Separation type shearing knife

A shearing knife and separate technology, which is applied to shearing devices, knives for shearing machine devices, metal processing equipment, etc., can solve the problems of high cost consumption of blades, improve efficiency, improve processing accuracy, and reduce shearing costs. The effect of shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

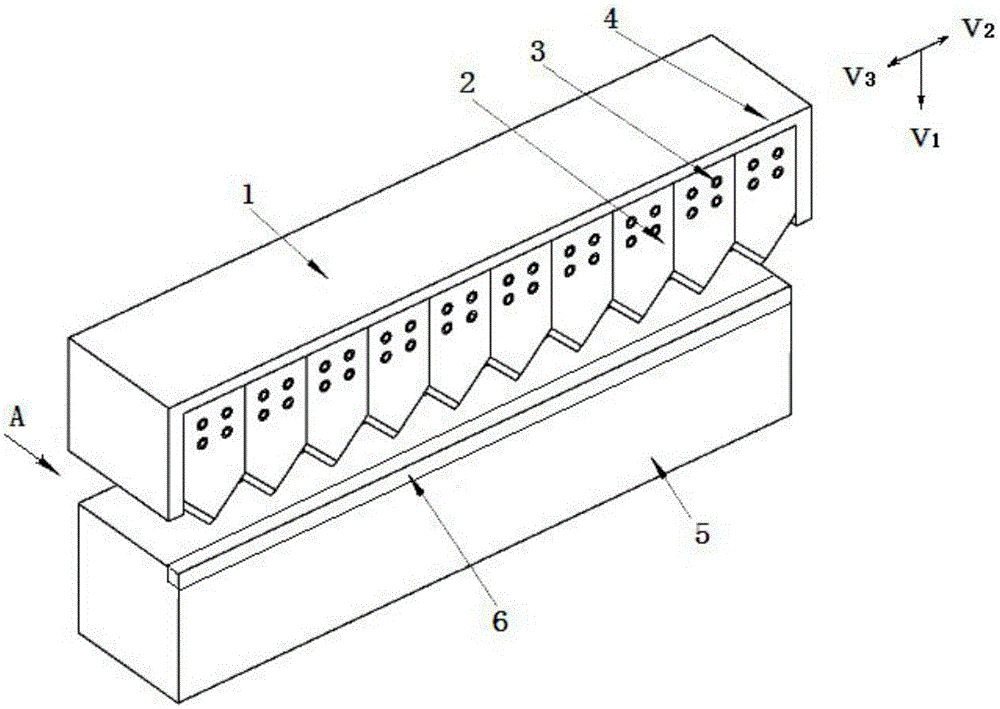

[0021] Such as figure 1 As shown, the present invention is made up of upper blade 1, screw 3, knife rest 4, base 5 and lower blade 6, wherein the front of knife rest 4 is provided with groove 7, and groove 7 is provided with threaded hole 8; Upper blade 1 is made of Composed of 5-10 blade monomers 2, each blade monomer 2 is fixed in the threaded hole 8 on the groove 7 via a screw 3, and 5-10 blade monomers 2 are closely arranged laterally in the groove 7; The lower blade 6 is affixed to the front upper corner of the base 5, and the distance between the vertical edge of the lower blade 6 and the back of the edge of the blade unit 2 is h 12 2-4mm.

[0022] The blade unit 2 of the upper blade 1 is driven by the hydraulic device of the shearing machine, and can move up and down and laterally.

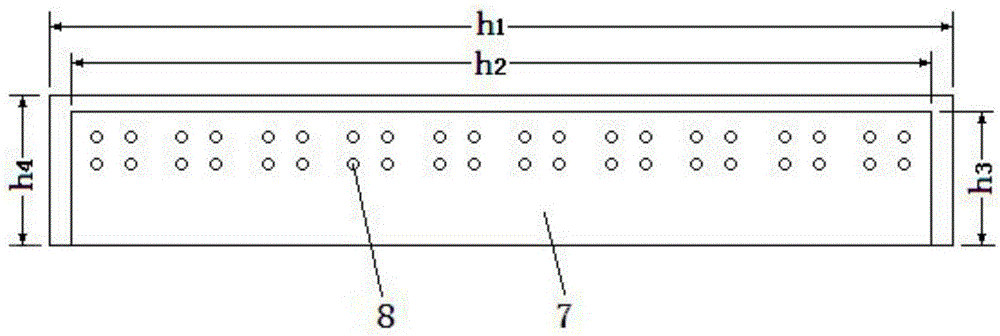

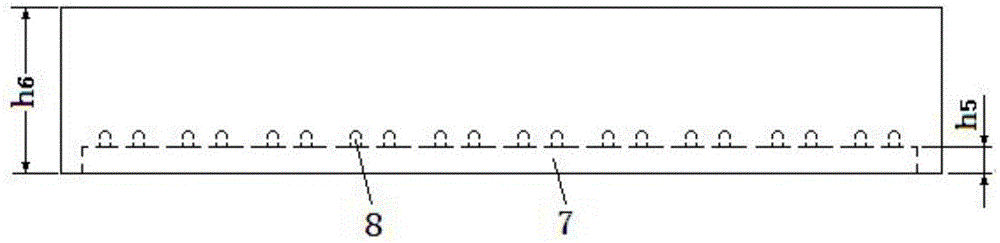

[0023] Such as figure 2 and image 3 As shown, the tool holder 4 is lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com