Shearing crusher cutter and crushing shaft device

A crusher and shearing technology, which is applied in the field of shearing crusher crushing shaft device, can solve the problems of crushing shaft damage, motor life reduction, motor burnout, etc., to achieve the effect of reducing resistance and improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

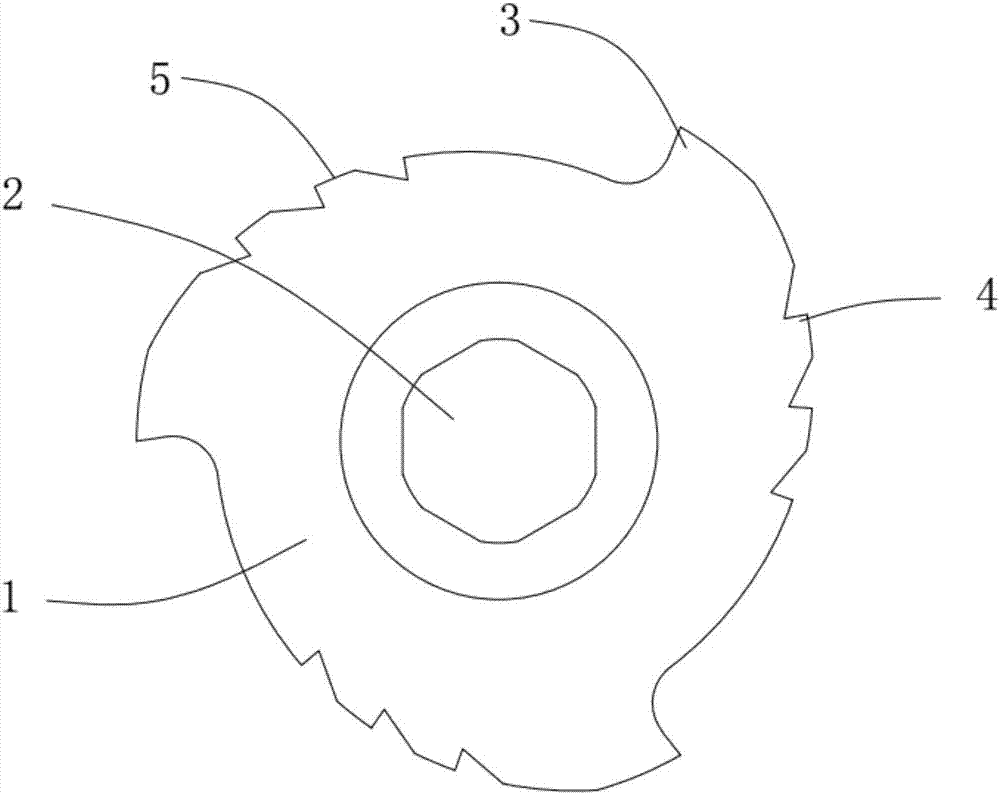

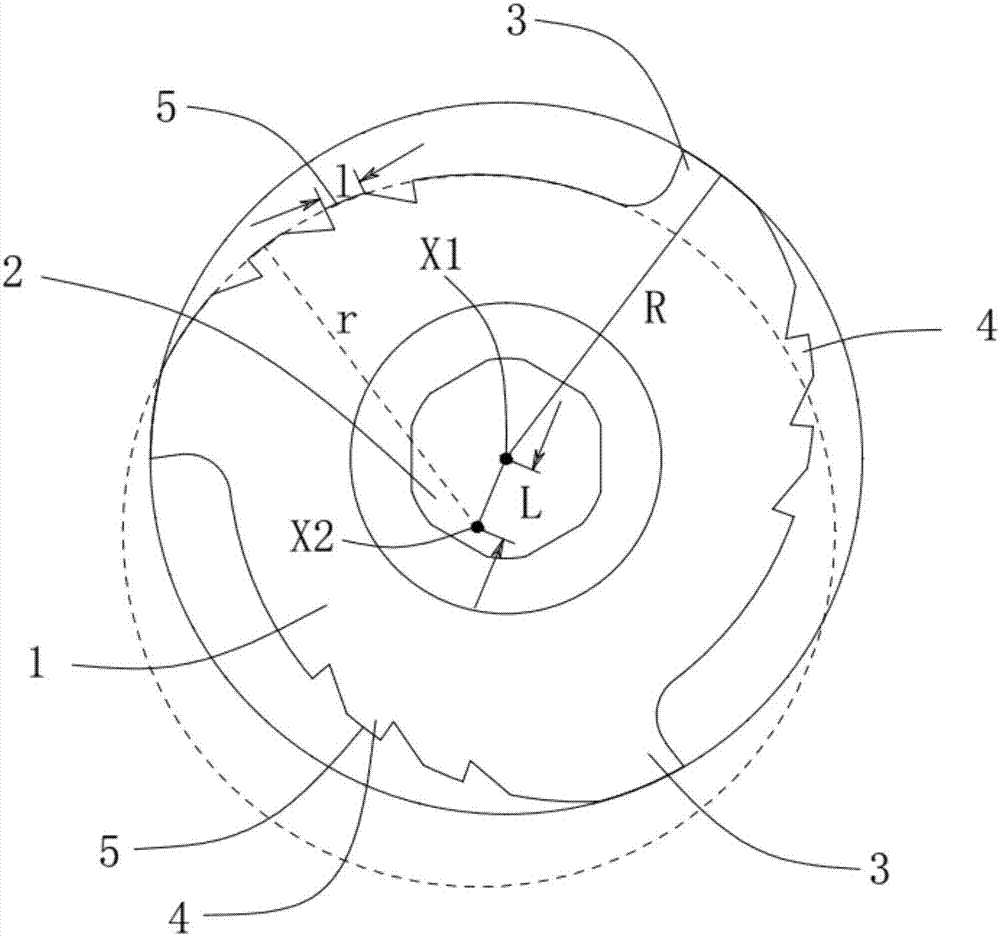

[0036] Such as Figure 1-2 As shown, the cutter of the present invention includes a cutter body 1 and a cutter shaft installation hole 2 arranged in the center of the cutter body 1 . The outer periphery of the cutter body 1 is provided with several main blades 3, and the several main blades 3 are evenly distributed on the outer periphery of the cutter body 1 with the cutter shaft mounting hole 2 as the center of circle;

[0037] It also includes several groups of auxiliary blades 4, each group of auxiliary blades 4 is arranged between two adjacent main blades 3, and each group of auxiliary blades 4 is located on different arc curves;

[0038] The distance between the main blade 3 and the shaft mounting hole 2 is greater than the distance between the secondary blade 4 and the shaft mounting hole 2 .

[0039] Several groups of secondary blades 4 are added to increase the cutting length of the shearing edge and improve the utilization rate of the cutter. When cutting bulk mater...

Embodiment 2

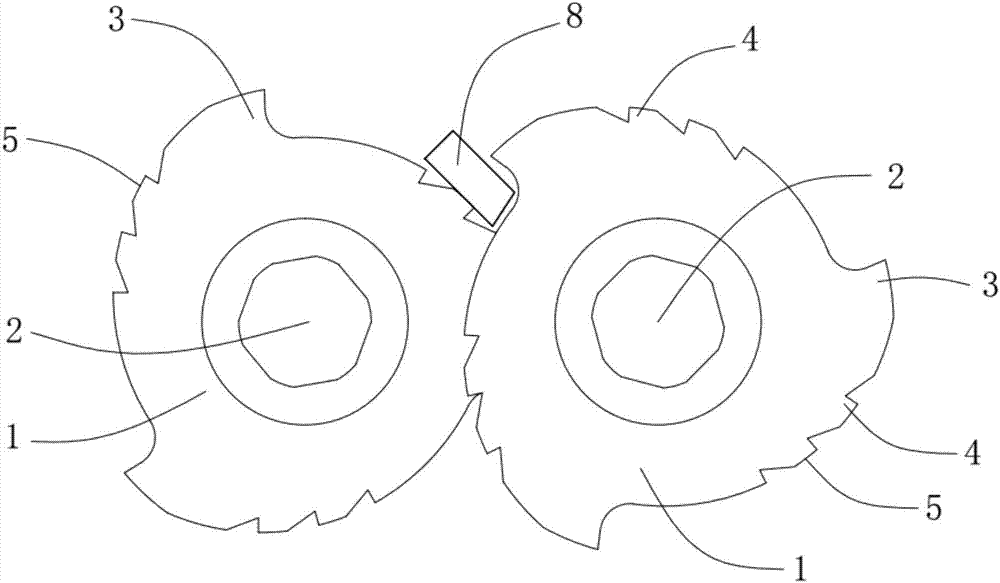

[0052] Such as Figure 3-4 Shown is the shearing crusher crushing shaft device applied to the shearing crusher cutter, which includes a cutter shaft and the shearing crusher cutter installed on the cutter shaft in the above-mentioned manner, the shearing crushing There are at least two machine knives, and a spacer 7 is arranged between the knife shaft and the shear crusher knives.

[0053] The cutter shaft includes a first cutter shaft 6 and a second cutter shaft 9, and at least two shearing crusher cutters are respectively arranged on the first cutter shaft 6 and the second cutter shaft 9, and at least two shearing crushers There is a gap between the knives;

[0054] The cutter of the shearing crusher on the first cutter shaft 6 and the cutter of the shearing crusher on the second cutter shaft 9 are mutually staggered during cooperation;

[0055] The shearing crusher cutter on the first cutter shaft 6 is opposite to the tooth mouth of the shearing crusher cutter 9 on the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com