Energy-efficient transmission mechanism of transverse cutting machine

A high-efficiency energy-saving, transmission mechanism technology, applied in transmission parts, mechanical equipment, metal processing, etc., can solve the problems of extreme vibration of the machine, large cutting resistance, large power loss, etc., to eliminate gear backlash, reduce The effect of motor power and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

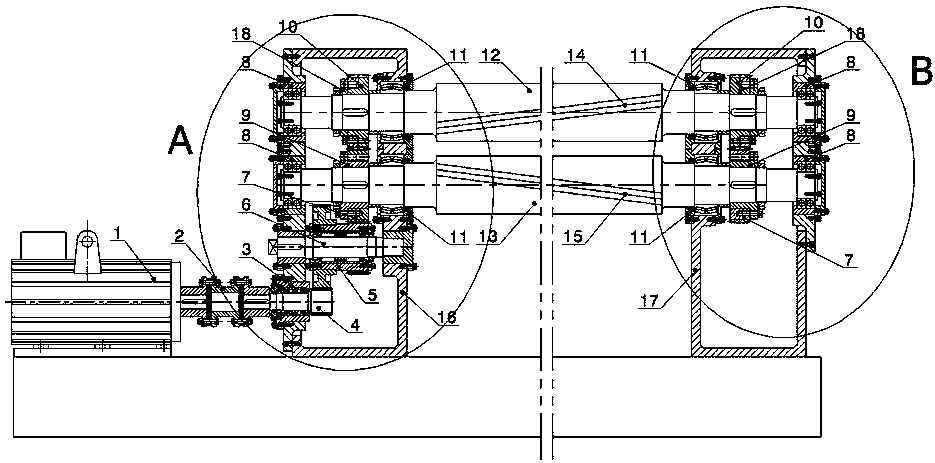

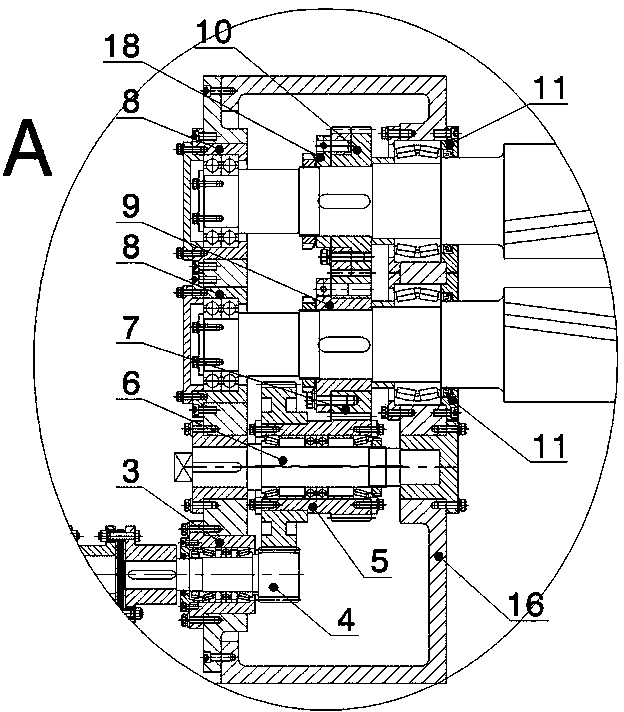

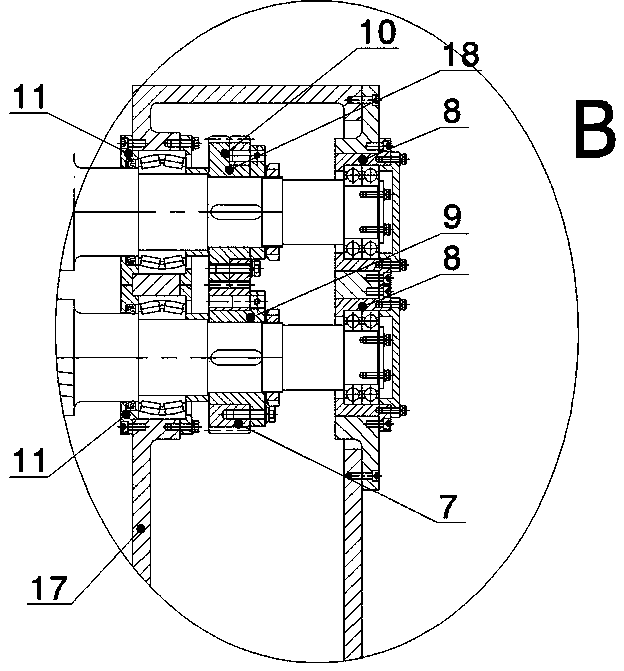

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] as attached figure 1 with 2 As shown, the high-efficiency and energy-saving cross-cutting machine provided by the present invention includes an upper knife roll 12, a lower knife roll 13, a left gear box frame 16 and a right gear box frame 17, an upper knife roll 12, a lower knife roll 13, The two ends are respectively arranged in the inner bearing seat 11 and the outer bearing seat 8 through self-aligning roller bearings and deep groove ball bearings, and any inner bearing seat 11 or outer bearing seat 8 is fixed on the gearbox frame 16, ensuring The positioning accuracy of the upper cutter roller 12 and the lower cutter roller 13, the upper cutter roller 12 is parallel to the axial direction of the lower cutter roller 13, the upper spiral cutter 14 is arranged on the peripheral surface of the upper cutter roller 12, and the upper spiral cutter 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com