Wiring piece, block terminal and method for cutting wire

A technology of lugs and distribution boxes, applied in the direction of connecting/terminating cables, electrical components, transportation and packaging, etc., can solve problems such as inability to form circuits, inability to efficiently perform cutting wires 507, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

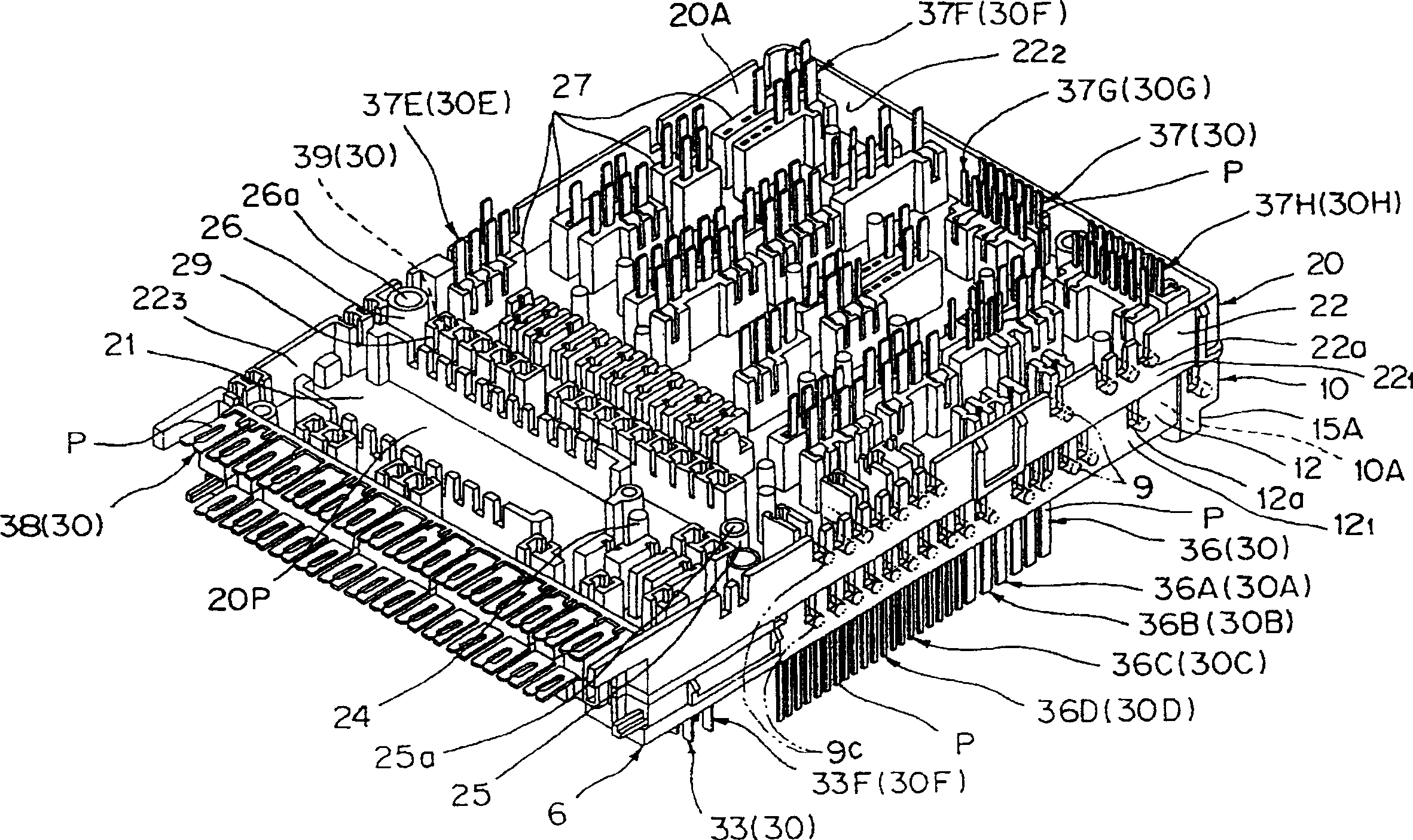

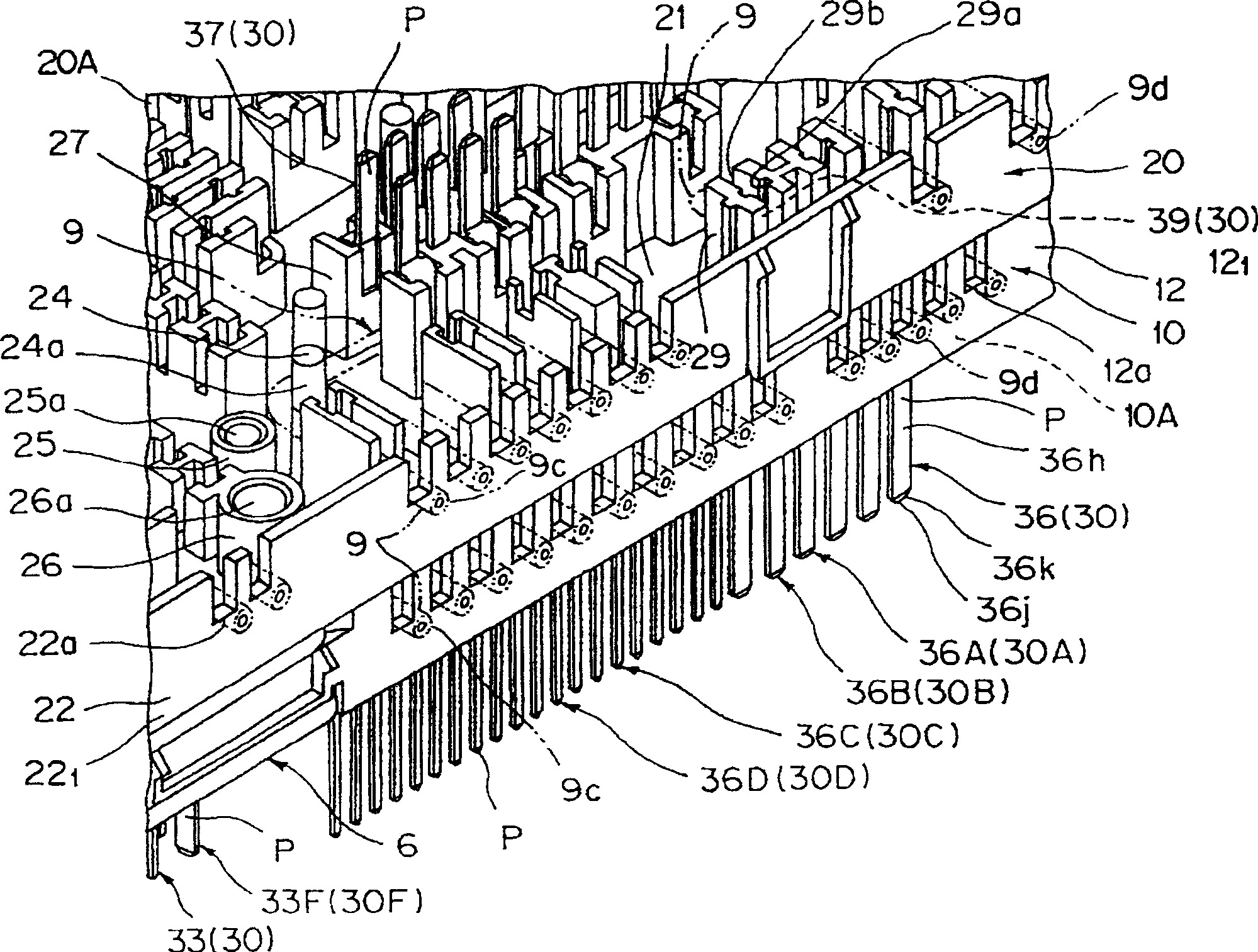

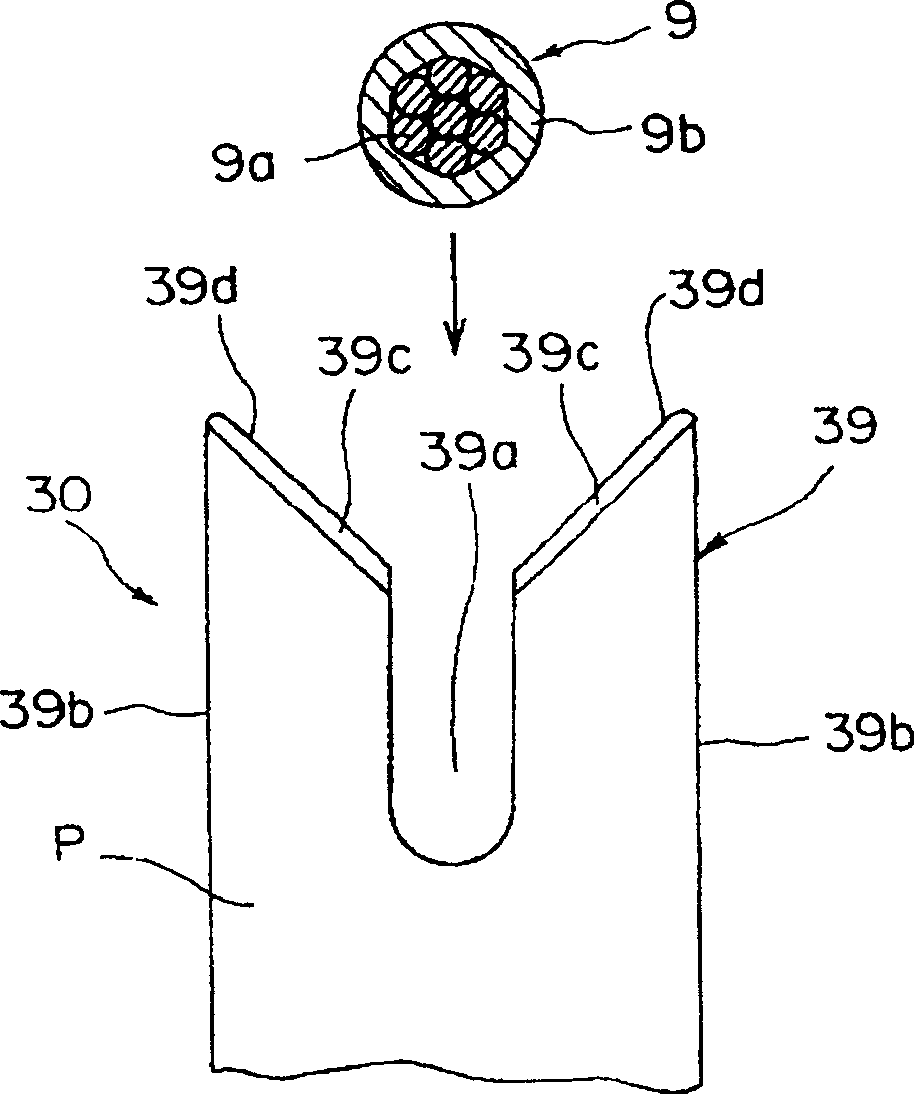

[0059] Hereinafter, a lug, a distribution box, and a wire cutting method embodying the present invention will be described in detail with reference to the accompanying drawings.

[0060] Figure 1 to Figure 9 A preferred embodiment of the present invention is shown, showing lugs, distribution boxes and wire cutting methods.

[0061] Referring to the upper and lower sides of lugs 10 and 20, as figure 1 and figure 2 As shown, the side on which the electrical contact portion 37 of the bus bar 30 protrudes from the lug 20 is the lower side. figure 1 and figure 2 The underside of lug 20 is shown. The side where the electrical contact portion 36 of the bus bar 30 protrudes from the lug 10 is the upper side, as figure 1 , 2 , 4 and 5.

[0062] Refer to attached Figure 6 For different directions of the distribution box 1, the side where the electronic unit 5 is disposed in the distribution box 70 is the upper side, and an example where the synthetic resin supporting memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com