Automatic titration method and application

An automatic titration and titration technology, which is applied in the direction of chemical analysis by titration, which can solve the problems of difference in titration end point, lack of judgment standards, and poor repeatability of rinsing test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

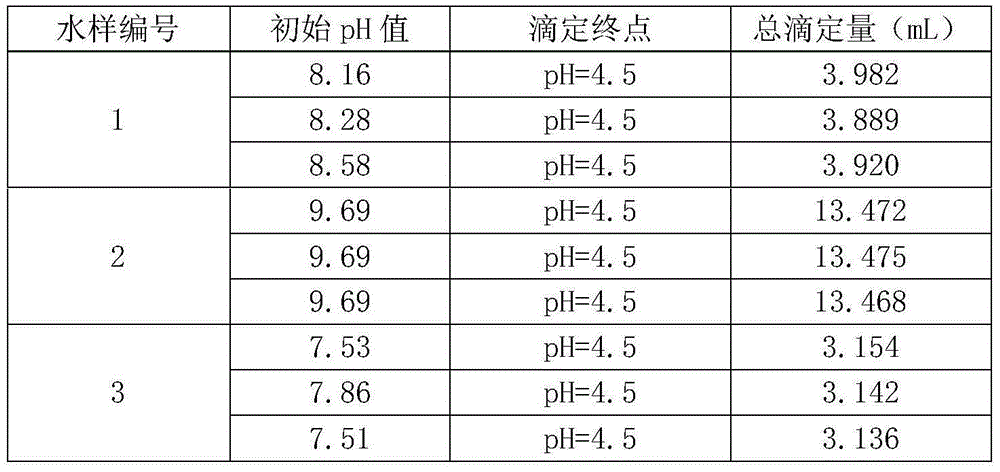

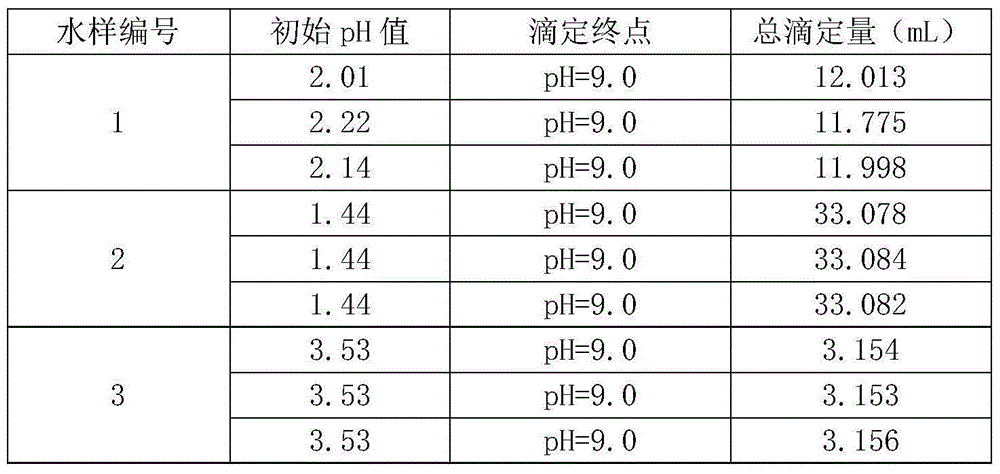

Examples

Embodiment 1

[0049] A kind of automatic titration method of embodiment 1 specifically comprises the following steps:

[0050] (1) Sampling and sample pretreatment: take the sample solution to be tested, filter it through a microporous membrane, and put it into a sample loading container;

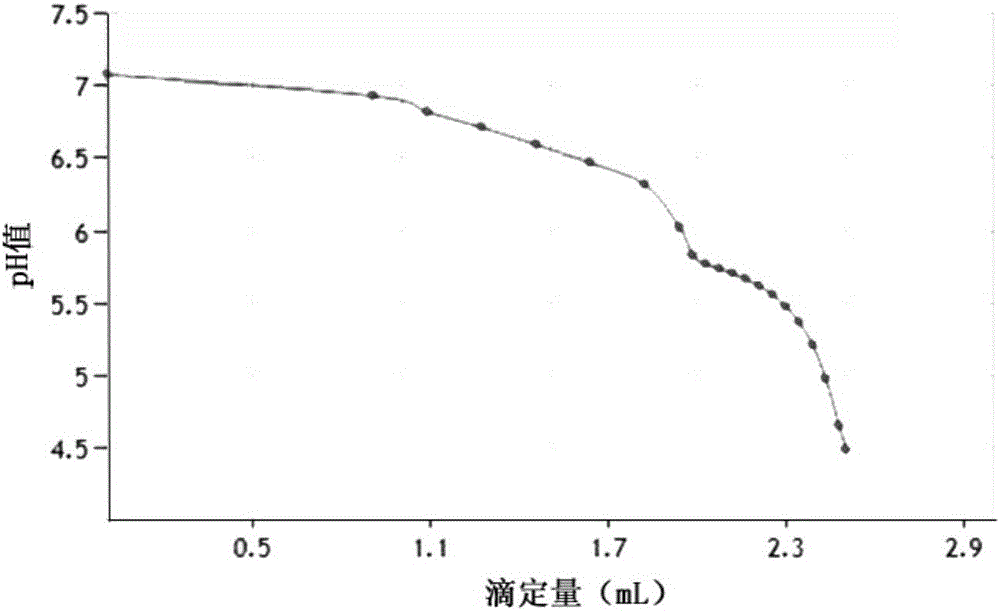

[0051] (2) Titrator preset: After inserting the burette and pH probe into the sample container, set the pre-stirring time of the titrator to 0.5min, the delay time to 20s, the speed 1 to 1mL / min, and the speed 2 to 0.1mL / min. min, the pH value of the speed control point, the pH value of the end point and the speed control amount of 15%;

[0052] (3) Titration in the first stage: after the test starts, pre-stirring is carried out. After the pre-stirring is over, the titrator starts titration at a set speed 1 until the pH value of the sample to be tested reaches the pH value of the speed control point;

[0053] (4) Titration in the second stage: after the pH value of the sample reaches the pH value of the...

Embodiment 2

[0059] A kind of automatic titration method of embodiment 2 specifically comprises the following steps:

[0060] (1) Sampling and sample pretreatment: take the sample solution to be tested, filter it through a water-based microporous membrane, and put it into a sample loading container;

[0061] (2) Titrator preset: After inserting the burette and pH probe into the sample container, set the pre-stirring time of the titrator to 2min, delay time to 30s, speed 1 to 3mL / min, speed 2 to 1mL / min, The pH value of the speed control point, the pH value of the end point and the speed control amount of 50%;

[0062] (3) Titration in the first stage: after the test starts, pre-stirring is carried out. After the pre-stirring is over, the titrator starts titration at a set speed 1 until the pH value of the sample to be tested reaches the pH value of the speed control point;

[0063] (4) Titration in the second stage: after the pH value of the sample reaches the pH value of the speed contro...

Embodiment 3

[0069] A kind of automatic titration method of embodiment 3 specifically comprises the following steps:

[0070] (1) Sampling and sample pretreatment: take the sample solution to be tested, filter it through a water system 0.45 μm microporous membrane, and put it into a sample loading container;

[0071] (2) Titrator preset: After inserting the burette and pH probe into the sample container, set the pre-stirring time of the titrator to 1min, the delay time to 10s, the speed 1 to 2mL / min, and the speed 2 to 0.5mL / min , the pH value of the speed control point, the pH value of the end point and the speed control amount of 30%;

[0072] (3) Titration in the first stage: after the test starts, pre-stirring is carried out. After the pre-stirring is over, the titrator starts titration at a set speed 1 until the pH value of the sample to be tested reaches the pH value of the speed control point;

[0073] (4) Titration in the second stage: after the pH value of the sample reaches the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com