Cup-shaped part with inner peripheral uneven surface section, method for manufacturing cup-shaped part, and device for manufacturing cup-shaped part

A manufacturing device and technology of concave-convex portion, which are applied to the field of cup-shaped member with inner peripheral concave-convex portion and its manufacturing and manufacturing device to achieve the effects of improving strength and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

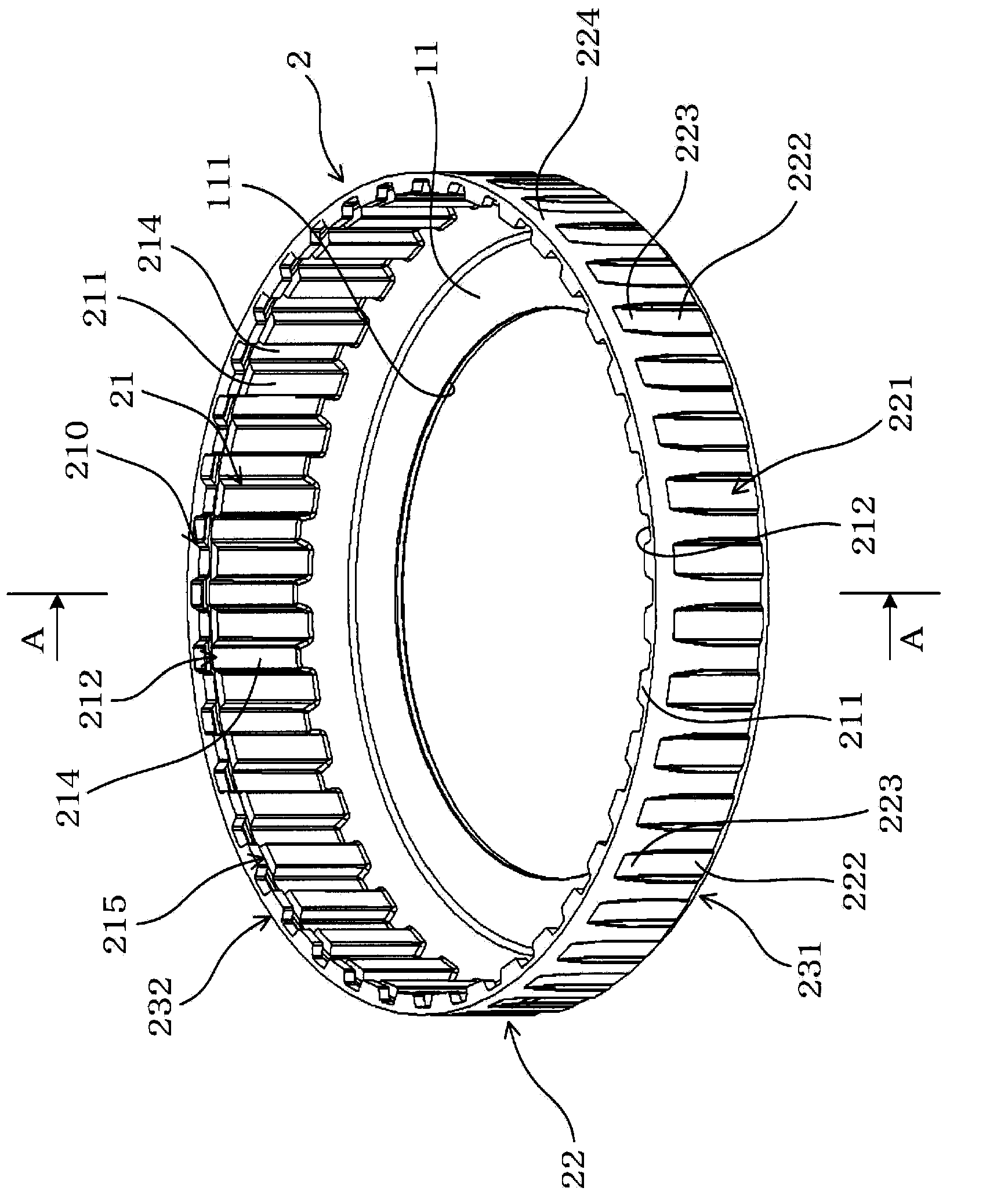

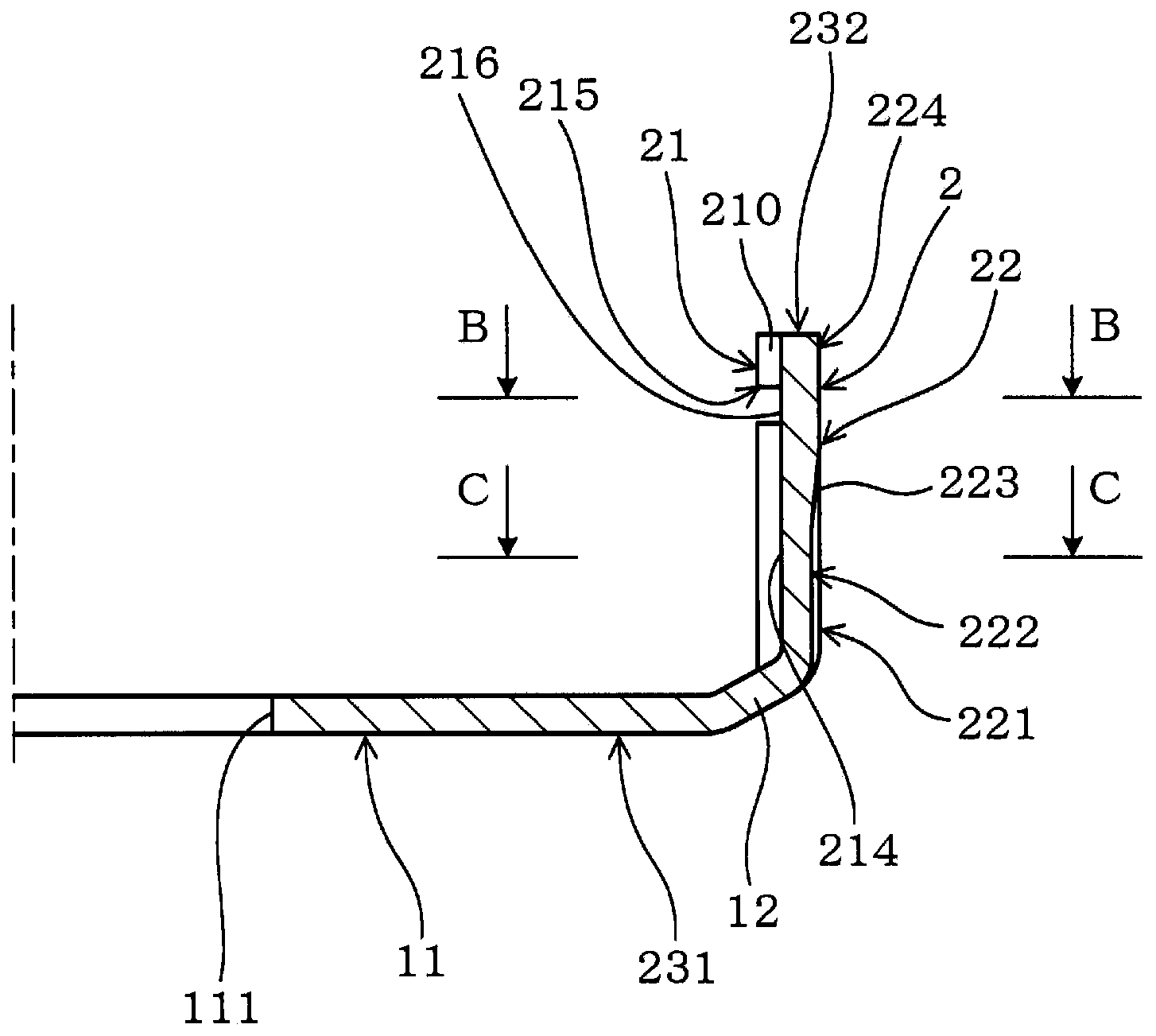

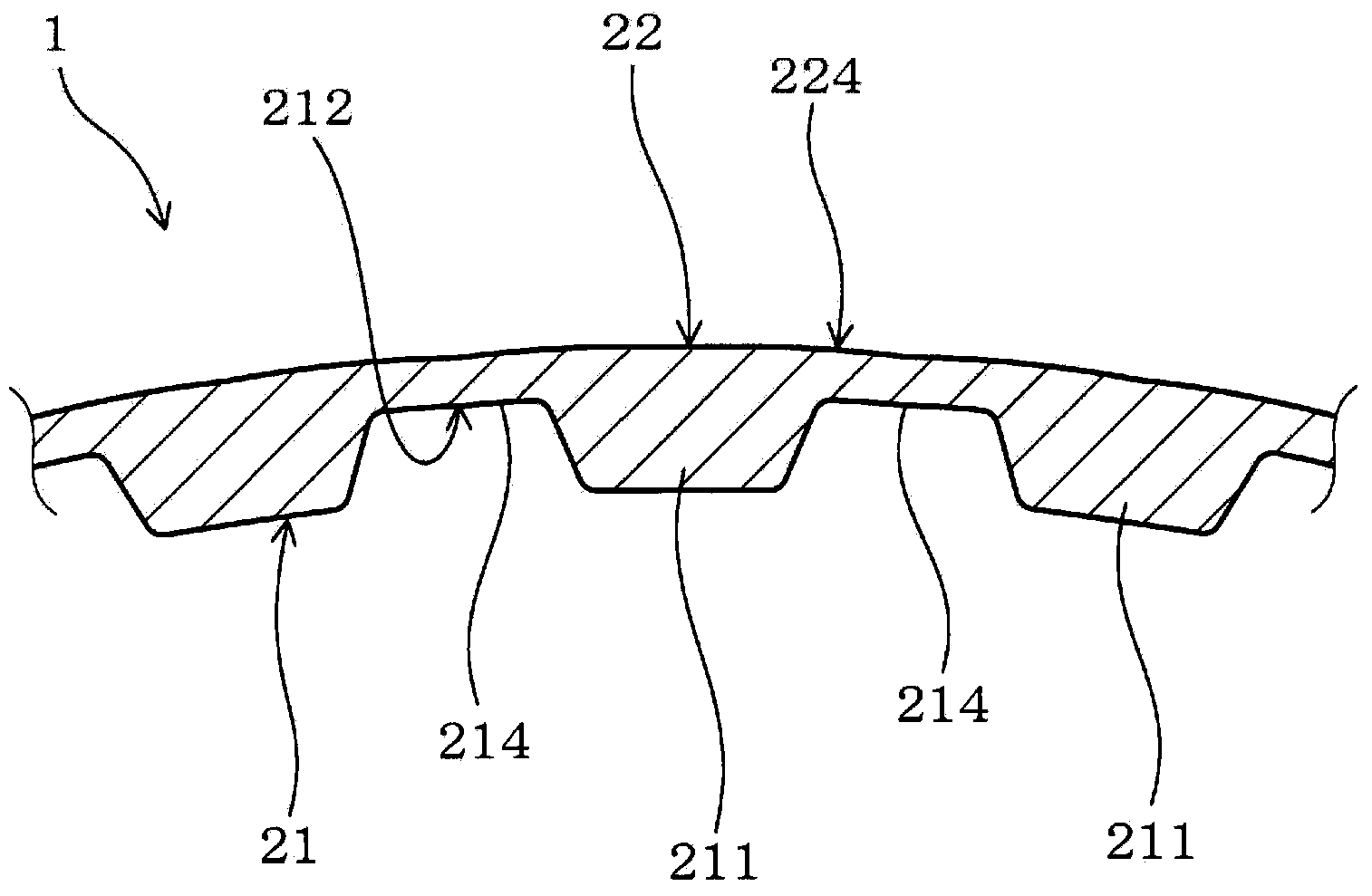

[0068] refer to Figure 1 to Figure 15 Examples of a cup-shaped member having an inner peripheral concave-convex portion, a manufacturing method, and a manufacturing apparatus thereof will be described.

[0069] Such as figure 1 As shown, the cup-shaped member 1 having the inner peripheral concave-convex portion 210 is formed by press working, and has a disk-shaped bottom 11 and a cylindrical portion 2 standing up from the outer periphery of the bottom 11 . In addition, the cup-shaped member 1 has an inner peripheral concave-convex portion 210, and the inner peripheral concave-convex portion 210 has a plurality of inner peripheral convex portions 211 and a plurality of inner peripheral concave portions 212. The entire length of the axial direction of the cylindrical portion 2 protrudes radially inward and extends along the axial direction of the cylindrical portion 2, and a plurality of the inner peripheral recesses 212 are respectively formed between adjacent inner peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com