Steel surface strengthening device with self-cleaning function

A surface-strengthening and self-cleaning technology, used in devices for coating liquids on surfaces, spraying devices, pre-treatment surfaces, etc., can solve the problems of low efficiency in cleaning steel, and it is difficult to clean square and round long steel tubes in one piece. , to ensure the effect of cleanliness and refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

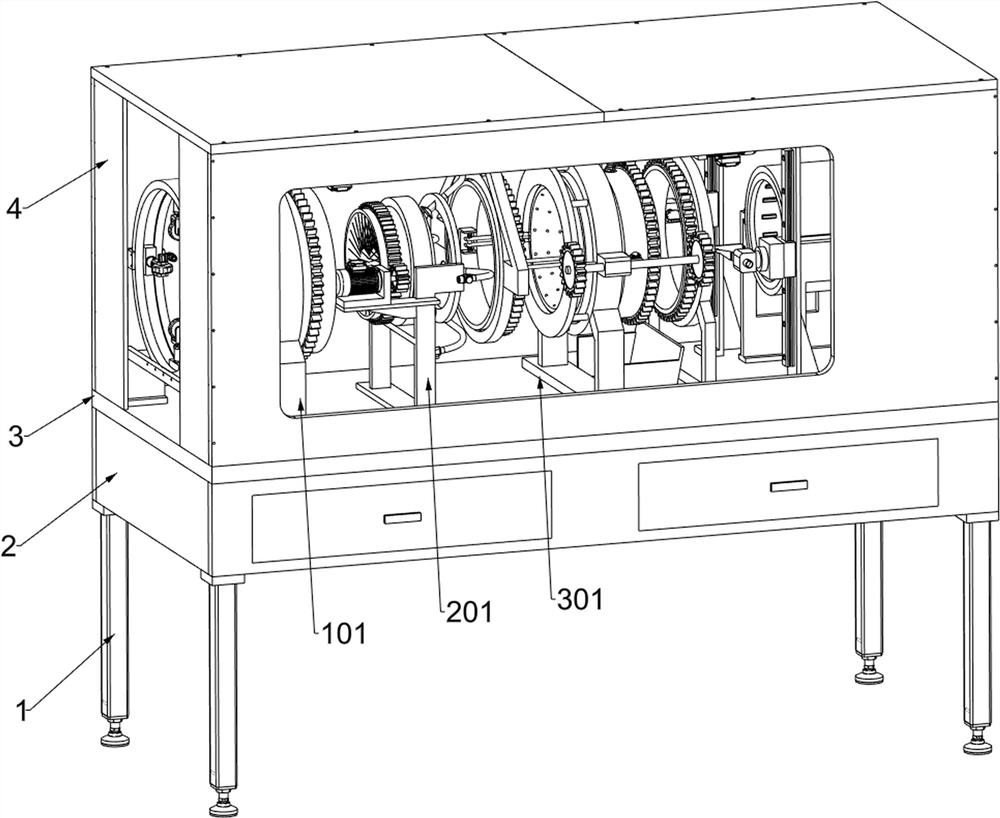

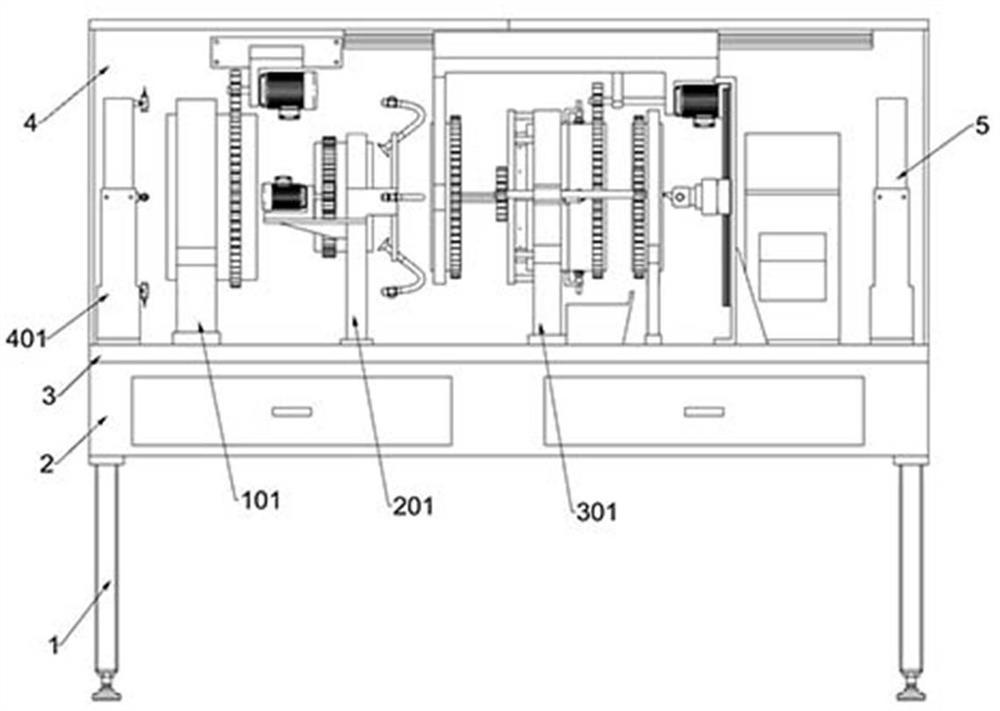

[0034] A steel surface strengthening device with self-cleaning function, such as Figure 1-2 As shown, it includes a bottom column 1, an overlap frame 2, a workbench 3, a top cover 4, an annular heater 5, a corrosion cleaning system, a surface cleaning system and a surface strengthening system; the bottom column 1 is provided with four; The upper part of the column 1 is fixed with a lap joint frame 2; the upper surface of the lap joint frame 2 is fixed with a workbench 3; the upper surface of the workbench 3 is fixed with a top cover 4; the left part of the upper surface of the workbench 3 is connected with a corrosion cleaning system; The cover 4 is connected to the corrosion cleaning system; the middle part of the upper surface of the workbench 3 is connected to the surface cleaning system; the right part of the upper surface of the workbench 3 is connected to the surface strengthening system; the top cover 4 is connected to the surface strengthening system; Ring heater 5, a...

Embodiment 2

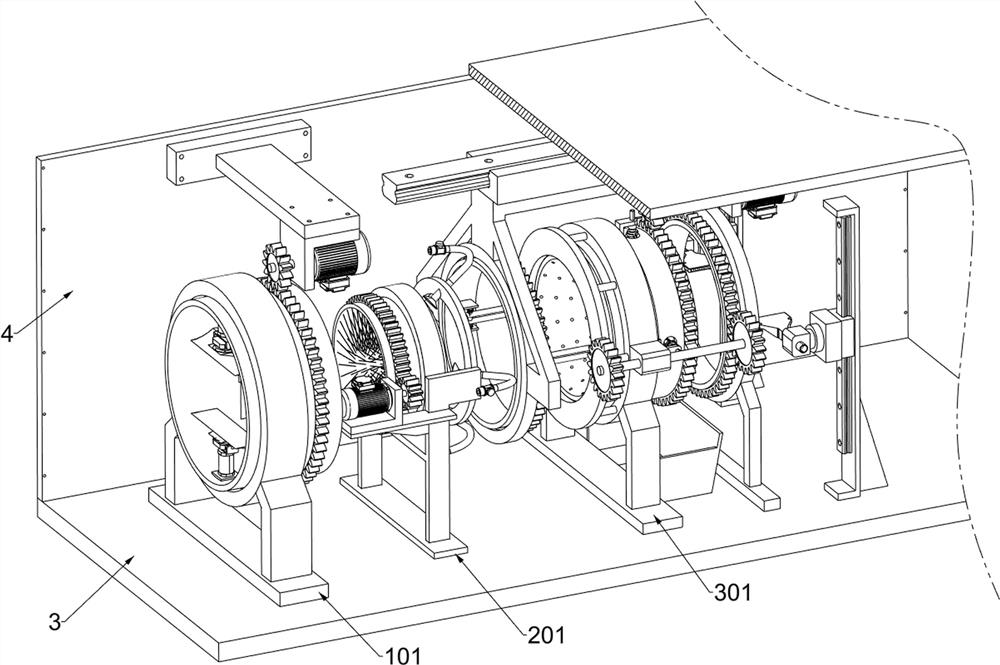

[0037] On the basis of Example 1, as figure 1 and Figure 3-5 As shown, the corrosion cleaning system includes a first support frame 101, a first annular track 102, a first annular carrying plate 103, a first gear ring 104, an adaptive cleaning assembly, a second fixed frame 106, a first servo motor 107 and A first spur gear 108; a first support frame 101 is welded to the left part of the upper surface of the worktable 3; a first annular track 102 is fixedly connected to the upper part of the first support frame 101; Mounting plate 103 ; the first annular track 102 extends from the right portion of the outer annular surface of the first annular mounting plate 103 , and a first gear ring 104 is fixed to the right portion of the outer annular surface of the first annular mounting plate 103 ; the first annular mounting plate 103 The left part of the inner surface and the right part of the inner surface are respectively fixed with two adaptive cleaning components, and the two ada...

Embodiment 3

[0043] On the basis of Example 2, as figure 1 , image 3 and Image 6 As shown, the surface cleaning system includes a second support frame 201, a second annular track 202, a second annular mounting plate 203, a second gear ring 204, a cleaning brush 205, a second servo motor 206, a second spur gear 207, an annular The connecting plate 208, the metal conduit 209 and the connecting valve 2010; the middle part of the upper surface of the workbench 3 is welded with a second support frame 201; the upper part of the second support frame 201 is fixed with a second annular track 202; A second annular mounting plate 203 is connected; the left portion of the outer surface of the second annular mounting plate 203 extends out of the second annular track 202, and the left portion of the outer surface of the second annular mounting plate 203 is fixed with a second toothed ring 204; the second annular The inner surface of the mounting plate 203 is fixed with a cleaning brush 205; the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com