A kind of large plastic Zrcuagalbe series bulk metallic glass and preparation method thereof

A metallic glass and large plasticity technology, which is applied in the field of large plastic ZrCuAgAlBe bulk metallic glass and its preparation, can solve the problems of difficulty in obtaining amorphous alloys and slowing down of cooling speed, so as to improve plastic deformation ability and reduce shear The effect of resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

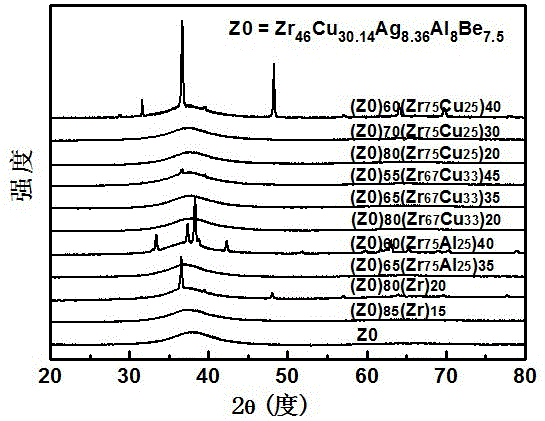

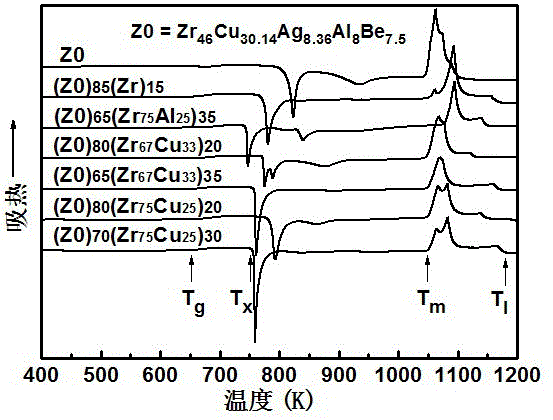

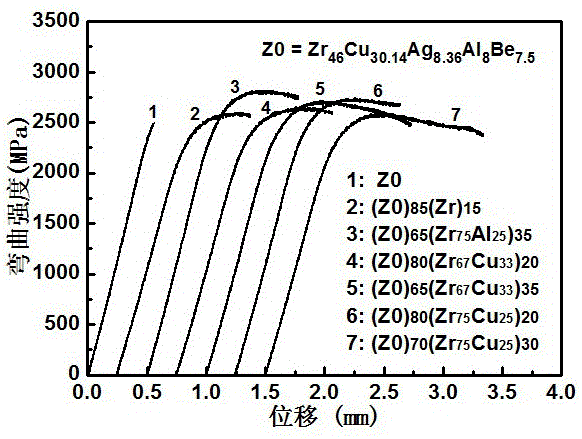

Image

Examples

preparation example Construction

[0030] The preparation method of the present invention comprises the following steps:

[0031] 1) Put Zr, Cu, Ag, Al, and Be metal raw materials in the first copper boat of the arc melting furnace according to the ratio of 46-58.5: 18.08-31.43: 4.6-8.36: 4.4-14.8: 4.13-7.5, Zr , Cu, Ag, Al, and Be metal raw materials have a mass purity of 99% to 99.999%; in addition, the Zr ingot is placed in the second copper boat of the arc melting furnace, and the quality of the Zr ingot is the same as that of Zr, Cu, Ag, Al, The ratio of the total mass of Be metal raw materials is 1:2 to 1:5;

[0032] 2) Vacuumize the arc melting furnace until the pressure in the furnace is 3×10 -3 Pa, and then fill the arc melting furnace with 98% Ar gas by volume until it is equal to the external atmospheric pressure;

[0033] 3) The Zr ingot in the second copper boat of the melting arc melting furnace consumes oxygen for 1-2 minutes, and the melting temperature is at least 2000 degrees Celsius;

[00...

Embodiment 1

[0042]1) Put Zr, Cu, Ag, Al, and Be metal raw materials in the first copper boat of the arc melting furnace according to the ratio of 46:30.14:8.36:8:7.5, Zr, Cu, Ag, Al, Be metal raw materials The respective mass purity is 99.9%, 99.95%, 99.999%, 99.8%, 99%; in addition, the Zr ingot is placed in the second copper boat of the electric arc melting furnace, and the quality of the Zr ingot is the same as that of Zr, Cu, Ag, Al, The total mass ratio of Be metal raw materials is 1:2;

[0043] 2) Vacuumize the arc melting furnace until the pressure in the furnace is 3×10-3Pa, and then fill the arc melting furnace with Ar gas with a volume percentage of 98% until it is equal to the external atmospheric pressure;

[0044] 3) The Zr ingot in the second copper boat of the melting arc melting furnace consumes oxygen for 1 minute, and the melting temperature is at least 2000 degrees Celsius;

[0045] 4) Then smelt the Zr, Cu, Ag, Al, and Be metal raw materials in the first copper boat o...

Embodiment 2

[0050] 1) Put Zr, Cu, Ag, Al, Be metal raw materials in the first copper boat of the arc melting furnace according to the ratio of 54.1:25.62:7.11:6.8:6.37, Zr, Cu, Ag, Al, Be metal raw materials The respective mass purity is 99.9%, 99.95%, 99.999%, 99.8%, 99%; in addition, the Zr ingot is placed in the second copper boat of the electric arc melting furnace, and the quality of the Zr ingot is the same as that of Zr, Cu, Ag, Al, The total mass ratio of Be metal raw materials is 1:4;

[0051] 2) Vacuumize the arc melting furnace until the pressure in the furnace is 3×10-3Pa, and then fill the arc melting furnace with Ar gas with a volume percentage of 98% until it is equal to the external atmospheric pressure;

[0052] 3) The Zr ingot in the second copper boat of the melting arc melting furnace consumes oxygen for 1.5 minutes, and the melting temperature is at least 2000 degrees Celsius;

[0053] 4) Then smelt the Zr, Cu, Ag, Al, Be metal raw materials in the first copper boat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com