Retainer, deep groove ball bearing, and bearing with seal

一种保持器、带密封的技术,应用在球轴承、轴承元件、轴和轴承等方向,能够解决降低密封转矩、减小接触面表面粗糙度、转矩降低等问题,达到降低密封转矩、提高燃料利用率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

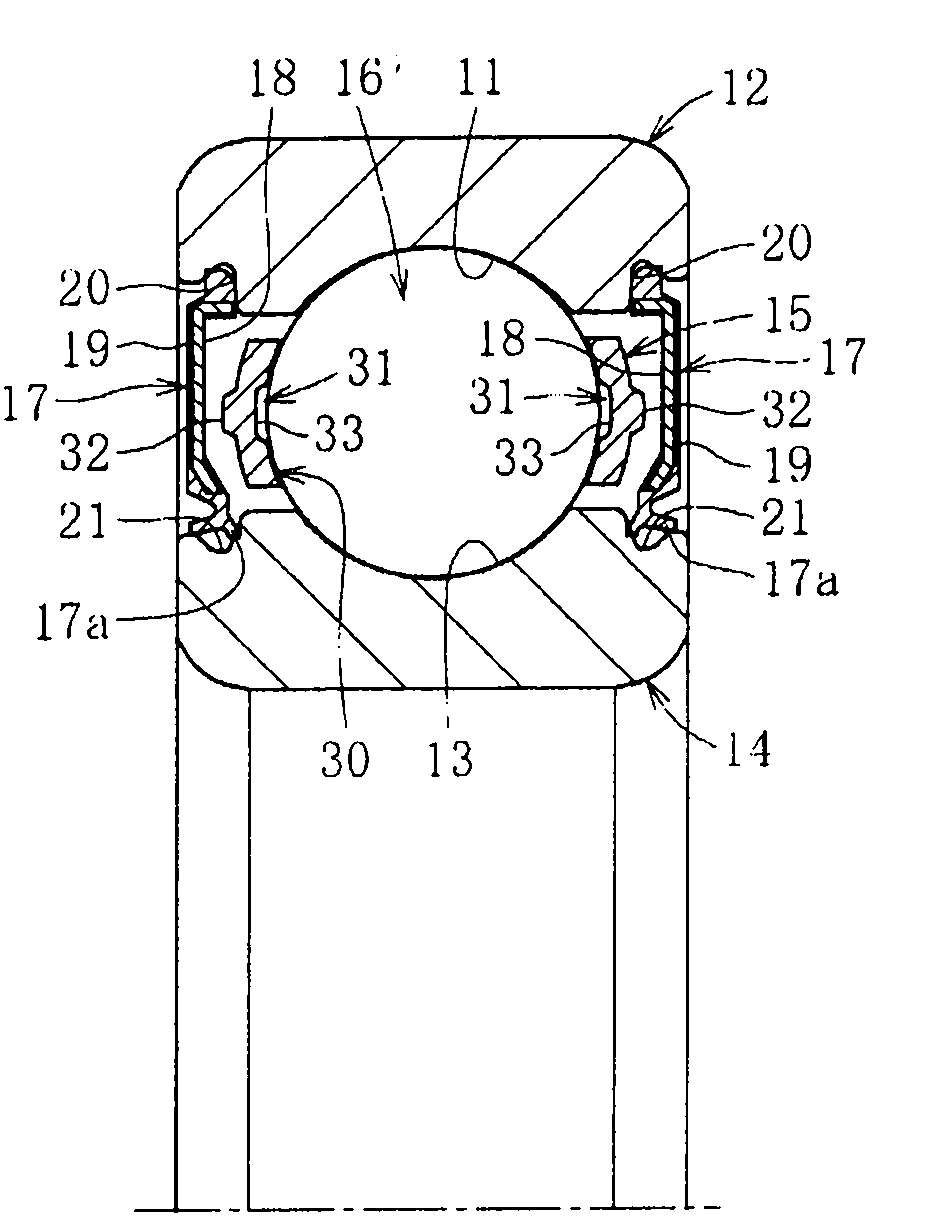

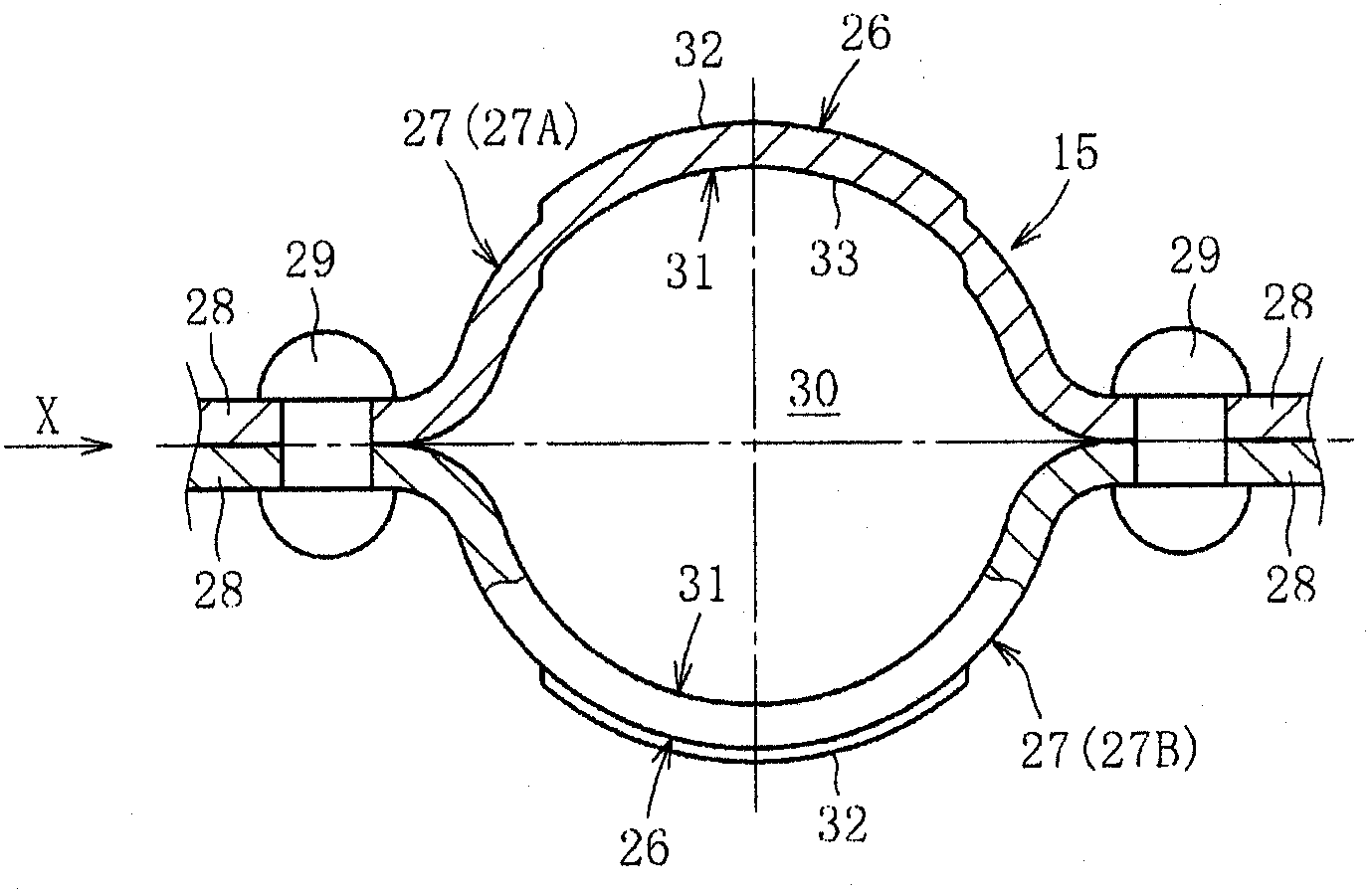

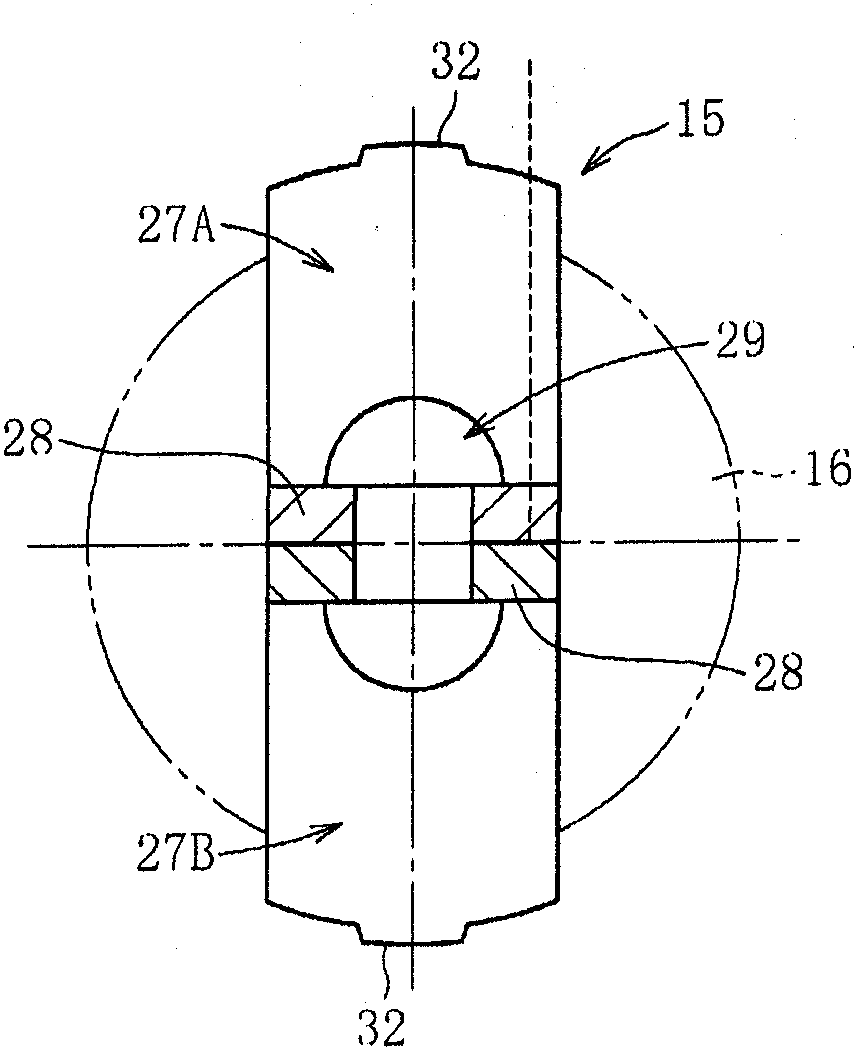

[0101] Make cages of shapes A, B, C, D, E, and F shown in Fig. 4 (metal cages: stamped products), and assemble them figure 1 ball bearing shown, and measure the resulting torque. The results are shown in Table 1 below. In Table 1, the standard product is a conventional product in which the ball non-contact portion 31 is not formed.

[0102] 【Table 1】

[0103]

Convex shape size

Steel ball-cage contact area (%)

Torque reduction rate (%)

Standard Parts

-

100

-

shape A

1.6×9.0

70

59

shape B

1.6×5.5

83

52

shape C

2.6×5.5

70

59

shape D

*1

70

62

shape E

*2

83

54

shape F

1.6×4.8

85

50

[0104] *1 Object after shifting the position of shape A from the P.C.D to the outer diameter side by 0.8mm

[0105] *2 The object after shifting the position of shape B from the P.C.D to the outer diameter side by 0.8mm...

Embodiment 2

[0110] Such as Figure 9 As shown, make a cage (metal cage: stamped product) with a slit 35, and use it to assemble Figure 8 For the ball bearing shown, the resulting torque was measured. At this time, the contact area is reduced by 30% compared to the standard part (holder without slit 35). As in Example 1, a rotational speed of 4000 r / min was applied with a radial load of 500 N applied. A part was immersed in lubricating oil (Toyota Genuine ATF T-4) at 30°C. At this time, the rotational torque is reduced by about 40%. That is, the standard is 0.152 Nm, and the cage having the slit 35 is 0.093 Nm. In addition, as the bearing, the outer diameter of the outer ring 12 is 72.0 mm, the inner diameter of the outer ring 12 is 60.2 mm, the outer diameter of the inner ring 14 is 47.0 mm, the inner diameter of the inner ring 14 is 35.0 mm, ball (steel Ball) 16 has an outer diameter of 11.1 mm. In addition, components of the same size were also used in Comparative Examples 1 and ...

Embodiment 3

[0116] FIG. 14 is a graph showing test results obtained by comparing the rotational torque of the bearing with seal according to this embodiment with that of a conventional bearing with seal. Such as Figure 14A As shown, the rotational torque in the bearing with a seal according to the embodiment is significantly reduced compared with the conventional product. The reason is that, if Figure 14B As shown, in the conventional products, as the main cause of the rotational torque, the resistance caused by the grease, (cage shear resistance + rolling resistance) and the sealing torque can be mentioned specifically. On the other hand, the embodiment Sealing torque in sealed bearings was ruled out as the main cause.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com