Rotary type banana combing machine

A drop-carding machine and rotary type technology is applied in the field of banana post-production processing machinery, which can solve the problems of increasing the incidence of microbial diseases, mechanical damage to the surface of bananas, and low efficiency of banana processing, so as to shorten the processing cycle, reduce physical labor, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

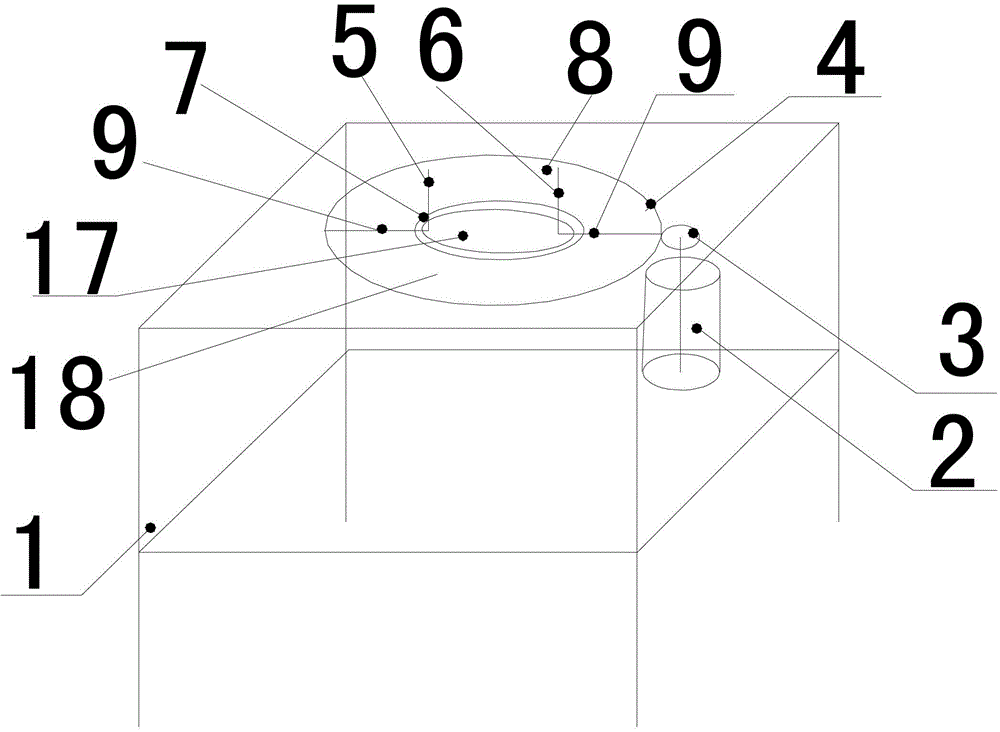

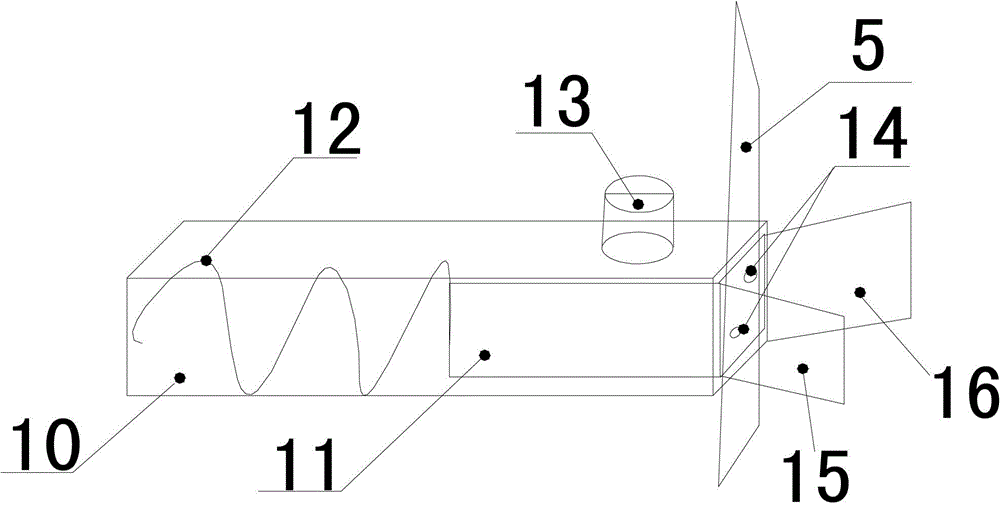

[0025] Such as Figure 1~2 Shown, a kind of rotary banana combing machine includes frame 1, motor 2, first gear 3, second gear 4, the first combing cutter 5, the second combing cutter 6, bearing 7, axle sleeve, The cutter head 8 and the tool holder 9; wherein, the upper surface of the frame 1 is fixed to the shaft sleeve, the outer surface of the shaft sleeve is fixed to the inner ring of the bearing 7, the position of the inner ring of the bearing 7 is the clamping hole 17, and the outer ring of the bearing 7 is fixed to the second Gear 4, fixed cutter head 8 on the upper end surface of second gear 4, fixed cutter rest 9 on cutter head 8, fixed first comb cutter 5 and second comb cutter 6 on cutter rest 9, first comb cutter 5 and the second comb cutter 6 around the clamping hole 17, the motor 2 drives the first gear 3 to rotate, and the first gear 3 drives the second gear 4 to rotate, so that the first comb cutter 5 and the second comb cutter 6 to perform rotary motion, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com