Neodymium iron boron magnetic powder as well as preparation method and application thereof

A neodymium-iron-boron and magnetic powder technology is applied in the manufacture of magnetic cores, inductors/transformers/magnets, electrical components, etc. Bonded NdFeB magnet application and other issues to achieve the effect of reducing mechanical damage, high coercivity, reducing amorphization and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the NdFeB magnetic powder provided by the embodiment of the present invention includes:

[0032] Ball milling treatment: put the coarse NdFeB alloy powder in a ball mill, and perform ball milling with a material-to-ball ratio of 1:6-10, the ball milling speed is 100-200rpm, and the ball-milling time is 2-4h; the coarse NdFeB alloy powder When placed in the ball mill, an organic solvent is also added together, and the organic solvent includes oleic acid and n-heptane with a volume ratio of 1:5-20.

[0033] For NdFeB rare earth permanent magnets with fine grains, uniform distribution, and well-defined intergranular phases, during the ball milling process, there is not much fracture along the brittle intergranular phases, but more transgranular phases Fracture causes a large number of defects in the original matrix; for the original matrix with relatively coarse grains and a certain texture, it is easier to preferentially fracture at the brittle p...

Embodiment 1

[0053] (1) Rare earth neodymium, iron boron, cobalt gallium and pure iron with a purity of 99.9% are used as raw materials, and Nd 14 Fe 75.5 co 4.5 B 5.6 Ga 0.4 (atomic ratio) ingredients.

[0054] (2) Put the above-mentioned prepared raw materials into a high-vacuum single-roller quick-quenching furnace, and evacuate to 10 -3 Pa and below, heat and melt each raw material, and keep it warm for 1min to homogenize the alloy composition. The melt temperature can reach 1550°C. The alloy strip is prepared by using a water-cooled copper roll, and the tangential line speed of the copper roll is 40m / s.

[0055] (3) The alloy strip is subjected to heat treatment at a temperature of 550° C. for 10 minutes.

[0056] (4) After the alloy strip is coarsely crushed in the glove box, it is sieved through a 300-mesh sieve, and the coarse magnetic powder, zirconia balls with a diameter of 3mm and 20ml of organic solvent, wherein the volume ratio of oleic acid and n-heptane is 1:5, are uni...

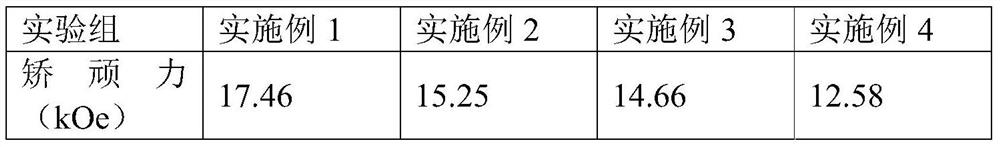

Embodiment 2-4

[0059] Embodiment 2-4 is basically the same as embodiment 1, and the difference is only that some ball milling parameters are different:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com