Patents

Literature

39results about How to "Reduce shear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

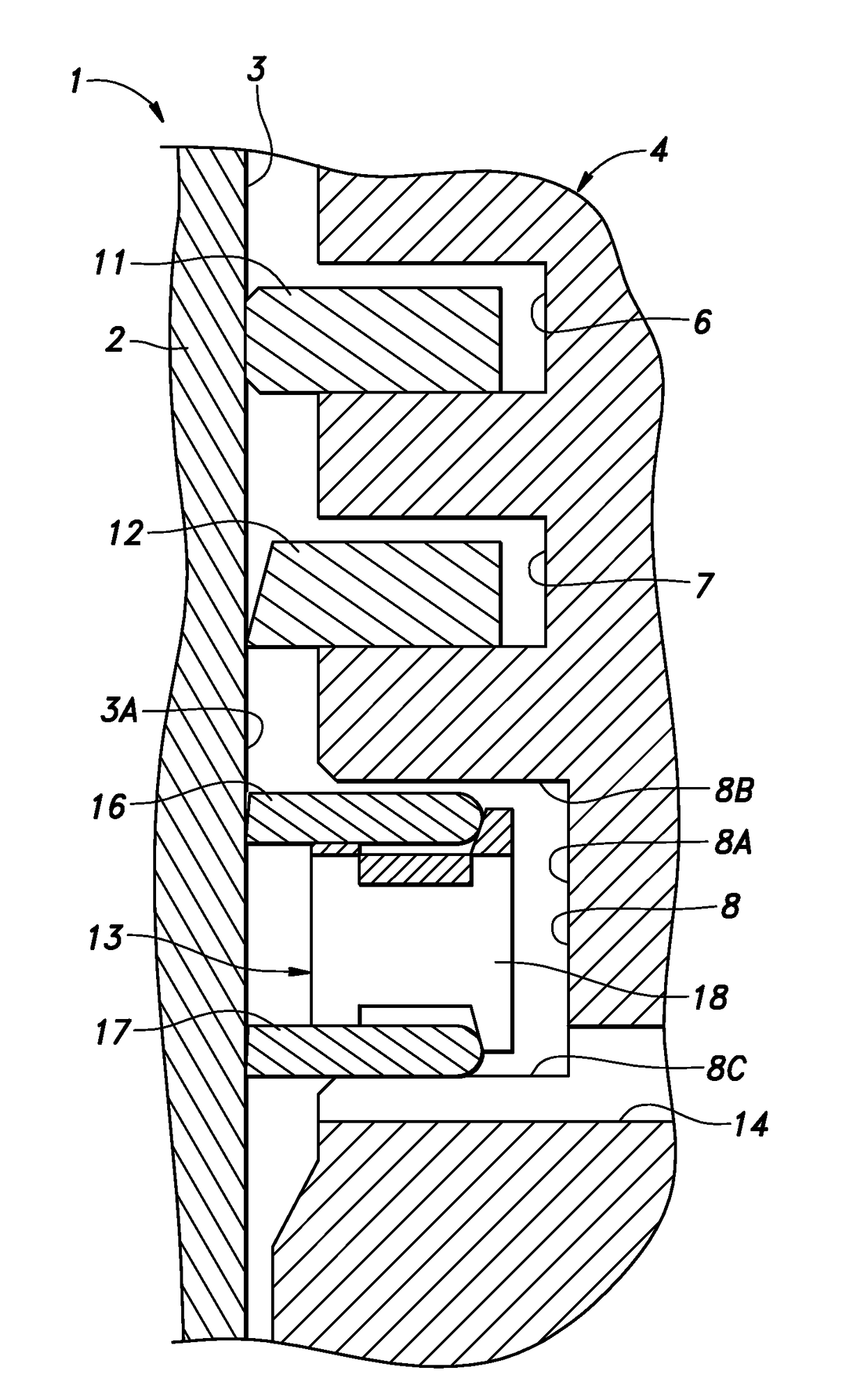

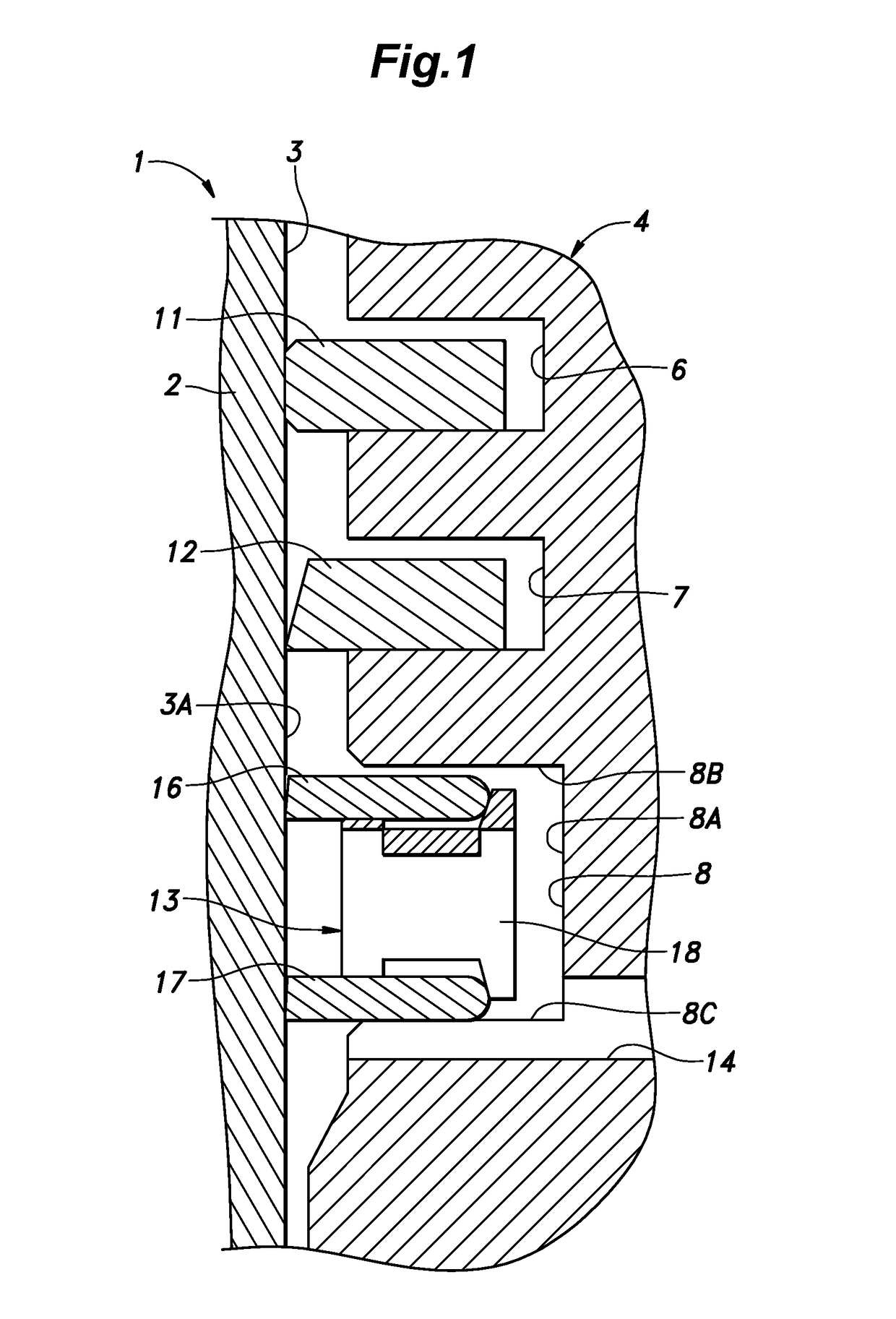

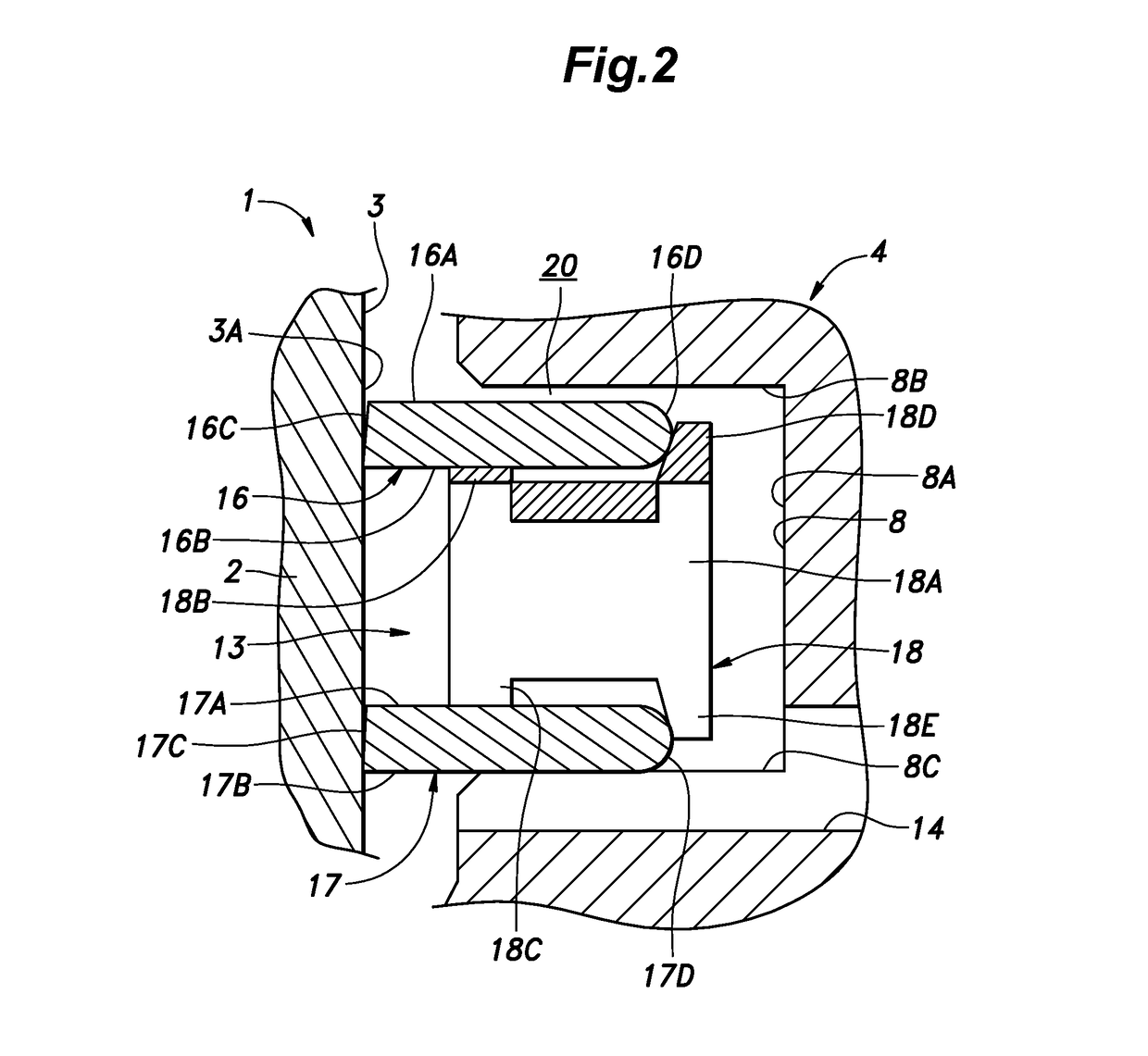

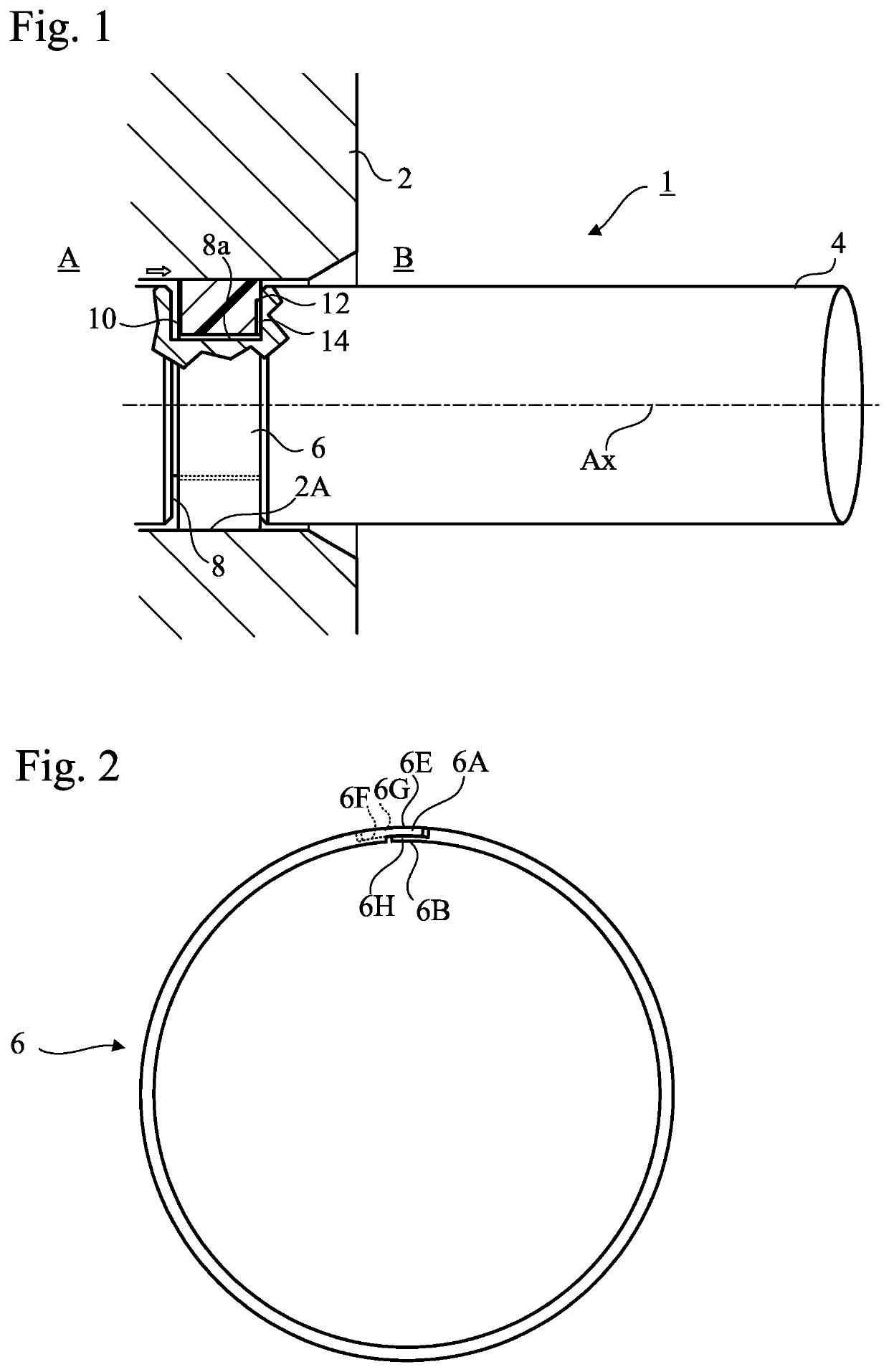

Oil ring

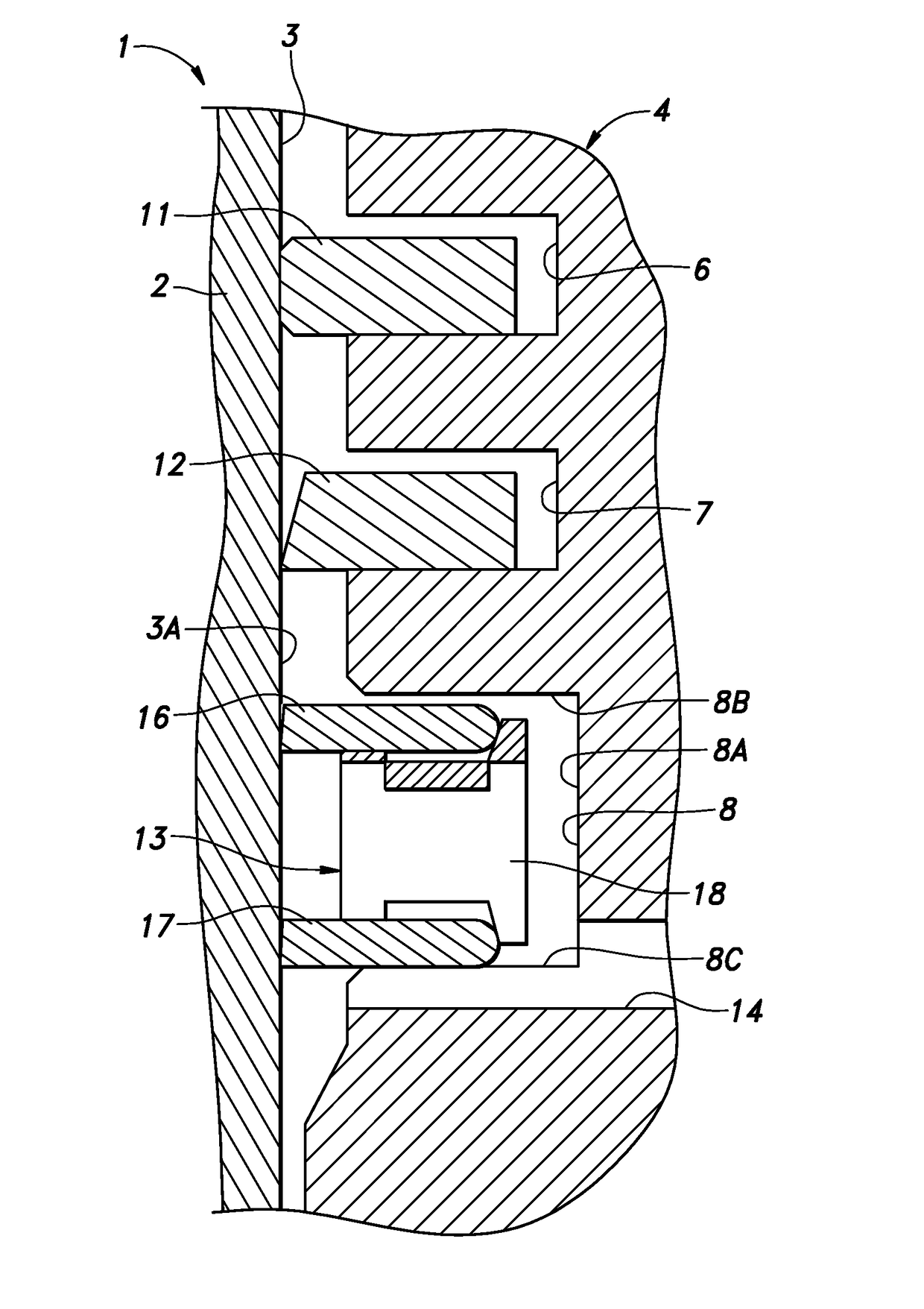

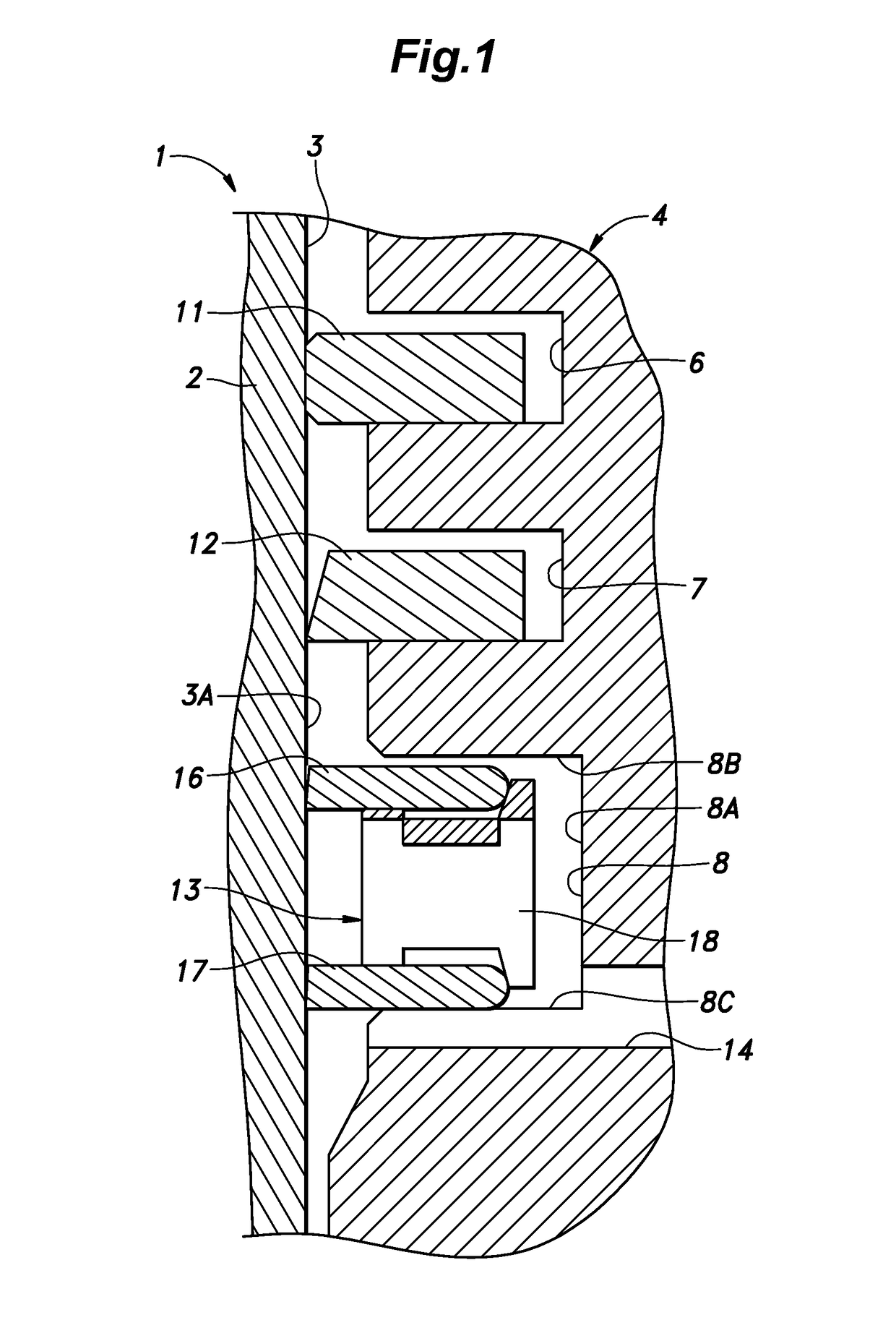

Provided is an oil ring (13) that can minimize the frictional resistance without impairing the oil control function such as the scraping of lubricating oil from the cylinder wall surface by the oil ring. The oil ring consists of an upper side rail (16), a lower side rail (17) and an annular expander (18) interposed between the two side rails, and is received in an oil ring groove (8) with a prescribed vertical clearance (20) that permits tilting of the side rails. An outer peripheral surface (16E, 17E) of each side rail is provided with a radially inward slant. Therefore, during the upward stroke of the piston, the upper side rail tilts in the radially outward direction so that the effective slant angle of the outer peripheral surface of the upper side ring is adjusted to an optimum value.

Owner:HONDA MOTOR CO LTD

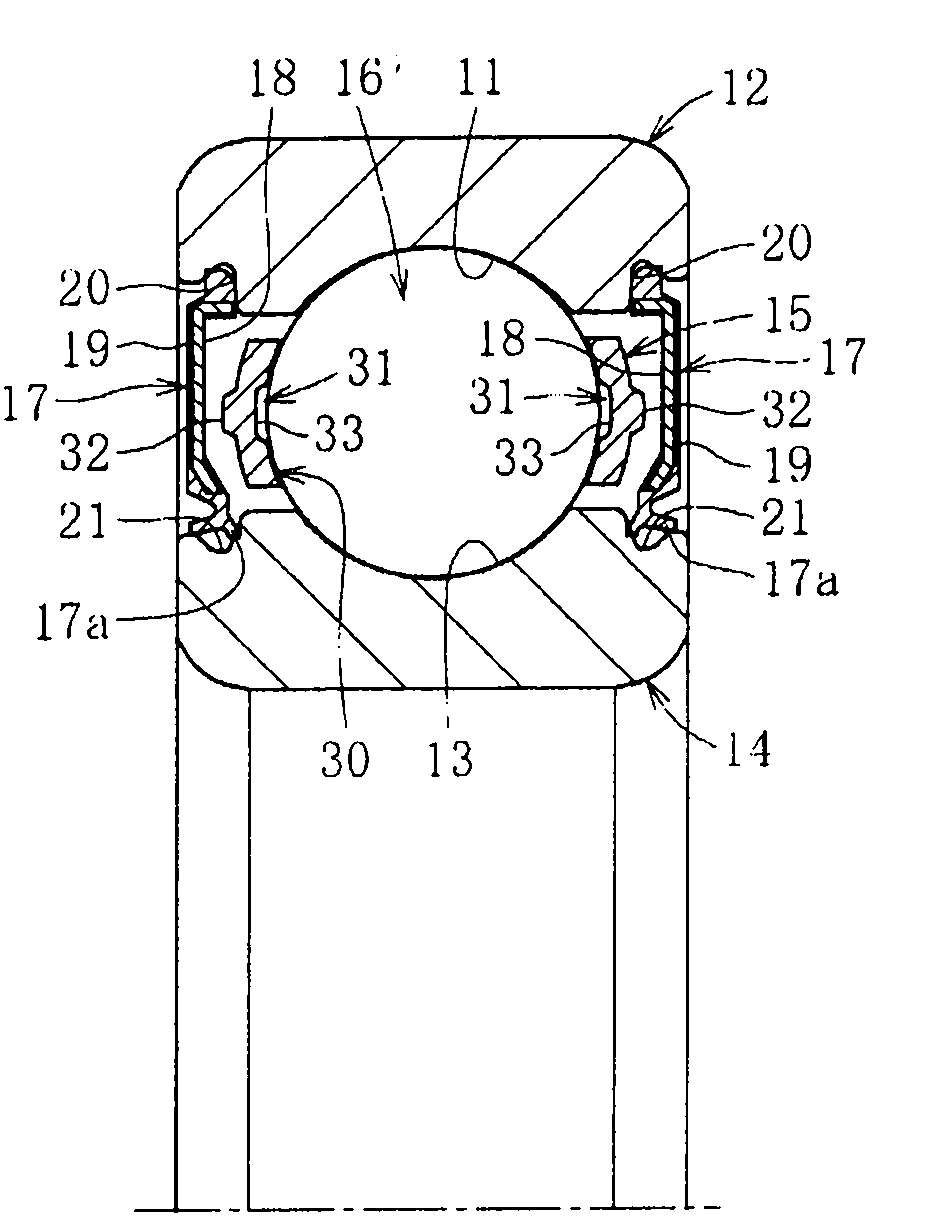

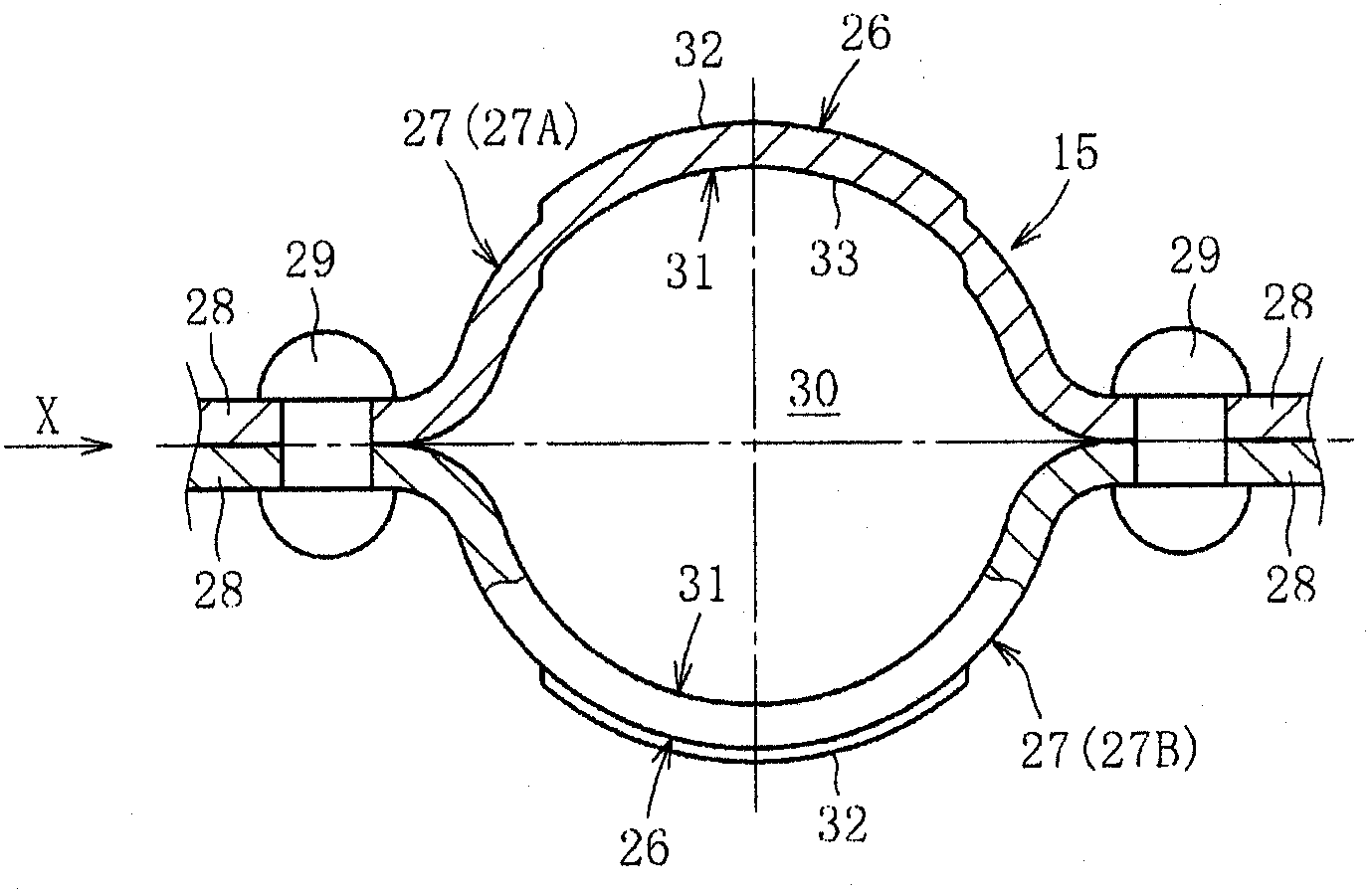

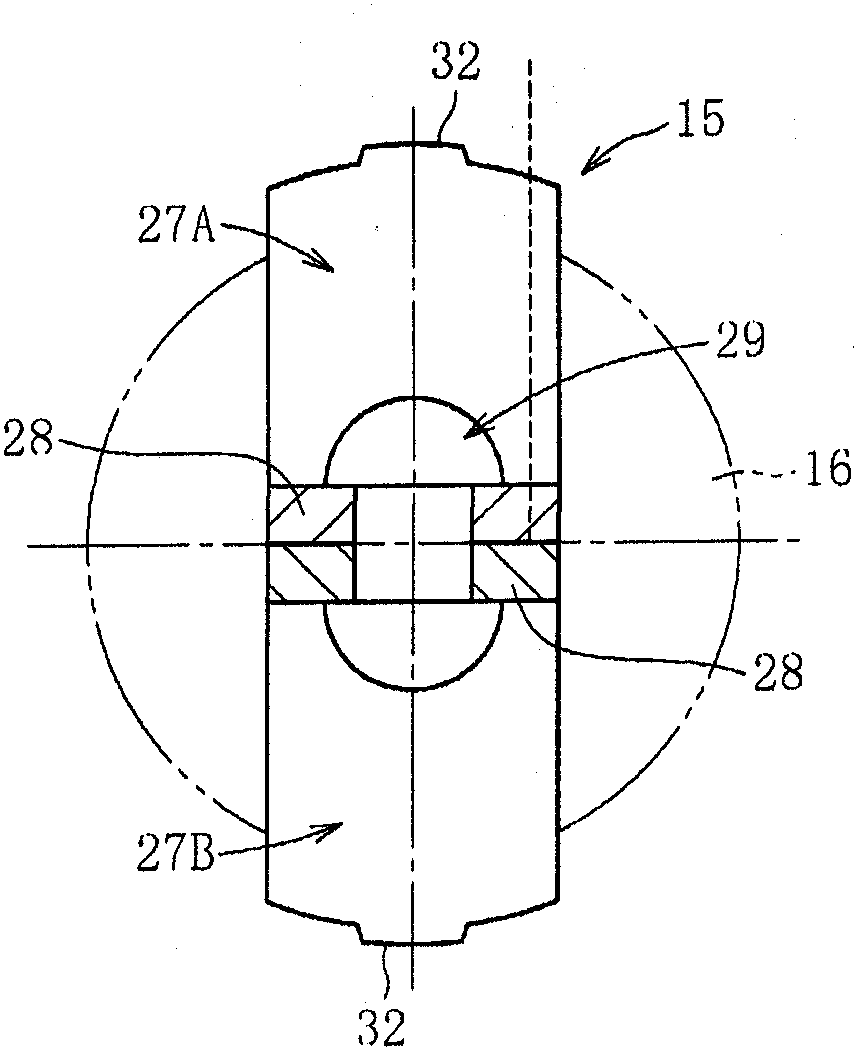

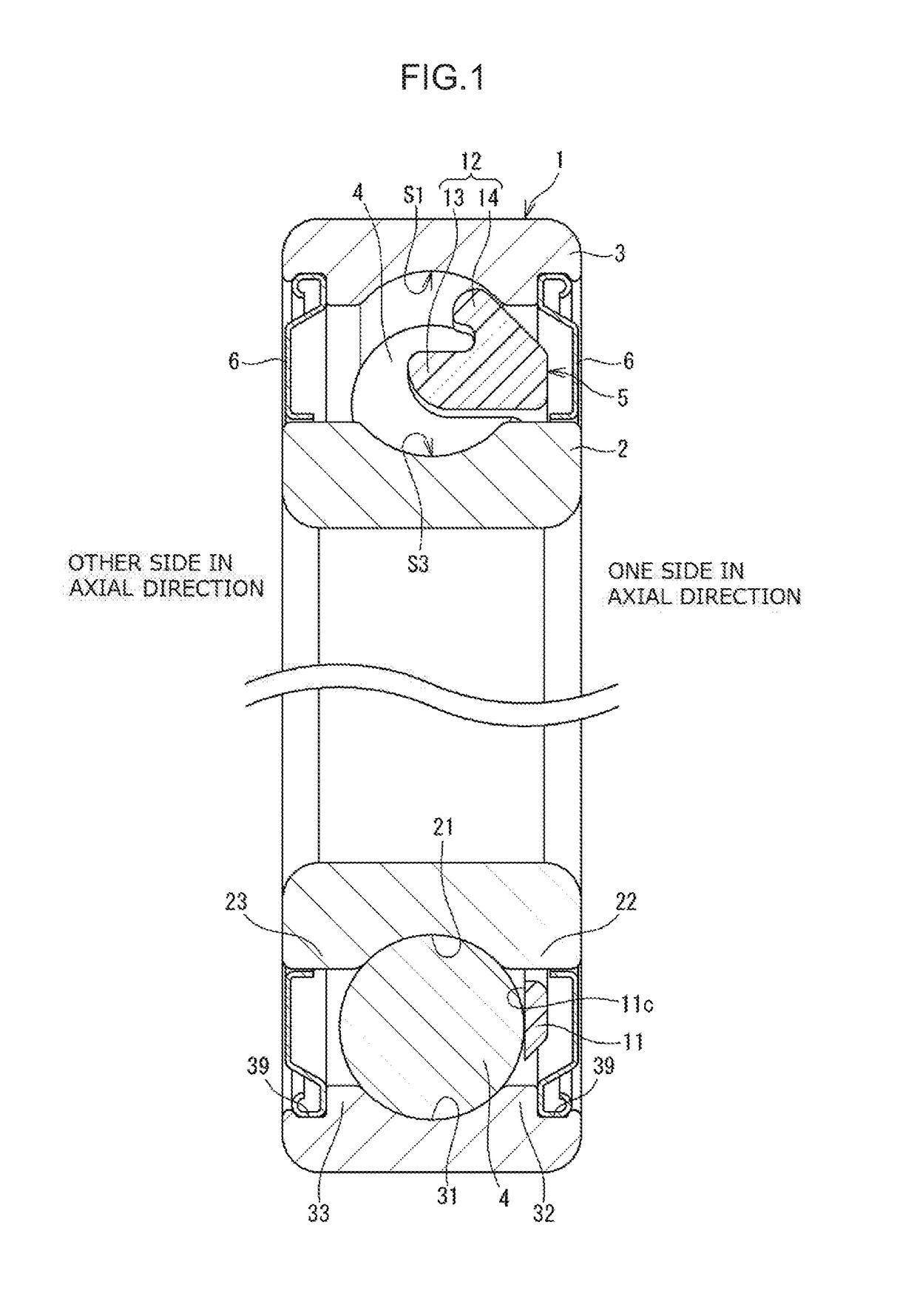

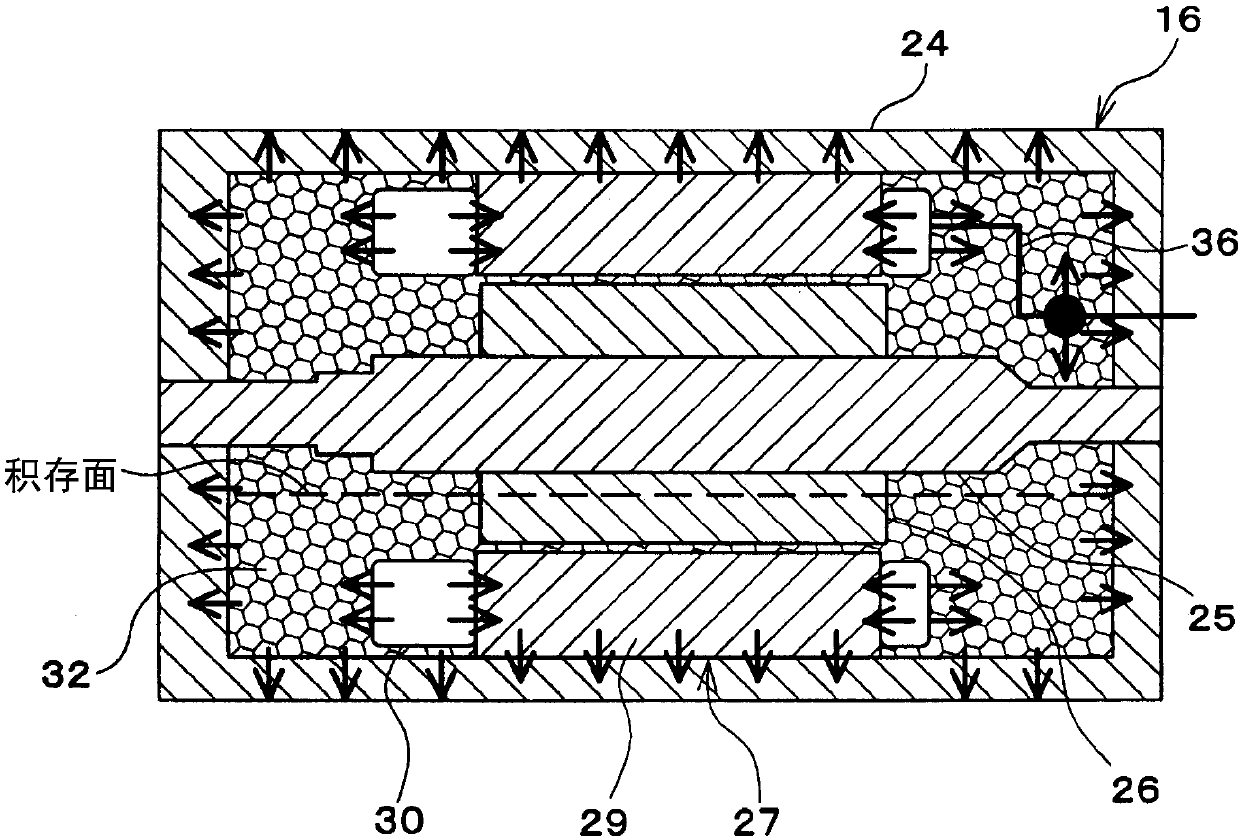

Retainer, deep groove ball bearing, and bearing with seal

ActiveCN102066786AReduced oil filmReliable formationBall bearingsBearing componentsForeign matterBall bearing

Provided are a retainer achieving low torque, a deep groove ball bearing using the retainer, and a bearing equipped with a seal, capable of preventing entry of foreign matter into the bearing and having sufficiently reduced seal torque. The retainer is formed by combining two annular holding plates (27A, 27B) each having hemispherical protrusions (26) circumferentially arranged at predetermined intervals. Pockets (30) for retaining balls (16) are formed by opposed hemispherical protrusions (26, 26). Contactless sections (31) with which a ball (16) does not make contact are formed on those surfaces of each pocket (30) which face the ball. The area of contact of each pocket (30) with the ball (16) is set less by 15% to 30% than the area of contact of the pocket (30) with the ball (16) when the contactless sections (31) are not provided. A seal member (17) is a contact seal in which a seal lip (17a) makes contact with the other raceway ring. The material of at least the front end of the seal lip (17a) is an easily wearable high wear material.

Owner:NTN CORP

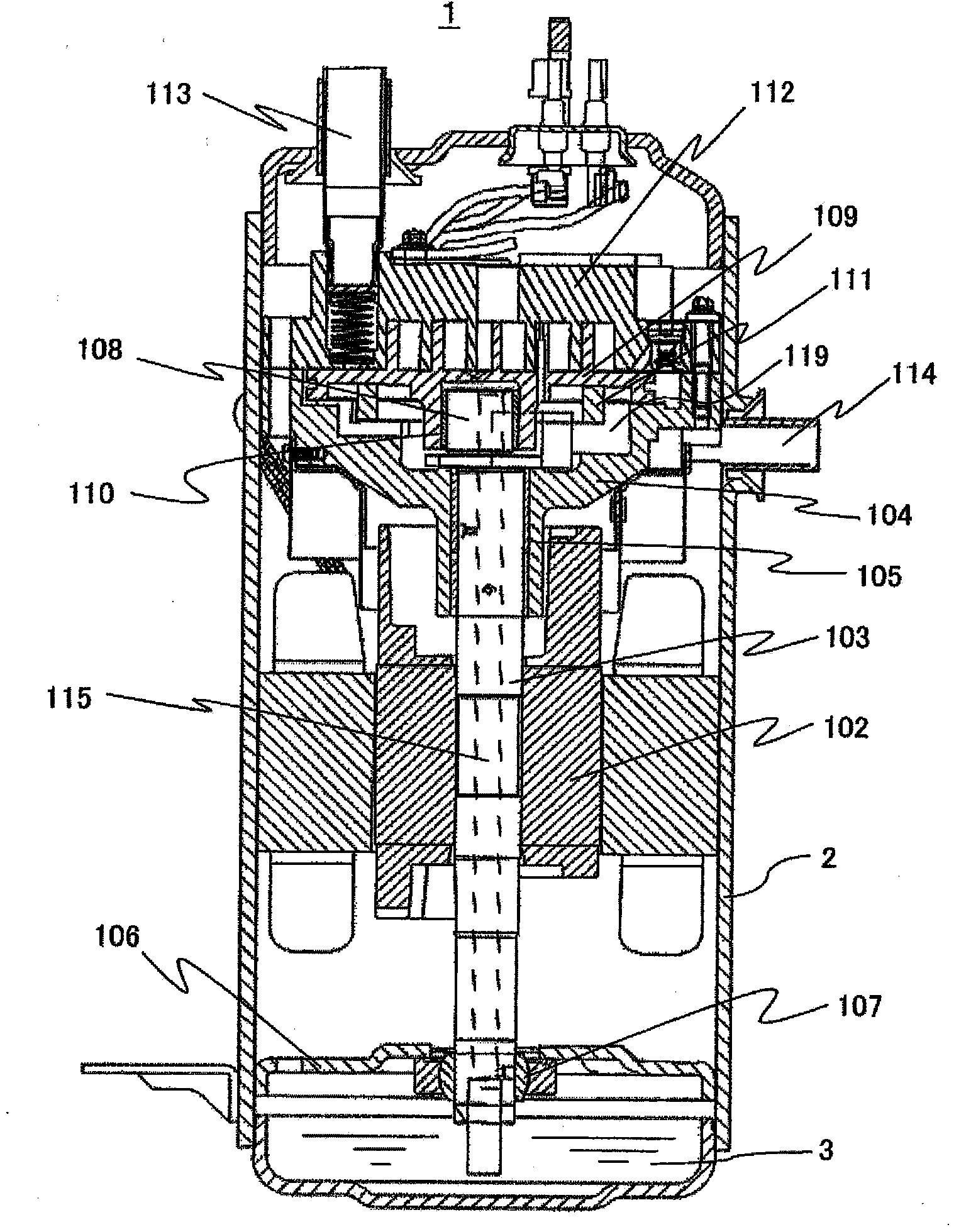

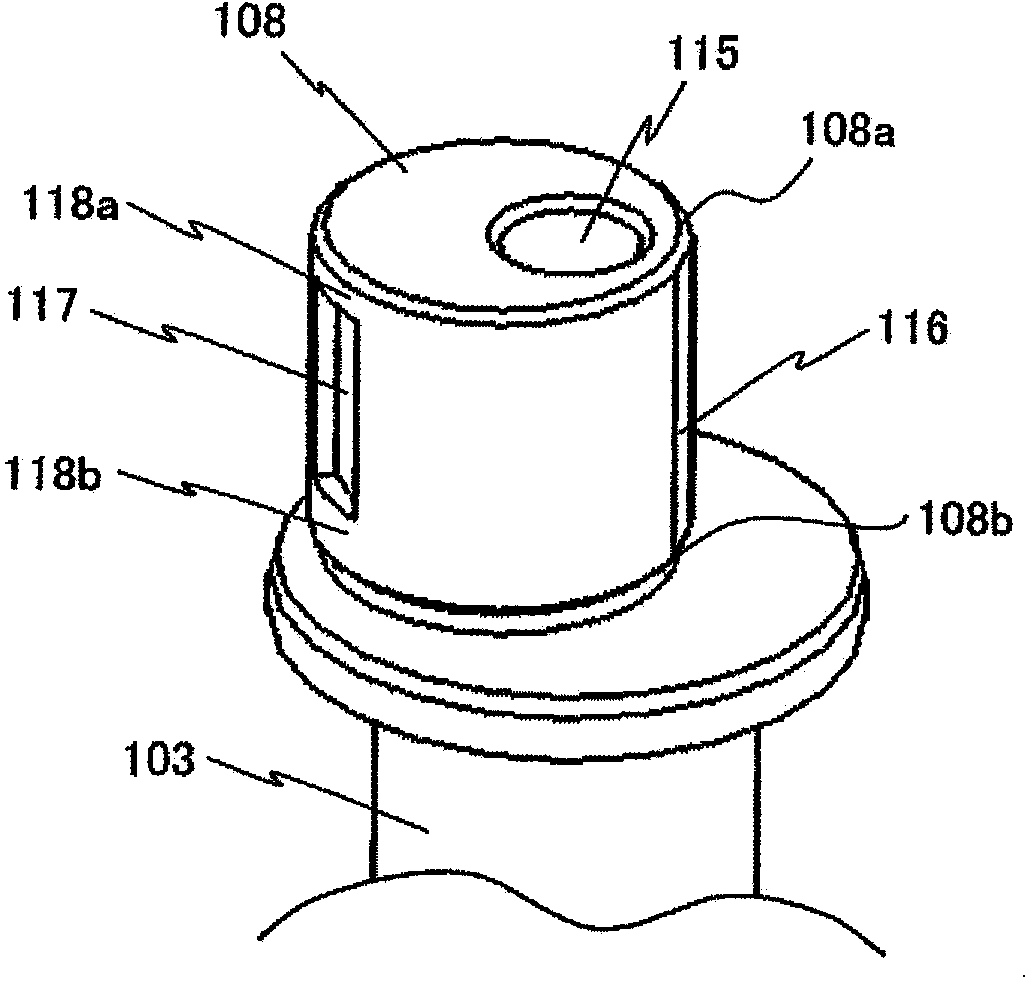

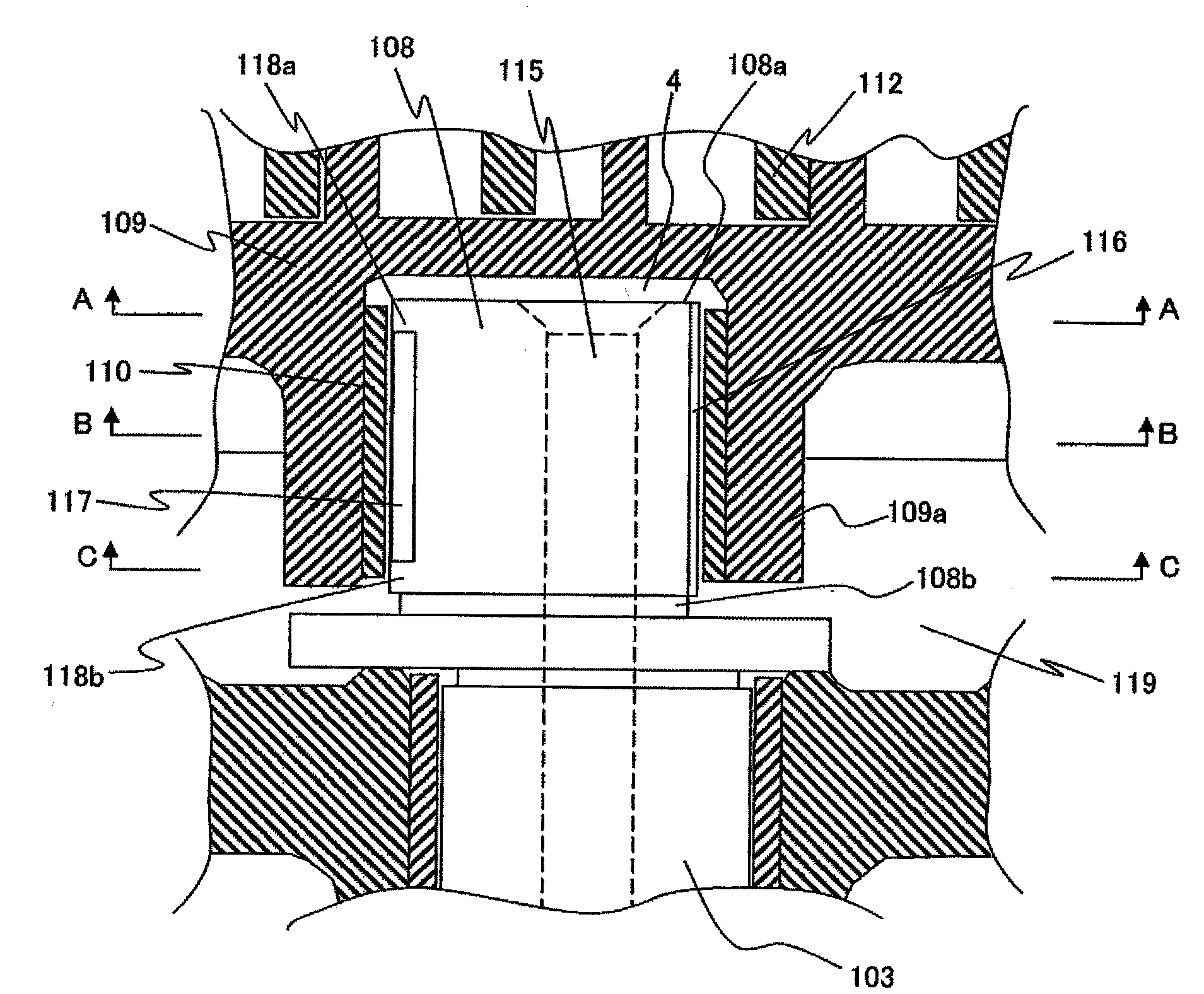

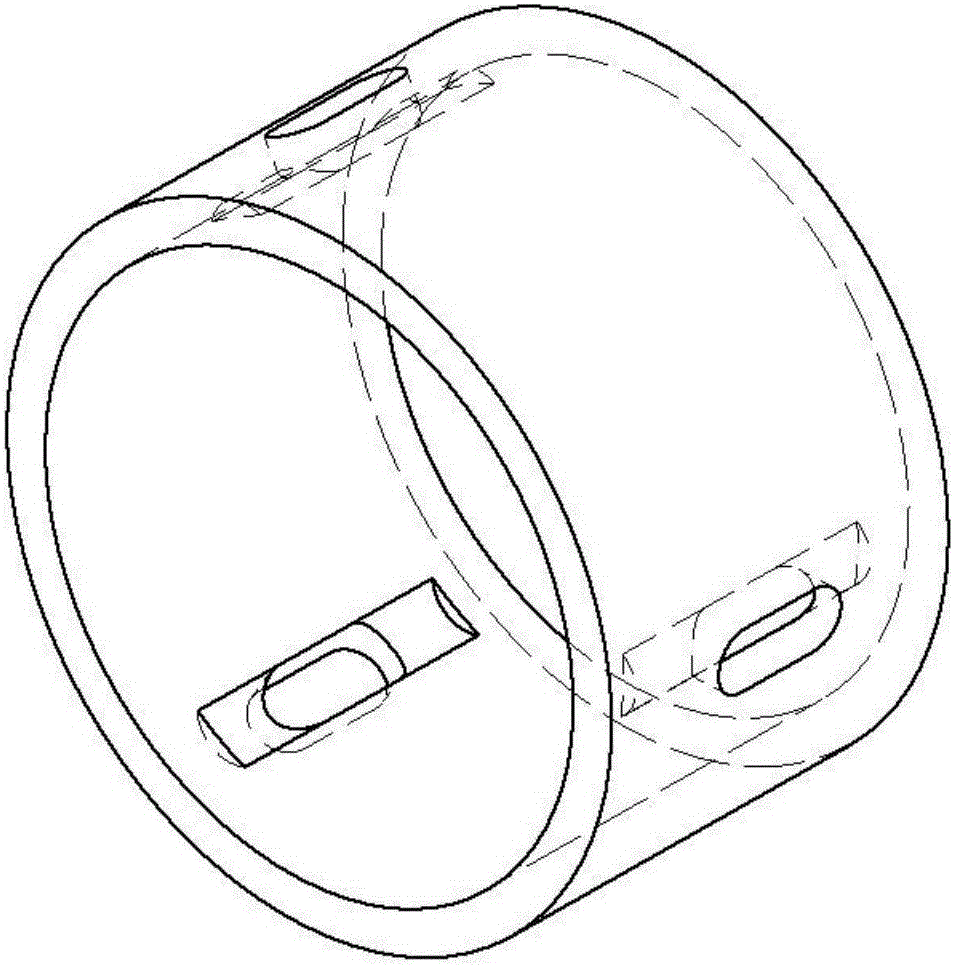

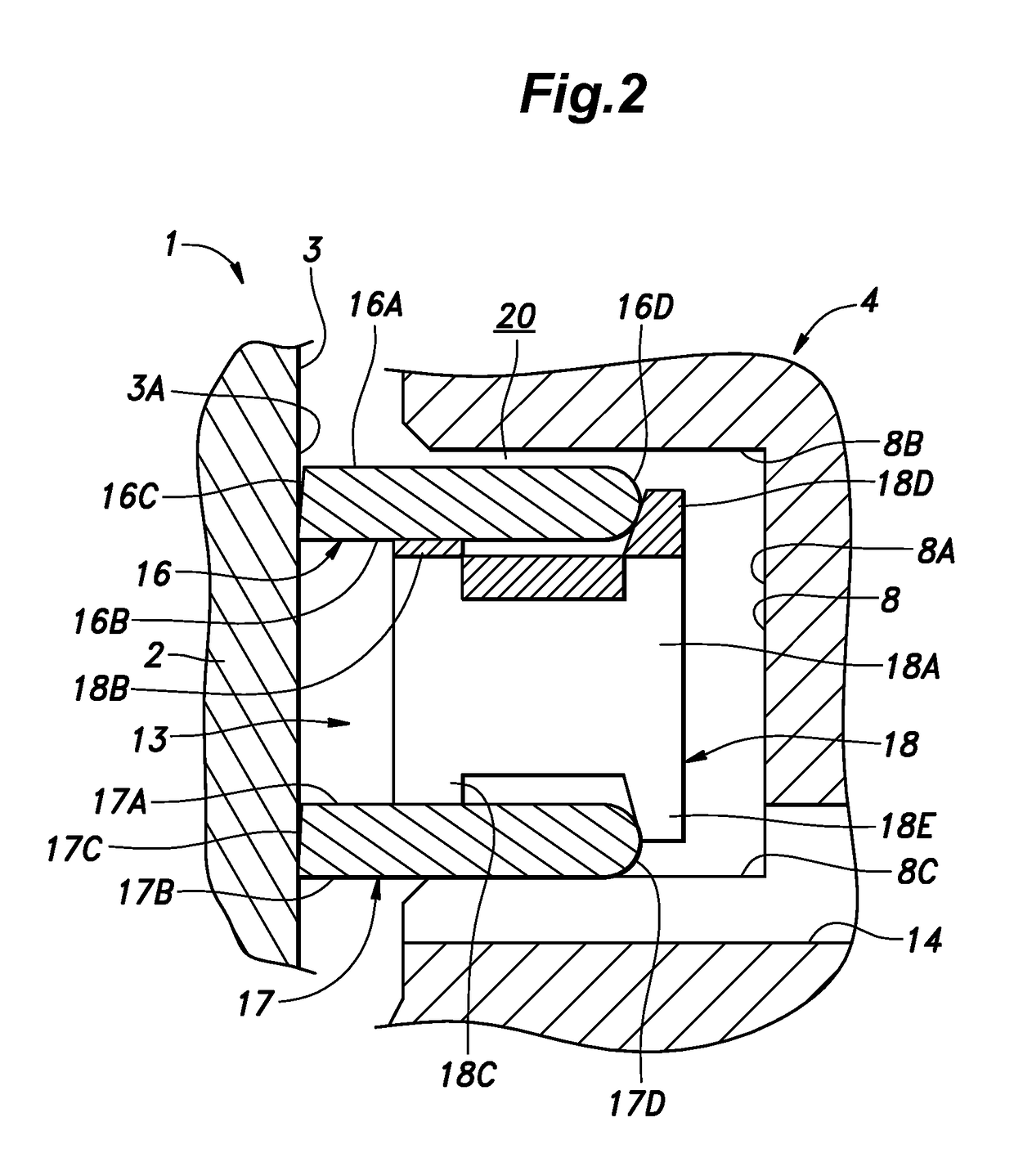

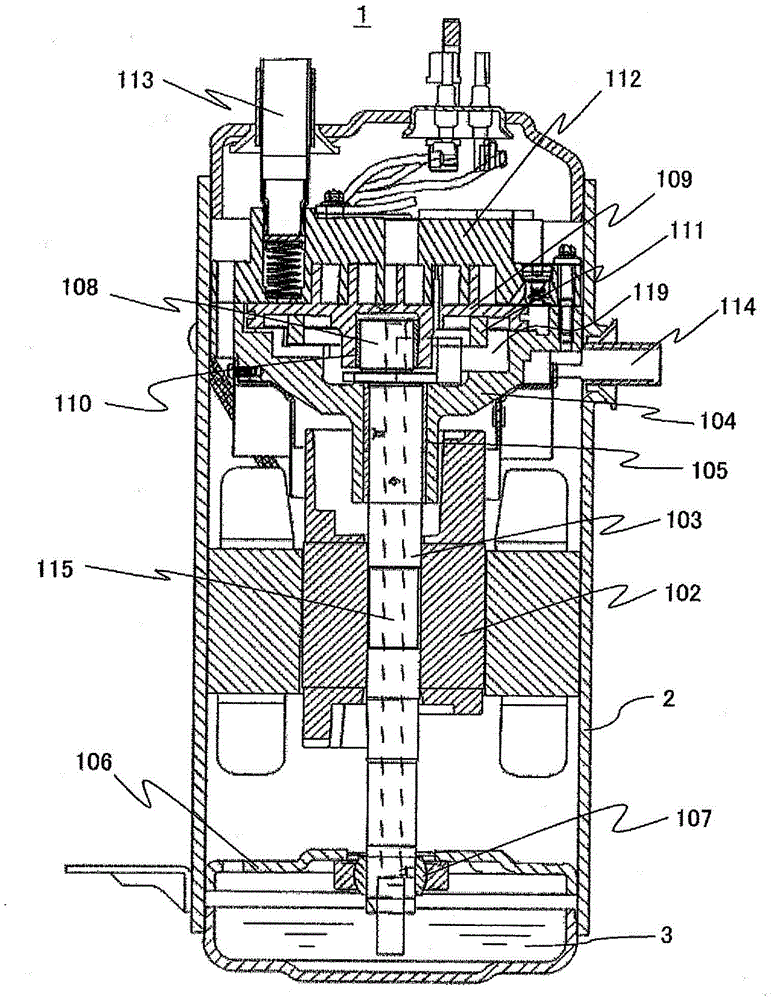

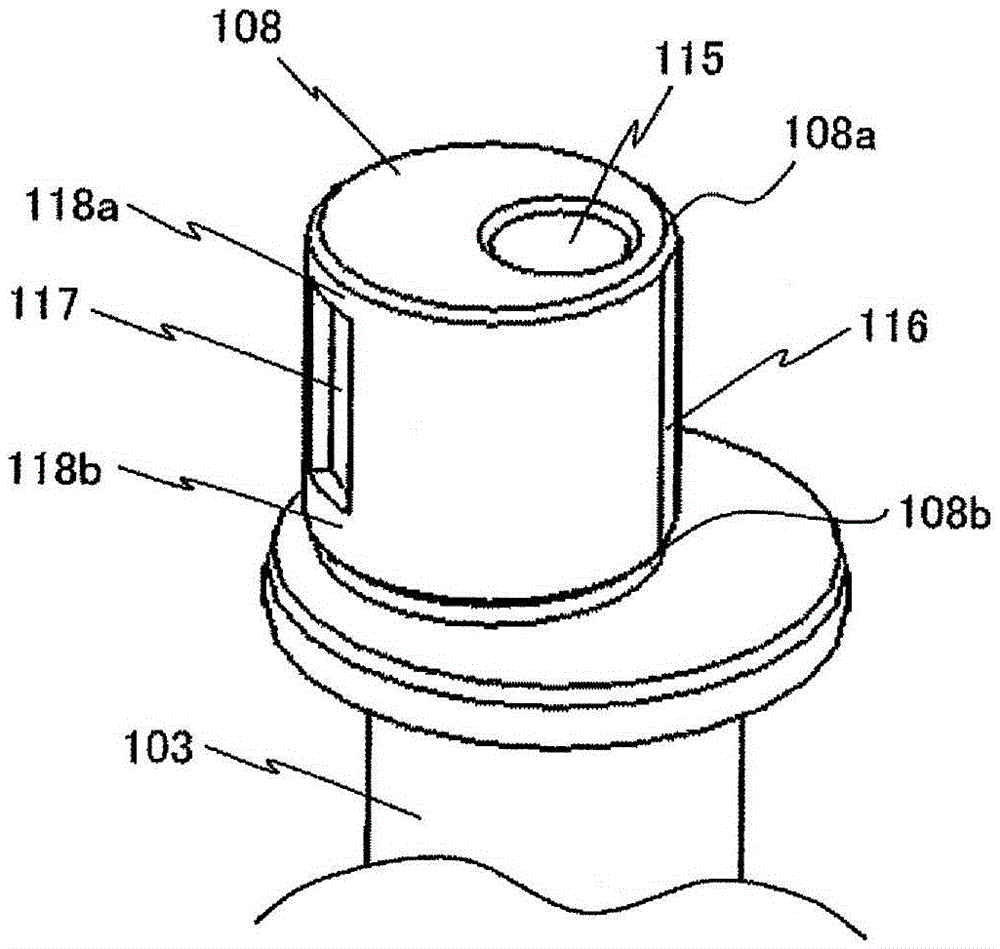

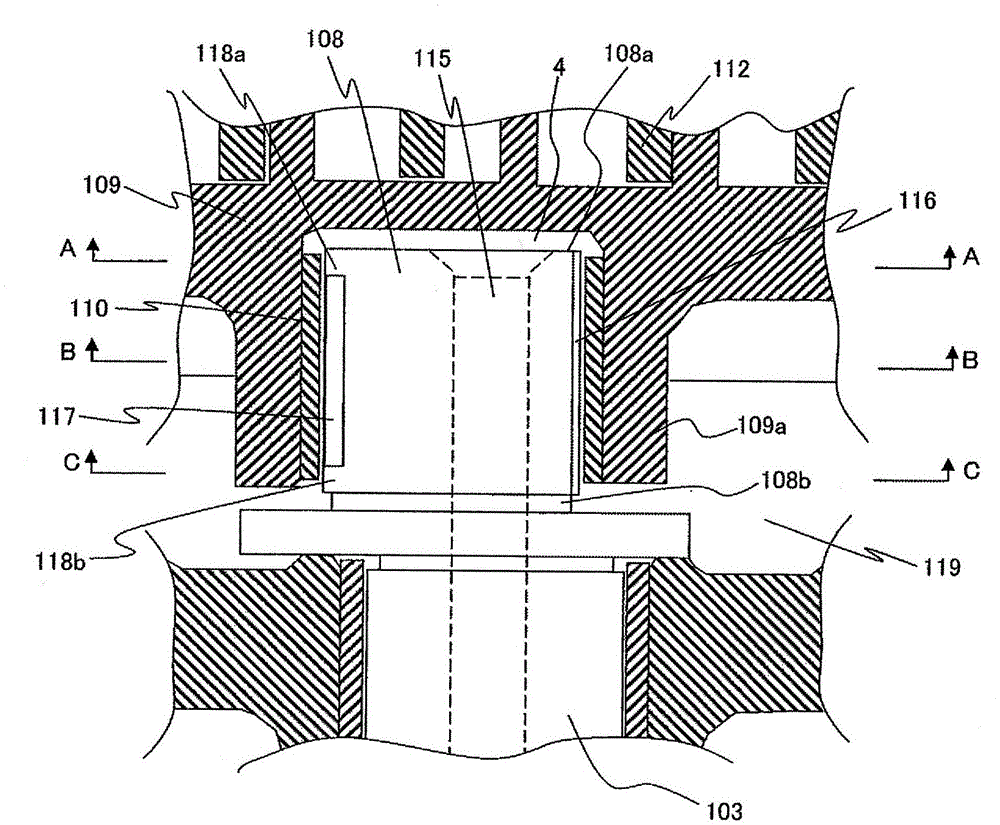

Scroll compressor

ActiveCN103502645AReduce shear resistanceReduce lossesRotary piston pumpsRotary piston liquid enginesLubricationOil supply

A scroll compressor equipped with: a stationary scroll (112); a rotating scroll (109); a crankshaft (103) at the end of which is an eccentric part (108); an oil supply hole (115) that penetrates the interior of the crankshaft in the axial direction and has an aperture part at the end face of the eccentric part; a rotating sliding bearing (110) that is provided on the rotating scroll, and engages the eccentric part and slides; and an oil supply passage (116) provided at the outer circumference of the eccentric part. The scroll compressor is constructed such that the interval between the eccentric part and the rotating sliding bearing is lubricated by means of lubricating oil supplied from the oil supply hole. A loss reduction groove (117) is provided separately from the oil supply passage at the outer circumference of the eccentric part in the axial direction, and seal parts (118a, 118b) are provided on the eccentric part end-face side and / or the eccentric part base side of this loss reduction groove. Thus, the shear resistance of the oil film due to the lubricating oil present between the outer circumferential surface of the eccentric part of the crankshaft and the inner circumferential surface of the rotating sliding bearing can be reduced, and bearing loss during fluid lubrication can be reduced.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

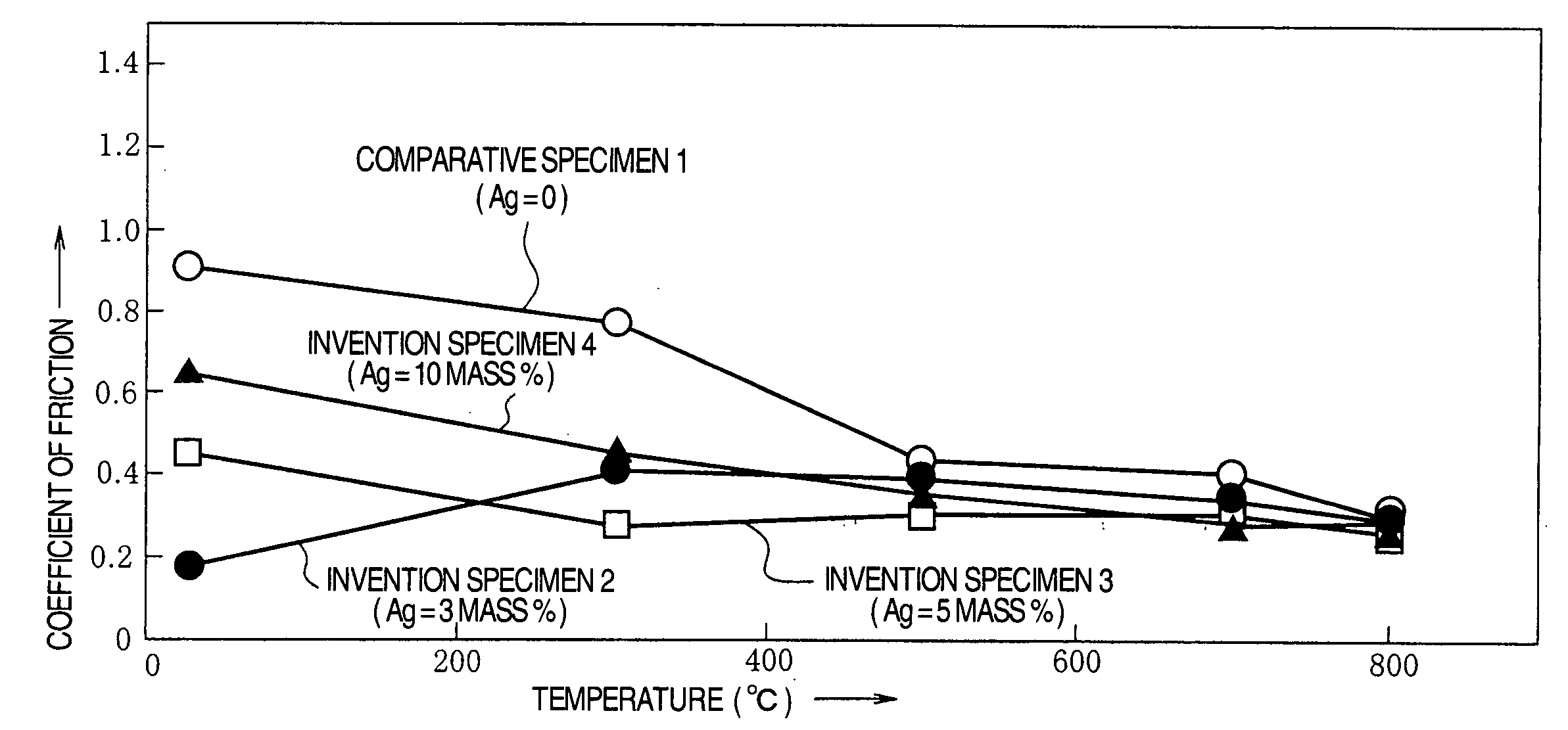

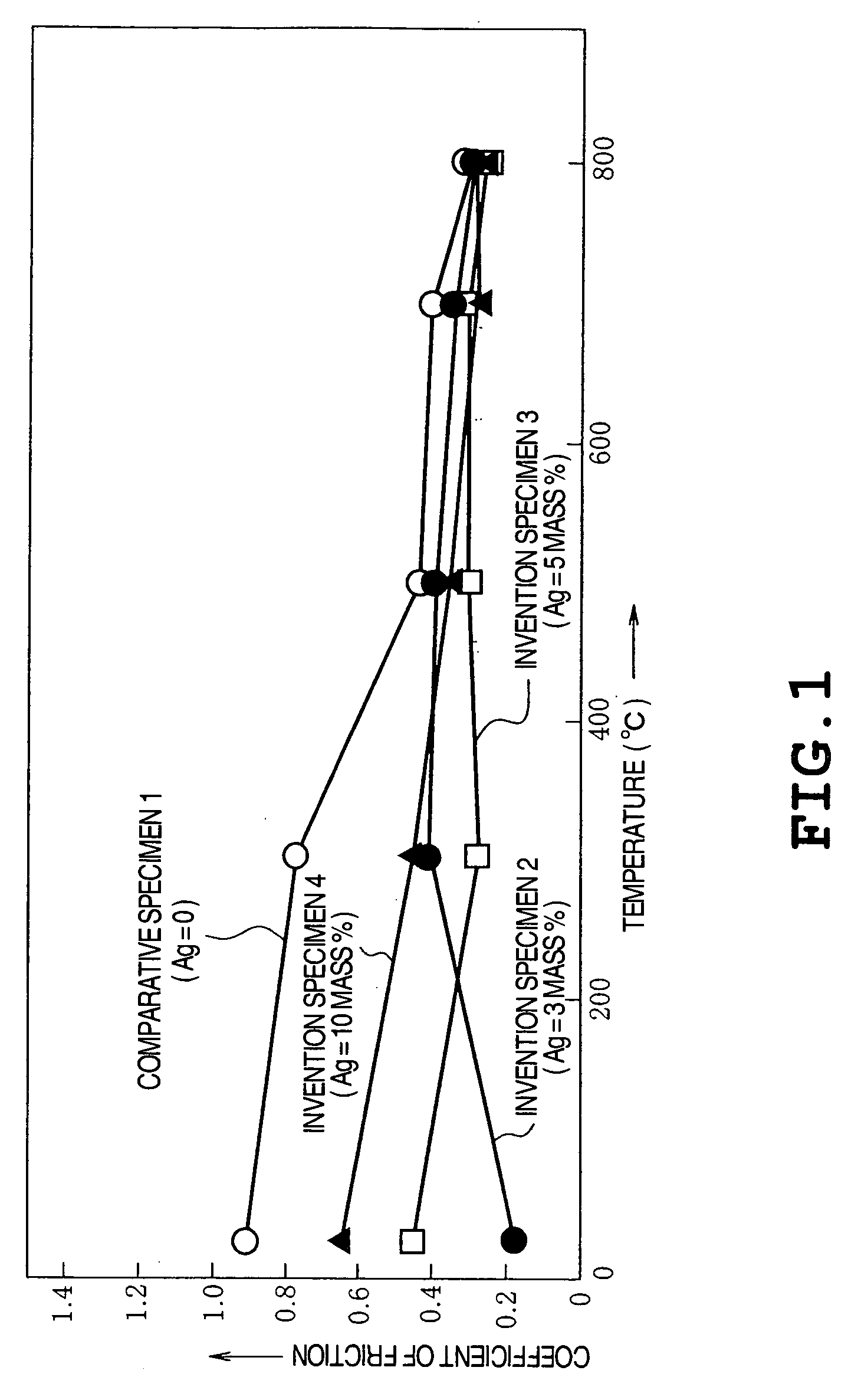

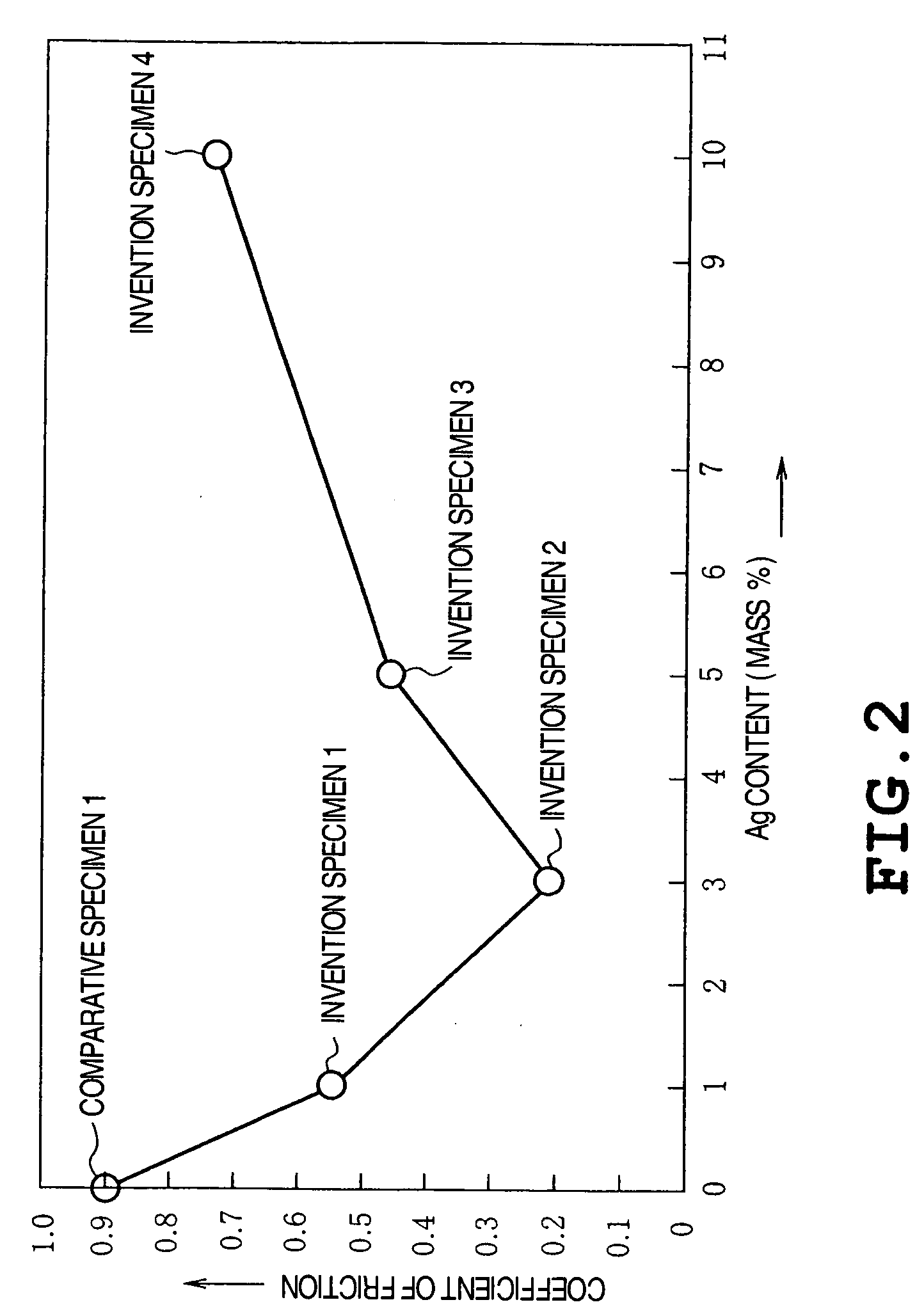

High temperature sliding alloy

InactiveUS20060237101A1Increased durabilityEasy to wearThin material handlingMetal layered productsMaterials scienceCoefficient of friction

A high temperature sliding alloy has a matrix 1 of a Ni-base alloy or a heat resistant Fe-base alloy, and contains, by mass, 1 to 35% hard particles consisting of a Co-base intermetallic compound dispersed therein, wherein 0.1 to 10% Ag is dispersed in the matrix. Ag is a soft metal, forms an ultrathin film on a sliding surface caused by sliding with a mating member, and presents a lubricating effect. When Ag forms the ultrafine film and spreads on the sliding surface, it works little as a frictional force against the mating member due to its low shear resistance, and accordingly can achieve a low coefficient of friction.

Owner:DAIDO METAL CO LTD

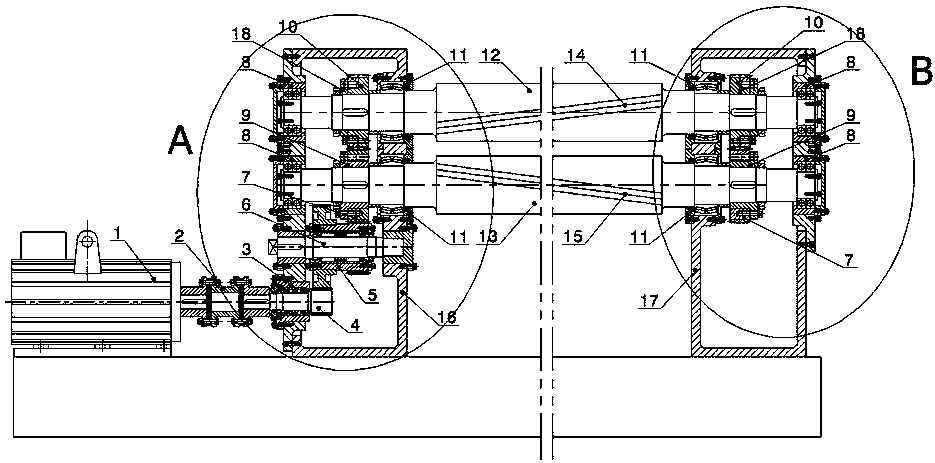

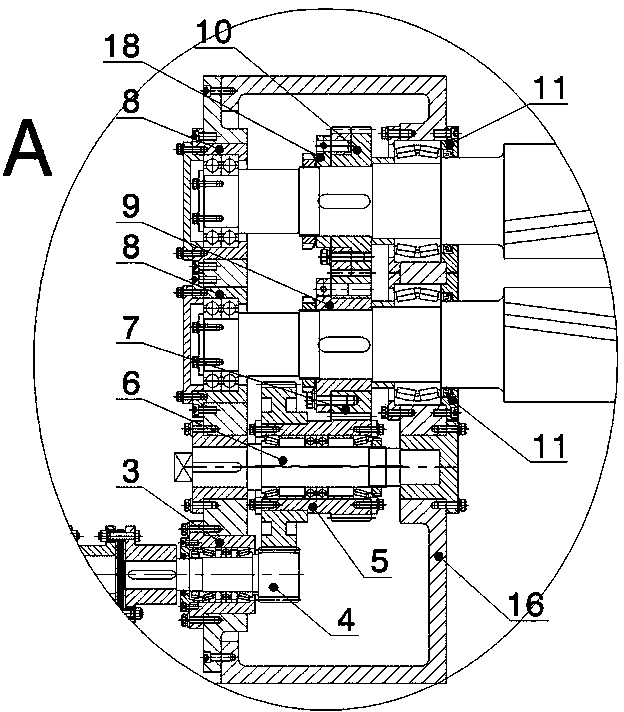

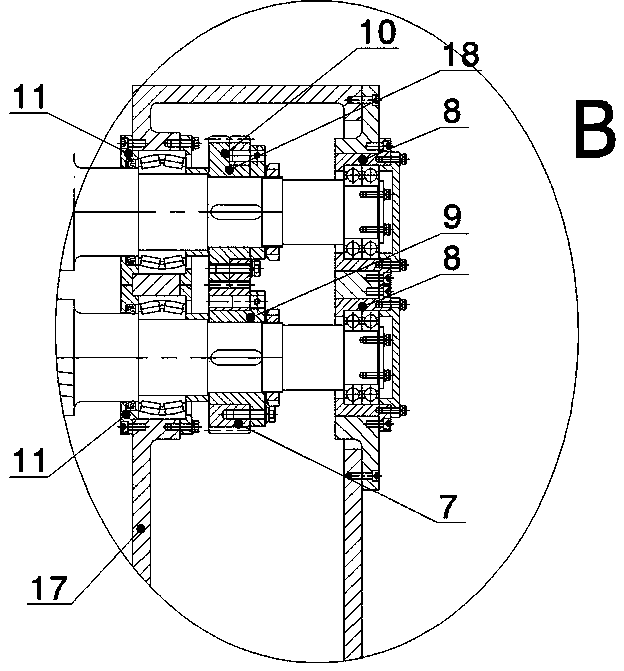

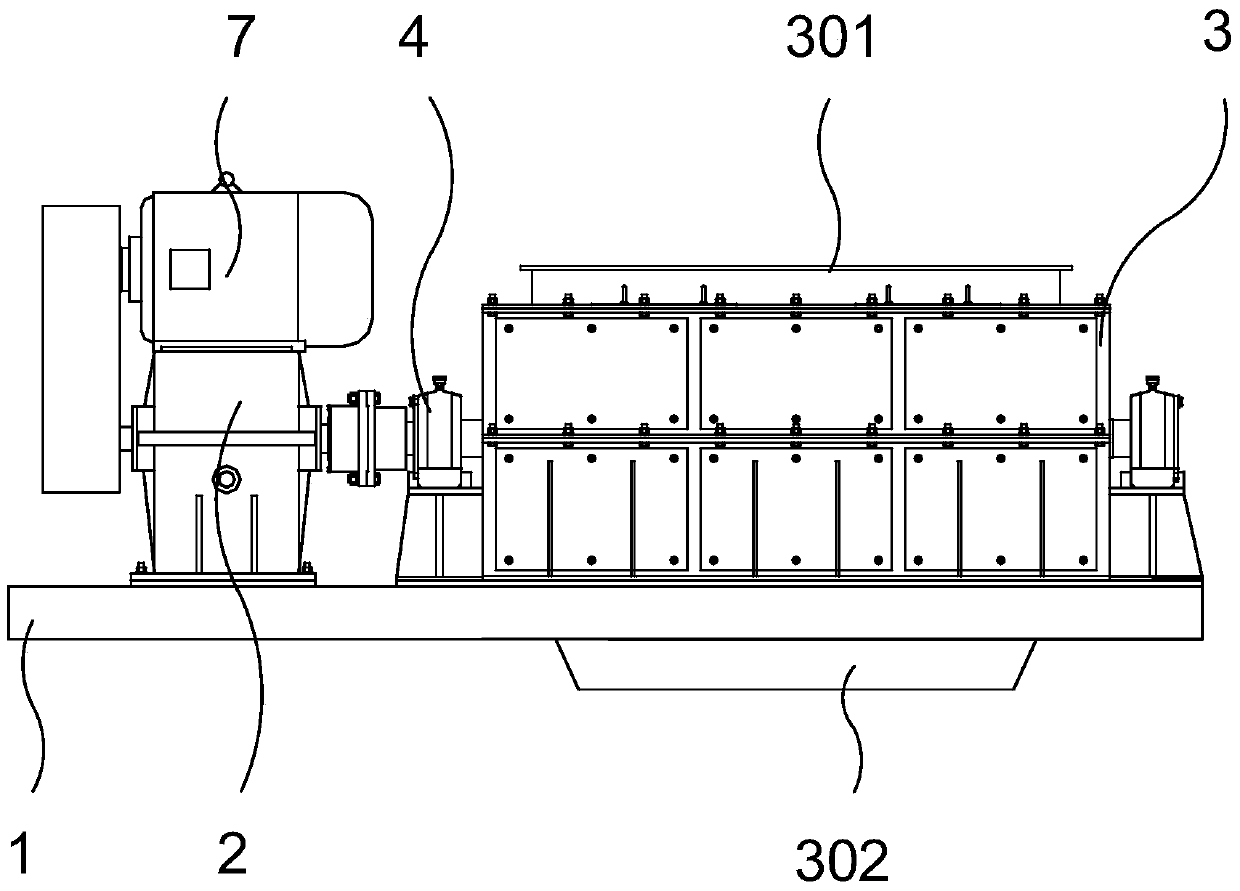

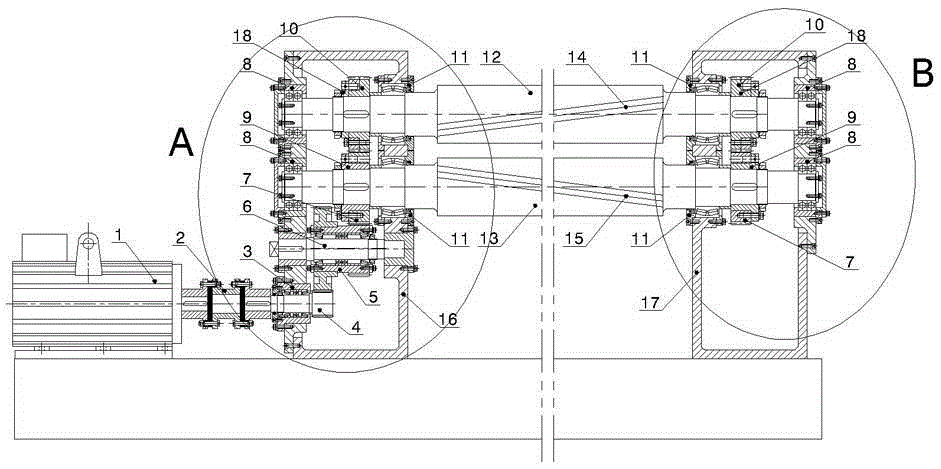

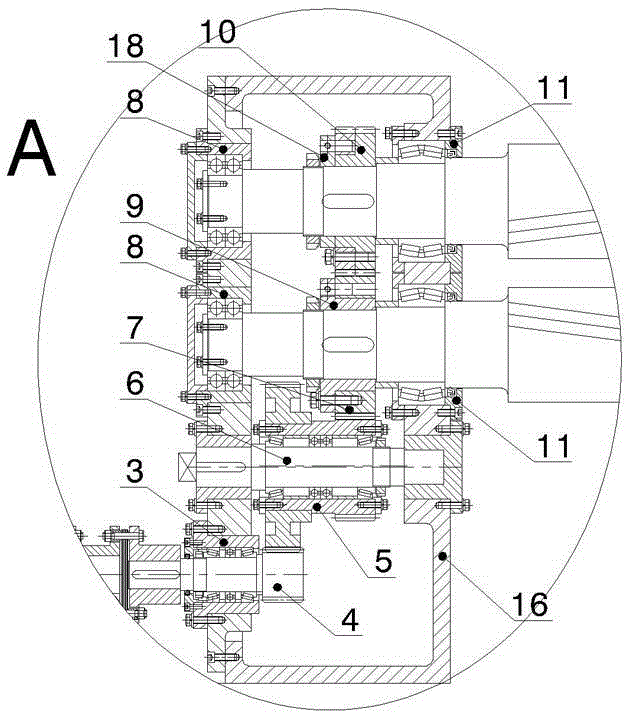

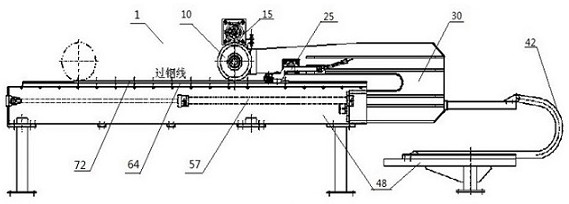

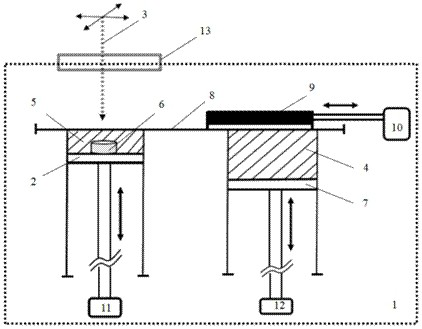

Energy-efficient transmission mechanism of transverse cutting machine

InactiveCN103737650AGuaranteed positioning accuracyLow powerMetal working apparatusGearing detailsBall bearingCoupling

The invention relates to an energy-efficient transmission mechanism of a transverse cutting machine. The energy-efficient transmission mechanism is characterized in that an upper knife roll and a lower knife roll are connected with a left gearbox rack and a right gearbox rack through inner bearing blocks and outer bearing blocks, upper knife roll gears are arranged at the two ends of the upper knife roll respectively, and lower knife roll gears are arranged at the two ends of the lower knife roll respectively. A driving motor is connected with an input gear shaft through two diaphragm couplings. The input gear shaft is sleeved with an eccentric bearing sleeve. An input gear of the input gear shaft is meshed with a big gear of a two-stage transmission gear set. A pinion of the two-stage transmission gear set is meshed with the corresponding lower knife roll gear. The lower knife roll gears are meshed with the corresponding upper knife roll gears. A self-aligning roller bearing is arranged in each inner bearing block, and a deep groove ball bearing is arranged in each outer bearing block. The energy-efficient transmission mechanism has the advantages of being large in reduction ratio and efficient and saving energy.

Owner:HEBEI SHENGLI PAPER CHEST EQUIP MFGCO

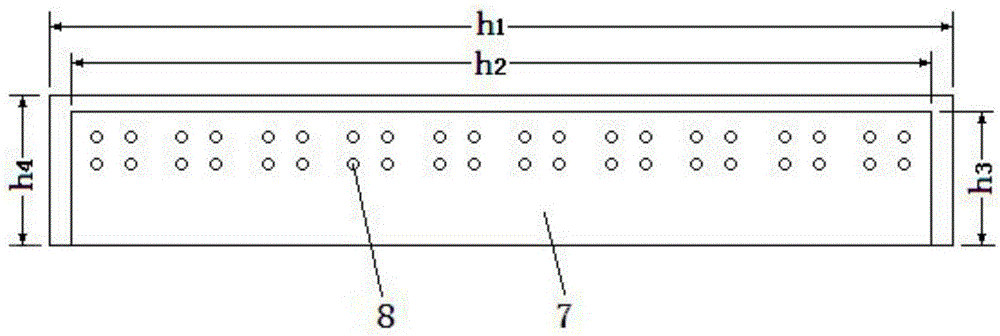

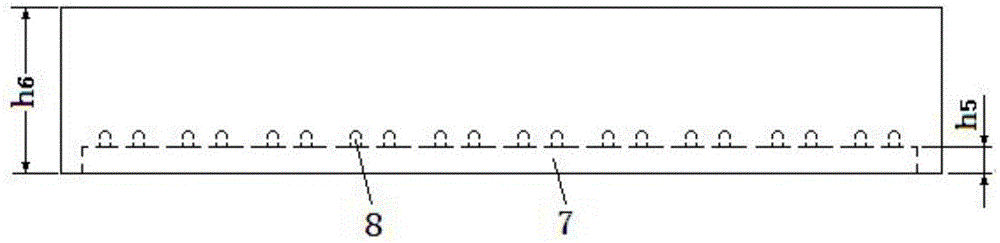

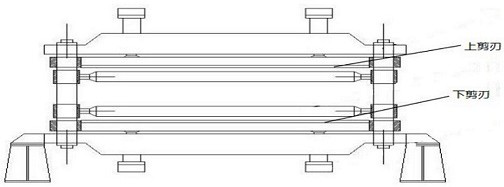

Separation type shearing knife

InactiveCN105522216AIncreased shear penetrationReduce shear resistanceShearing toolsTransverse shearEngineering

The invention discloses a separating type shearing knife, and belongs to the technical field of metal cutting. A groove 7 is formed in the front surface of a knife rest, and a threaded hole is formed in the groove; an upper blade consists of 5-10 blade units, each blade unit is fixedly connected to the threaded hole in the groove through a bolt, and the 5-10 blade units are transversely and tightly arranged in the groove; a lower blade is fixedly connected to a front upper corner of the base; and a distance h12 between a perpendicular cutting edge of the lower blade and the back surface of the cutting edge of each blade unit is 2-4mm. According to the separating type shearing knife disclosed by the invention, the tip parts of the blade units are manufactured to be triangular, and the knife tips can effectively increase shearing penetrating capacity, so that the shearing resistance is reduced, and the efficiency is improved; meanwhile, each position of the knife body during shearing is different in stress impact, so that the invalid blade unit can be independently replaced when local blade unit is invalid, and therefore, the cost is reduced; and meanwhile, the combined type upper blade carries out transverse shearing motion, so that the roughness of a sheared surface of a sheared material is reduced, and processing precision is improved.

Owner:JILIN UNIV

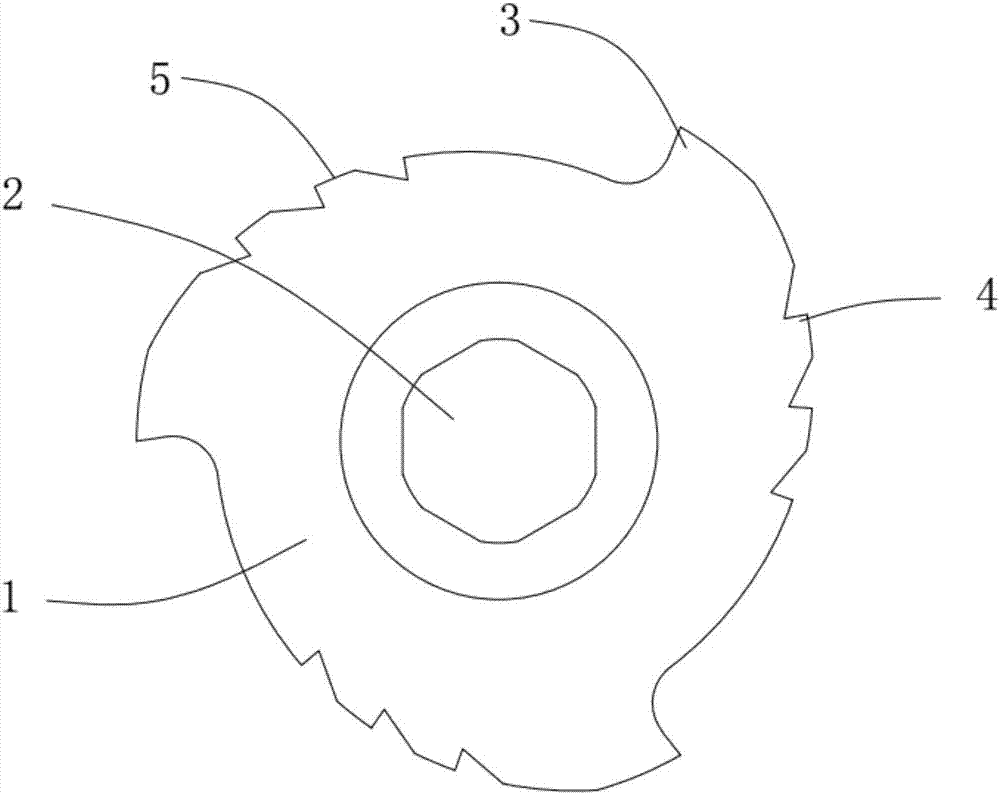

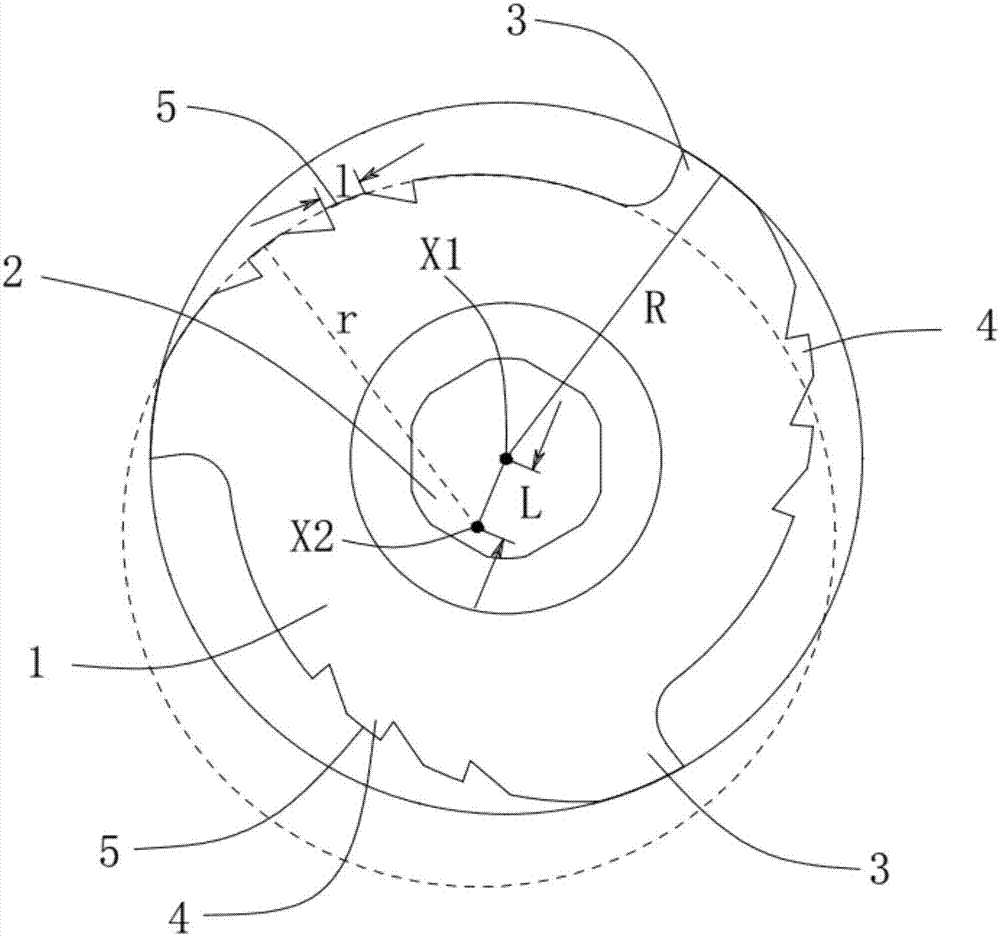

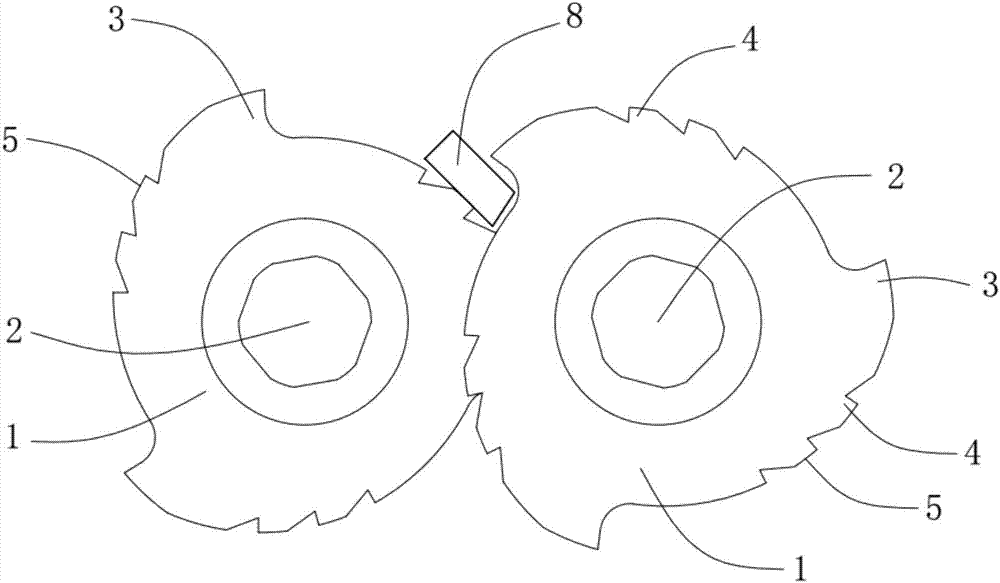

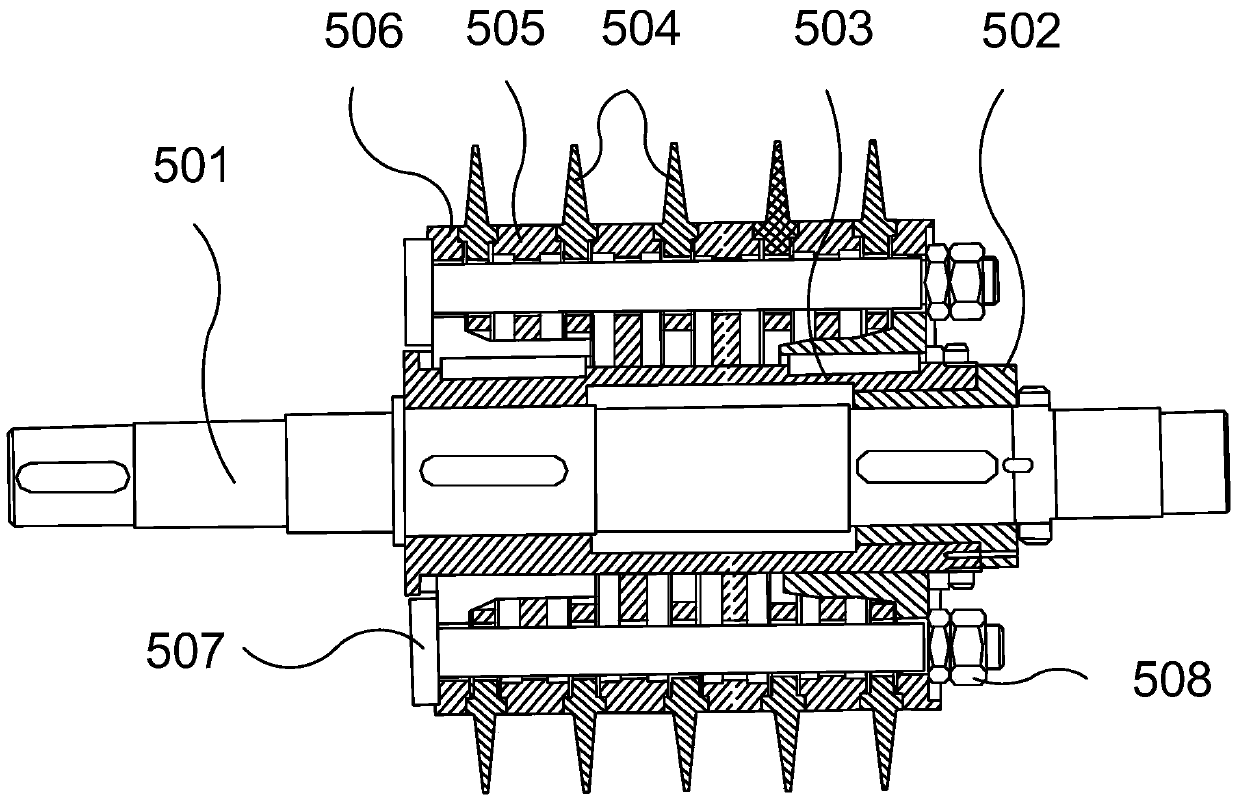

Shearing crusher cutter and crushing shaft device

The invention belongs to the technical field of fine crushing, and in particular, discloses a shearing crusher cutter and a crushing shaft device of a shearing crusher applying the cutter. The cutter comprises a cutter body, and a cutter shaft mounting hole formed in the center of the cutter body; and multiple main edges are arranged at the outer periphery of the cutter body, and are uniformly distributed on the outer peripheral edge of the cutter body with the cutter shaft mounting hole as the circle center. The cutter further comprises multiple sets of secondary edges; each set of secondary edges is arranged between two adjacent main edges; and the distances from the main edges to the cutter shaft mounting hole are larger than the distances from the secondary edges to the cutter shaft mounting hole. The crushing shaft device comprises a cutter shaft, and cutters mounted on the cutter shaft; at least two cutters are provided; and spacing sleeves are arranged between the cutter shaft and the cutters. The cutter can fully crush materials to be crushed to improve the crushing efficiency, and relatively prolongs the service life of a crushing shaft and a motor.

Owner:ZHAOQING HI TECH ZONE GUOZHUAN TECH CO LTD

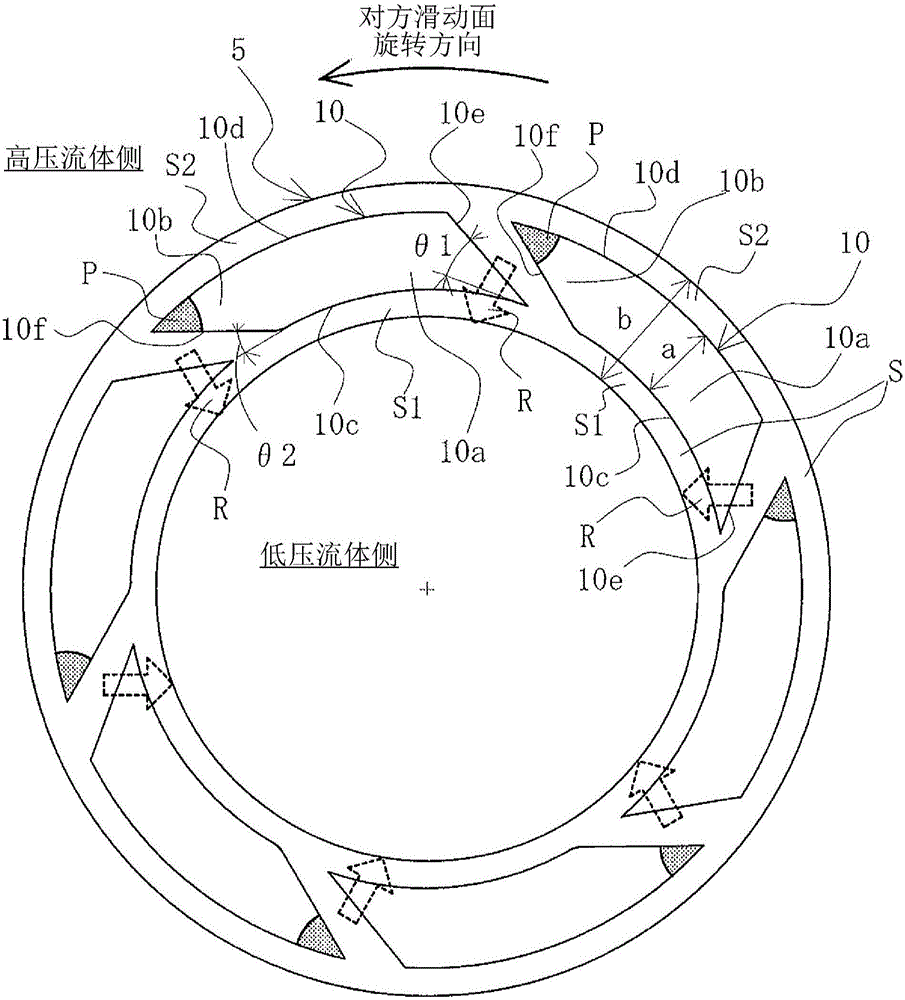

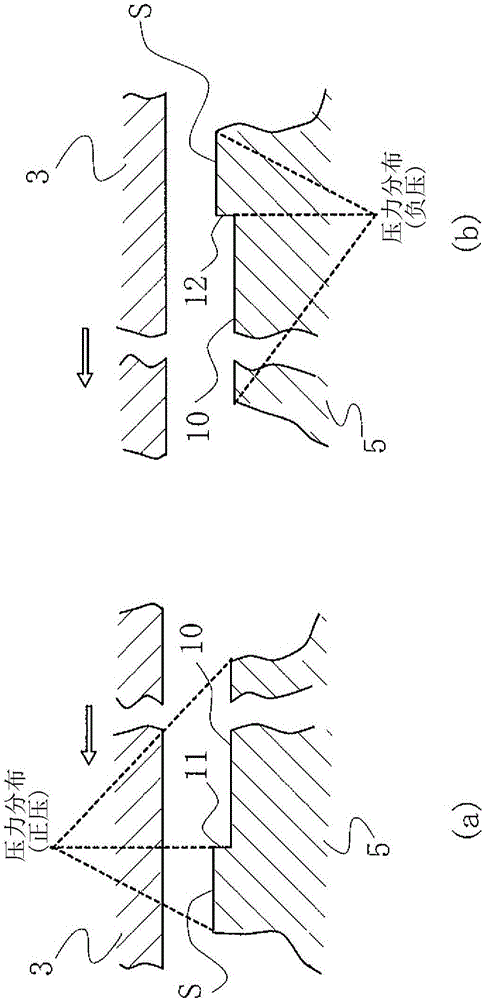

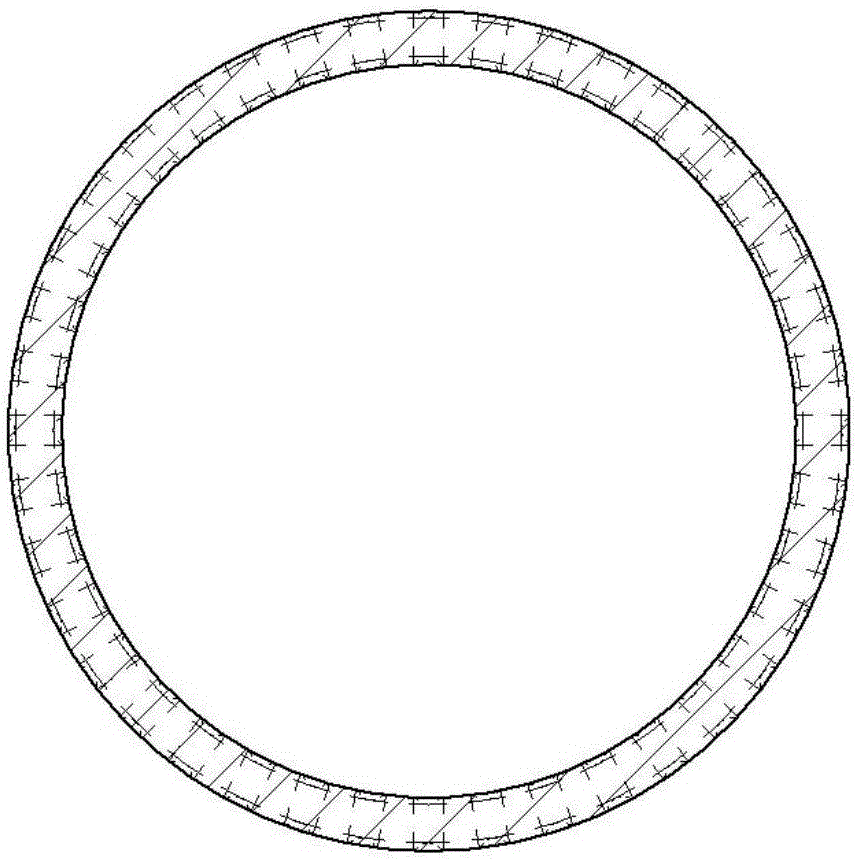

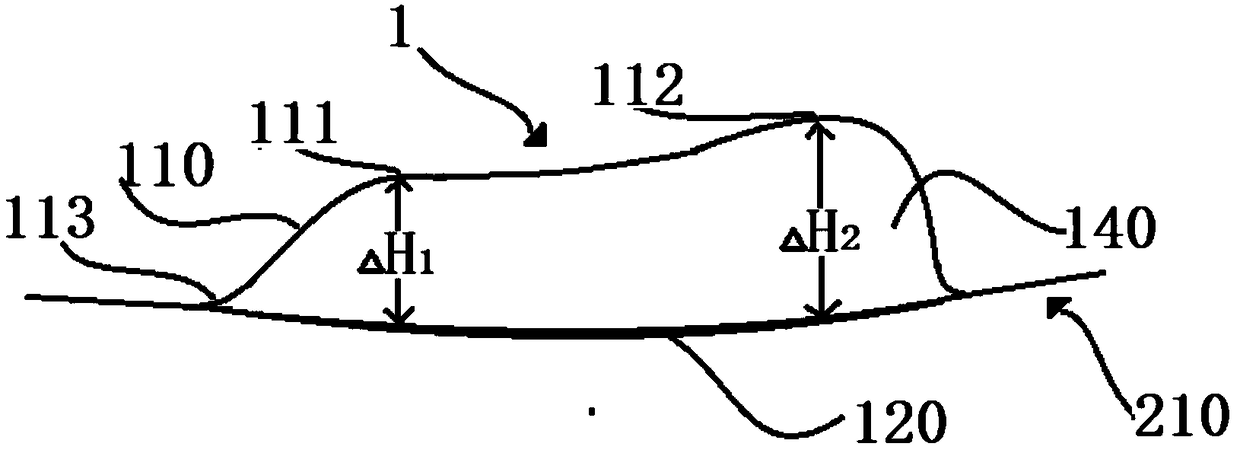

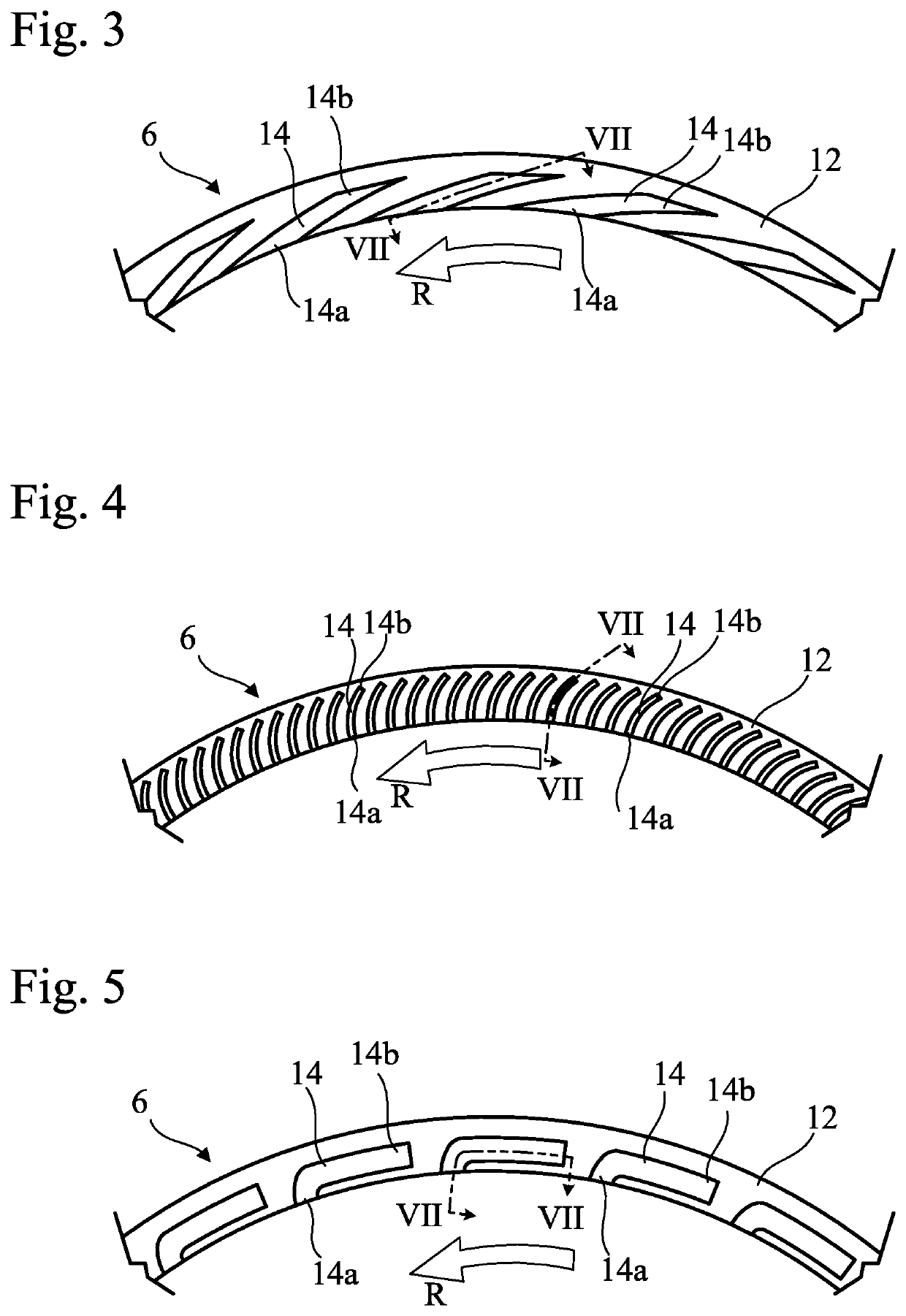

Sliding component

In the present invention, movement of a fluid from an upstream cavitation region to a downstream positive pressure generation region is smoothened, a negative pressure generation origin is enlarged, and cavitation regions are disposed over almost the whole circumference of a low-pressure fluid side. The present invention is characterized in that: dimples (10) are formed along a circumferential direction at an approximately constant width from an upstream cavitation formation region (10a) to a downstream positive pressure generation region (10b); an upstream starting end (10e) of the cavitation formation region (10a) forms a tapered shape inclined along the rotational direction of an opposing sliding surface from the low-pressure fluid side toward a high-pressure fluid side, and is disposed so as to overlap in the radial direction with the positive pressure generation region (10b) of the dimple (10) that is disposed upstream; and the low-pressure fluid-side end (10f) of the positive pressure generation region (10b) forms a tapered shape inclined along the rotational direction of the opposing sliding surface from the low-pressure fluid side toward the high-pressure fluid side, and is smoothly connected to the low-pressure fluid-side end (10c) of the cavitation formation region (10a).

Owner:EAGLE INDS

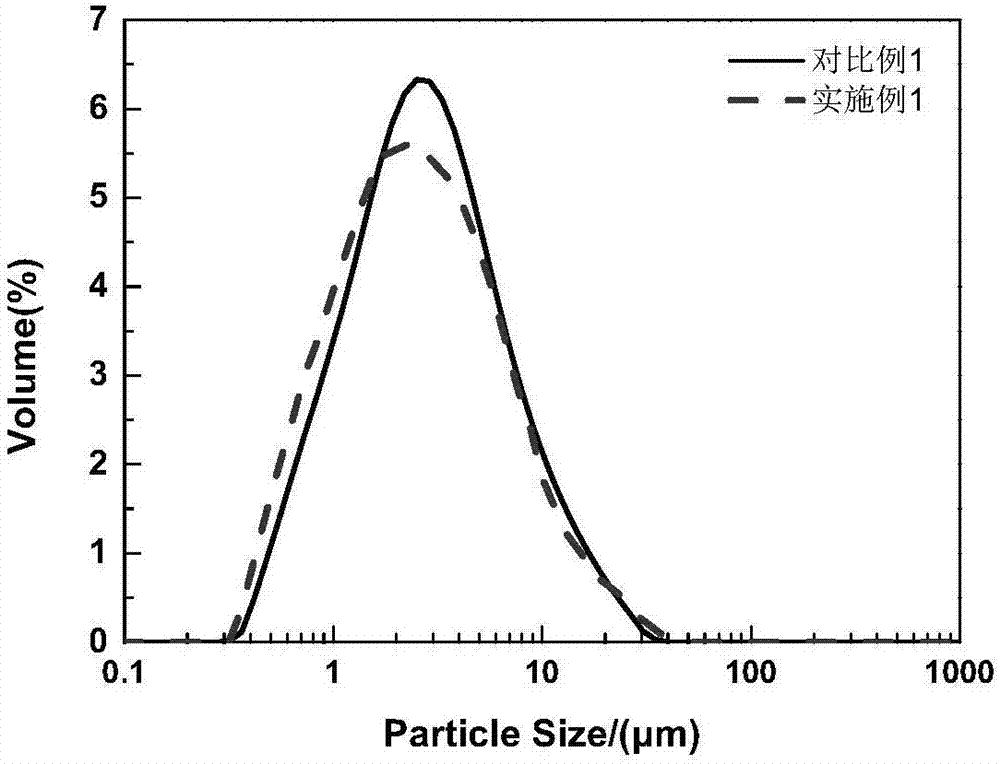

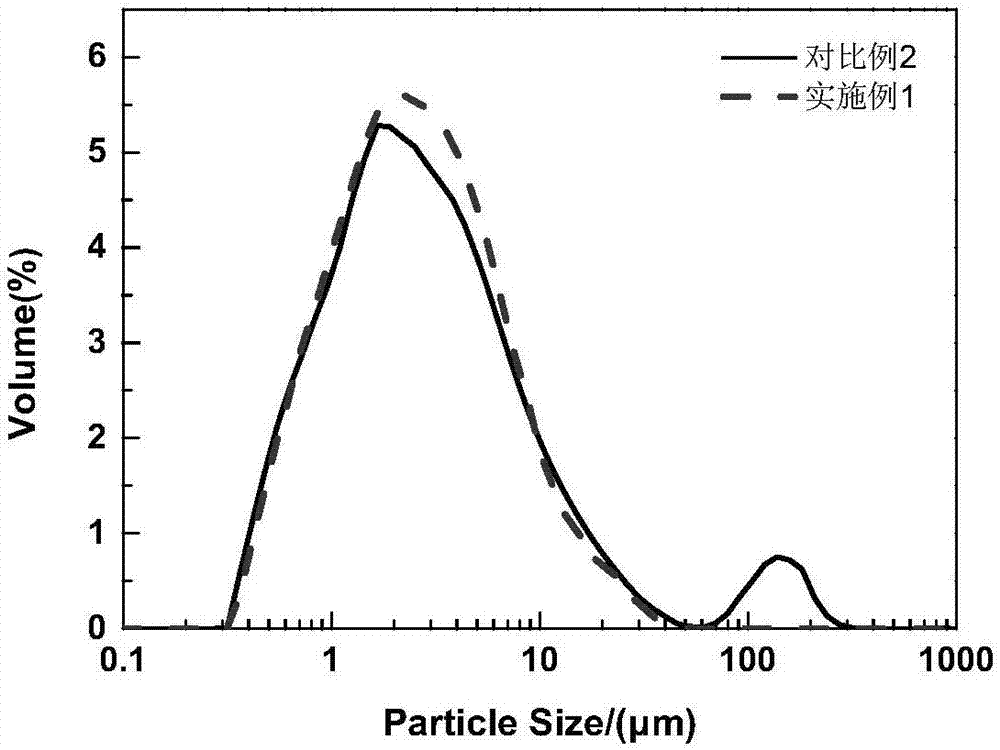

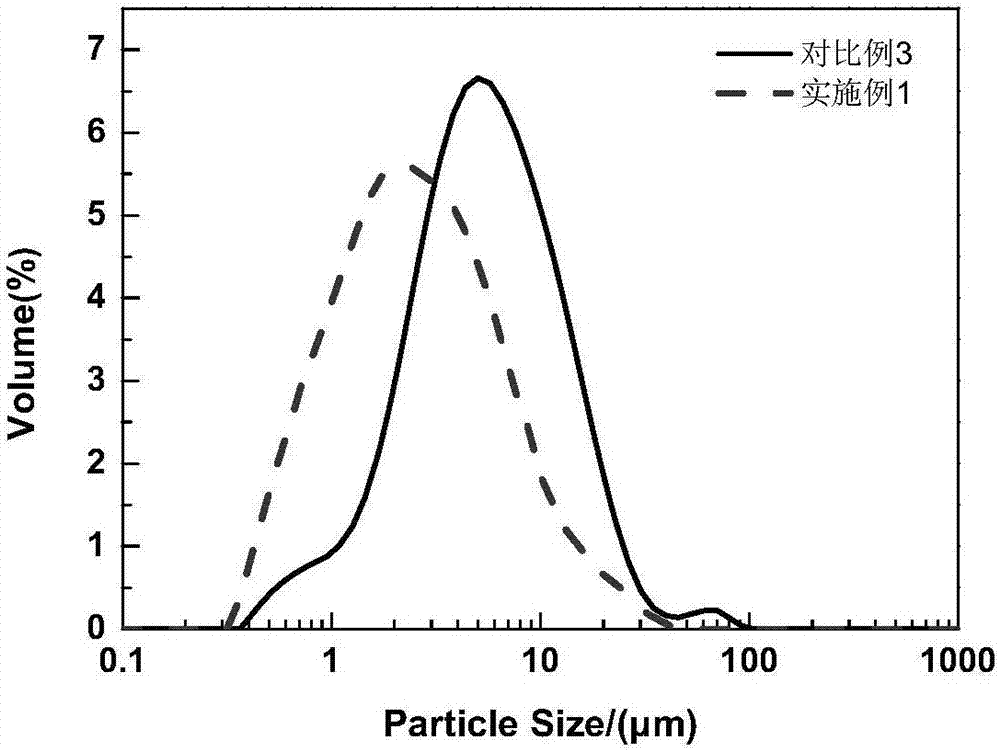

Pulpy metakaolin-base concrete admixture, and preparation method and application of admixture

The invention provides a pulpy metakaolin-base concrete admixture and a preparation method of the admixture. The admixture comprises a dry base, a composite dispersant and water, wherein the dry base consists of 30-90% by mass percentage of metakaolin and 10-70% by mass percentage of fly ash sinking beads; a mass ratio of the water to the dry base is (30-180):100; the composite dispersant consists of hydroxyethyl cellulose and a naphthalene water reducing agent; the hydroxyethyl cellulose accounts for 0.005-2.0% of the mass of the dry base; the naphthalene water reducing agent accounts for 0.001-1.0% of the mass of the dry base. The admixture reduces an adverse effect of the metakaolin on the working performance of concrete by utilizing combined action of the metakaolin, the fly ash sinking beads and the dispersant, and significantly improves the strength uniformity, the dispersity and the stability of a test block.

Owner:WUHAN UNIV OF TECH

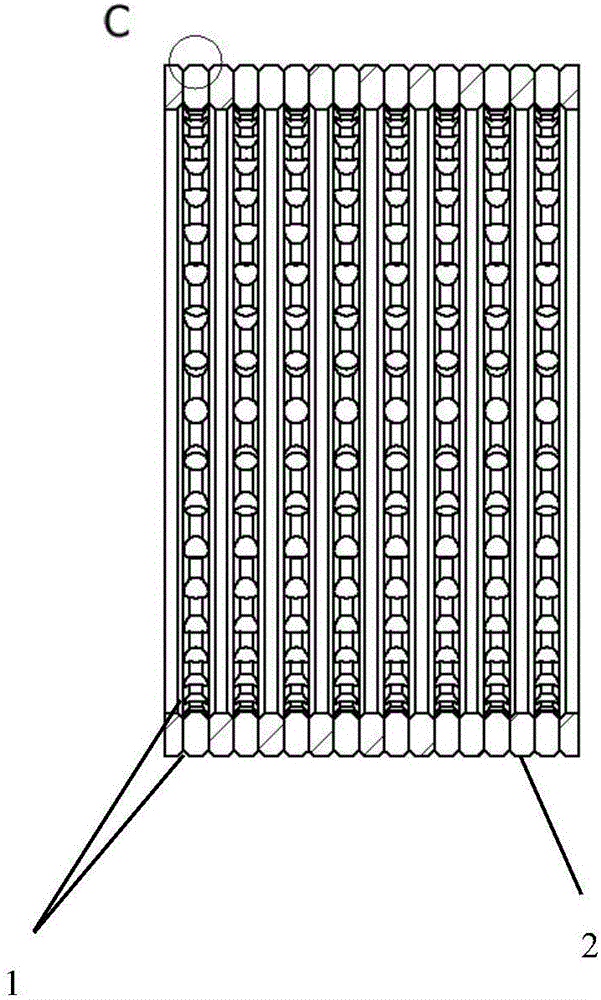

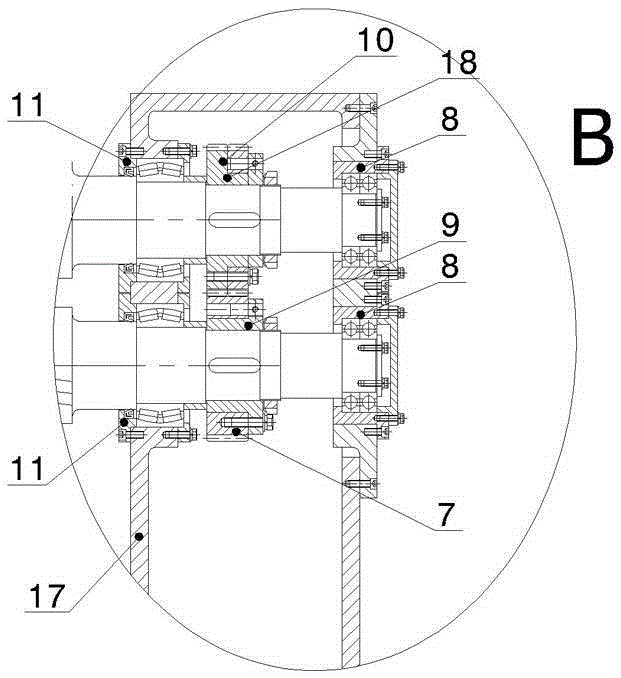

Floating bearing of turbocharger

InactiveCN106545577AFlow through effectivelyReduce shear resistanceShaftsBearing componentsTurbochargerLubrication

The invention discloses a floating bearing of a turbocharger. The floating bearing comprises a floating bearing body, namely a floating sleeve, wherein a plurality of annular oil grooves are formed in inner and outer surfaces of the floating sleeve; the cross section of each annular oil groove is isosceles triangle-shaped; a ridge structure is arranged between every two adjacent annular oil grooves; through oil holes which penetrate through a wall of the floating sleeve are uniformly formed in the floating sleeve along a circumferential direction and an axial direction; and penetration positions of the oil holes are located on the ridge structures. The floating bearing has the beneficial effects that the annular oil grooves on the inner and outer surfaces of the floating sleeve form an unsmooth surface, and shearing resistance formed when lubrication oil flows by the unsmooth surface provided with the longitudinal annular oil grooves is smaller than that formed when the lubrication oil flows by a smooth surface, so that the lubrication oil can effectively flow by the surface, and an aim of drag-reduction is reached. Furthermore, the through oil holes are uniformly formed in the floating sleeve, and on the condition that the lubrication oil is used for lubrication, the oil holes have high capability of lubrication oil storage and oil film forming.

Owner:BEIJING UNIV OF TECH

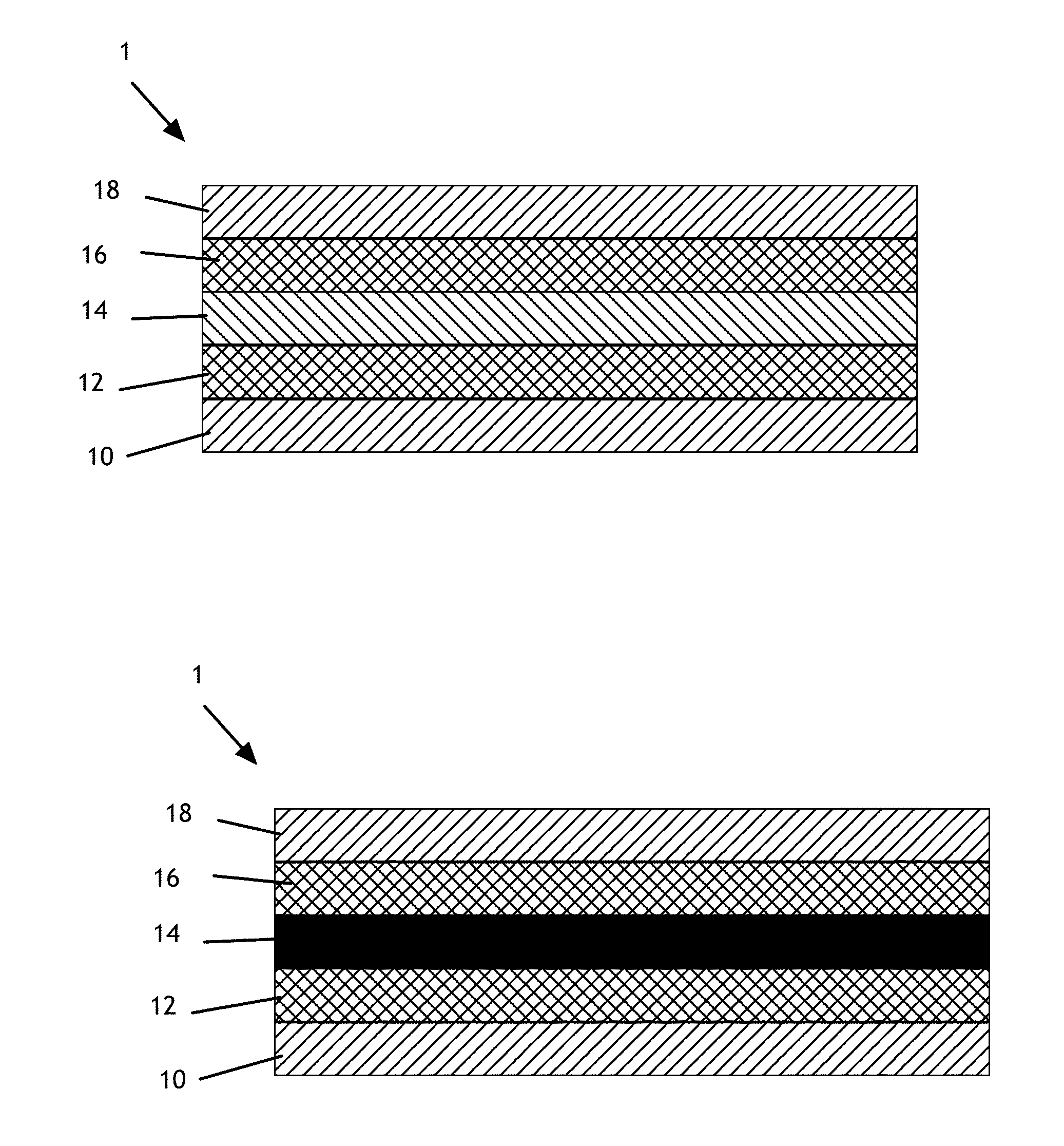

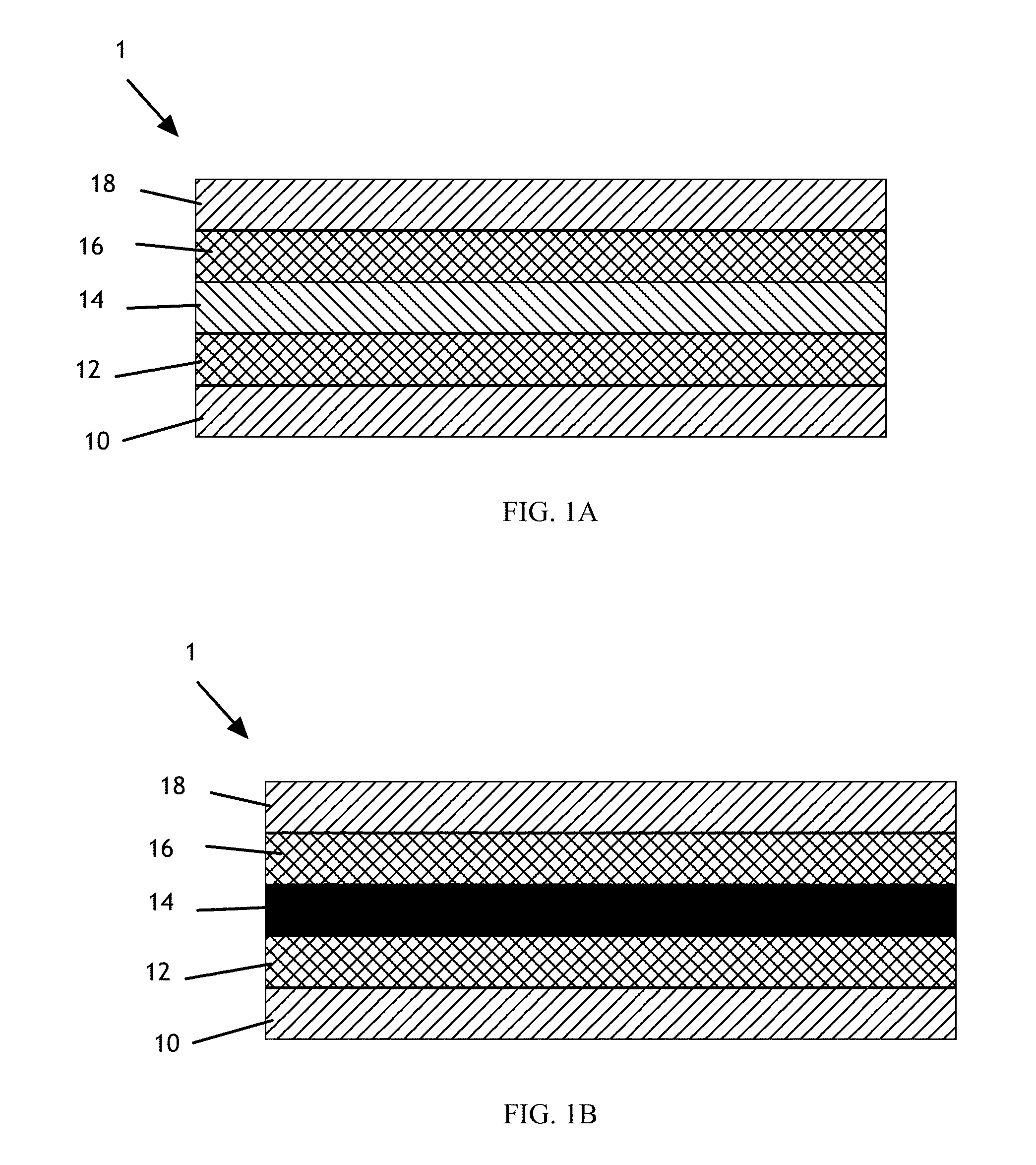

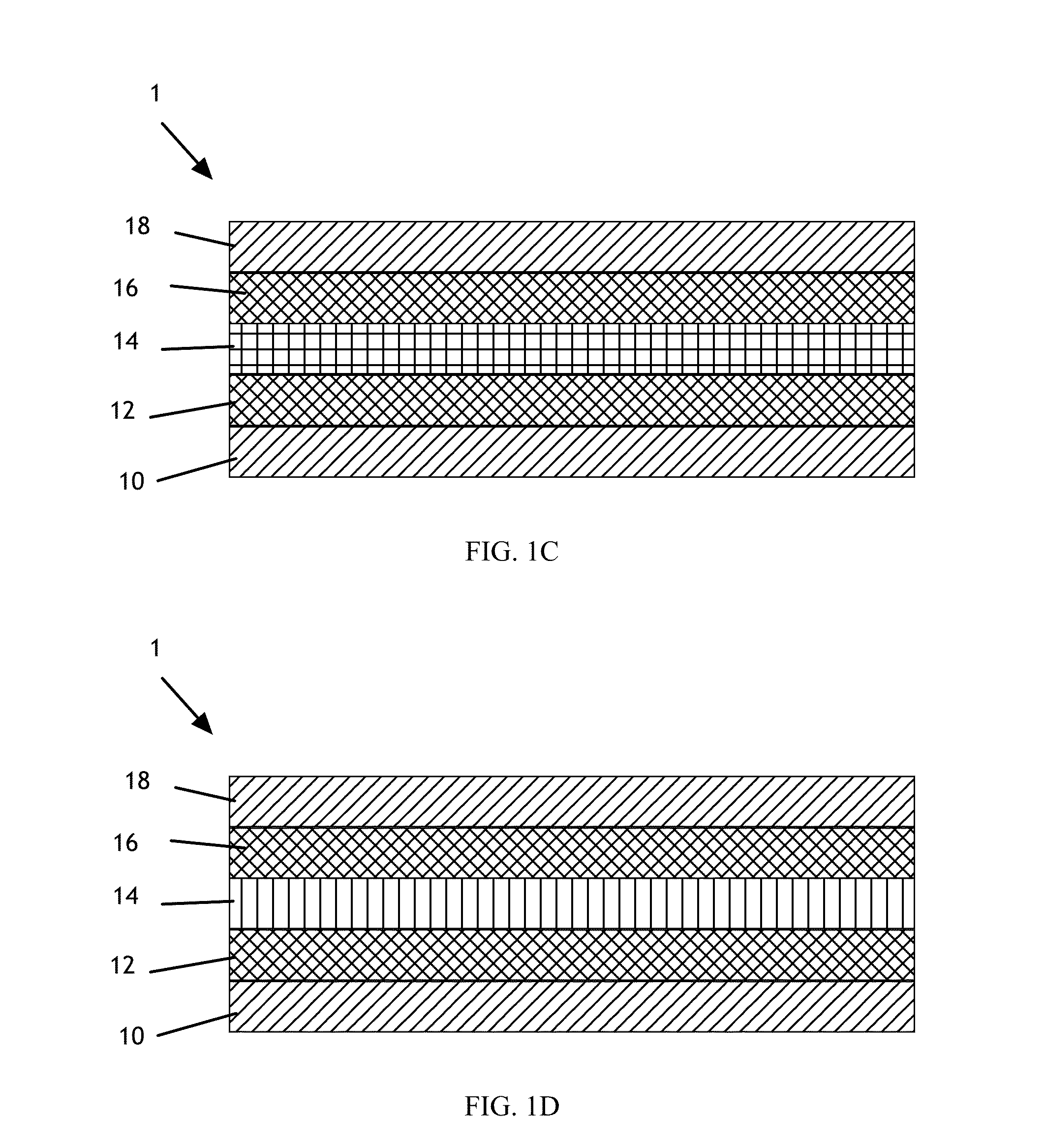

Multi-layer film

InactiveUS20150258755A1Increase softnessHigh drapePersonal careSynthetic resin layered productsFilm structureMembranous layer

A multi-layer film structure including two outermost film layers each comprising a polyethylene blend and an inorganic filler and at least three film layers disposed between the two outermost film layers, each of the at least three film layers comprising at least one of a polyethylene blend, a mono-component polyethylene and an inorganic filler.

Owner:FIRST QUALITY PRINT & PACKAGING

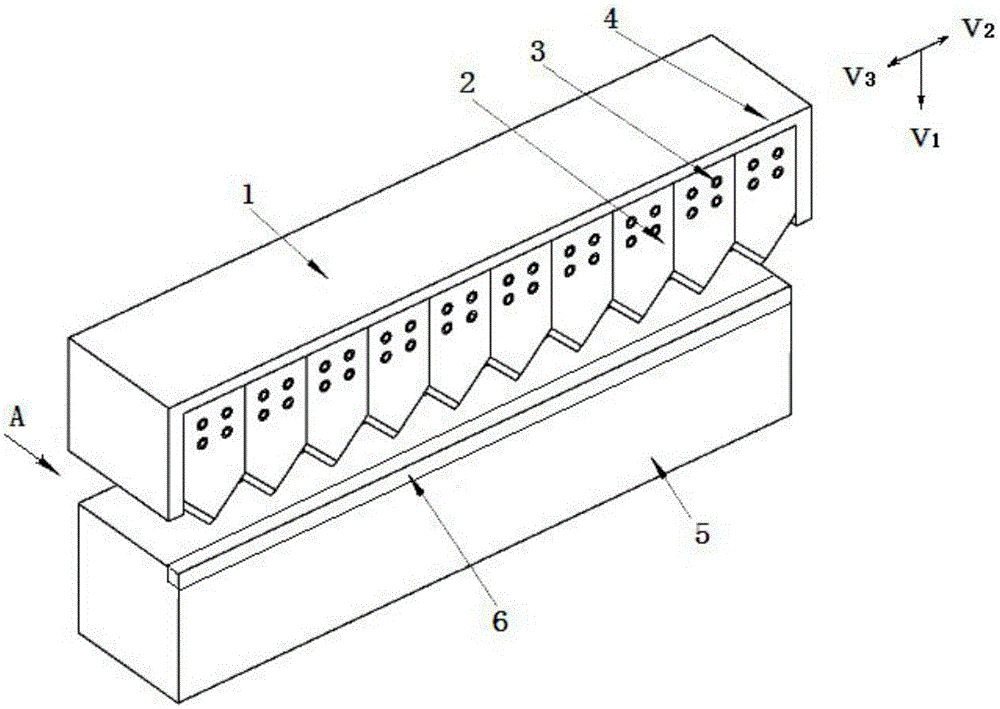

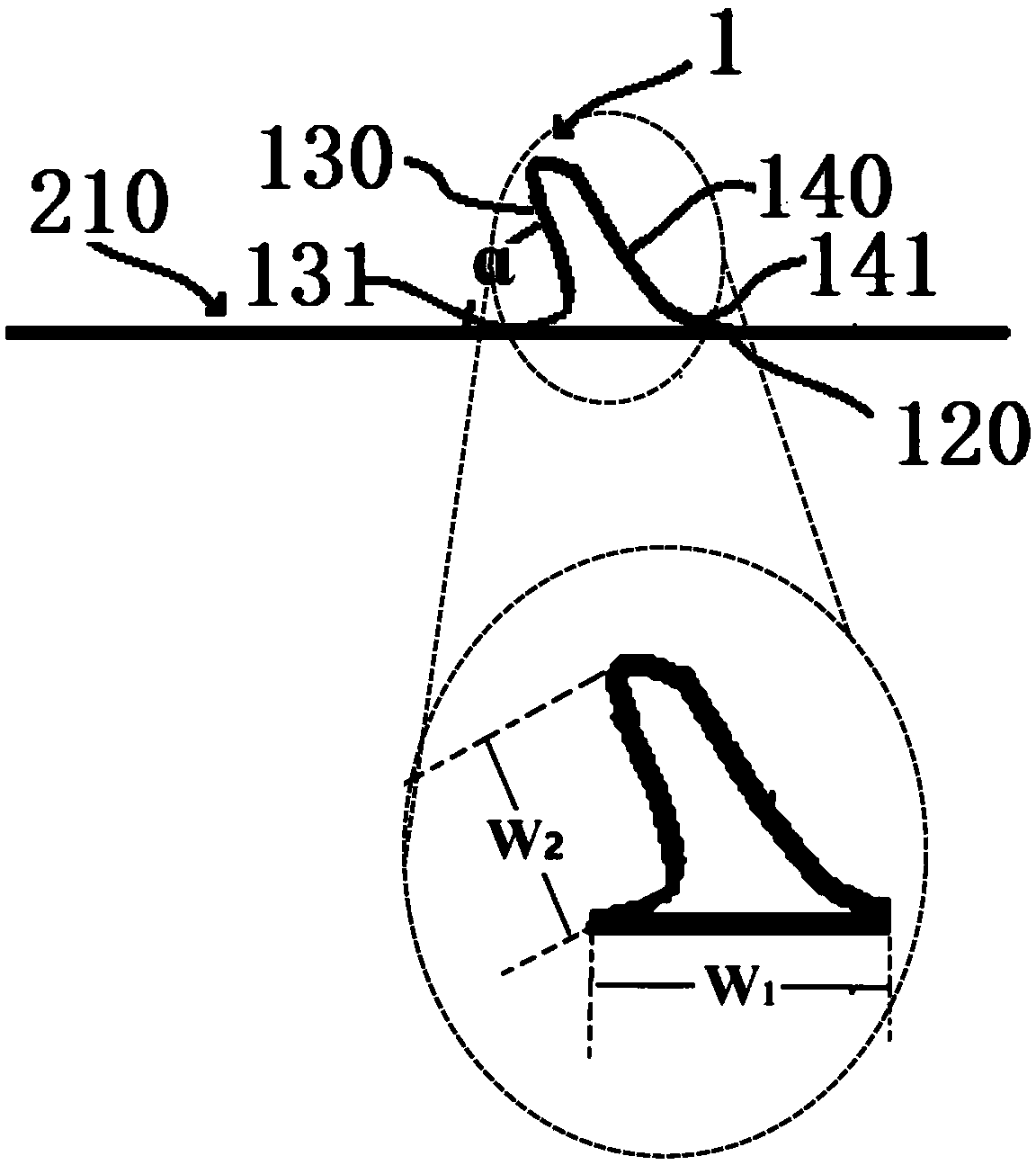

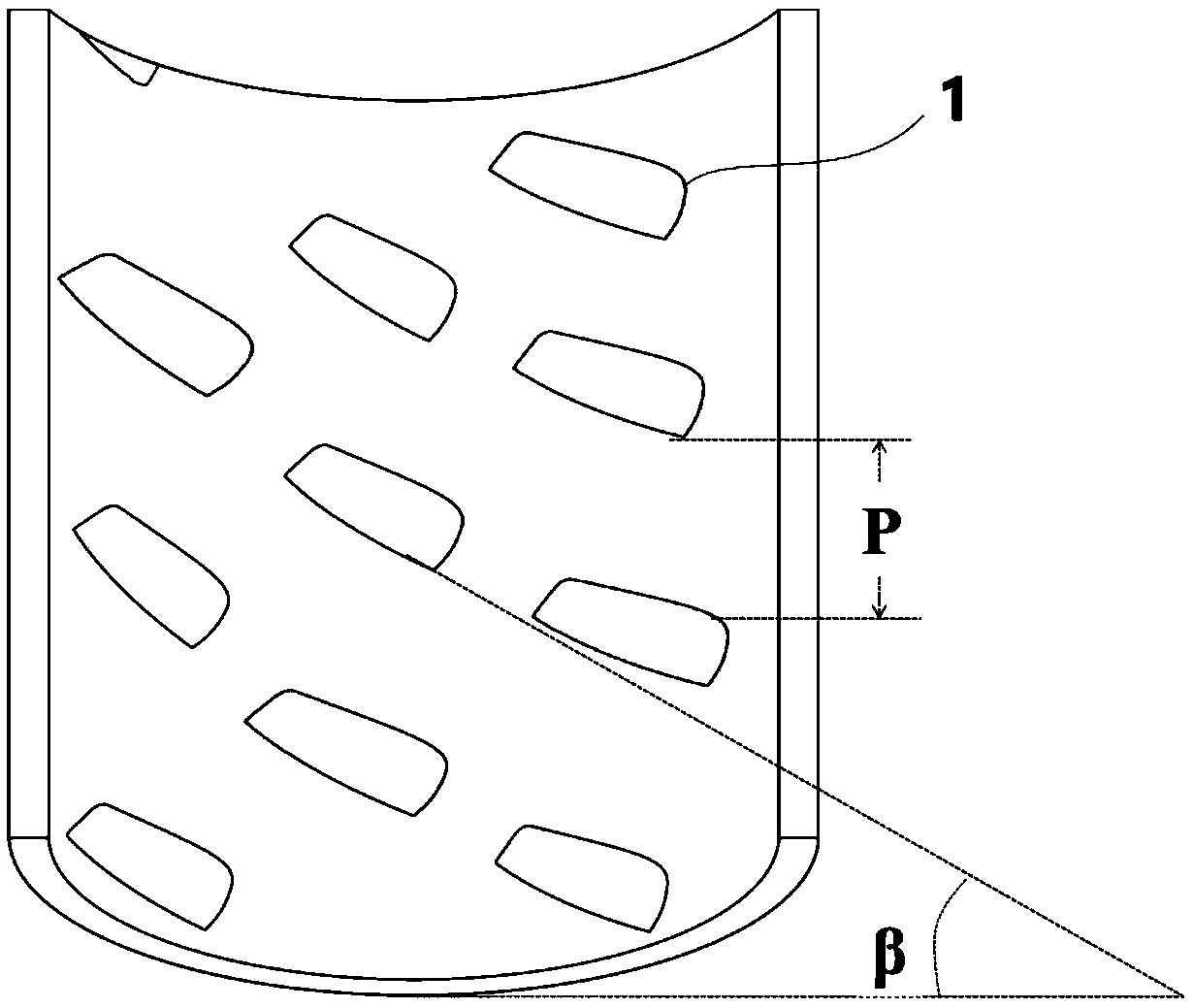

Buffering rib of rotary drum screen and rotary drum screening machine

The invention discloses buffering ribs of a rotary drum screen and a rotary drum screening machine and belongs to the field of material screening equipment. Each buffering rib comprises a bottom surface and a first side surface, wherein the bottom surface is matched and connected with the inner side wall of a screen mesh; the first side surface is connected with the bottom surface, the first sidesurface is opposite to the feed end of the screen mesh, and a certain included angle is formed between the first side surface and the inner side wall of the screen mesh; the buffering ribs are uniformly distributed on the inner side wall of the screen mesh, and longitudinal extending directions of the buffering ribs are at certain inclined angles relative to a longitudinal central axis of the screen mesh; and finally, the buffering ribs are uniformly distributed in a circumferential spiral connection state in the screen mesh. According to the buffering ribs disclosed by the invention, materials can be stirred and propelled, the work area of the screen mesh of the rotary drum screening machine is effectively enlarged, and the blocking rate of the screen mesh is greatly reduced, so that thescreening quantity of the rotary drum screening machine is indirectly increased, and the work efficiency is improved. Besides, the rotary drum screening machine disclosed by the invention has the advantages of being simple in structure, reasonable in design and easy to manufacture.

Owner:安徽马钢嘉华新型建材有限公司

Preparation method of high-grade road emulsified asphalt

InactiveCN103819691AImprove frost resistanceGood long-term storageBuilding insulationsTetrahydrofuranAcetone

The invention relates to a preparation method of high-grade road emulsified asphalt. The method adopts the technical scheme that the method comprises the steps: catalytic cracking heavy residual oil is heated to be 120-160 DEG C in a heating furnace and then fed into a stirring kettle; a diluent, namely acetone or tetrahydrofuran is added according to the fact that the ratio of the catalytic cracking heavy residual oil to the diluent is (2.5-3):100; the catalytic cracking heavy residual oil is diluted to be low-viscosity residual oil; the reaction viscosity is reduced; an emulsifier, a stabilizer, an antifreezing agent, a surfactant, the low-viscosity residual oil and water are fed into a colloid mill at a ratio; the temperature of the colloid mill is kept to be 75-90 DEG C; the high-grade road emulsified asphalt is prepared via the colloid mill. The method has the benefits that the diluent dilutes the heavy residual oil, so that the viscosity of the residual oil is reduced, the shear resistance in an emulsion process is reduced, and the reaction efficiency is improved; by virtue of the antifreezing agent, the freezing resistance is good, the long-term storage property is good, the oversize residual amount of the asphalt is less, and a pungent smell generated due to heating and volatilization of alcohol soap lye preparation process and an emulsified asphalt production process during single alcohol use; the surfactant increases a softening point of an emulsified asphalt product.

Owner:KENLI SANHE NEW MATERIAL TECH

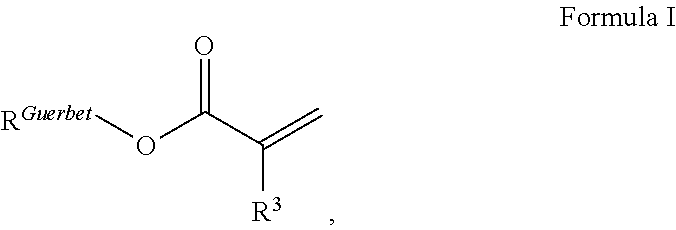

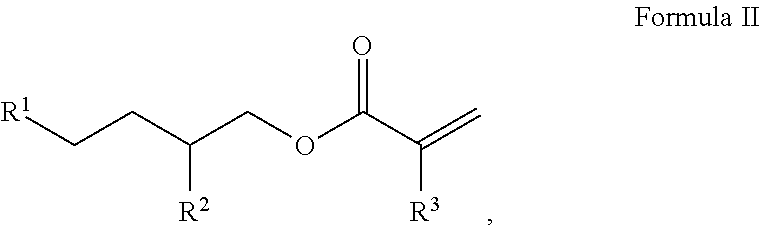

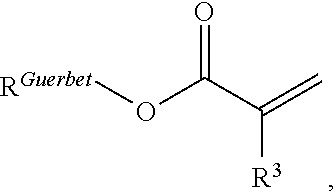

Multilayer Pressure-Sensitive Adhesive Films With Pressure-Sensitive Adhesives Derived From 2-Alkyl Alkanols

InactiveUS20140234562A1Lower surface energyReduce the amount of solutionLamination ancillary operationsLaminationMethacrylateMultilayer membrane

The present invention is directed to a multilayer pressure sensitive adhesive (PSA) film, having a first pressure sensitive adhesive layer and at least one opposing layer, characterized in that the first pressure sensitive adhesive layer comprises a pressure-sensitive adhesive composition comprising (co)polymers of: a) (meth)acrylate ester of 2-alkyl alkanols wherein the molar carbon number average of said 2-alkyl alkanols is 12 to 32; and optionally b) (meth)acrylate esters of C1-12 alkanols; wherein the molar carbon number average of the alkanols of the a) and b) (meth)acrylic acid esters is 12 to 32; wherein the at least one opposing layer comprises at least one filler material selected from the group of filler particles, wherein the filler particles are expanded perlite. The invention is also directed to a method for the manufacturing of such a multilayer PSA film and its use.

Owner:3M INNOVATIVE PROPERTIES CO

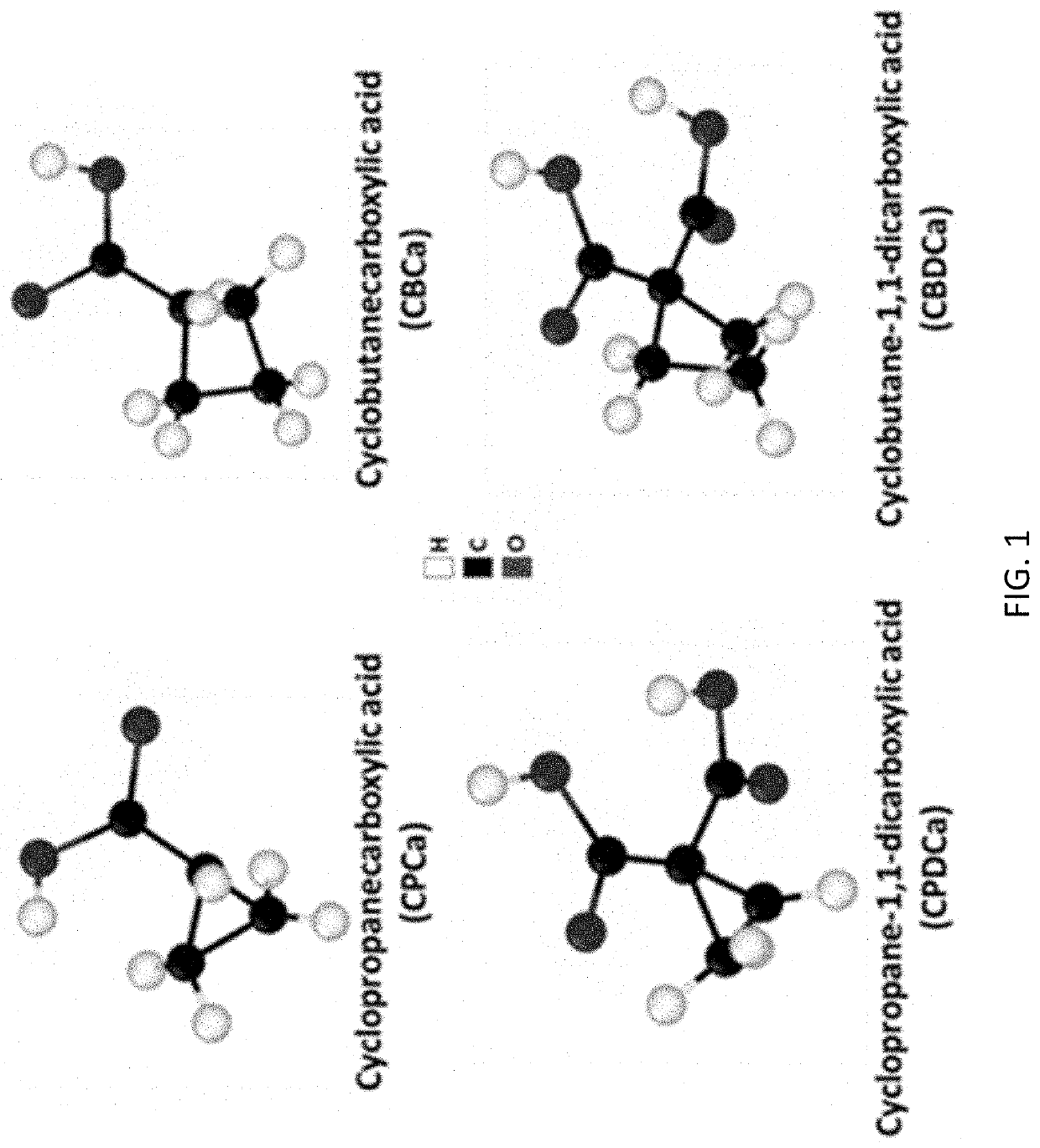

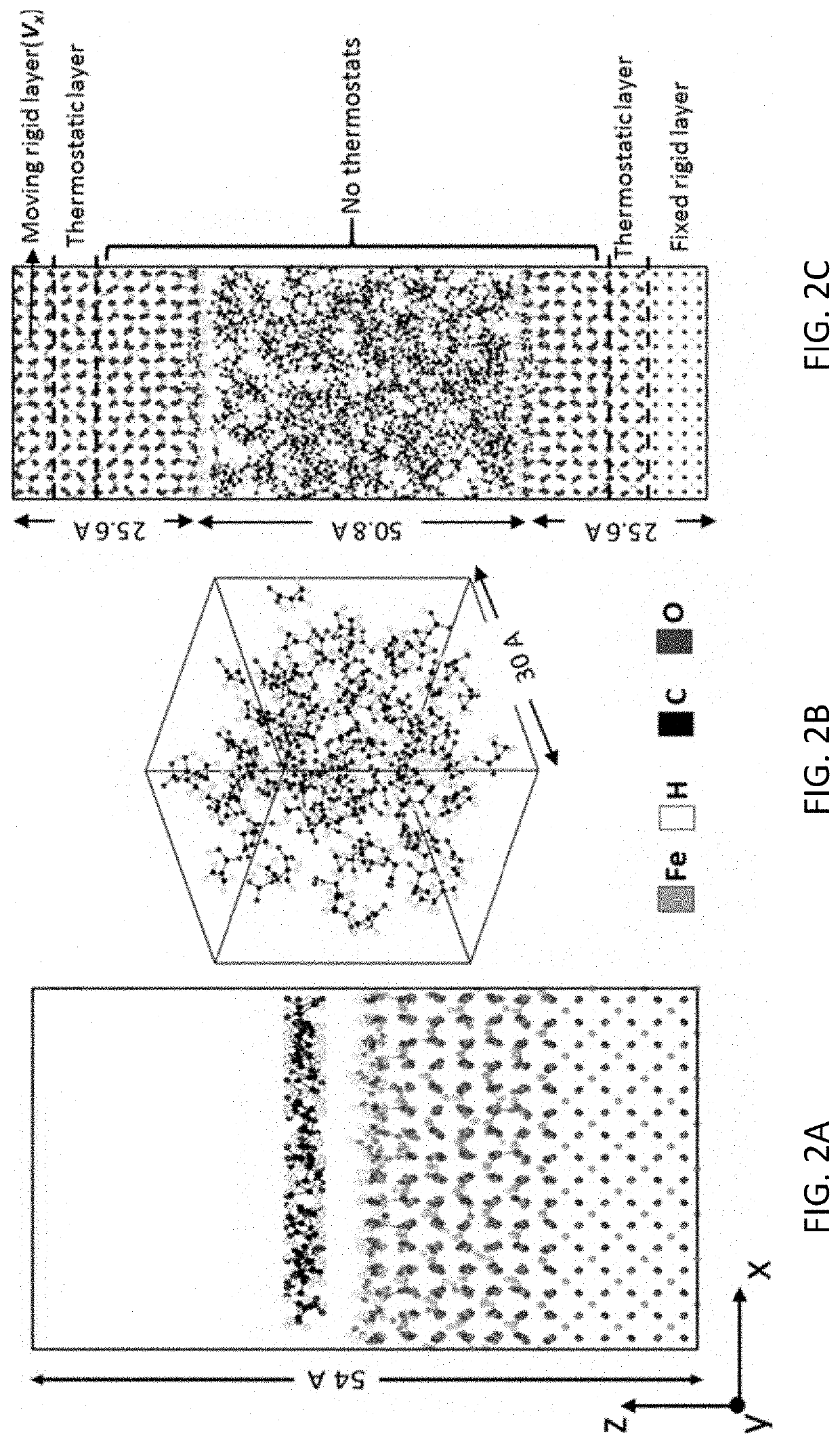

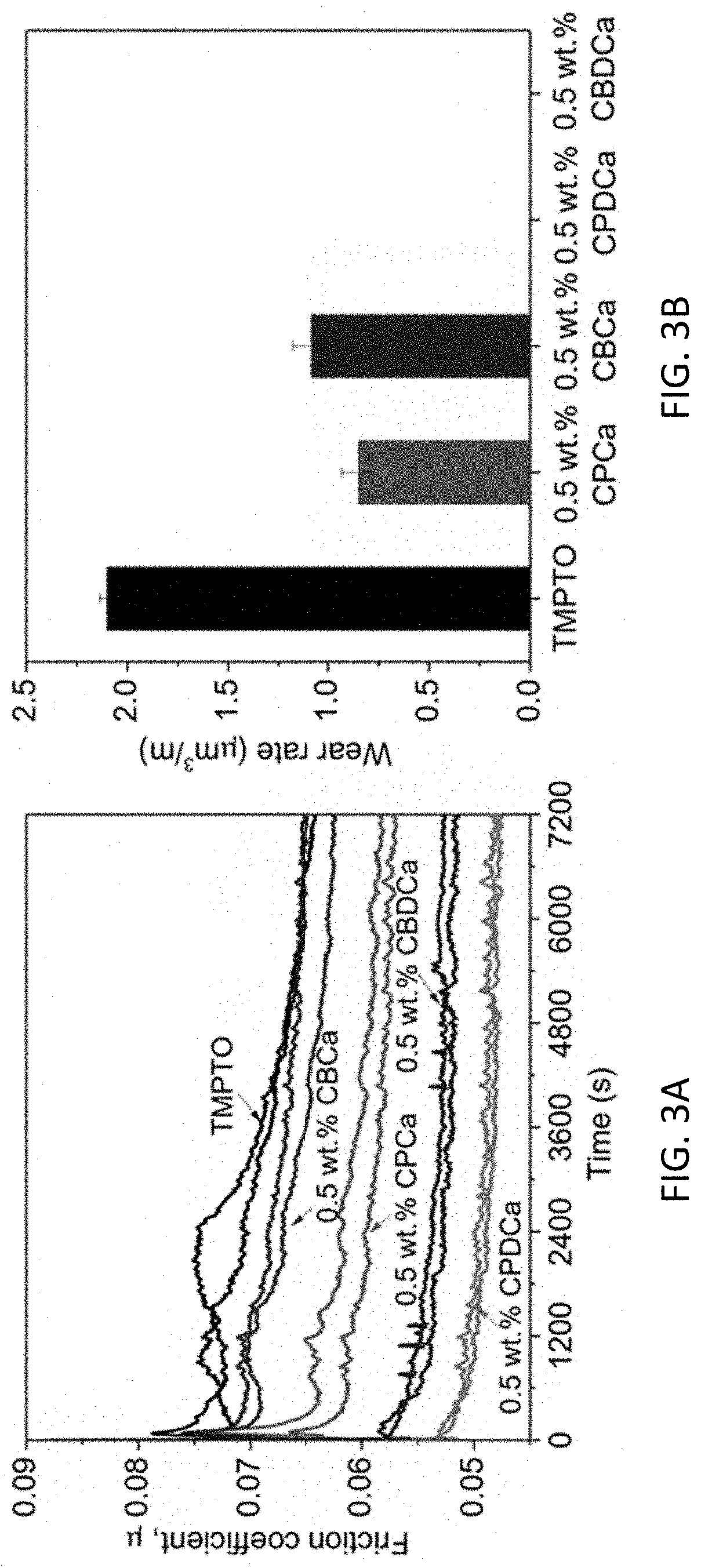

Lubricant compositions, and synthesizing methods and applications of same

A lubricant composition includes a base lubricant and a plurality of lubricant additive molecules functioning as precursor molecules to induce tribopolymerization and forming in situ protective tribofilm with desirable robustness and low shear resistance. Each lubricant additive molecule includes one or more surface-active groups attractable to target surface, and a carbon containing component operable connected to the one or more surface active groups. The carbon containing component comprise a carbon ring structure having a high ring strain that is metastable and activatable with a ring-opening reaction. A less stable carbon ring structure is more readily activated to the intermediate state, preferable to form more active fragments. Increasing the adsorption strength further is beneficial to prolonging the residence time of additive molecules on the target surface, thereby facilitating the dissociation of molecules and subsequent polymerization.

Owner:NORTHWESTERN UNIV

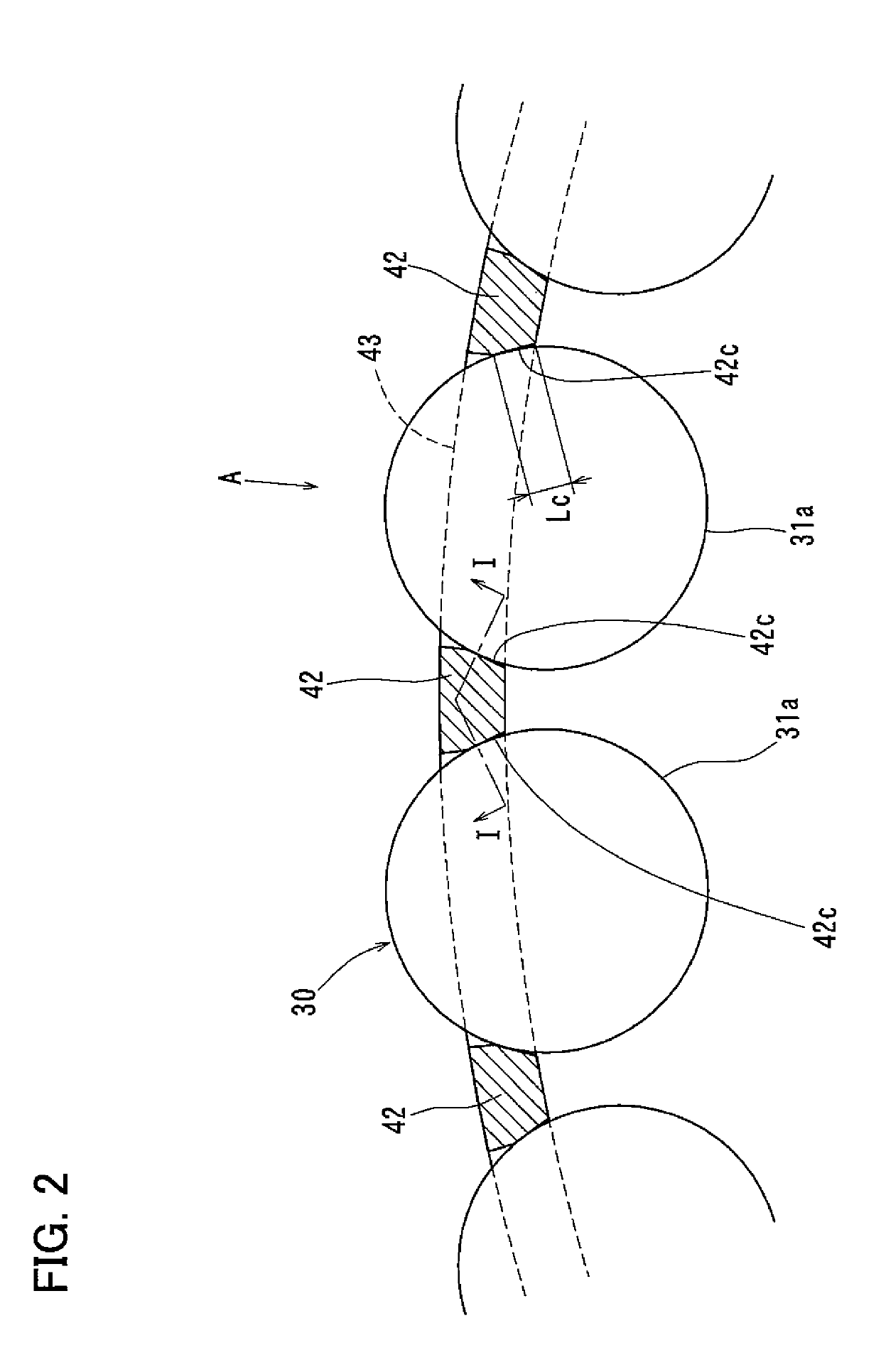

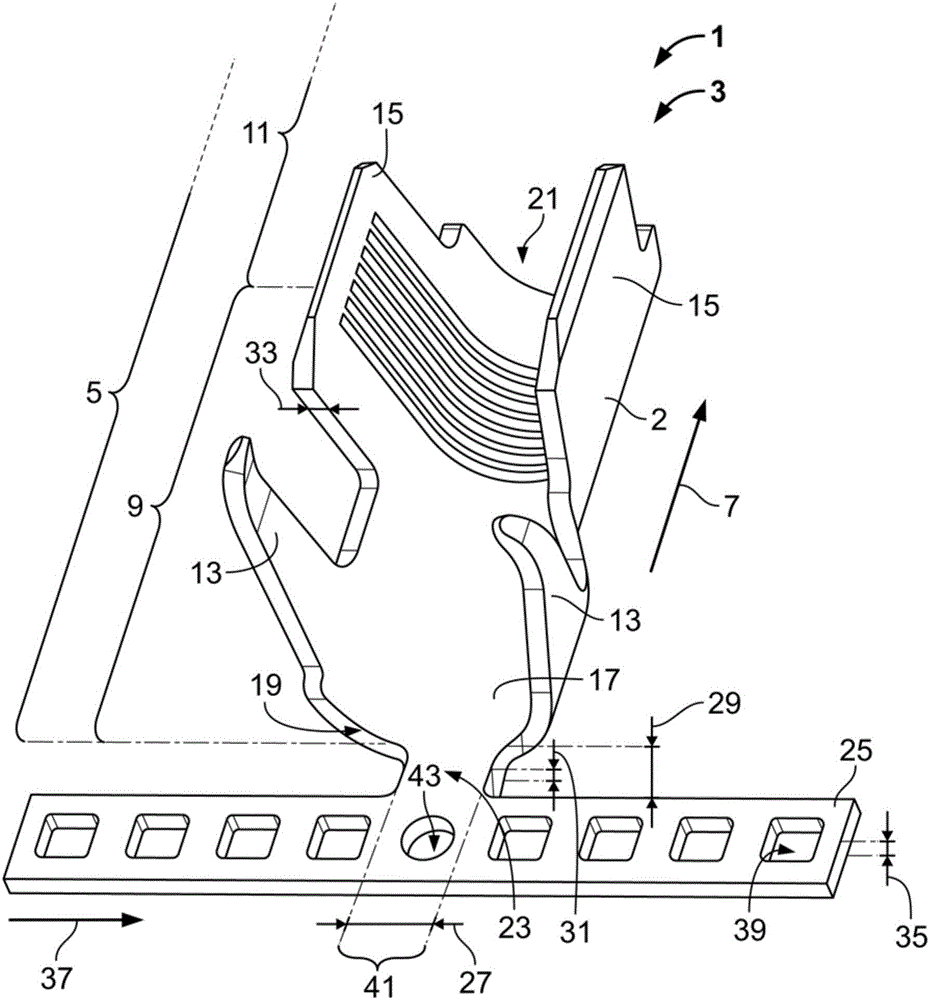

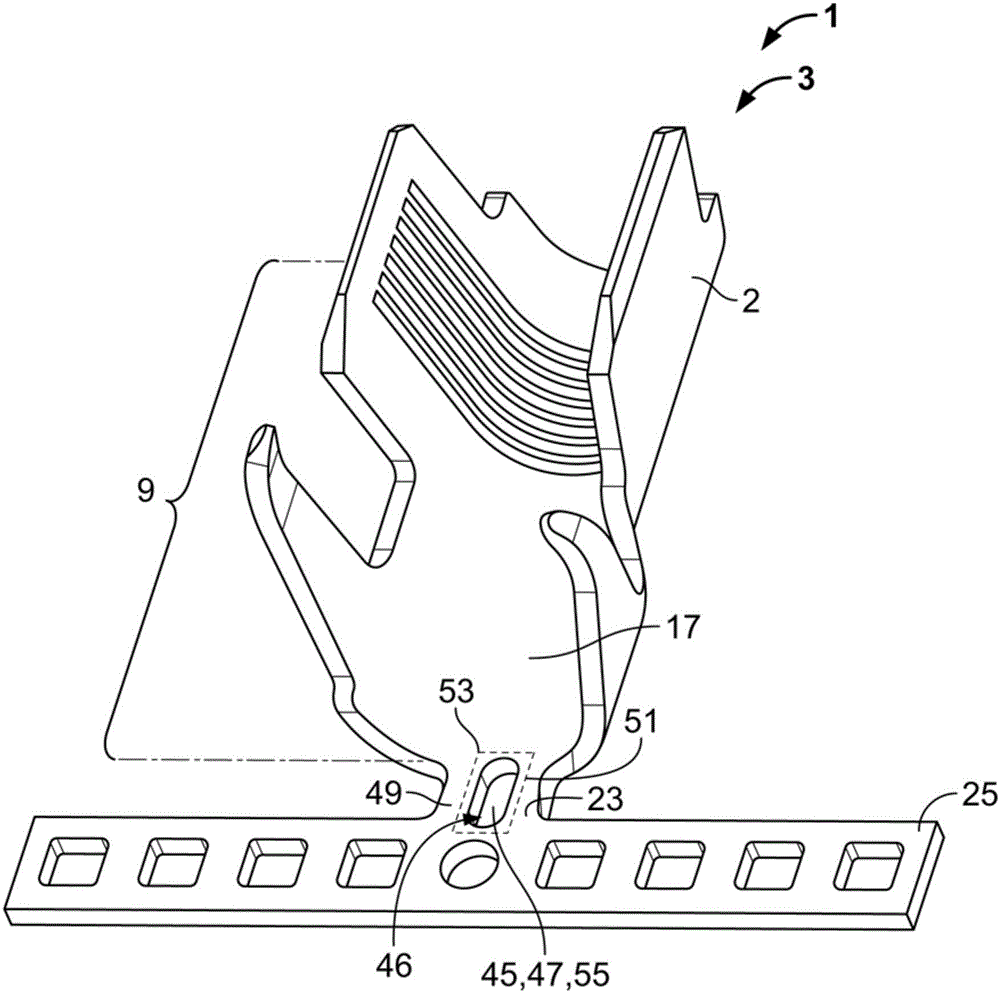

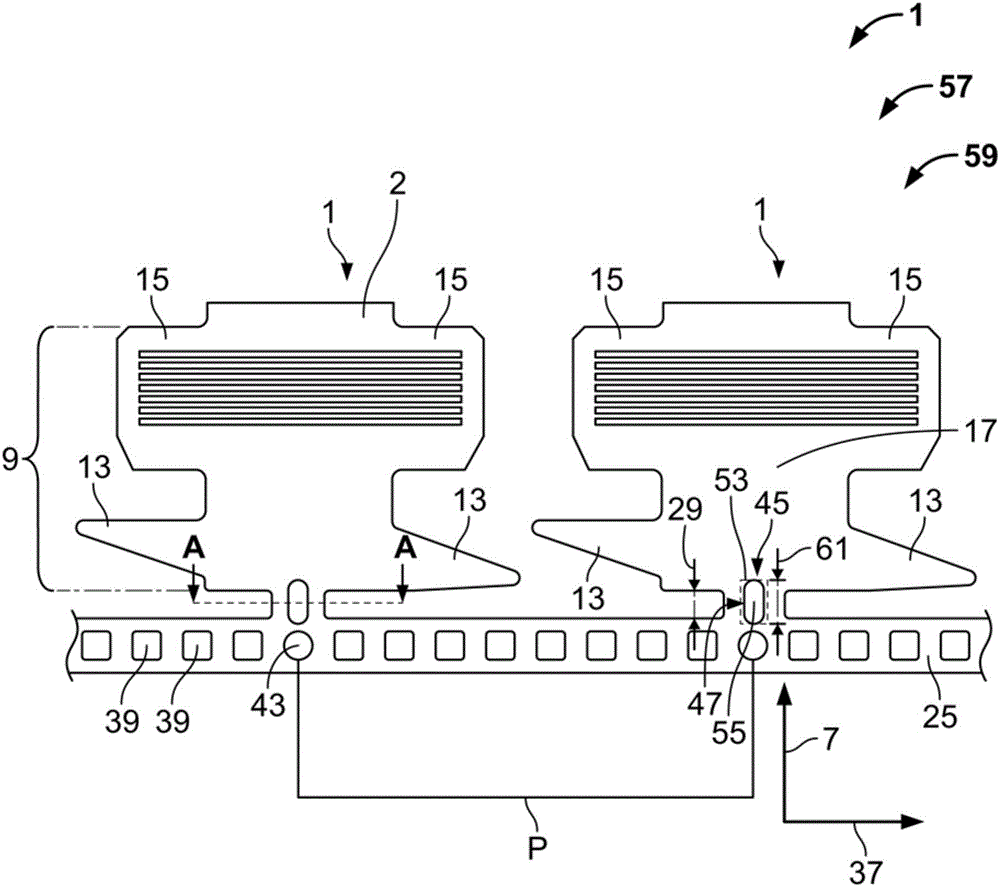

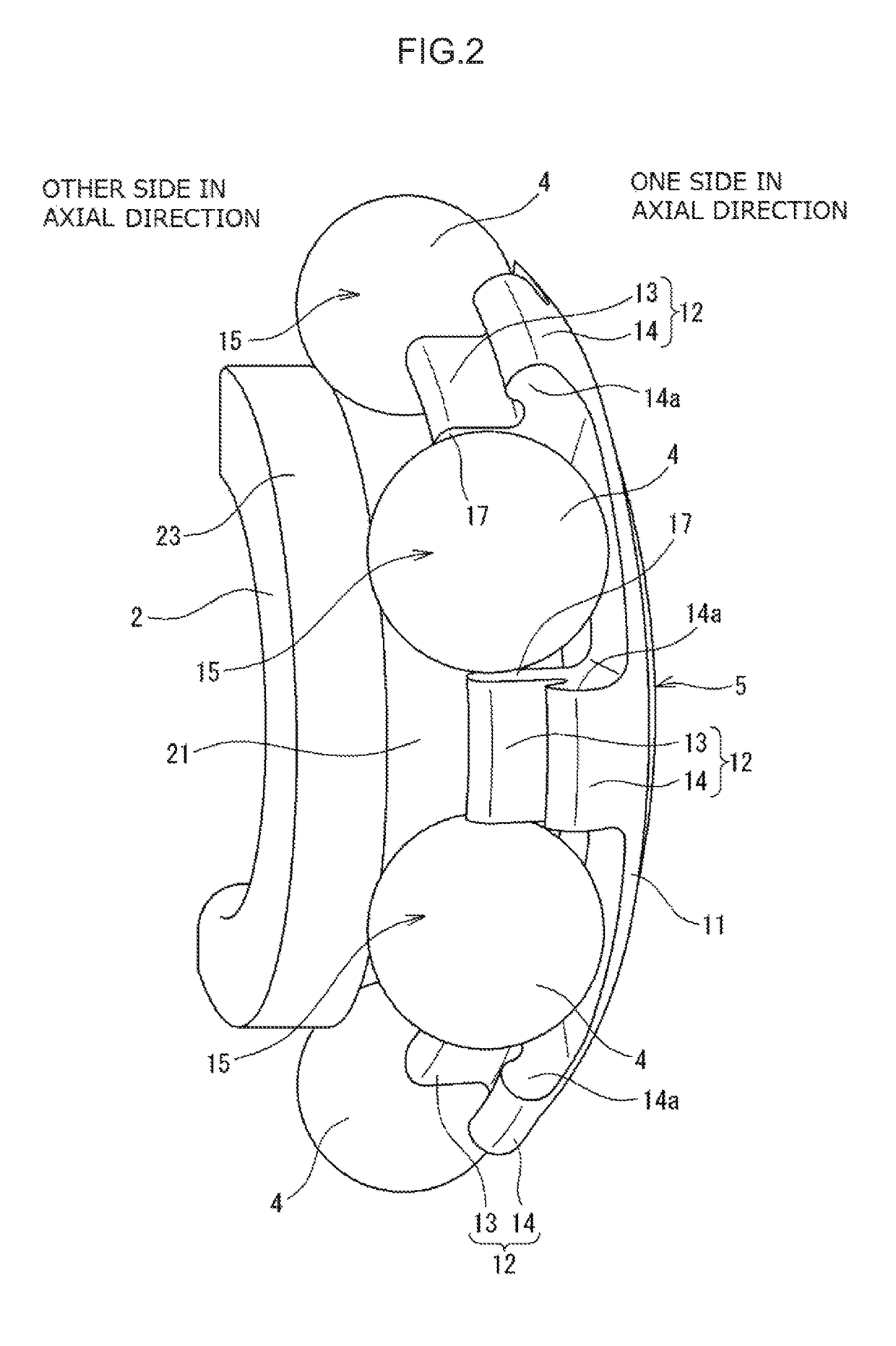

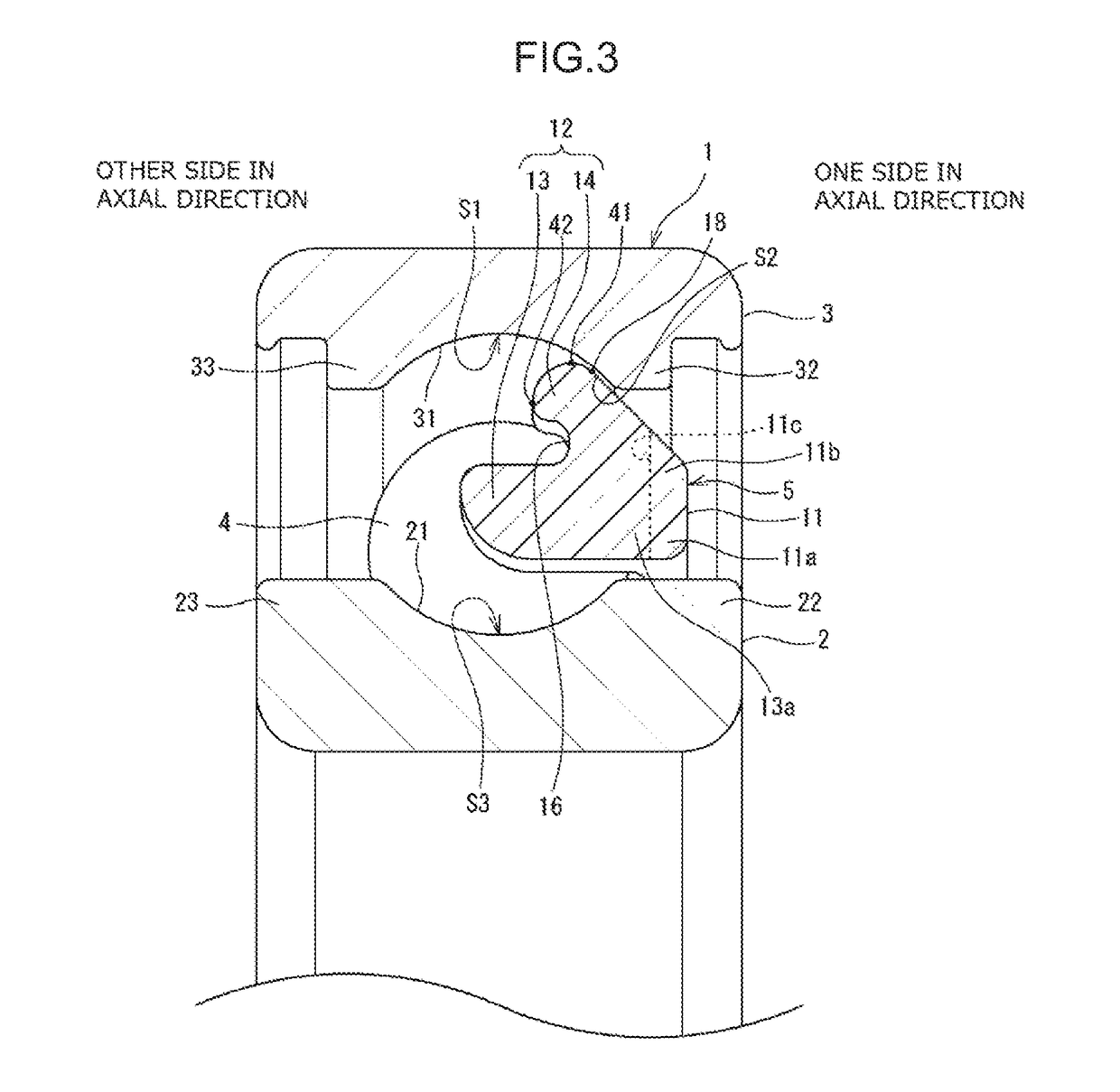

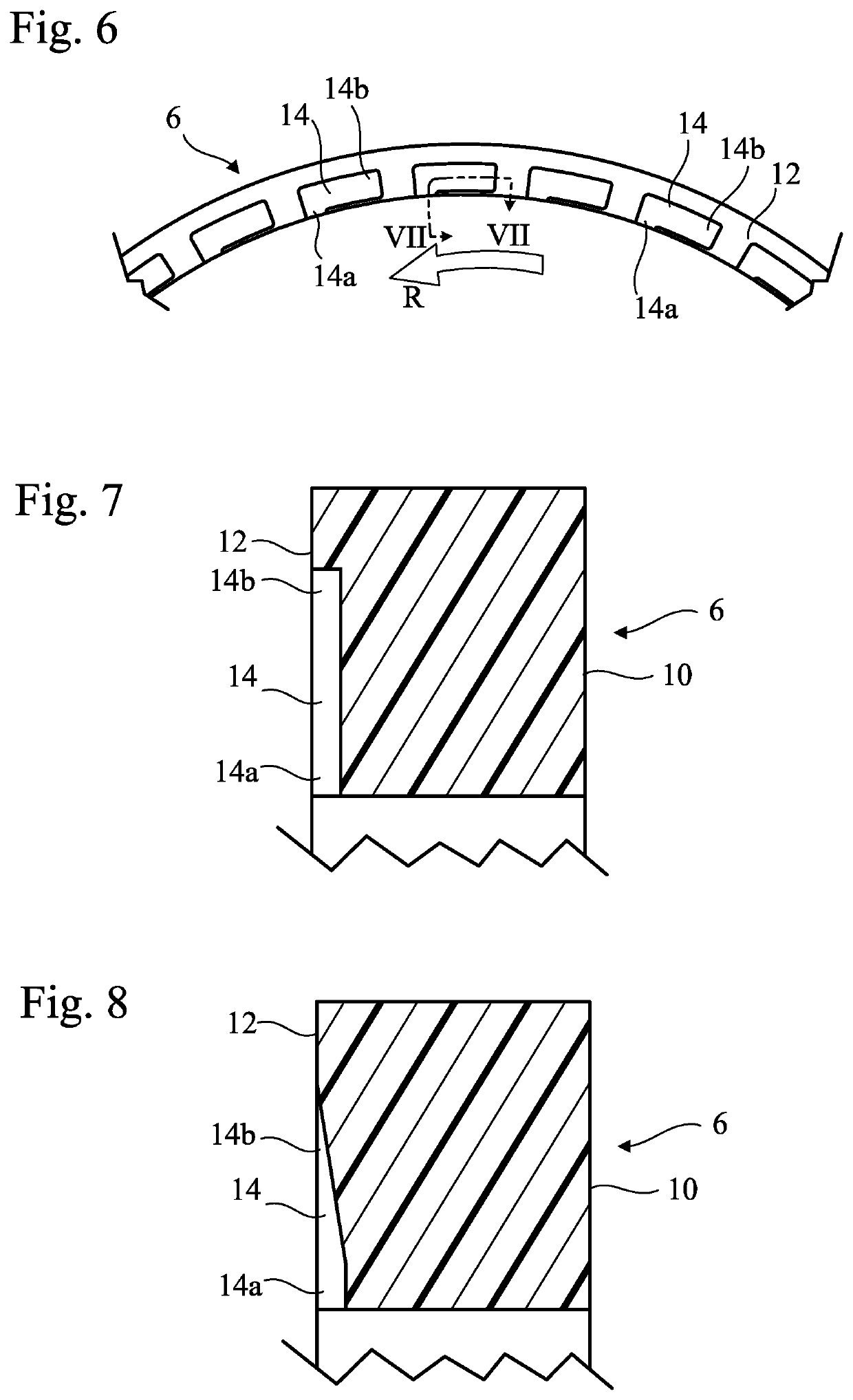

Retainer and tapered roller bearing

ActiveUS10330146B2Reducing stirring resistance of oilReduce shear resistanceRoller bearingsShaftsEngineeringMechanical engineering

A retainer of a tapered roller bearing includes crossbars having guide surfaces which circumferentially contact the tapered rollers. The crossbars are also formed with first recessed surfaces and second recessed surfaces which are both in the form of cutouts circumferentially recessed from the respective guide surfaces to reduce stirring resistance and shear resistance of oil. To reduce the contact lengths between the rolling surface central portions of the tapered rollers and the guide surfaces, the guide surfaces are smoothly convex in the longitudinal direction of the tapered rollers.

Owner:NTN CORP

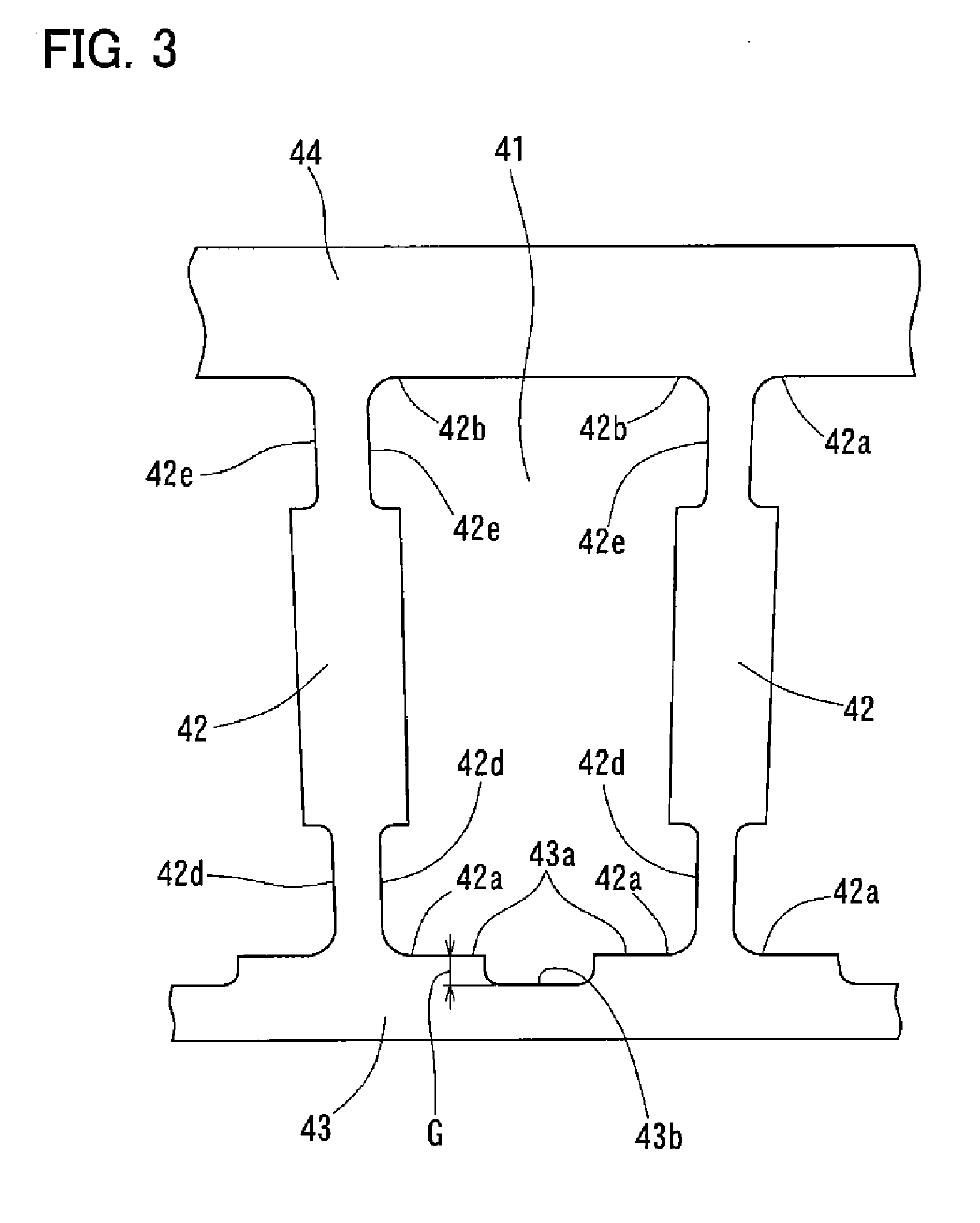

Sheet metal part with improved connection tab geometry

ActiveCN106532308AExtend the lifespanReduce the cross-sectional areaContact member manufacturingCoupling contact membersEngineeringMetal

The invention relates to a sheet metal part with a connector portion oriented along a connector direction, and a connection tab, the connection tab being connected to the connector portionand having a connection cross-section area oriented essentially perpendicular to the connector direction. The invention further relates to a method of producing a sheet metal part with improved connection tab geometry. Sheet metal parts of the prior art and method for producing said sheet metal parts have the disadvantage that the shear resistance of the connection tab, which is connecting the sheet metal part with a carrier-strip, increases with the sheet metal thickness, which in turn demands for more robust, that is thicker, upper shear arms. The invention solves these problems by providing at least one weakened zone in the connection tab, in which the shear resistance of the connection tab is reduced compared to an unprocessed connection tab of the same construction type and size, and by providing a method for producing said weakened zone or zones in the connection tab.

Owner:TE CONNECTIVITY GERMANY GMBH +1

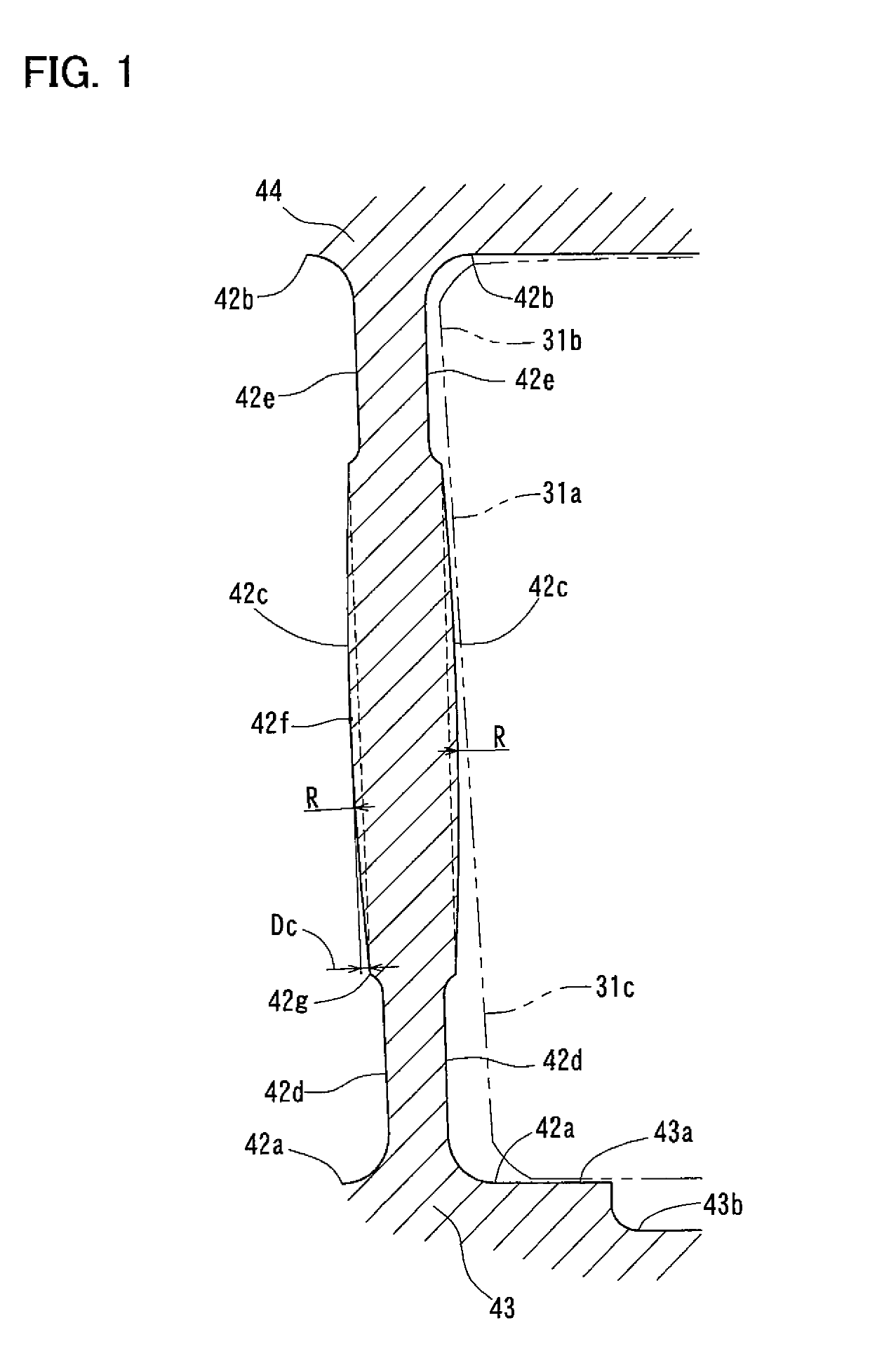

Piston assembly

Provided is an oil ring (13) for a piston assembly that can minimize the frictional resistance without impairing the oil control function such as the scraping of lubricating oil from the cylinder wall surface by the oil ring. The oil ring consists of an upper side rail (16), a lower side rail (17) and an annular expander (18) interposed between the two side rails, and is received in an oil ring groove (8) with a prescribed vertical clearance (20) that permits tilting of the side rails. An outer peripheral surface (16E, 17E) of each side rail is provided with a radially inward slant. Therefore, during the upward stroke of the piston, the upper side rail tilts in the radially outward direction so that the effective slant angle of the outer peripheral surface of the upper side ring is adjusted to an optimum value.

Owner:HONDA MOTOR CO LTD

Ball bearing

Owner:JTEKT CORP

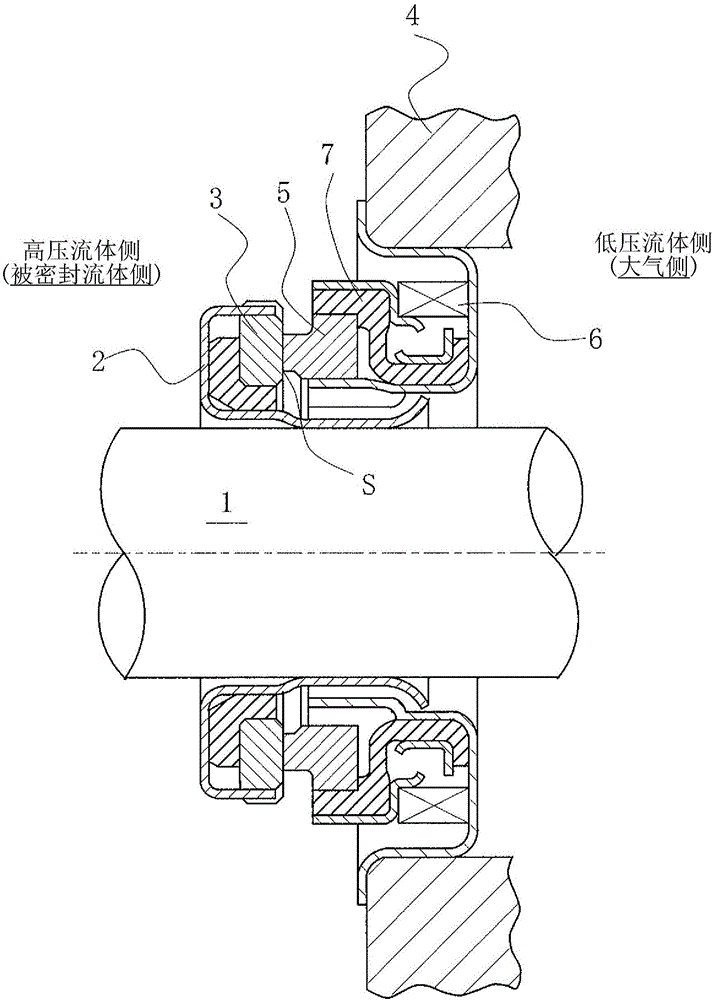

Seal ring and sealed structure

A circular annular seal ring made of a resin is disposed between an inner member and an outer member that rotate relative to each other. The outer member includes a liquid-storing space and an inner surface having a circular cross section. The inner member is disposed in the liquid-storing space and includes a circumferential groove. The seal ring is stationary relative to the outer member and is slidably disposed in the circumferential groove of the inner member. Grooves are formed on an end surface on an external space side of the seal ring. Each groove has an end portion that opens at an inner peripheral surface of the seal ring, and extends in a direction opposite to a main rotational direction of the inner member relative to the seal ring from the open end portion, but does not extend in the main rotational direction from the open end portion.

Owner:NOK CORP

Abrasion resisting lubricant

InactiveCN101671593AImprove wear resistanceReduce lubricationAdditivesHexagonal crystal systemFuel oil

The invention discloses an abrasion resisting lubricant, comprising 75-90 parts of base lubricant, 3-6 parts of viscosity improver, 3-6 parts of pour point depressant and 5-15 parts of nano boron silicide. Nano boron silicide abrasion resisting agent is added in the abrasion resisting lubricant of the invention, the nano boron silicide abrasion resisting agent is a novel high temperature resistinglubricant material with a layered structure, and has a hexagonal crystal system layered structure similar to silicon; boron and silicon between every two layers are overlapped in a stagger way, the shear resistance of sliding along inter-layer is small, thus being easy to slide; the invention has excellent lubricating property, can obviously reduce abrasion of an engine, increase power of the engine, prolong the service life of engine oil and save fuel oil.

Owner:王其凯

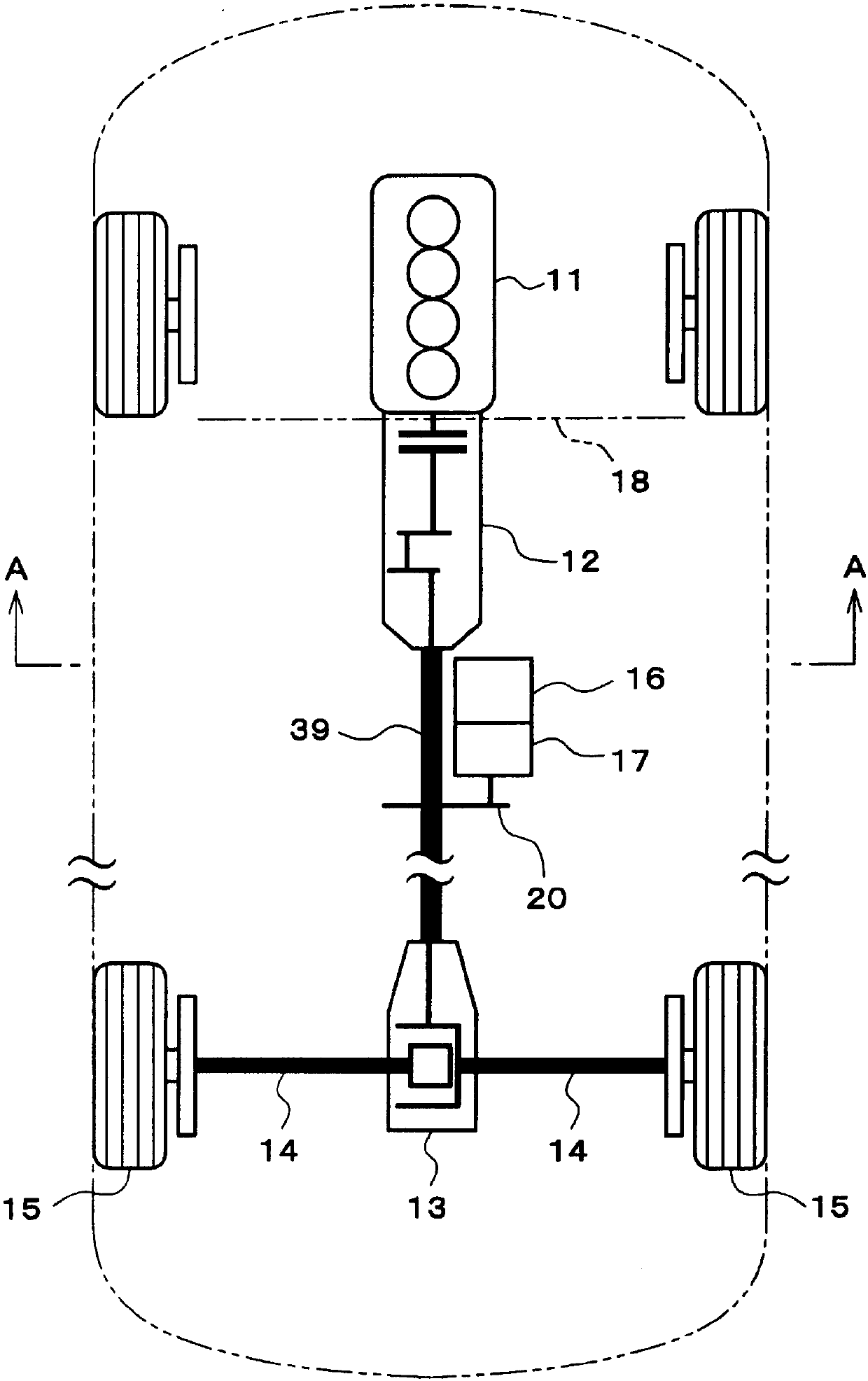

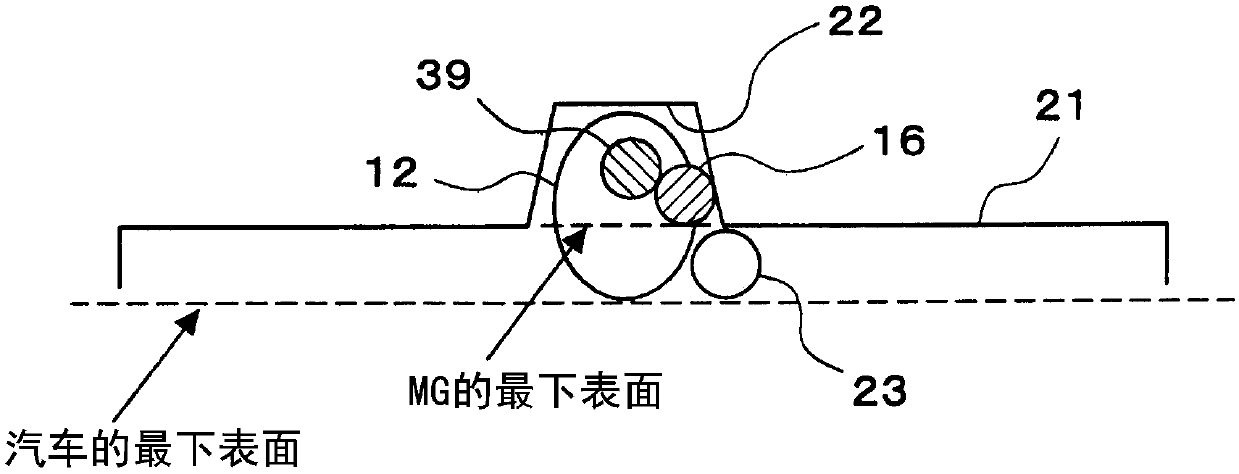

Device for driving vehicle

InactiveCN107921857AAvoid short circuitImprove efficiencyHybrid vehiclesPlural diverse prime-mover propulsion mountingPowertrainMotor–generator

A device for driving a vehicle is provided with an engine (11) serving as a power source for the vehicle and a transmission (12) connected to the engine (11). The engine (11) and the transmission (12)are longitudinally disposed so that the axial direction of the output shaft of the engine (11) is oriented in the longitudinal direction of the vehicle. The driving device is provided with a motor generator (MG) (16) serving as a power source for the vehicle and a decelerator (17) connected to the MG (16). The MG (16) and the decelerator (17) are disposed on the outside of an engine compartment in which the engine (11) is accommodated. The output shaft of the decelerator (17) is linked, so as to enable transmission of power, to a powertrain for transmitting the power from the output shaft ofthe transmission (12) to driveshafts (14) for wheels (15).

Owner:DENSO CORP

Production method of non-autoclaved PHC (prestressed high-intensity concrete) pipe pile with good distribution convenience

ActiveCN107459303AIncrease viscosityReduce the difficulty of operationBulkheads/pilesEngineeringHigh intensity

The invention relates to a production method of a non-autoclaved PHC (prestressed high-intensity concrete) pipe pile with good distribution convenience. The production method is characterized in that a slow-release water reducer is used to prepare non-autoclave concrete, distribution of the pipe pile concrete is finished before the slow-release water reducer plays its role in water reducing, centrifuging phase is entered via mold assembly and tensioning, a slow-release admixture then acts, mobility of the concrete increases gradually during centrifuging to arrive at centrifugal formation, and standing, steam-curing and demolding are performed to finish the production of the non-autoclaved PHC pipe pile. The production method has the advantages that the pipe pile concrete is of wet disperse granulate form during distribution, the problem is solved that distribution is difficult for the non-autoclaved pipe pile concrete due to excessively high viscosity, and the production method is particularly suitable for the production of thin-walled pipe piles.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

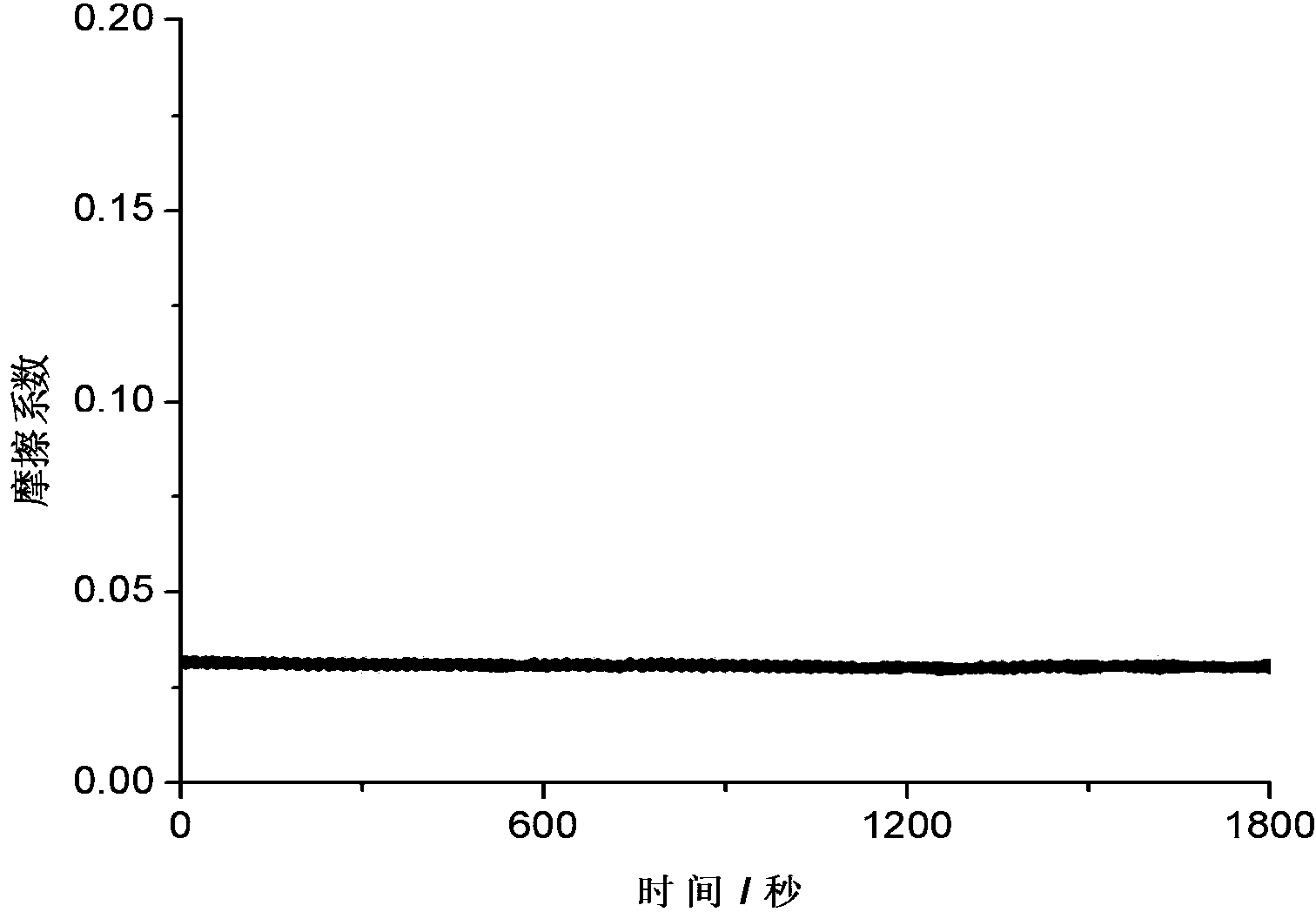

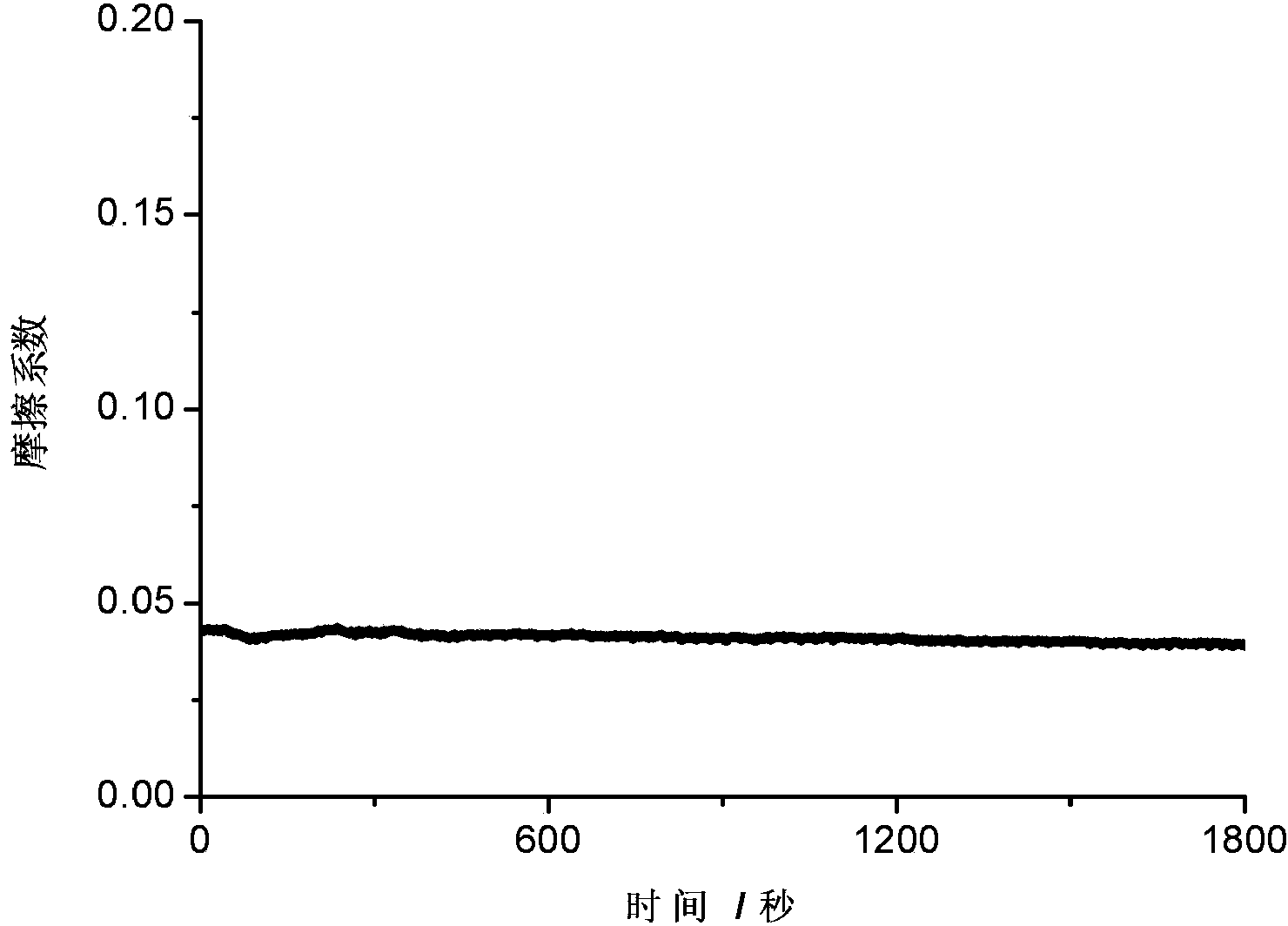

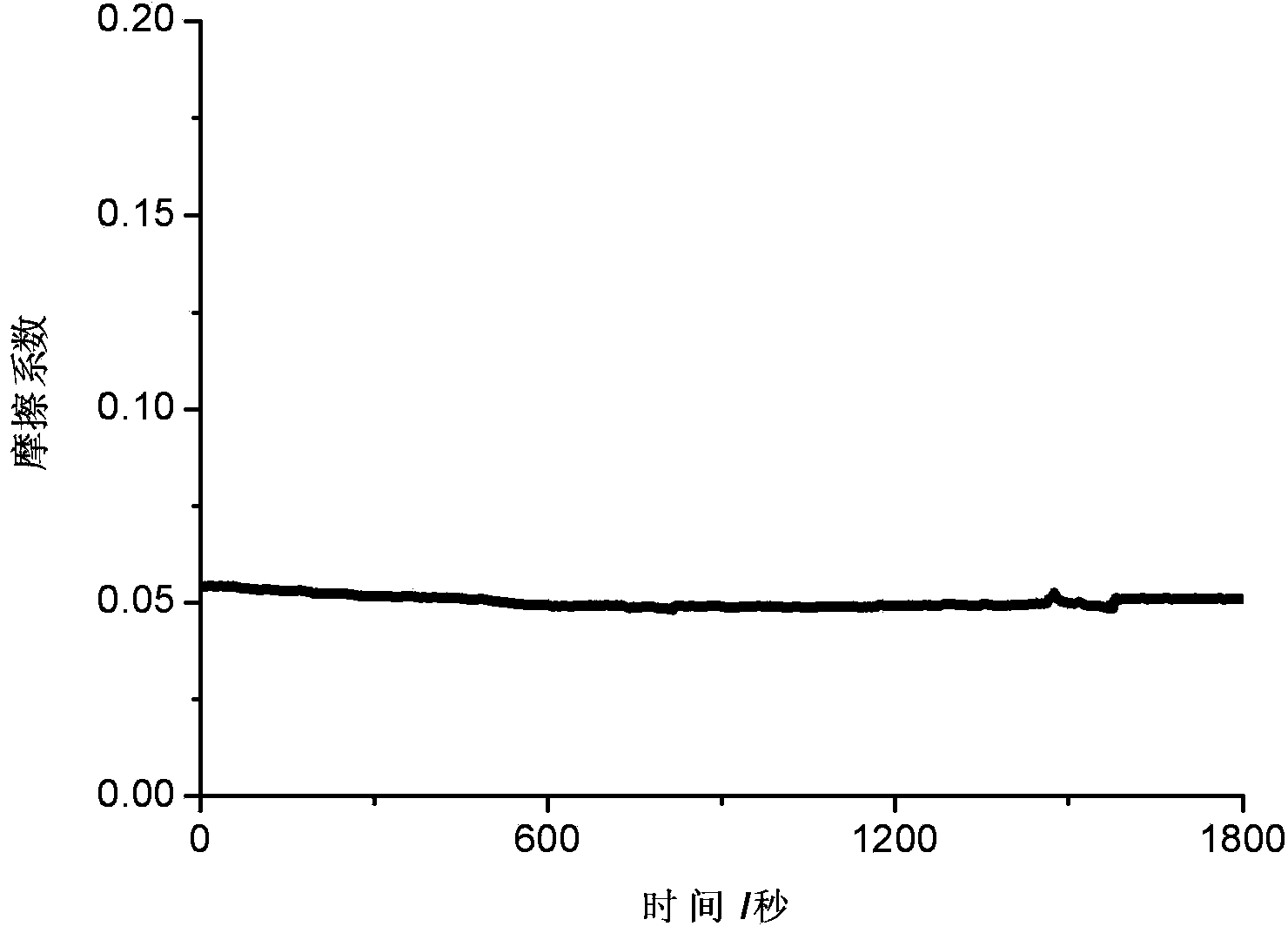

Water-based lubricant composition for ceramic friction pair

InactiveCN102899153BSave materialMeet the needs of water-based lubricationLubricant compositionSilica particleWater based

The invention discloses a water-based lubricant composition for a ceramic friction pair, which contains nanoscale silicon dioxide particles, hydramine, a magnesium compound, phytate, nanoscale graphite particles and water. The water-based lubricant composition for the ceramic friction pair provided by the invention has the advantages of low friction coefficients and good abrasion resistance, thereby effectively protecting a surface of the ceramic friction pair and prolonging the service life of the ceramic friction pair.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

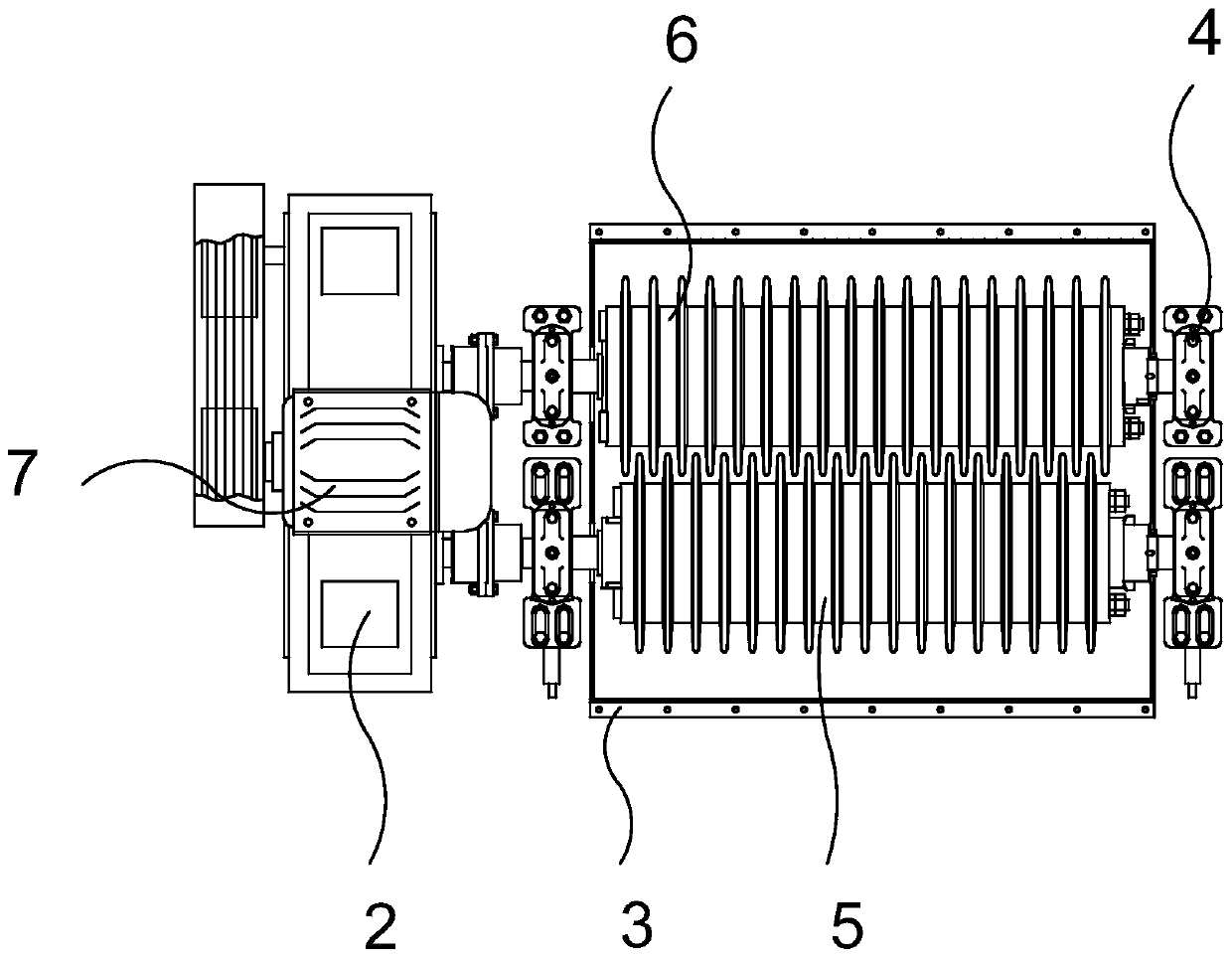

Coke cutting machine

The invention discloses a coke cutter which comprises a rack, a motor, a gearbox, a coke cutting box, a bearing pedestal set, a master coke cutting roller and a slave coke cutting roller. The motor, the gearbox, the coke cutting box and the bearing pedestal set are arranged on the rack. The master coke cutting roller and the slave coke cutting roller are arranged in the coke cutting box in parallel through the bearing pedestal set. The motor is in transmission connection with the gearbox, and an output shaft of the gearbox is in transmission connection with the master coke cutting roller. The master coke cutting roller and the slave coke cutting roller each comprise a roller shaft, a plurality of pull rods, a roller shaft sleeve arranged on the roller shaft through an end sleeve, a plurality of gear rings arranged on the roller shaft sleeve, spacer rings arranged at the positions, between the adjacent gear rings, of the roller shaft sleeve, and end discs arranged at the positions, on the outer sides of the gear rings at the two ends, of the roller shaft sleeve. The end discs, the gear rings and the spacer rings are in fastened connection through the pull rods and pull rod nuts. Each gear ring comprises a disc-shaped gear ring disc body and a plurality of main cutter teeth evenly distributed on the periphery of the gear ring disc body. Slope faces are formed on three sides of the main side face of each main cutter tooth, and the contact position of every two adjacent slope faces is of a corner angle structure. The gear rings of the master coke cutting roller and the gear rings of the slave coke cutting roller are staggered, and the coke cutter is good in coke cutting quality.

Owner:MIYI JINXIU MACHINERY MFG

A high-efficiency and energy-saving transmission mechanism for a cross-cutting machine

InactiveCN103737650BLow powerGuaranteed positioning accuracyMetal working apparatusGearing detailsBall bearingElectric machine

The invention relates to an energy-efficient transmission mechanism of a transverse cutting machine. The energy-efficient transmission mechanism is characterized in that an upper knife roll and a lower knife roll are connected with a left gearbox rack and a right gearbox rack through inner bearing blocks and outer bearing blocks, upper knife roll gears are arranged at the two ends of the upper knife roll respectively, and lower knife roll gears are arranged at the two ends of the lower knife roll respectively. A driving motor is connected with an input gear shaft through two diaphragm couplings. The input gear shaft is sleeved with an eccentric bearing sleeve. An input gear of the input gear shaft is meshed with a big gear of a two-stage transmission gear set. A pinion of the two-stage transmission gear set is meshed with the corresponding lower knife roll gear. The lower knife roll gears are meshed with the corresponding upper knife roll gears. A self-aligning roller bearing is arranged in each inner bearing block, and a deep groove ball bearing is arranged in each outer bearing block. The energy-efficient transmission mechanism has the advantages of being large in reduction ratio and efficient and saving energy.

Owner:HEBEI SHENGLI PAPER CHEST EQUIP MFGCO

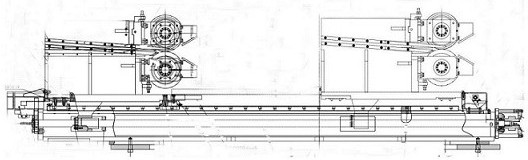

Roller shear

PendingCN114535687AReduce shear resistanceReduce operating energy consumptionShearing machinesShearing machine accessoriesCircular discHydraulic motor

The invention discloses a roller shear which is used for shearing plates and strips. The roller shear comprises an upper shear blade in the shape of a circle shear; the upper shear blade, the transmission system, the gap adjusting device and the height adjusting device are mounted on the movable frame; the transmission system comprises a hydraulic motor, a planetary reducer, a chain wheel and a roller chain; the hydraulic cylinder pushes the moving frame to move along the sliding rail; the support is composed of a machined part, a welded part, channel steel and the like, and a sliding rail is installed on the support; the movable frame is connected with the bracket through the drag chain; the lower shear blade is mounted on the bracket; the gap adjusting device comprises a ratchet wrench and a swing arm, a bearing is arranged below the swing arm, a roller is arranged at the front section below the swing arm, and the distance between the bearing and the sliding rail is adjusted through the wrench and the swing arm; the height adjusting device mainly comprises a bolt, a nut and a key and is used for adjusting the height of the upper shear blade. The shearing resistance is reduced, the shearing quality is improved, the movable frame can be moved away after shearing of the roller shear, and the space is saved.

Owner:SHANXI TAIGANG ENG TECH

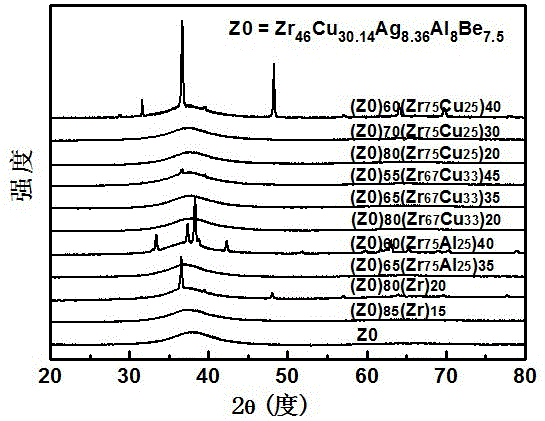

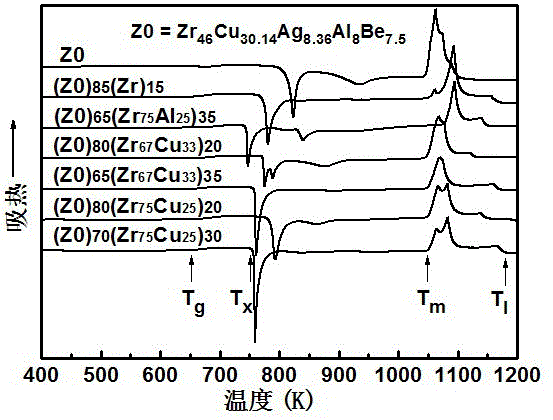

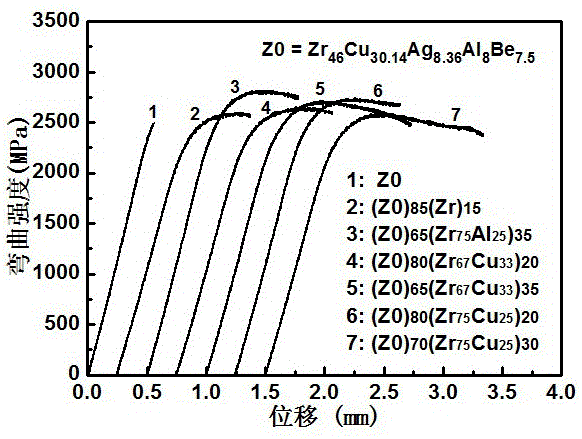

A kind of large plastic Zrcuagalbe series bulk metallic glass and preparation method thereof

The invention discloses high-plasticity ZrCuAgAlBe bulk metal glass and a preparation method thereof. The high-plasticity ZrCuAgAlBe bulk metal glass has the structural formula: [Zr46Cu30.14Ag8.36Al8Be7.5](100-x)(Zr100-yMy)x. The preparation method comprises the steps of placing all metal raw materials into an arc-melting furnace; placing a Zr ingot into the arc-melting furnace, and charging Ar gas after evacuating; melting the Zr ingot in the arc-melting furnace to consume oxygen; then, melting all the metal raw materials to obtain an alloy melt, or opening a bottom vacuum valve to absorb all the metal raw materials into a copper mould, and completely cooling to obtain the high-plasticity ZrCuAgAlBe bulk metal glass. The bulk metal glass disclosed by the invention is favorable in plasticity, relatively high in glass forming capacity, high in strength and hardness and favorable in thermal stability, wear resistance and corrosion resistance so as to have wide application prospects, and the maximum size of a completely-amorphous alloy rod is about 6mm.

Owner:ZHEJIANG UNIV

scroll compressor

ActiveCN103502645BReduce shear resistanceReduce lossesRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The scroll compressor of the present invention comprises: a fixed scroll (112); an orbiting scroll (109); a crank shaft (103) having an eccentric portion (108) at the end; and an oil supply hole (115) having an opening on the end surface of the eccentric part; a revolving sliding bearing (110) provided on the revolving scroll and slidingly engaged with the eccentric part; provided on the outer periphery of the eccentric part The lubricating oil supplied from the oil supply hole lubricates the space between the eccentric part and the swivel sliding bearing through the oil supply passage (116). An axial loss reduction groove (117) is provided on the outer periphery of the eccentric portion independently of the oil supply passage, and at least one of the end face side and the base end side of the eccentric portion in the loss reduction groove is Equipped with sealing parts (118a, 118b). Thereby, the shear resistance of the oil film due to the lubricating oil present between the outer peripheral surface of the eccentric portion of the crankshaft and the inner peripheral surface of the orbiting sliding bearing can be reduced, thereby reducing bearing loss during fluid lubrication.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Laser rapid prototyping method and device easy for solid separation

PendingCN114505498ALow static strengthReduce shear resistanceAdditive manufacturing apparatusIncreasing energy efficiencyPhysicsLight scan

The invention provides a laser rapid prototyping method and device easy for solid separation, and belongs to the technical field of laser rapid prototyping. According to the laser rapid prototyping method easy for solid separation, an isolation layer is arranged between a powder laying substrate and a processed solid by changing the processing parameters and the scanning angle of a laser scanning assembly; the characteristics of low static strength and low shearing resistance of the isolating layer are utilized to easily separate the manufactured entity from the powder laying substrate, so that the appearance structure of the processed entity is prevented from being damaged in the separation process; according to the laser rapid prototyping device easy for solid separation, all-directional closed transfer of powder between the powder feeding cylinder and the prototyping cylinder can be realized, so that powder waste is avoided.

Owner:JINAN SENFENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com