Patents

Literature

36results about How to "Increase cutting length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

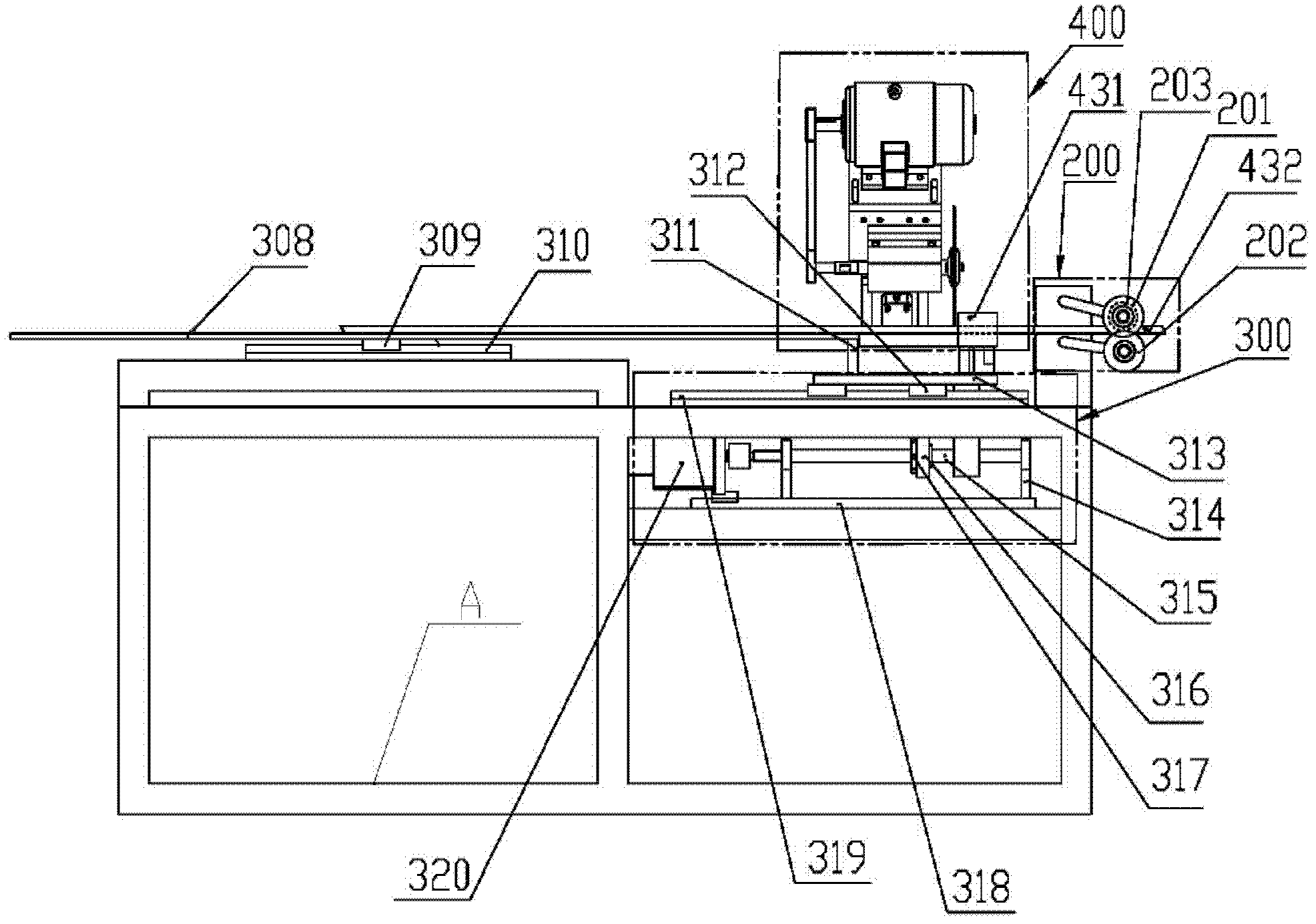

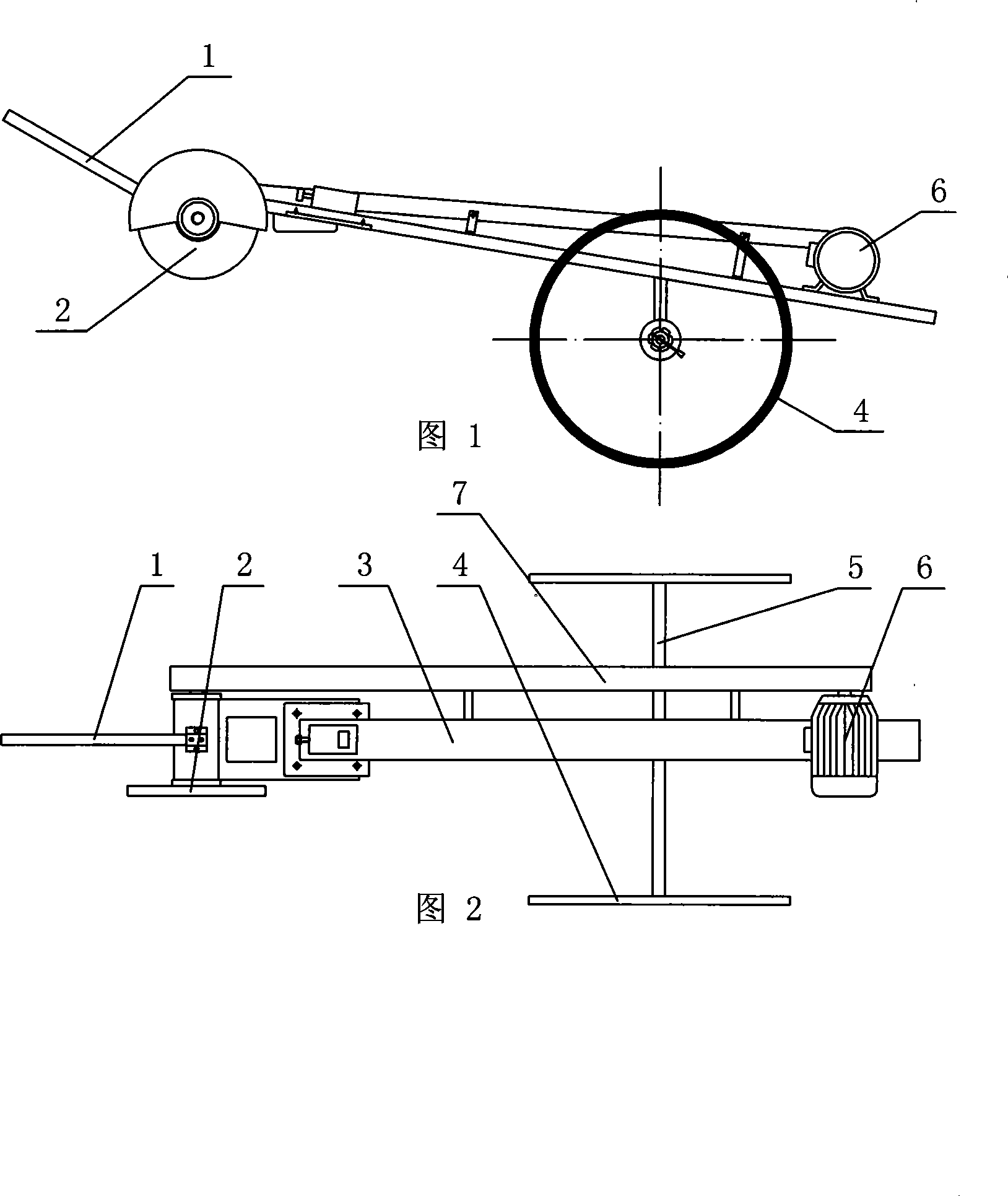

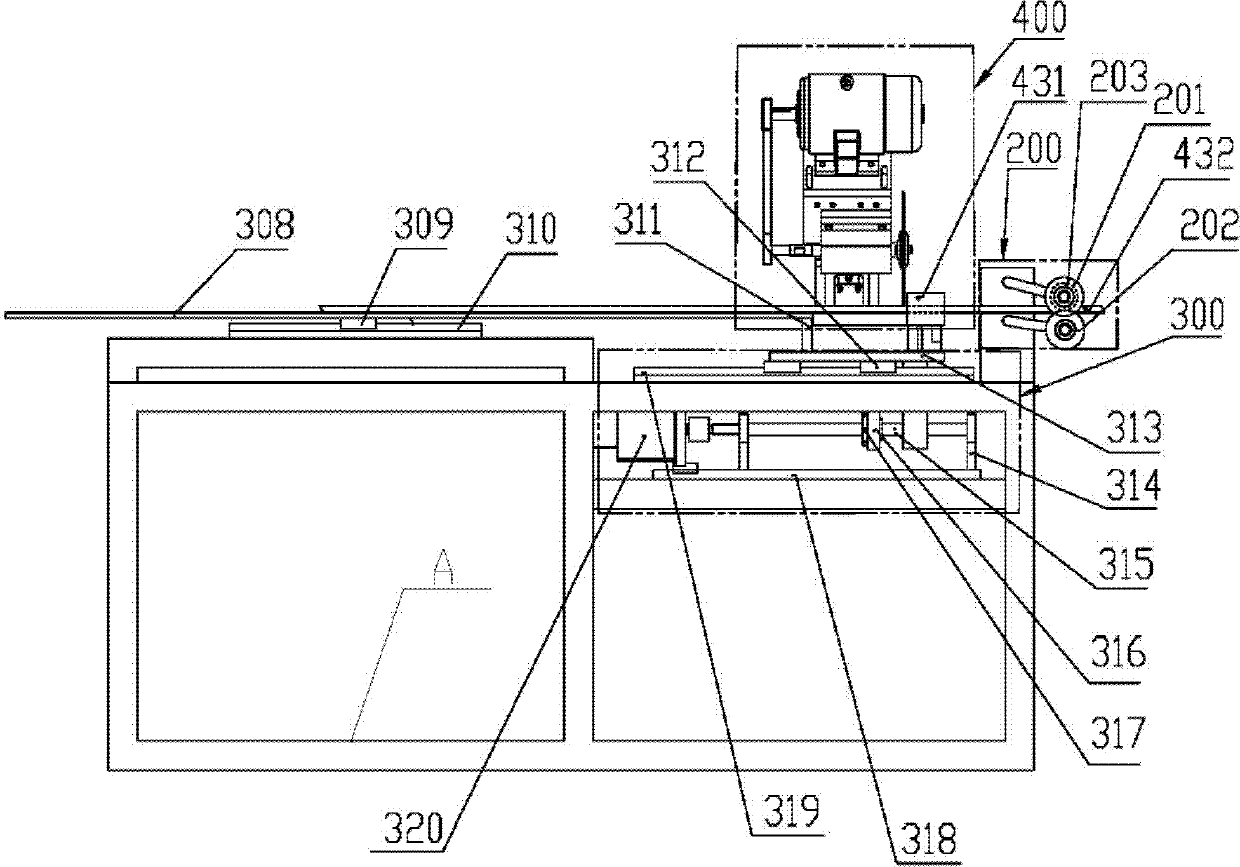

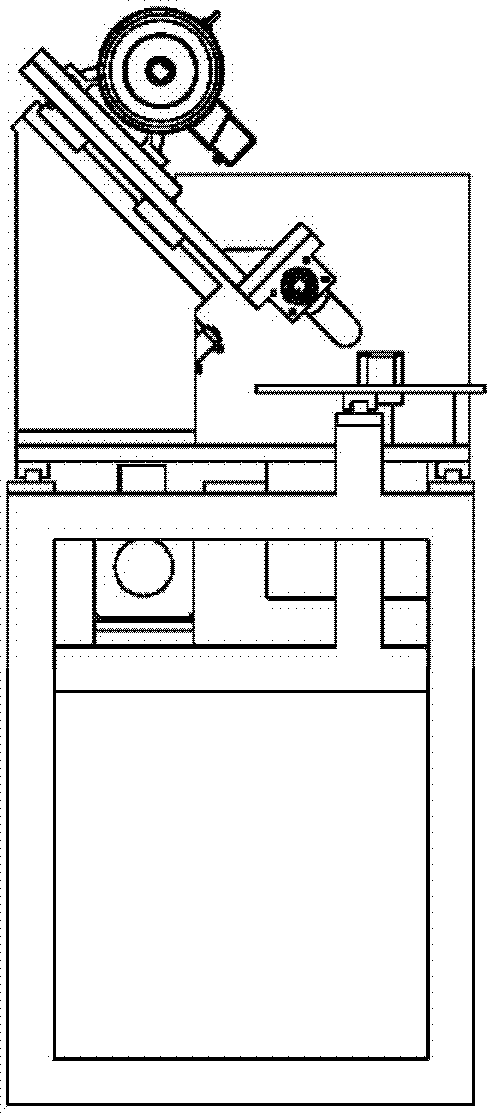

High-precision cutting machine

ActiveCN102350543AEasy to controlImprove flatnessMetal sawing devicesShearing control devicesProgrammable logic controllerControl system

The invention discloses a high-precision cutting machine, comprising a feeding device, a feeding speed detecting device, a material cutting device, a cutting device drive mechanism and a discharging device, wherein the feeding speed detecting device is used for acquiring the running speed data of a material and transmitting the running speed data to a main control system; and the main control system is used for controlling the cutting device to synchronously advance at the speed identical to the running speed of the material along a direction consistent to the advancing direction of the material while controlling the cutting device to perform cutting. In the cutting machine disclosed by the invention, an encoder is used for acquiring the running speed of the material and sending out pulse signals, a PLC (Programmable Logic Controller) is used for extracting the pulse signals of the encoder and performing accumulation operation on the pulse signals, when an accumulated value reaches a set value inside the PLC, a cutting length for the material is indicated to be reached, and the PLC sends out a cutting instruction, so that a cutting position during each cutting is accurately controlled; in addition, a cutting tool advances synchronously with the material during cutting, so that the cutting position does not change relatively, and the precision of the cutting length can reach + / -0.5mm.

Owner:ZHEJIANG XINGYU AUTO PARTS CO LTD

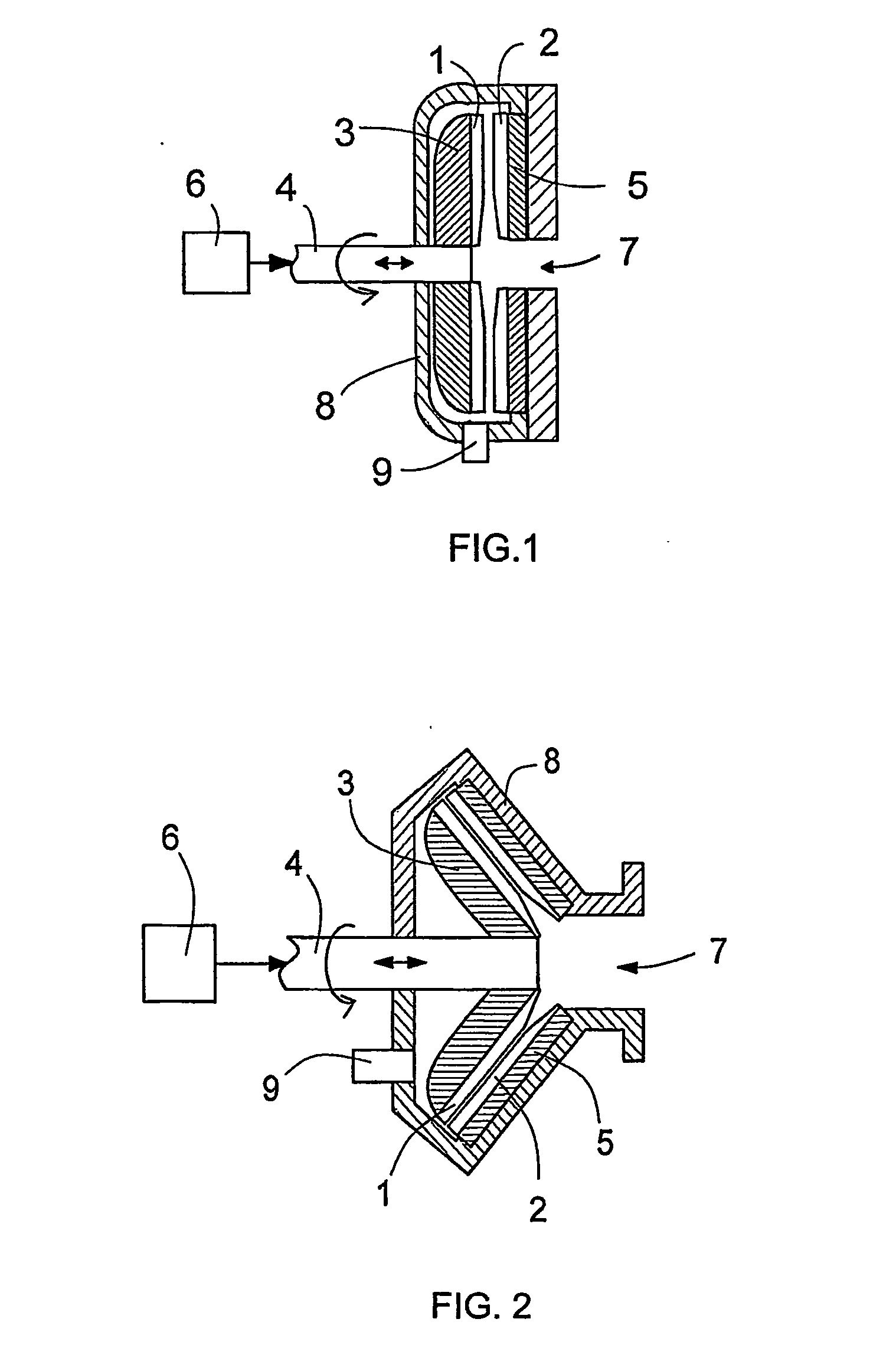

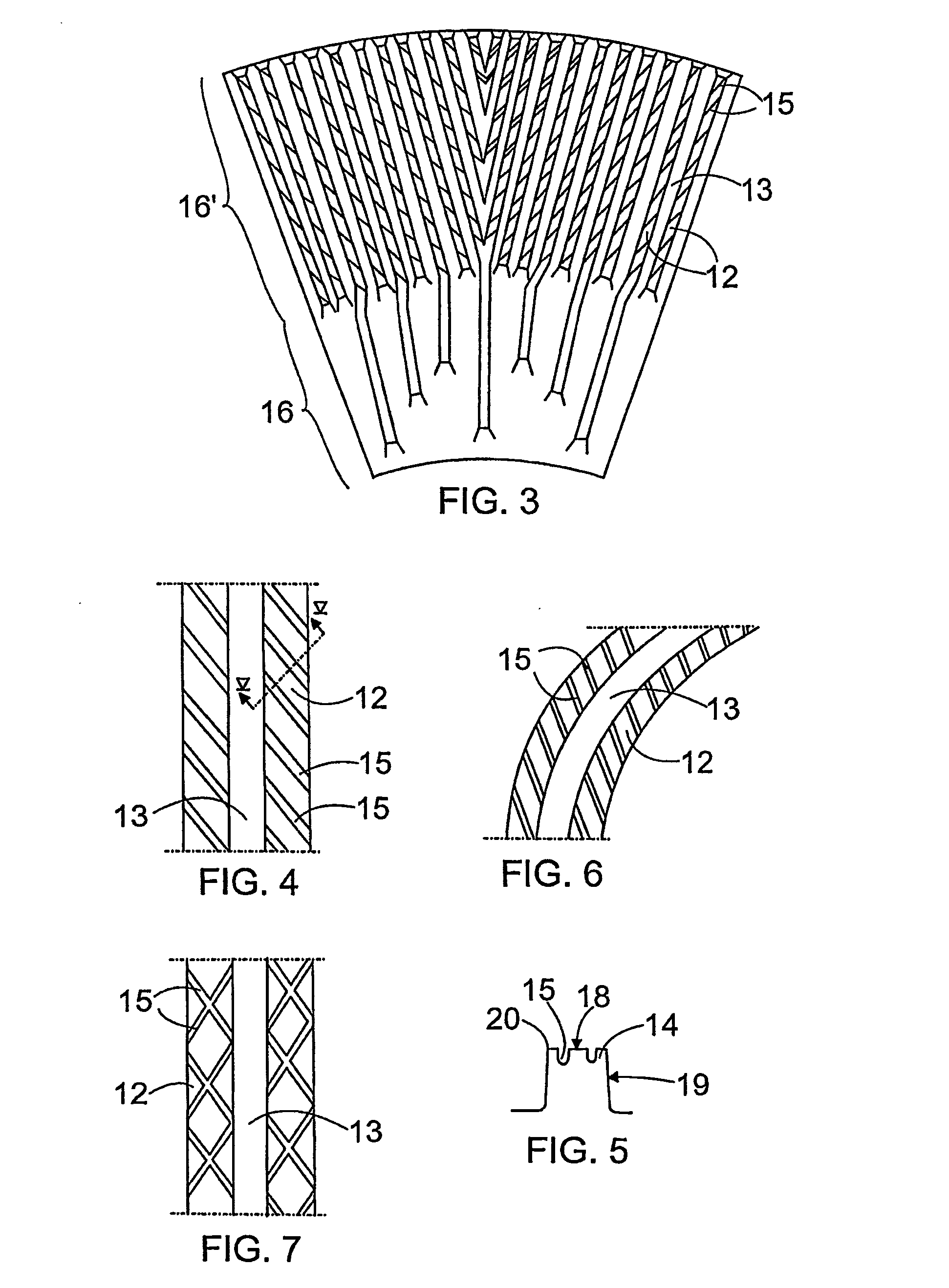

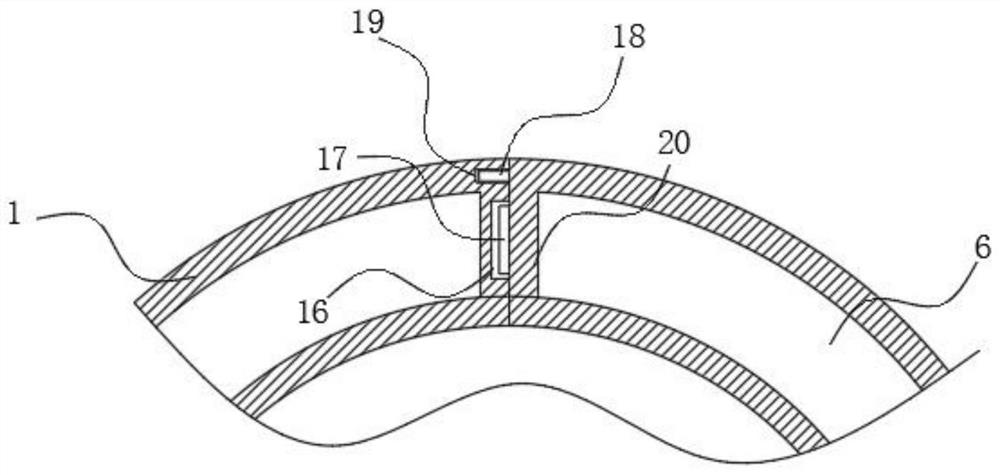

Refining surface and a blade segment for a refiner

ActiveUS20070084952A1Large capacityIncrease cutting lengthCocoaGrain treatmentsMaterials scienceMetallurgy

Owner:VALMET TECH INC

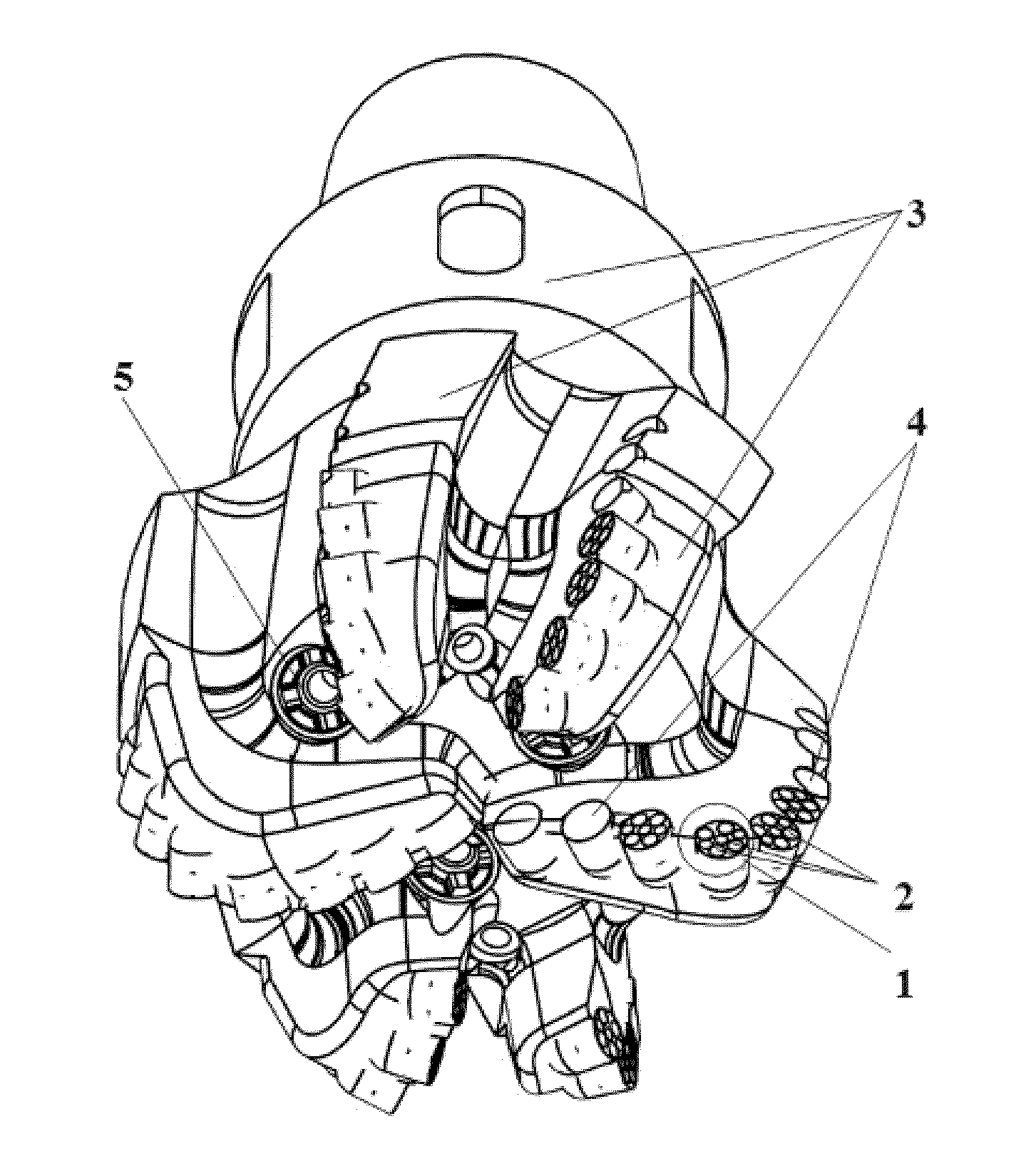

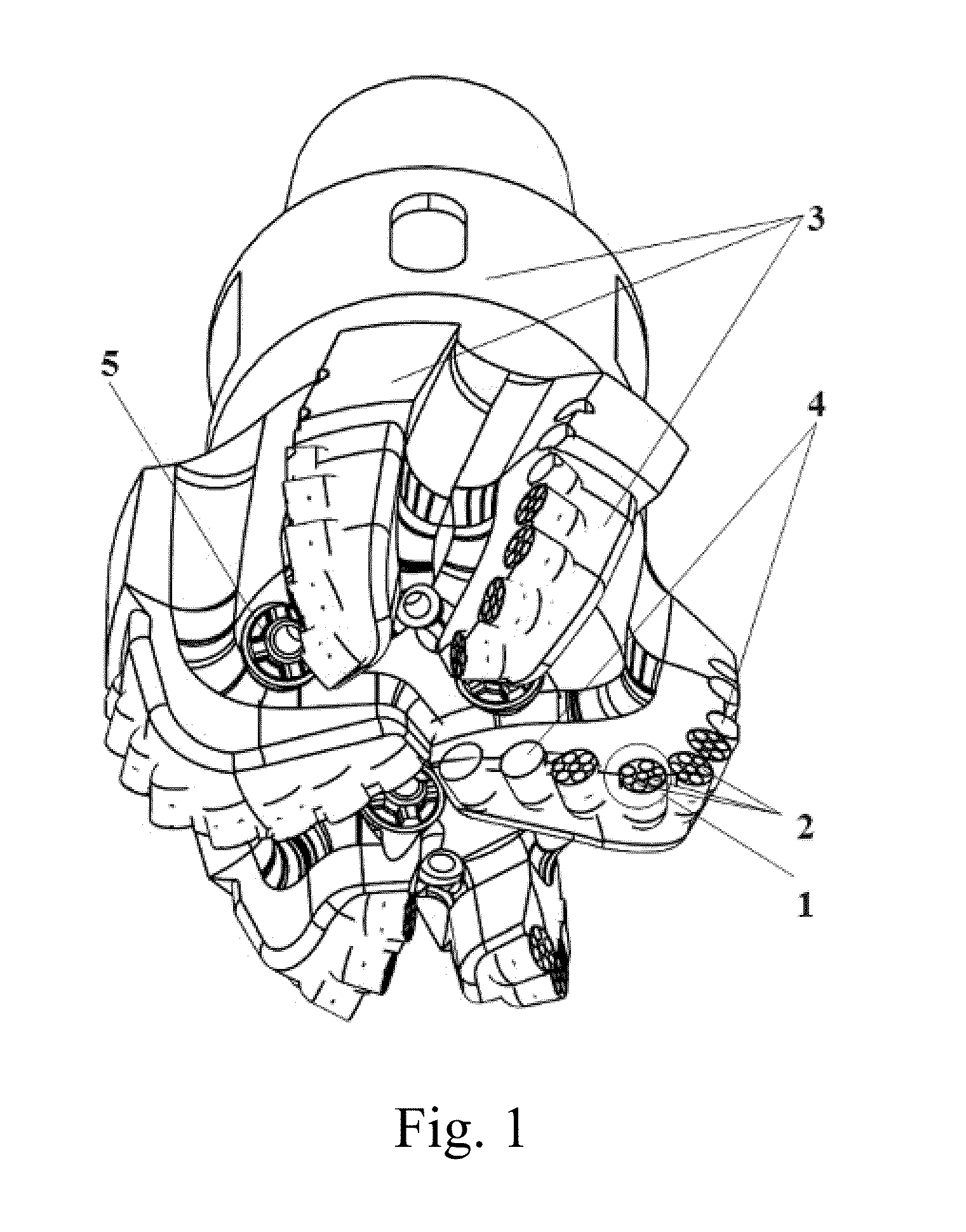

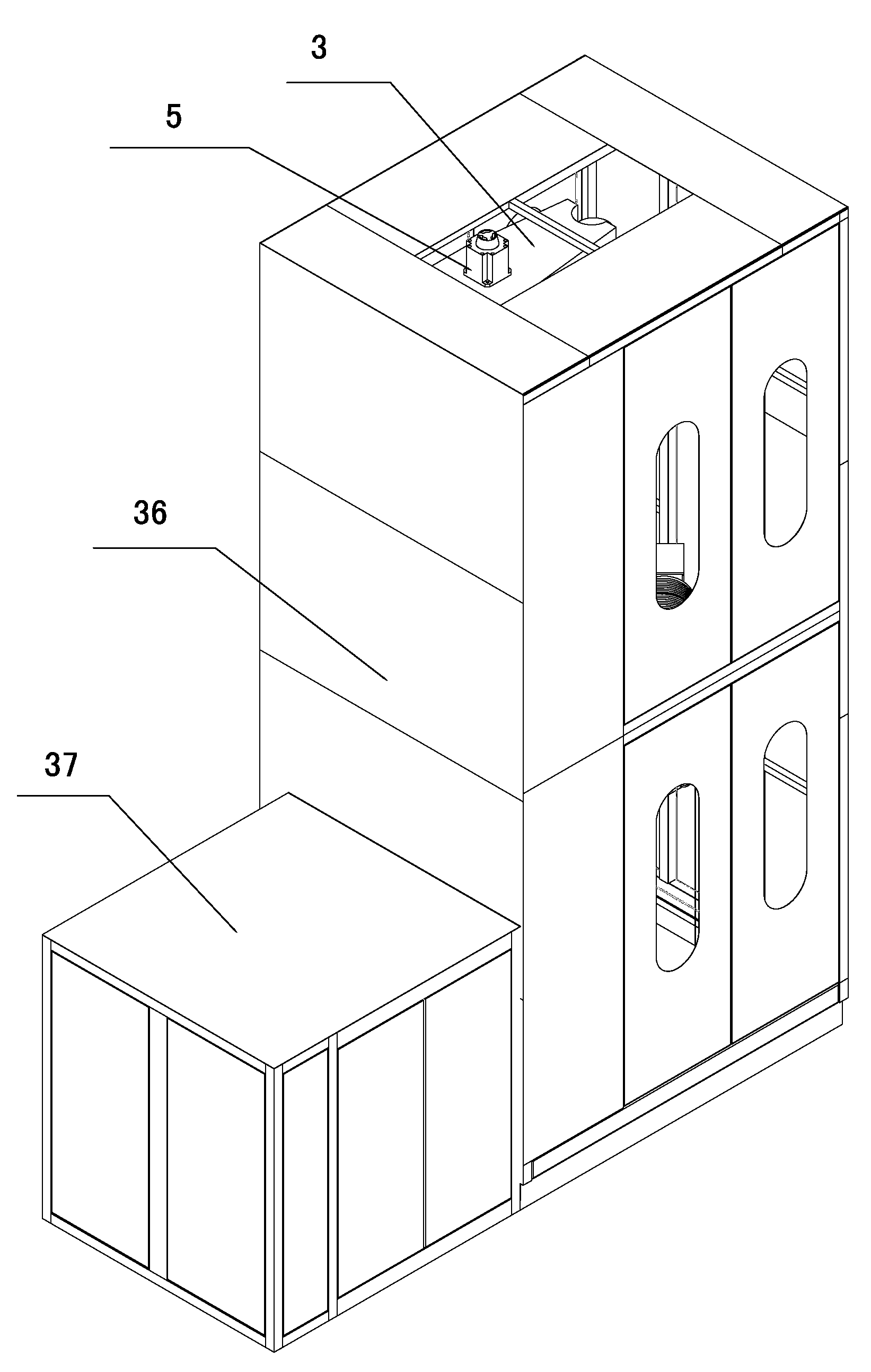

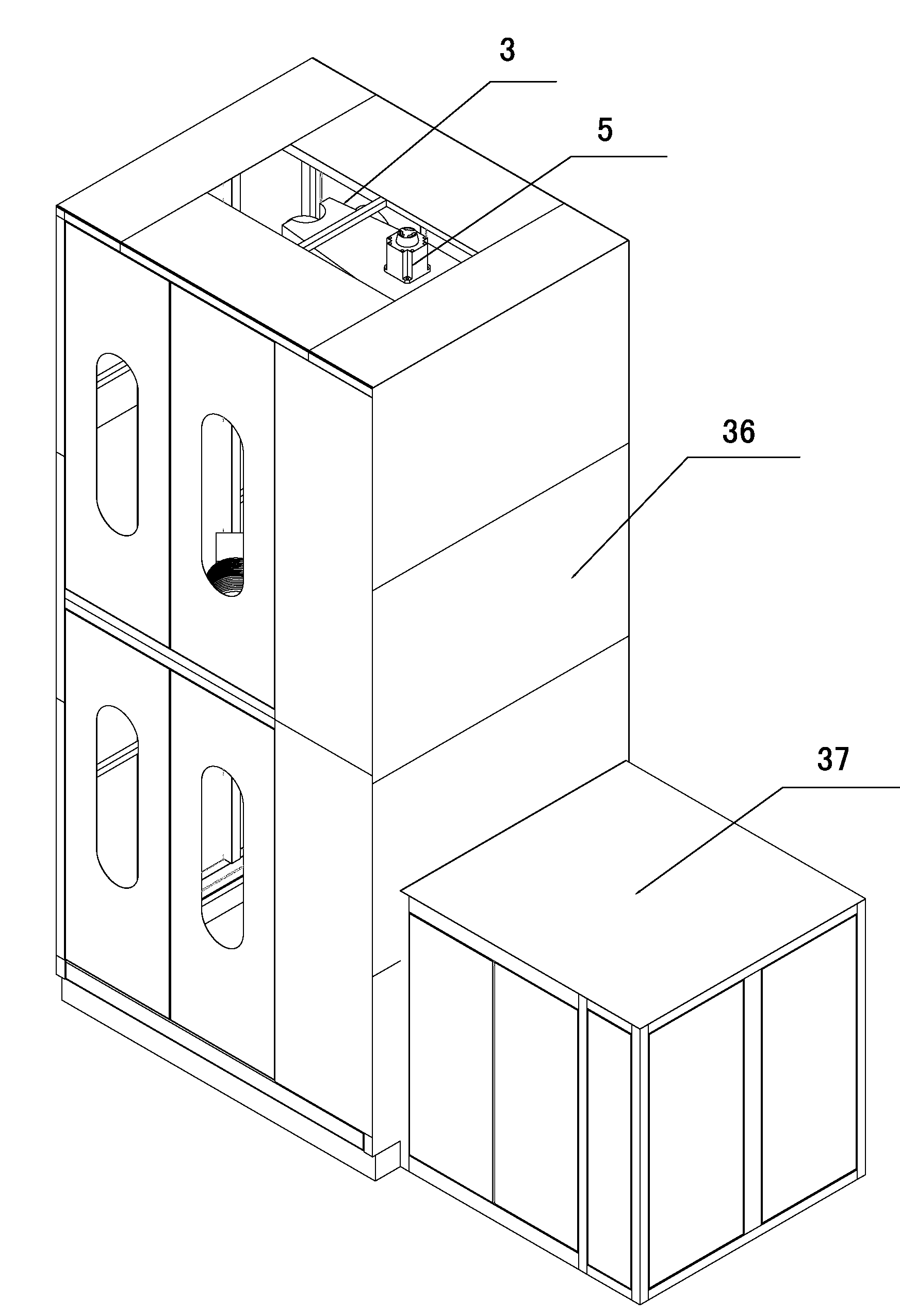

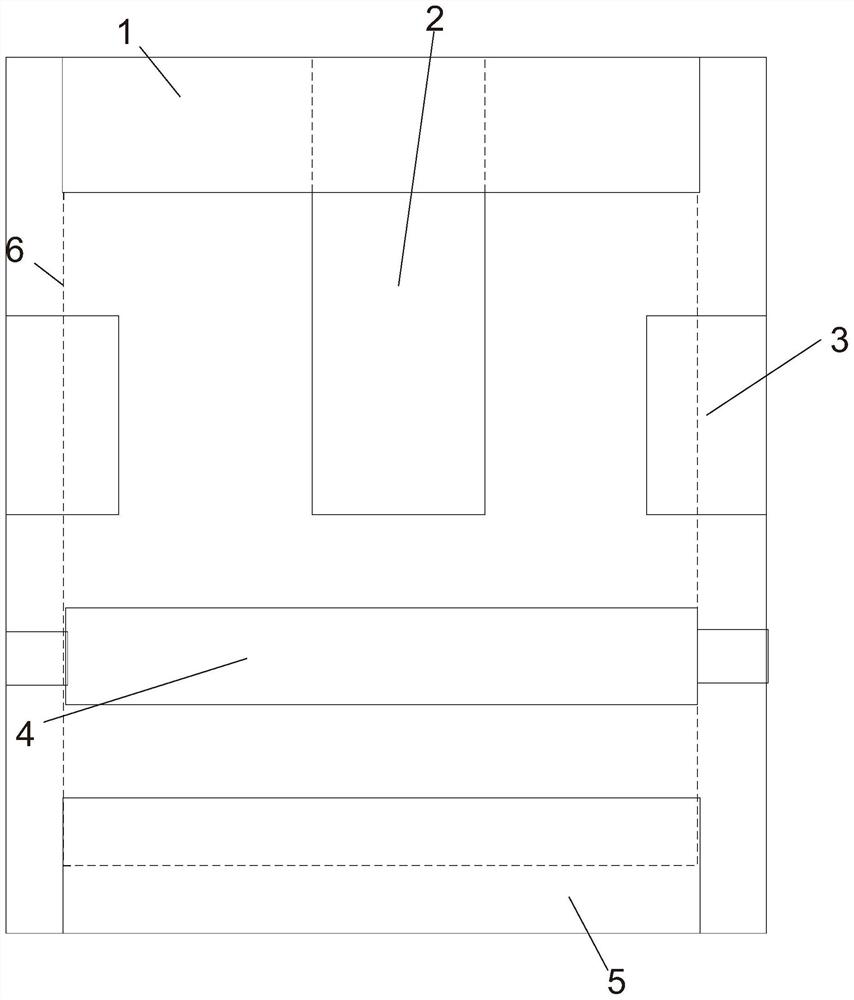

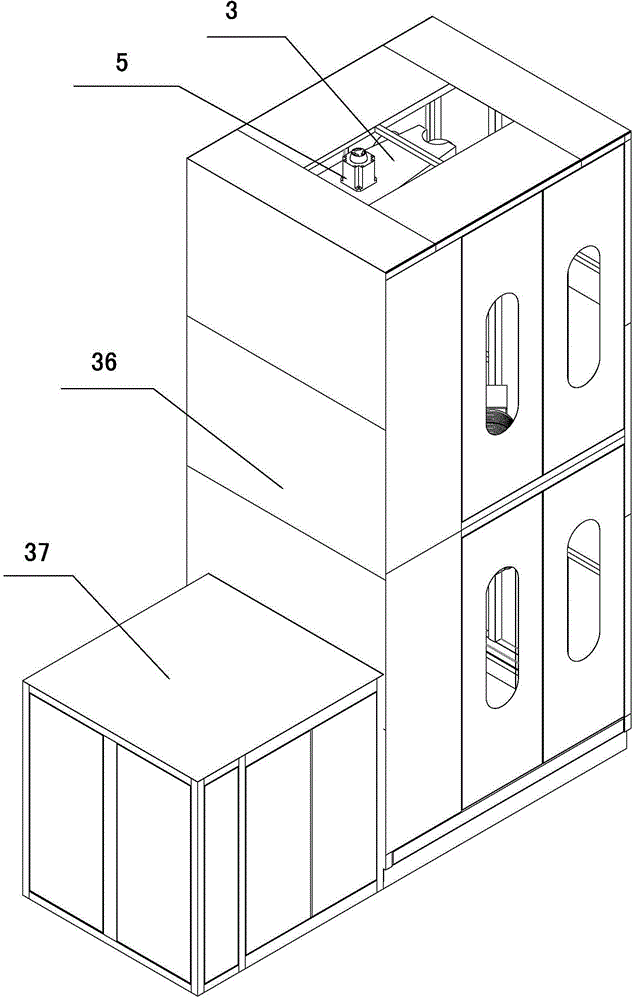

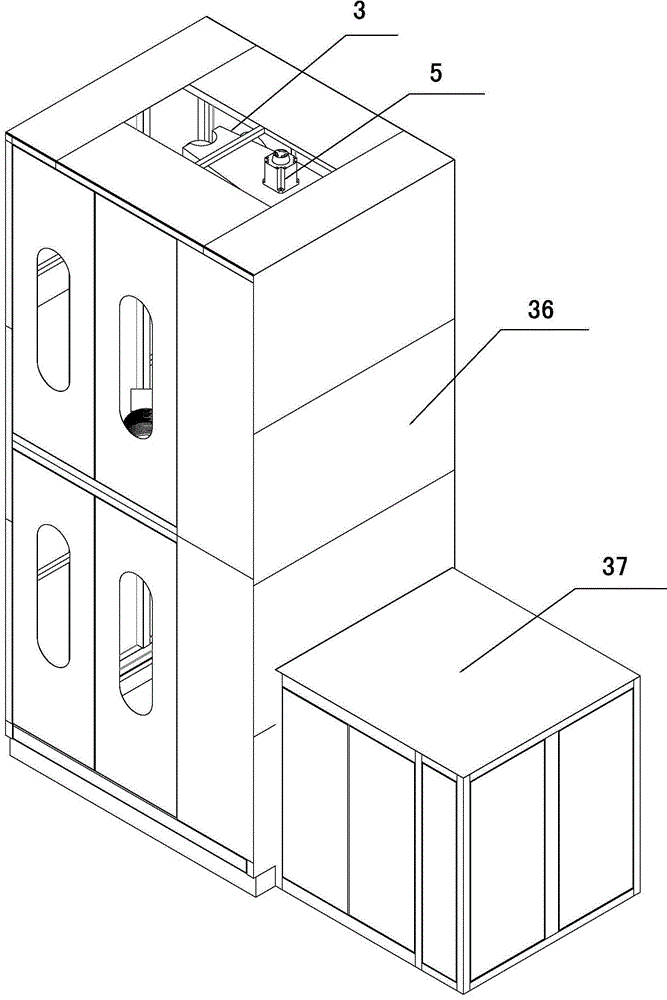

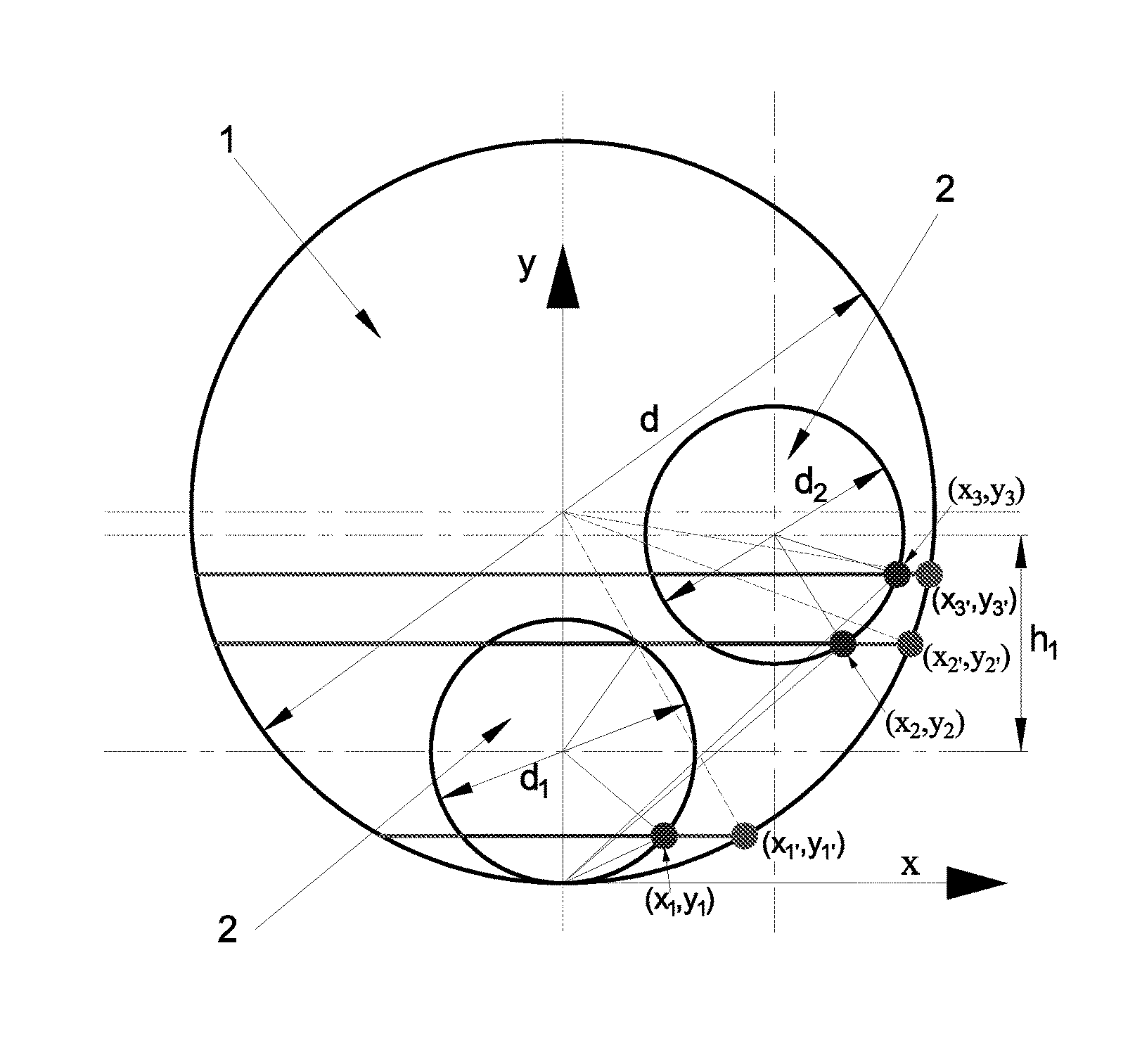

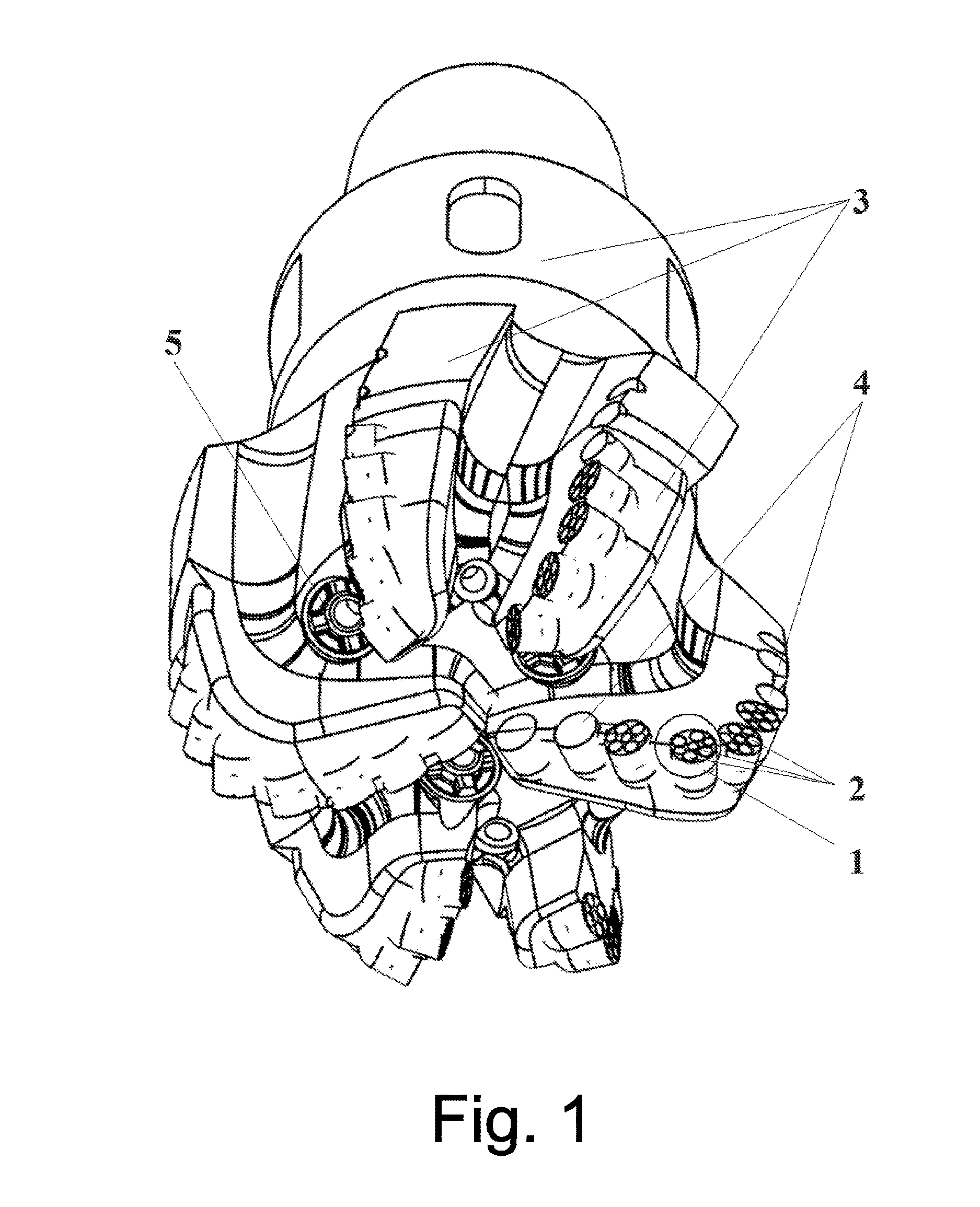

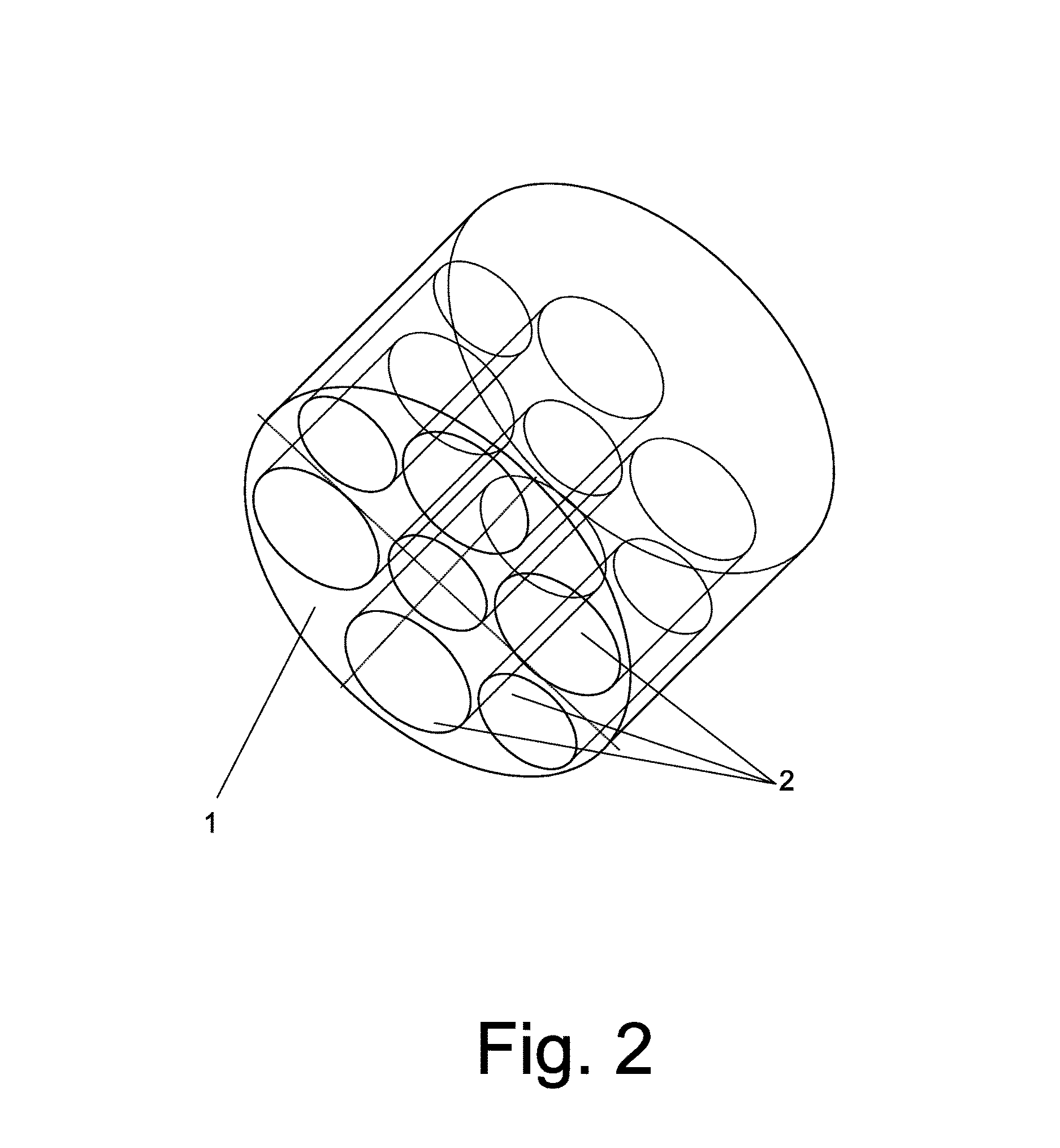

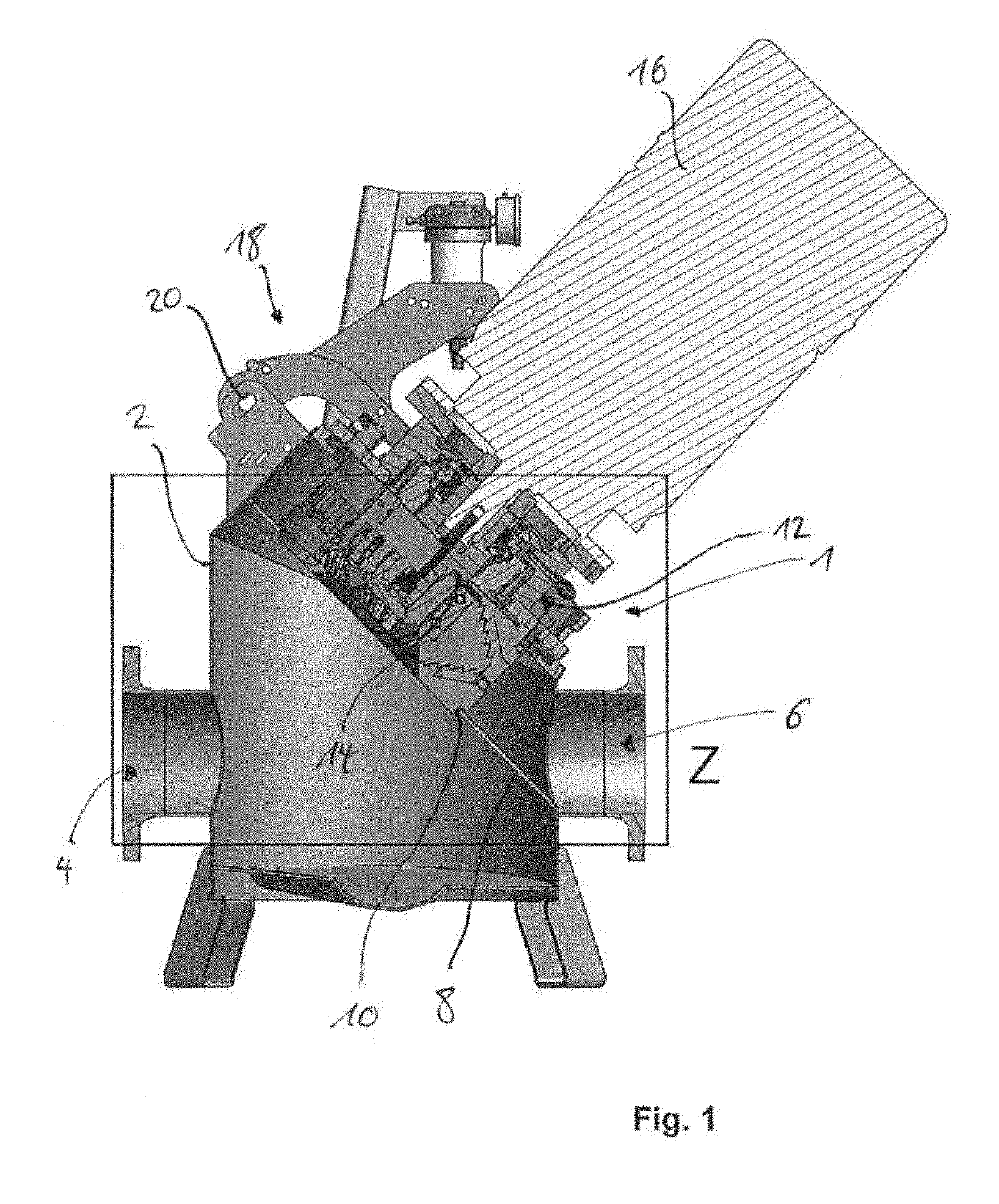

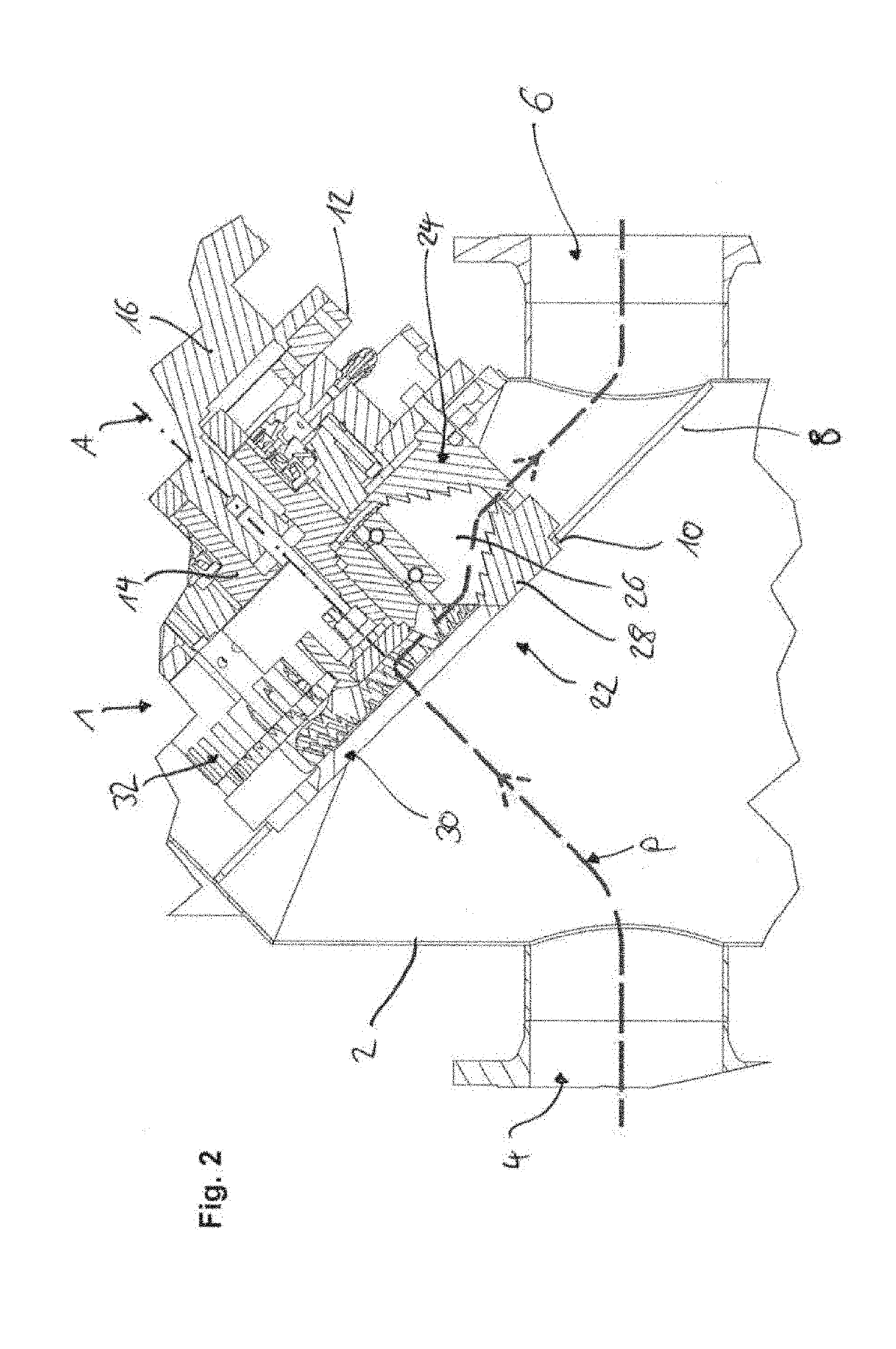

Modular cutting-teeth drill bit with controllable drilling specific pressure

ActiveUS20130341100A1Convenient ArrangementImprove performanceDrill bitsConstructionsModular unitEngineering

A modular cutting-teeth drill bit with controllable drilling specific pressure comprises a module (1), a modular unit (2), a bit body (3), conventional cutting teeth (4) and a nozzle (5). According to mechanical performance of the rocks in the strata drilled and requirements of drilling well, a combination of shapes, sizes and numbers of the module and the modular unit is optimized; effective abrasion edge length of the cutting element on a certain portion of the bit is controlled; and a constant specific pressure of the cutting element of the bit during the drilling process is maintained. The modular cutting-teeth bit substantially improves the effective abrasion volume of the cutting element, and improves the effective utilization rate of the cutting element.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

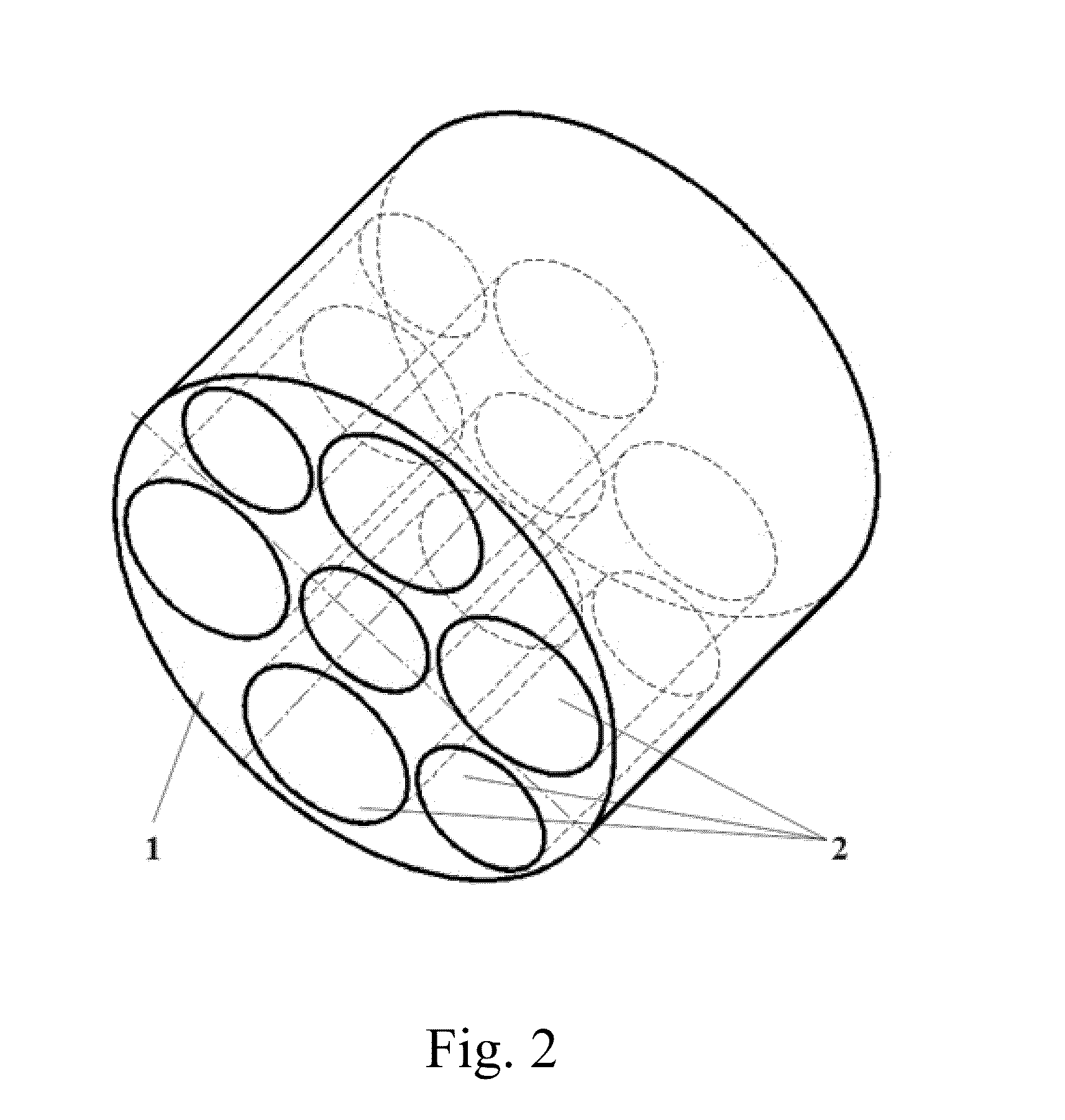

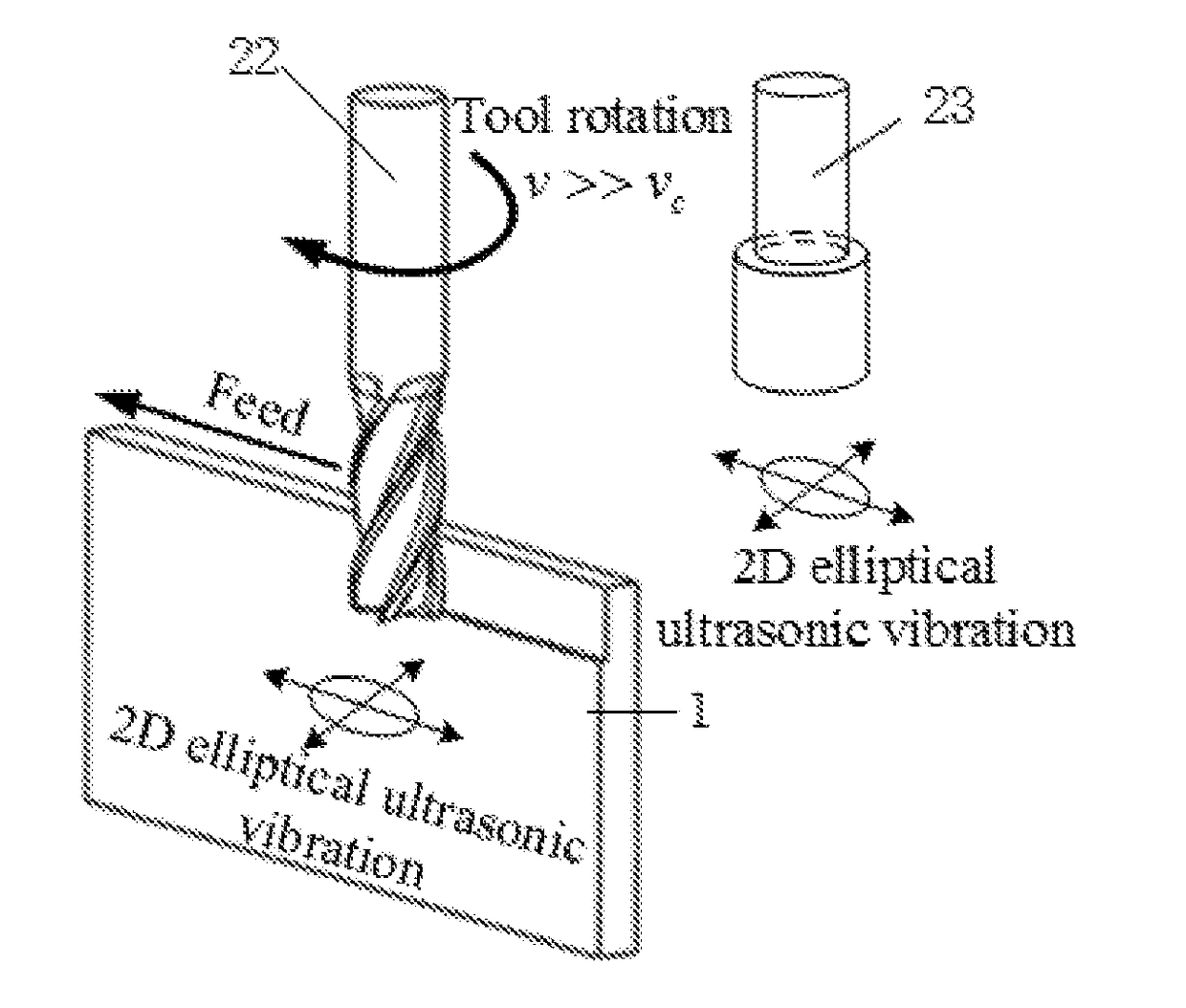

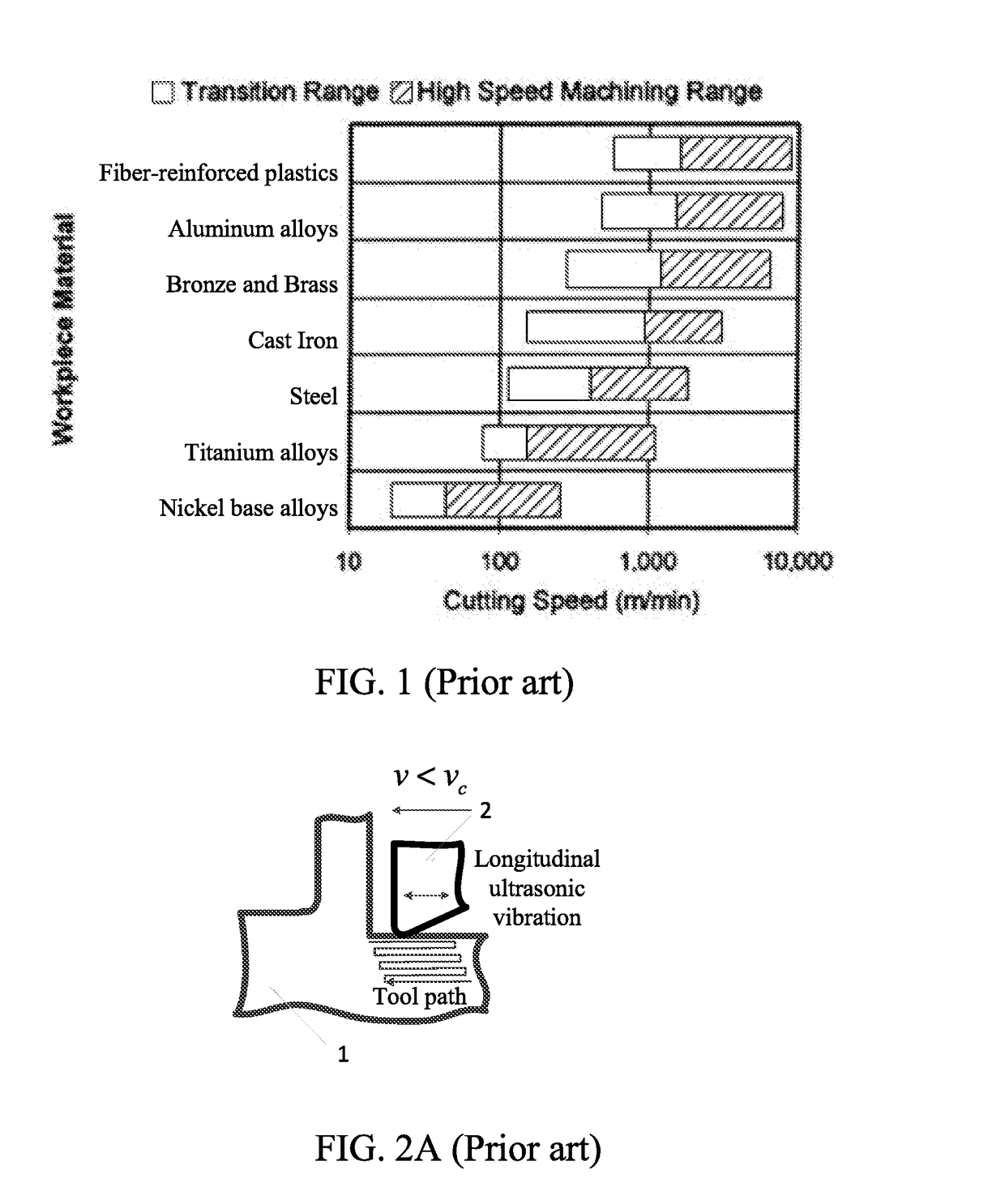

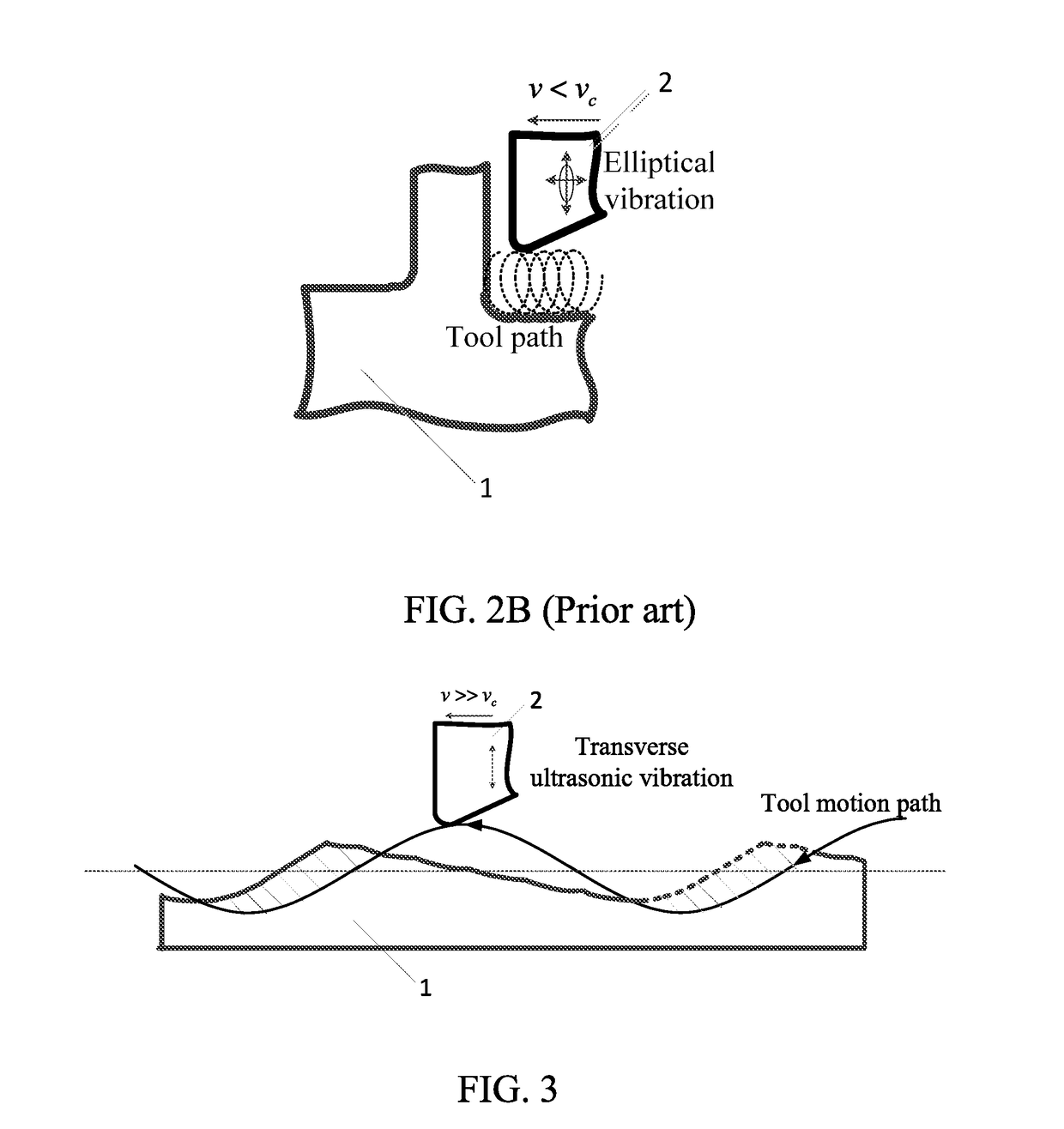

High-speed precision interrupted ultrasonic vibration cutting method

ActiveUS20170100781A1Low cutting speedMachining efficiency is limited largelyAircraft componentsWorkpiecesAviationEngineering

A high-speed precision interrupted ultrasonic vibration cutting method includes steps of: (1) installing an ultrasonic vibration apparatus on a machine tool, and stimulating a cutting tool to generate a transverse vibration, so as to realize varieties of machining processes; (2) realizing an interrupted cutting process by setting cutting parameters and vibration parameters to satisfy an interrupted cutting conditions; and (3) turning on the ultrasonic vibration apparatus and the machine tool, and starting a high-speed precision interrupted ultrasonic vibration cutting process. High-speed precision interrupted ultrasonic vibration cutting is able to be realized through the above steps during machining of difficult-to-machine materials in aviation and aerospace fields. A cutting speed is enhanced significantly, and exceeds a critical cutting speed of a conventional ultrasonic vibration cutting method and an elliptical ultrasonic vibration cutting method and even a high speed range of a traditional cutting method.

Owner:BEIHANG UNIV

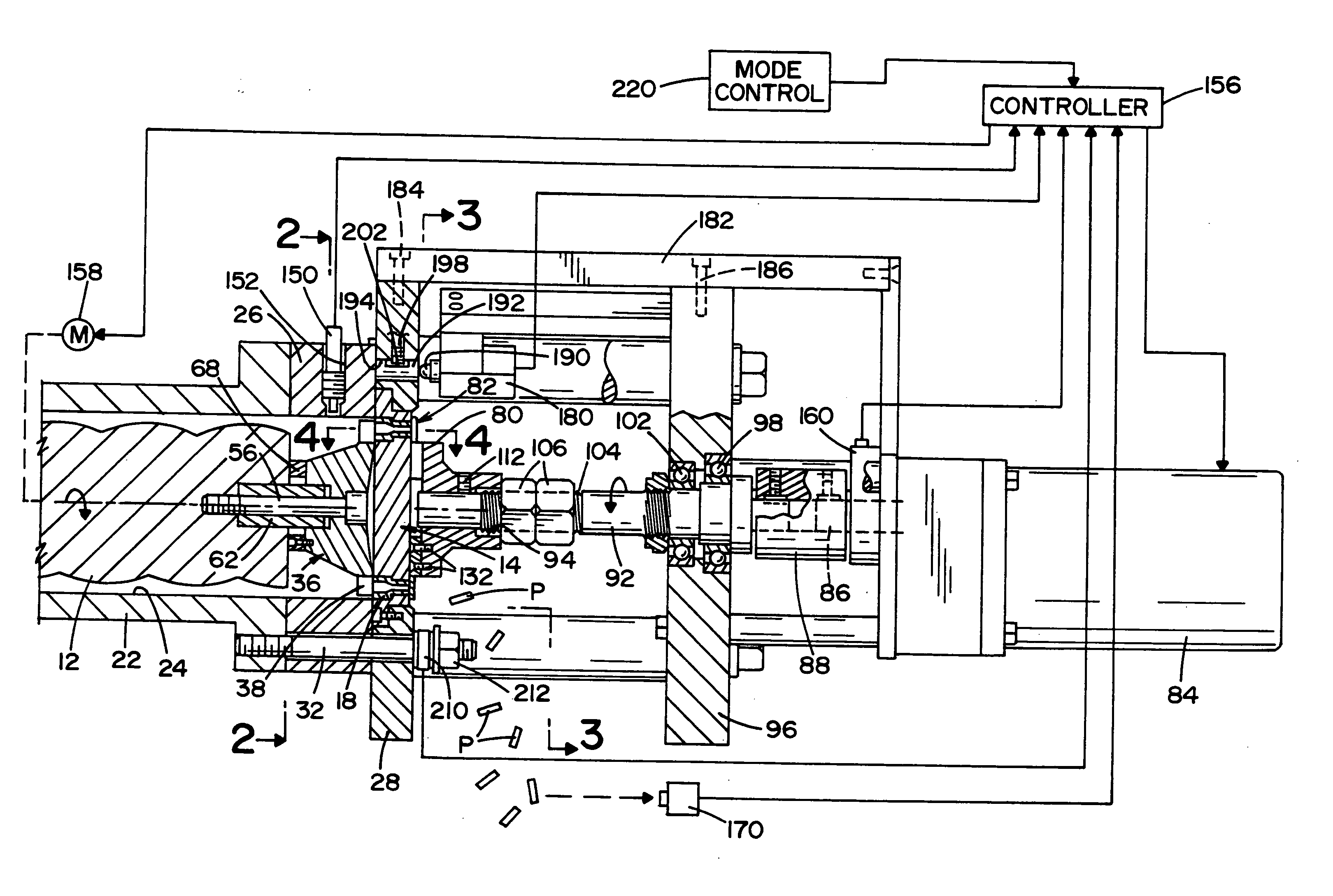

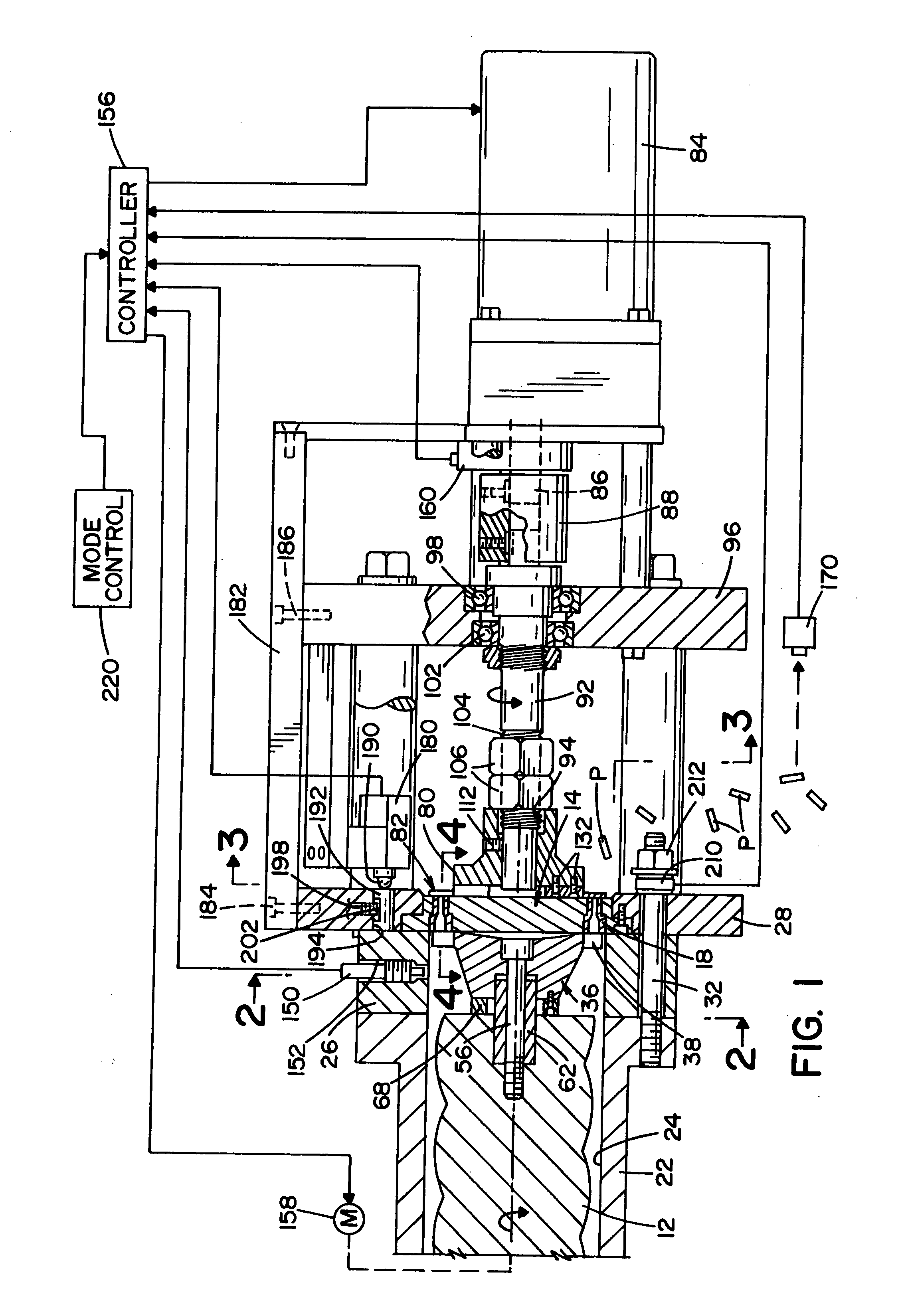

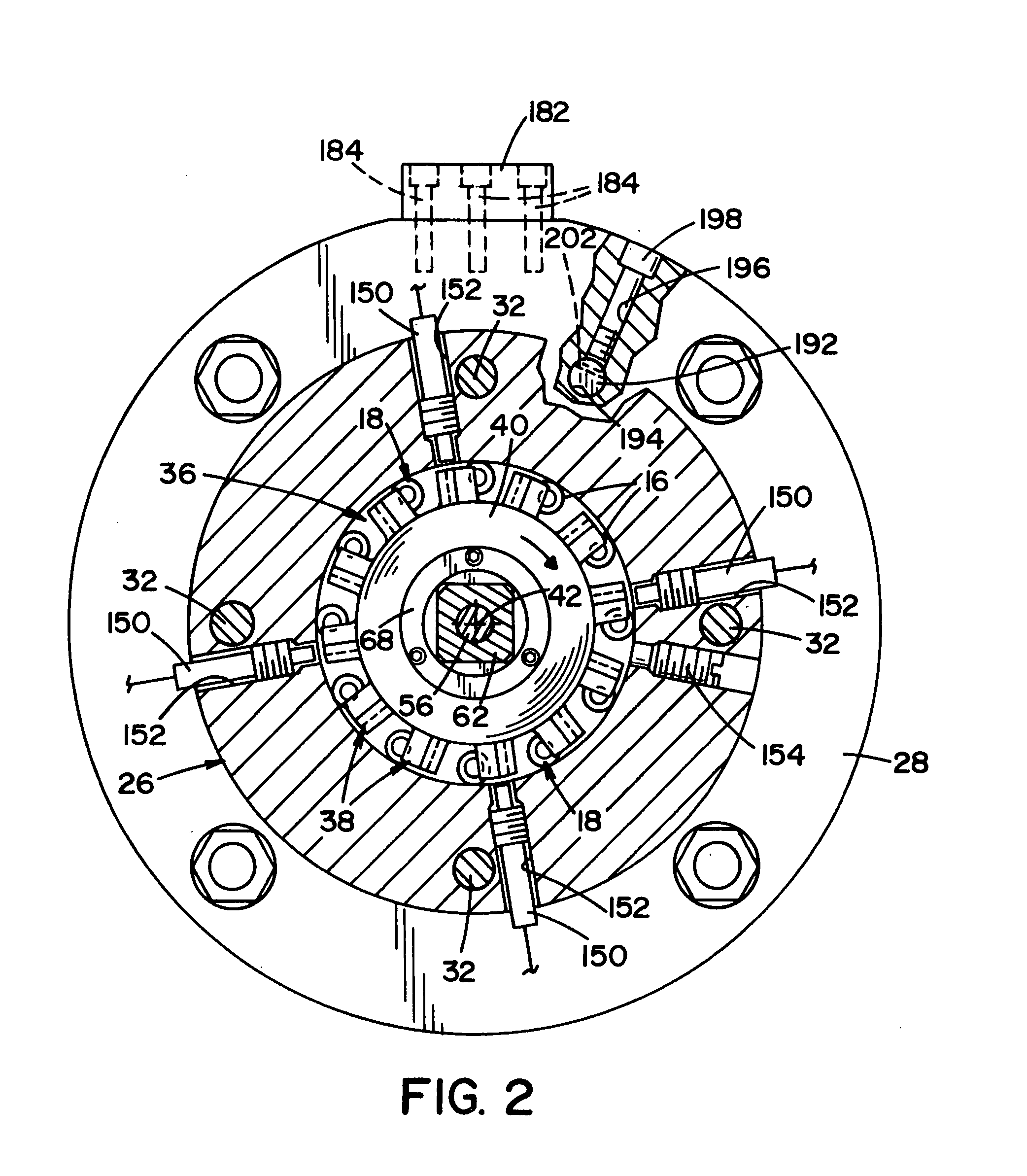

Pulse wave modulator cutting assembly

ActiveUS20070259067A1Increase the number ofReduce throughputMouldsFrozen sweetsEngineeringPulsed wave

A cutting assembly for cutting a material extruded from a die can include a wiper adapted to connect to an auger or a rotating member, a die holder plate disposed adjacent the wiper, a cutter member disposed downstream from the die holder plate, and a pressure sensor.

Owner:JMP INDS

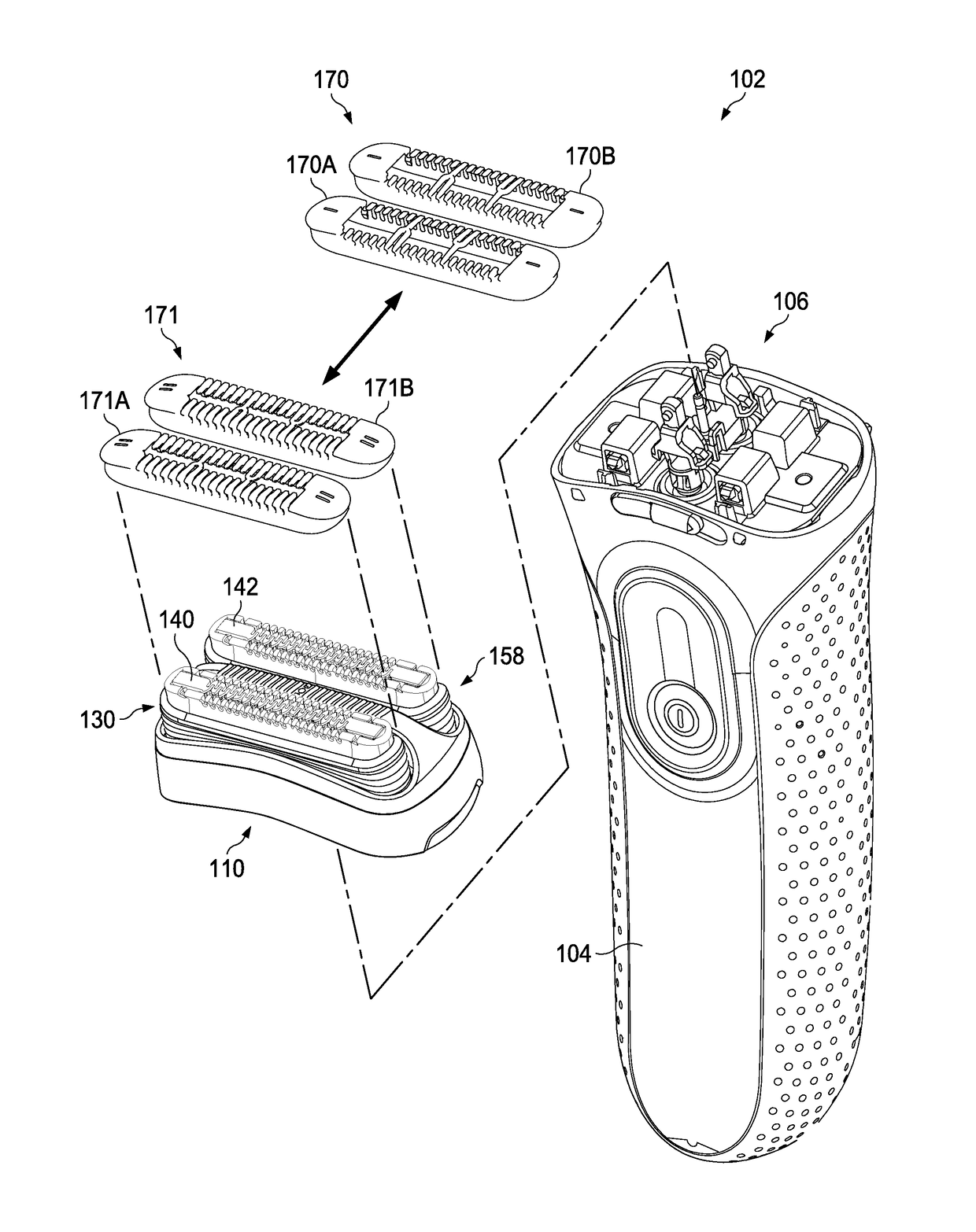

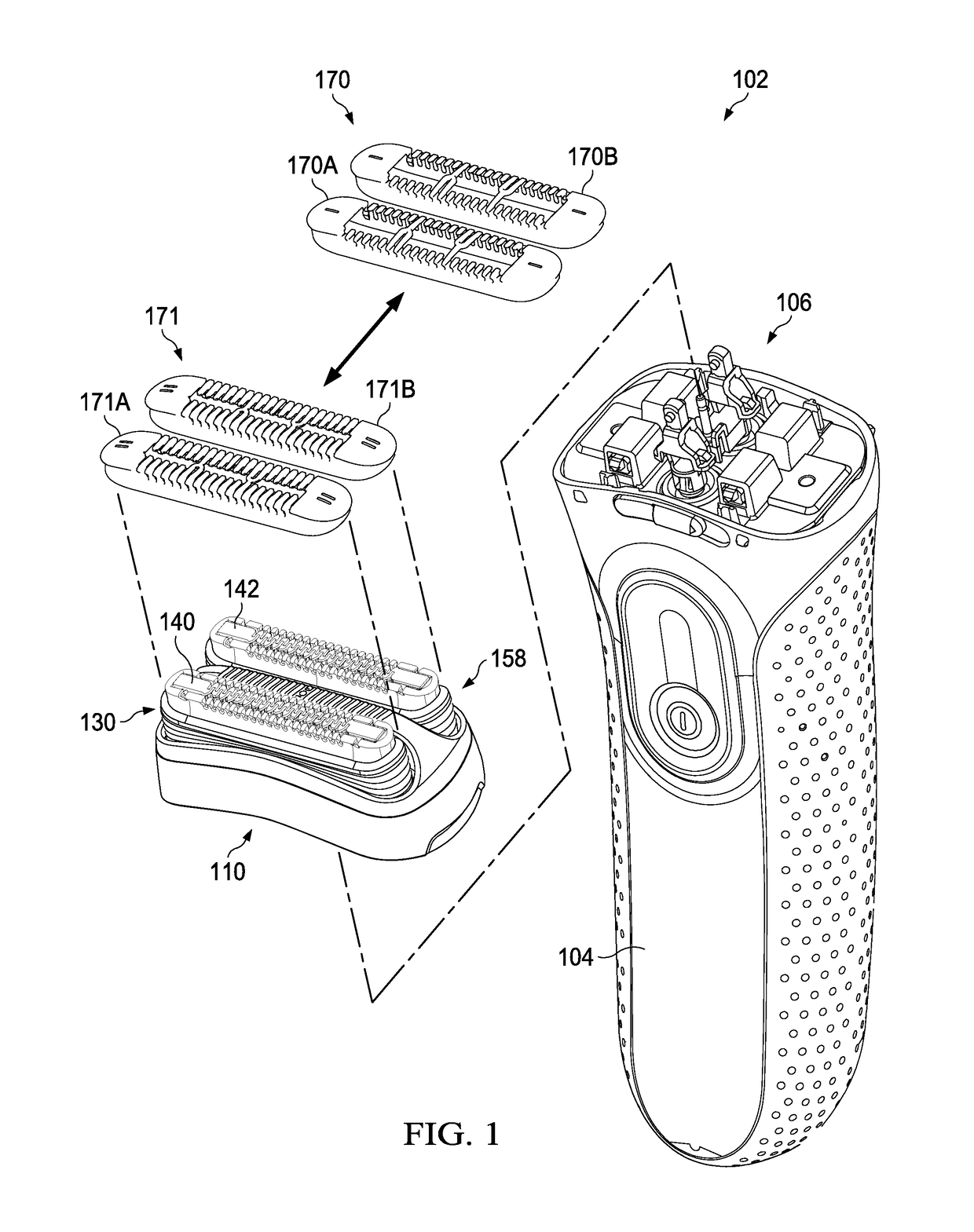

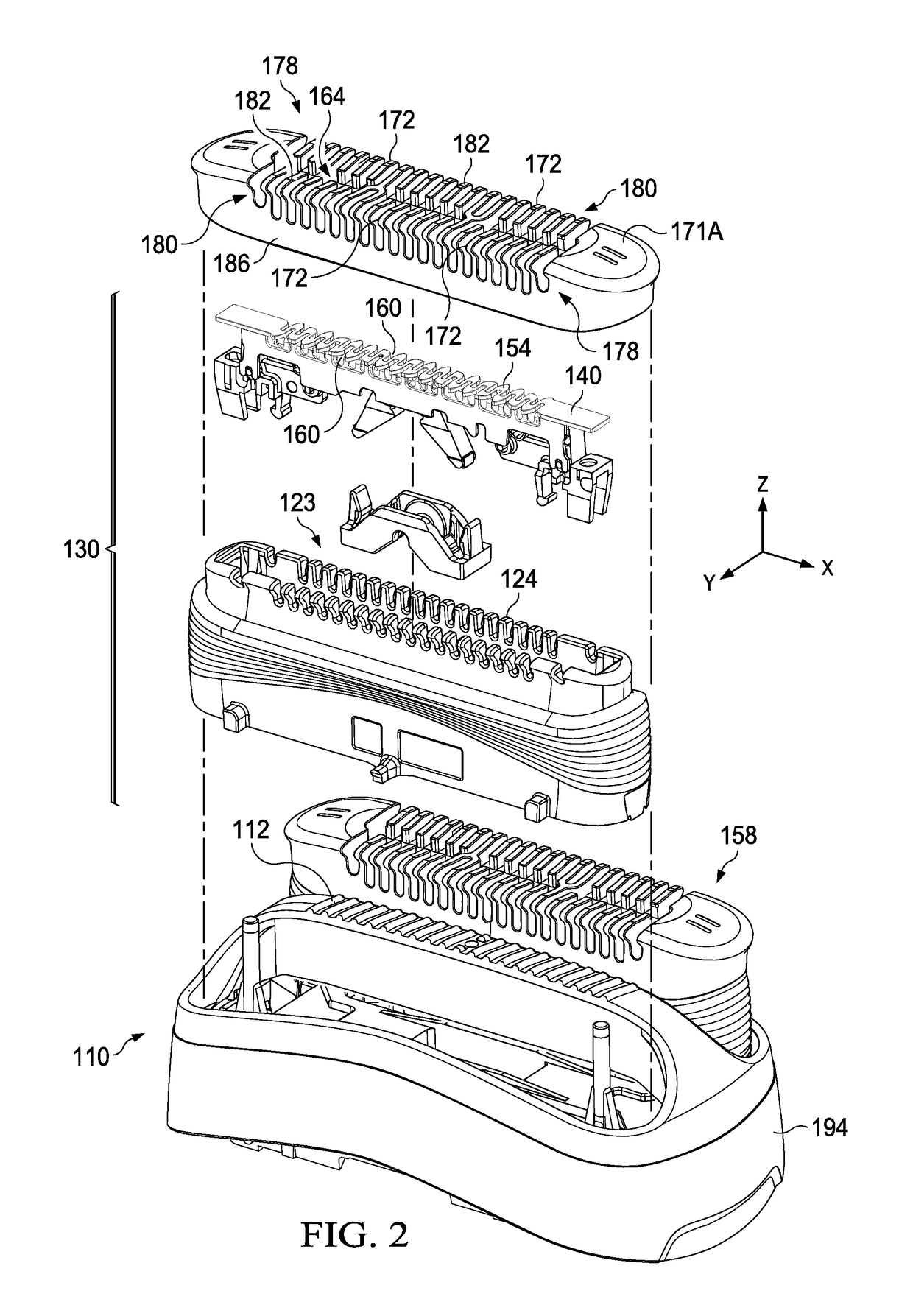

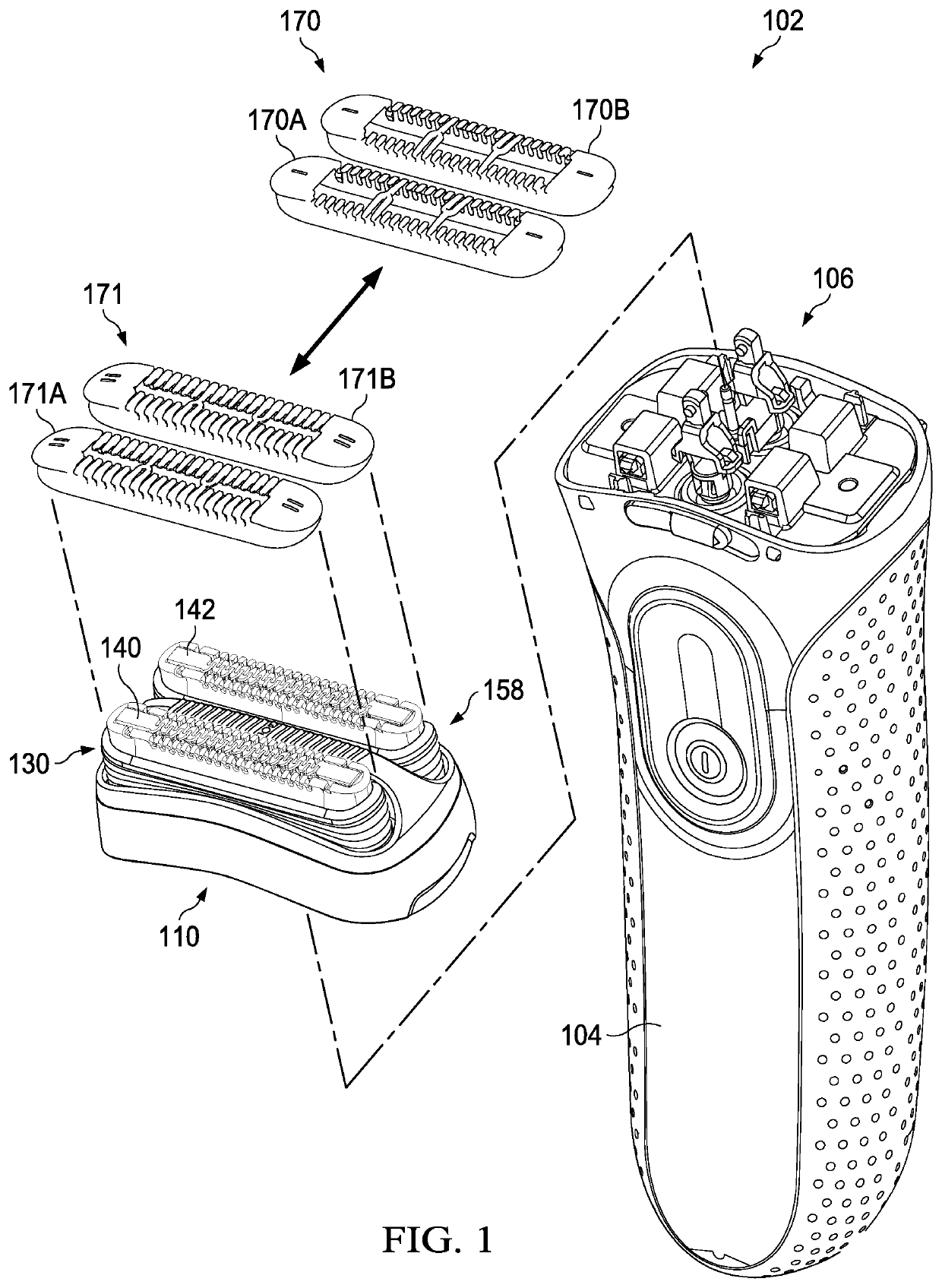

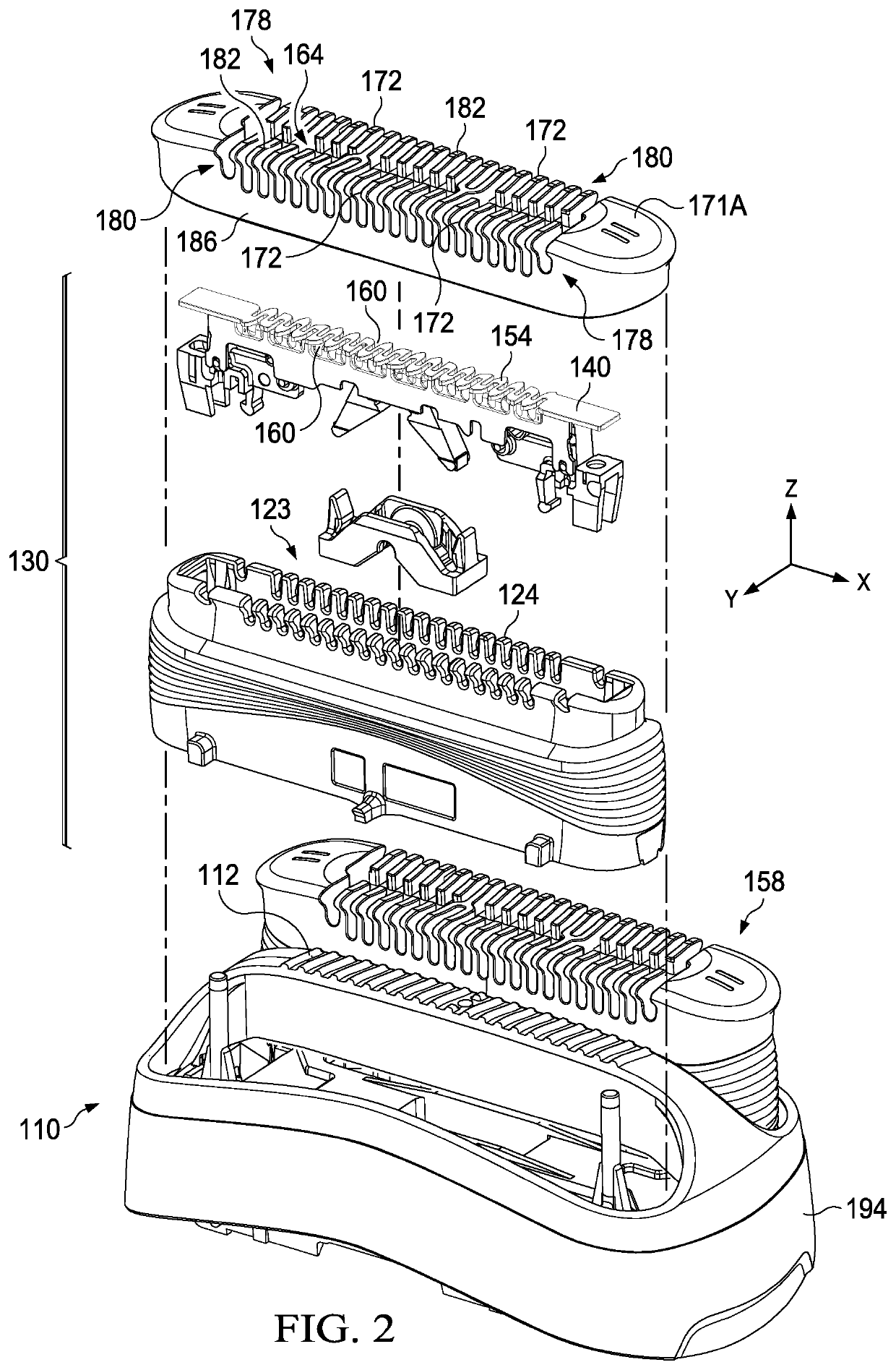

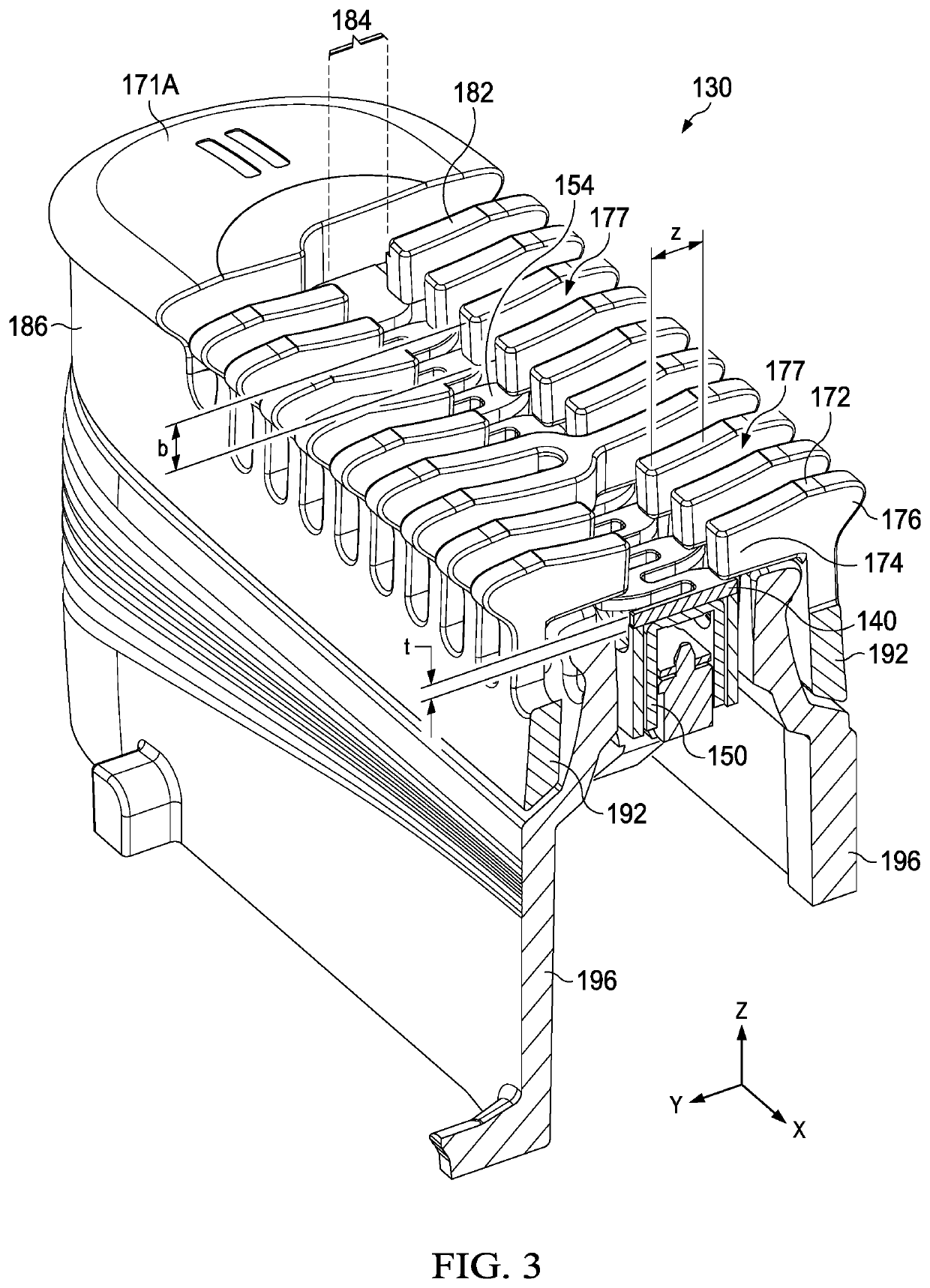

Beard trimmer

ActiveUS20180085943A1Increase contour followingImprove usabilityMetal working apparatusRazor BladeStructural engineering

An electric hair cutting kit comprises a handle with a motor for driving a beard trimmer head portion and a shaver head portion. The shaver head portion is attachable to the handle and has at least a first shaver unit, which is provided with a first foil-type outer shaver cutter and a first inner shaver cutter.

Owner:BRAUN GMBH

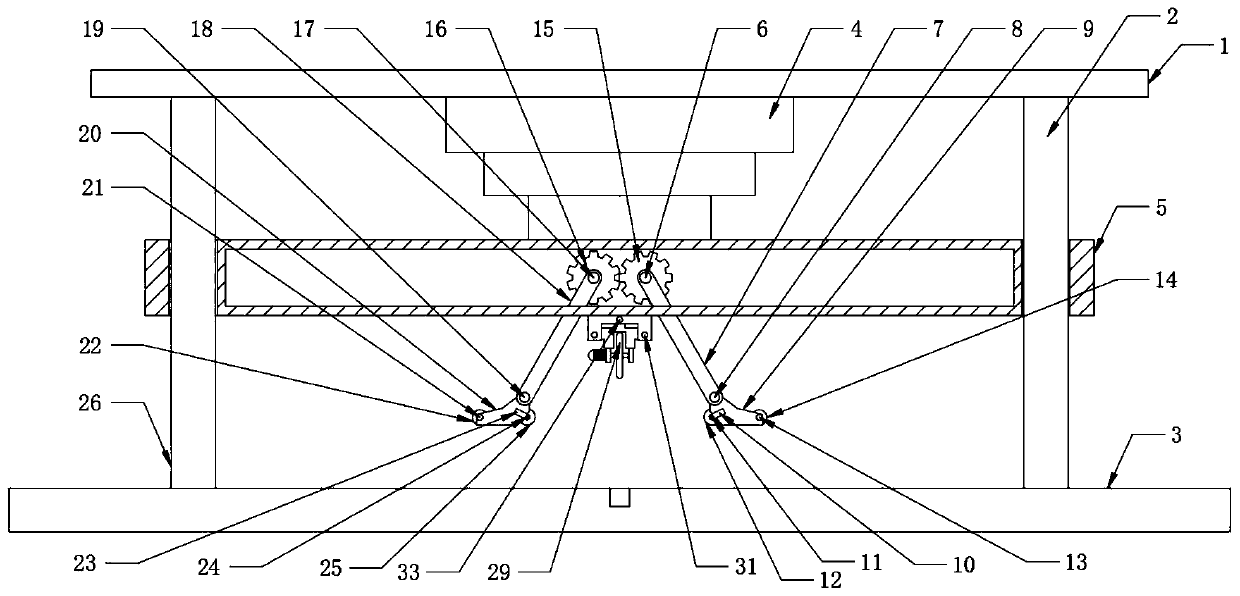

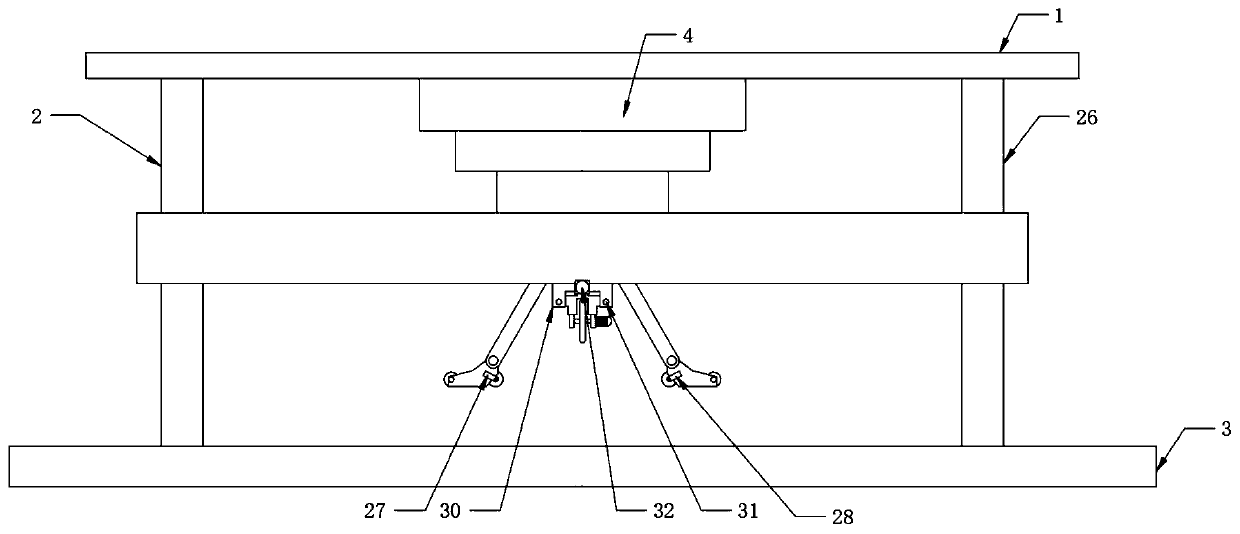

Textile fabric cutting device

The invention relates to the technical field of textile equipment, and discloses a textile fabric cutting device. The textile fabric cutting device comprises a top seat, a first guide rod and a base,wherein the bottom of the top seat is fixedly connected with the top end of the first guide rod; the bottom end of the first guide rod is fixedly connected with the top end of the base; and the bottomend of the top seat is fixedly connected with an air cylinder. According to the textile fabric cutting device, a transmission gear, a driven gear, a first transmission arm, a second transmission arm,a first pressing plate, a second pressing plate, a first right press roller, a second right press roller, a first left press roller, a second left press roller and the like are arranged; and after atransmission seat performs descending, and when the first pressing plate and the second pressing plate are in contact with the surface of cloth, the first pressing plate and the second pressing plateare pushed by the first transmission arm and the second transmission arm to simultaneously move towards the two ends of the cloth, and the cloth is straightened while the cloth is pressed, so that thecloth is prevented from wrinkling, the problem that the cloth needs to be pressed and fixed separately when the cloth is cut is solved, and the problem that the cutting area of the cloth is prone towrinkling is avoided.

Owner:南通市联缘染业有限公司

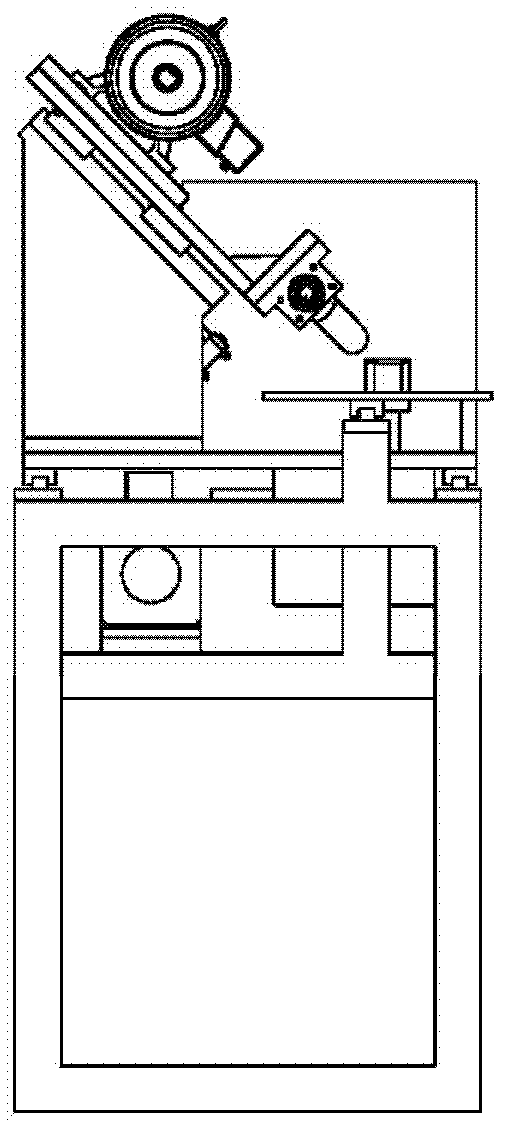

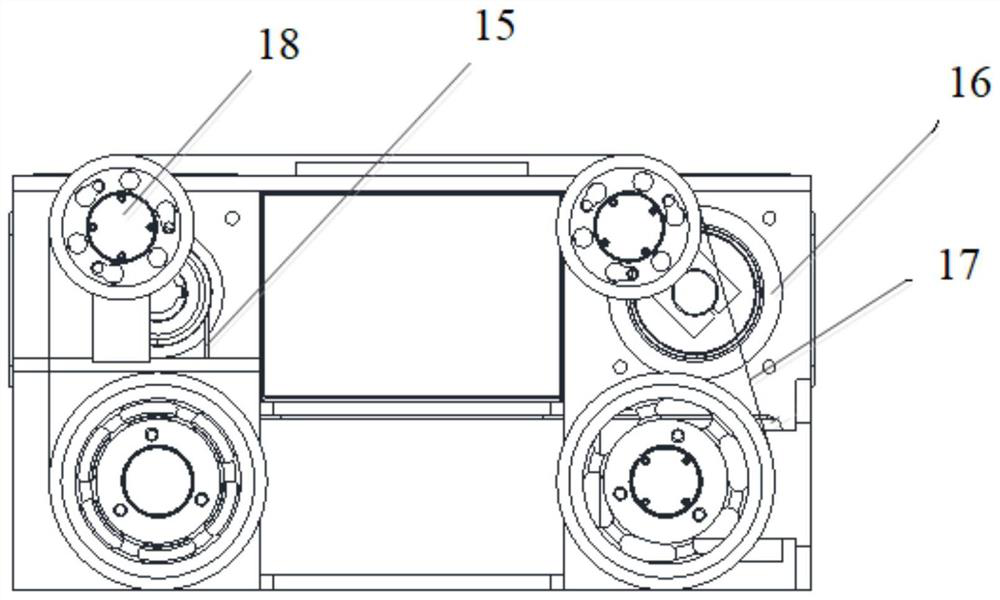

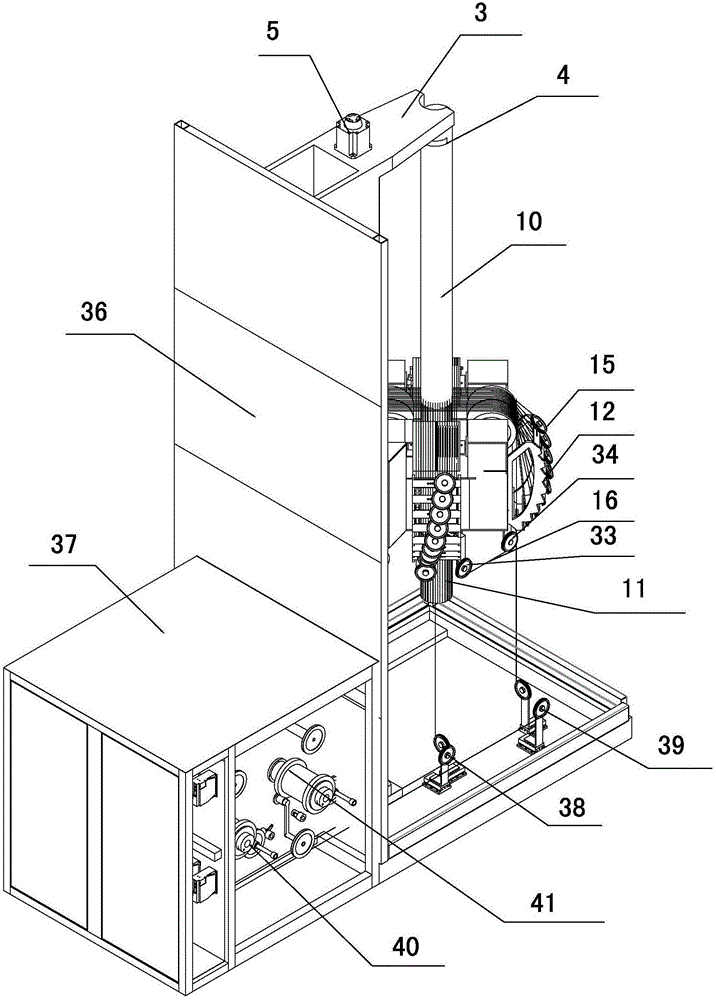

Silicon wafer wire cutting machine

PendingCN107379297AImprove cutting efficiencyReduce losses such as shortingFine working devicesWire cuttingElectric machinery

The invention discloses a silicon wafer wire cutting machine. The silicon wafer wire cutting machine comprises a frame, a cutting chamber and a wire barrel chamber. The cutting chamber is internally provided with a cutting head and a winding and unwinding wheel tool. The wire barrel chamber comprises a main plate, a winding and unwinding wheel unit, two wire guiding wheel tools arranged below winding and unwinding wheels, wire guiding wheel tool movable bases connected with the wire guiding wheel tools, two transverse movement frames, two tension arm motors, tension arms connected with the tension arm motors, and tension arm guiding wheels arranged at the lower ends of the tension arms, and the transverse movement frames are horizontally arranged. The silicon wafer wire cutting machine has the beneficial effects that the guiding wheel arrangement structure is optimized, the wire barrel installing manner is horizontal installation, the winding displacement load of horizontal installation is uniform, and the number of guiding wheels is reduced; and due to reduction of the number of the wire guiding wheels, the breaking tension of a steel wire is increased firstly, and then fluctuation of tension entering a wire net becomes small; and jumping of the wire barrel is weak, winding displacement is more stable, and arm swinging is stable when the tension arms run. By means of the silicon wafer wire cutting machine, broken wires are effectively monitored, and wire net empty pulling and other losses caused by wire breaking are reduced.

Owner:江阴市展照科技有限公司

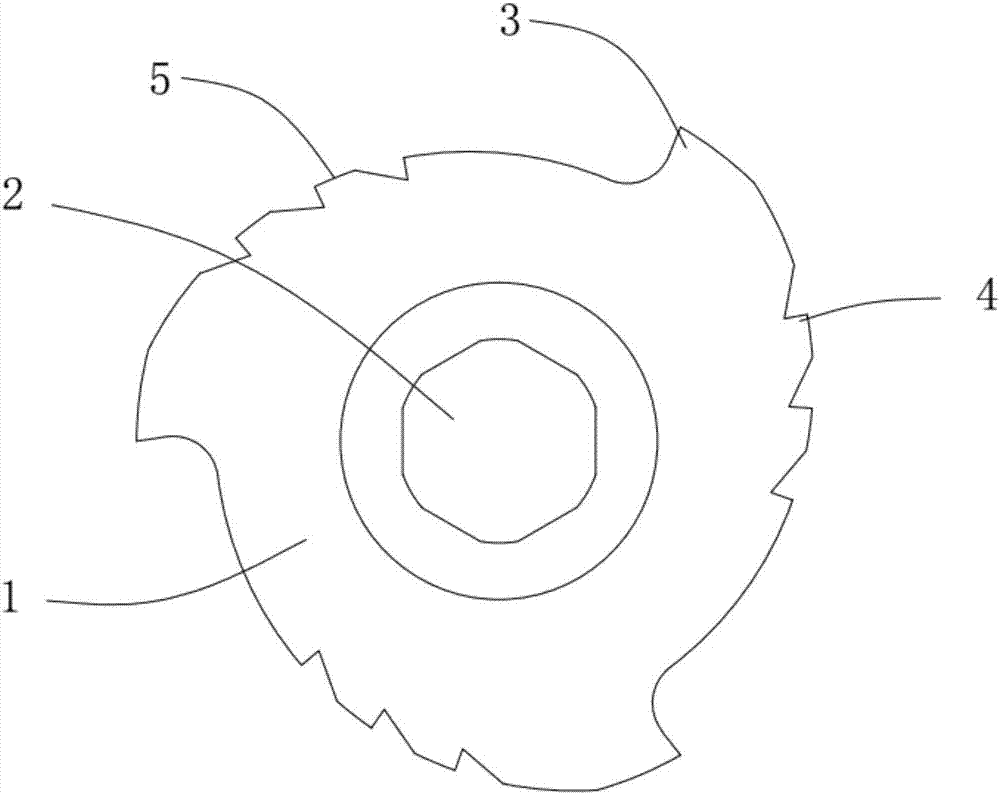

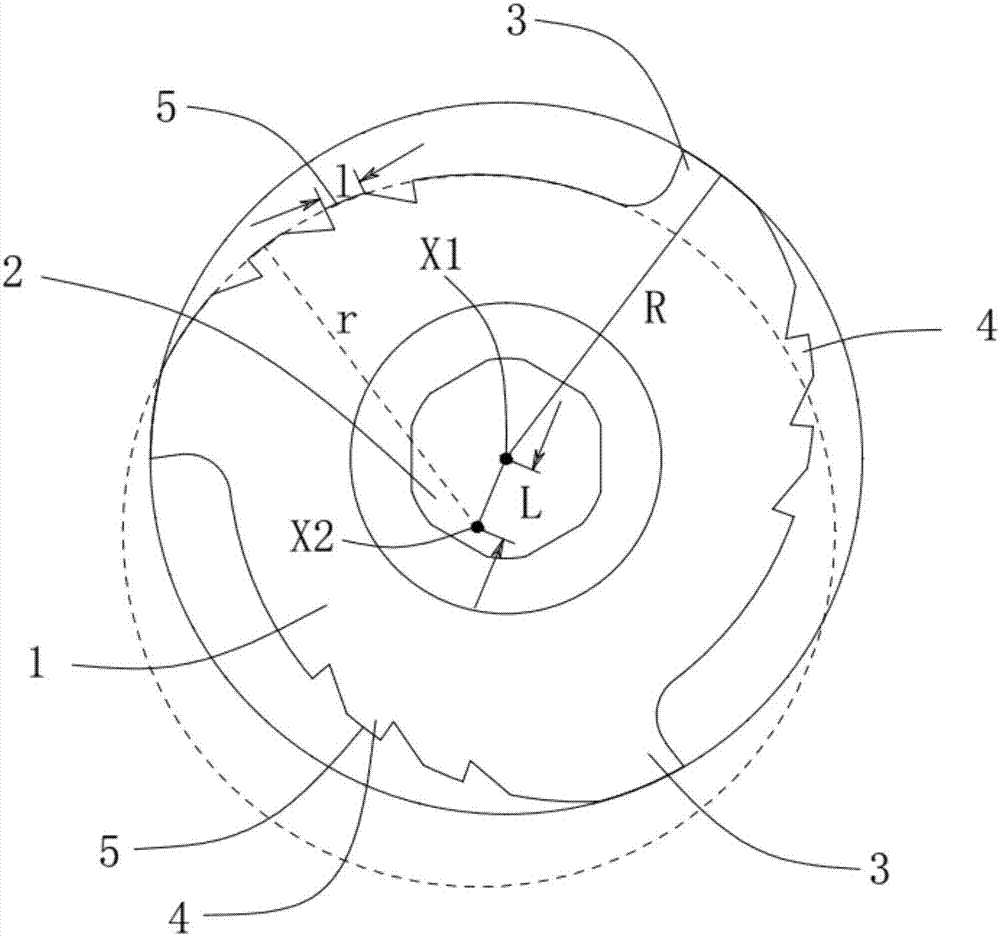

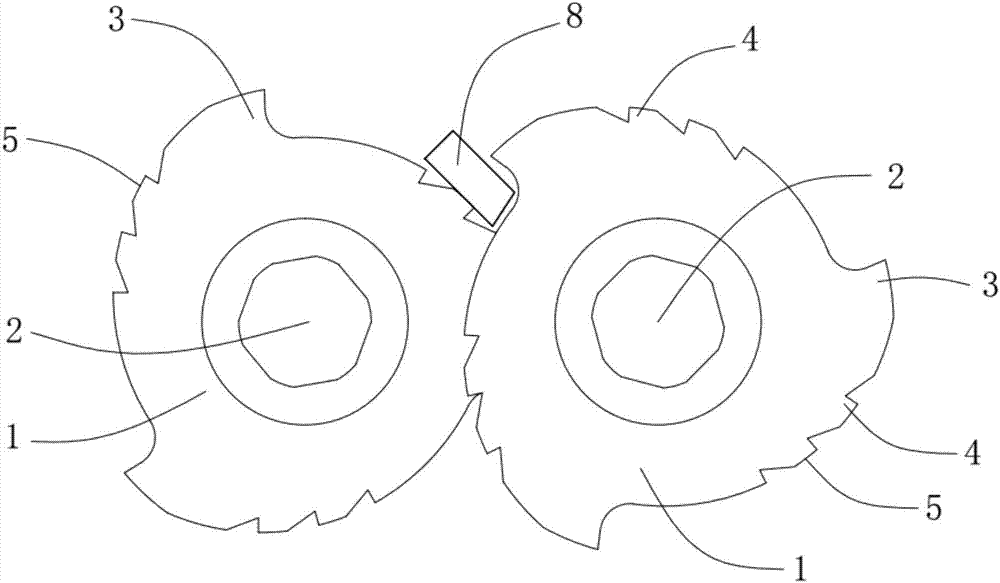

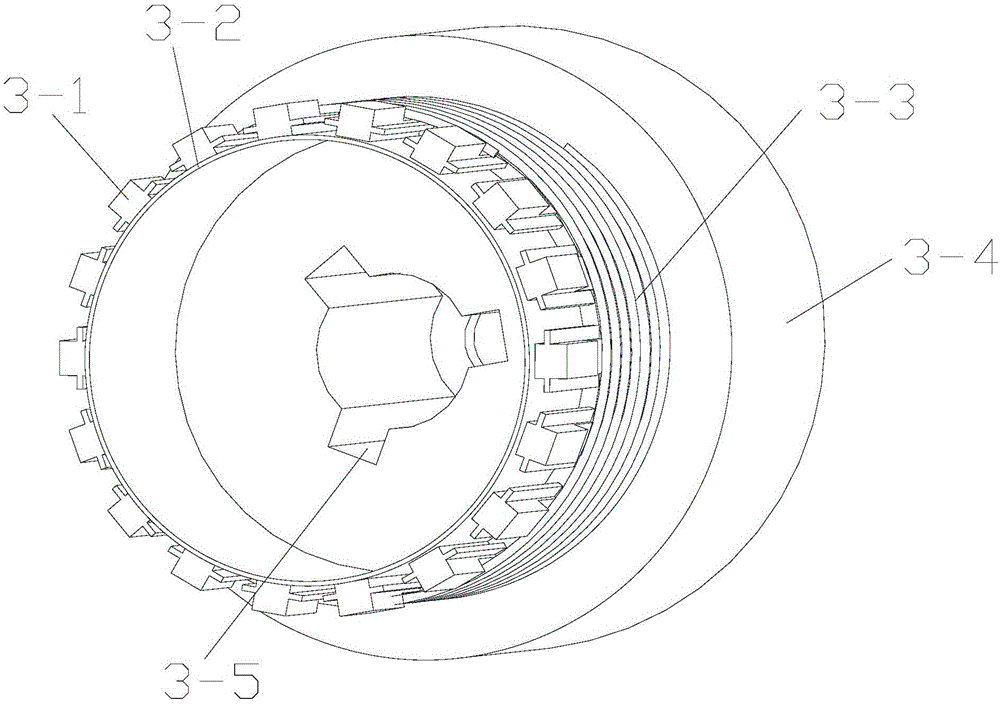

Shearing crusher cutter and crushing shaft device

The invention belongs to the technical field of fine crushing, and in particular, discloses a shearing crusher cutter and a crushing shaft device of a shearing crusher applying the cutter. The cutter comprises a cutter body, and a cutter shaft mounting hole formed in the center of the cutter body; and multiple main edges are arranged at the outer periphery of the cutter body, and are uniformly distributed on the outer peripheral edge of the cutter body with the cutter shaft mounting hole as the circle center. The cutter further comprises multiple sets of secondary edges; each set of secondary edges is arranged between two adjacent main edges; and the distances from the main edges to the cutter shaft mounting hole are larger than the distances from the secondary edges to the cutter shaft mounting hole. The crushing shaft device comprises a cutter shaft, and cutters mounted on the cutter shaft; at least two cutters are provided; and spacing sleeves are arranged between the cutter shaft and the cutters. The cutter can fully crush materials to be crushed to improve the crushing efficiency, and relatively prolongs the service life of a crushing shaft and a motor.

Owner:ZHAOQING HI TECH ZONE GUOZHUAN TECH CO LTD

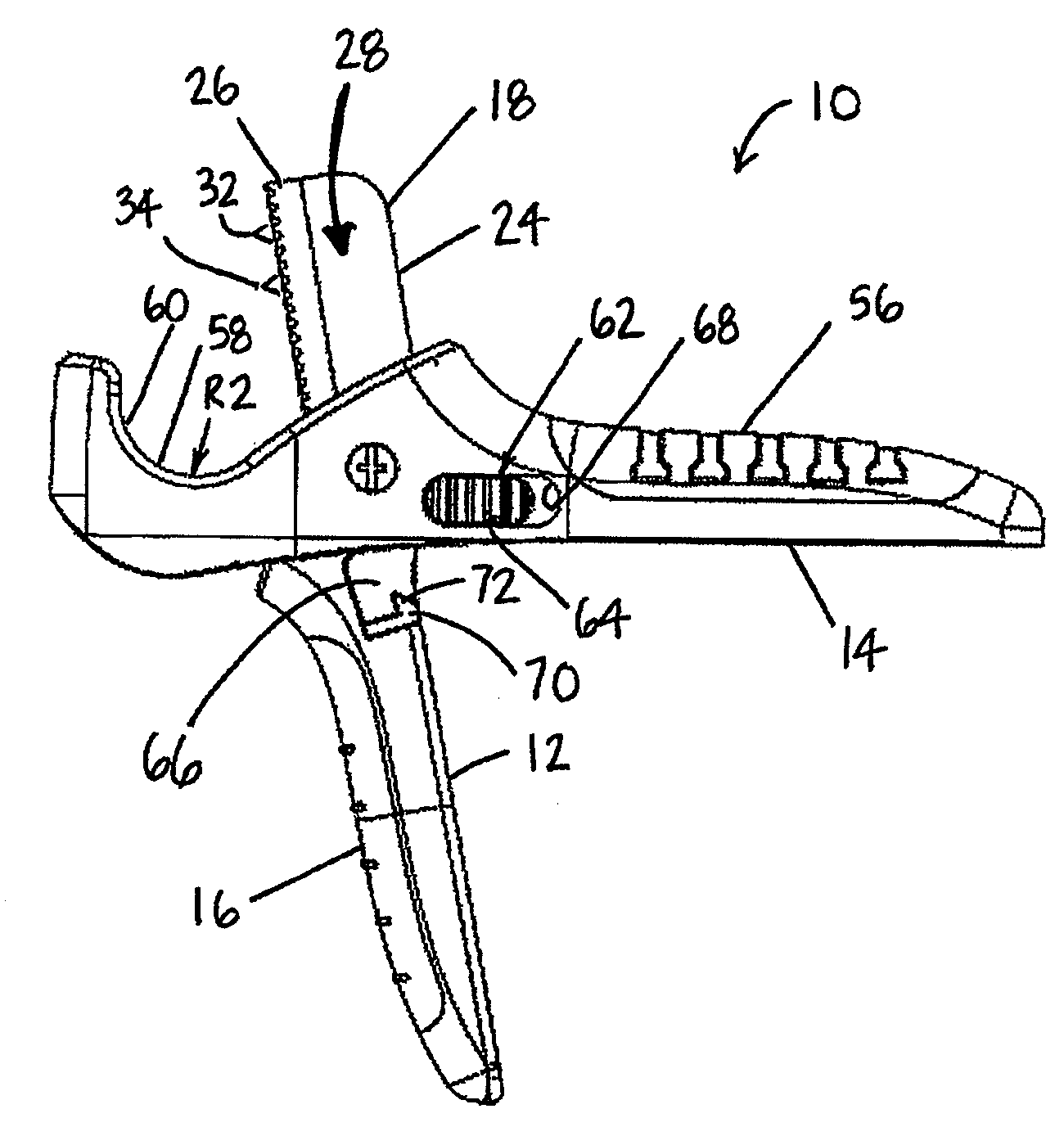

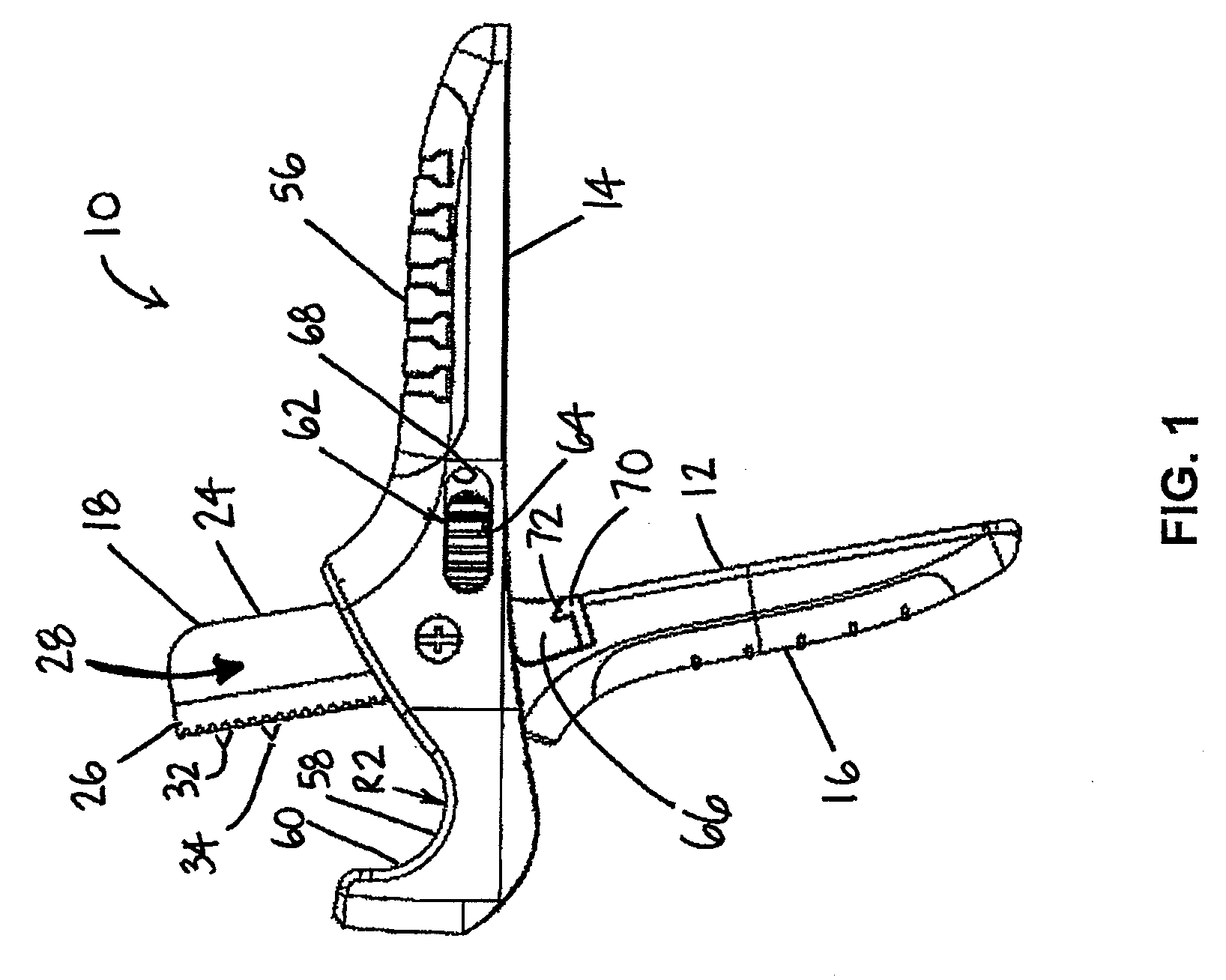

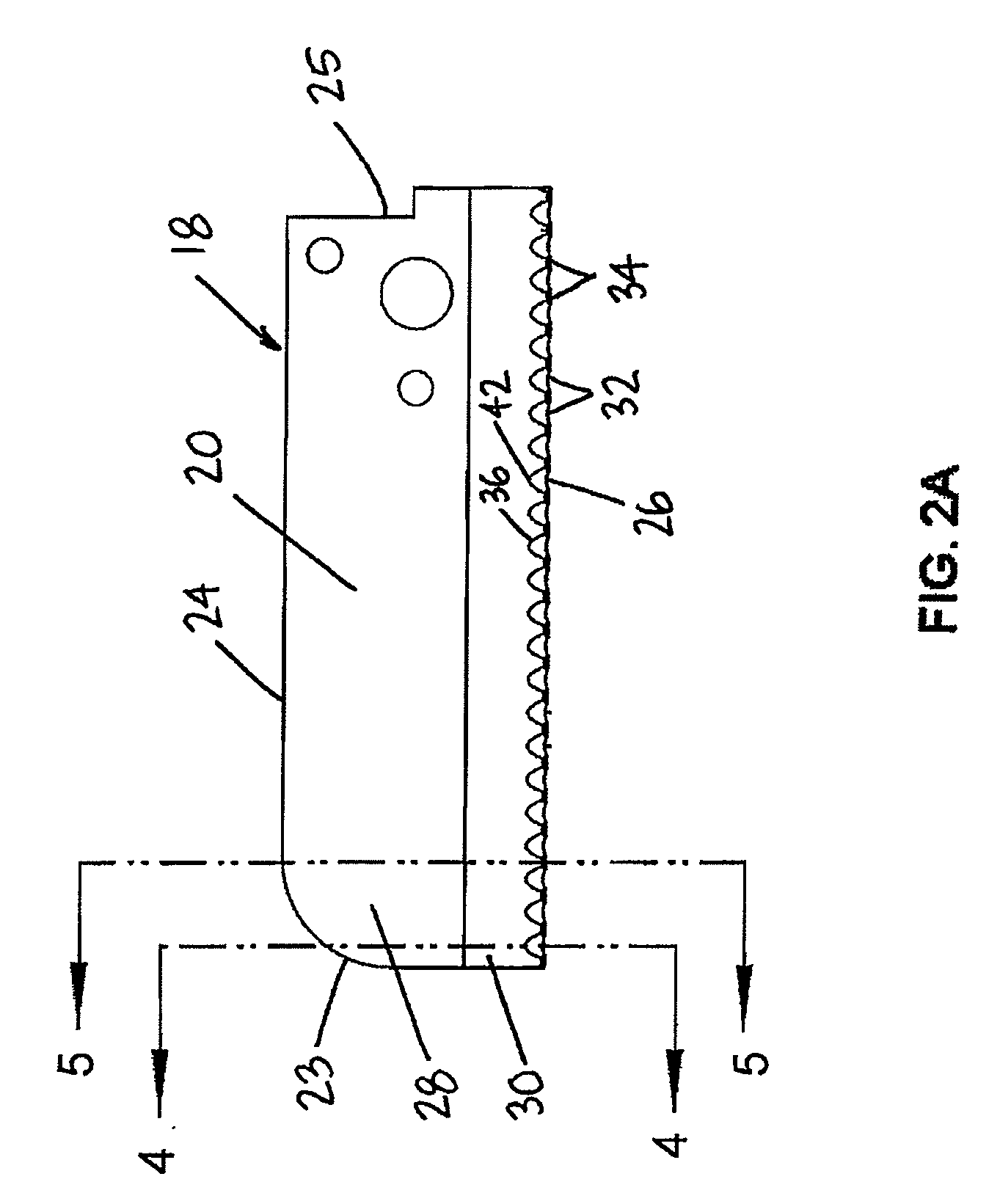

Serrated Pipe Cutter and Serrated Blade Therefor

InactiveUS20100146795A1Improve cutting performanceIncrease cutting lengthPortable power-driven toolsTube shearing machinesEdge surfaceEngineering

A serrated pipe cutter comprising handles pivotally coupled together and movable between first and second positions; wherein the first handle includes a grip at one end and a blade at an opposite end; the blade includes an elongated cutting edge which defines a cutting edge surface tapering inwardly, a plurality of serrations extending along the cutting edge, and a plurality of cutting tips extending between adjacent serrations. Each serration defines a cutting edge surface, a substantially concave facet tapering inwardly, and a linear serration cutting edge extending between adjacent cutting tips. Each cutting tip defines a cutting tip surface tapering inwardly and a linear cutting tip edge extending between adjacent serrations, at least a portion of which is offset from at least a portion of the serration cutting edge.

Owner:BLACK & DECKER INC

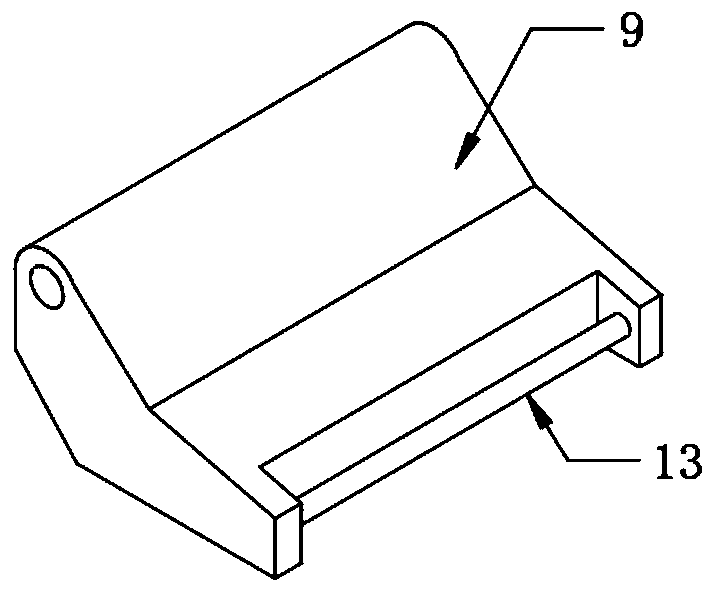

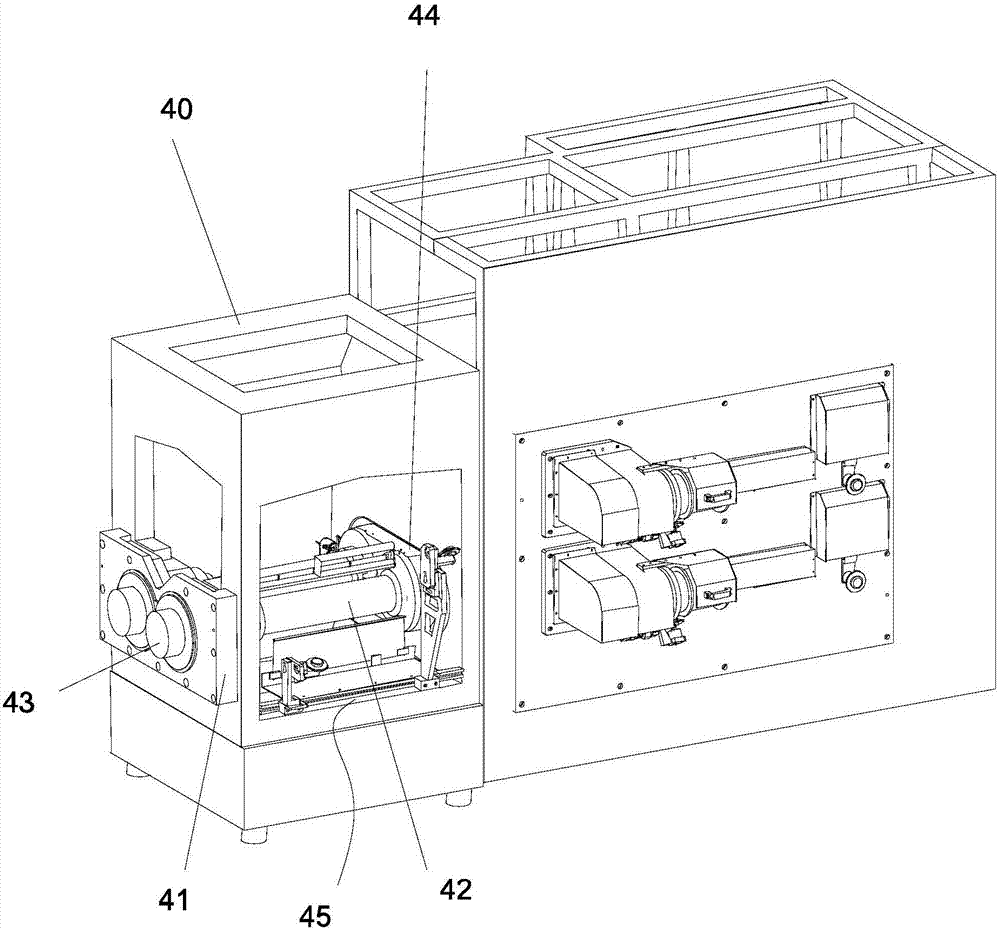

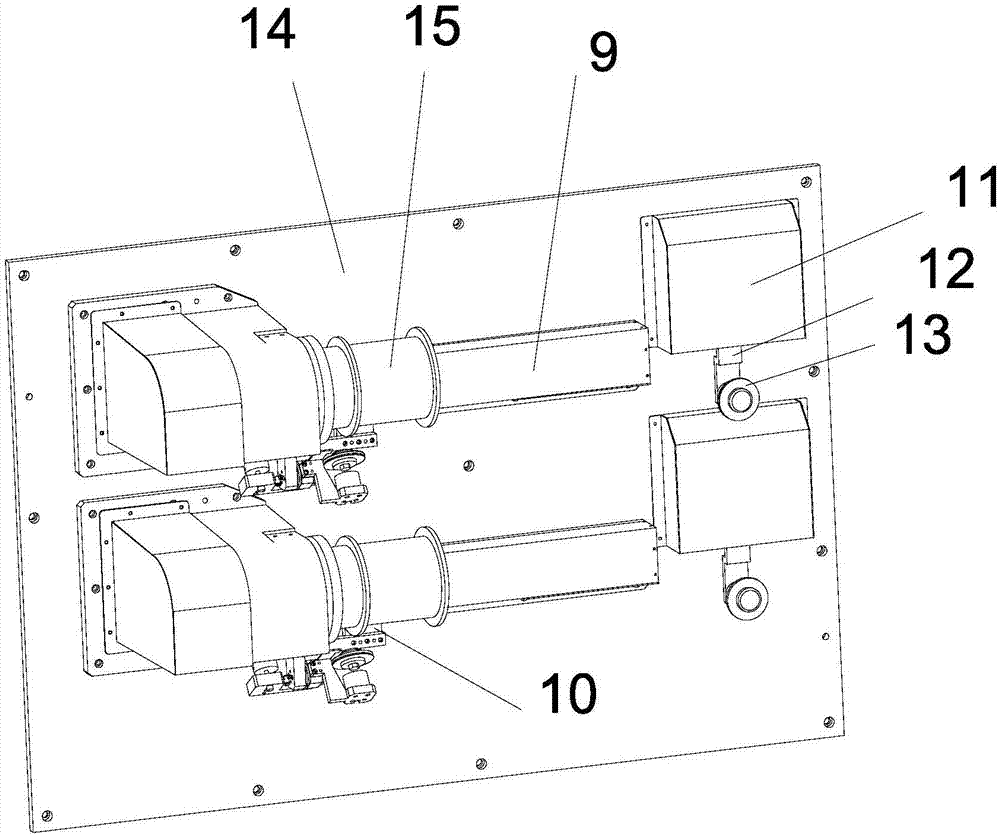

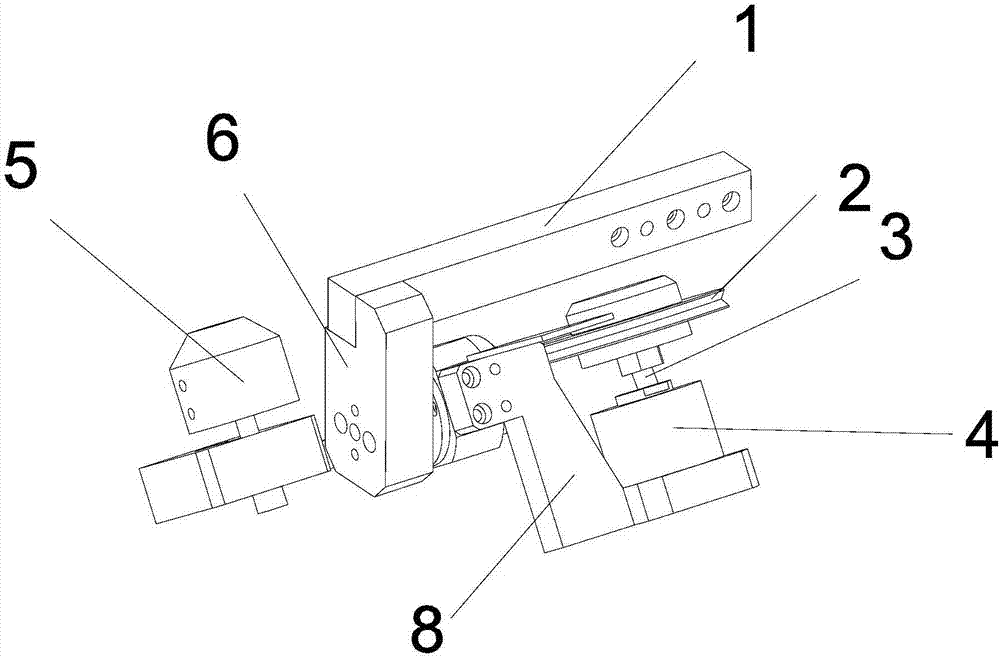

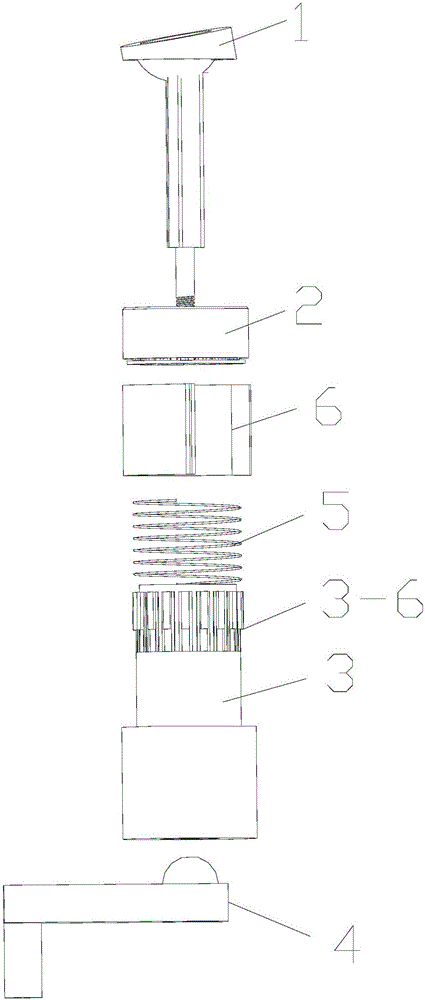

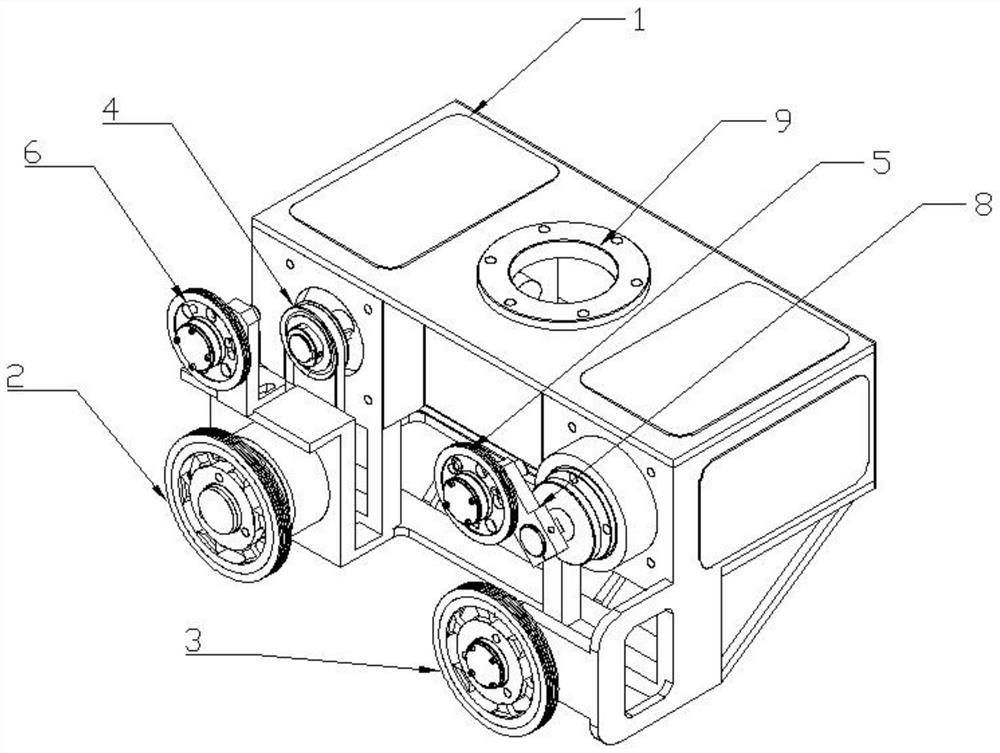

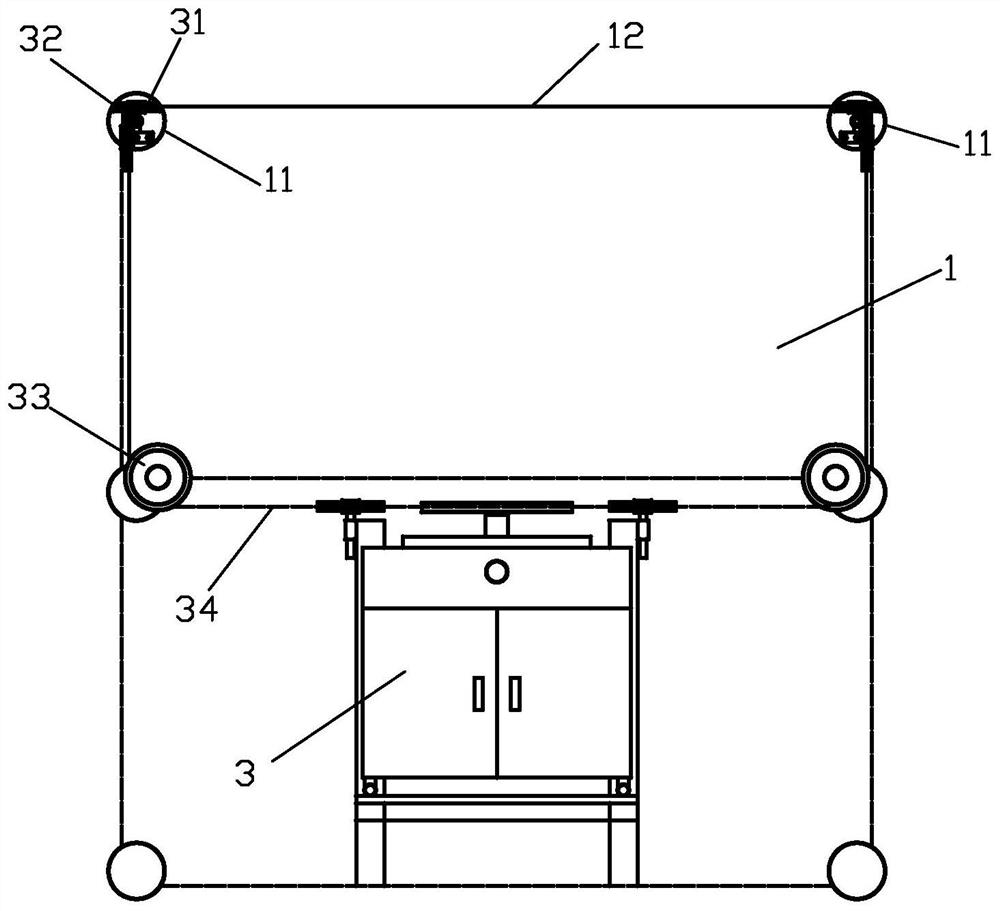

Winding machine head of multi-wire cutting machine and cutting machine

InactiveCN103182751AReduce the chance of breakageRealize single wire cuttingFine working devicesWinding machineDrive wheel

The invention discloses a winding machine head of a multi-wire cutting machine and the cutting machine. The winding machine head comprises even numbers of winding wheel supports, winding wheels, lead screw module connecting blocks, and drive wheels with the same quantity as that of the winding wheel supports, wherein each winding wheel support is fixedly arranged together, the winding wheel supports and the lead screw module connecting blocks are fixedly arranged together, at least one winding wheel installing board which is arranged vertically is arranged on each winding wheel support, one winding wheel is arranged on each winding wheel support, the plane where the winding wheels are positioned is tangent with the drive wheels, the axes of the two sets of opposite driving wheels are in parallel with one another, each drive wheel comprises a driving wheel and a driven wheel, which are coaxially arranged with each other, and a driving wheel motor drives one driving wheel to rotate. After the winding machine head is used, through the specific structural design of the drive wheels and the winding wheels, and in combination with steering wheels, the single-line cutting can be realized, the cutting length can be effectively prolonged, the possibility for breaking a diamond wire can be reduced, and the production efficiency can be improved.

Owner:高本龙 +1

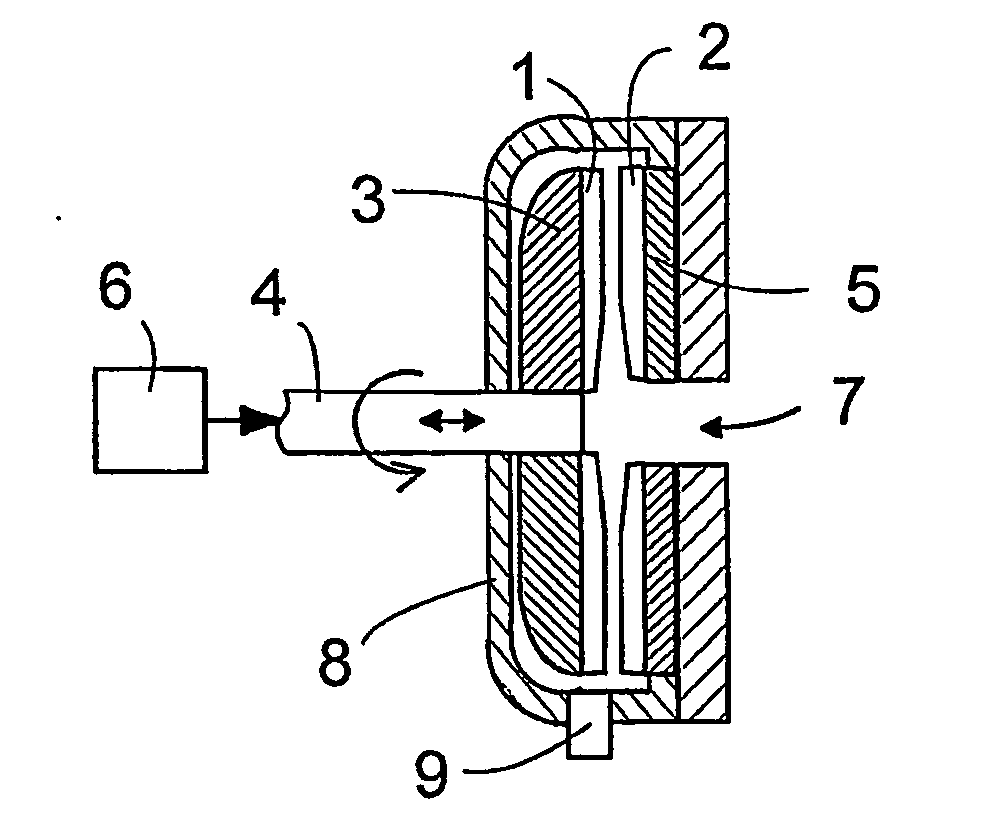

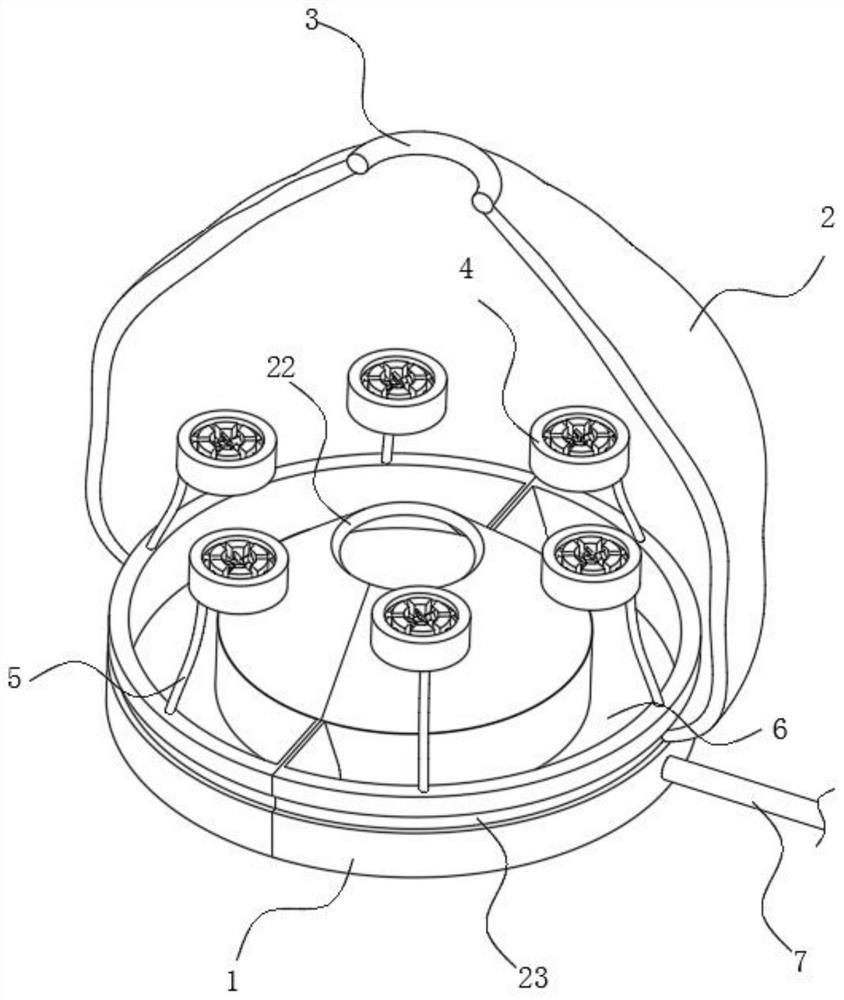

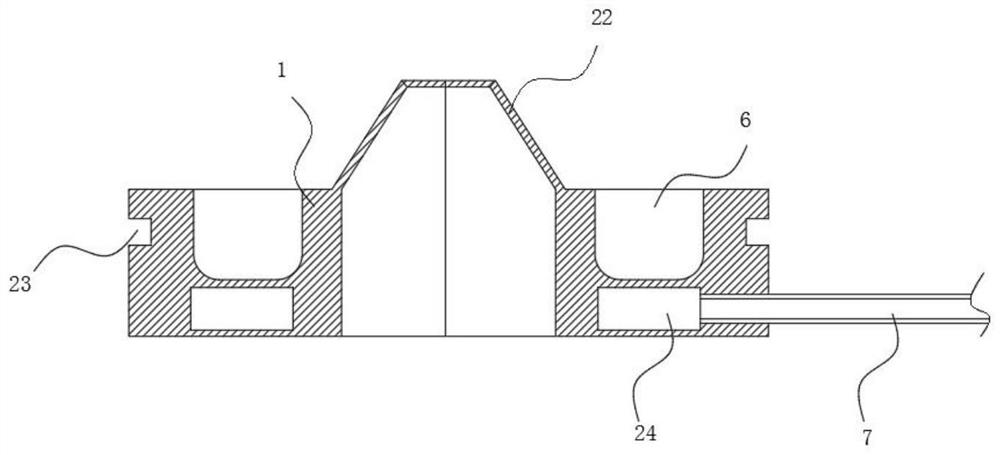

Prepuce anastomat

ActiveCN106725753AAvoid displacementQuality improvementSurgical staplesEngineeringSurgical instrument

The invention belongs to the technical field of surgical instruments and relates to a prepuce anastomat. The prepuce anastomat comprises a glans holder, a slide staple chamber, a body, a knife closing mechanism and a buffering compression mechanism. The body comprises a staple ejector and a circumcision knife, the staple ejector is positioned on the outer side of the front end of the body, and the circumcision knife is positioned on the inner side of the staple ejector and extends to the front of the staple ejector. The slide staple chamber with anastomosis staples mounted at the front end sleeves the staple ejector, and the buffering compression mechanism which pushes the slide staple chamber forwards is mounted between the slide staple chamber and the body. The glans holder for fixing tissues is provided with a knife abutting ring matched with the circumcision knife and staple anvils matched with the anastomosis staples in the slide staple chamber. By backward movement of the knife closing mechanism, the glans holder clings to the slide staple chamber, pushes the slide staple chamber to move backwards to get close to the circumcision knife, and finally pushes the slide staple chamber to make the staple ejector eject the anastomosis staples. The prepuce anastomat has advantages of simple structure and improvement of surgical quantity and surgical comfort.

Owner:吴健强

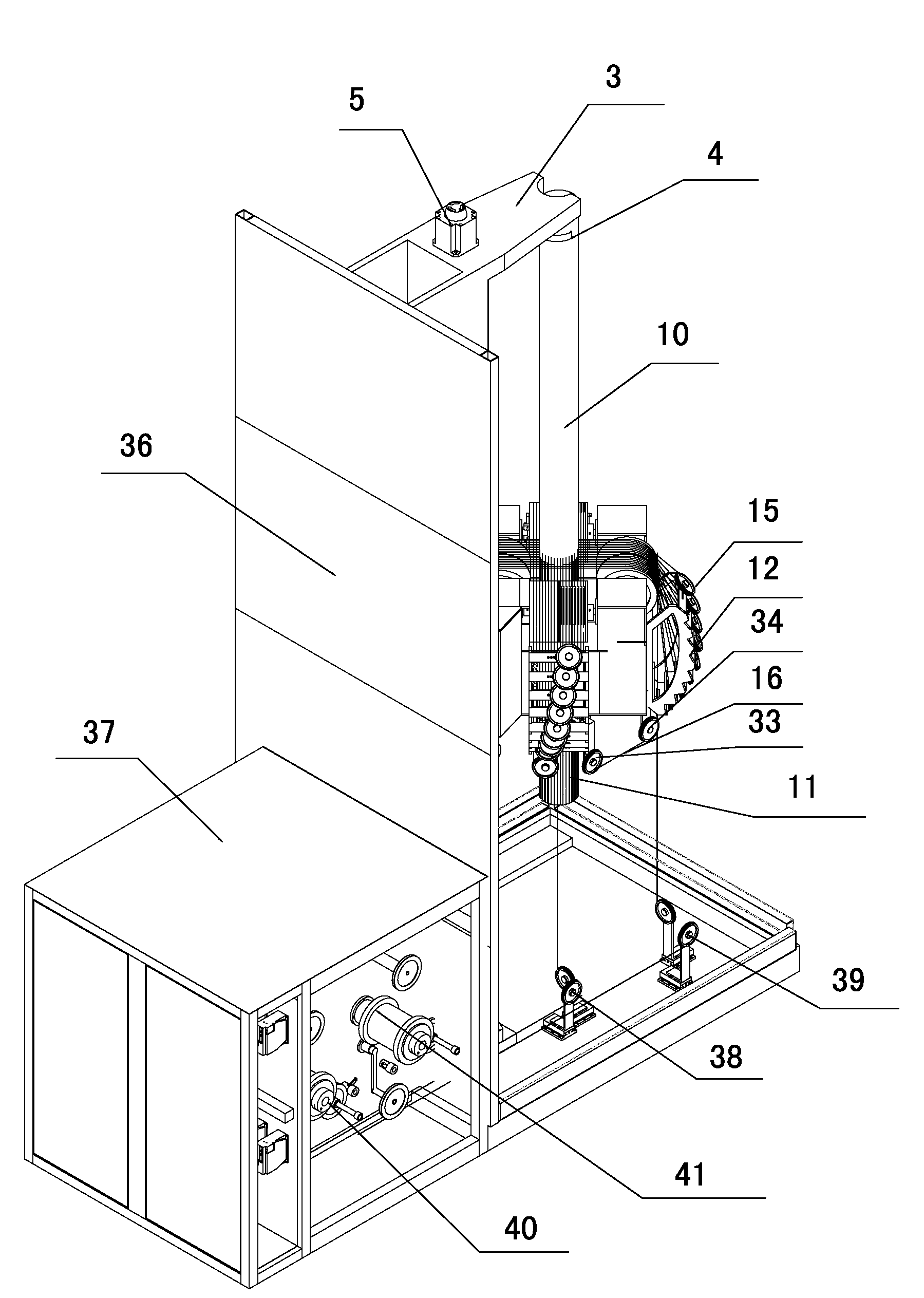

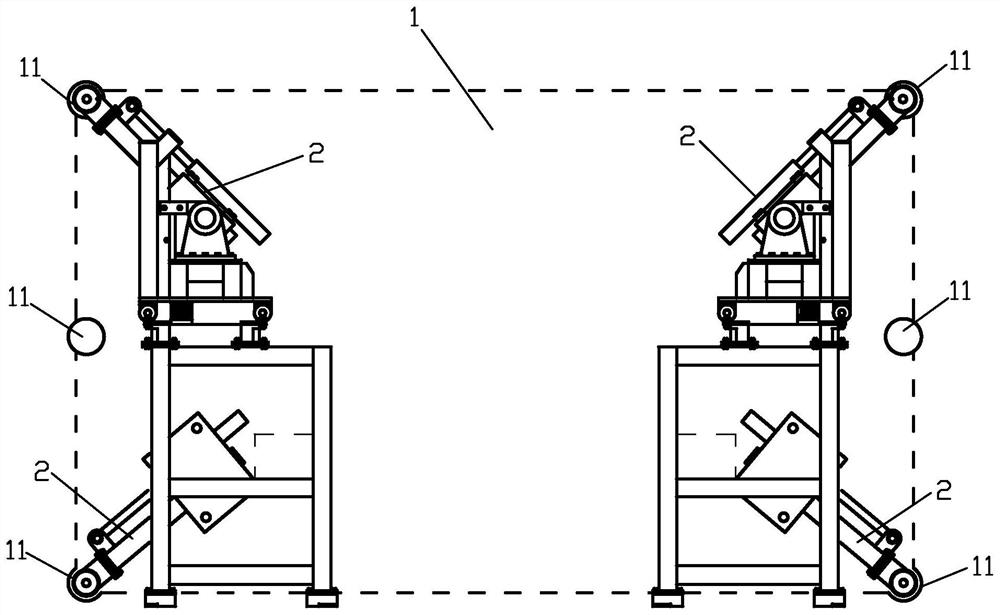

Robot flexible diamond wire cutting system

The invention discloses a robot flexible diamond wire cutting system. The cutting system comprises a cutting knife head and a mechanical arm for driving the cutting knife head to rotationally cut, wherein the cutting knife head comprises a cutting knife head frame; a main cutting motor is fixed on the cutting knife head frame; an output shaft of the main cutting motor is connected with a main cutting wheel in a power mode; an auxiliary cutting wheel is arranged on one side, corresponding to the main cutting wheel, of the cutting knife head frame; and a cutting wire net formed by diamond wiresis wound between the main cutting wheel and the auxiliary cutting wheel in a sleeving mode. The multi-shaft linkage mechanical arm is combined with the diamond wire cutting knife head, so that the purpose of flexible cutting is achieved; hard articles can be cut by using less driving force, so that energy is saved, cutting seams are small, and loss of cutting materials and energy consumption are low; and by arranging a transmission wheel and a yielding groove, the motor and the cutting wheels are not arranged coaxially, the cutting space of the diamond wire net is released, and larger materials are allowed and prevented from interfering or colliding with each other in the cutting process.

Owner:QINGDAO GAOCE TECH CO LTD

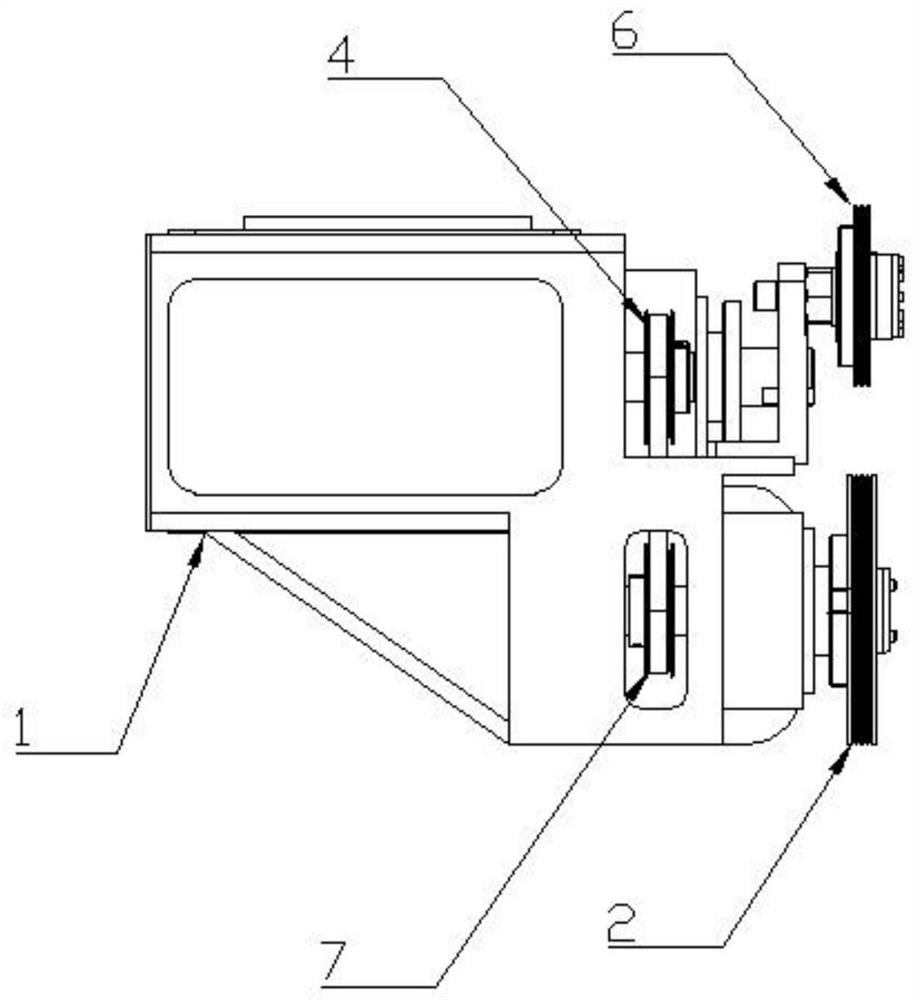

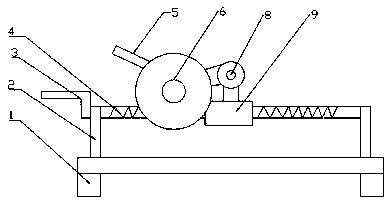

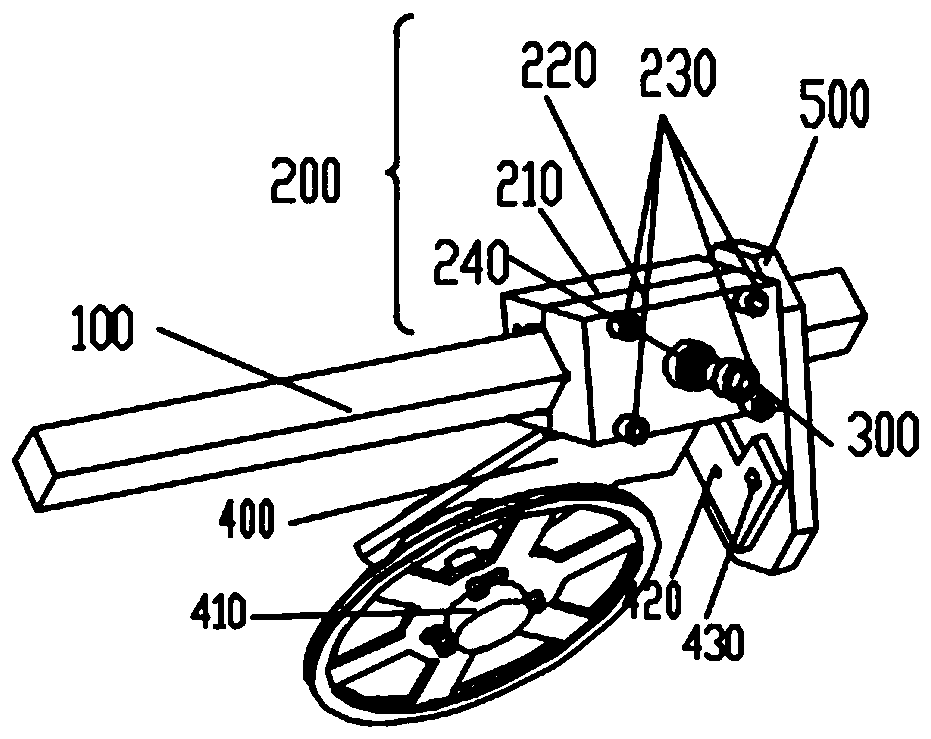

Walking cutter

InactiveCN101508036AEasy to operateIncrease cutting lengthShearing machinesMetal working apparatusElectric machineryEngineering

The invention relates to a walking cutting machine, and belongs to the field of cutting machines. The walking cutting machine adopts a technical proposal that the walking cutting machine comprises a motor, a transmission device and a cutter wheel. The walking cutting machine is characterized in that the motor, the transmission device and the cutter wheel are arranged on a machine frame; the lower side on the front part of the machine frame is provided with wheels, and the tail end of the machine frame is provided with the cutter wheel which is positioned on one side of the machine frame and extends out of the machine frame; and the upper part at the front end of the machine frame is provided with the motor, and an output shaft of the motor is connected with the cutter wheel through the transmission device. The walking cutting machine has the advantages of simple structure, convenient processing, low manufacturing cost and strong practicability, and is particularly suitable for small factories. The walking cutting machine also has small investment and convenient use. In order to conveniently push the cutting machine to lift and descend the cutter wheel, the machine frame is also provided with a handle.

Owner:马光玉

Mine cave stone mining method

ActiveCN112377195AIncrease spaceImprove the efficiency of material collectionUnderground miningSurface miningMining engineeringMechanical engineering

The invention discloses a stone mining method for a mine hole. The stone mining method comprises the steps that at least six guide holes are drilled in the working face of a mine area; a top line, a bottom line, two middle lines, two first vertical lines and a second vertical line are cut on the working surface through the at least six guide holes; the first stone core is broken and taken out between the two first vertical lines; cutting is performed to take out the second stone core between the two center lines, and forming an upper ore material by the ore material between the center line onthe upper side and the top line; an abutting piece is inserted between the two middle lines so as to abut against the mineral material; back-cutting is performed on the upper ore material in a linearcutting mode; at least two supporting pieces are inserted between the two middle lines, the abutting pieces are processed so that the upper ore material can move to press against the supporting pieces, and the interval between every two adjacent supporting pieces forms a forking space for forking equipment to be inserted; and materials are taken by adopting forking equipment. The mineral materialtaking device has the advantages that mineral materials can be taken out through the forking device, large-size mineral materials can be taken out, and the material taking efficiency can be improved.

Owner:江显秋 +1

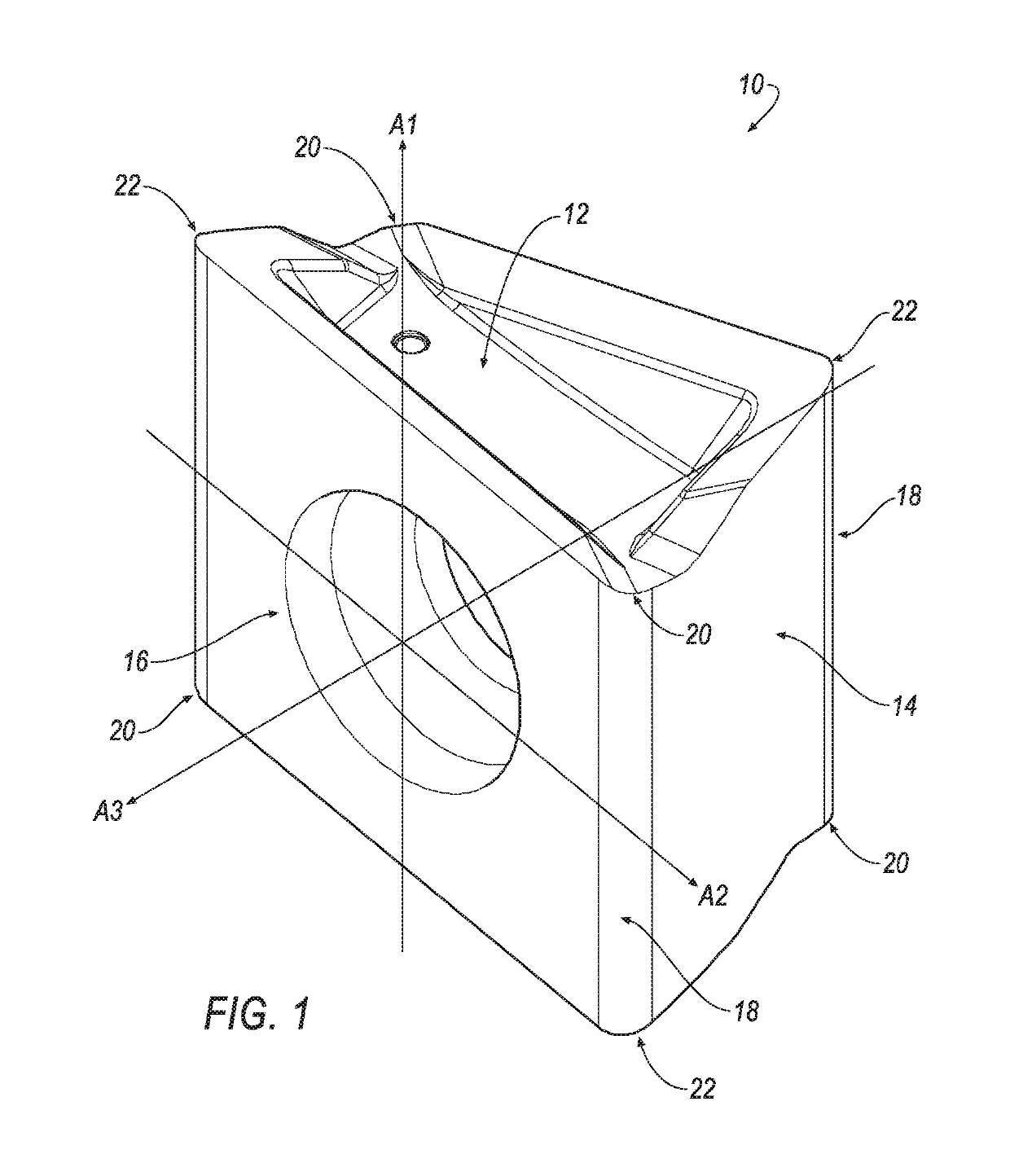

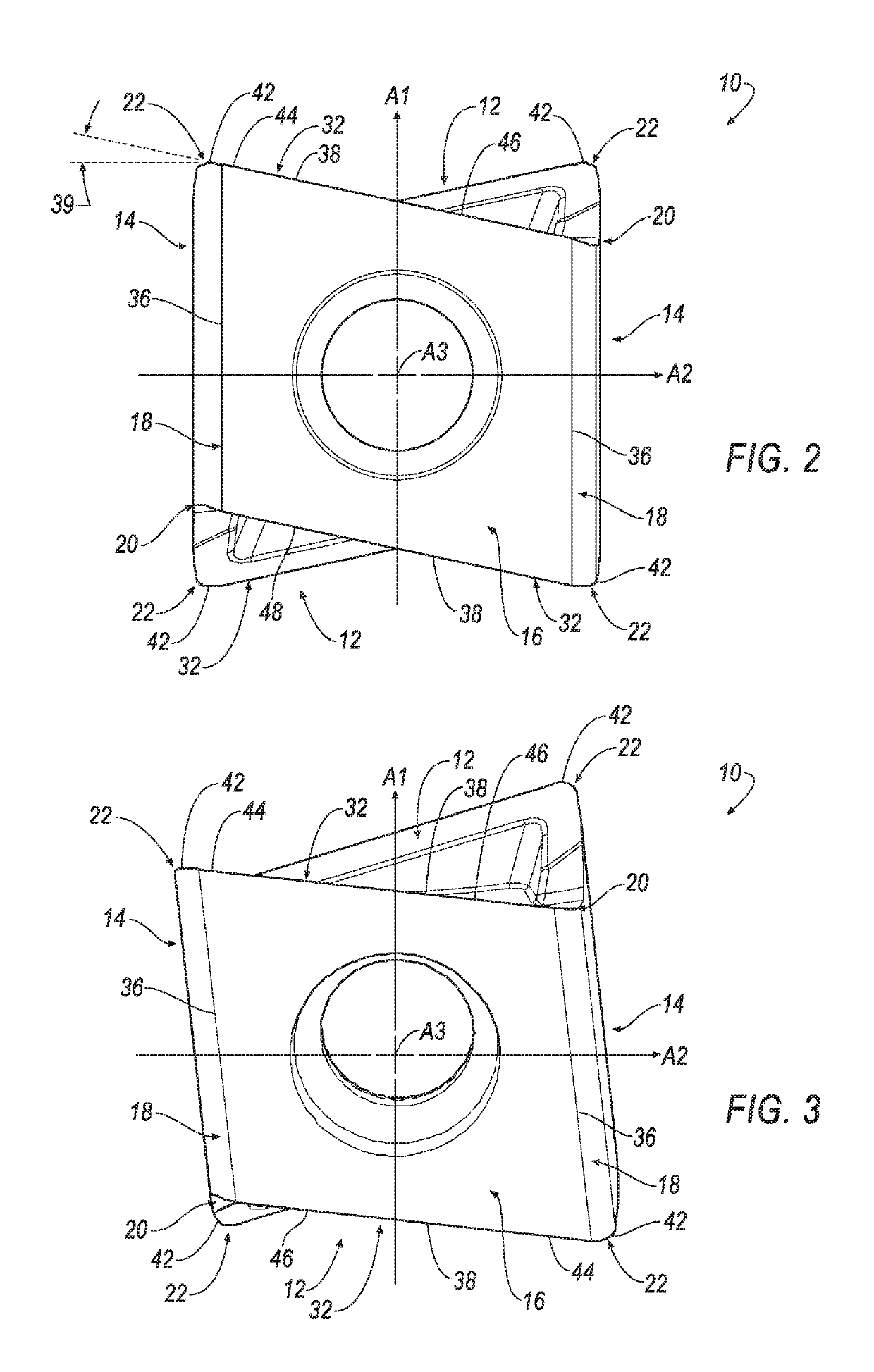

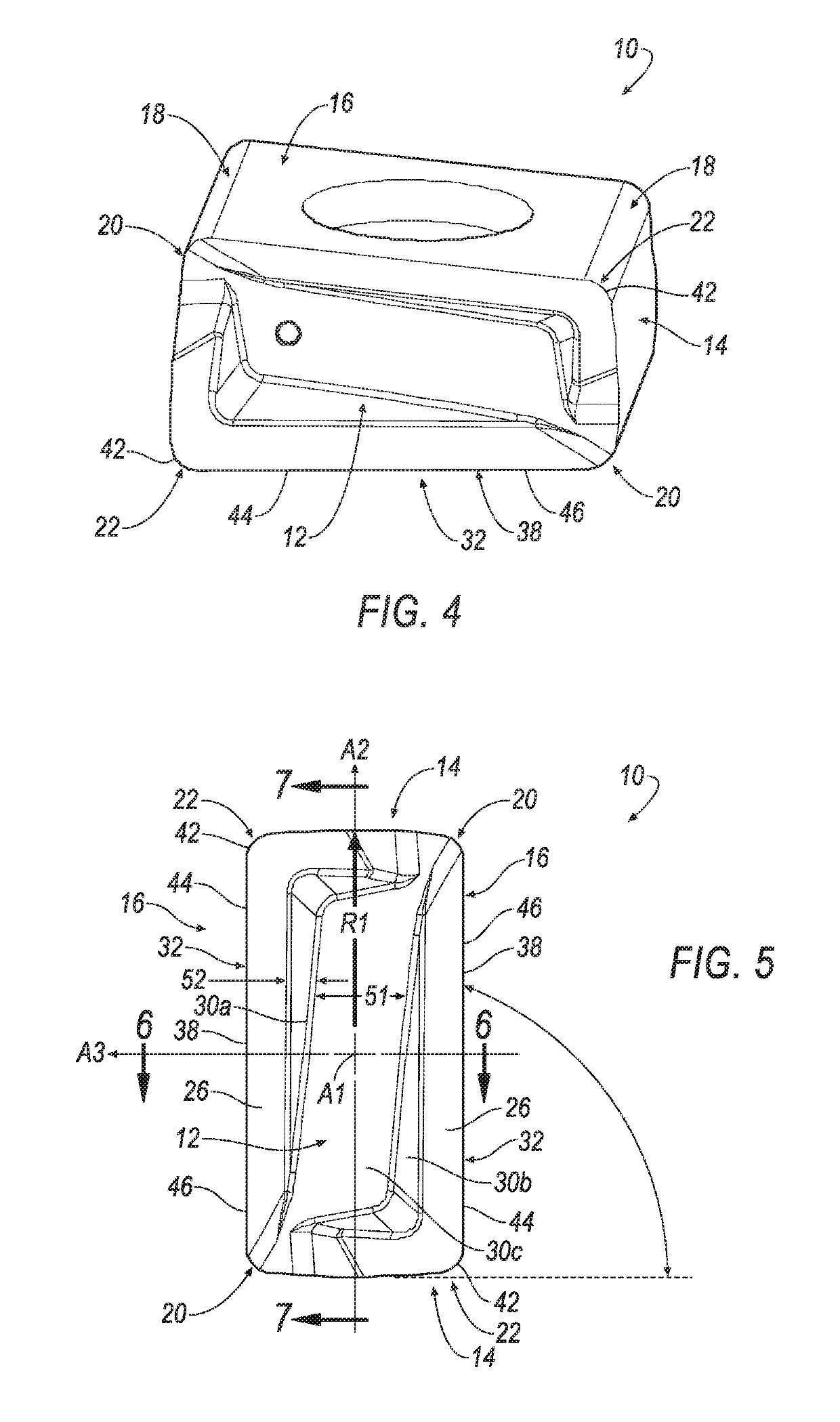

Tangentially mounted indexable cutting insert with convex-shaped minor side surfaces and concave-shaped end surfaces

ActiveUS10421134B2Increase cutting lengthImprove the quality of the finishMilling cuttersTurning toolsMechanical engineeringEngineering

A cutting insert having two opposing end surfaces, two identical opposing major side surfaces and two identical opposing minor side surfaces. Each end surface of the insert has a concave-shaped seating surface for contacting the insert pocket the insert pocket along an entire length of the cutting insert. The minor side surfaces are convex-shaped. The concave-shaped seating surface and the convex-shaped minor side surfaces enable the cutting insert to be accurately tangentially mounted in the insert pocket.

Owner:KENNAMETAL INC

High-precision cutting machine

ActiveCN102350543BEasy to controlImprove flatnessMetal sawing devicesShearing control devicesProgrammable logic controllerControl system

The invention discloses a high-precision cutting machine, comprising a feeding device, a feeding speed detecting device, a material cutting device, a cutting device drive mechanism and a discharging device, wherein the feeding speed detecting device is used for acquiring the running speed data of a material and transmitting the running speed data to a main control system; and the main control system is used for controlling the cutting device to synchronously advance at the speed identical to the running speed of the material along a direction consistent to the advancing direction of the material while controlling the cutting device to perform cutting. In the cutting machine disclosed by the invention, an encoder is used for acquiring the running speed of the material and sending out pulse signals, a PLC (Programmable Logic Controller) is used for extracting the pulse signals of the encoder and performing accumulation operation on the pulse signals, when an accumulated value reaches a set value inside the PLC, a cutting length for the material is indicated to be reached, and the PLC sends out a cutting instruction, so that a cutting position during each cutting is accurately controlled; in addition, a cutting tool advances synchronously with the material during cutting, so that the cutting position does not change relatively, and the precision of the cutting length can reach + / -0.5mm.

Owner:ZHEJIANG XINGYU AUTO PARTS CO LTD

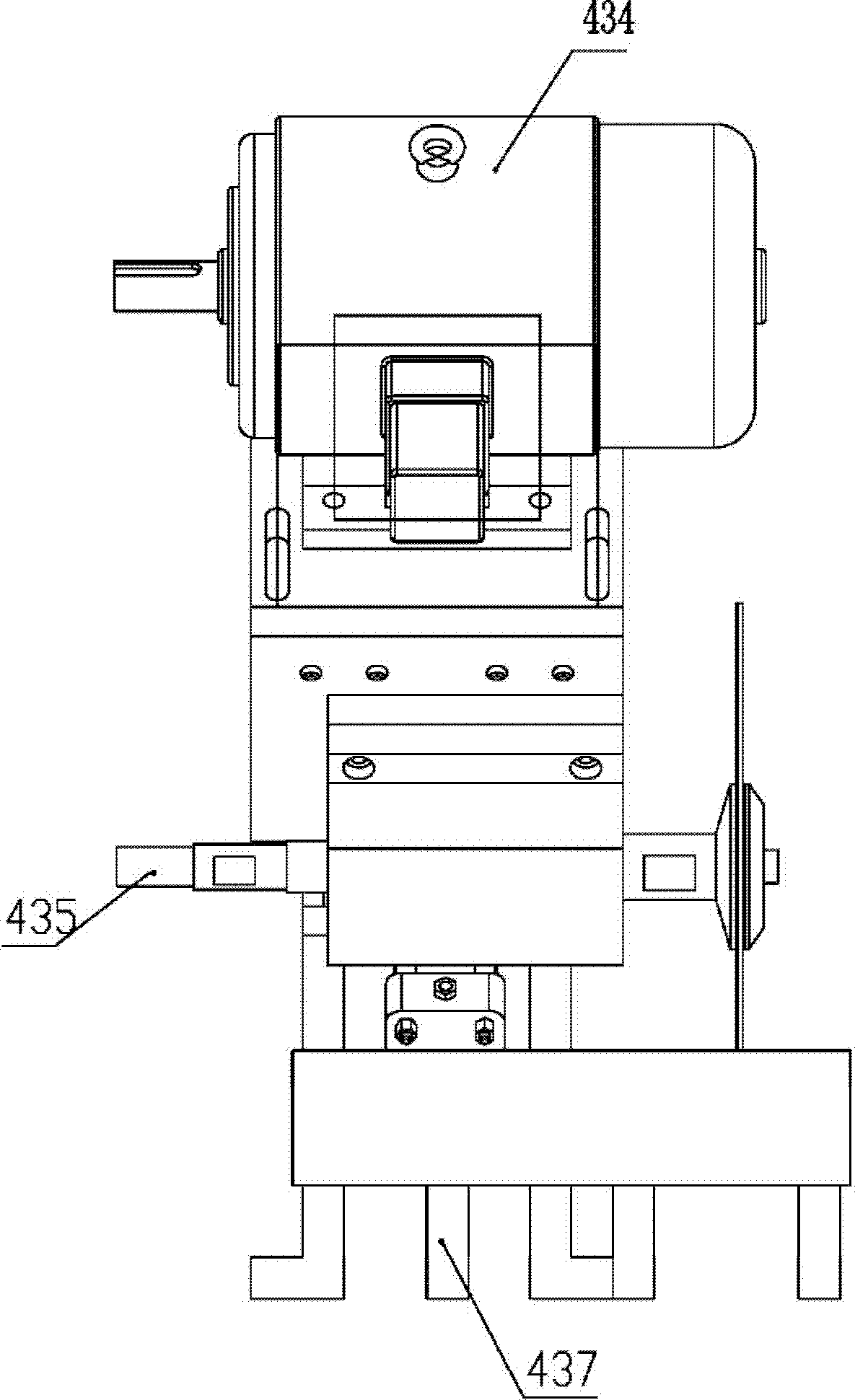

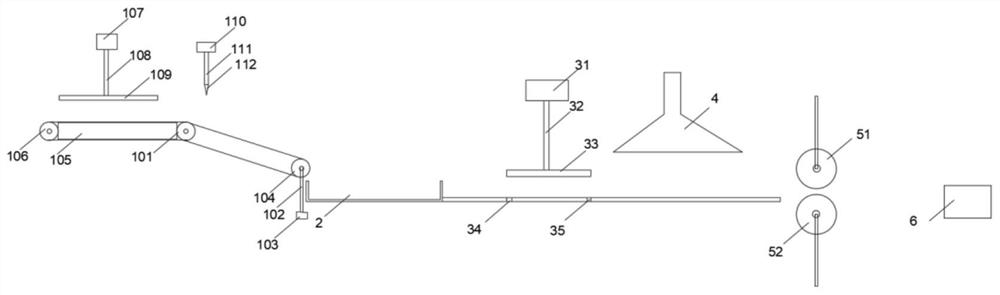

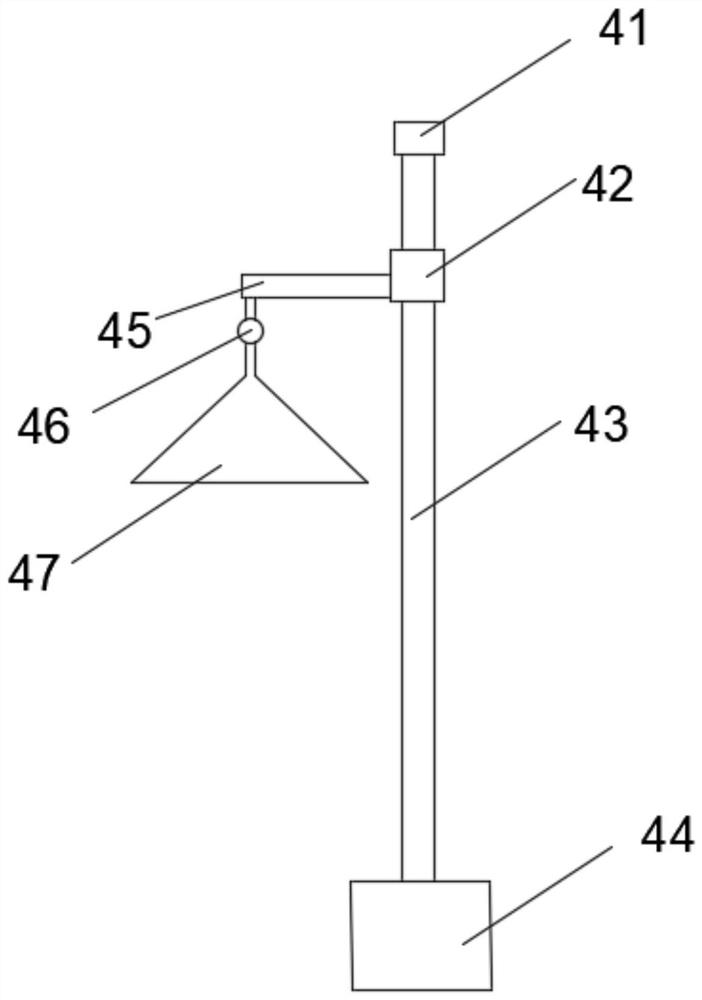

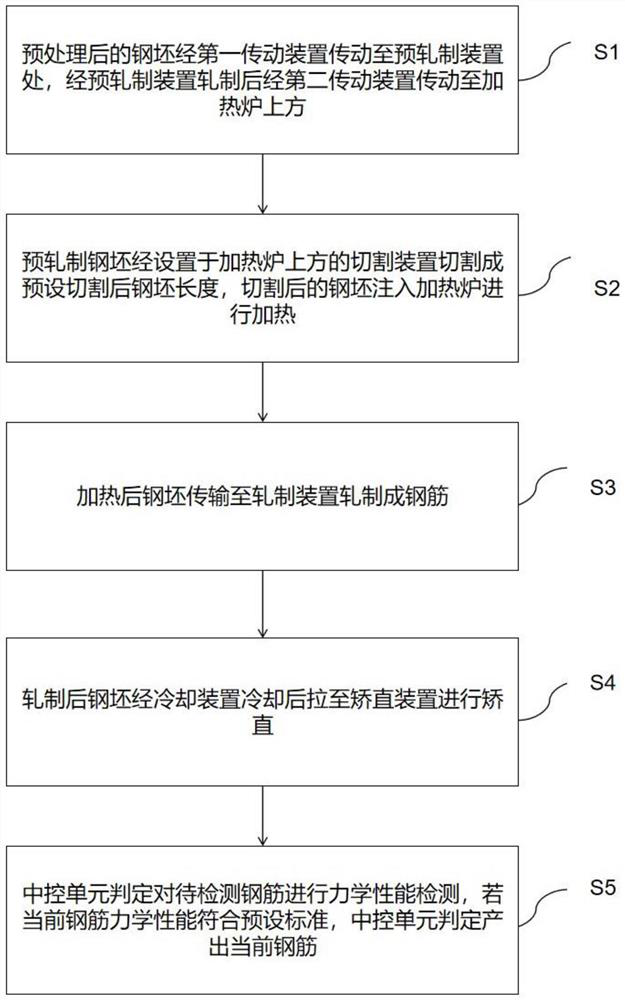

Hot-rolled steel bar MG400 preparation method based on electric furnace smelting resin anchor rod

ActiveCN113953761AAchieve stabilityIncrease speedProcess efficiency improvementBuilding reinforcementsRebarElectric furnaces

The invention relates to a hot-rolled steel bar MG400 preparation method based on an electric furnace smelting resin anchor rod. The method comprises the following steps that S1, a pretreated steel billet is transmitted to a pre-rolling device through a first transmission device, is rolled by the pre-rolling device, and is transmitted to a position above a heating furnace through a second transmission device; S2, a pre-rolled steel billet is cut into a preset cut steel billet length through a cutting device arranged above the heating furnace, and the cut steel billet is injected into the heating furnace to be heated; S4, the rolled steel billet is cooled through a cooling device and then pulled to a straightening device to be straightened; and S5, a central control unit judges that a to-be-detected steel bar is subjected to mechanical property detection. The central control unit is arranged, and the preset cut steel billet length, the rolling force of the rolling device and the cooling efficiency are adjusted through the central control unit, so that the mechanical property of the produced steel bar meets the preset standard.

Owner:福建三宝钢铁有限公司

Efficient fish tofu slicing device

PendingCN114654511ARealize the driving effectAutomate the processMetal working apparatusReciprocating motionEngineering

The invention discloses an efficient fish tofu slicing device, and relates to the technical field of fish tofu slicing processing, the efficient fish tofu slicing device comprises a rack, a guide plate is fixed on a vertical frame, a sliding frame is slidably mounted on the guide plate in a reciprocating manner, a transmission column is fixed on the sliding frame, and a plurality of cutting avoiding grooves distributed at equal intervals are formed in a storage container; slicing assemblies intermittently corresponding to the cutting receding grooves are installed at the bottom of the lifting plate, a driving assembly is connected to the rotating shaft, and the driving assembly is used for driving the storage container to slide in a stepping mode. According to the fish tofu slicing device, the driving effect on the slicing assembly is achieved through vertical reciprocating lifting of the lifting plate, the slicing assembly can slice fish tofu in the storage container while performing vertical reciprocating motion, and when the lifting plate drives the slicing assembly to move upwards and the rotating shaft rotates, the storage container can be driven by the driving assembly to move in a stepping mode, so that the slicing effect is improved. The automatic and orderly slicing operation of the fish tofu in the storage container is realized, and the slicing processing efficiency of the fish tofu is greatly improved.

Owner:山东丸美佳食品有限公司

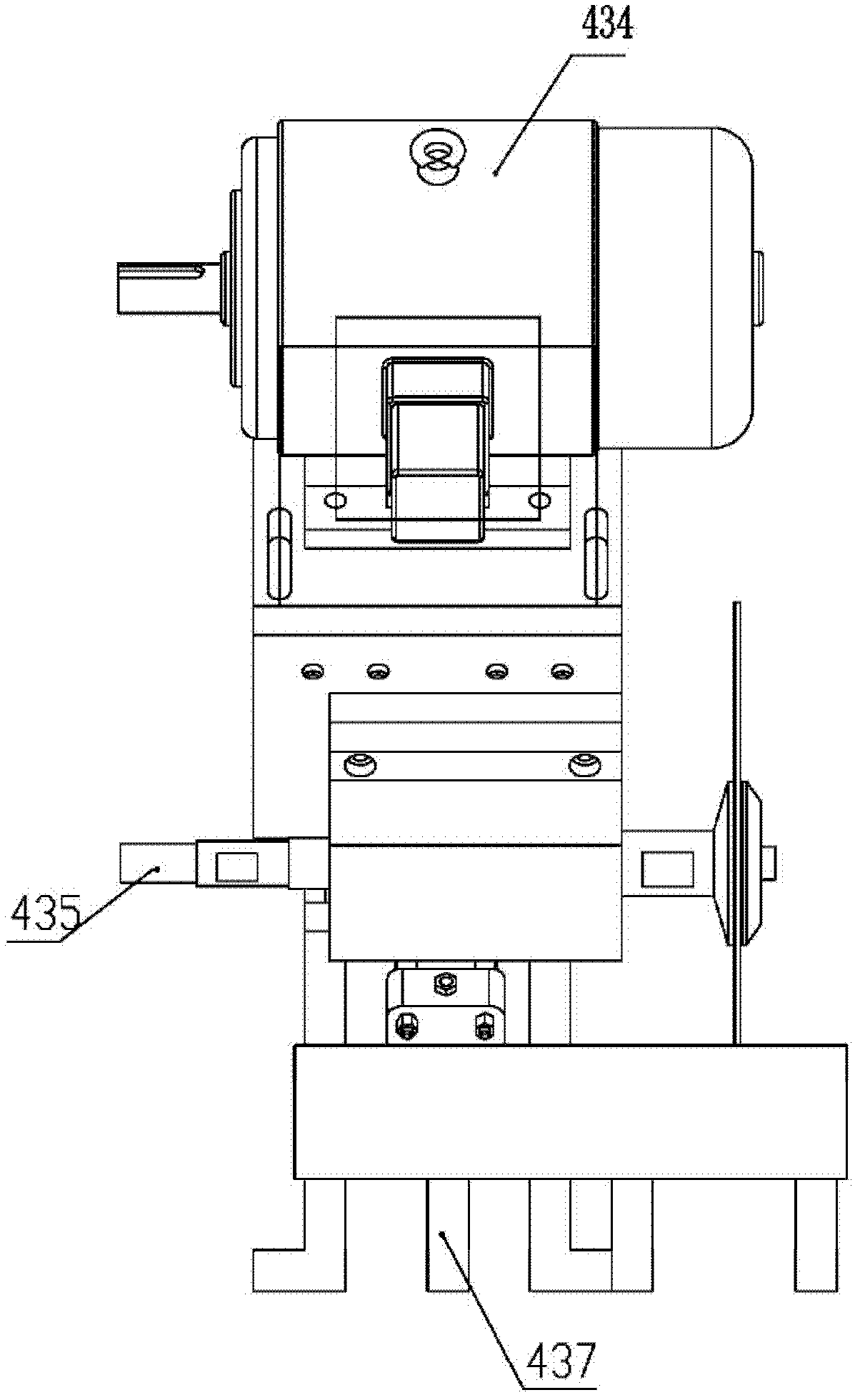

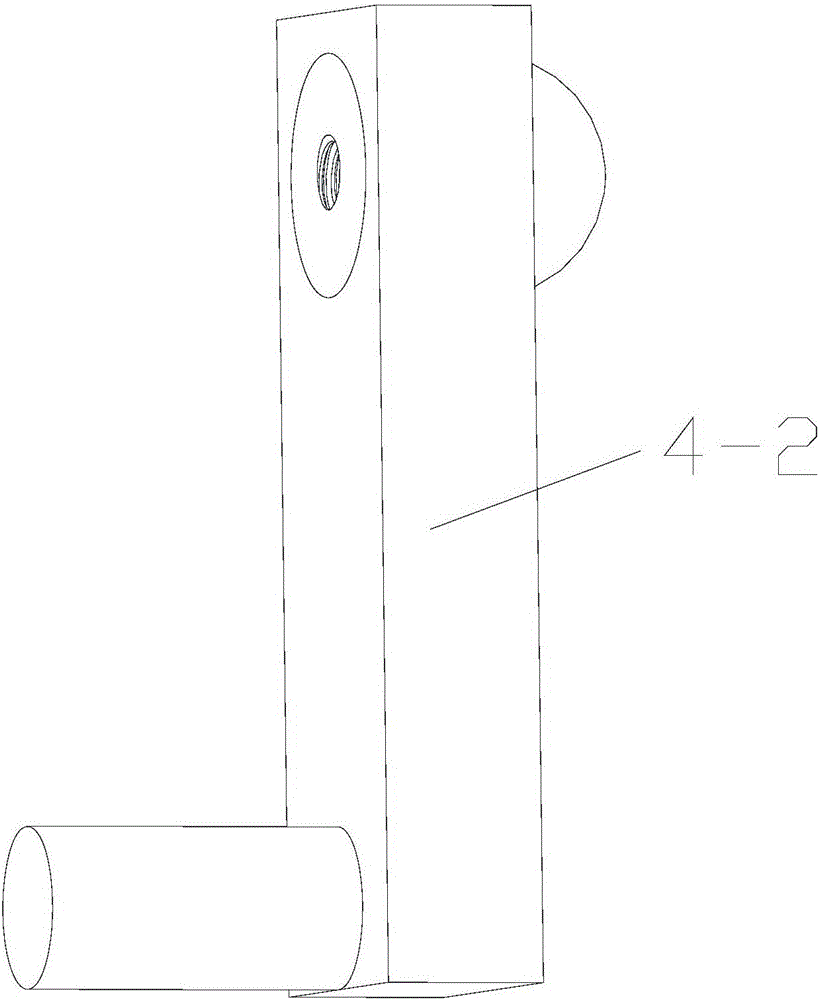

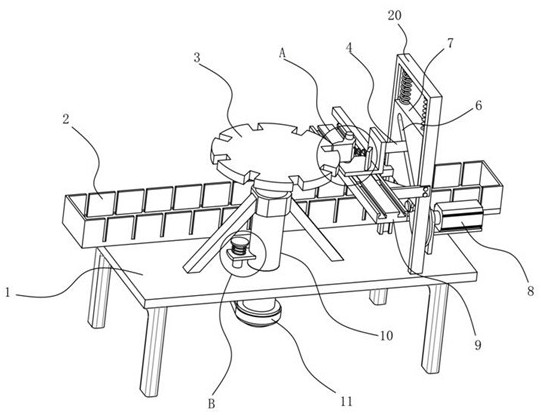

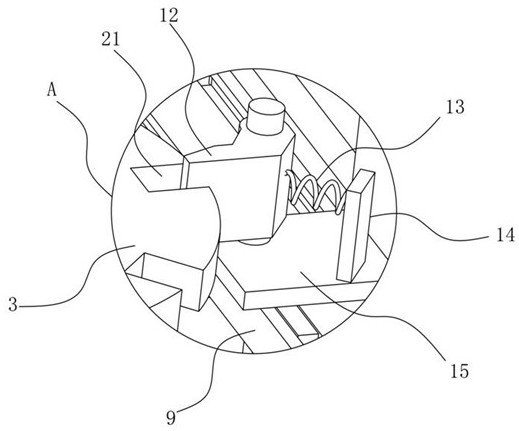

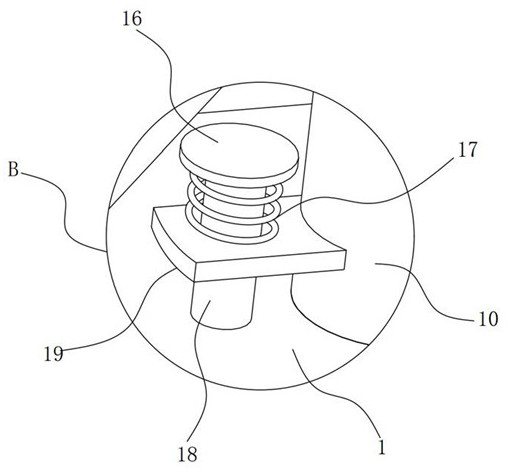

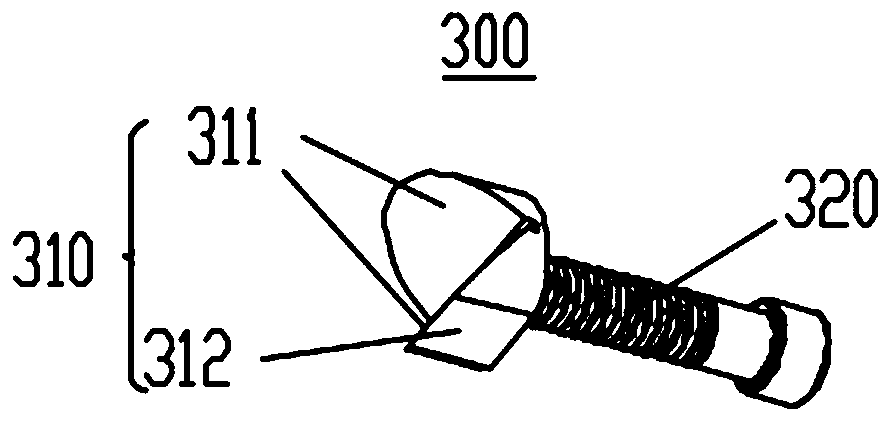

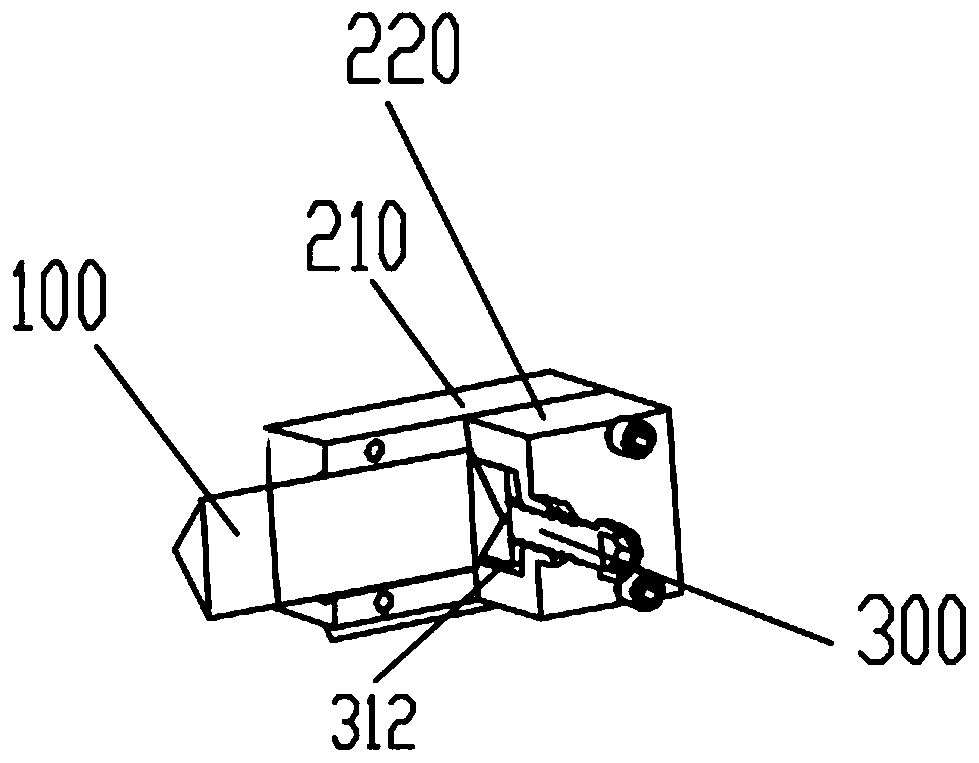

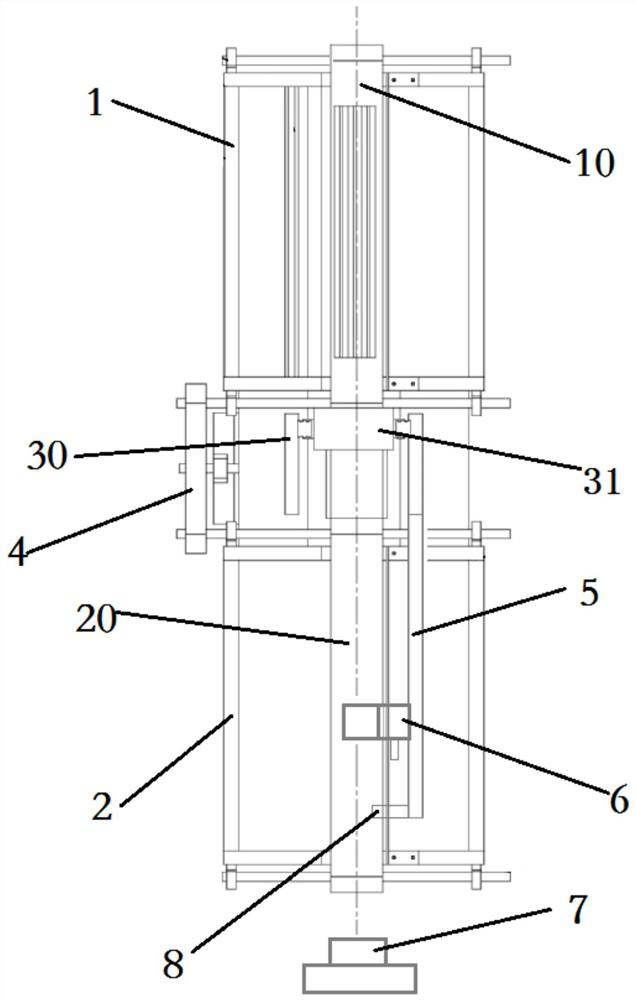

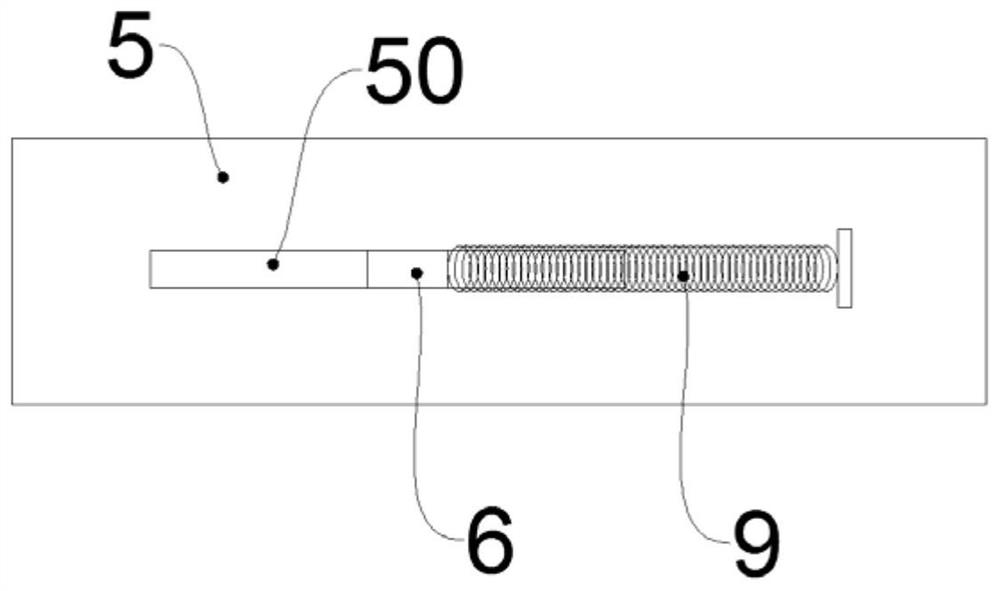

Floating cutter based on lead screw transmission

InactiveCN108818700AIncrease cutting lengthQuality improvementMetal working apparatusEngineeringMechanical engineering

The invention discloses a floating cutter based on lead screw transmission. The floating cutter comprises a rack which is provided with support frames, and the two support frames are provided, and located on the right and left sides of the rack separately; the upper end of each support frame is provided with a lead screw in a sleeving manner, and each screw rod is provided with a sleeve fixedly connected to a movable bracket; the tail end of each movable bracket is connected to a cutting device which is provided with a handle; and the left end of each lead screw is fixedly connected to a rocker. The cutting device can be moved through swing of the rocker horizontally, and the cutting length of the cutter is prolonged indirectly; and the cutting quality is improved, and the time and labor forces for moving materials during cutting are further saved.

Owner:董莉

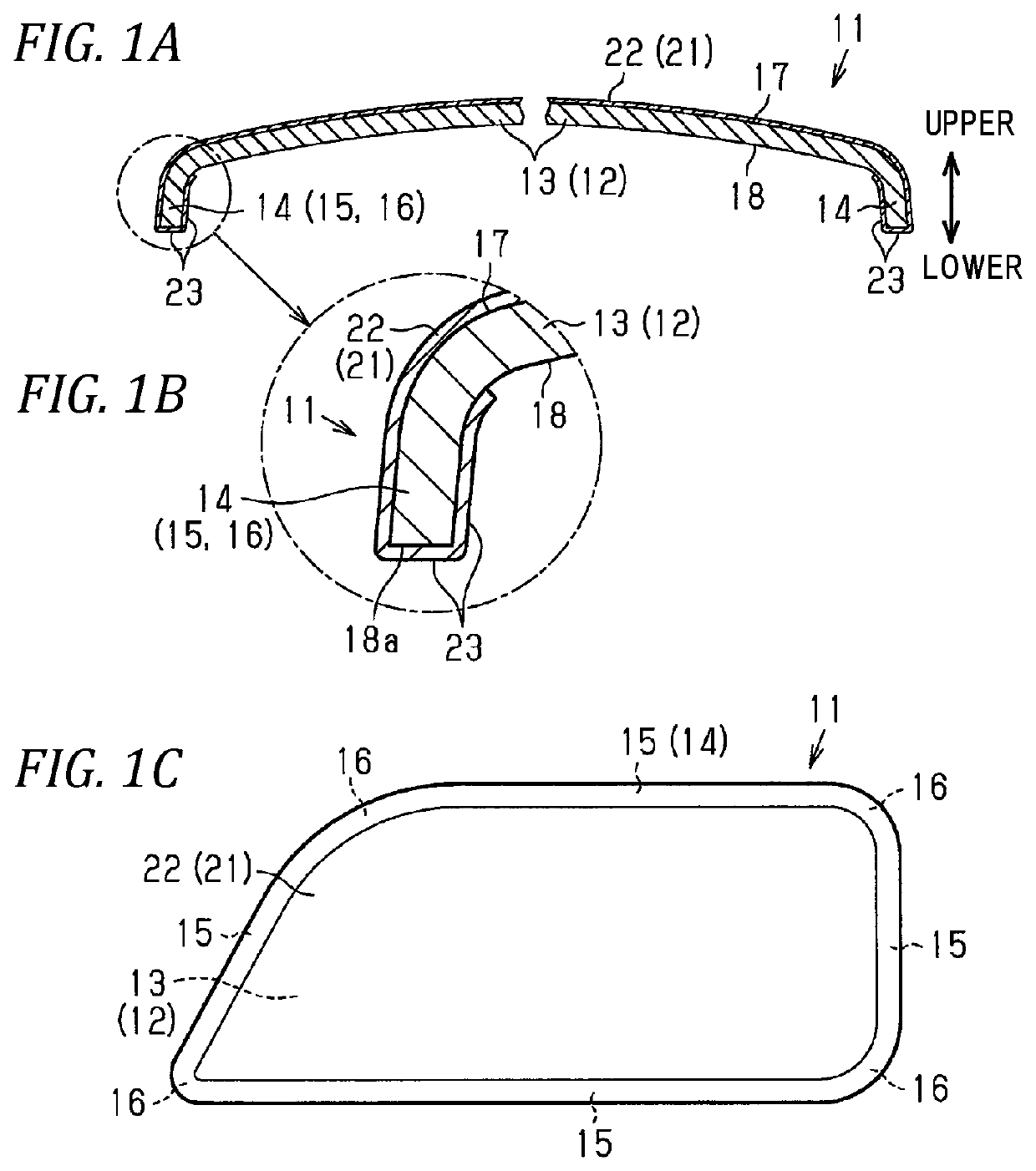

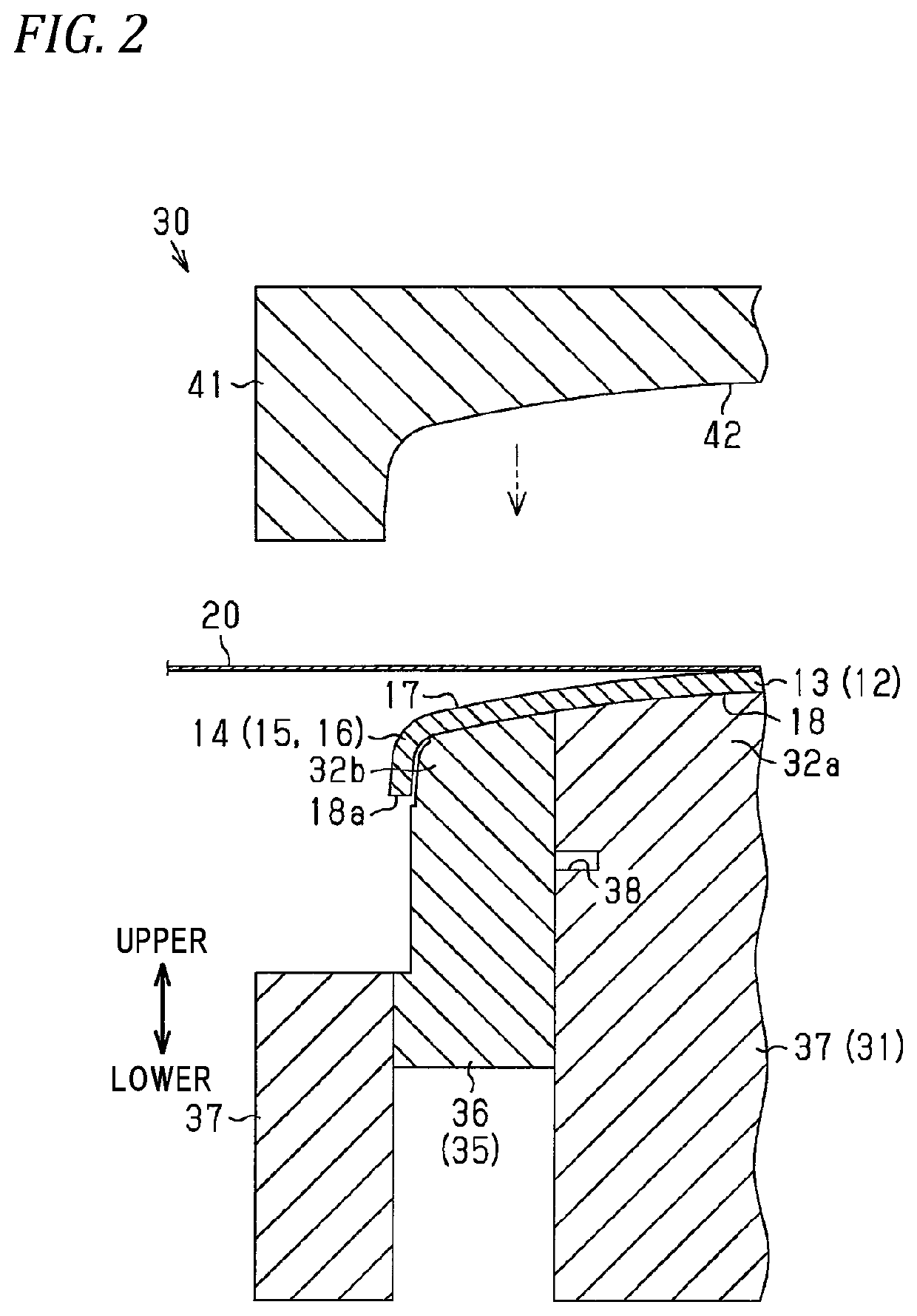

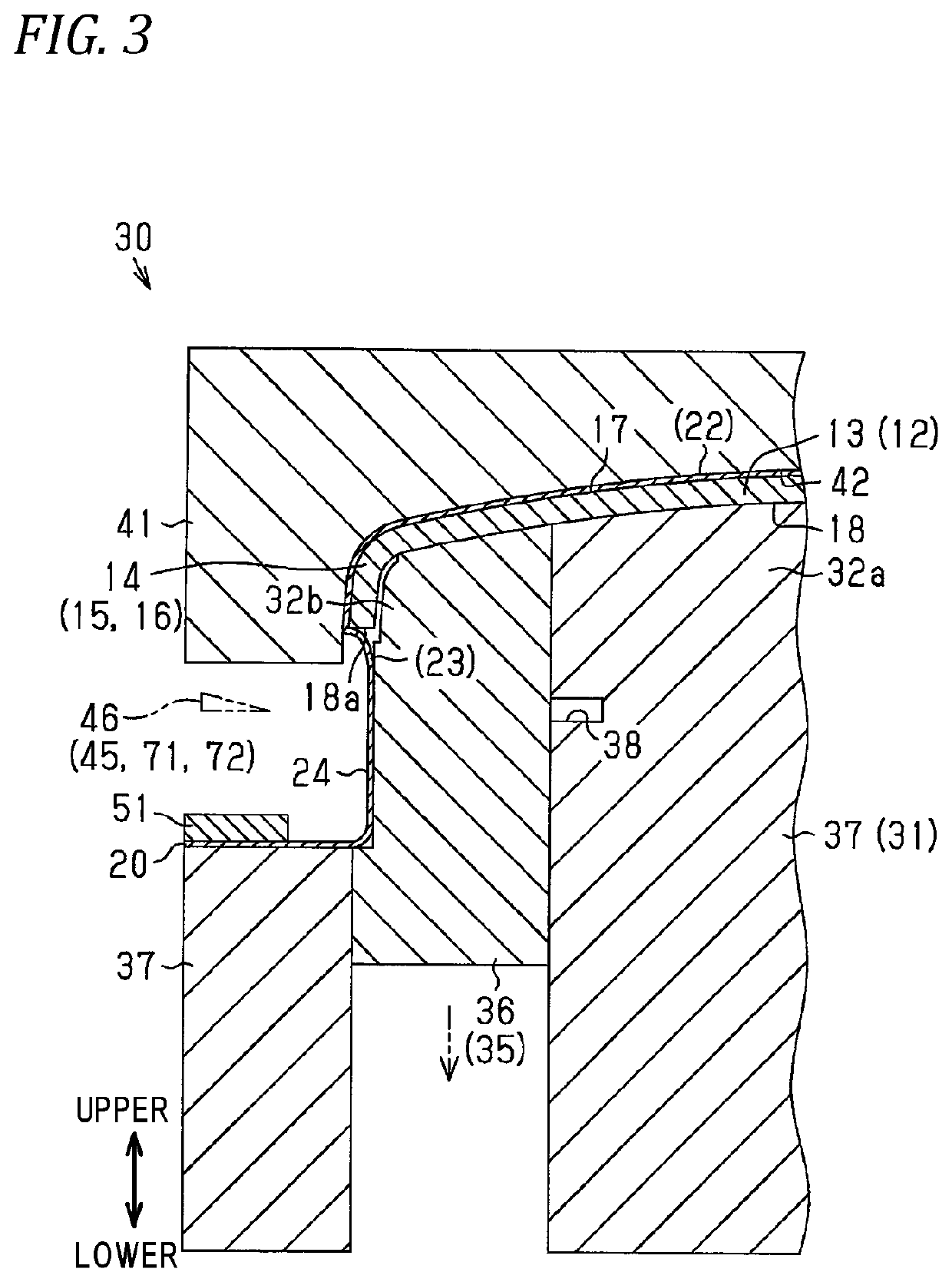

Method of manufacturing product with skin

ActiveUS10717224B2Suppress excessive elongationIncrease cutting lengthDomestic articlesMechanical engineeringComposite material

A method of manufacturing a product with skin includes: attaching a preformed base material to a vacuum forming die on a back surface of the base material, disposing a skin material as a material of the skin on a front surface of a base material, and sucking the skin material through the vacuum forming die and the base material to deform a main portion of skin material so as to be in close contact with the front surface of the base material; cutting a surplus portion of the skin material not being in close contact with the front surface of the base material with a trim blade so that a distal end portion remains around the main portion, thereby forming the skin having the distal end portion; and winding the distal end portion of the skin around the back surface of the base material by a winding mechanism.

Owner:TOYODA GOSEI CO LTD

Process for increasing shearing length of cold-rolled circle shear

PendingCN112589178AExtended shear distanceIncrease productivityShearing machinesMetal rolling arrangementsEngineeringStructural engineering

The invention provides a process for increasing the shearing length of a cold-rolled circle shear. The process comprises the steps of shear material selection and mixed assembly and use of upper and lower shear different hardness, a first loop, pressing rollers, circle shear mechanisms, a driving roller mechanism and a second loop are included, the first loop and the second loop can be sleeved with strip steel, the strip steel is distributed between the first loop and the second loop, the strip steel makes contact with the two pressing rollers up and down and is connected with the two pressingrollers, the circle shear mechanisms are symmetrically arranged on the left side and the right side of the strip steel and comprise an upper circle shear and a lower circle shear, the upper circle shear and the lower circle shear are made of different materials, the upper circle shear is made of 7CrMo3V2Si, the lower circle shear is made of W6Mo5Cr4V2, and 0.5 mm is reserved in the later period of machining of the upper circle shear and the lower circle shear for ultra-fine grinding treatment. The shearing distance of the circle shear is prolonged, the occurrence of cutter breakage is reduced, the production efficiency of a cold rolling unit can be improved, and the input cost of the circle shear is reduced.

Owner:天津市新天钢冷轧薄板有限公司

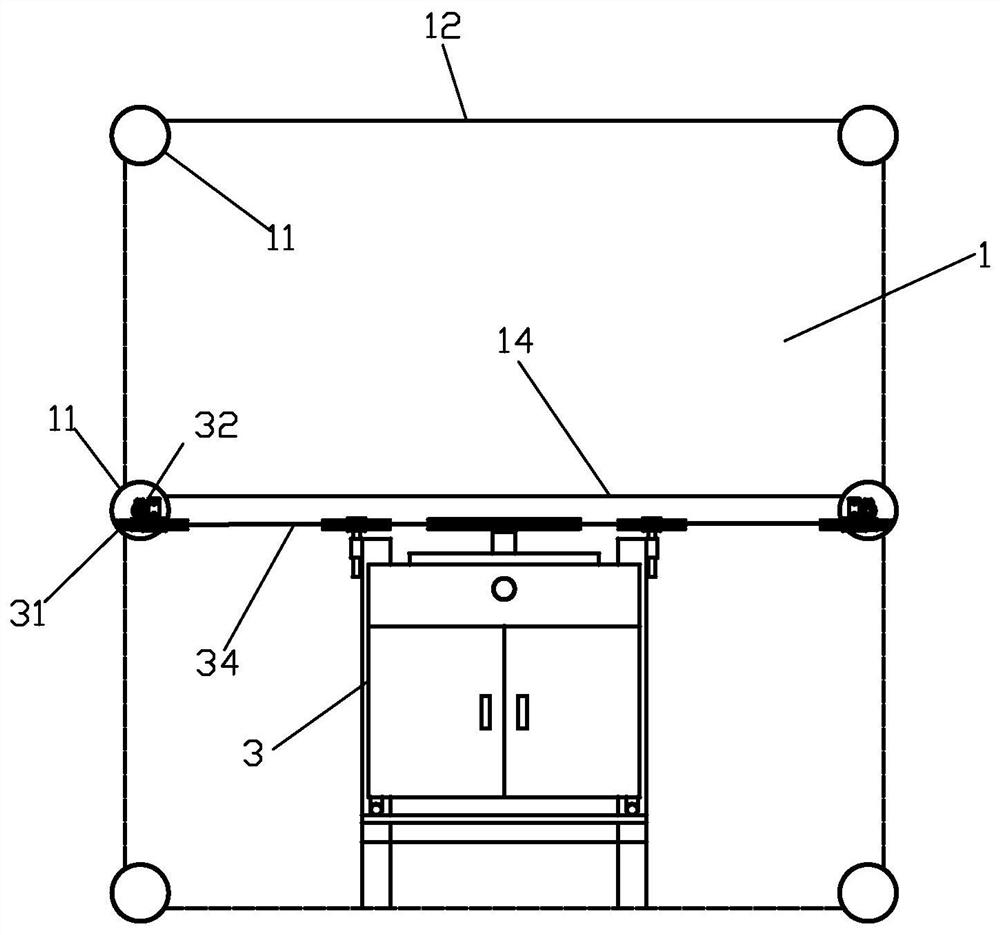

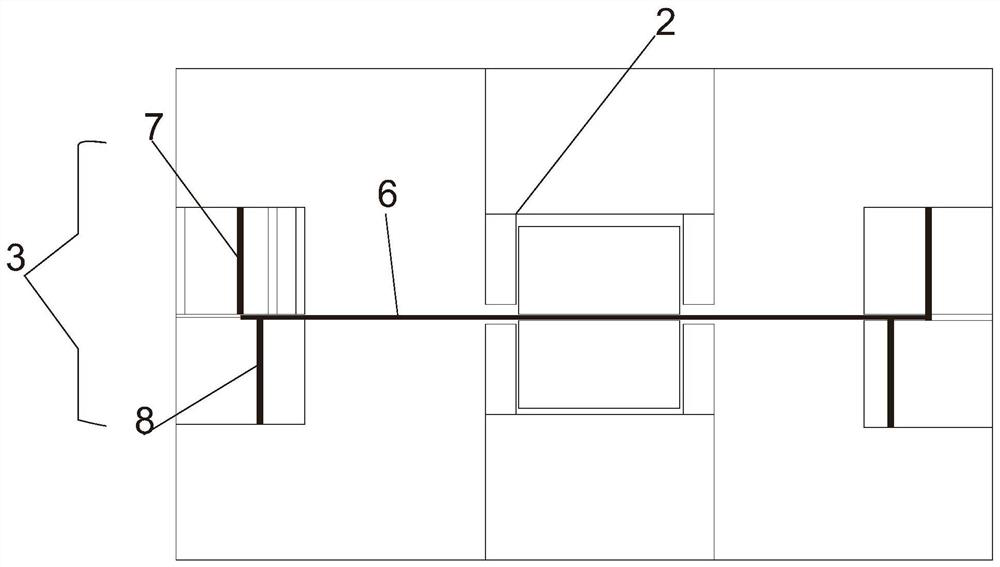

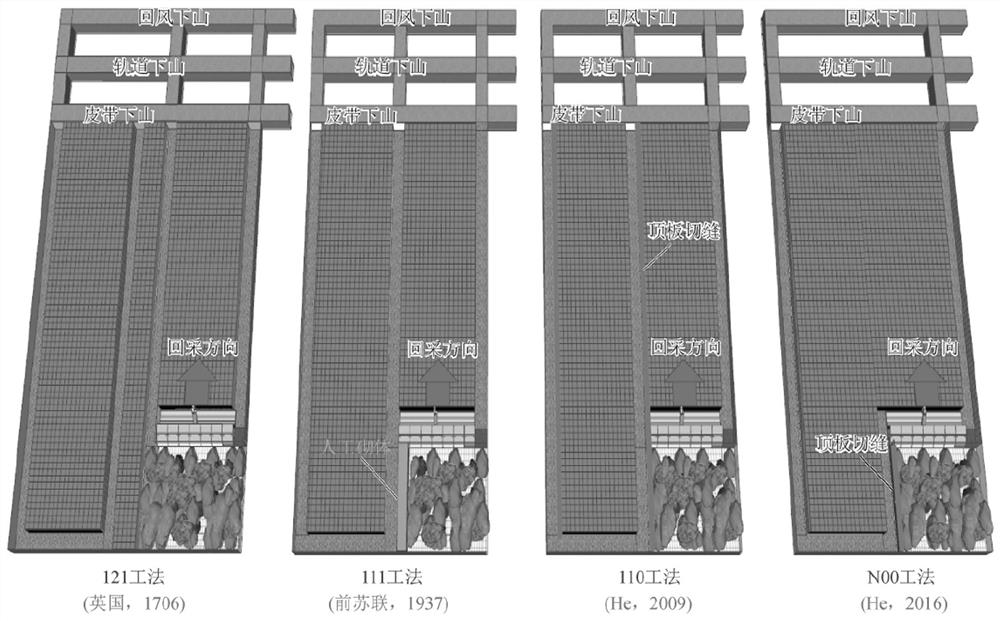

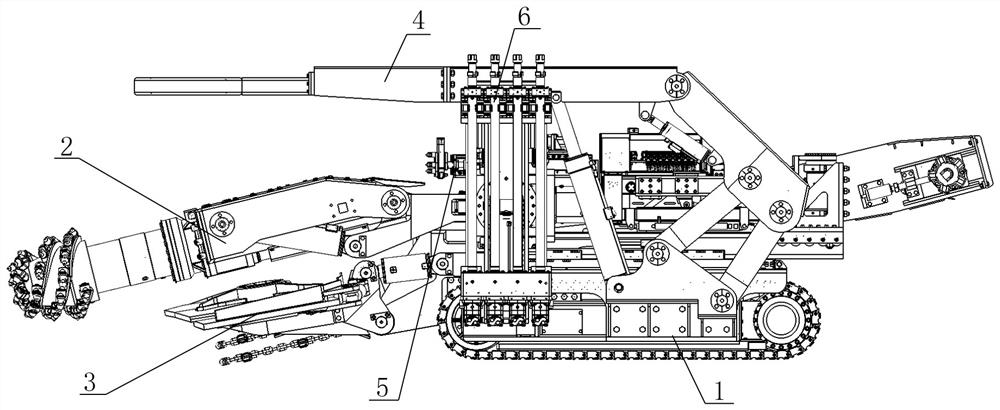

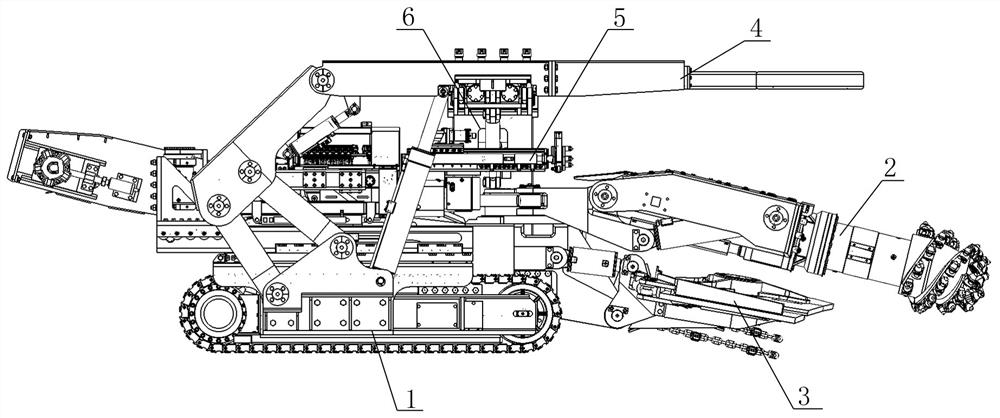

Thin coal seam N00 construction method mining, cutting and anchoring system

PendingCN114810058AIncrease cutting lengthGuaranteed stabilityUnderground miningSurface miningMining engineeringMachine

The thin coal seam N00 construction method mining, cutting and anchoring system comprises a walking mechanism and a cutting mechanism, a shovel plate mechanism, a supporting mechanism, an anchor rod mechanism and a joint cutting mechanism which are arranged on the walking mechanism, and is characterized in that the walking mechanism is composed of a lower base and two walking tracks fixed to the two sides of the lower base; an upper base capable of moving front and back in the length direction of the walking crawler belt is arranged on the lower base, guide columns, first telescopic oil cylinders and positioning blocks are arranged on the two sides of the upper base, the positioning blocks are fixed to the lower base, the guide columns can be inserted into the positioning blocks in a front-back moving mode, and the cutting mechanism and the shovel plate mechanism are fixed to the front end of the upper base. According to the thin coal seam N00 construction method mining, cutting and anchoring system, the upper base is driven by the first telescopic oil cylinder to move forwards on the lower base, the cutting length of the cutting mechanism to a coal seam roadway can be extended under the condition that the whole machine is not moved, and the phenomenon that dead corners which cannot be cut exist on the two sides of the roadway when a cutting head can only rotate is avoided.

Owner:山东兖煤黑豹矿业装备有限公司

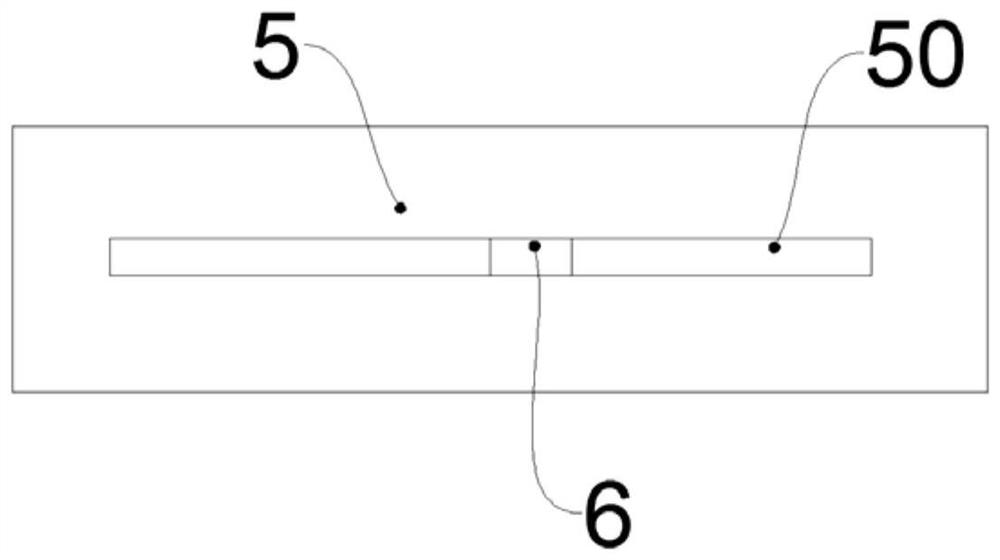

Adjusting device for wire passing wheel of wire cutting machine

PendingCN110774465AImprove stabilityFree and fast movement to adjust positioningWorking accessoriesGrinding machinesWire cuttingMachine

The invention provides an adjusting device for a wire passing wheel of a wire cutting machine. The adjusting device comprises a long-bar-shaped sliding rail which is transversely arranged, a transverse moving sliding block and a fastening mechanism. The transverse moving sliding block is arranged on the long-bar-shaped sliding rail in a sleeving manner and can slide along the long-bar-shaped sliding rail. A threaded hole is formed in one side of the transverse moving sliding block, and the transverse moving sliding block is used for driving the wire passing wheel to move along the long-bar-shaped sliding rail. The fastening mechanism comprises a bolt and a pressing block, the pressing block is provided with a clamping groove matched with the outer side surface of the long-bar-shaped sliding rail, the bolt is screwed in the threaded hole of the transverse moving sliding block, one end of the bolt penetrates out of the transverse moving sliding block and is connected with the pressing block so that the pressing block can abut against the long-bar-shaped sliding rail, and the surface of at least one side of the clamping groove of the pressing block is in a rectangular shape. By meansof the adjusting device for the wire passing wheel of the wire cutting machine, the adjusting stability of the wire passing wheel can be improved, and free and fast moving, adjusting and positioning of the wire passing wheel are ensured, and the production efficiency is improved.

Owner:晶海洋半导体材料(东海)有限公司

Beard trimmer

ActiveUS10792824B2Improve abilitiesEase of use and comfortMetal working apparatusStructural engineeringMechanical engineering

An electric hair cutting kit comprises a handle with a motor for driving a beard trimmer head portion and a shaver head portion. The shaver head portion is attachable to the handle and has at least a first shaver unit, which is provided with a first foil-type outer shaver cutter and a first inner shaver cutter.

Owner:BRAUN GMBH

Winding head and cutting machine of multi-wire cutting machine

InactiveCN103182751BReduce the chance of breakageRealize single wire cuttingFine working devicesWinding machineMotor drive

The invention discloses a winding machine head of a multi-wire cutting machine and the cutting machine. The winding machine head comprises even numbers of winding wheel supports, winding wheels, lead screw module connecting blocks, and drive wheels with the same quantity as that of the winding wheel supports, wherein each winding wheel support is fixedly arranged together, the winding wheel supports and the lead screw module connecting blocks are fixedly arranged together, at least one winding wheel installing board which is arranged vertically is arranged on each winding wheel support, one winding wheel is arranged on each winding wheel support, the plane where the winding wheels are positioned is tangent with the drive wheels, the axes of the two sets of opposite driving wheels are in parallel with one another, each drive wheel comprises a driving wheel and a driven wheel, which are coaxially arranged with each other, and a driving wheel motor drives one driving wheel to rotate. After the winding machine head is used, through the specific structural design of the drive wheels and the winding wheels, and in combination with steering wheels, the single-line cutting can be realized, the cutting length can be effectively prolonged, the possibility for breaking a diamond wire can be reduced, and the production efficiency can be improved.

Owner:高本龙 +1

Modular cutting-teeth drill bit with controllable drilling specific pressure

ActiveUS9562398B2Increase volumeIncrease of effective abrasion volumeDrill bitsConstructionsModular unitEngineering

A modular cutting-teeth bit having controllable specific pressure for drilling includes: a module (1), a modular unit (2), a bit body (3), conventional cutting teeth (4) and a nozzle (5). According to mechanical performance of the rocks in the strata drilled and requirements of drilling well, a combination of shapes, sizes and numbers of the module and the modular unit is optimized; effective abrasion edge length of the cutting unit on a certain portion of the bit is controlled; and a constant specific pressure of the cutting unit of the bit during the drilling process is maintained.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

Device for collecting papain

The invention discloses a papain collecting device which comprises two sets of collecting frames, each collecting frame is of an arc-shaped structure design, a containing cavity is formed in the outer surface of the upper end of each collecting frame, a baffle is fixedly connected to the arc-shaped end face of each collecting frame, the collecting frames and the baffles are of an integrated structure, and the collecting frames are arranged in the containing cavities. An inserting block and a magnetic block are fixedly connected to the left end of the right collecting frame, and an inserting groove and a butt joint groove are formed in the positions, corresponding to the inserting block and the magnetic block, of the left collecting frame; the space for collecting papaya juice in the diaphragm can be separated from the external space under the mutual cooperation of the rubber band, the diaphragm and the binding groove, so that the internal collected papaya juice is kept isolated from the external space, an air conditioner is communicated with an air delivery pipe while the papaya juice is collected, cold air is injected into the refrigerating cavity, and the refrigerating effect is improved. When the papaya juice is collected, the papaya juice is cooled and preserved.

Owner:GUANGXI SUBTROPICAL CROPS RES INST GUANGXI SUBTROPICAL AGRI PROD PROCESSING RES INST

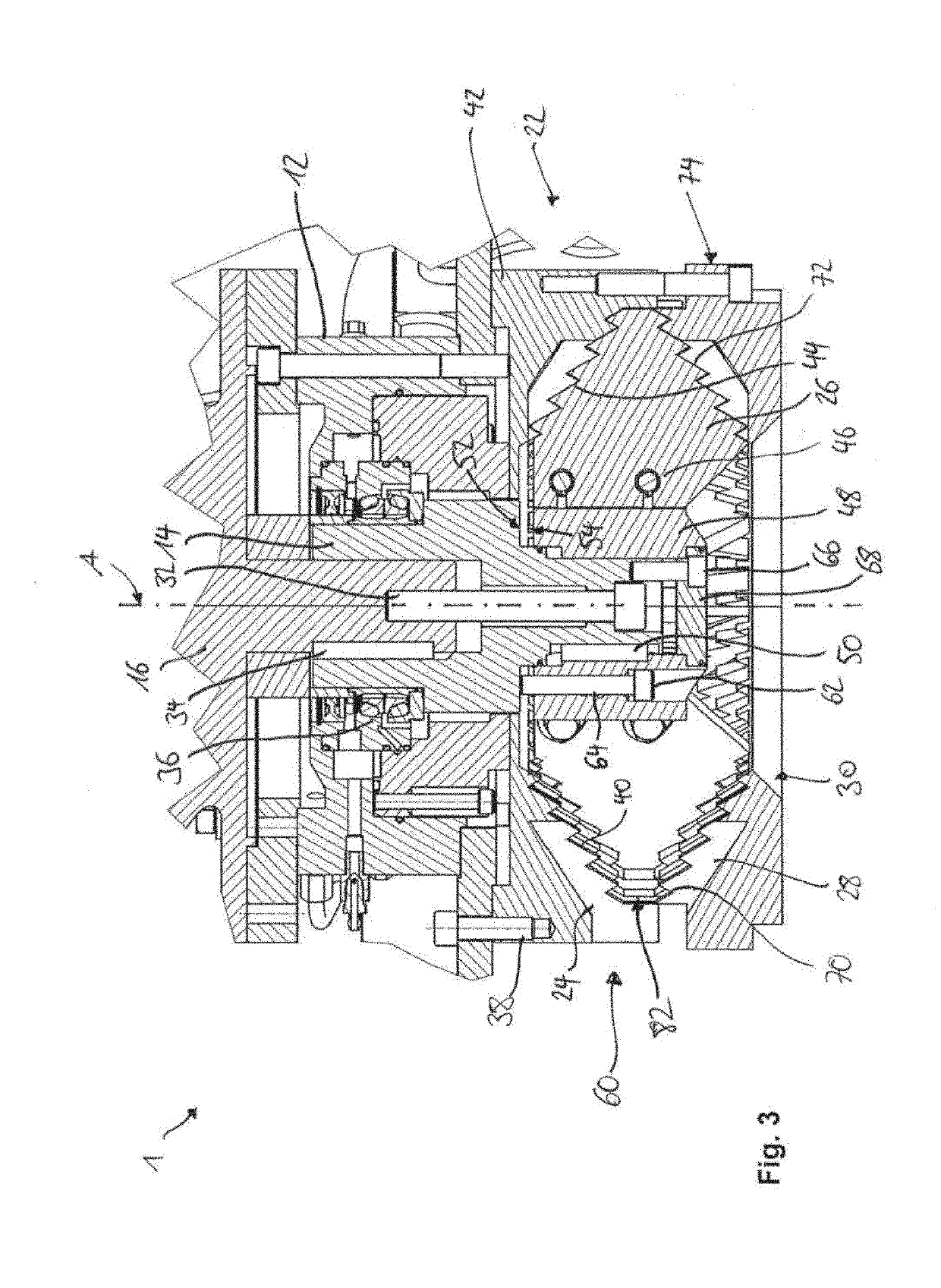

Fine comminutor

ActiveUS20190210034A1Cost effective productionIncreased complexityGrain treatmentsRotational axisEngineering

A comminution device comprises a plurality of first cutting elements having first serrated cutting edges disposed on a first circular path; a second cutting element having a second serrated cutting edge corresponding to the first serrated cutting edges for cutting through cutting material, the second cutting element being displaceable about an axis of rotation on a second circular path concentric with the first circular path. The second serrated cutting edge comprises a plurality of jags and each jag comprises a radially inner flank and a radially outer flank, each at an angle to the axis of rotation. A drive rotationally drives the second cutting element about the axis of rotation and an adjustment mechanism by which the plurality of first cutting elements and the second cutting element are displaceable relative to each other axially in the direction of the axis of rotation, that a cutting gap between them is adjustable.

Owner:HUGO VOGELSANG MASCHINENBAU GMBH

Aluminum profile cutting device

PendingCN113510309AIncrease cutting lengthImprove ranging accuracyMeasurement/indication equipmentsMetal working apparatusLaser rangingEngineering

The invention provides an aluminum profile cutting device which comprises a feeding table, a discharging table, a cutting machine, a laser ranging module, a side plate and a baffle. The feeding table comprises a feeding conveying belt, the discharging table comprises a discharging conveying belt, and the cutting machine is located between the feeding conveying belt and the discharging conveying belt. The laser ranging module is located on one side of the output end of the discharging conveying belt and right faces the baffle, the side plate is fixedly installed on the discharging table, a sliding way is arranged on the side plate, and the baffle is slidably connected with the sliding way and located above the discharging conveying belt. The accuracy of the cutting length of an aluminum profile can be improved, and the problems of low efficiency and large error caused by manual measurement and marking in the existing aluminum profile cutting are solved.

Owner:广东言铝铝业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com