TC4 titanium alloy submerged-arc welding flux and preparation method and application thereof

A submerged arc flux, titanium alloy technology, applied in arc welding equipment, welding equipment, welding equipment and other directions, can solve the problems of poor side wall fusion, coarsening of microstructure and grains, slag inclusion in pores, etc., to improve arc stability, The effect of reducing the generation of hydrogen-induced cracks and increasing the basicity of the flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

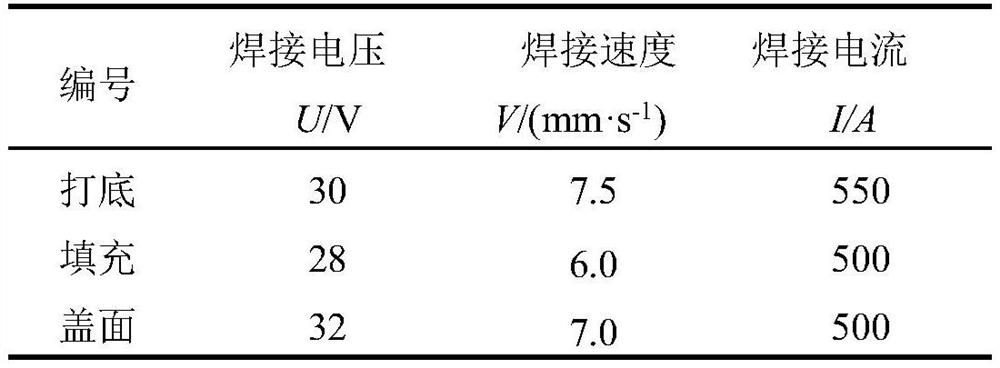

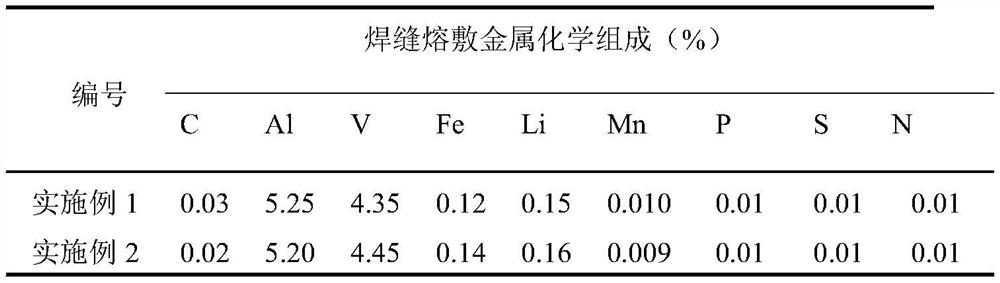

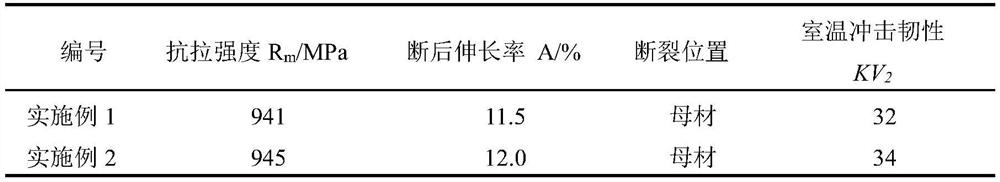

Embodiment 1

[0025] Embodiment 1: a kind of TC4 titanium alloy submerged arc welding flux of the present embodiment is prepared by binder and powder, and wherein powder is made of BaCl by mass fraction 2 : 4.5%, LiF: 2.0%, NaF: 4.9% and the balance of CaF 2 Mixed, the binder is high modulus potassium sodium water glass, the modulus is 2.8 to 3.1, the ratio of potassium to sodium is 3:1, the mass fraction of the binder in the flux is 4%, and the powder The mass percentage content of H is ≤0.003%, the mass percentage content of N is ≤0.005%, the mass percentage content of O is ≤0.010%, the mass percentage content of S is ≤0.003%, and the mass percentage content of P is ≤0.003%.

[0026] Described flux preparation method is carried out as follows:

[0027] Step 1: Mix and dry mix the raw material powders according to the powder ratio for 4 minutes, then add the binder and continue stirring for 5 minutes to obtain the mixture;

[0028] Step 2: Dry the mixture obtained in step 1 at low temper...

Embodiment 2

[0029] Embodiment 2: a kind of TC4 titanium alloy submerged arc welding flux of the present embodiment is prepared from binder and powder, wherein powder is made of BaCl by mass fraction 2 : 5%, LiF: 2.1%, NaF: 5.1% and balance CaF 2 Mixed, the binder is high modulus potassium sodium water glass, the modulus is 2.8 to 3.1, the ratio of potassium to sodium is 3:1, the mass fraction of the binder in the flux is 4%, and the powder The mass percentage content of H is ≤0.003%, the mass percentage content of N is ≤0.005%, the mass percentage content of O is ≤0.010%, the mass percentage content of S is ≤0.003%, and the mass percentage content of P is ≤0.003%.

[0030] Described flux preparation method is carried out as follows:

[0031] Step 1: Mix and dry mix the raw material powders according to the powder ratio for 4 minutes, then add the binder and continue stirring for 5 minutes to obtain the mixture;

[0032] Step 2: Dry the mixture obtained in step 1 at low temperature at 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com