Ceramic superfine homogenizing and emulsifying machine

An emulsifier and ceramic technology, applied in grain processing, etc., can solve the problems of increasing the difficulty of stator ceramic blades and stator processing, reducing the working strength of stator ceramic blades, increasing installation deviation, etc., to achieve easy processing and production, and small shear resistance , to speed up the delivery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

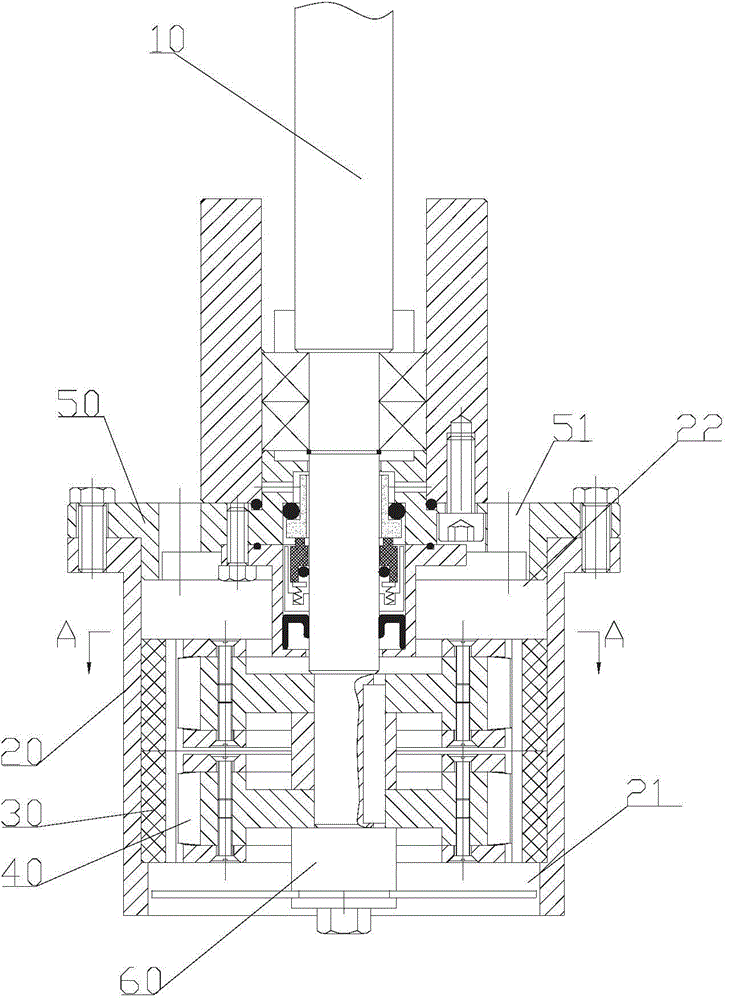

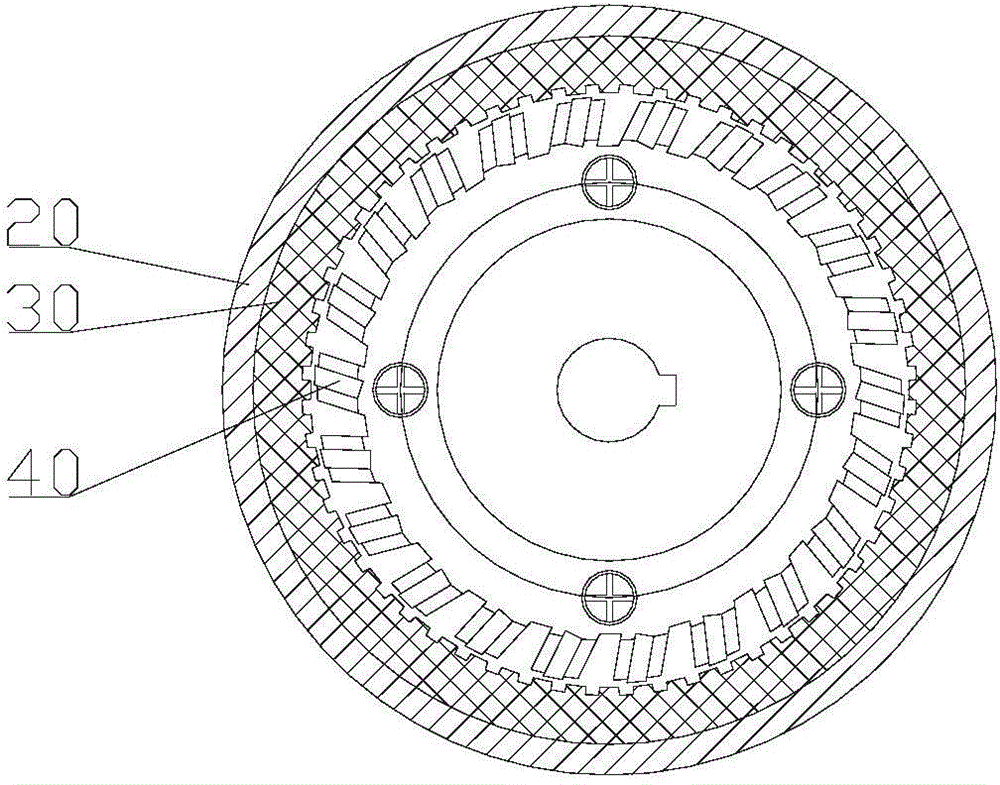

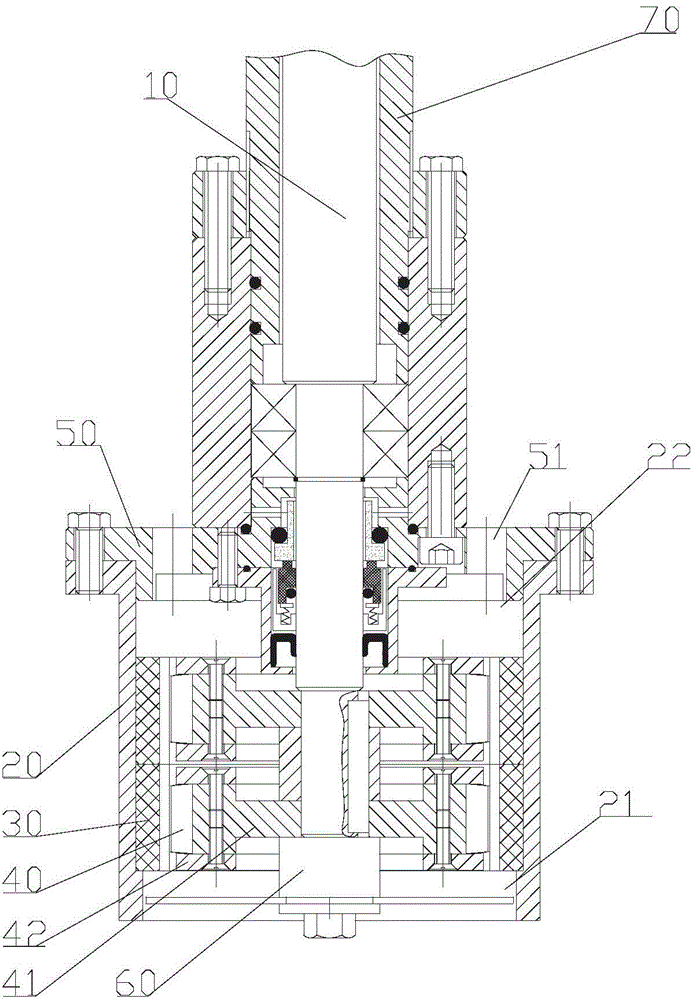

[0030] In order to achieve the purpose of the present invention, as Figure 1 to Figure 2 As shown, in one of the embodiments of the present invention, a ceramic ultrafine homogeneous emulsifier is provided, including:

[0031] Homogeneous axis 10;

[0032] A housing 20, which is hollow cylindrical and sleeved on one end of the homogeneous shaft 10, the housing 20 is provided with a material inlet 21 and a material outlet 22;

[0033] A ceramic stator ring 30, which is arranged on the circumferential inner wall of the housing 20;

[0034] The centrifugal rotor includes a plurality of centrifugal rotor ceramic blades 40 arranged on the circumferential surface of the homogeneous shaft 40 along the circumferential direction of the homogeneous shaft 10. The centrifugal rotor ceramic blades 40 are located inside the ceramic stator ring 30 and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com