Method and apparatus for materials cooperation disinfection and enzyme dulling with impulse electric field and magnetic field

A technology of pulsed electric field and pulsed magnetic field, applied in the field of pulsed electric field and magnetic field to synergistically sterilize materials and inactivate enzymes, can solve the problems that the sterilization rate of pulsed magnetic field cannot be fully satisfied, the quality of food that affects the sterilization effect, and the temperature rise is relatively large. Achieve the effect of improving the effect of sterilization and killing enzymes, maintaining nutritional value and flavor, and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below in conjunction with embodiment.

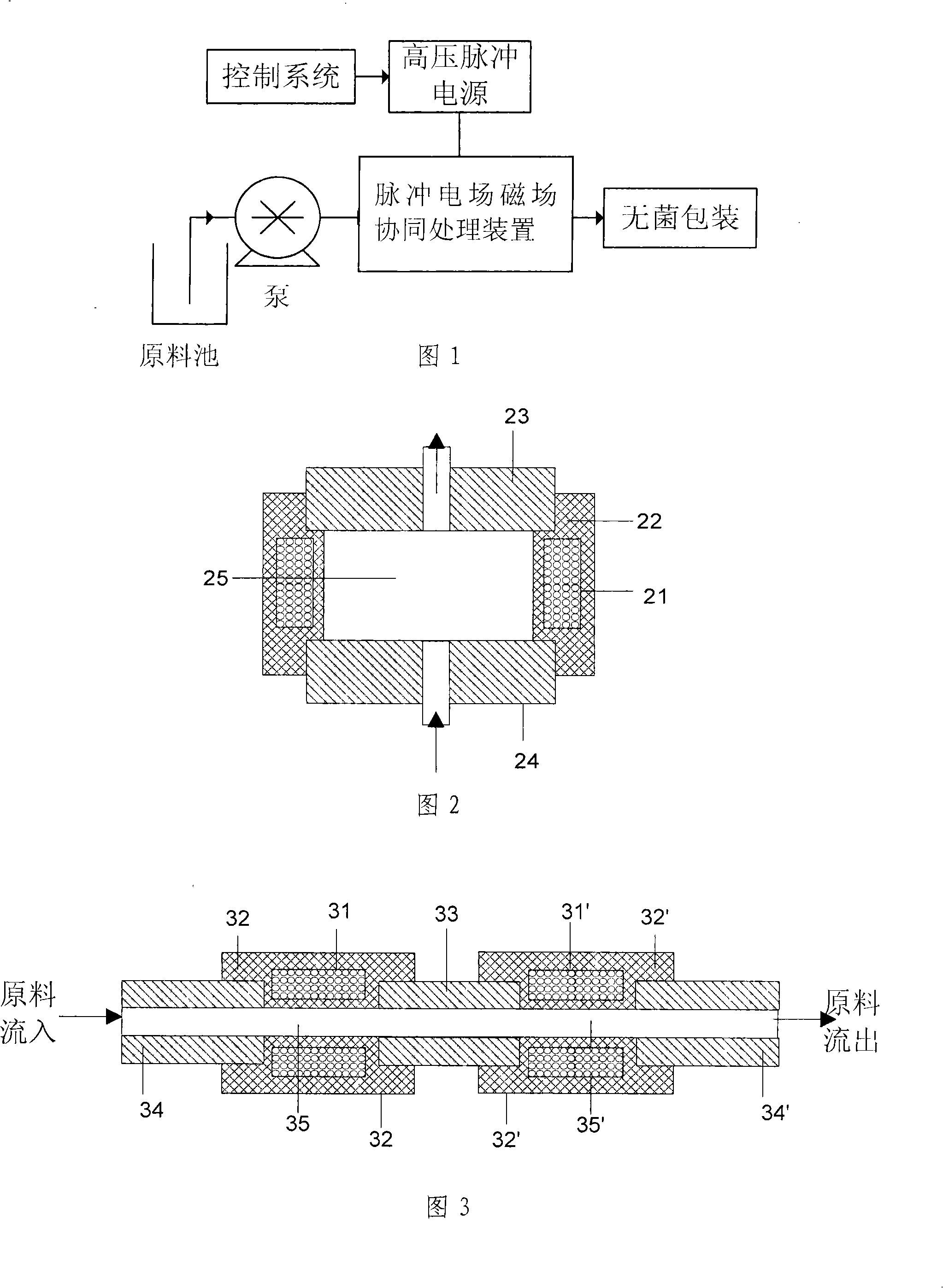

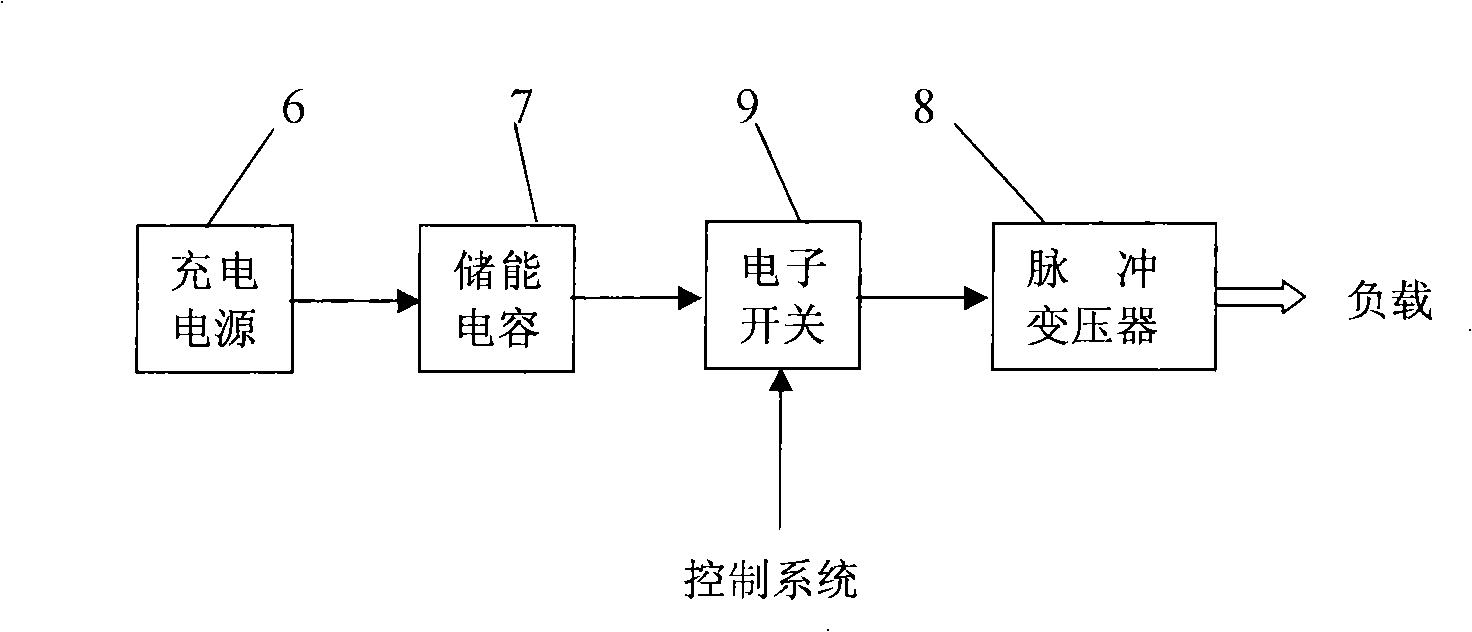

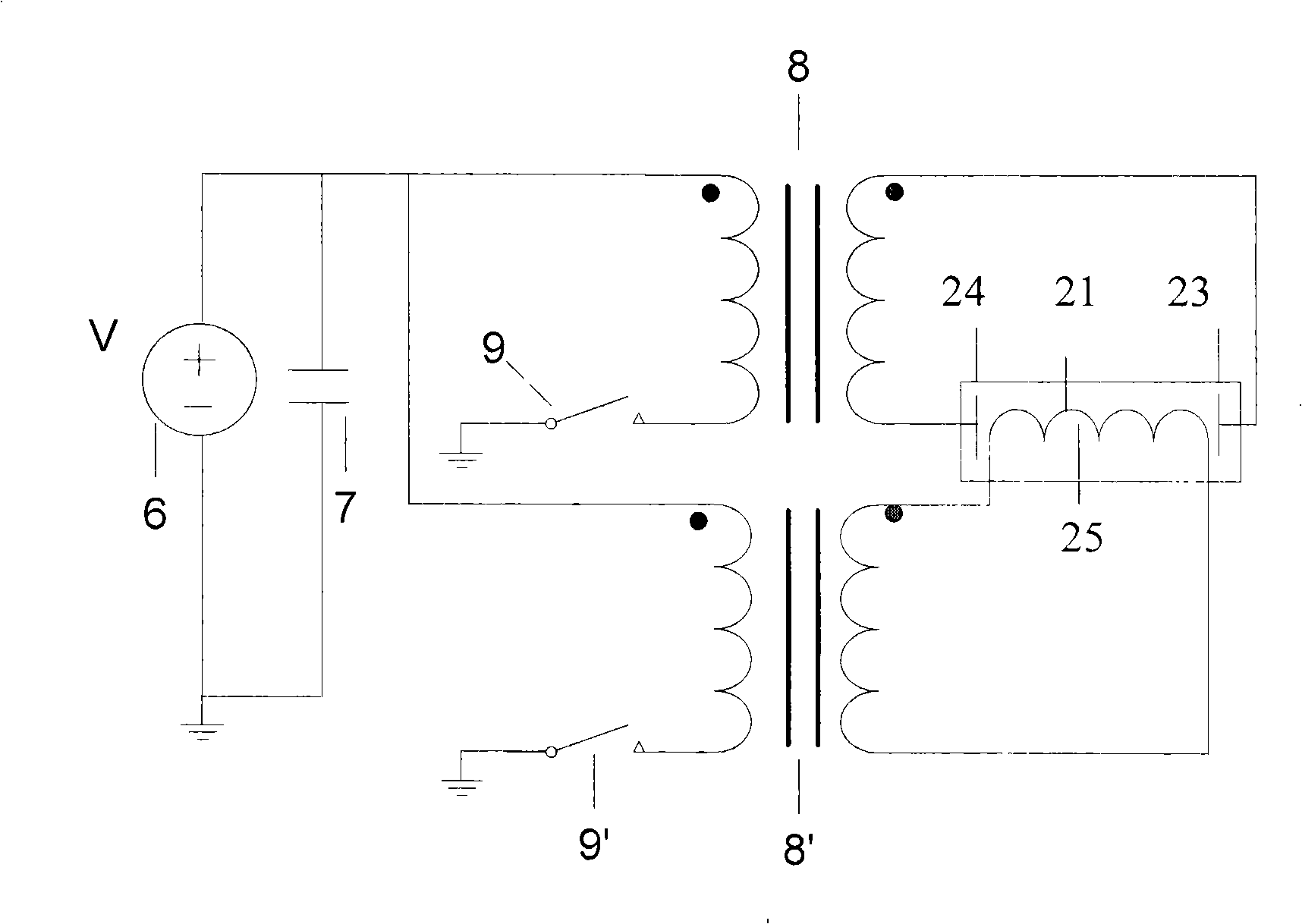

[0023] The pulsed electric field and magnetic field designed according to the method of the present invention are as shown in Figure 1 to material synergistic sterilization blunt enzyme equipment, mainly comprise at least one high-voltage pulsed power supply, control system, electromagnetic shielding system and pulsed electric field magnetic field cooperative processing device etc., this pulsed electric field The magnetic field cooperative processing device is provided with a through processing area. In Fig. 1, the liquid material in the raw material cylinder is pumped into the processing area in the pulse electric field magnetic field co-processing device through the pump, and the high-voltage pulse power supply applies a pulse electric field of 5-100kV / cm and a power of 0.1T-50T through the co-processing device. The pulsed magnetic field performs electromagnetic co-processing on the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com