Sheet metal part with improved connection tab geometry

A metal sheet and connector technology, which is applied in the field of sheet metal parts, can solve the problems of cables affecting crimping, high load, difficulty in cutting and synchronously processing sheet metal parts, etc., so as to reduce shear resistance and reduce material strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

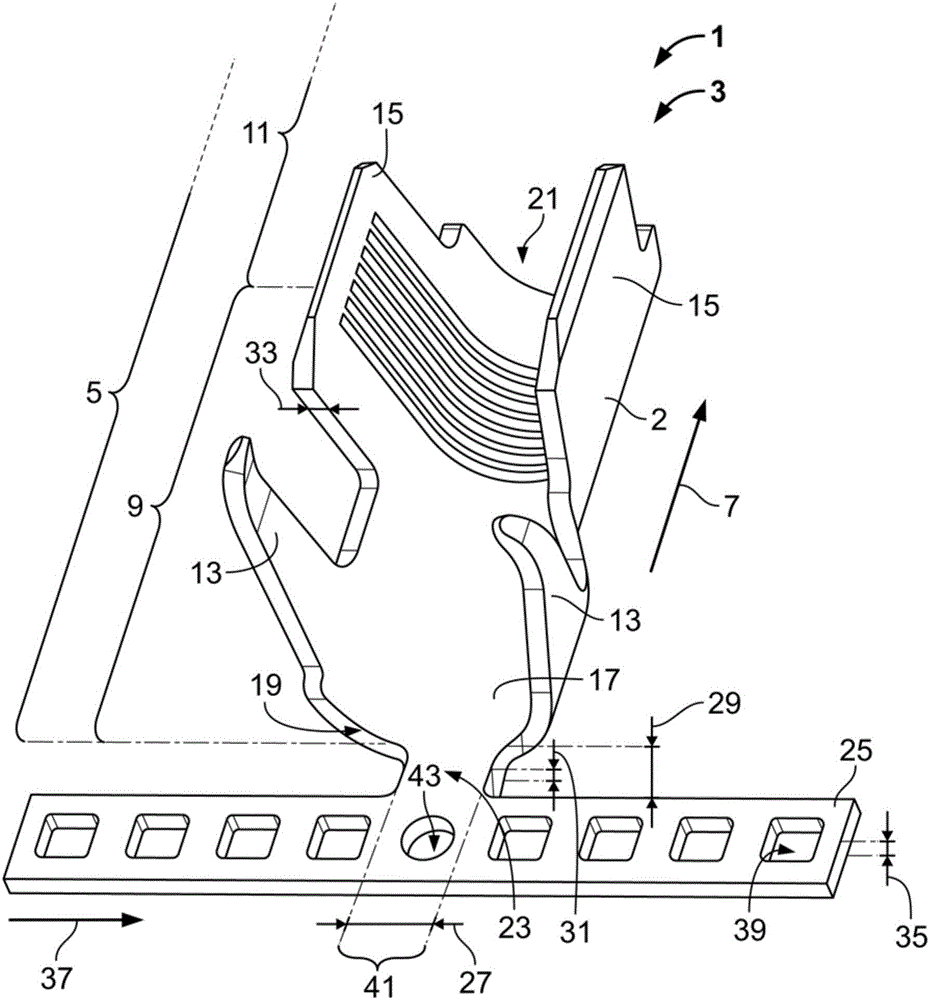

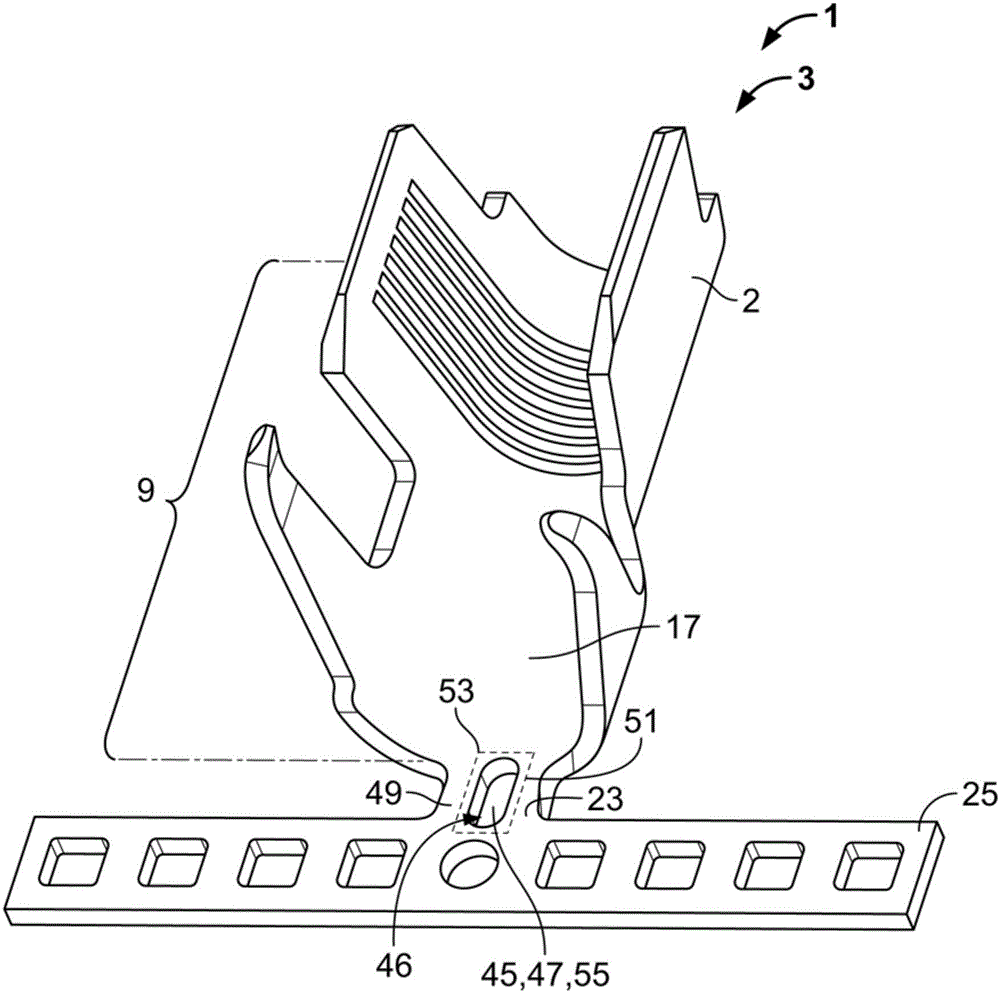

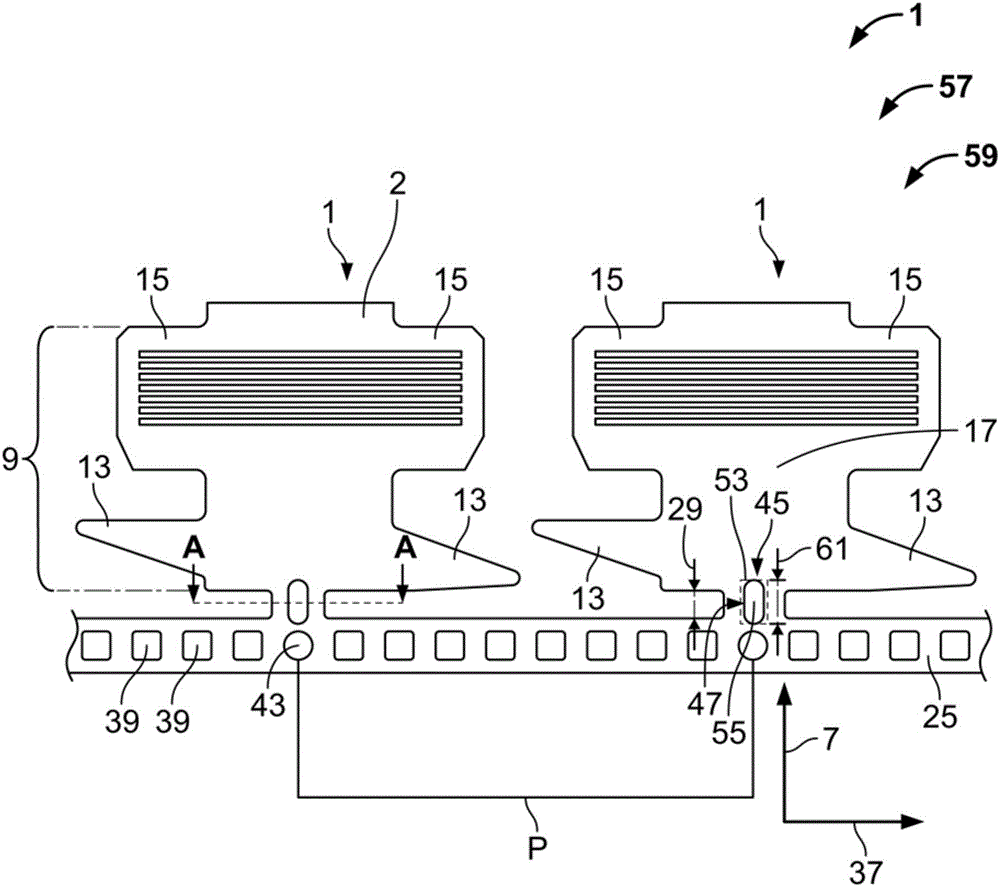

[0067] figure 1 A prior art sheet metal part 1 is shown, which is stamped and bent from sheet metal 2 . The sheet metal part 1 is shown in a stamped (or otherwise formed) and bent state 3 . The sheet metal part 1 comprises a connector part 5 oriented in a connector direction 7 .

[0068] The connector part 5 comprises a crimping area 9 and a connector area 11, which is not in the figure 1 shown in .

[0069] The sheet metal part 1 also comprises two insulating crimping arms 13 and two wire crimping arms 15, while the number and / or shape of the crimping arms 13, 15 is shown as an exemplary embodiment of the sheet metal part 1 , and can vary in different embodiments.

[0070] Between the crimping arms 13 , 15 , a crimping base 17 extends in the connector direction from the cable end 19 of the sheet metal part 1 into the connector region 11 .

[0071] In the stamped and bent state 3, the crimping arms 13, 15 form a receiving portion 21 suitable for receiving a wire including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com