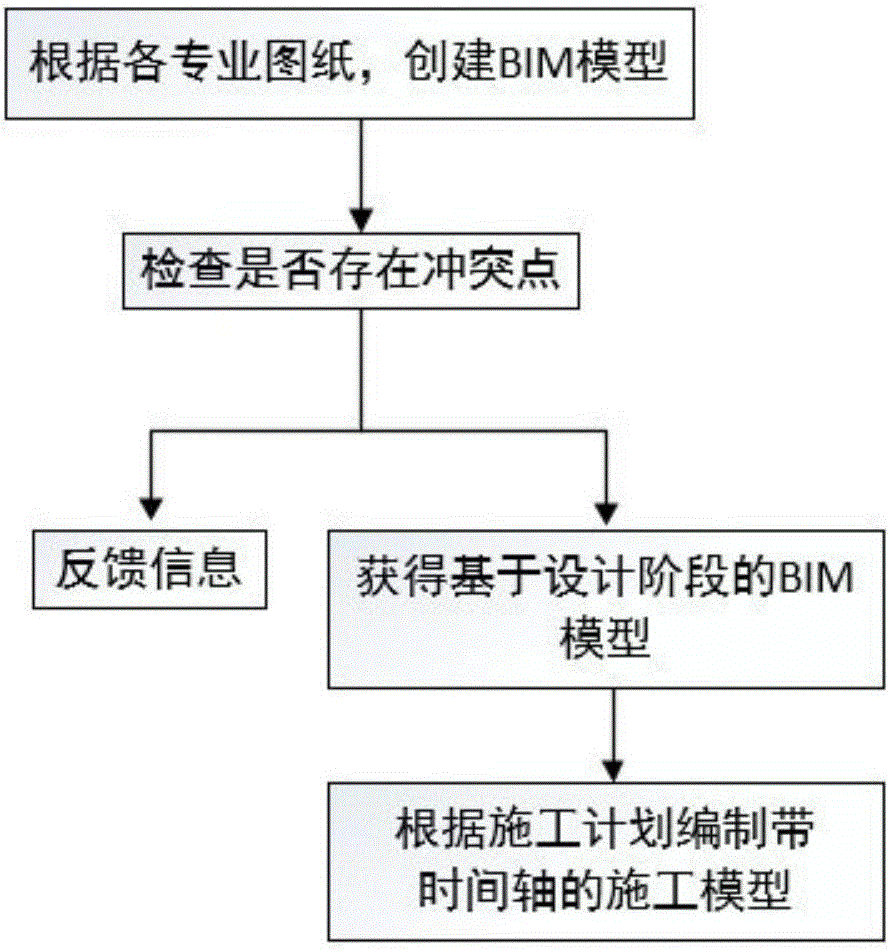

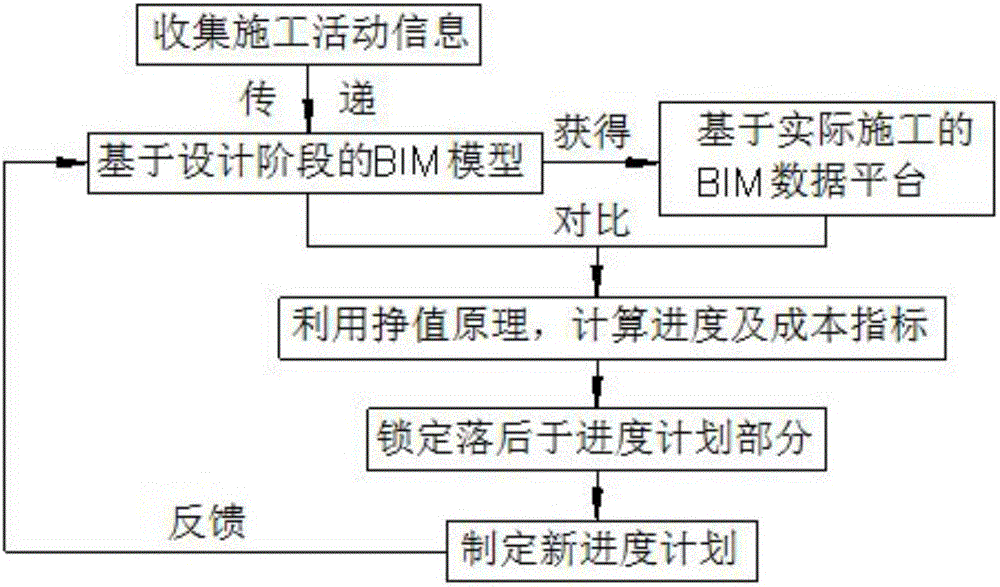

BIM project progress and cost management system based on earned value theory

InactiveCN106022587AQuick compilationFast and Accurate BudgetOffice automationResourcesProgram planningCost Controls

The invention discloses a BIM project progress and cost management system based on an earned value theory. The system comprises steps of establishing a BIM building model based on design paper and adding an environmental factor simulating a construction field; collecting construction activity information and associating the construction activity information with corresponding engineering information in the BIM building model; comparing and analyzing the engineering amount of current real complete part and the engineering amount of a planned complete part on the basis of the earned value theory and determining whether a project progress lags, and determining whether project cost exceeds planned cost by comparing generated cost with current budget amount. The BIM project progress and cost management system based on the earned value theory is used in building projects, may clear the project progress and cost control case, may feed back the project progress and cost control state in a visualized way by using the BIM building model, and has a wide application prospect.

Owner:广州络维建筑信息技术咨询有限公司

Real-time monitoring method for growth characters of tea trees in intensive cultivation

ActiveCN103439265AAchieve high quality and high yieldImprove qualityUsing subsonic/sonic/ultrasonic vibration meansColor/spectral properties measurementsBudTea leaf

The invention discloses a real-time monitoring method for growth characters of tea trees in intensive cultivation. The method comprises the following steps: performing real-time data acquisition by a tea tree living body growth character data acquisition device based on online location, transmitting the acquired data to an artificial comprehensive management center through a wireless communication way to process, wherein the acquired data comprises current location data acquired by a locating mechanism, fresh tea leaves spectrum data acquired by a high spectrum imaging sensor, and average growth height of fresh tea leaves measured by an ultrasonic wave sensor, and judging the best fresh tea leaf picking time based on that the data and a picking judgment model established off line are combined by the artificial comprehensive management center. The picking judgment model comprises a bud size growth measurement model based on average growth height, a yield correlation model and a quality correlation model based on the high spectrum image data. The real-time monitoring method for the growth characters of the tea trees in intensive cultivation is beneficial to realizing of intensive cultivation and automation in planting of the tea trees.

Owner:湖南星索尔航空科技有限公司

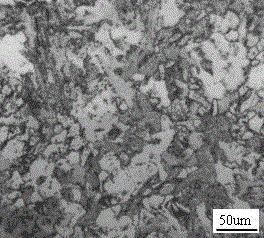

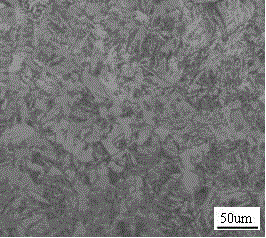

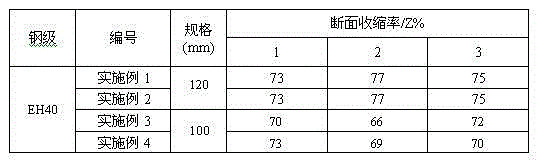

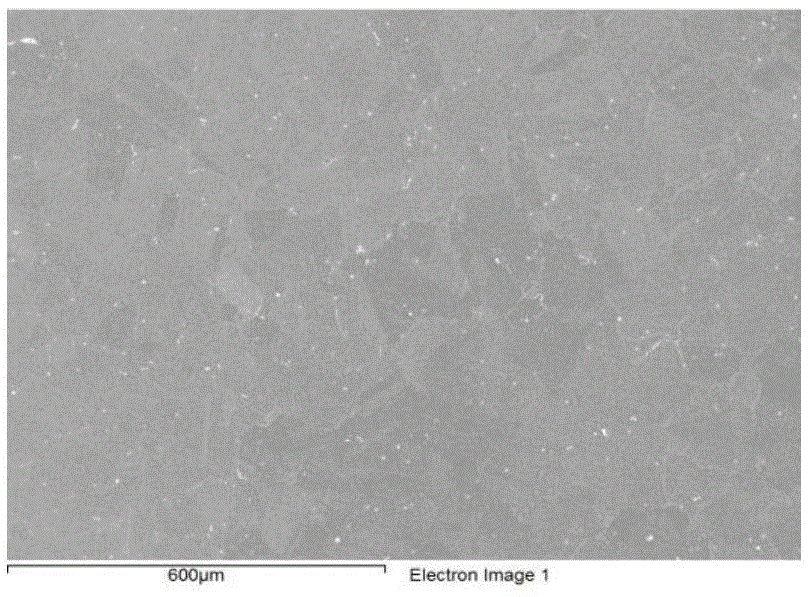

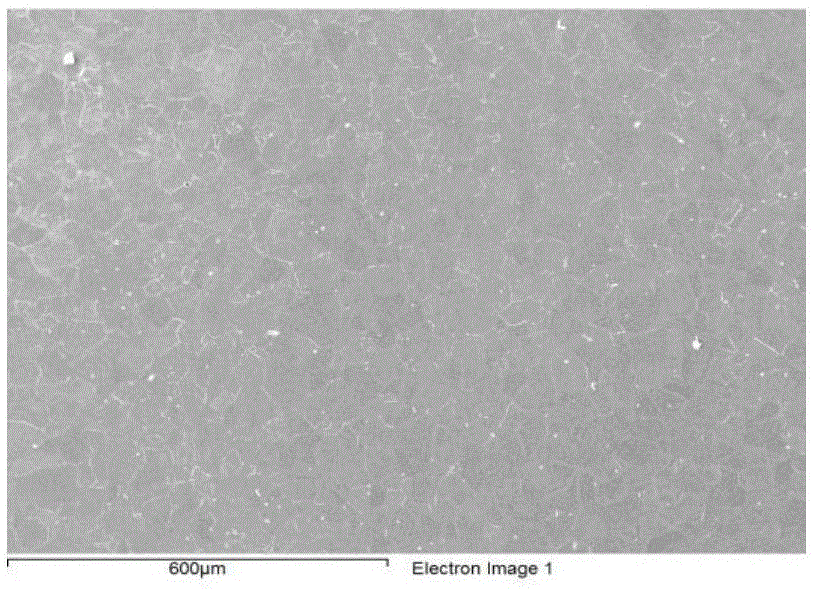

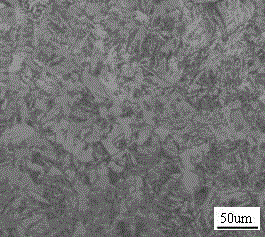

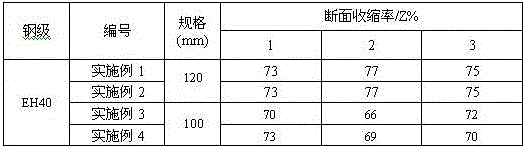

Extra-thick tempering EH40 steel for ocean engineering and preparation method thereof

The invention relates to extra-thick tempering EH40 steel for ocean engineering. A steel plate comprises the following chemical components by weight percent: 0.12 to 0.15 percent of C, 0.15 to 0.50 percent of Si, 1.30 to 1.60 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.0050 percent of S, 0.020 to 0.050 percent of Nb, 0.020 to 0.050 percent of V, 0.008 to 0.020 percent of Ti, 0.15 to 0.40 percent of Ni, 0.10 to 0.20 percent of Cr, and balance of Fe and unavoidable impurity elements. The manufacturing process of the steel plate comprises the steps of smelting, casting, reheating, rolling and tempering. The tempering process is used for substituting the normalizing process to produce a low-scaling-ratio extra-thick plate, so that the adverse effect caused by the center segregation can be avoided.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

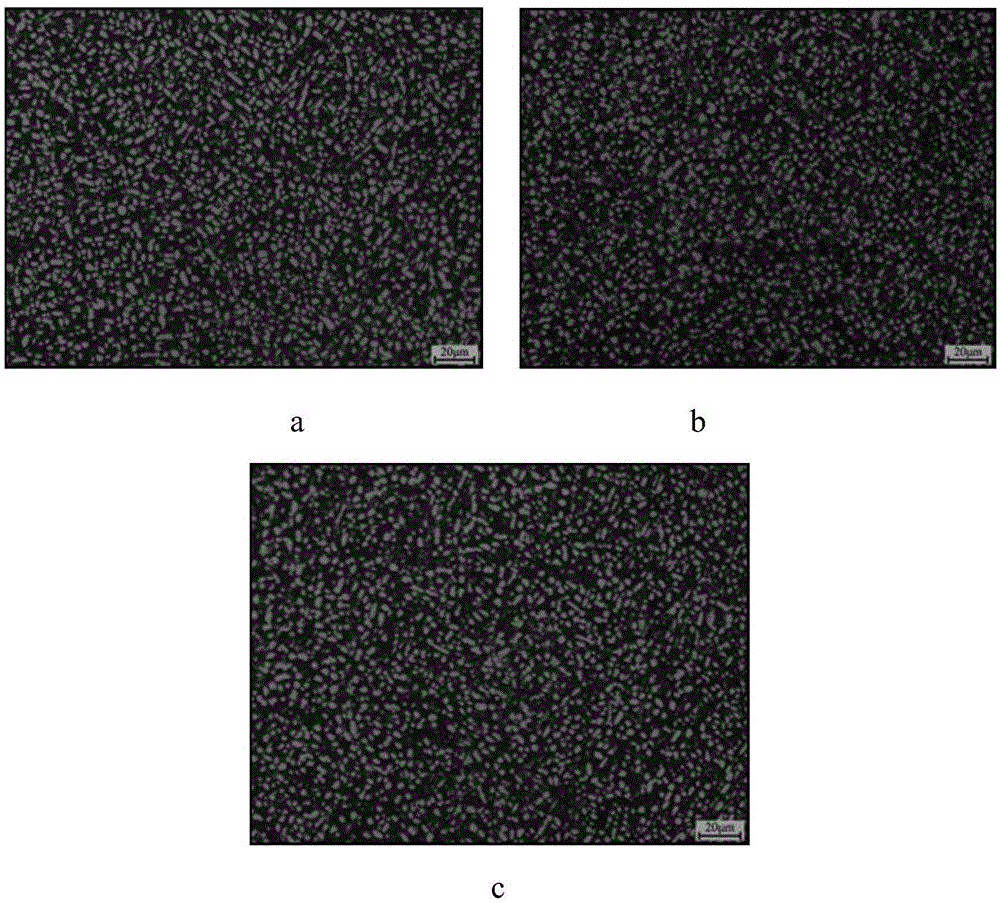

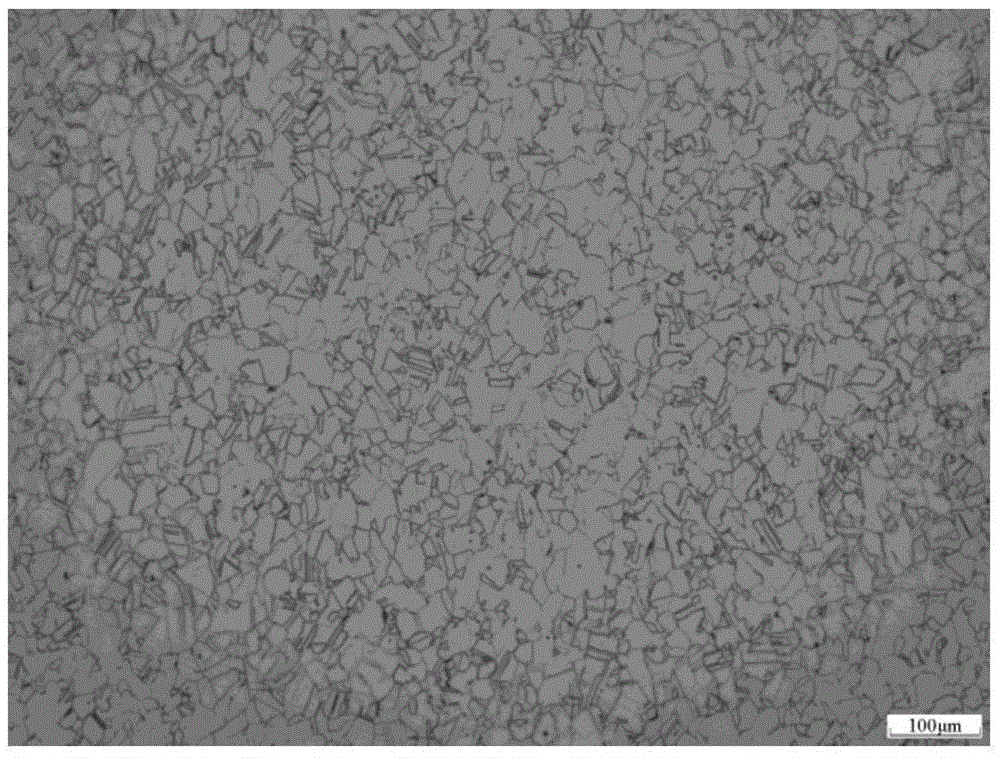

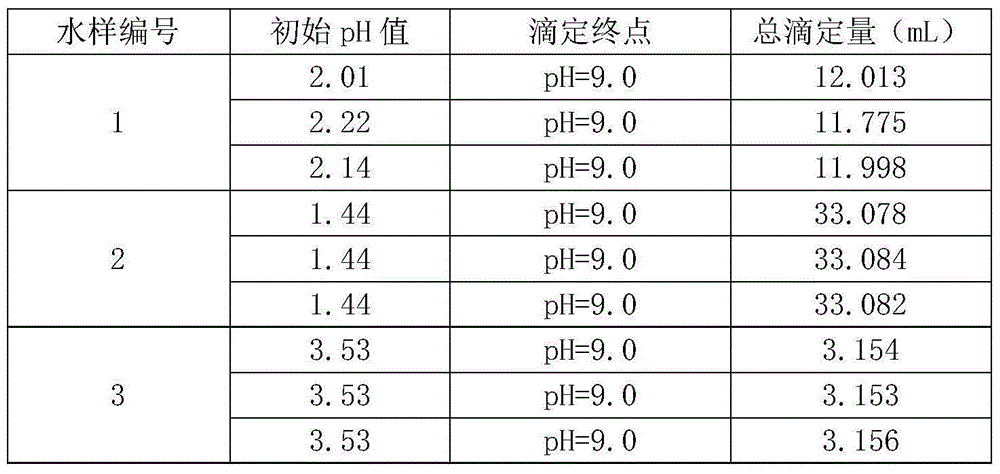

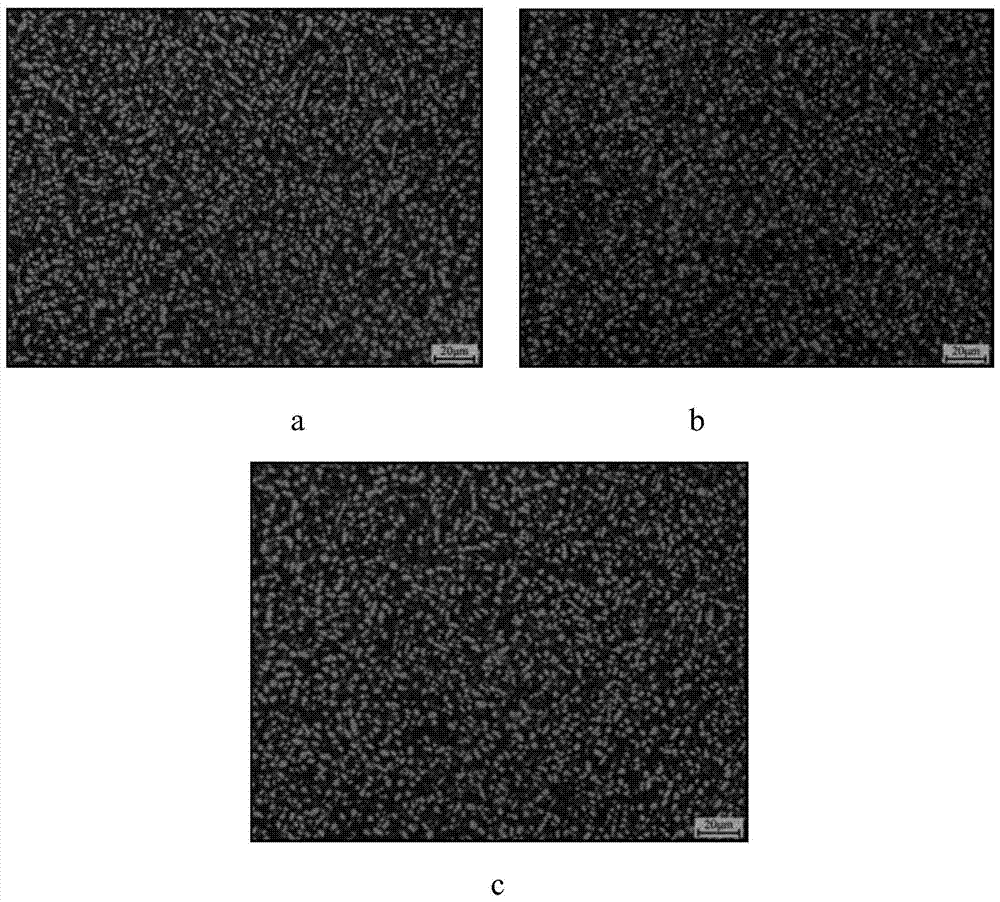

Forging method for improving microstructure uniformity of TC18 titanium alloy bars

The invention discloses a forging method for improving the microstructure uniformity of TC18 titanium alloy bars. The method comprises the following steps: heating TC18 titanium alloy ingots, carrying out upsetting and rolling forging once, and pressing down the forged ingots in a downward pressing process to crush an original cast microstructure; and carrying out upsetting and rolling forging on the obtained forging stock at a temperature being greater than a beta phase transition point 2-3 times, carrying out upsetting and rolling forging on the obtained forging stock at a temperature being smaller than the beta phase transition point 2-4 times to prepare a 16-surface object, and carrying out precise forging on the 16-surface object at a temperature of Tbeta-50DEG C once to finally produce TC18 titanium alloy bars with the diameter of 160-260mm. The method improves the microstructure uniformity of the TC18 titanium alloy bars and effectively reduces the deformation microstructure risk through adopting a less upsetting and rolling + high control precision precise forging technology on the premise of guaranteeing the refinement and fragmentation of the microstructure; and the method reduces the production cost and the quality risk and shortens the production period of the bars through reducing the forging frequency and adopting continuous melting, and is suitable for large-scale batch production of the TC18 titanium alloy bars.

Owner:西部超导材料科技股份有限公司

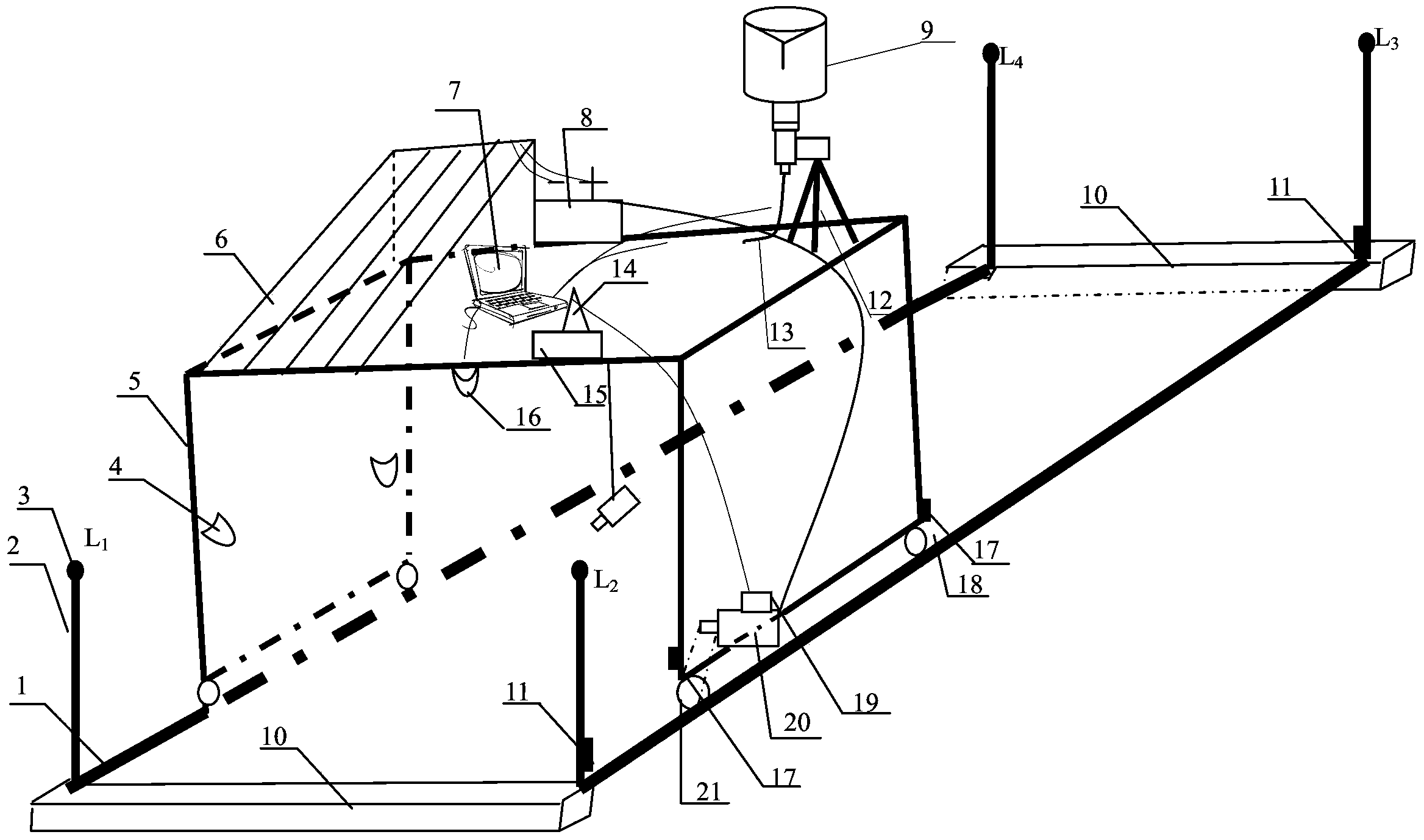

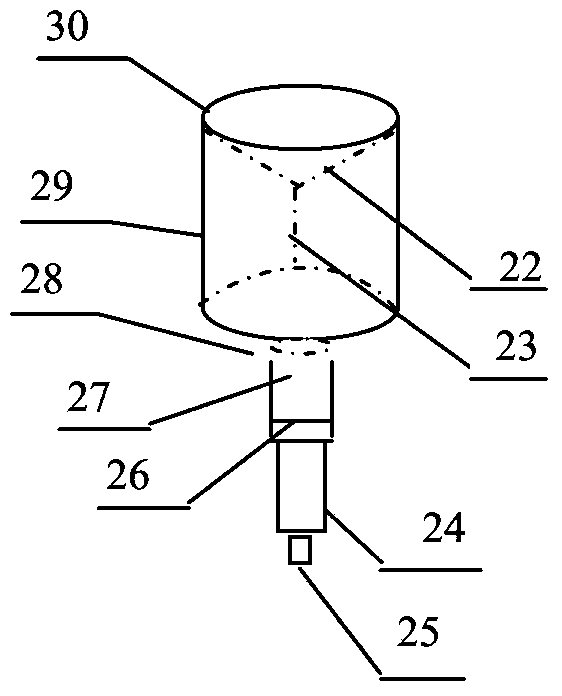

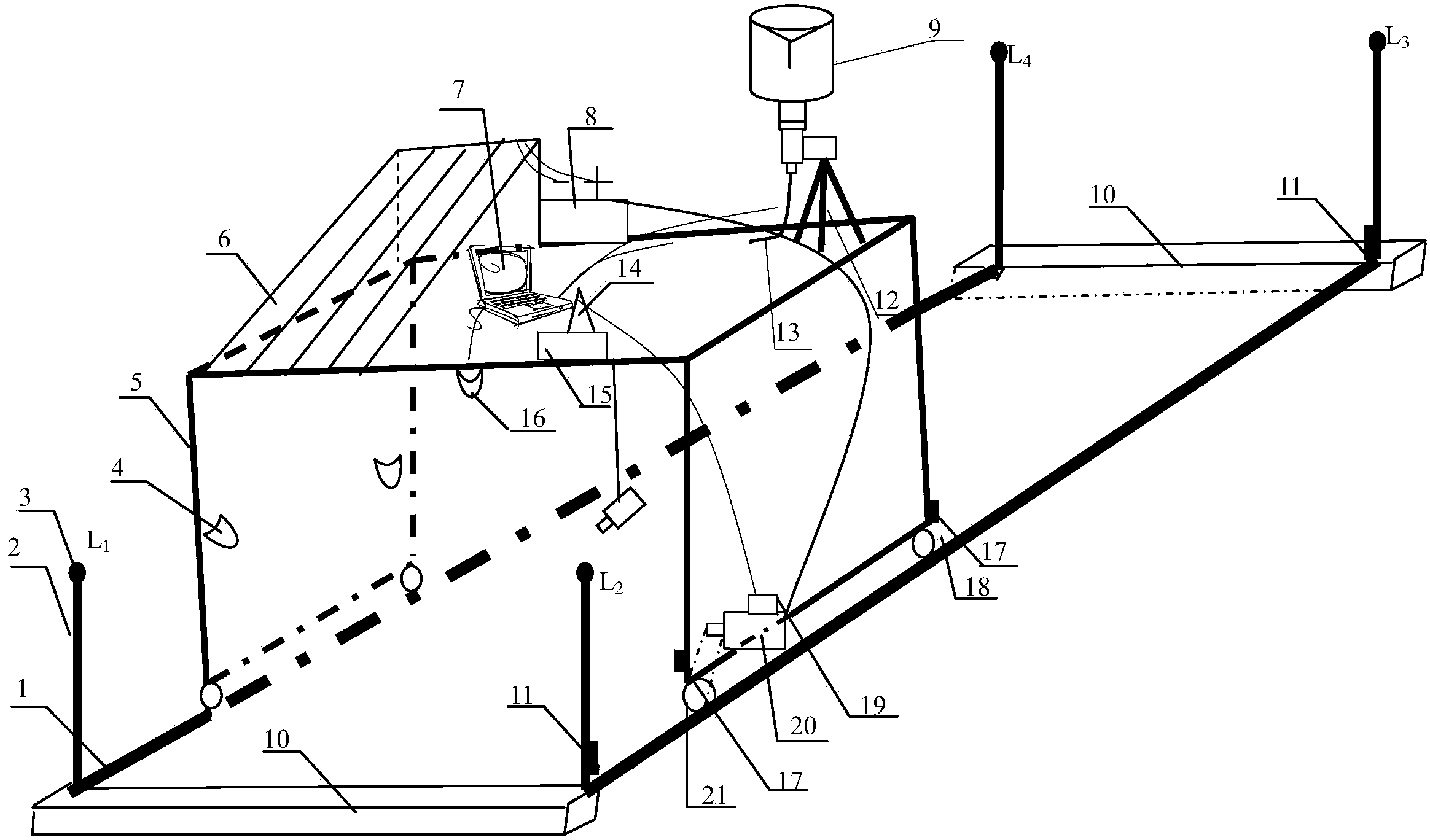

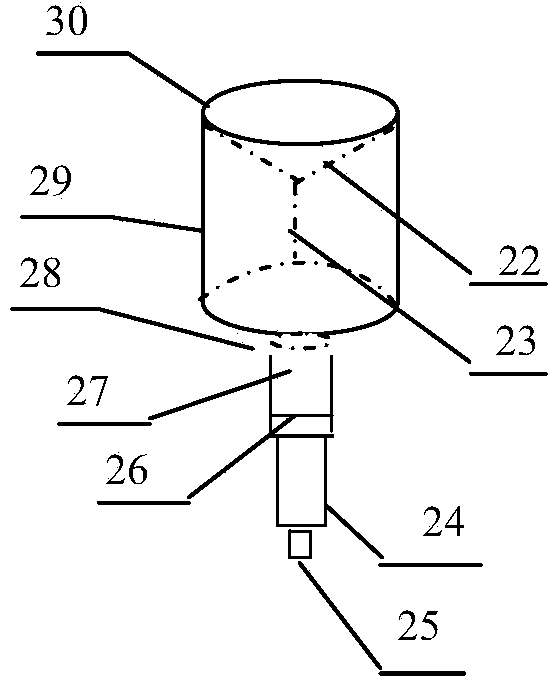

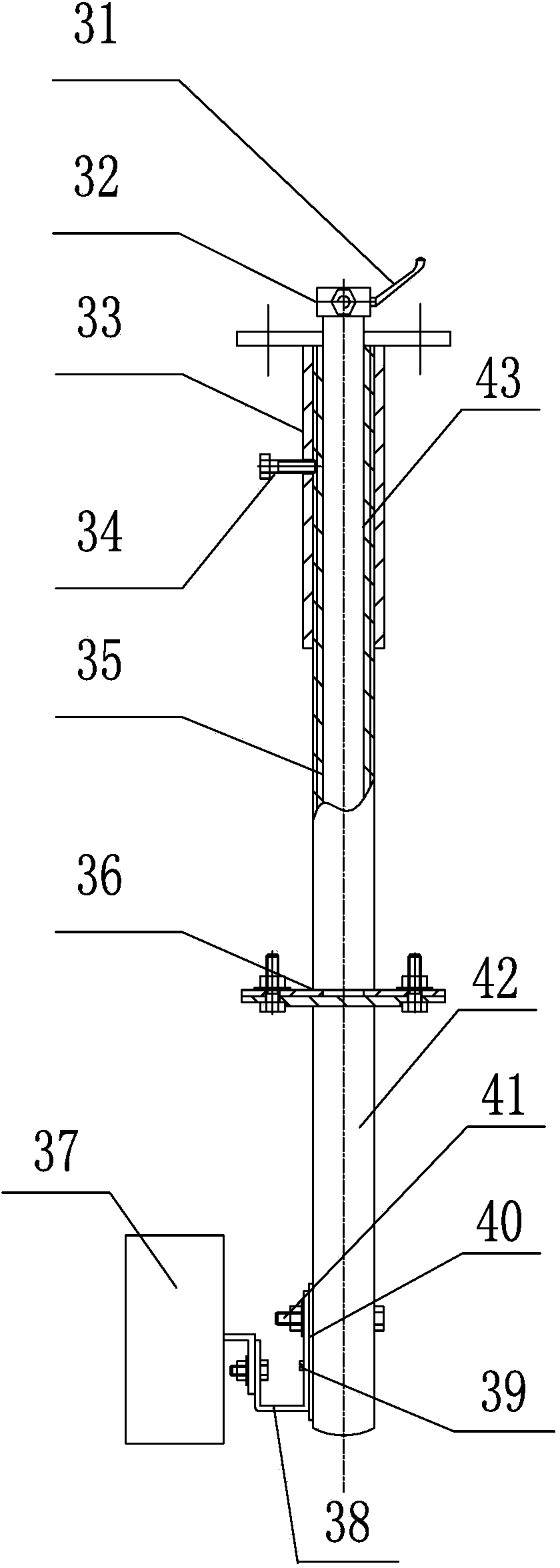

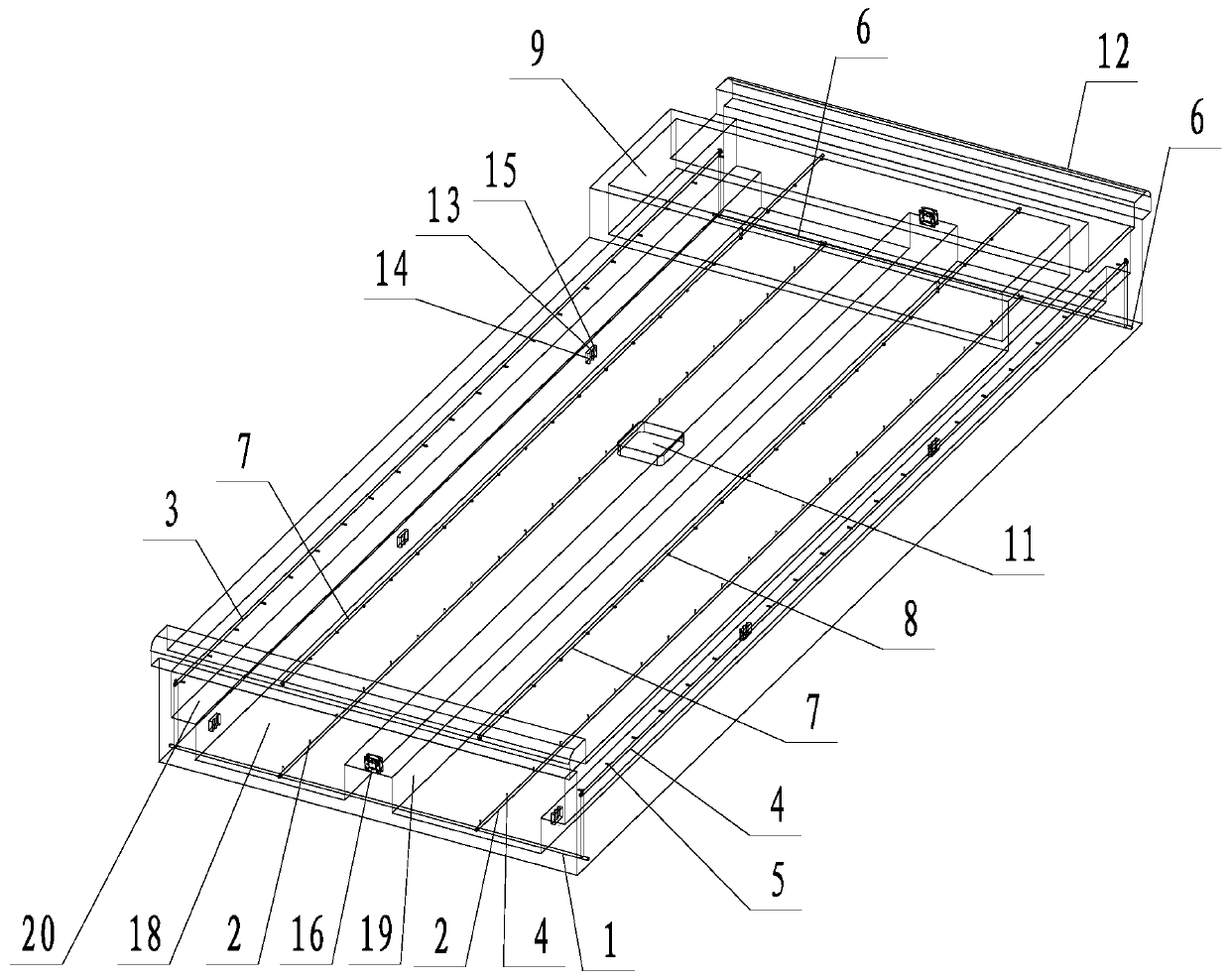

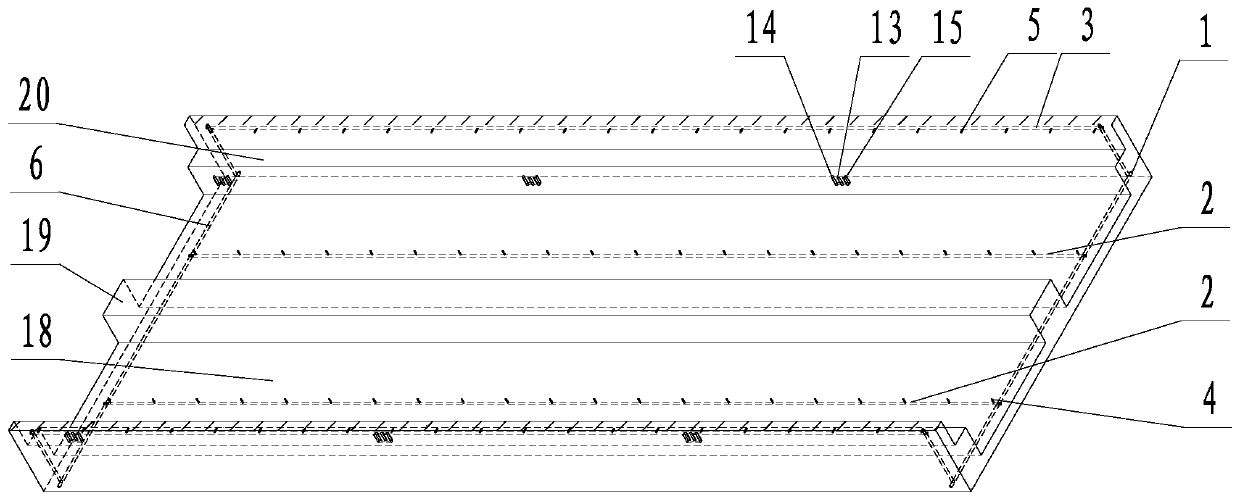

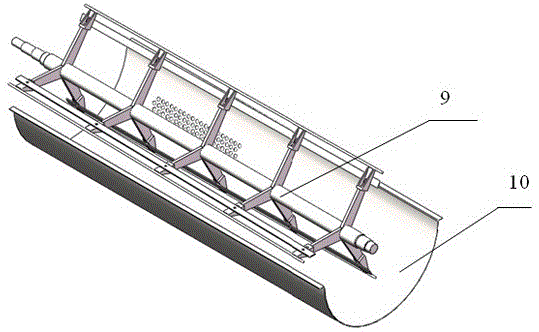

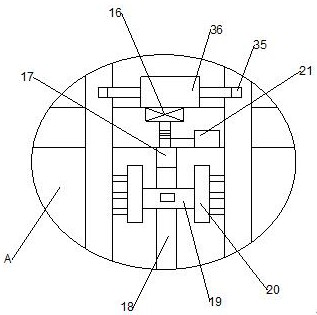

Device for data acquisition of fertility characteristics of tea tree living body based on online positioning

ActiveCN103439264ARealize fine plantingAchieve high quality and high yieldUsing subsonic/sonic/ultrasonic vibration meansRaman scatteringAgricultural engineeringLiving body

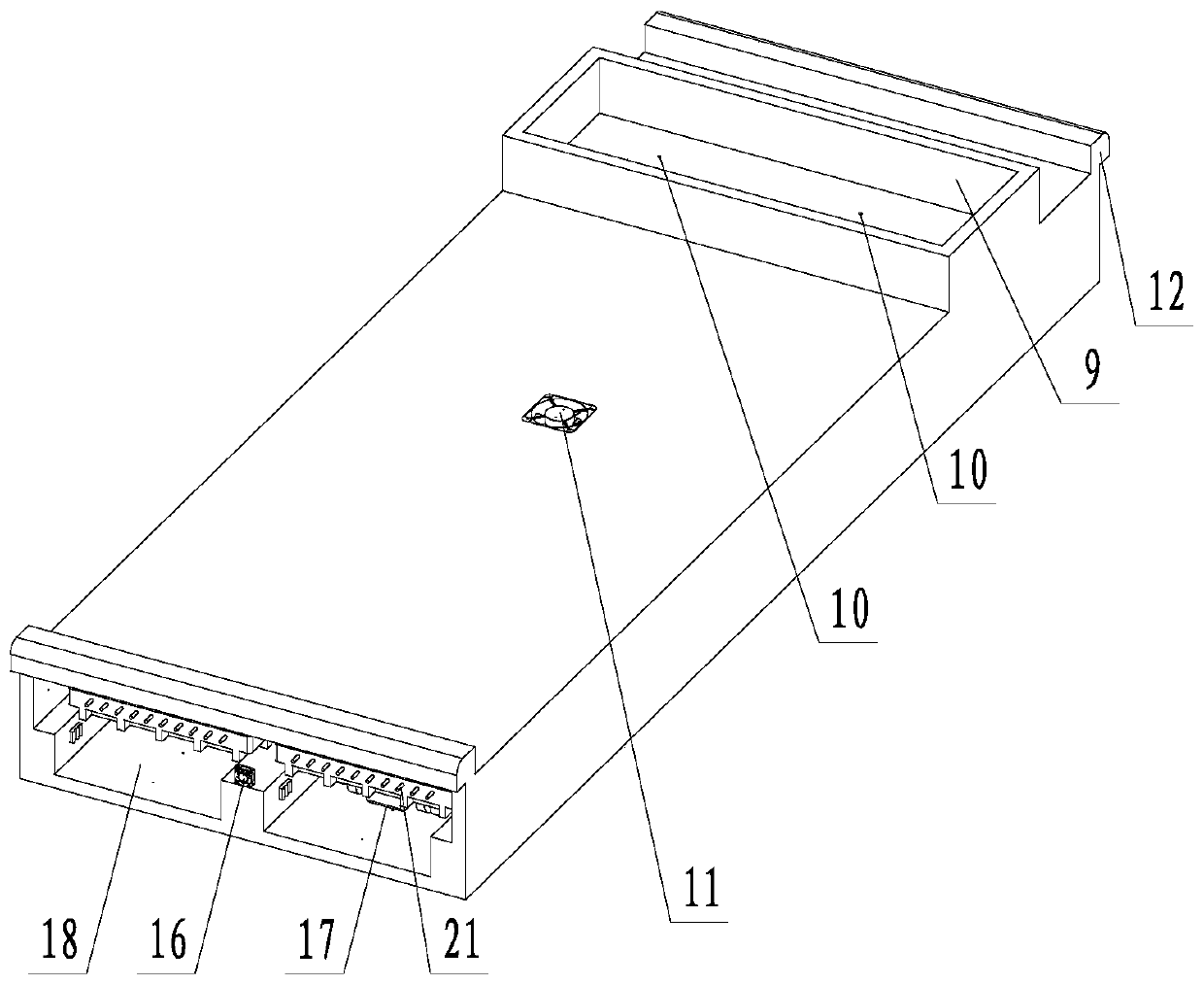

The invention discloses a device for data acquisition of fertility characteristics of a tea tree living body based on online positioning. Four vertical supporting rods (2) are arranged on four corners of a rectangle covering the tea tree plantation zone; a colored mark (3) is arranged at the top end of each supporting rod; a guide rail (1) is arranged on each of the two long sides of the rectangle; four pulleys and a motor (20) used for driving the supporting rods are arranged at the bottom of a frame (5); an omnibearing visual sensor (9) is fixed onto a tripod (12) arranged at the top end of the frame; a computer (7), a storage battery (8), an ultrasonic sensor (16) and a wireless transmitter (14) are further arranged on the frame; a hyperspectrum sensor is also arranged at the top of the frame; the device for data acquisition of fertility characteristics of the tea tree living body based on online positioning has the characteristic of high automation degree, so as to provide infrastructure for fine plantation of tee trees.

Owner:湖南星索尔航空科技有限公司

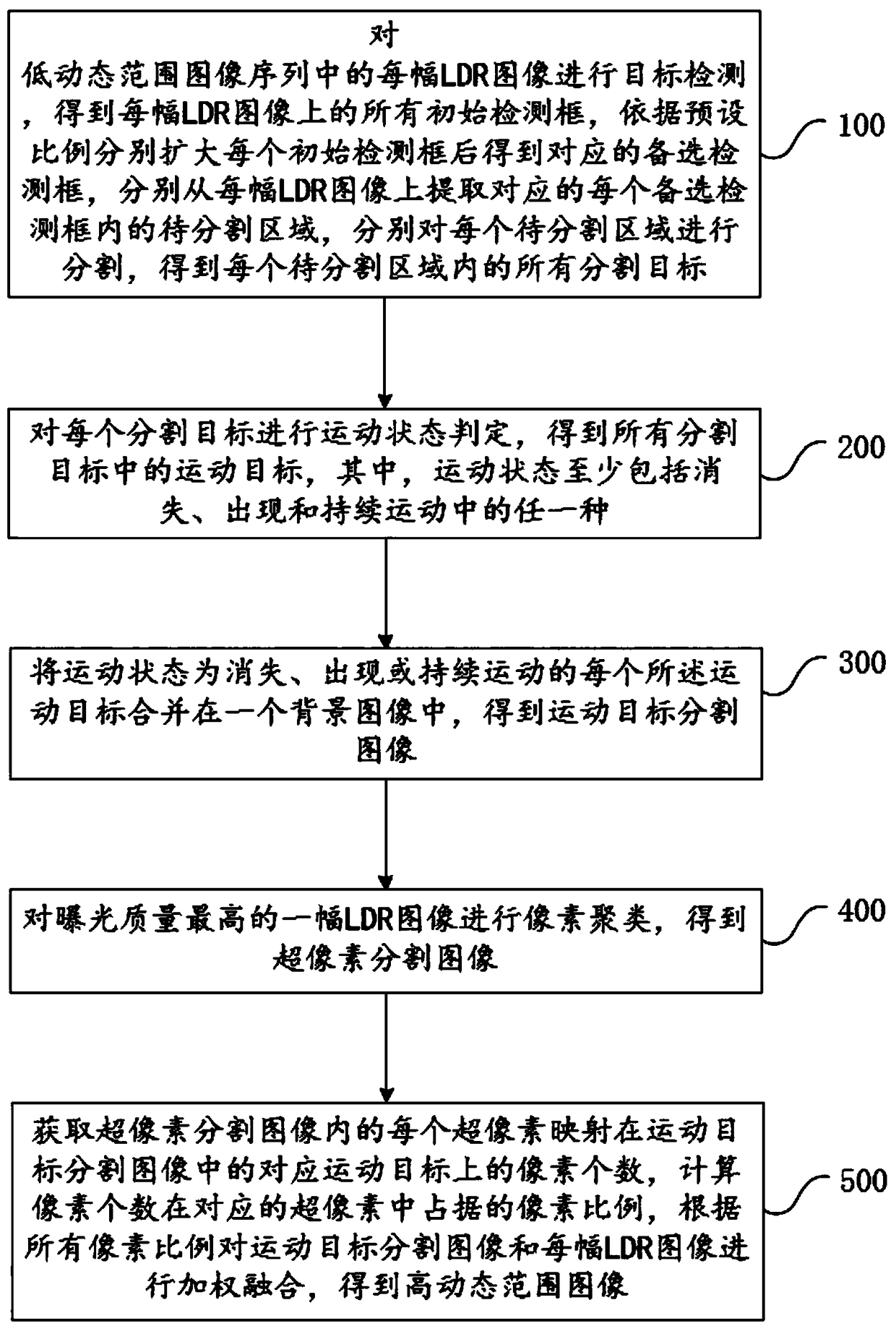

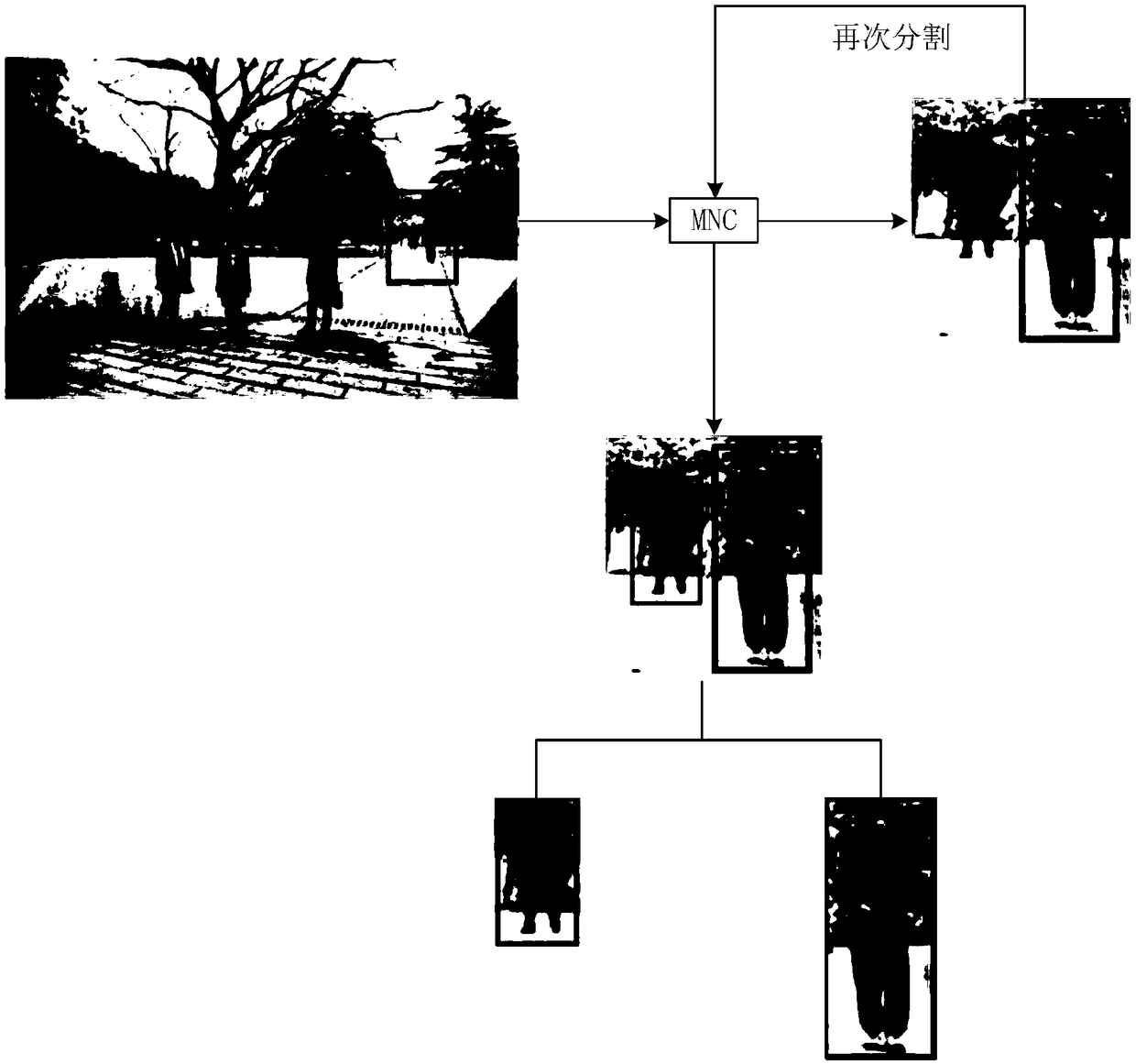

A fusion method and a fusion system of high dynamic range images

InactiveCN109360163ARaise the ratioTarget details are clearImage enhancementImage analysisSuperpixel segmentationImage sequence

The invention relates to a fusion method and a fusion system of high dynamic range images. The method comprises the following steps of: performing target detection on each LDR image in a low dynamic range image sequence to obtain an initial detection frame, expanding the initial detection frame according to a preset proportion, extracting a region to be segmented in an alternative detection framefrom the LDR image, and segmenting the region to be segmented to obtain a segmented target; The moving state of the segmented object is judged, and the moving object is merged into a background imageto obtain the segmented image of the moving object. Pixel clustering is performed on the LDR image with the highest exposure quality, a super pixel segmentation image is acquired, and the moving object segmentation image and each LDR image are weighted and fused according to the number of pixels of each super pixel mapped on the moving object in the moving object segmentation image to obtain a high dynamic range image. The invention improves the accuracy of moving object detection and judgment, and makes the moving object in the high dynamic range image clearer.

Owner:SHENZHEN JIMUYIDA TECH CO LTD

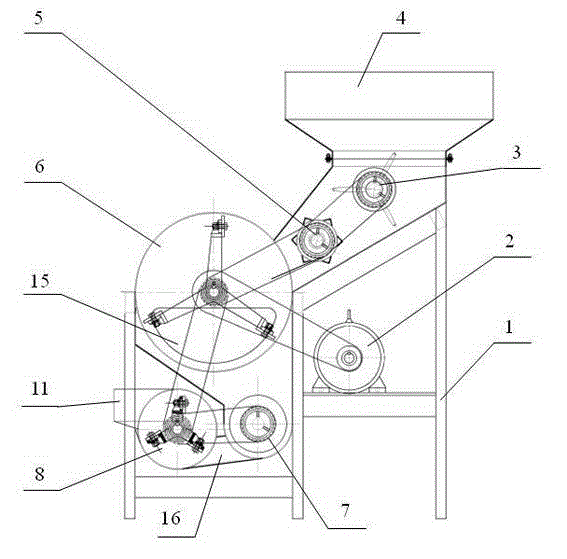

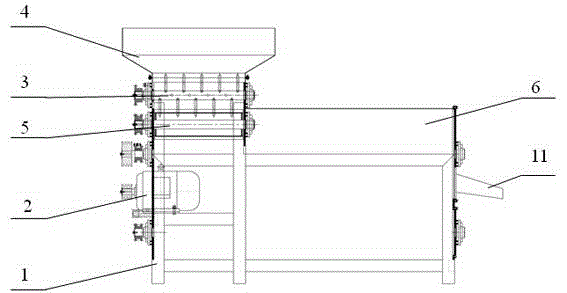

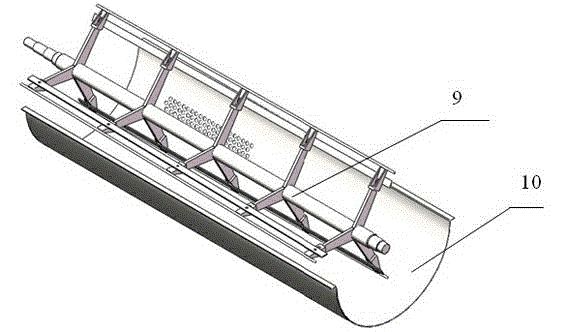

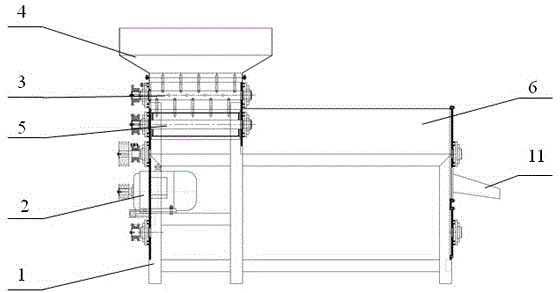

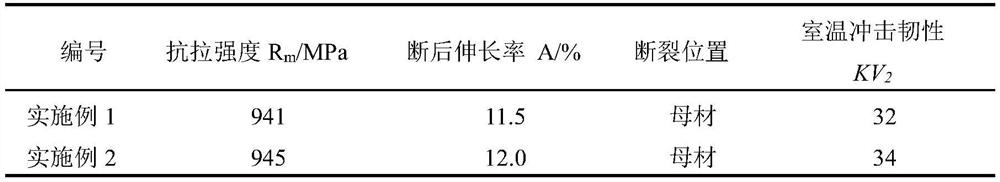

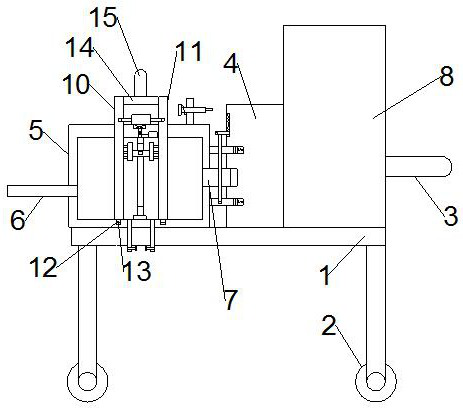

Seed melon crushing seed-taking machine

InactiveCN103329685AEffective hygienic separationNovel structureSievingScreeningProduction lineMotor drive

The invention discloses a seed melon crushing seed-taking machine, wherein a feed hopper, a motor, a crushing device, a skin and pulp separation device, a spiral crushing delivery device and a seed and pulp separation device are arranged on a rack of the seed-taking machine; the motor drives the crushing device, the skin and pulp separation device, the spiral crushing delivery device and the seed and pulp separation device; the feed hopper is arranged above an inlet of the crushing device, and an outlet of the crushing device is communicated with an inlet of the skin and pulp separation device; the bottom end of the skin and pulp separation device adopts a screen structure and communicated with the spiral crushing delivery device; an outlet of the spiral crushing delivery device is communicated with the seed and pulp separation device. According to the invention, the effective and sanitary separation of the seed melon skin, pulp and seeds is realized, and the indicators of all separated items meet various indicator requirements for the follow-up processing. The novel seed melon crushing seed-taking machine disclosed by the invention has the following characteristics: the machine is designed according to the production line for full utilization of seed melons, the structure is novel, simple and practical, the entire crushing and separation process is completed through automation, the processing efficiency is high, and the productivity reaches 10 tons per hour.

Owner:甘肃靖远银农籽瓜科技有限公司 +1

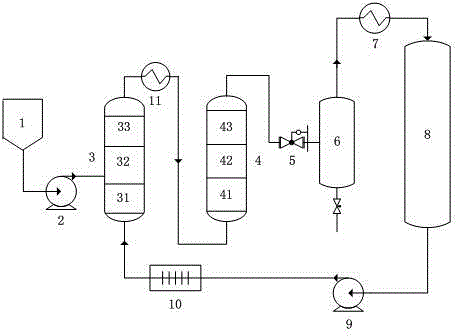

Heavy oil separation method

ActiveCN103059921AAvoid entrainmentImprove separation efficiencyTreatment with plural serial refining stagesOil separationFuel oil

The invention discloses a heavy oil separation method. With heavy oil as the raw material, the method adopts a mixed solvent composed of two solvents i.e. A and B with different molecular weights for extraction in two stages of extraction sections connected in series. Specifically, the method comprises: first conducting extraction at a first stage extraction section which has a pressure and temperature higher than the critical pressure and critical temperature of the solvents; introducing the supercritical fluid obtained at the first stage extraction section and the extracted distillate oil into a second stage extraction section, further performing separation at the same pressure and an operating temperature between the critical temperature of A and B, subjecting the supercritical fluid from the second stage extraction section and the extracted distillate oil to pressure reduction, and then bringing them into a separator; and adjusting the extraction pressure to obtain narrow distillates of different boiling ranges. The method disclosed in the invention increases the yield of extracted distillate oil, and also guarantees fine separation at the same time. The method has the characteristics of high separation precision and high selectivity, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite strengthening and toughening technology of high-tensile Fe-Ni-Cr-based high-temperature corrosion-resisting alloy

The invention discloses a composite strengthening and toughening technology of a high-tensile Fe-Ni-Cr-based high-temperature corrosion-resisting alloy. According to the composite strengthening and toughening technology, beneficial microelements are controlled by the compounding ratio of alloy components and the matching of specific vacuum-induction melting and an electro slag remelting duplex smelting technology, then a composite strengthening and toughening technique is adopted, namely isothermal controlled forging is adopted, forged meta-stable-state tissues are reserved in the alloy through quick cooling, and ageing strengthening is directly adopted. According to the composite strengthening and toughening technology disclosed by the invention, the corrosion resisting property of the Fe-Ni-Cr alloy is guaranteed, besides, the impact toughness (especially low-temperature impact toughness) of the alloy, the room-temperature tensile strength of the alloy, and the yield strength of the alloy can achieve a high level, and the combination property of the alloy disclosed by the invention is superior to that of the Incoloy925 alloy regulated by the American ASTM technical standard.

Owner:HENAN INST OF ENG

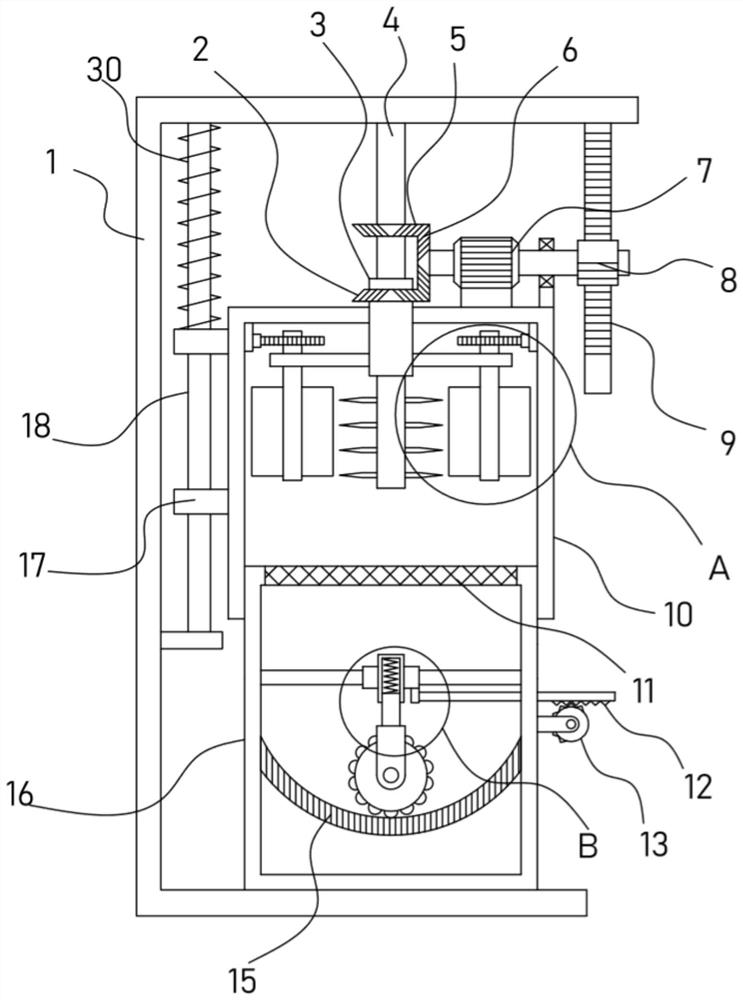

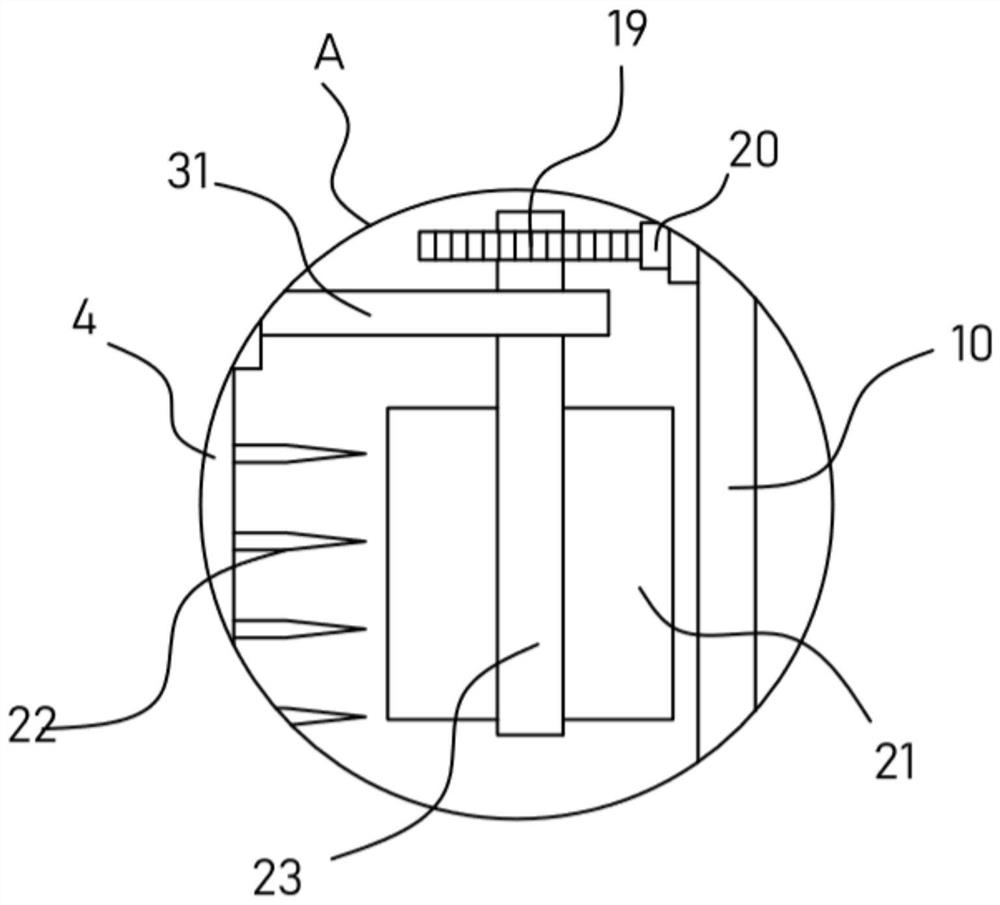

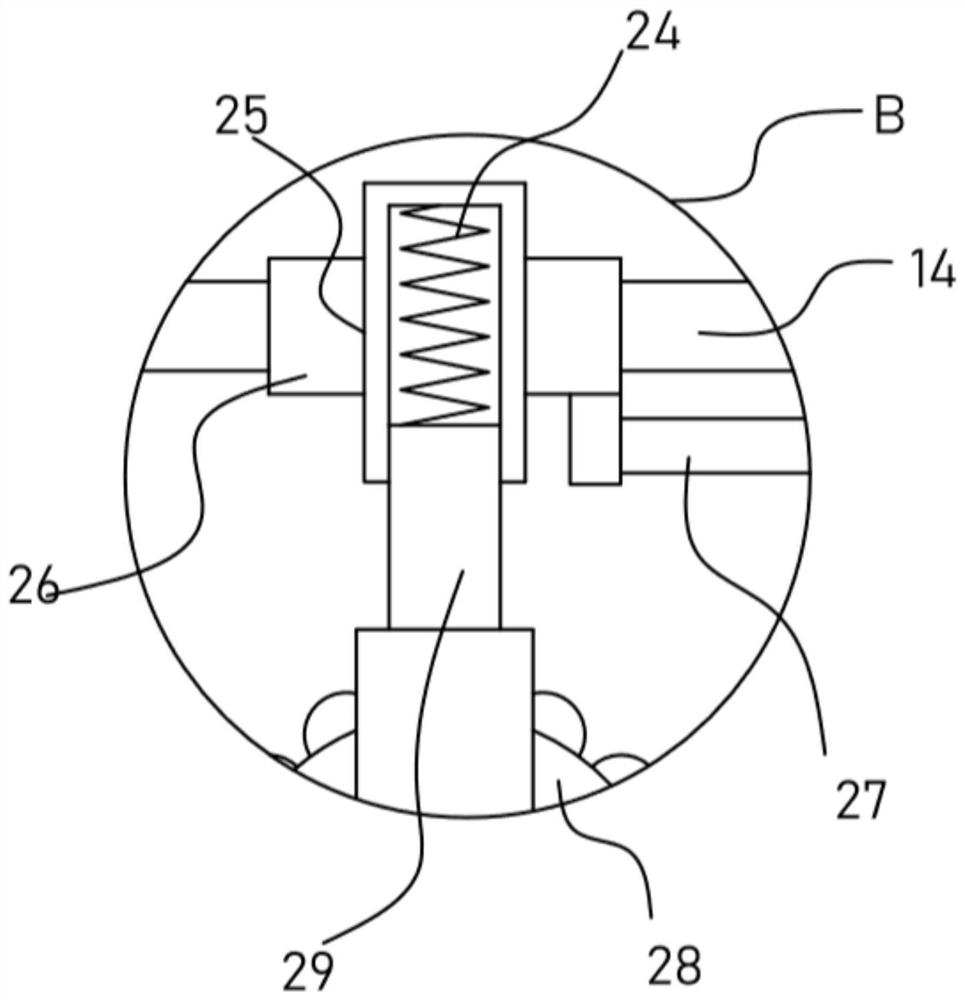

Grain crushing and grinding device for food processing

InactiveCN112108227AFully brokenFully detailedGrain treatmentsReciprocating motionAgricultural engineering

The invention discloses a grain crushing and grinding device for food processing, and relates to the technical field of food processing. The grain crushing and grinding device comprises a fixing frame, an arc-shaped mesh plate is arranged in a grinding box, a dispersing mechanism is in transmission connection with a crushing mechanism, and a lifting mechanism for driving a crushing box to vertically lift is in transmission connection with a double-shaft motor; a translation mechanism is arranged on the fixing frame, and a grinding mechanism abutting against the arc-shaped mesh plate is installed on the translation mechanism. According to the grain crushing and grinding device for the food processing, grains inside the crushing box are rotationally crushed and refined through the arranged crushing mechanism, the arranged lifting mechanism can drive the crushing box to vertically lift, namely the crushing mechanism can vertically lift to be continuously adjusted, and the effect of fullycrushing the grains in different position areas in the crushing box is achieved; and the arranged dispersing mechanism can achieve the dispersing effect of the grains, the crushing sufficient degree is higher, the arranged grinding mechanism can be driven by the translation mechanism to do transverse reciprocating motion and repeatedly grind the grains, and sufficient refining of the grains is effectively guaranteed.

Owner:盐池县荣桂昌食品科技有限公司

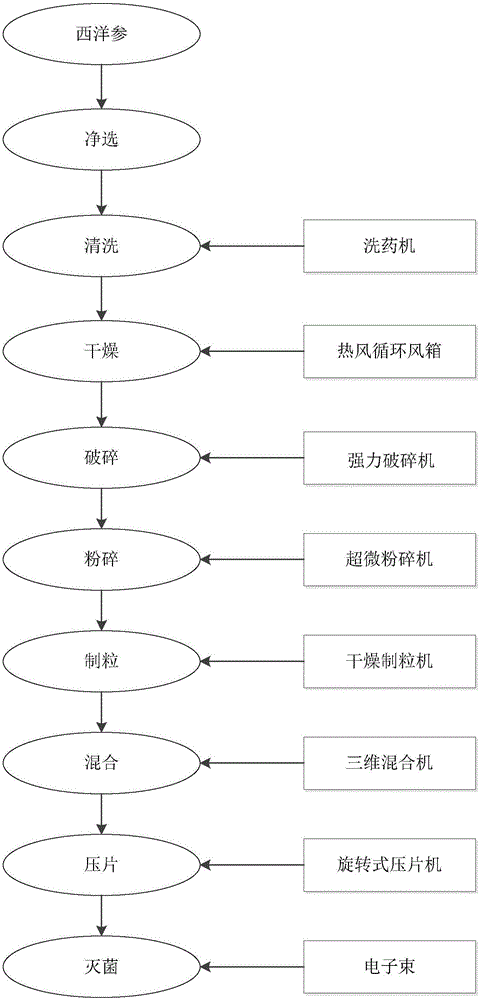

Preparation method of panax quinquefolius raw powder tablets

InactiveCN105902587ADisintegrates quicklySpeed up entryNervous disorderPill deliveryBioavailabilityProcessing cost

The invention discloses a preparation method of panax quinquefolius raw powder tablets, and belongs to the technical field of health care products. The method comprises nine steps: sorting, cleaning, drying, crushing, grinding, granulating, mixing, tabletting and sterilizing. The panax quinquefolius raw powder tablets do not contain any auxiliary materials; the bioavailability of product is increased; the product is more convenient to use, with longer guarantee period, lower processing cost, good dispersibility, miscibility and absorbability, thus the effective constituents of panax quinquefolius enter human body quickly; the original taste is reserved, and the health care function is increased; moreover, the dosage can be exponentially reduced, thereby effectively increasing utilization ratio of rare resources.

Owner:HEBEI LIN YITANG MEDICAL CO LTD

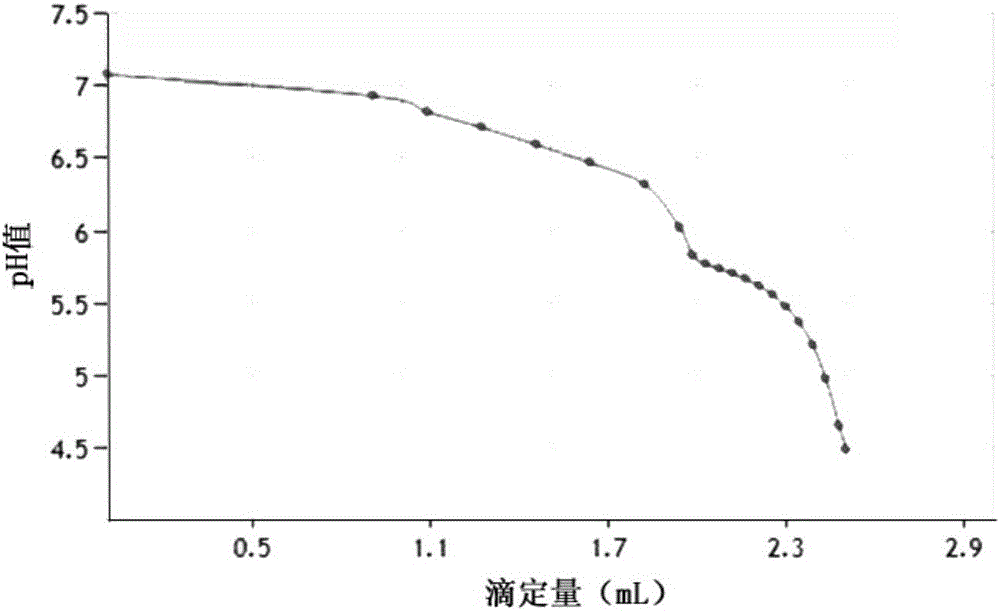

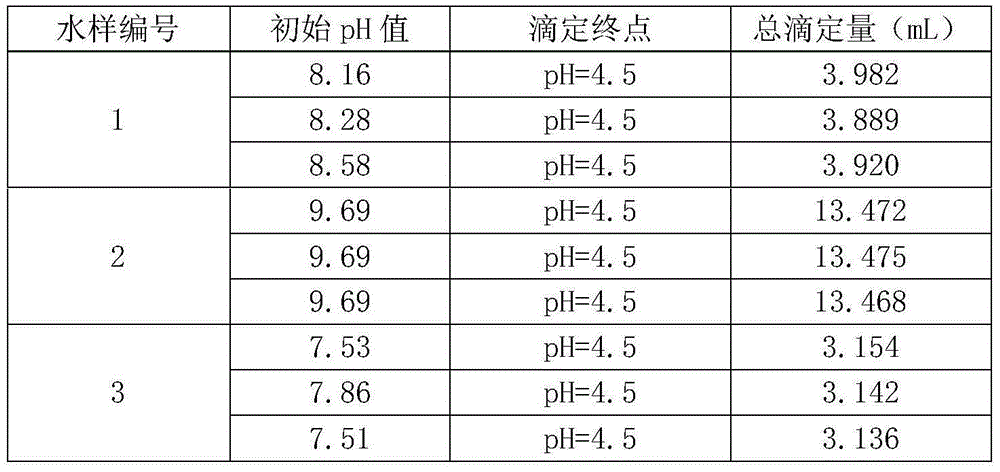

Automatic titration method and application

ActiveCN105116098AAdequate responseImprove accuracyChemical analysis using titrationChemical reactionData acquisition

The invention discloses an automatic titration method which includes the following steps of 1, sampling and sample pretreatment, 2, titrator presetting, 3, first-stage titration, 4, second-stage titration, 5, speed-regulation control quantity point post-titration and 6, data acquisition. The automatic titration method is a test method capable of accurately and scientifically judging the titration end point, the mode of setting speed-regulation control point and speed-regulation control quantity is adopted, and the refinement of the titration process is guaranteed; meanwhile, after the speed-regulation control quantity point is reached, a mode of dropwise adding and delayed judgment is adopted, so that the accuracy of the titration end point can be effectively guaranteed. A fully automatic mode is adopted for the automatic titration method, the influences, on the measurement result, of manual operation are avoided, and the measurement result is high in accuracy and good in repeatability; the automatic titration method can be used for rinse performance tests.

Owner:CHINA HOUSEHOLD ELECTRIC APPLIANCE RES INST

A kind of extra-thick quenched and tempered marine engineering eh40 steel and its preparation method

The invention relates to extra-thick tempering EH40 steel for ocean engineering. A steel plate comprises the following chemical components by weight percent: 0.12 to 0.15 percent of C, 0.15 to 0.50 percent of Si, 1.30 to 1.60 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.0050 percent of S, 0.020 to 0.050 percent of Nb, 0.020 to 0.050 percent of V, 0.008 to 0.020 percent of Ti, 0.15 to 0.40 percent of Ni, 0.10 to 0.20 percent of Cr, and balance of Fe and unavoidable impurity elements. The manufacturing process of the steel plate comprises the steps of smelting, casting, reheating, rolling and tempering. The tempering process is used for substituting the normalizing process to produce a low-scaling-ratio extra-thick plate, so that the adverse effect caused by the center segregation can be avoided.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

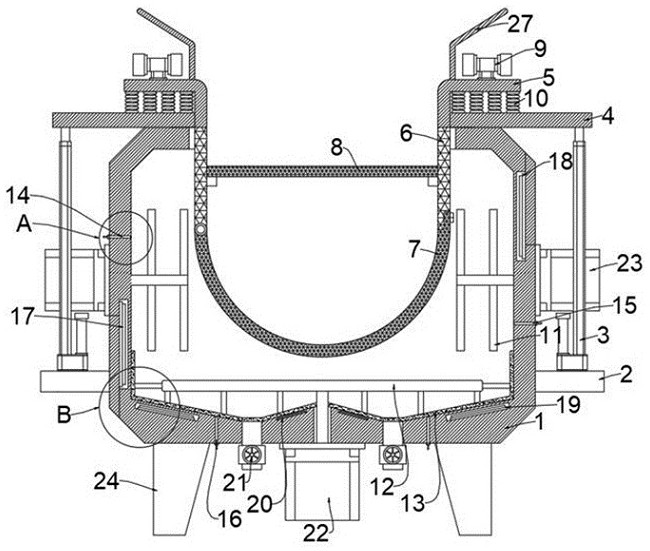

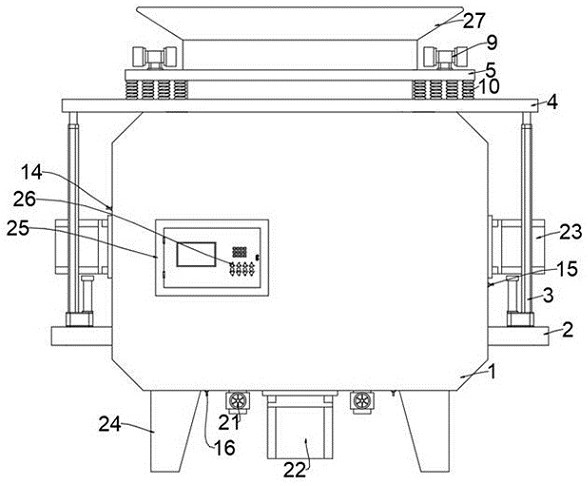

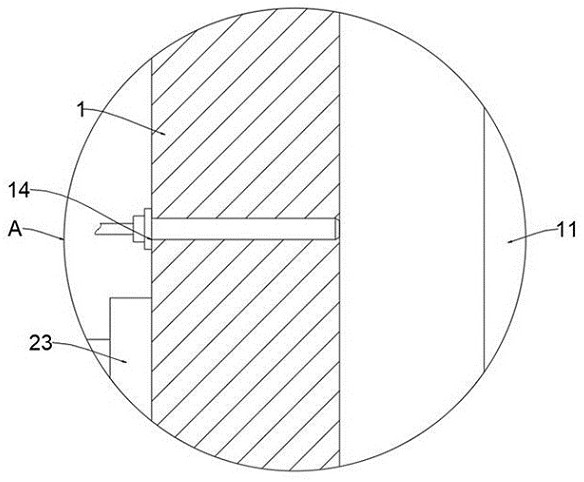

Steam curing kiln and steam curing method

InactiveCN111360992AGuaranteed refinementGuaranteed stabilityCeramic shaping apparatusThermodynamicsProcess engineering

The invention discloses a steam curing kiln and a steam curing method. The steam curing kiln comprises a kiln body, a steam control device, a water control device, a roller shutter door, a ventilationdevice and a master controller. A plurality of temperature sensors are arranged inside the kiln body. The steam control device comprises a steam inlet pipe, a first steam pipe and a second steam pipe. The first steam pipe and the second steam pipe communicate with the steam inlet pipe independently. The first steam pipe is provided with a plurality of first steam outlets. A first steam valve is arranged at the position of each first steam outlet. The second steam pipe is provided with a plurality of second steam outlets. A second steam valve is arranged at the position of each second steam outlet. The water control device comprises water spray pipes. Each water spray pipe is provided with a plurality of water spray ports. A water spray regulating valve is arranged at the position of eachwater spray port. The master controller is electrically connected with the ventilation device, the roller shutter door, the temperature sensors, the first steam valves, the second steam valves and thewater spray regulating valves respectively. With the steam curing kiln and the steam curing method, it can be implemented that temperatures of all points in the kiln can be accurately controlled, andthe quality and the production efficiency of track boards are improved.

Owner:北京智创赋能技术开发中心(有限合伙)

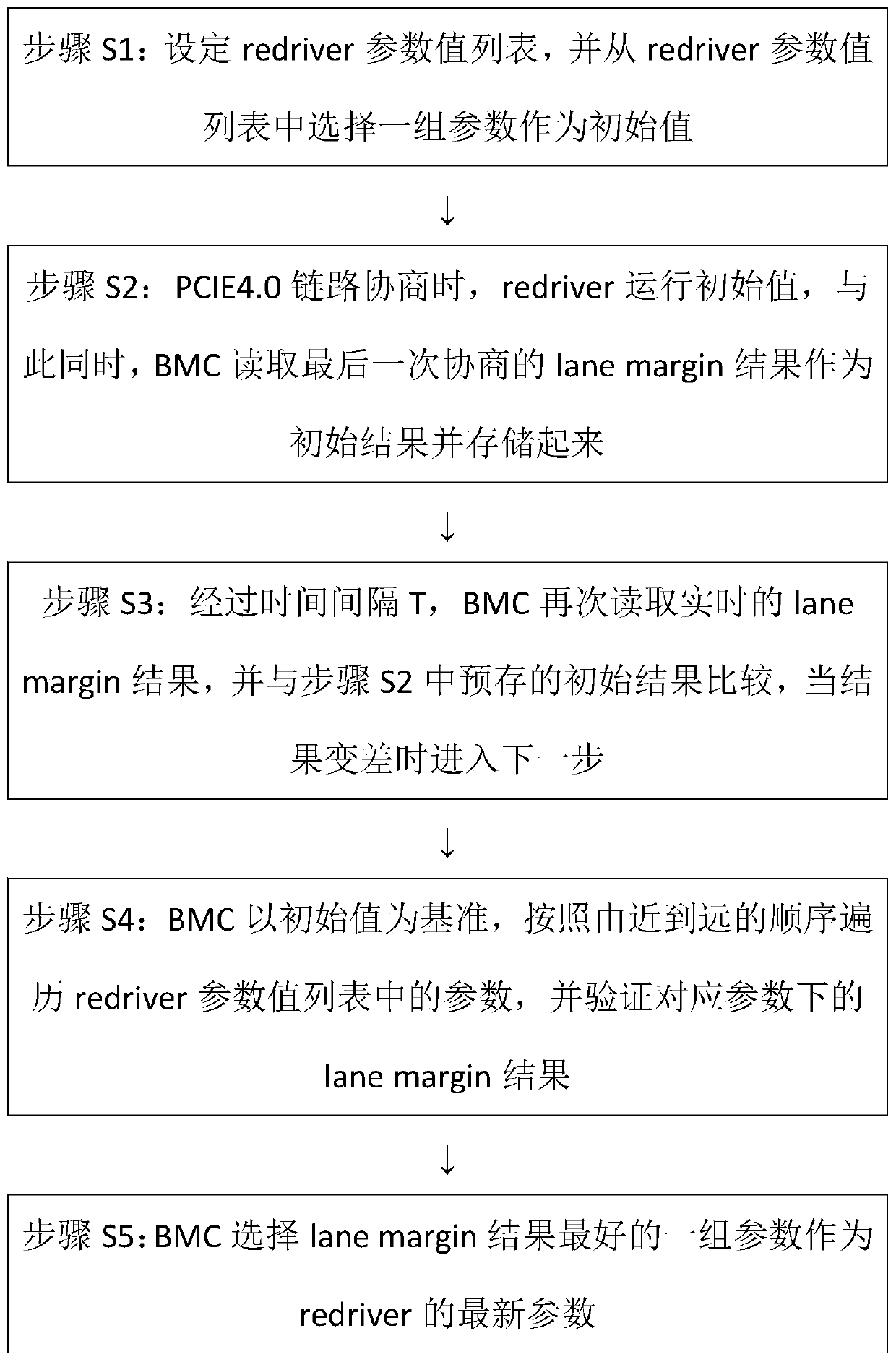

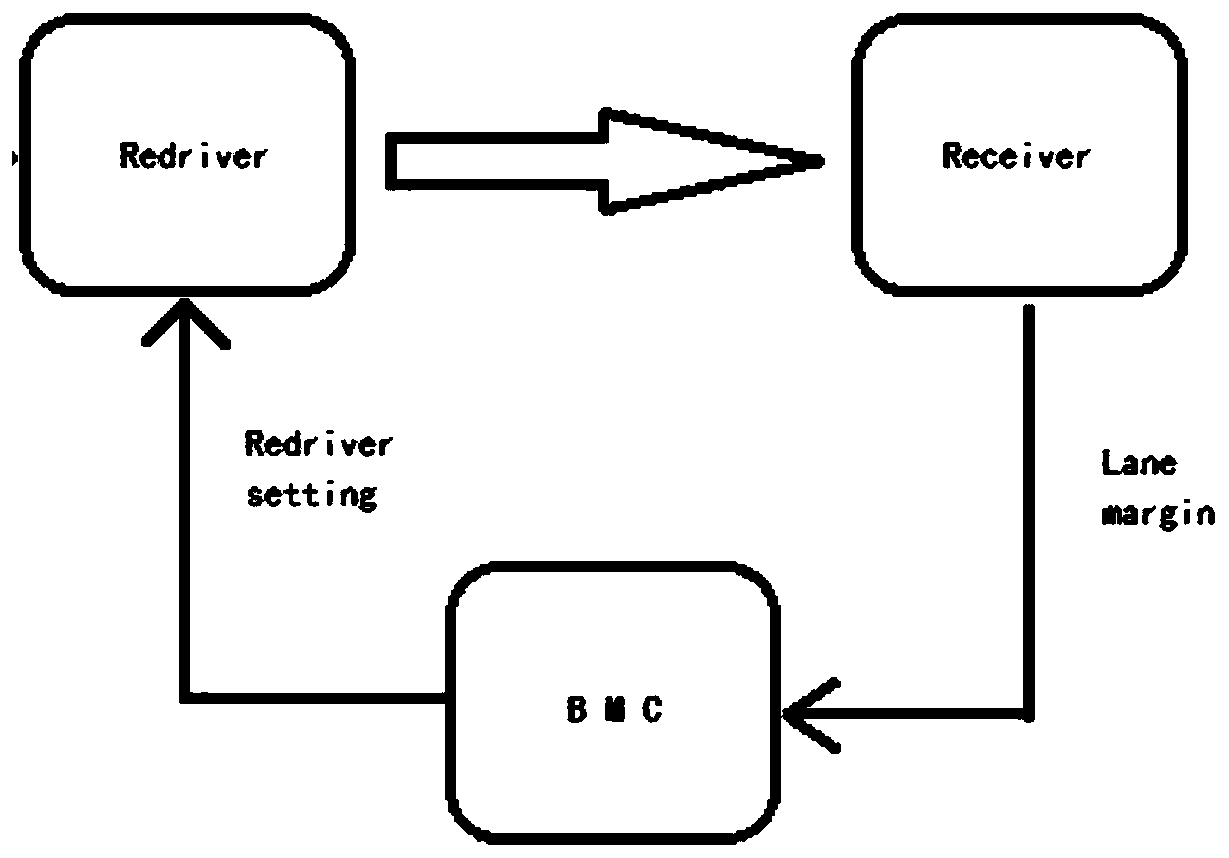

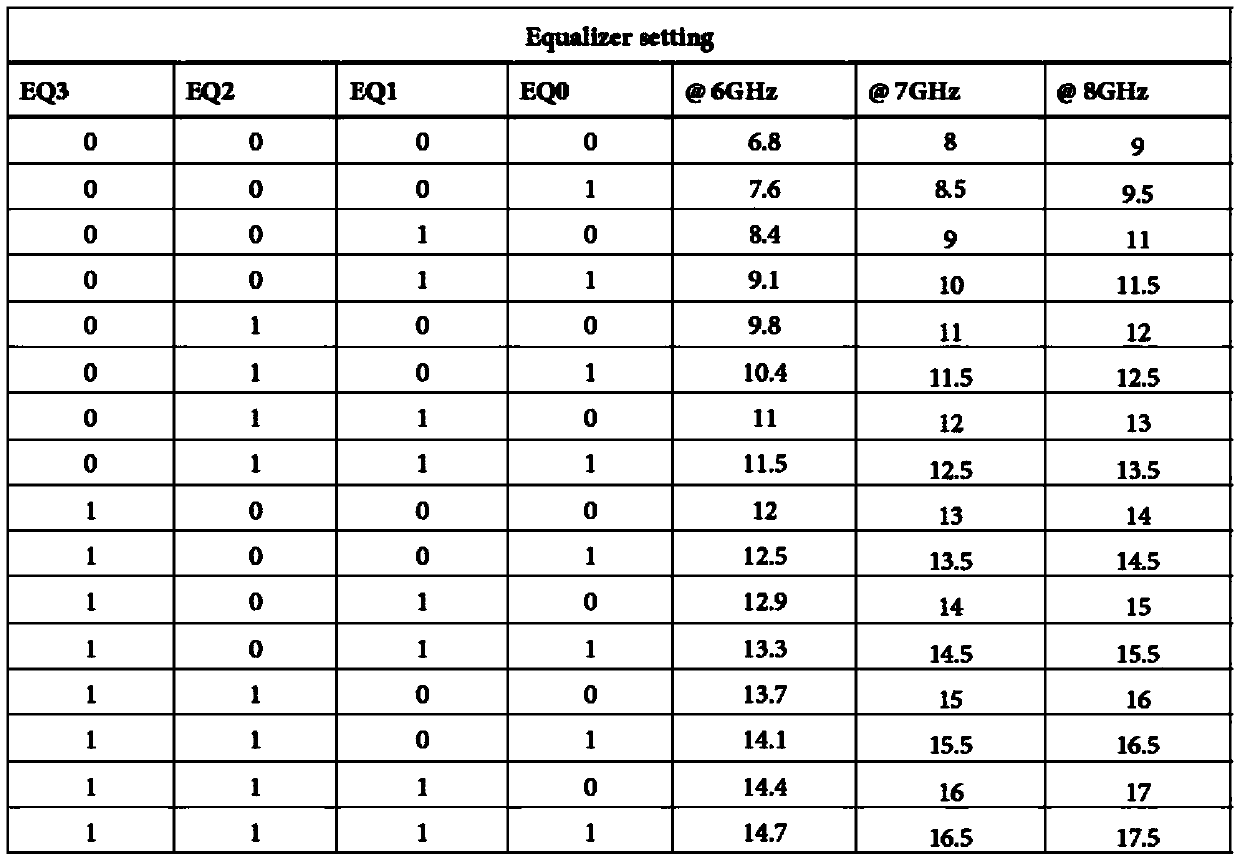

Method and device for realizing redriver parameter self-adaption in PCIE 4.0 link

ActiveCN110377547AImprove signal qualityAvoid influenceElectric digital data processingSignal qualityBaseboard

The invention provides a method and a device for realizing redriver parameter self-adaption in a PCIE4.0 link, and the method comprises the following steps: setting a redriver parameter value list, and selecting a group of parameters from the redriver parameter value list as initial values; when PCIE4.0 link negotiation is carried out, enabling the redriver to operate the initial value, and enabling the BMC to read the lane marker result of the last negotiation as the initial result and store the initial result; after the time interval T, enabling the BMC to read the real-time lane margin result again and compare the real-time lane margin result with the initial result pre-stored in the step S2, and when the result becomes poor, entering the next step; enabling the BMC to take the initialvalue as a reference, traverse parameters in the redriver parameter value list according to a sequence from near to far, and verify a lane marker result under the corresponding parameter; and enablingthe BMC to select a group of parameters with the best lane margin result as the latest parameters of the redriver. The device comprises a BMC (Baseboard Management Controller) used for correcting a parameter value of a redriver according to a lane margin result; and the redriver is used for operating the parameter values corrected by the BMC. The PCIE 4.0 signal quality is monitored at regular time through the BMC, and the redriver parameter is adjusted in real time according to the change of the signal quality.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

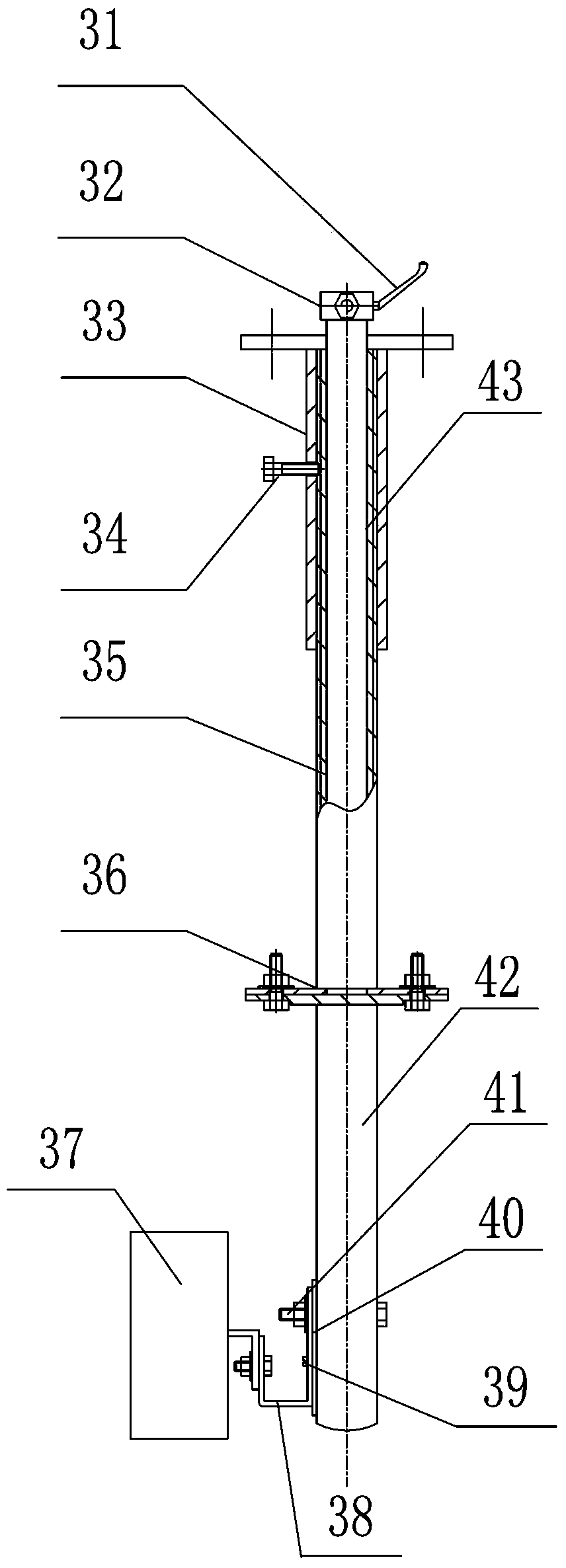

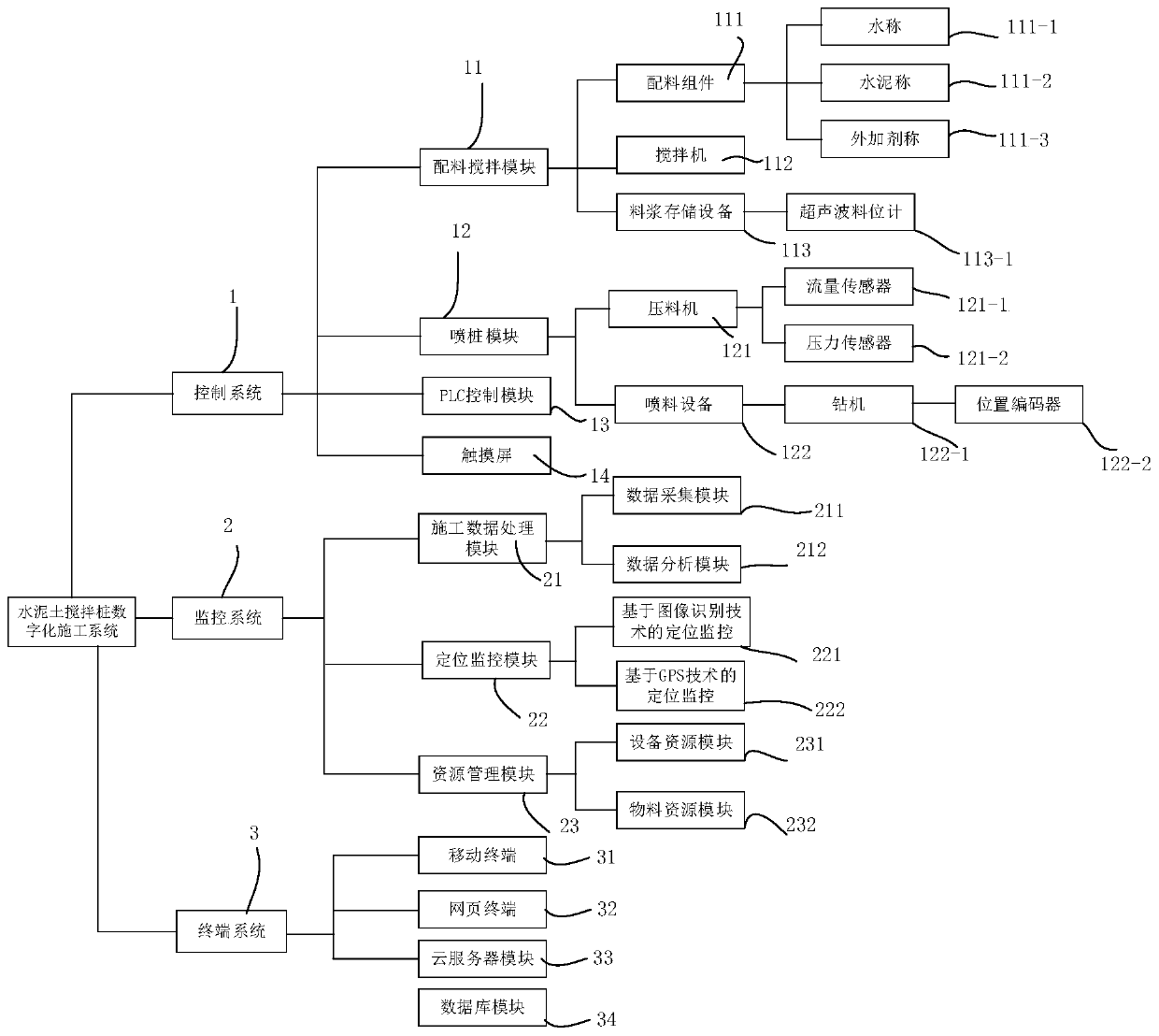

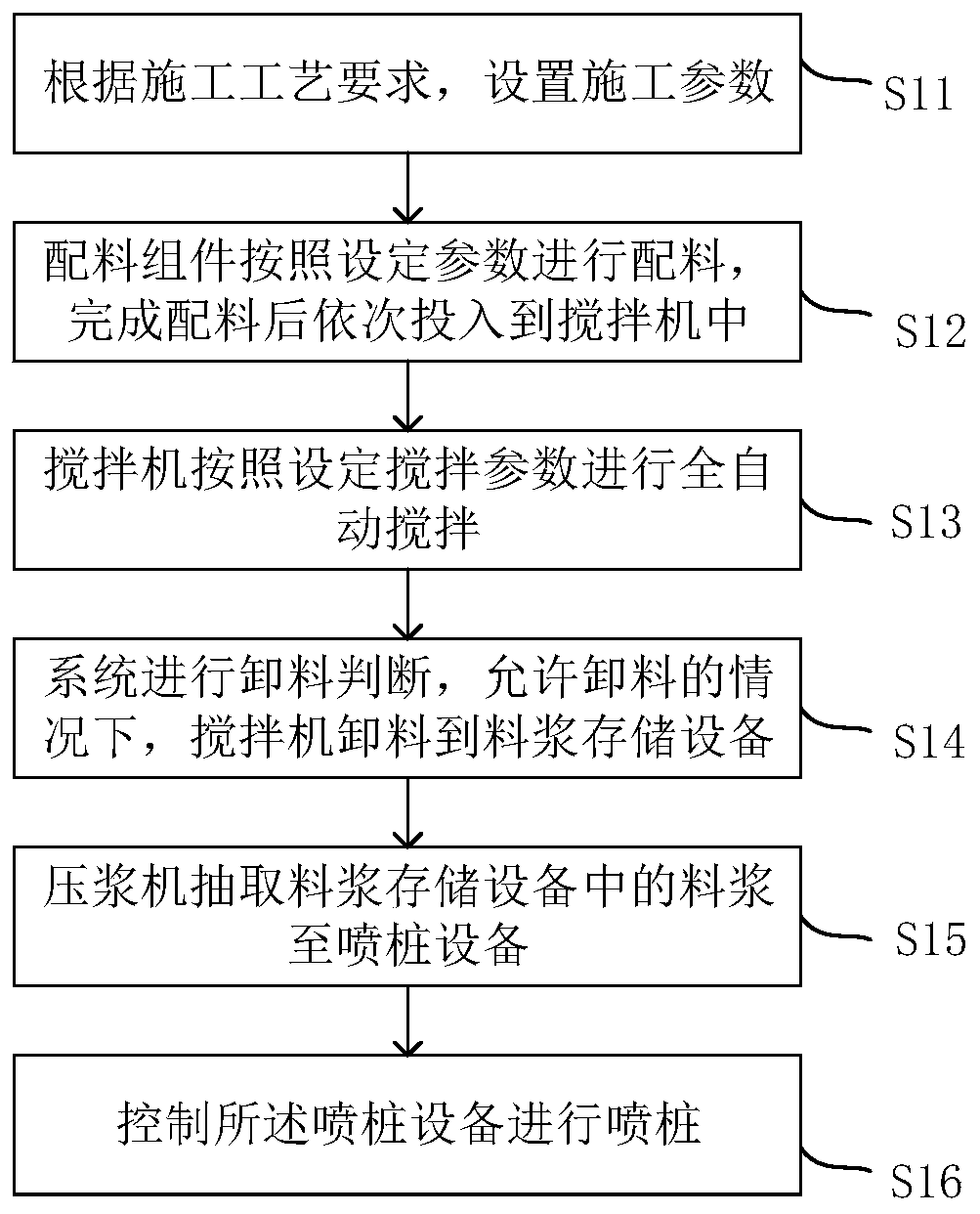

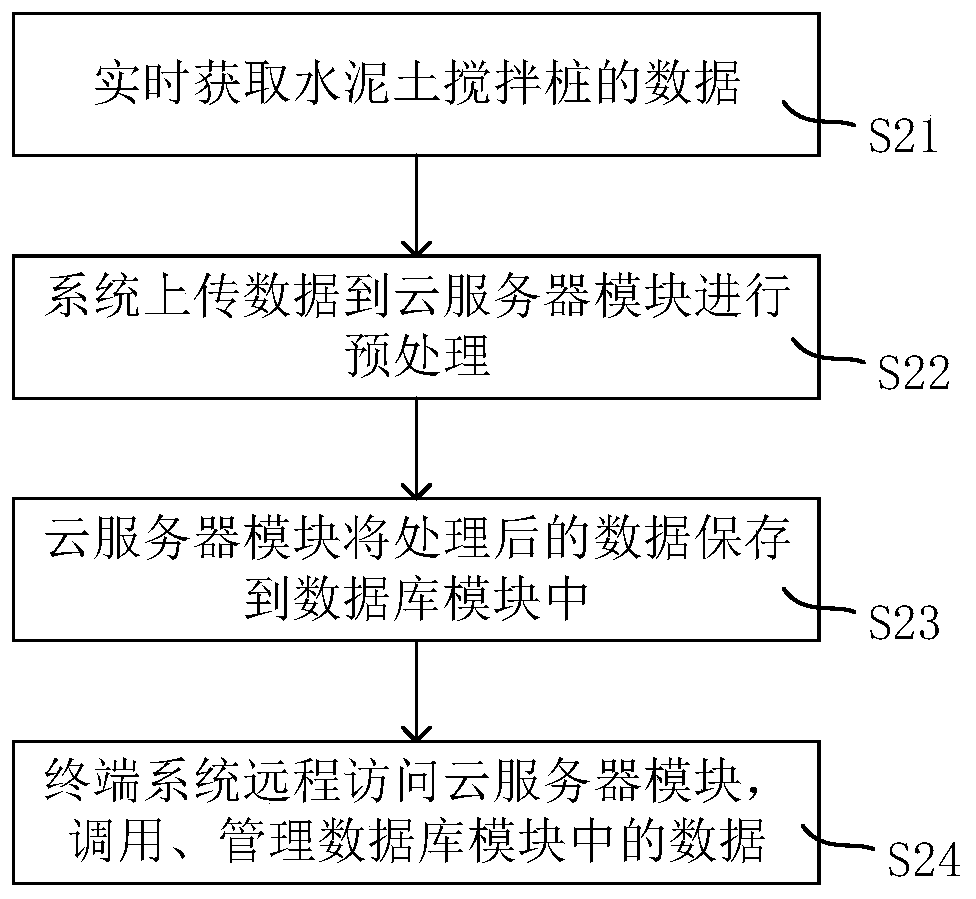

Digital construction system and method for cement mixing piles

InactiveCN111007793AGuaranteed normalizationGuaranteed refinementProgramme control in sequence/logic controllersBulkheads/pilesProcess engineeringTerminal system

The invention discloses a digital construction system and method for a cement mixing pile. The digital construction system comprises a control system, a monitoring system and a terminal system. The control system comprises an ingredient stirring module, a pile spraying module, a PLC control module and a touch screen. The ingredient stirring module, the pile spraying module and the touch screen areelectrically connected with the PLC control module. The monitoring system comprises a construction data processing module, a positioning monitoring module and a resource management module. Parameters, positions and operation conditions of a cement mixing pile machine are comprehensively integrated through the monitoring system, construction data are monitored and analyzed in real time, the standardization and accuracy of construction are improved, and the monitoring system, the terminal system and the touch screen are electrically connected to achieve data transmission with the control system. According to the digital construction system and method adopting the scheme, the construction efficiency and the construction quality are improved, and the construction process is more standardized,finer and more intelligent.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG +1

High-performance hard alloy material

The invention discloses a high-performance hard alloy material, and belongs to the field of hard alloy materials. The high-performance hard alloy material is prepared by the following raw materials inparts by weight: 65-80 parts of WC, 5-10 parts of Co, 10-15 parts of TiC, 3-8 parts of Ni, and 0.2-0.7 part of grain growth inhibiting agent; preferentially, the high-performance hard alloy materialis prepared by the following raw materials in parts by weight: 70-75 parts of WC, 7-9 parts of Co, 12-14 parts of TiC, 4-6 parts of Ni, and 0.3-0.5 part of grain growth inhibiting agent; the grain growth inhibiting agent is TaC; and the weights of all the components have the following relations: Ni / (Co+Ni) is not more than 0.4 and not less than 0.3; and (0.06WC+0.2TiC) / (WC+Co+TiC+Ni) is not more than 0.08 and not less than 0.05. Through improvement of the formula, the high-performance hard alloy material reduces adding of such expensive materials as Co and TaC, so that the production cost is reduced; and through reasonable batching, the hardness, the toughness and the cutting performance of the finally prepared high-performance hard alloy material are greatly improved compared with a traditional hard alloy material.

Owner:技锋精密刀具(马鞍山)有限公司

Production process for large-thickness explosive welding 09MnNiDR composite plate for ultralow-temperature pressure container

ActiveCN105364294AImprove the bonding strength of the interfaceFfect processabilityDomestic vesselsWelding/soldering/cutting articlesDetonationSS - Stainless steel

The invention discloses a large-thickness explosive welding metal composite plate for an ultralow-temperature pressure container, and a production process, and relates to a process for S31603 and S30403 stainless steel plates, and a large-thickness explosive welding composite plate of 09MnNiDR steel plates for an ultralow-temperature pressure container. The invention provides a simple and convenient, economic, and practical method. The method comprises the following steps: laying prepared low-detonation-velocity explosives on a composite plate according to a design explosive height, and after the completion of the explosive laying, laying high-detonation-velocity explosives with a width of 30mm and a depth which is equal to the design height along long side parts, so as to control the detonation wave movement direction of the low-detonation-velocity explosives to be close to the rolling direction of a base plate, so that the corrugations of bonding interfaces of the composite plate are distributed along the rolling direction of the base plate, and the bonding strength of the bonding interfaces of the composite plate is reinforced. By virtue of a furnace-charge preheating, segmented spraying and rapid cooling process, the problem that the mechanical properties of the core part of the large-thickness explosive welding metal composite plate cannot meet design requirements is solved, and the needs of deep-cooling equipment manufacturing industry on large-thickness explosive welding metal composite plate are met.

Owner:舞钢神州重工金属复合材料有限公司

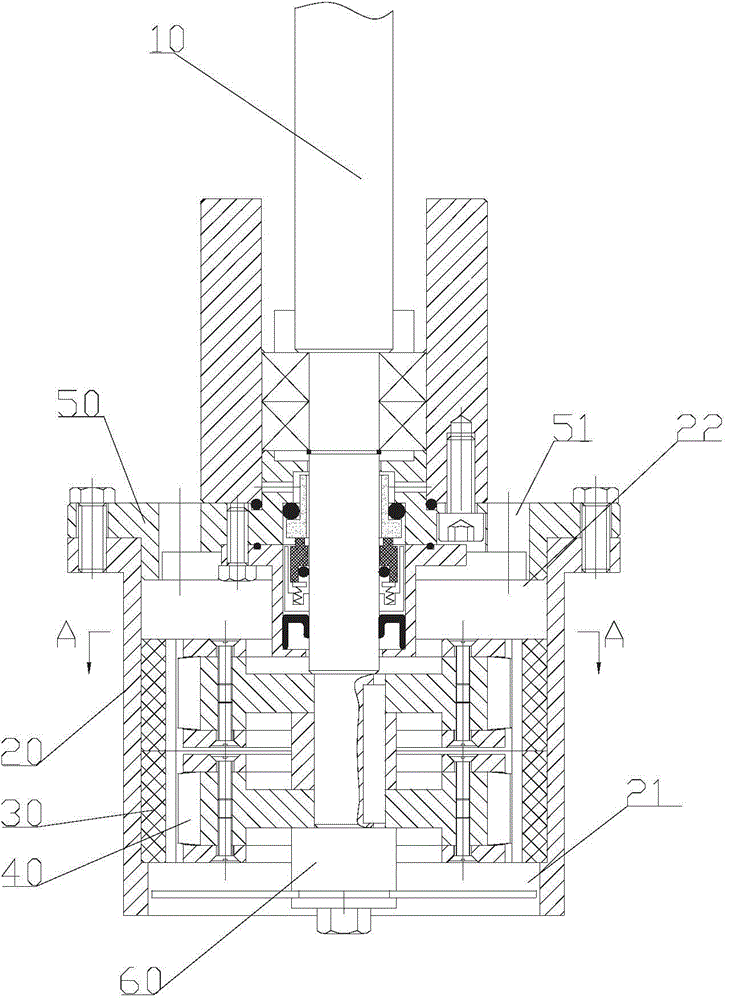

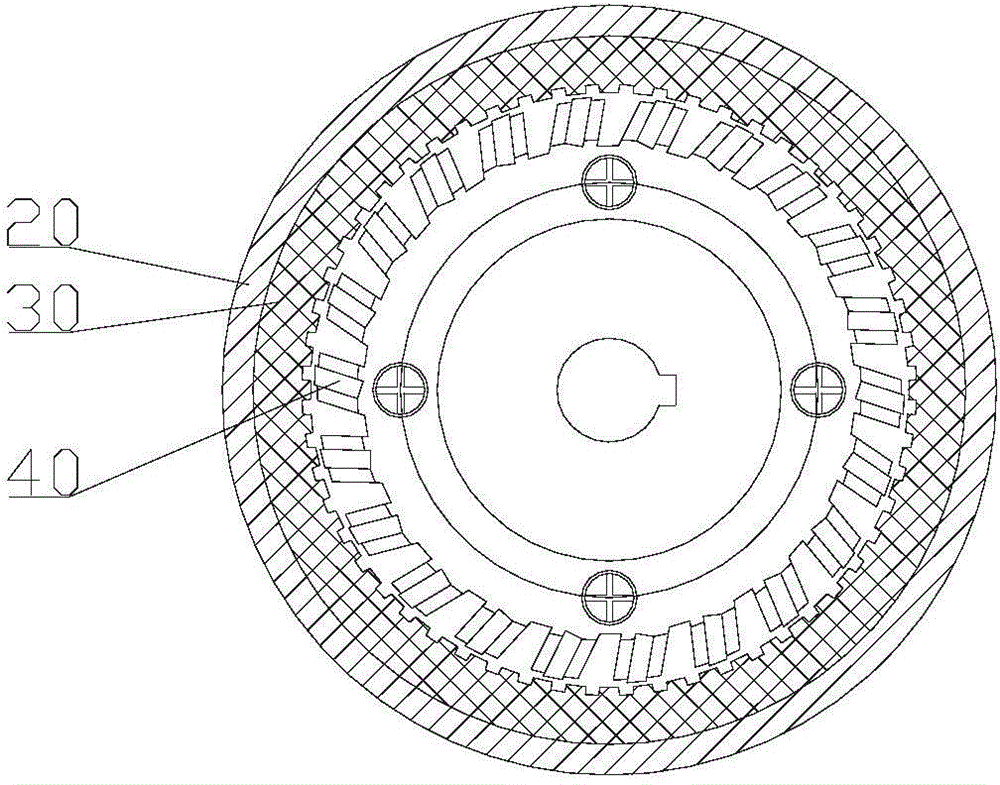

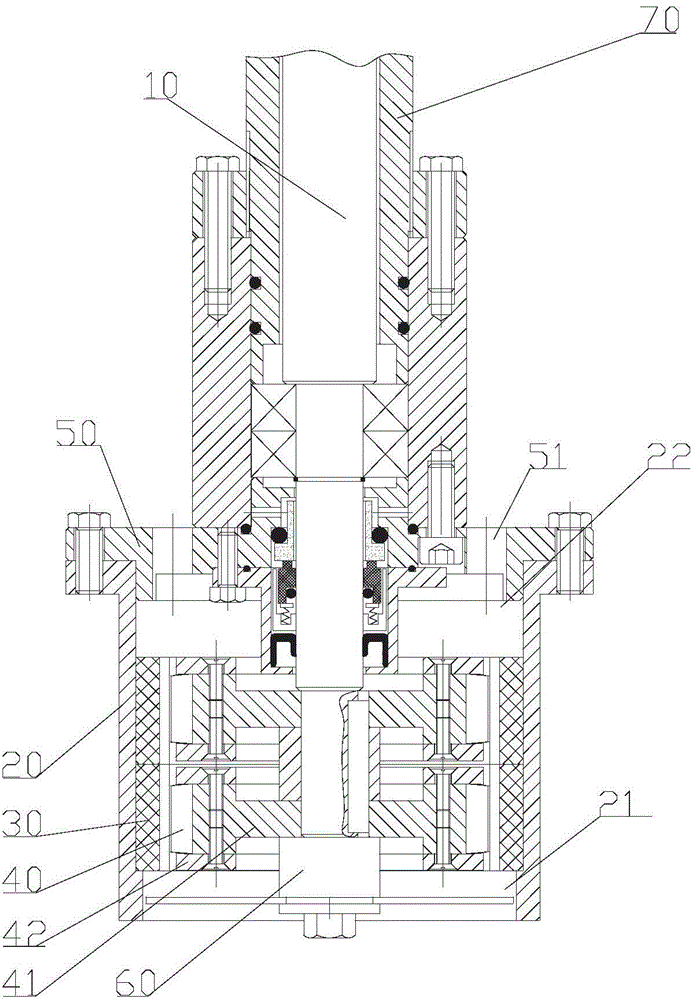

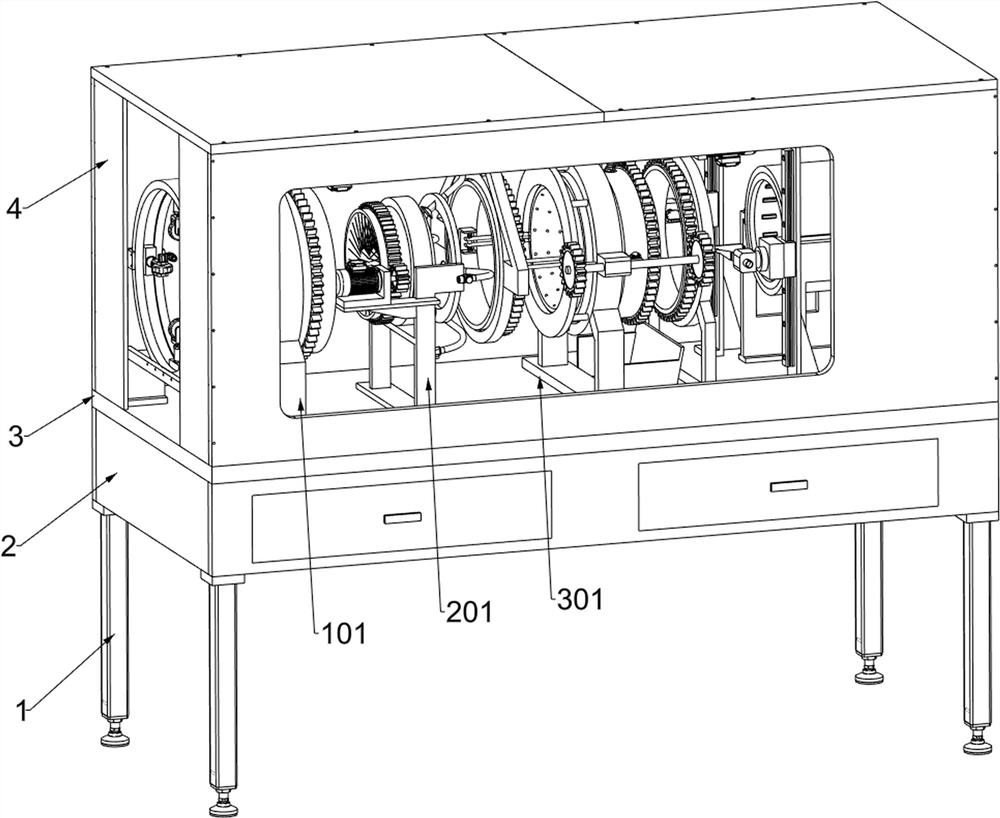

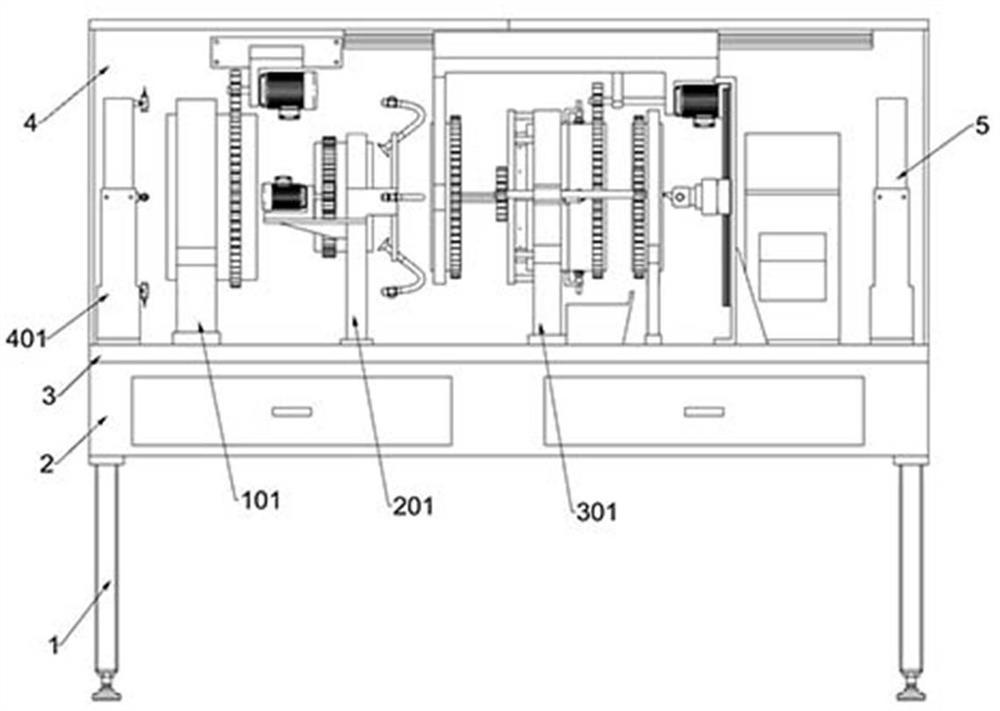

Ceramic superfine homogenizing and emulsifying machine

The invention discloses a ceramic superfine homogenizing and emulsifying machine. The machine comprises a homogenizing shaft; an outer shell, which sleeves on one end of the homogenizing shaft; a ceramic stator ring, which is arranged on the circumferential inner wall of the outer shell; a centrifugal rotor ceramic blade, which is arranged in the inner side of the ceramic stator ring and forms an inclined angle with the ceramic stator ring; a connecting flange, which sleeves on the homogenizing shaft and is arranged in the material outlet; and a material absorbing disc, which is arranged in the material inlet. The centrifugal rotor ceramic blade and the ceramic stator ring are arranged to form an inclined angle, so the shearing between the two is performed in a point-contact mode, the shearing resistance is small, the efficient is high, the material temperature rising is low, and the particle fineness of the grinded material is improved. The ceramic stator ring is directly arranged on the circumferential inner wall of the outer shell, thus the processing and production of ceramic stator ring become easier, the installation and exchange are simple and convenient, and at the same time the work strength of the ceramic stator ring is guaranteed. Moreover, the material absorbing disc can continuously supply materials to the place between the ceramic stator ring and the centrifugal ceramic cutter in a high rotation speed, and the material transportation is accelerated.

Owner:南通市通州区三槐机械制造有限公司

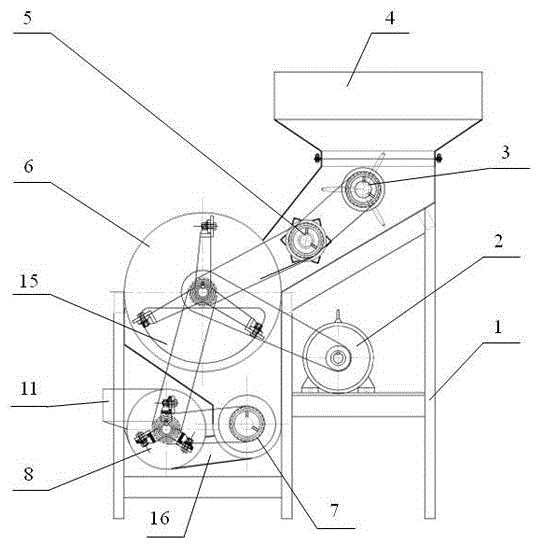

Seed melon crushing and seed taking machine

InactiveCN103329685BEffective hygienic separationNovel structureSievingScreeningMotor drivePulp and paper industry

The invention discloses a seed melon crushing seed-taking machine, wherein a feed hopper, a motor, a crushing device, a skin and pulp separation device, a spiral crushing delivery device and a seed and pulp separation device are arranged on a rack of the seed-taking machine; the motor drives the crushing device, the skin and pulp separation device, the spiral crushing delivery device and the seed and pulp separation device; the feed hopper is arranged above an inlet of the crushing device, and an outlet of the crushing device is communicated with an inlet of the skin and pulp separation device; the bottom end of the skin and pulp separation device adopts a screen structure and communicated with the spiral crushing delivery device; an outlet of the spiral crushing delivery device is communicated with the seed and pulp separation device. According to the invention, the effective and sanitary separation of the seed melon skin, pulp and seeds is realized, and the indicators of all separated items meet various indicator requirements for the follow-up processing. The novel seed melon crushing seed-taking machine disclosed by the invention has the following characteristics: the machine is designed according to the production line for full utilization of seed melons, the structure is novel, simple and practical, the entire crushing and separation process is completed through automation, the processing efficiency is high, and the productivity reaches 10 tons per hour.

Owner:甘肃靖远银农籽瓜科技有限公司 +1

Steel surface strengthening device with self-cleaning function

PendingCN114657576AImprove cleanlinessGuaranteed refinementHollow article cleaningPretreated surfacesPipeDust particles

The invention relates to the field of steel cleaning, in particular to a steel surface strengthening device with a self-cleaning function. The technical problems that in the prior art, the steel cleaning efficiency is low, and square and round long pipe steel is difficult to integrally clean are solved. According to the technical scheme, the steel surface strengthening device with the self-cleaning function comprises a workbench, a corrosion cleaning system and the like; the left part of the upper surface of the workbench is connected with a corrosion cleaning system. Before strengthening, adaptive derusting operation is carried out according to the shape of the steel pipe; an annular brush made of hard plastic is used for conducting secondary cleaning on the derusted steel pipe in a rotating mode, residual rust particles and dust particles on the surface of the steel pipe are effectively cleaned away, meanwhile, residual cleaning liquid on the surface of the steel pipe is removed through the flexibility of sponge, a side protection material is sprayed on the surface of the steel pipe, and the surface of the steel pipe is protected. And the sprayed protective layer is dried and guided, so that the thickness of the protective liquid on the surface of the steel pipe is consistent, and covering is complete.

Owner:江苏如石机械股份有限公司

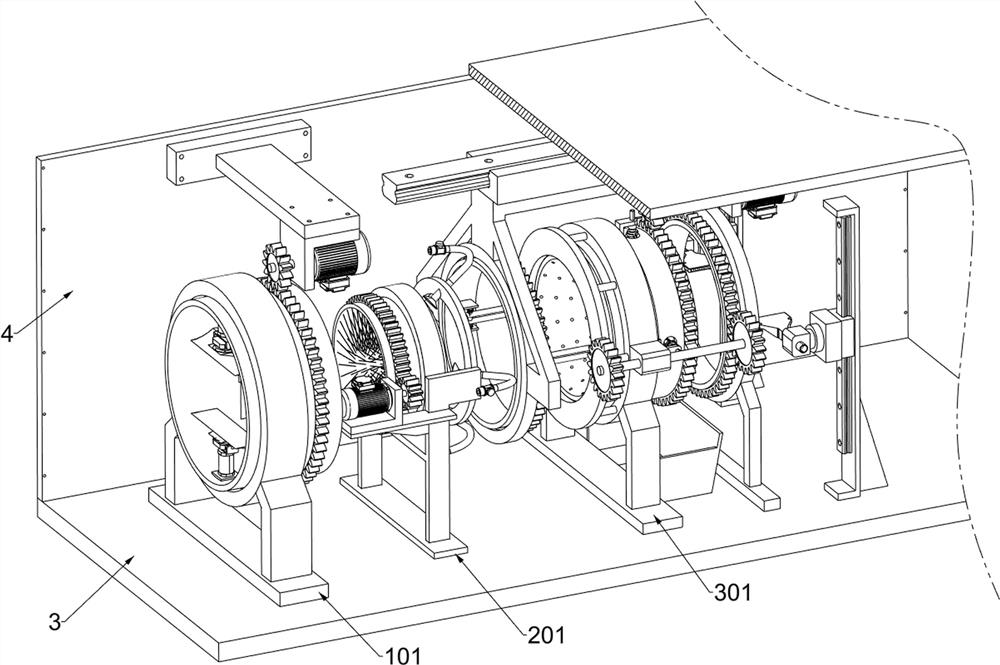

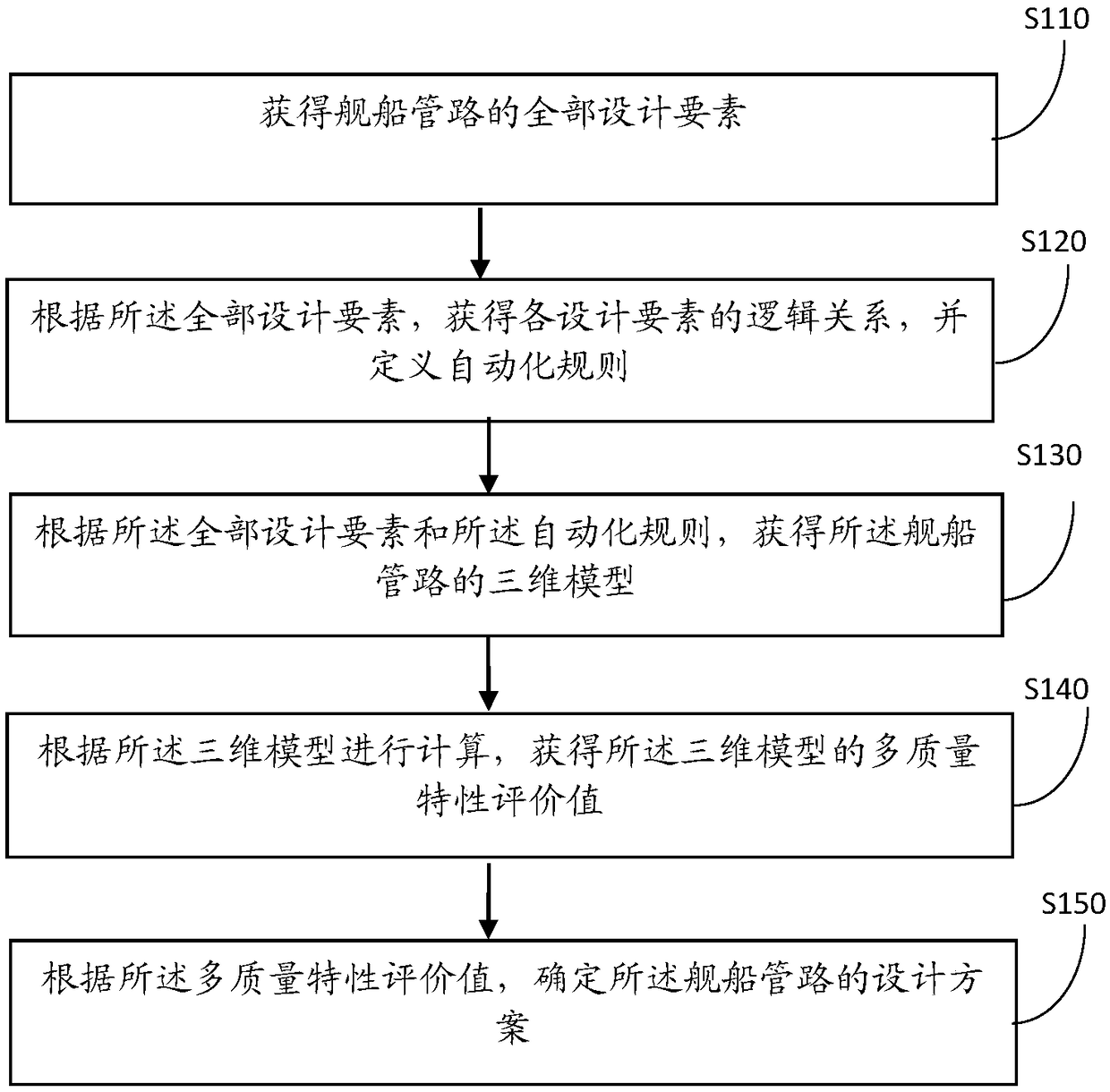

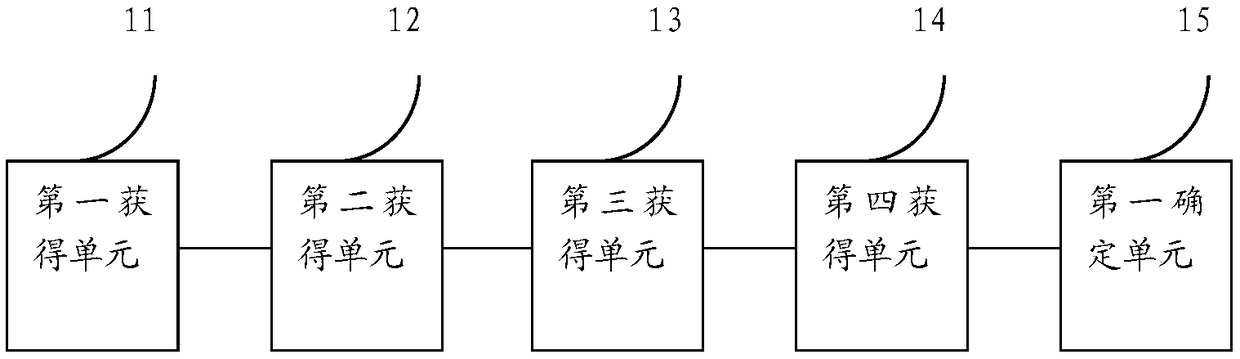

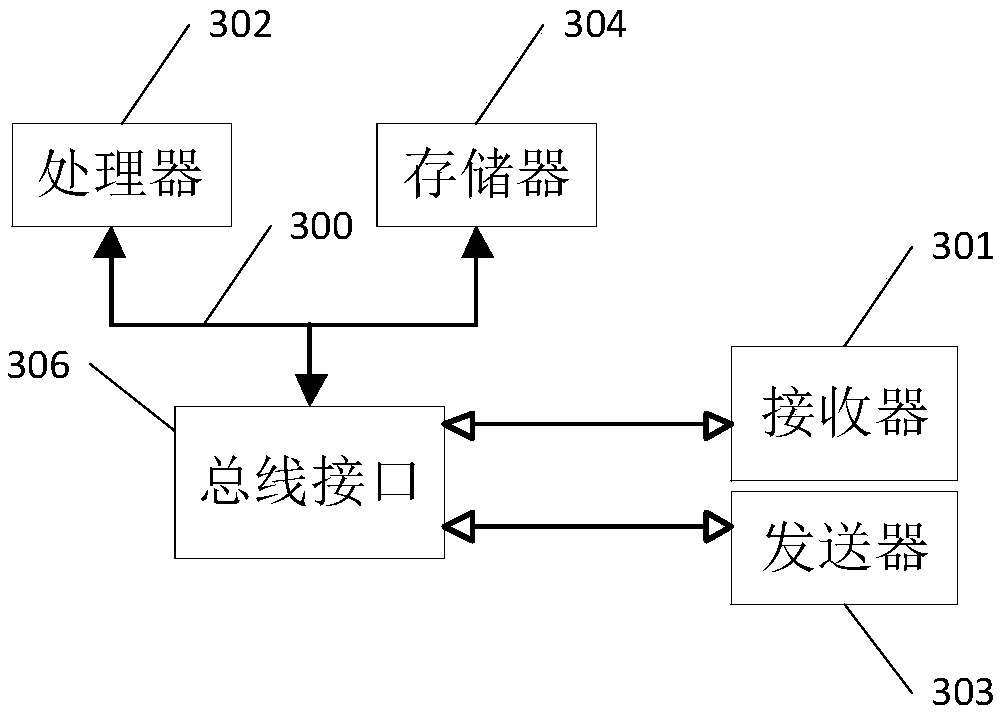

A method and device for three-dimensional design of a ship pipeline

PendingCN109325281AGuaranteed refinementImprove performanceGeometric CADDesign optimisation/simulationSystems designMaintainability

The invention provides a method and device for three-dimensional design of a ship pipeline. The method comprises the steps of obtaining all design elements of the ship pipeline; obtaining the logicalrelations of each design element according to all the design elements, and defining automation rules; obtaining a three-dimensional model of the ship pipeline according to the all design elements andthe automation rules; calculating according to the three-dimensional model to obtain a multi-quality characteristic evaluation value of the three-dimensional model; according to the multi-mass characteristic evaluation value, determining a design scheme of the ship pipeline. The method solves the technical problems of performance design optimization, maintainability evaluation, lack of definitionof producibility, and serious disconnection between 3D and simulation calculation, and achieves the effects that the pipeline refinement degree is improved, the pipeline multi-characteristic fast analysis and simulation make the scheme performance better, the automatic inspection and evaluation is realized, the refinement and accuracy of the design scheme is ensured, users can locate the design bottleneck of the pipeline system more easily and faster, and the efficiency is improved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

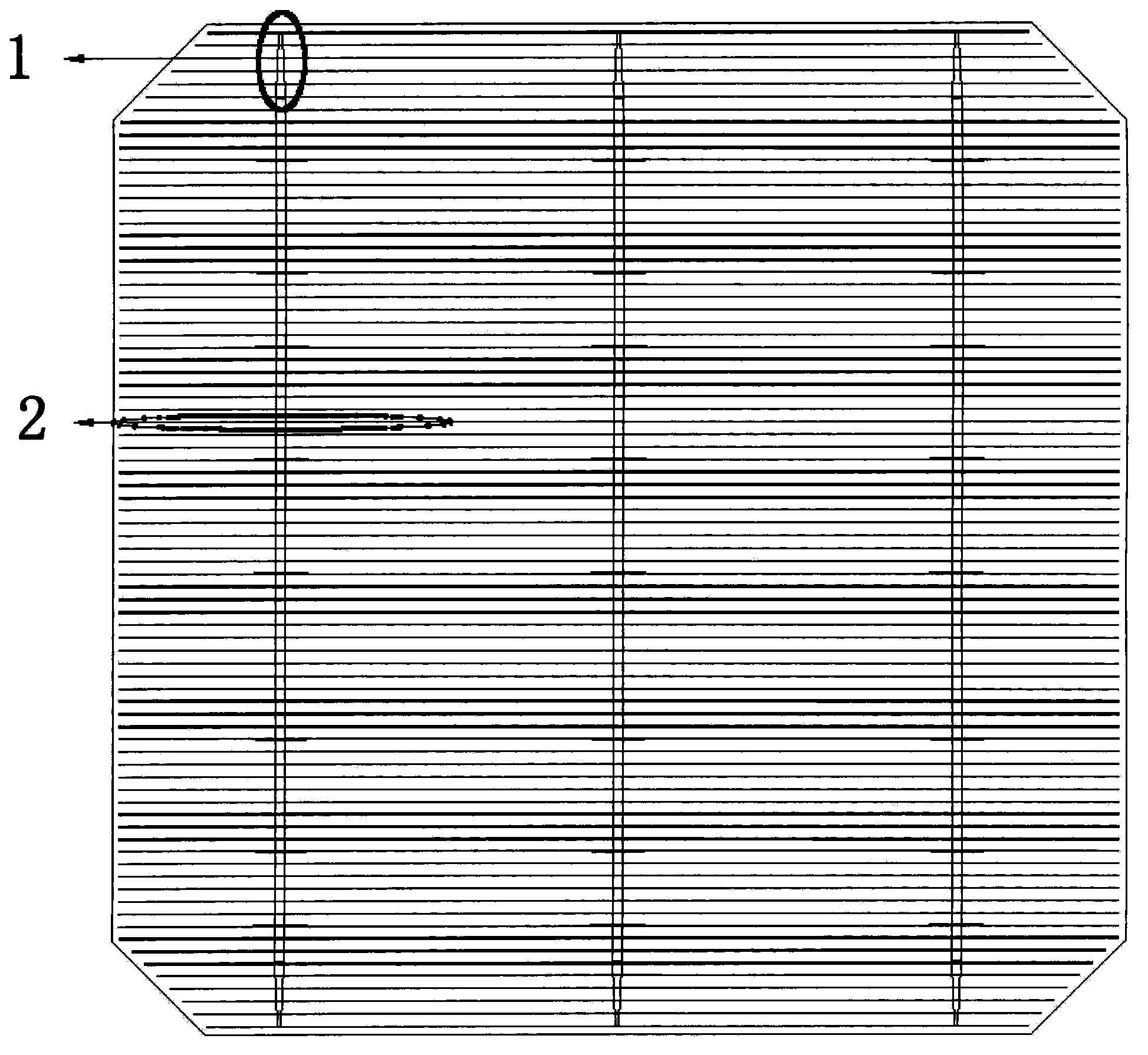

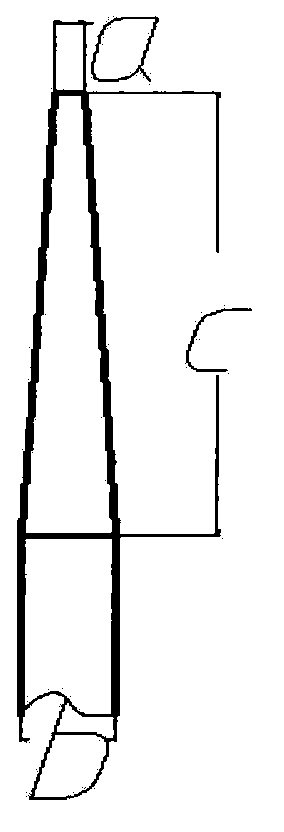

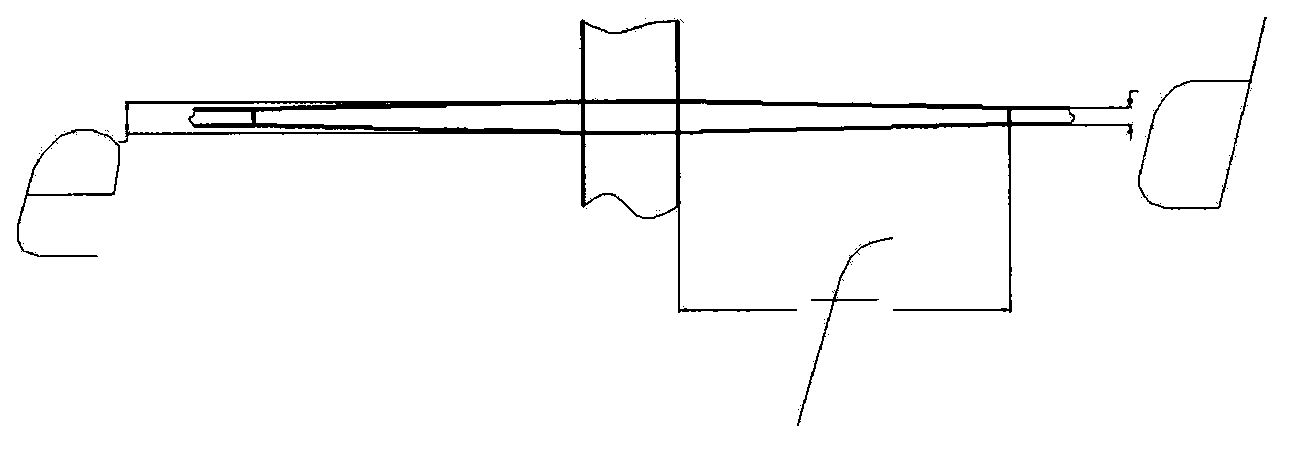

Solar cell with three gate electrode structures

InactiveCN103840016AGuaranteed refinementReduce shading areaPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention relates to a solar cell with three gate electrode structures. A front face gate line structure comprises three symmetrical primary gate lines and a plurality of evenly distributed secondary gate lines perpendicular to the primary gate lines, one primary gate line is located on the center line of a silicon wafer, and the two ends of each primary gate line and the part, connected with the corresponding primary gate line, of each secondary gate line are respectively of a gradual change type structure. A back face structure comprises three primary gate lines corresponding to the front face gate lines, and asymmetric direction signs smaller than the width of the gate lines exist in the grate line direction. According to the gradual change type structures of the two ends of the primary gate lines, the two ends of each primary gate line gradually narrow down and are of a trapezoid gradual change stricture. According to the gradual change stricture of each secondary gate line, in the junction of the secondary gate line and the corresponding primary gate line, the width of the position, close to the corresponding primary gate line, of the secondary gate line is large, the secondary gate line gradually narrows down when far away from the corresponding primary gate line, and when the secondary gate line reaches a certain length, the width of the secondary gate line is the smallest and will no longer change. The solar cell with the three gate electrode structures can lower cell cost, improve the efficiency of solving problems, and improve the efficiency of a battery piece to a certain extent.

Owner:SHAANXI TIANHONG SILICON IND

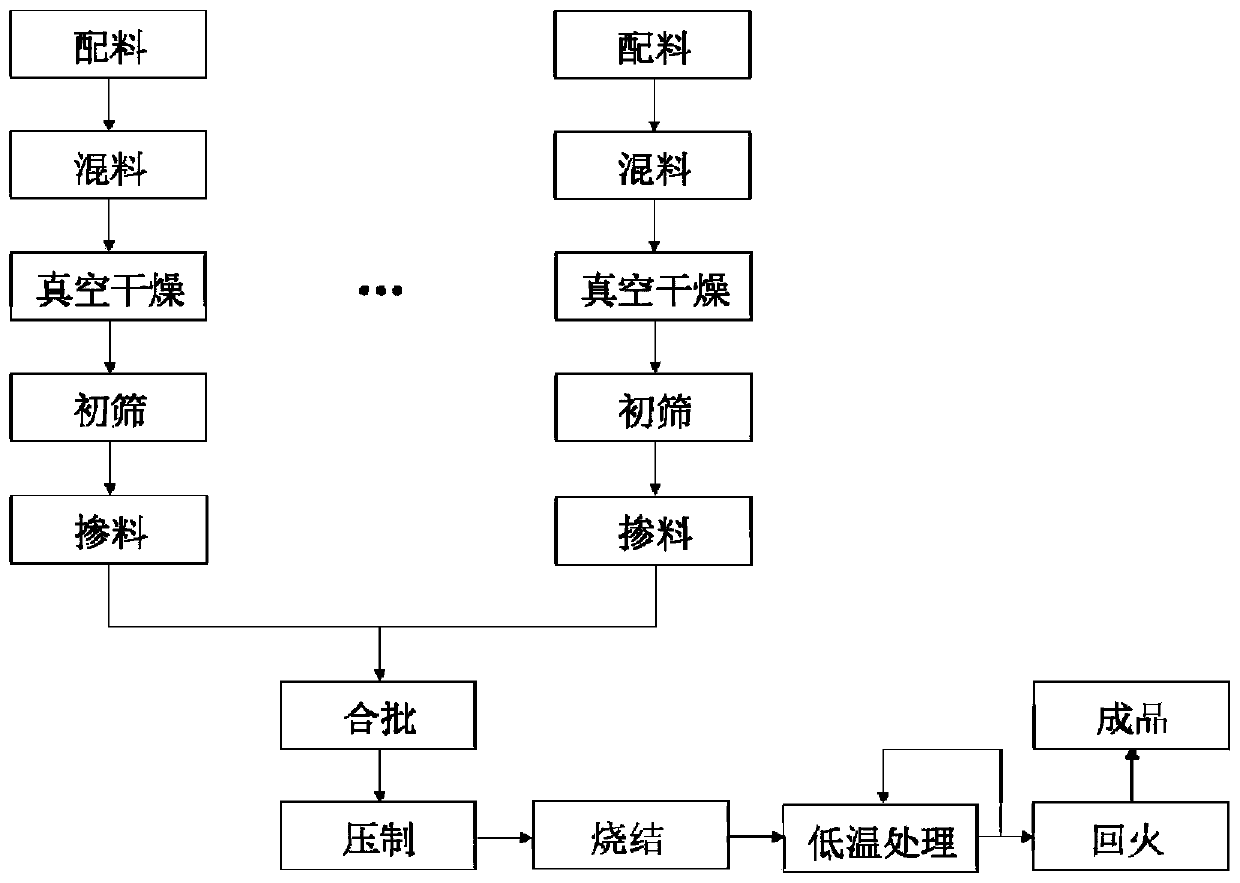

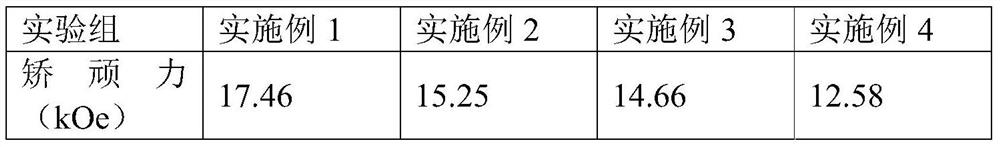

Neodymium iron boron magnetic powder as well as preparation method and application thereof

InactiveCN111681867AReduce mechanical damageReduce oxidationMagnetic core manufactureOrganic solventAlloy

The invention relates to the technical field of permanent magnet materials, and discloses neodymium iron boron magnetic powder and a preparation method and application thereof. The preparation methodof the neodymium iron boron magnetic powder comprises the steps: ball milling treatment, specifically, placing coarse neodymium-iron-boron alloy powder in a ball mill, carrying out ball milling according to the material-ball ratio of 1: 6-10 at the ball milling rotating speed of 100-200 rpm for 2-4 h; and putting the crude neodymium-iron-boron alloy powder into a ball mill, and simultaneously adding an organic solvent capable of submerging the material balls, wherein the organic solvent comprises oleic acid and n-heptane in a volume ratio of 1: (5-20). According to the preparation method, thespecific organic solvent is added in a low-energy ball milling mode, so that damage to the magnetic powder in the ball milling process is reduced, and high coercive force can be kept while the magnetic powder is refined. The neodymium iron boron magnetic powder is prepared through the method and is suitable for being applied to automobile parts and electronic or electrical equipment.

Owner:SOUTH CHINA UNIV OF TECH

Plaster decocting equipment with automatic temperature control adjusting function

InactiveCN112402257AEvenly heatedIncrease heatPharmaceutical product form changeDomestic articlesMedicinal herbsTemperature control

The invention discloses plaster decocting equipment with an automatic temperature control adjusting function, and relates to the technical field of plaster decocting equipment. The problems that currently, when people decoct plaster, upper, middle and lower layers of the plaster are affected by the outside, consequently, the temperatures are different, effective components in medicinal materials cannot be well excited, the temperature is not easy to control in the plaster decocting process, the medicinal materials are prone to burn, and consequently, the product quality is greatly influenced are solved. An upper heating plate is installed at the upper end of one side in a decocting box, a middle heating plate is installed at the lower end of the other side in the decocting box, bottom heating plates are installed on the two sides of the lower end in the decocting box correspondingly, and a temperature compensation heating plate is installed at the lower end in the decocting box; the temperature compensation heating plate, the bottom heating plates, the middle heating plate and the upper heating plate are all fixedly connected with the decocting box; and an upper temperature sensoris installed at the upper end of the other side in the decocting box.

Owner:江西回医堂中医药科技有限公司

High-ductility soluble aluminum alloy, preparation method and application

PendingCN114686734AReduce ingot segregationGuaranteed refinement and dissolution performance stabilityFluid removalFurnace typesDuctilityIngot casting

The invention discloses a high-ductility soluble aluminum alloy as well as a preparation method and application thereof, and the aluminum alloy comprises the following elements in percentage by weight: 1.5 wt% of Mg, 1wt% of Ga, 0.7 wt% of In, 1wt% of Sn and the balance of Al and inevitable impurity elements. The soluble aluminum alloy is obtained by smelting and ingot casting of the components, homogenization treatment, hot extrusion treatment and aging treatment. The soluble aluminum alloy material can be used as a material of a fracturing tool for shale oil and gas exploitation. The soluble aluminum alloy prepared through the method has the advantages of high ductility, good toughness, high strength, solubility and controllable solubility.

Owner:SHAANXI UNIV OF SCI & TECH

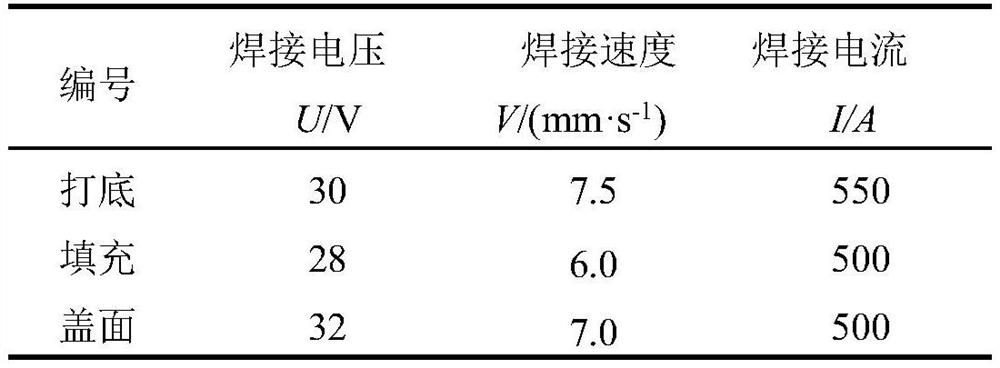

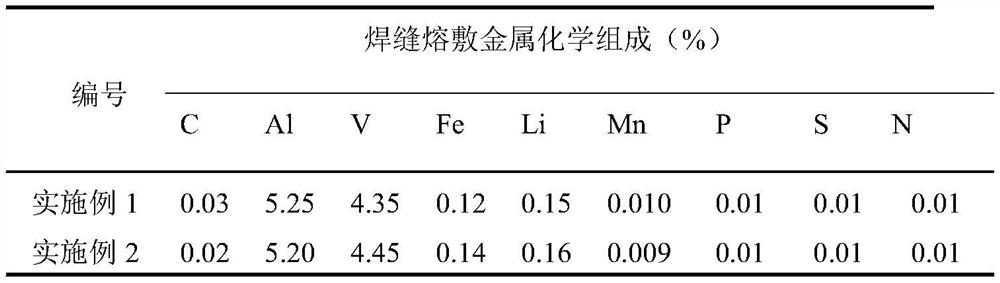

TC4 titanium alloy submerged-arc welding flux and preparation method and application thereof

InactiveCN114260616AControl mechanical propertiesImprove mechanical propertiesArc welding apparatusWelding/cutting media/materialsSlag (welding)Adhesive

The invention discloses a TC4 titanium alloy submerged-arc welding flux and a preparation method and application thereof. The invention belongs to the technical field of welding materials. The invention provides a TC4 titanium alloy submerged-arc welding flux and a preparation method and application thereof. The flux is prepared from an adhesive and powder, wherein the powder is formed by mixing the following components in percentage by mass: 4.5%-5.5% of BaCl2, 1.8%-2.1% of LiF, 4.8%-5.1% of NaF and the balance of CaF2. The method comprises the following steps: step 1, mixing and dry-stirring the raw material powder according to the powder ratio, then adding the adhesive, and continuously stirring to obtain a mixture; and 2, the mixture obtained in the step 1 is subjected to low-temperature drying, high-temperature sintering and sieving after being cooled to the room temperature, and the TC4 titanium alloy submerged-arc welding flux is obtained. The welding flux is matched with a TC4 titanium alloy submerged-arc welding wire for submerged-arc welding. According to the flux, the proportion of all the components of the flux is scientifically adjusted, and the viscosity, the surface tension and the fluidity of slag are optimized. And when the alloy is matched with a TC4 titanium alloy submerged-arc welding wire for submerged-arc welding, the alloy has good welding process performance and mechanical performance.

Owner:HARBIN WELDING INST LTD

High-temperature soluble aluminum alloy, preparation method and application

ActiveCN114717456ARefine the grain sizeReduce segregationProcess efficiency improvementSealing/packingIngot castingShale oil and gas

The invention discloses a high-temperature soluble aluminum alloy, a preparation method and application, and the aluminum alloy comprises the following elements in percentage by weight: 1.5 wt% of Mg, 0.1 wt% of Ga, 0.7 wt% of In, 0.6 wt% of Sn and the balance of Al and inevitable impurity elements. The soluble aluminum alloy is obtained through smelting and ingot casting of all the components and then heat treatment and aging treatment. The soluble aluminum alloy material can be used as a material of a fracturing tool for shale oil and gas exploitation. The soluble aluminum alloy prepared through the method is controllable in dissolution in a high-temperature environment and good in mechanical property and dissolution rate.

Owner:SHAANXI UNIV OF SCI & TECH

Lentinus edodes cultivation device capable of increasing zinc-rich content

PendingCN113133383AImprove surface load carrying capacityHigh activitySievingScreeningBiotechnologyNutrition

The invention discloses a lentinus edodes cultivation device capable of increasing zinc-rich content. The lentinus edodes cultivation device comprises a spraying device, a spraying base and a fine box, wherein moving pulleys are symmetrically arranged at the bottom of the spraying base, a spraying head is arranged on the upper portion of the spraying base, a mounting box is arranged on one side of the spraying head in a communicating mode through a water pump, an access port is formed in one side of the fine box, and a butt joint pipe is arranged on the other side of the fine box. Through modification treatment of modified zeolite powder, the surface bearing capacity of the zeolite powder is improved, the activity of the zeolite powder is improved, and the action area of a nutrient and lentinus edodes is increased by bearing the nutrient, so that the growth efficiency of the lentinus edodes is improved; and the zinc content of each 100 g of the lentinus edodes product is 0.815 mg which is 0.155 mg higher than the zinc content in the Chinese food composition table, and the lentinus edodes product is a zinc-rich food material.

Owner:交口县韦禾农业发展有限公司

A Forging Method for Improving Microstructure Uniformity of tc18 Titanium Alloy Bar

The invention discloses a forging method for improving the uniformity of the structure of TC18 titanium alloy bar, which includes: heating the ingot of TC18 titanium alloy, and performing upsetting and drawing forging once, and the pressing process requires uniform speed pressing to break the original as-cast structure Carry out 2 to 3 times of upsetting and drawing forging above the β transformation point of the forging billet, and then perform 2 to 4 times of upsetting and drawing forging of the forging billet below the β transformation point to obtain a hexahedron, and the hexahedron is placed in the Τβ‑ Under the condition of 50°C, the 1-fire precision forging is carried out, and finally a TC18 titanium alloy rod with a diameter of 160-260 mm is obtained. On the premise of ensuring the refinement and fragmentation of the structure, the present invention improves the structure uniformity of the TC18 titanium alloy rod by adopting the precise forging process with less upsetting and high control precision, and effectively reduces the risk of deformation texture; and, by reducing Reheating times and continuous remelting reduce production costs and quality risks, while shortening the production cycle of bars, which is suitable for large-scale batch production of TC18 titanium alloy bars.

Owner:西部超导材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com