Patents

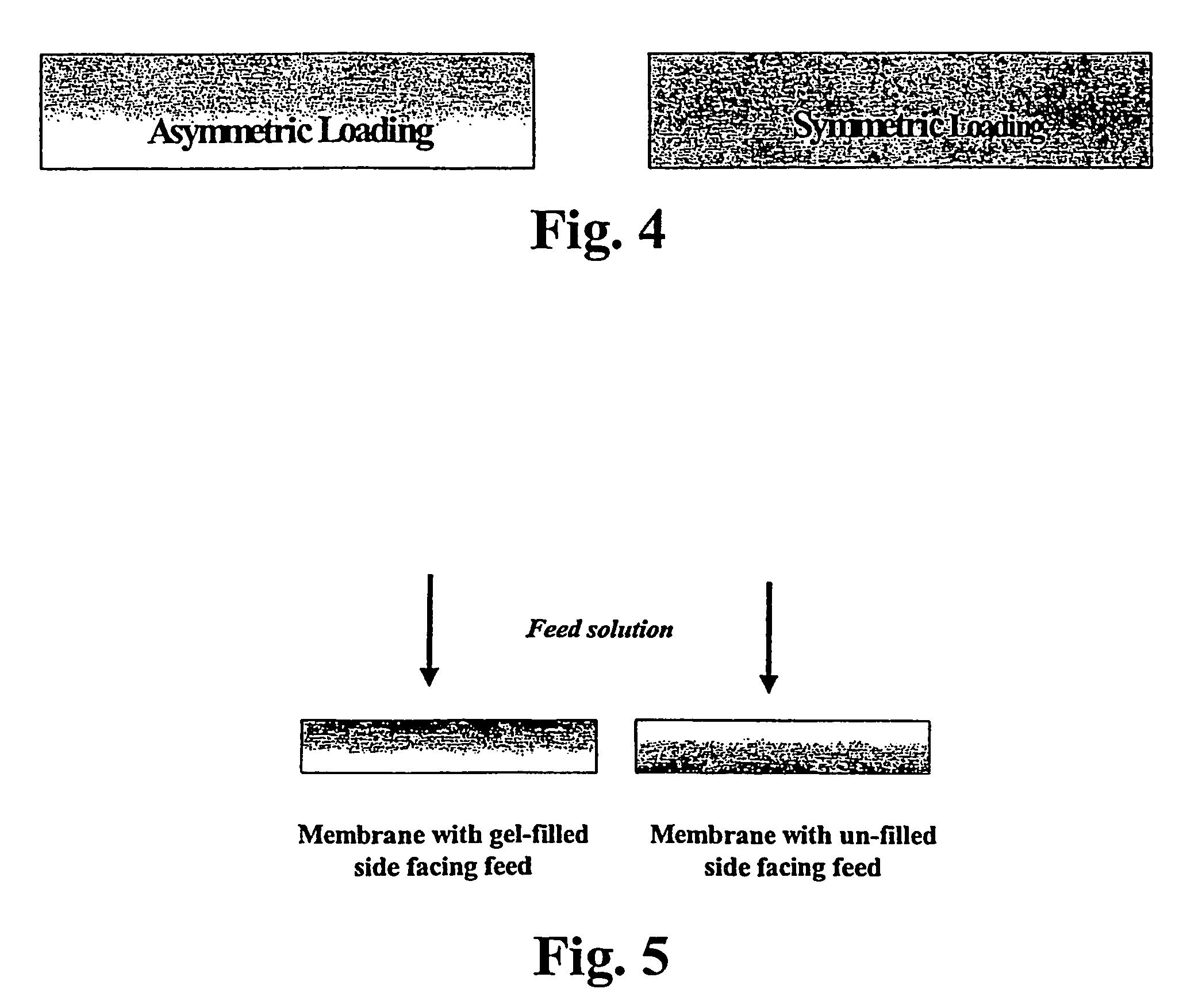

Literature

45results about How to "Ensure penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intracutaneous microneedle array apparatus

InactiveUS20050209565A1Sufficient separation distanceGreater transdermal fluxElectrotherapySurgical needlesEngineeringBiological fluids

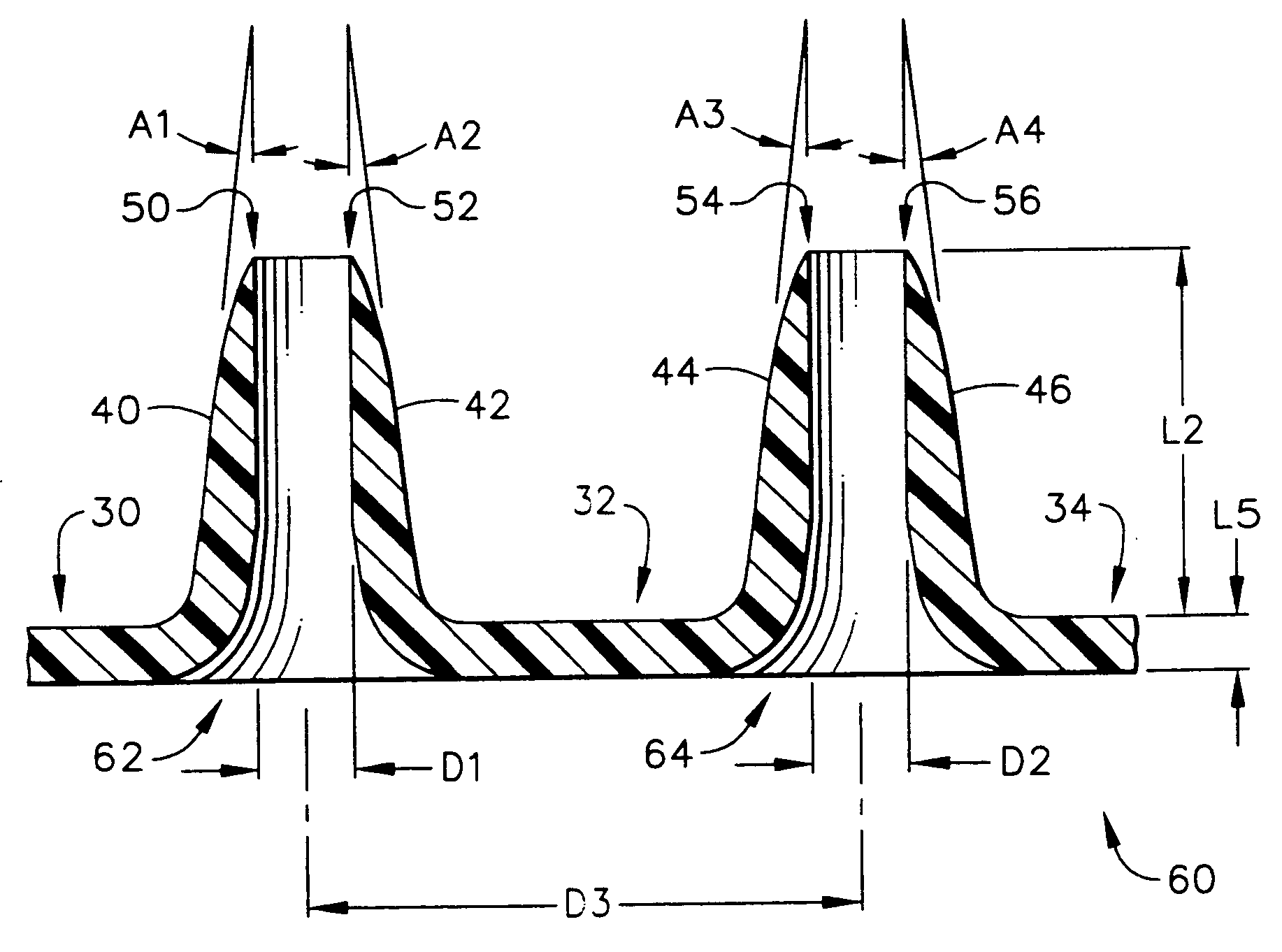

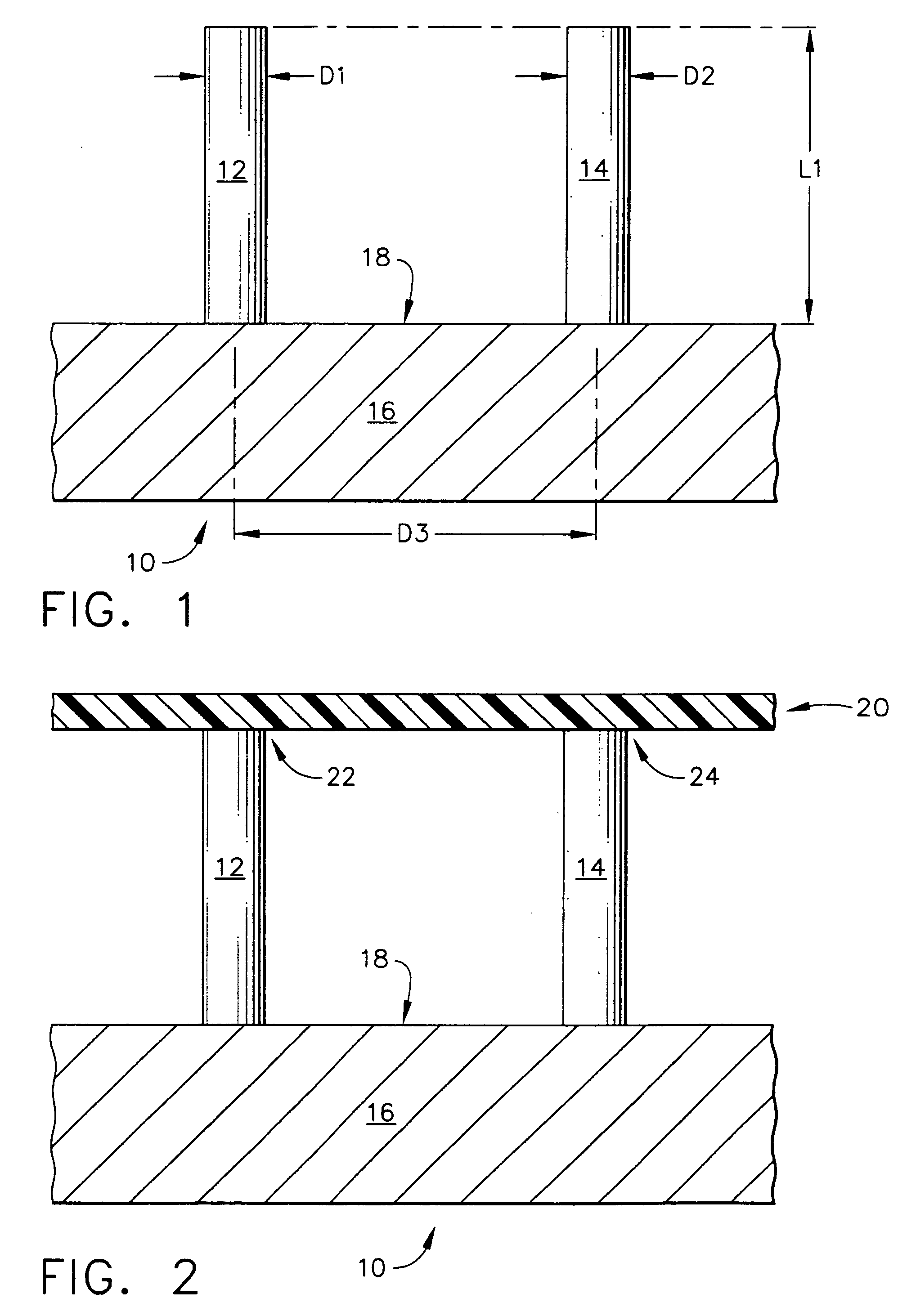

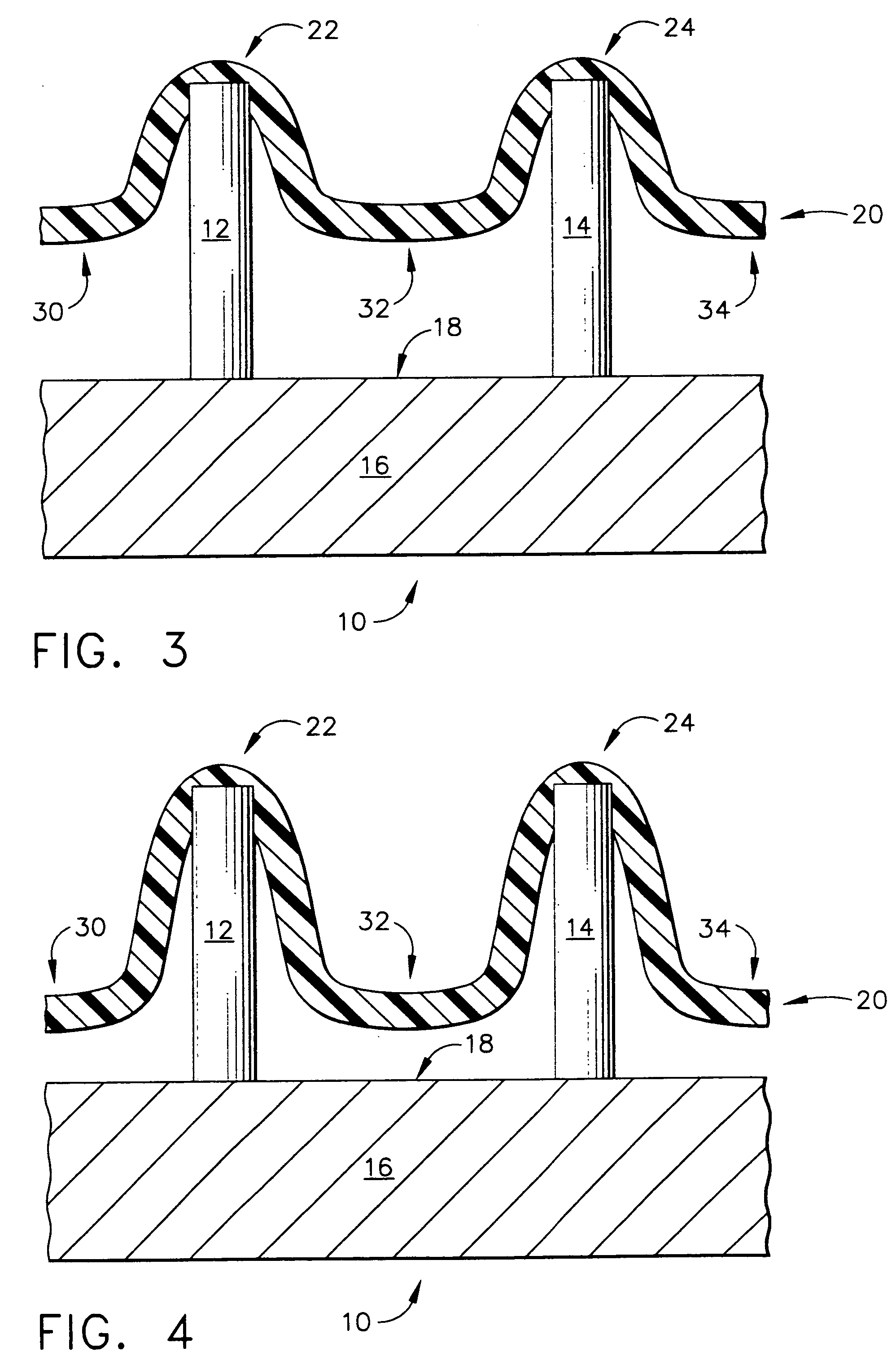

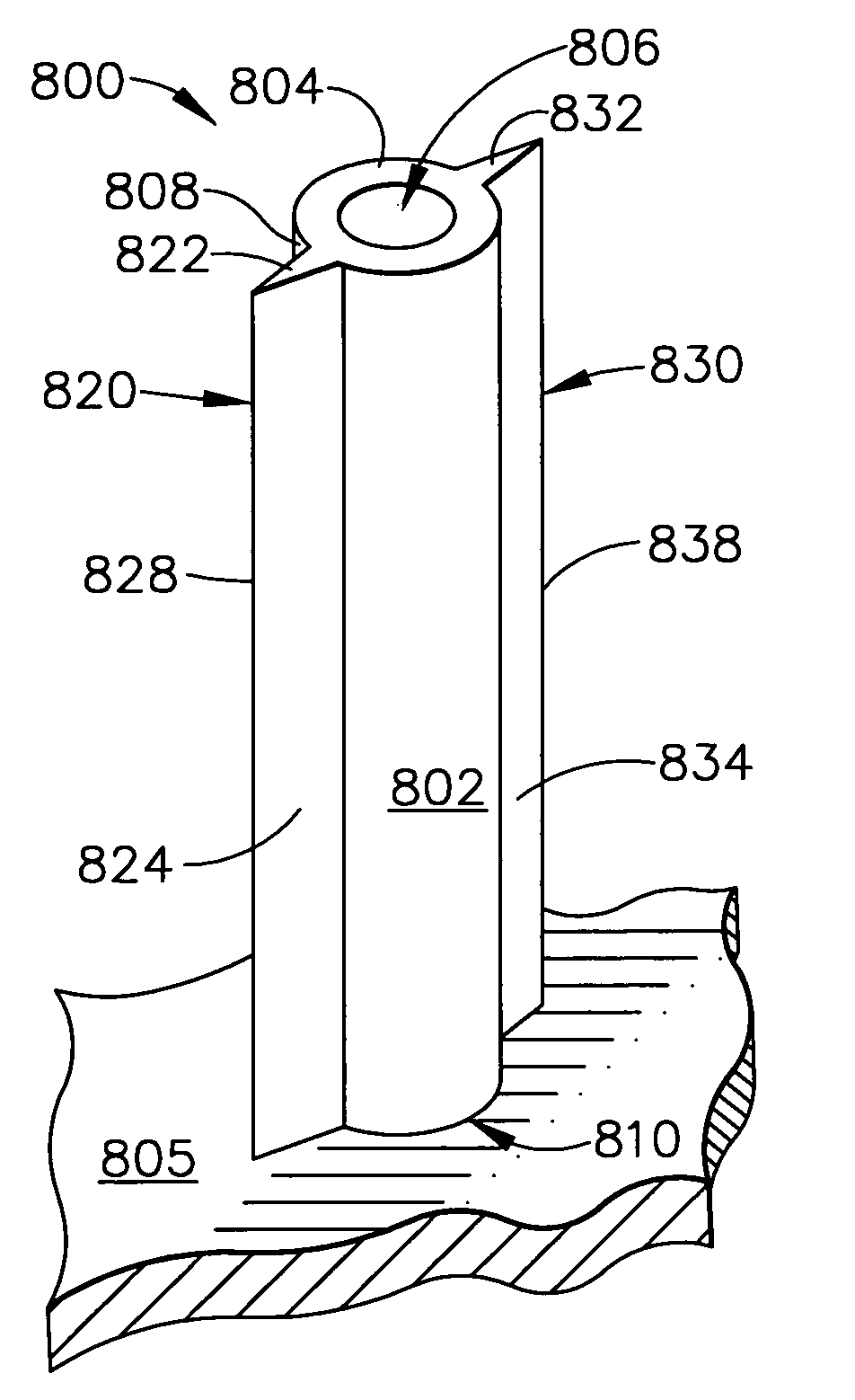

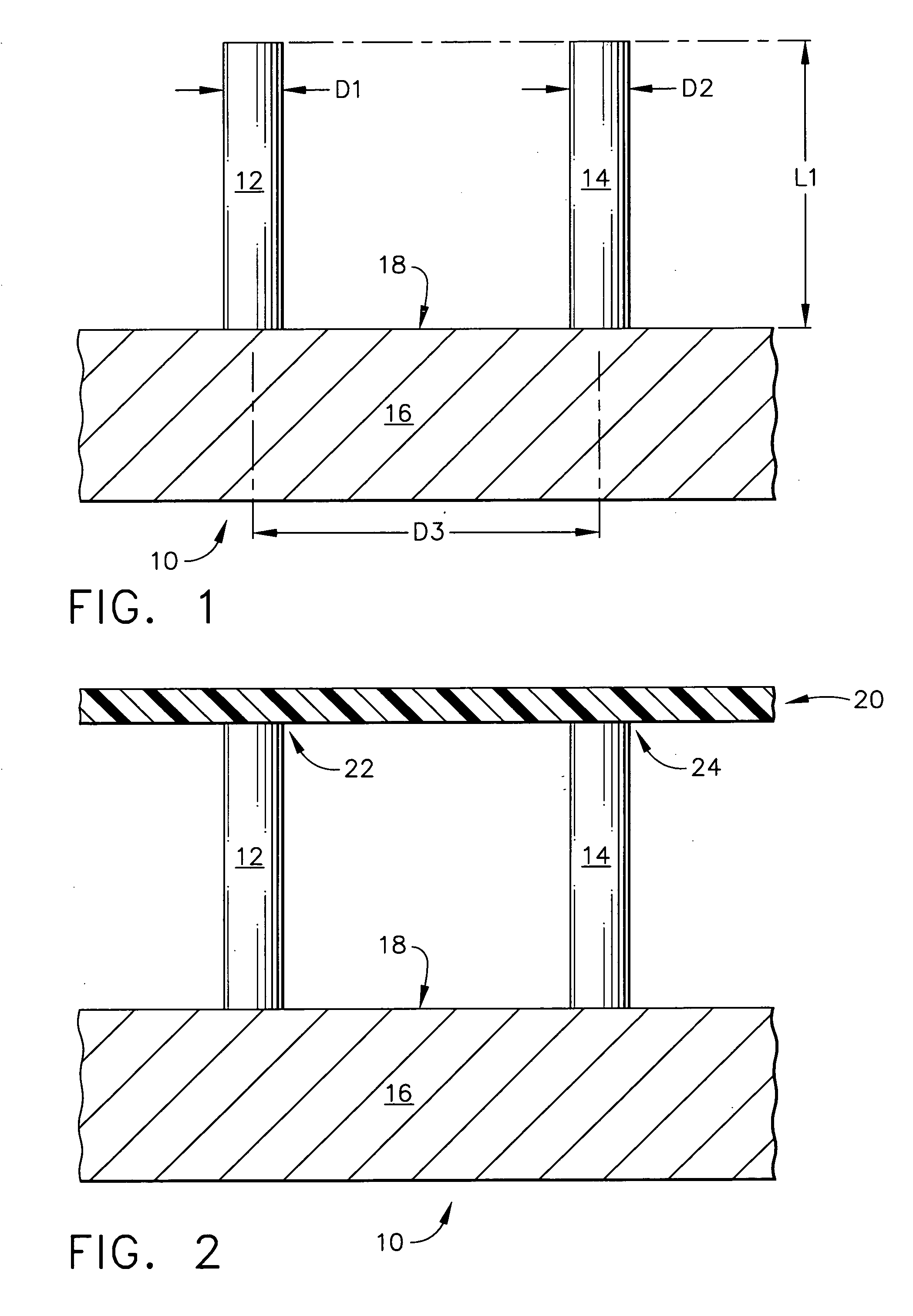

Improved microneedle arrays are provided having a sufficiently large separation distance between each of the individual microneedles to ensure penetration of the skin while having a sufficiently small separation distance to provide high transdermal transport rates. A very useful range of separation distances between microneedles is in the range of 100-300 microns, and more preferably in the range of 100-200 microns. The outer diameter and microneedle length is also very important, and in combination with the separation distance will be crucial as to whether or not the microneedles will actually penetrate the stratum corneum of skin. For circular microneedles, a useful outer diameter range is from 20-100 microns, and more preferably in the range of 20-50 microns. For circular microneedles that do not have sharp edges, a useful length for use with interstitial fluids is in the range of 50-200 microns, and more preferably in the range of 100-150 microns; for use with other biological fluids, a useful length is in the range of 200 microns—3 mm, and more preferably in the range of 200-400 microns. For circular microneedles having sharp side edges, a useful length for use with interstitial fluids is in the range of 50-200 microns, and more preferably in the range of 80-150 microns; for use with other biological fluids, a useful length is again in the range of 200 microns—3 mm, and more preferably in the range of 200-400 microns. For solid microneedles having a star-shaped profile with sharp edges for its star-shaped blades, a useful length for use with interstitial fluids is in the range of 50-200 microns, and more preferably in the range of 80-150 microns; for use with other biological fluids, a useful length is again in the range of 200 microns—3 mm, and more preferably in the range of 200-400 microns, while the radius of each of its blades is in the range of 10-50 microns, and more preferably in the range of 10-15 microns.

Owner:CORIUM INC

Intracutaneous microneedle array apparatus

InactiveUS6931277B1Facilitate biological fluid samplingIncrease transdermal flow rateElectrotherapyMicroneedlesStratum corneumEngineering

Improved microneedle arrays are provided having a sufficiently large separation distance between each of the individual microneedles to ensure penetration of the skin while having a sufficiently small separation distance to provide high transdermal transport rates. A very useful range of separation distances between microneedles is in the range of 100–300 microns, and more preferably in the range of 100–200 microns. The outer diameter and microneedle length is also very important, and in combination with the separation distance will be crucial as to whether or not the microneedles will actually penetrate the stratum corneum of skin. For circular microneedles, a useful outer diameter range is from 20–100 microns, and more preferably in the range of 20–50 microns. For circular microneedles that do not have sharp edges, a useful length for use with interstitial fluids is in the range of 50–200 microns, and more preferably in the range of 100–150 microns; for use with other biological fluids, a useful length is in the range of 200 microns–3 mm, and more preferably in the range of 200–400 microns. For circular microneedles having sharp side edges, a useful length for use with interstitial fluids is in the range of 50–200 microns, and more preferably in the range of 80–150 microns; for use with other biological fluids, a useful length is again in the range of 200 microns–3 mm, and more preferably in the range of 200–400 microns. For solid microneedles having a star-shaped profile with sharp edges for its star-shaped blades, a useful length for use with interstitial fluids is in the range of 50–200 microns, and more preferably in the range of 80–150 microns; for use with other biological fluids, a useful length is again in the range of 200 microns–3 mm, and more preferably in the range of 200–400 microns, while the radius of each of its blades is in the range of 10–50 microns, and more preferably in the range of 10–15 microns.

Owner:CORIUM INC

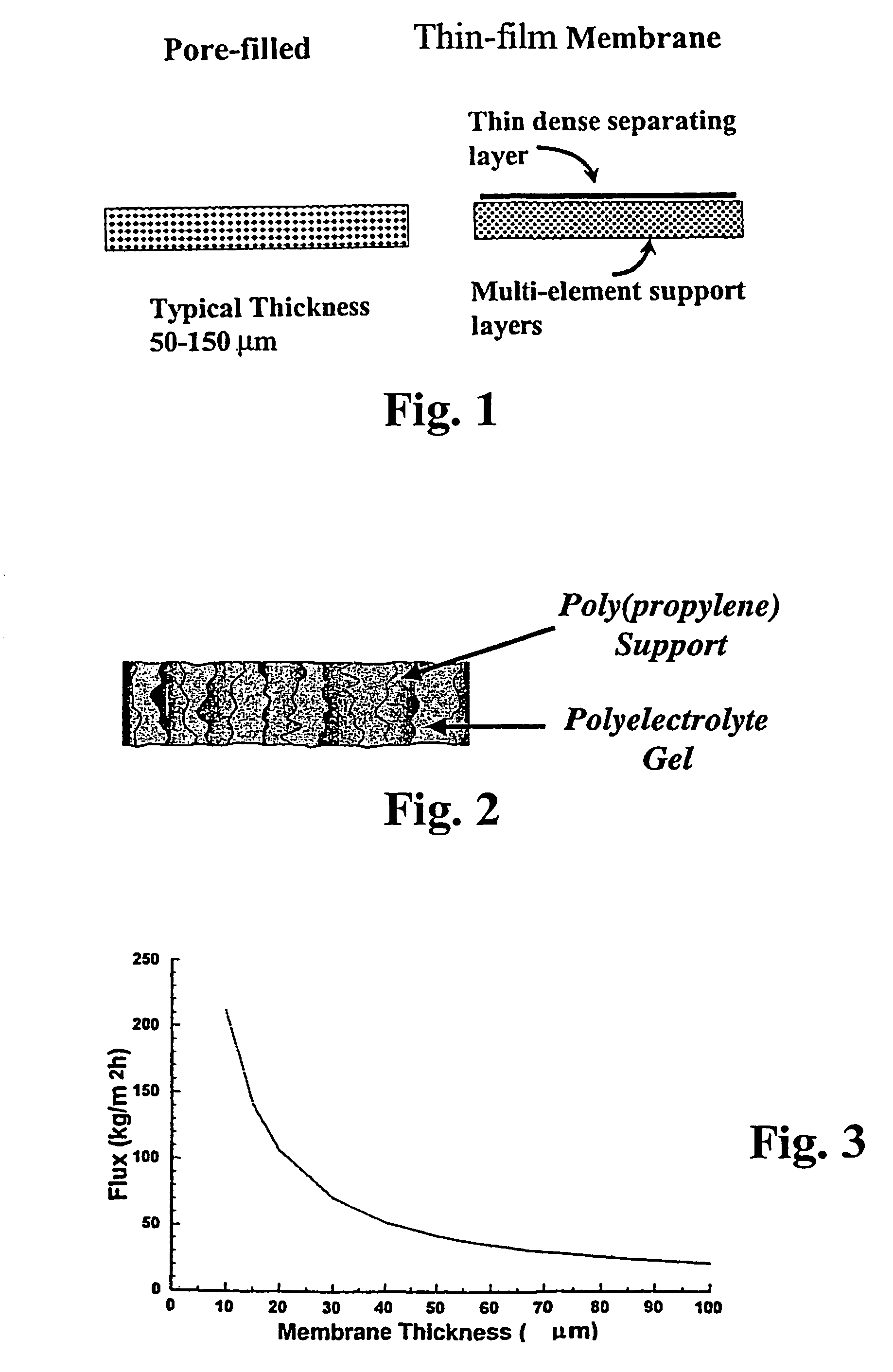

Asymmetric gel-filled microporous membranes

InactiveUS20050011826A1Excellent propertyImprove throughputMembranesSemi-permeable membranesCrystallographyVolumetric Mass Density

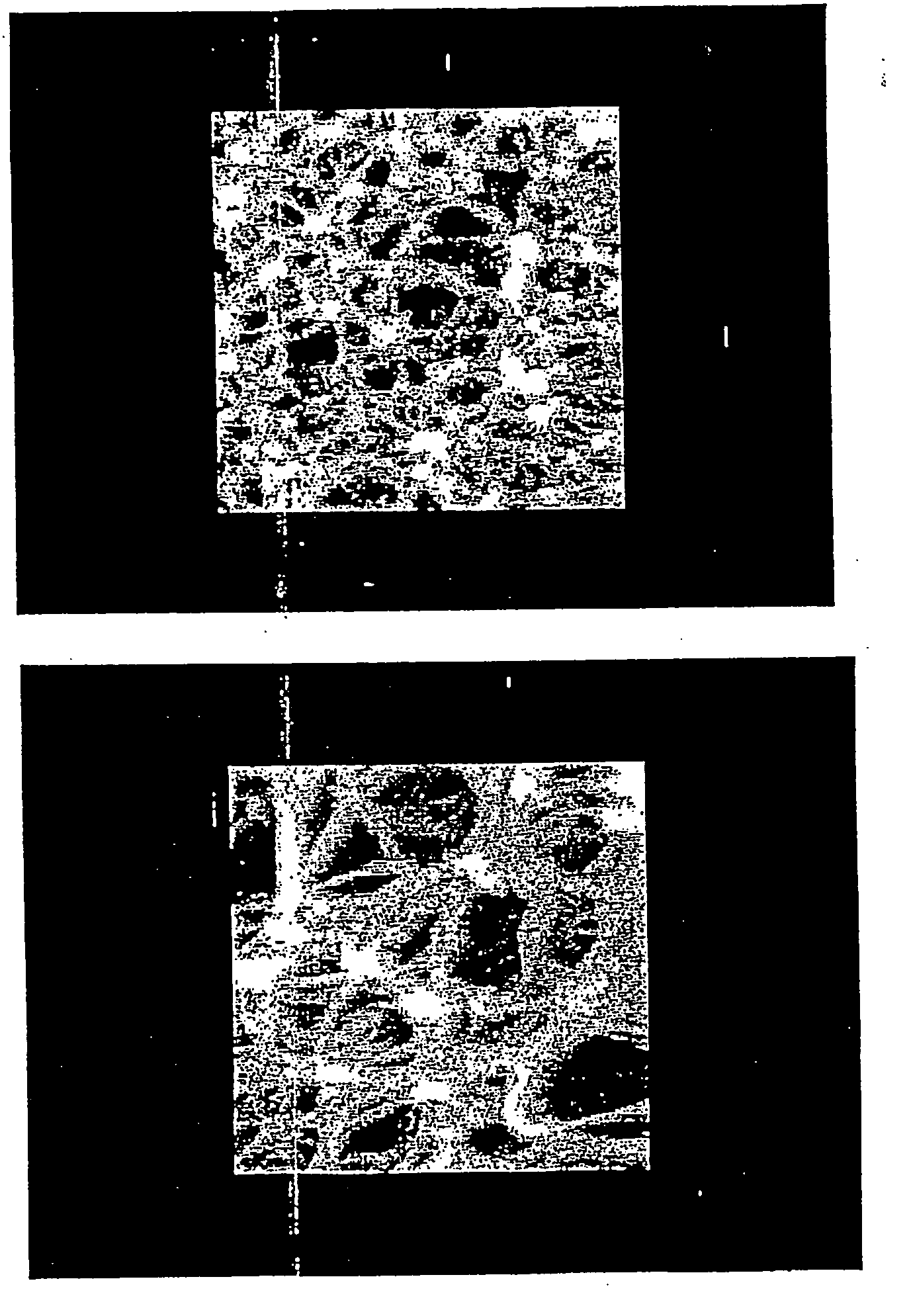

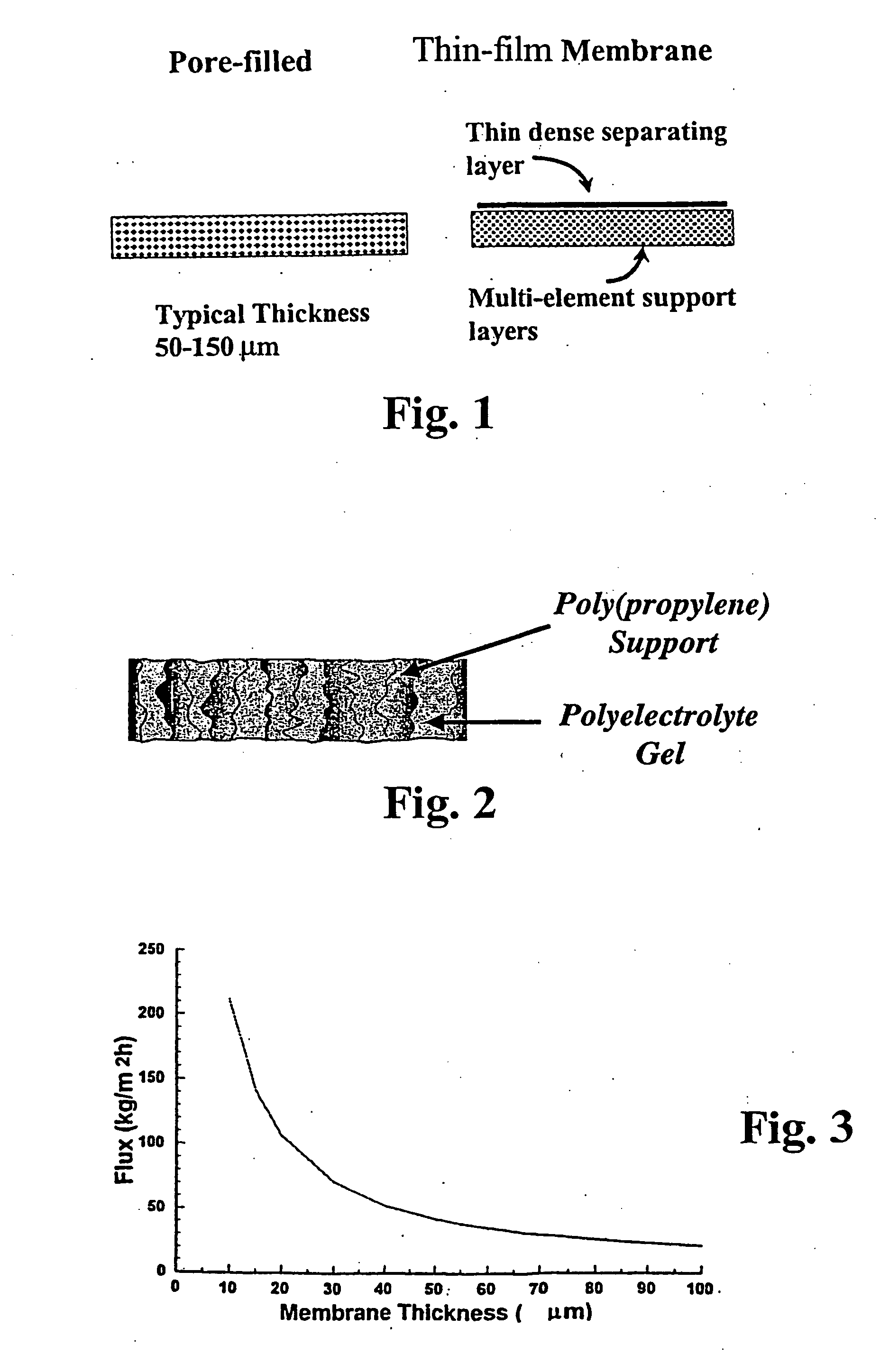

The invention provides asymmetric membranes composed of a microporous substrate whose pores contain a crosslinked gel, the density of the crosslinked gel being greater at or adjacent to one major surface of the membrane than the density at the other major surface. The membranes are useful for separating matter from liquids and display good flux and good rejection at low pressure.

Owner:MCMASTER UNIV

Asymmetric gel-filled microporous membranes

InactiveUS7247370B2Excellent propertyImprove throughputSemi-permeable membranesMembranesCrystallographyVolumetric Mass Density

The invention provides asymmetric membranes composed of a microporous substrate whose pores contain a crosslinked gel, the density of the crosslinked gel being greater at or adjacent to one major surface of the membrane than the density at the other major surface. The membranes are useful for separating matter from liquids and display good flux and good rejection at low pressure.

Owner:MCMASTER UNIV

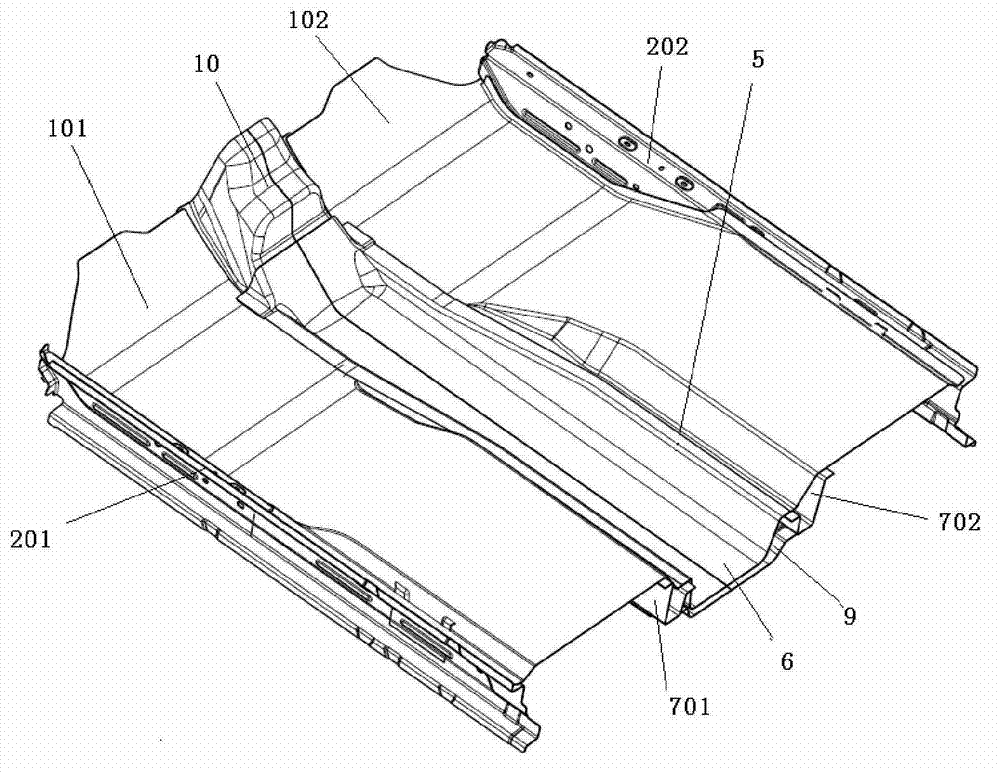

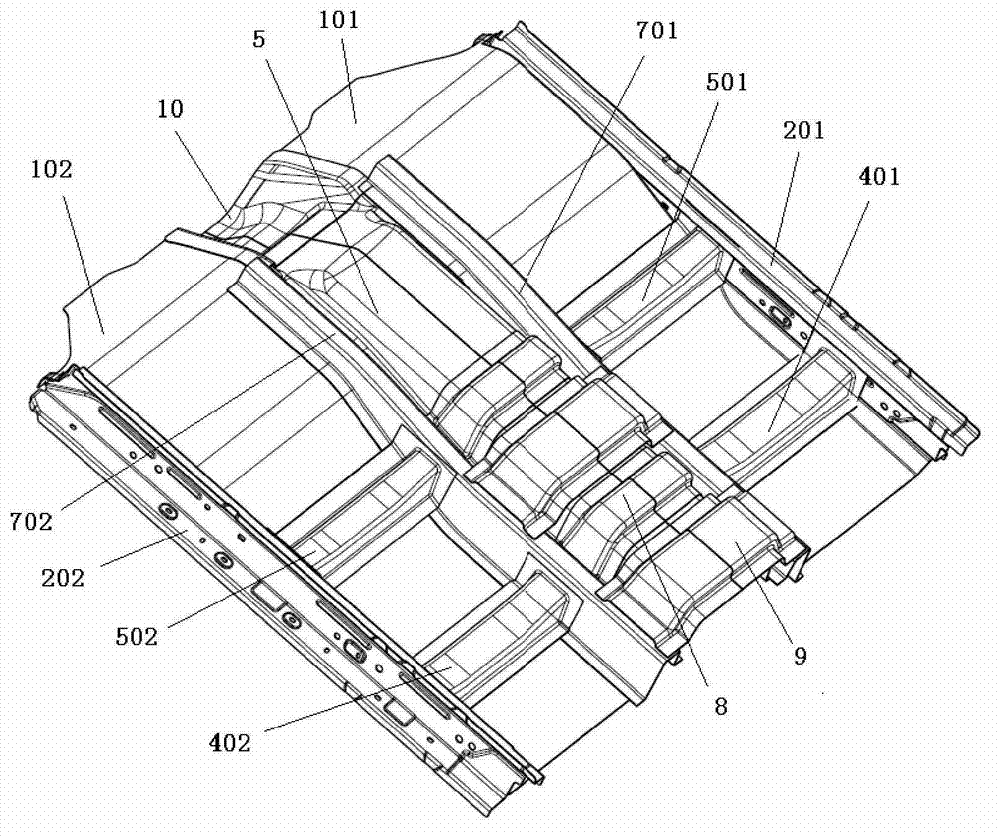

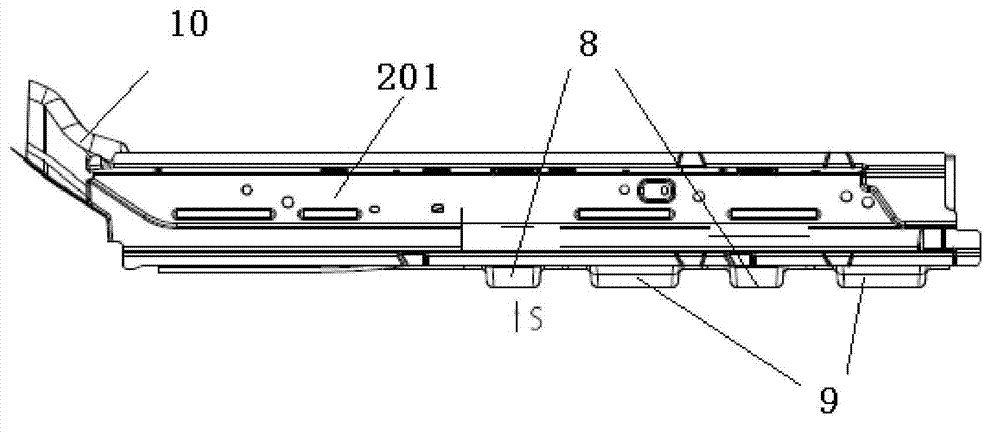

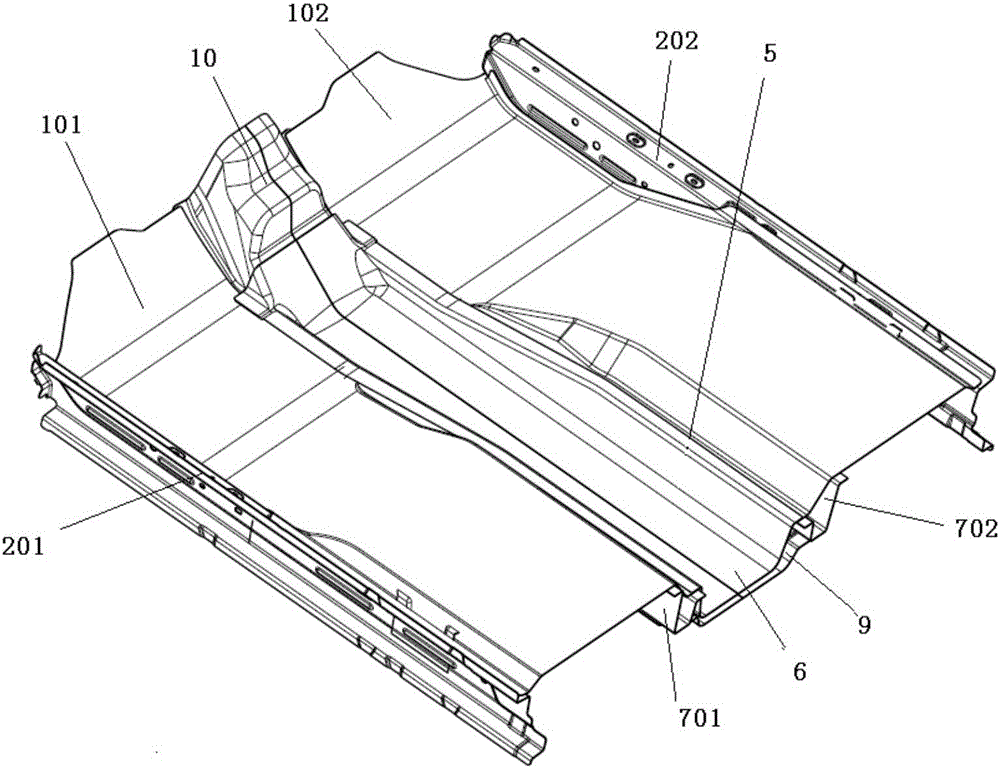

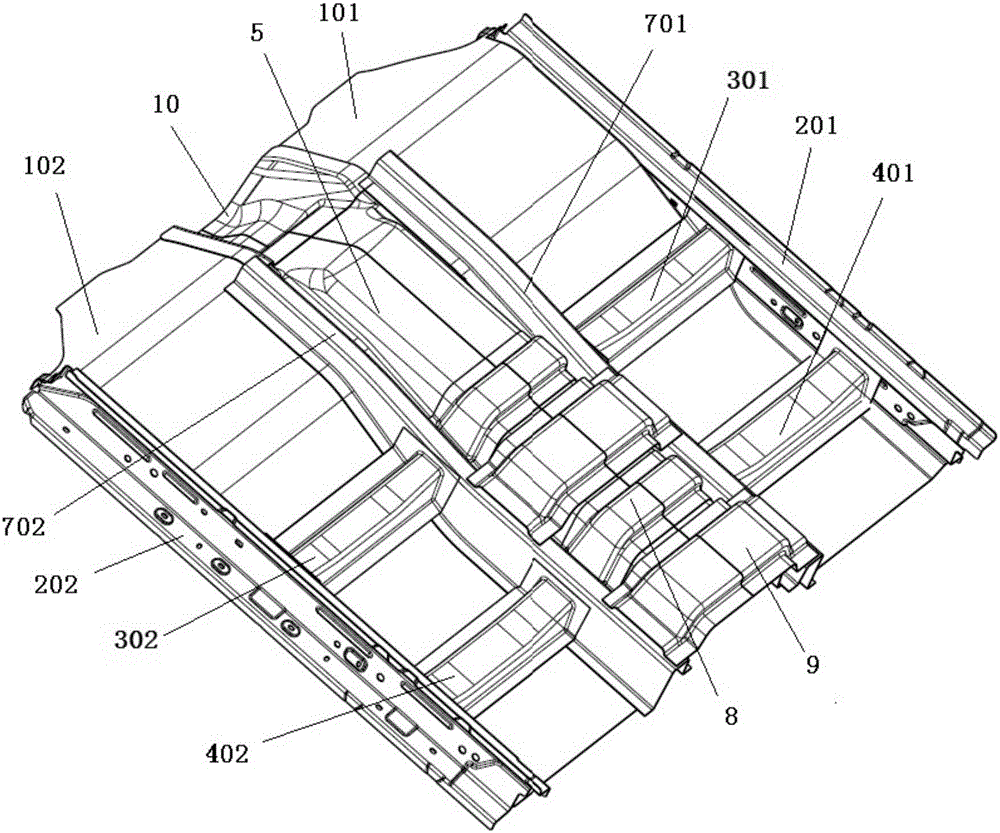

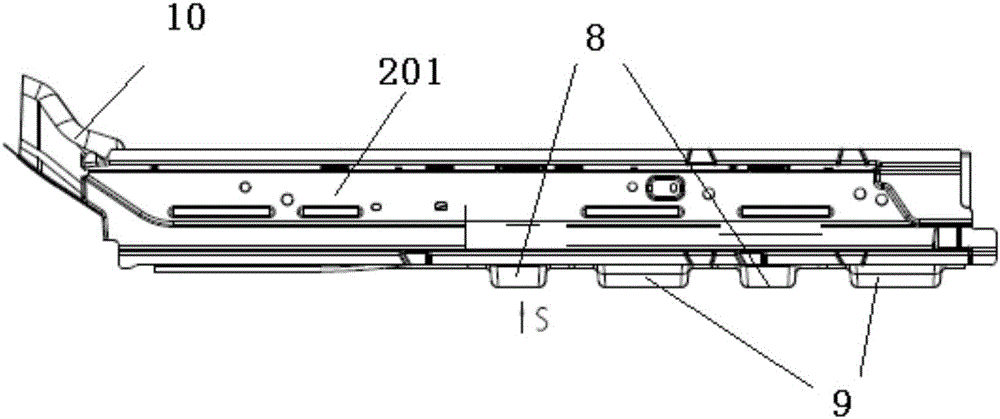

Automobile front floor assembly

ActiveCN102862612ASmall structural changesEasy to manufactureSuperstructure subunitsNacelleCost savings

The invention discloses an automobile front floor assembly which is arranged between a cabin assembly and a back floor assembly of an automobile and comprises a front floor body. The front floor body defines a center passage extending longitudinally along the automobile, and the center passage protrudes to the outside of the body of the automobile so that the cross section of the front floor body is in an inverted n-shaped approximately. The center passage of the automobile front floor assembly provides wider space for holding a motorcycle, so that the automobile front floor assembly is more suitable for a motorcycle and car combination mode. Besides, other structures on the automobile front floor assembly require small modification, the automobile front floor assembly is simple in manufacturing and cost-saving.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

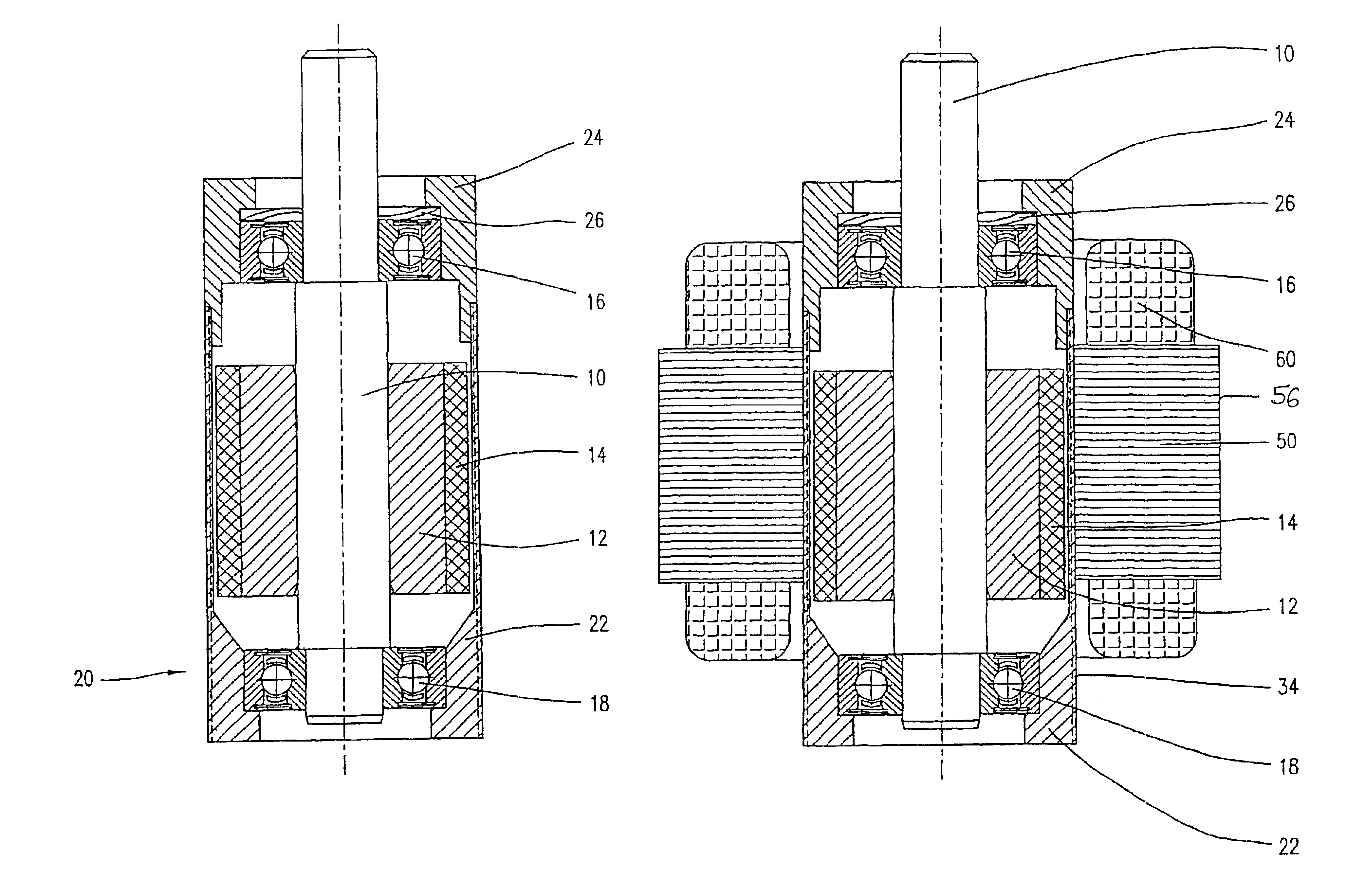

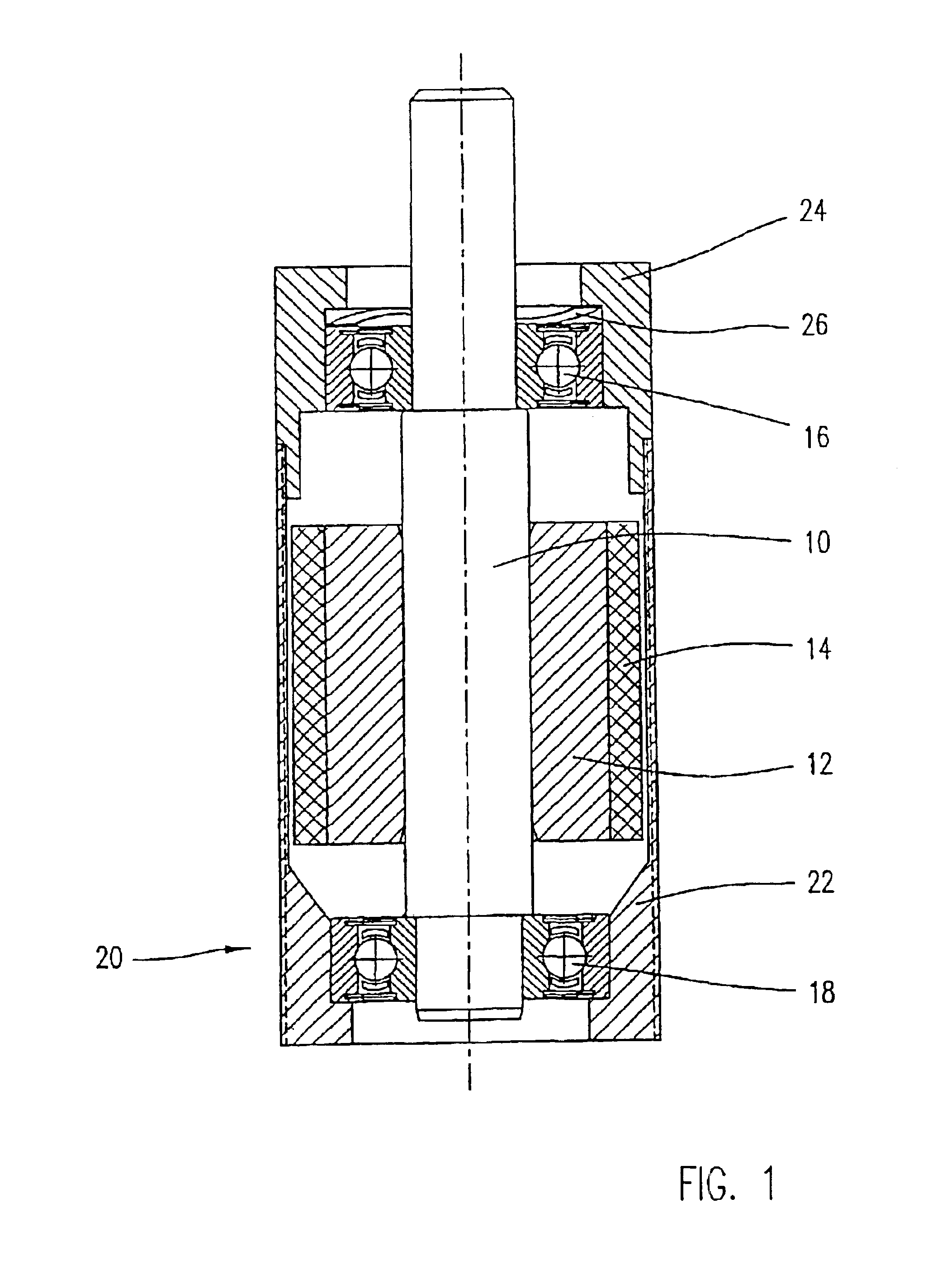

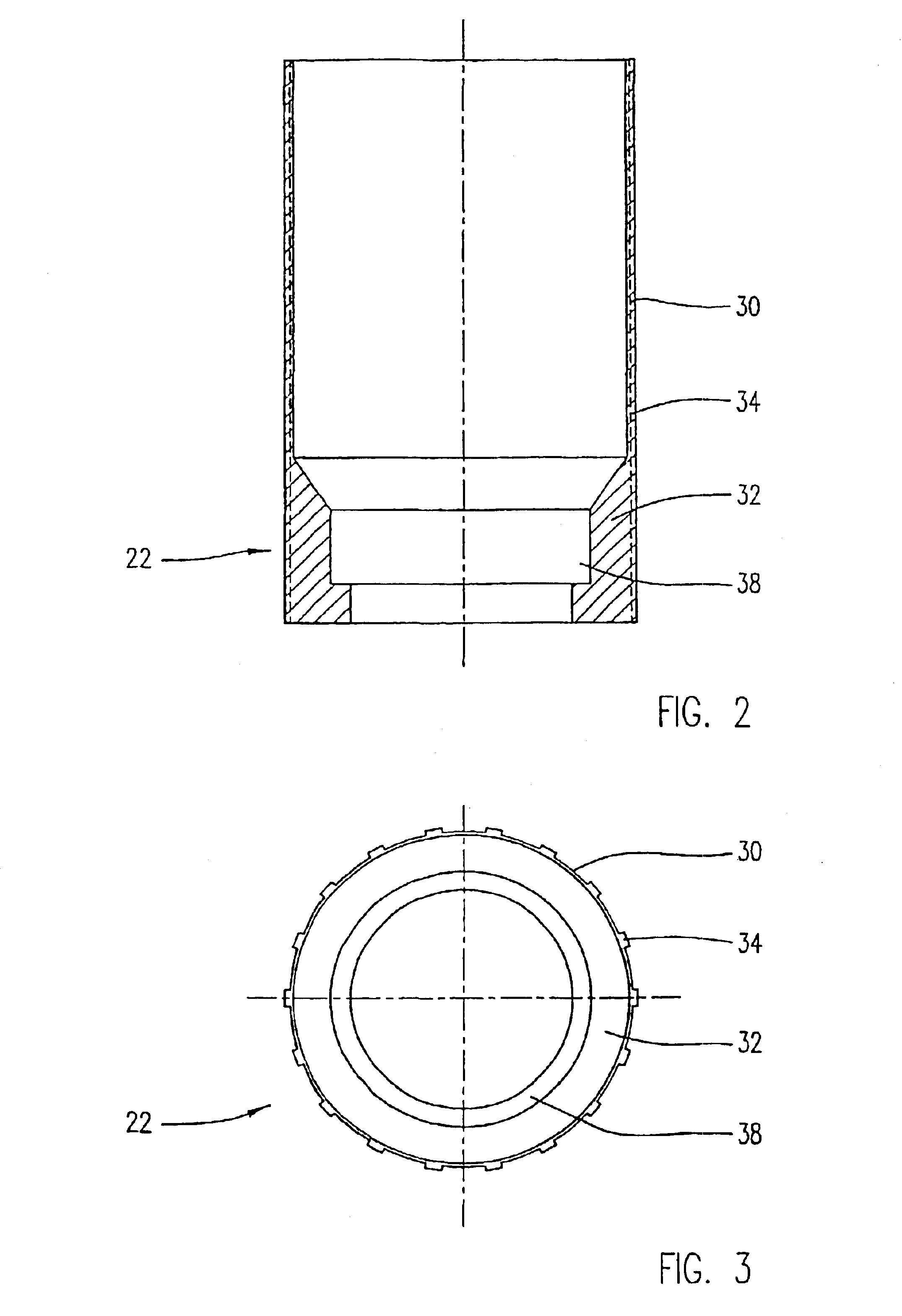

Rotor assembly for an electric motor and electric motor with internal rotor

InactiveUS6919659B2Simple and compactAvoid Insufficient SealingMagnetic circuit rotating partsManufacturing stator/rotor bodiesMagnetStator

An electric motor having a stator arranged on a sleeve; and a rotor assembly having a rotor shaft and at least one permanent magnet arranged on the rotor shaft, the rotor shaft being rotatbly housed in the sleeve. An external dimension of the rotor assembly and an internal dimension of the stator are selected such that the rotor assembly is free to move in the axial direction while the rotor assembly is inserted into the stator. The rotor assembly is aligned within the stator in the magnetic center of the stator by self-centering magnetic forces.

Owner:MINEBEAMITSUMI INC

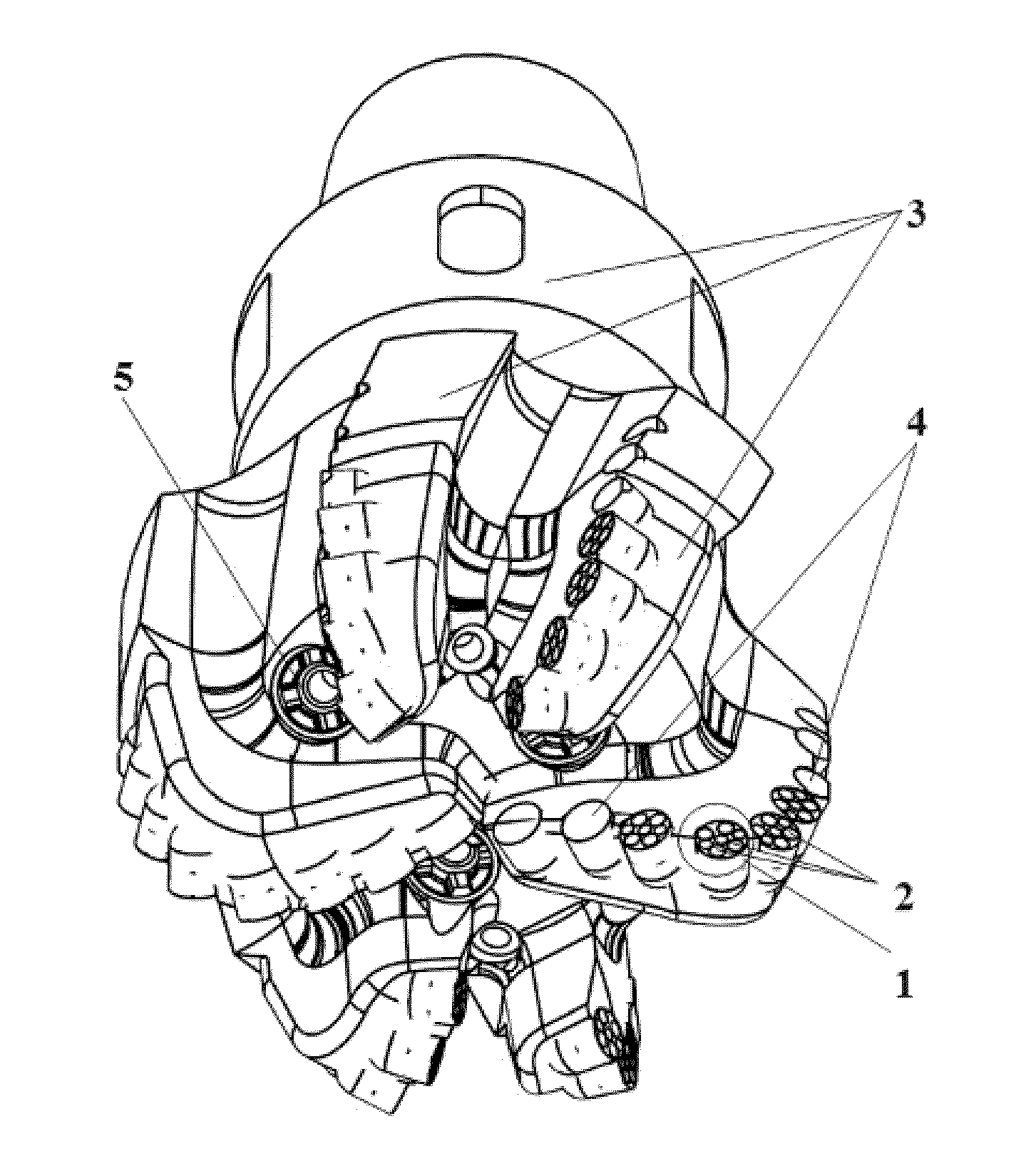

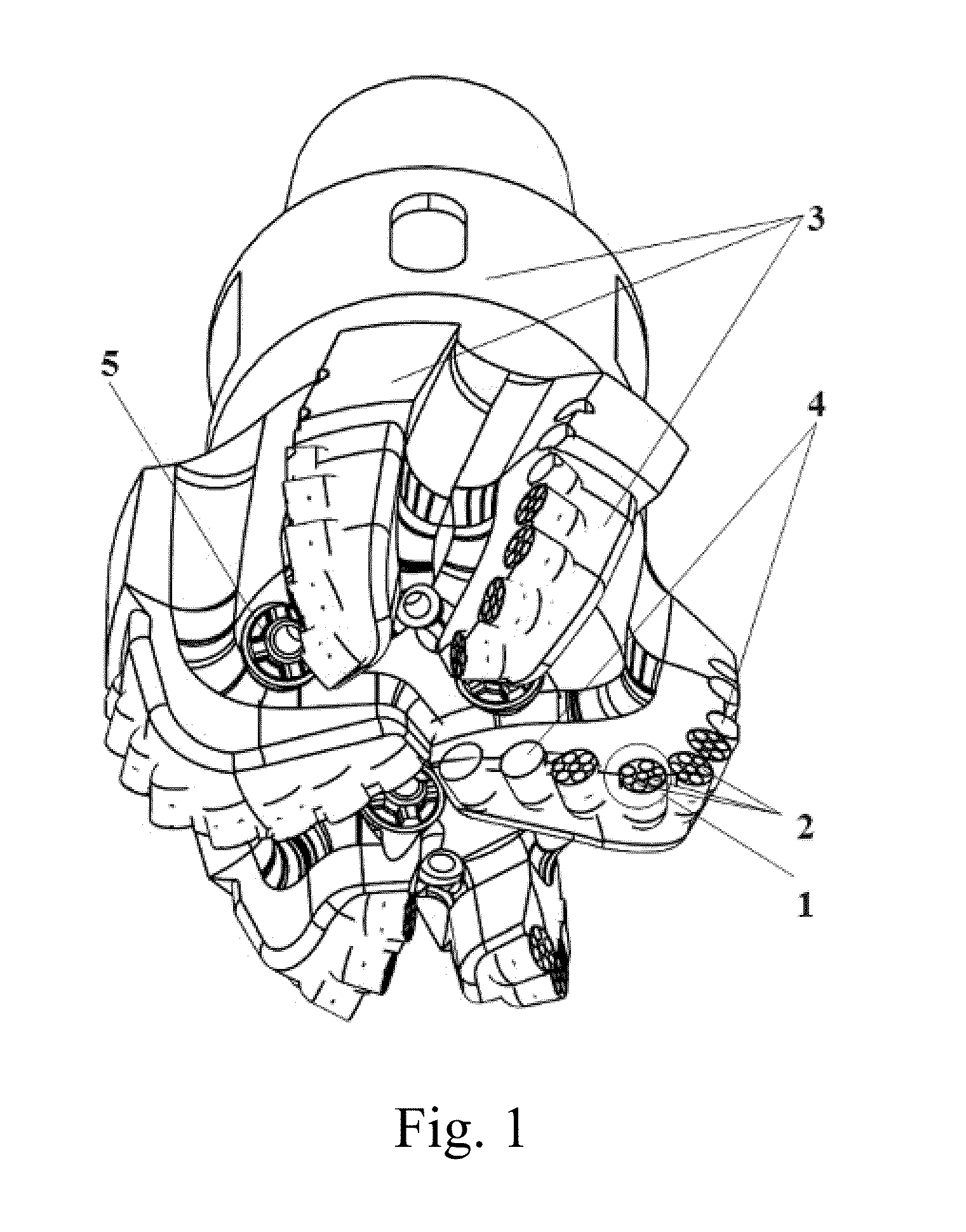

Modular cutting-teeth drill bit with controllable drilling specific pressure

ActiveUS20130341100A1Convenient ArrangementImprove performanceDrill bitsConstructionsModular unitEngineering

A modular cutting-teeth drill bit with controllable drilling specific pressure comprises a module (1), a modular unit (2), a bit body (3), conventional cutting teeth (4) and a nozzle (5). According to mechanical performance of the rocks in the strata drilled and requirements of drilling well, a combination of shapes, sizes and numbers of the module and the modular unit is optimized; effective abrasion edge length of the cutting element on a certain portion of the bit is controlled; and a constant specific pressure of the cutting element of the bit during the drilling process is maintained. The modular cutting-teeth bit substantially improves the effective abrasion volume of the cutting element, and improves the effective utilization rate of the cutting element.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

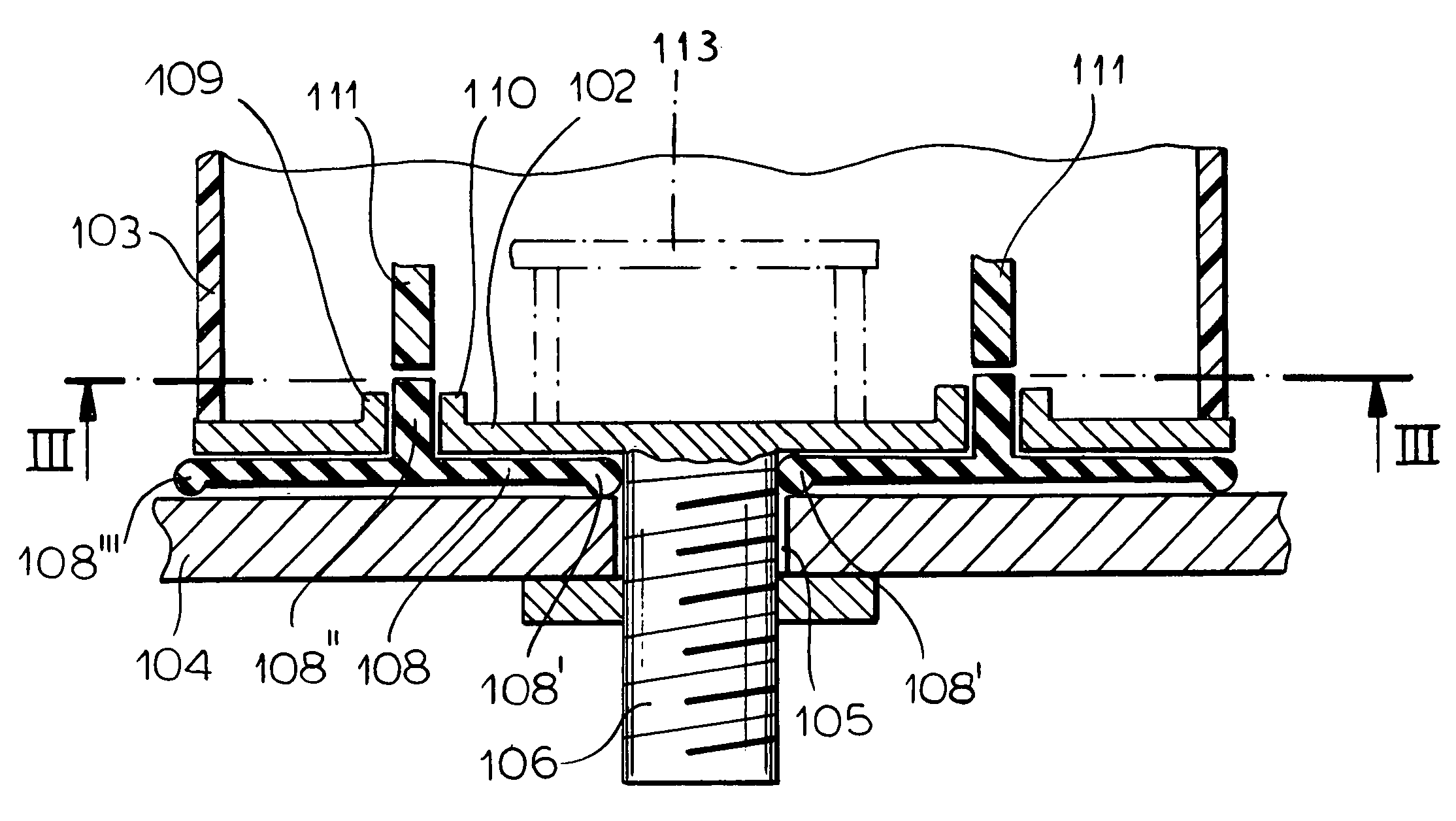

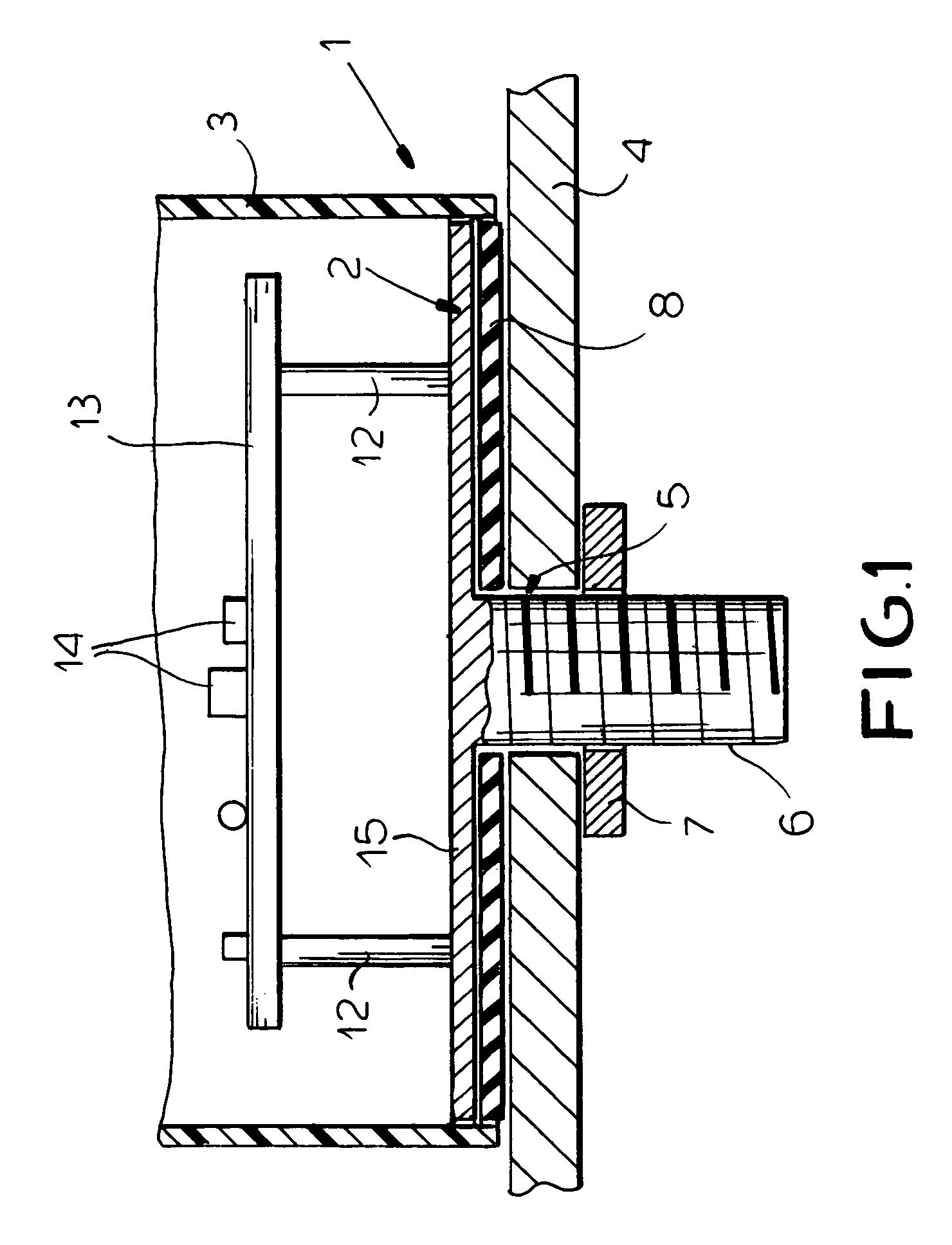

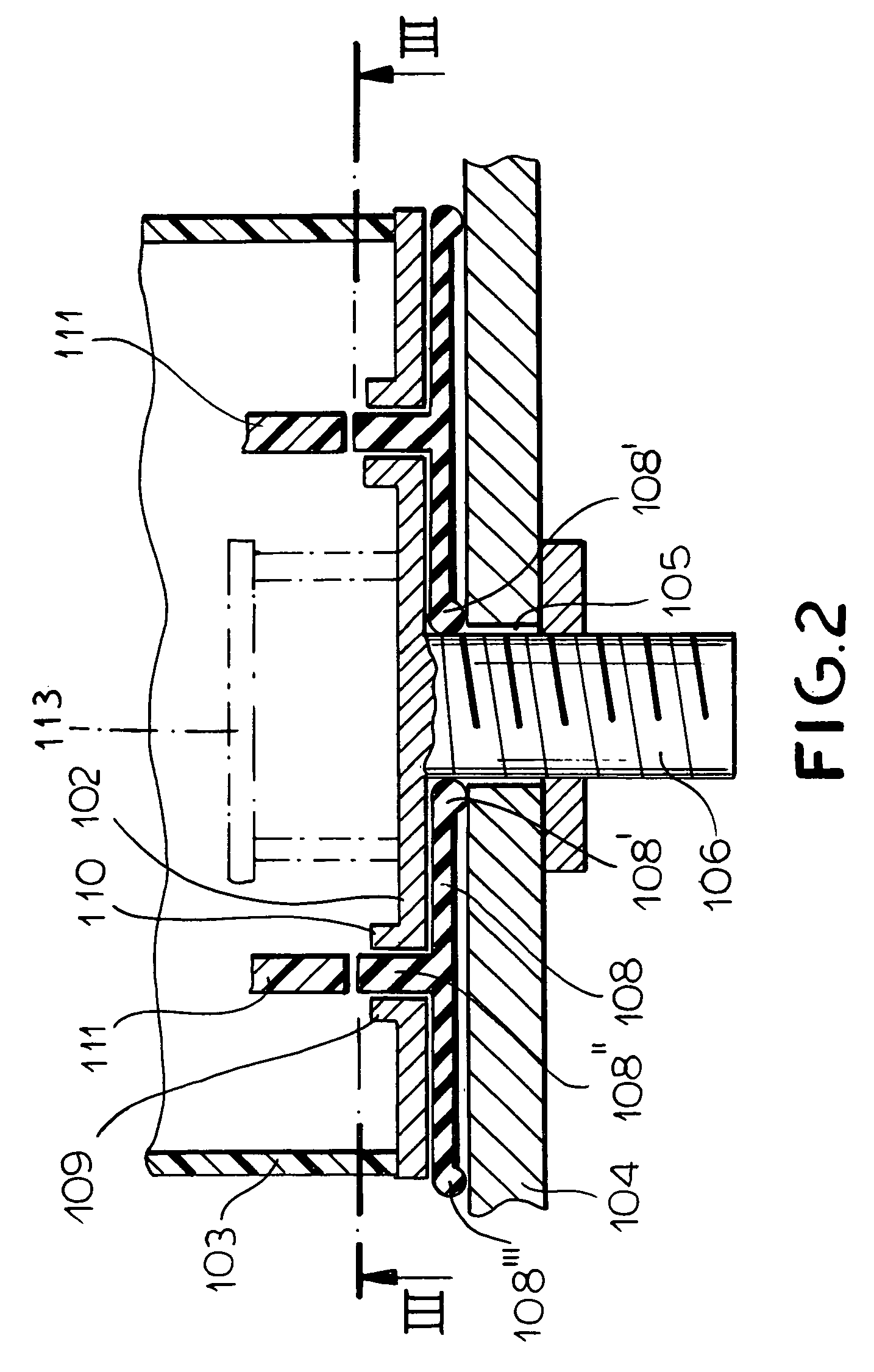

Antenna assembly with injection-molded seal

InactiveUS6999033B2Prevent rusting of the margins of the holePrevent rustAntenna supports/mountingsAntenna adaptation in movable bodiesInjection molding processEngineering

Owner:HIRSCHMANN ELECTRONICS GMBH & CO KG

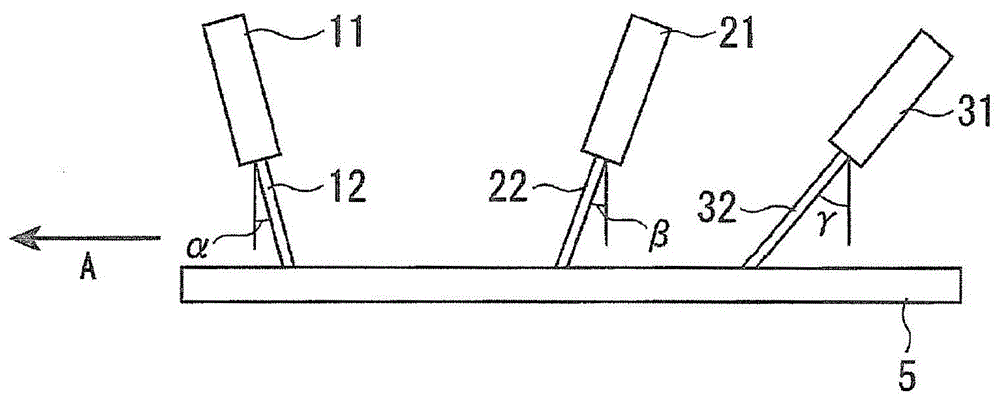

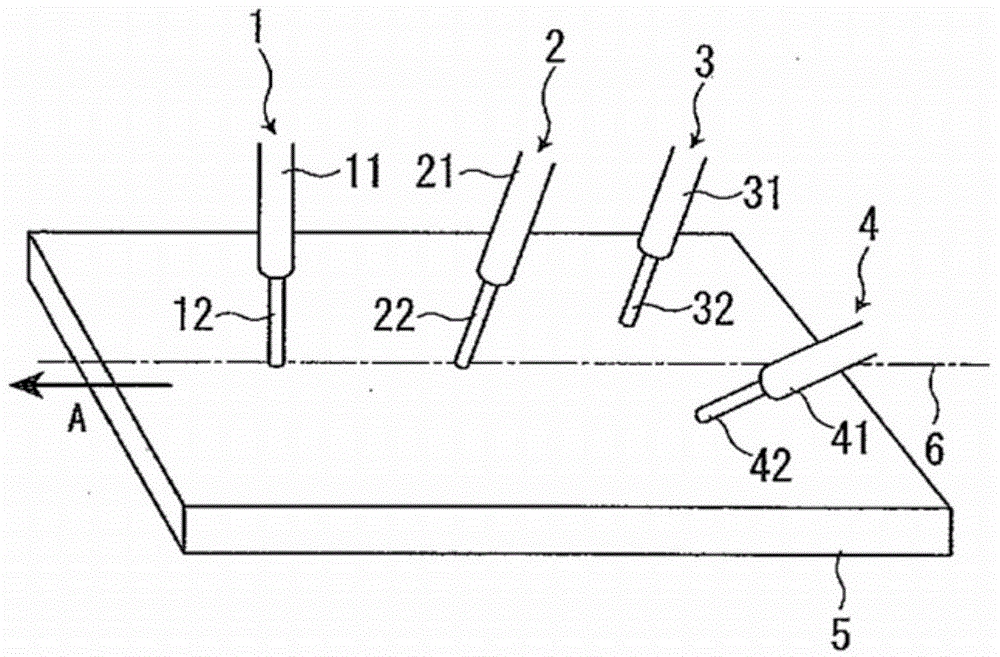

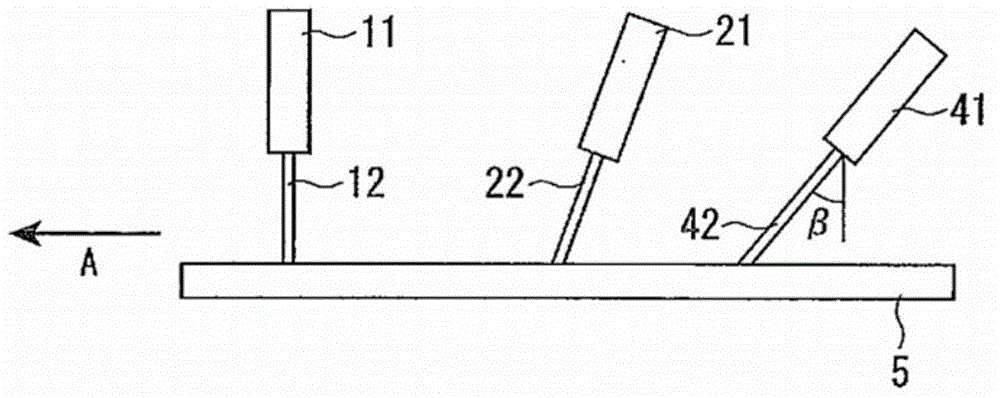

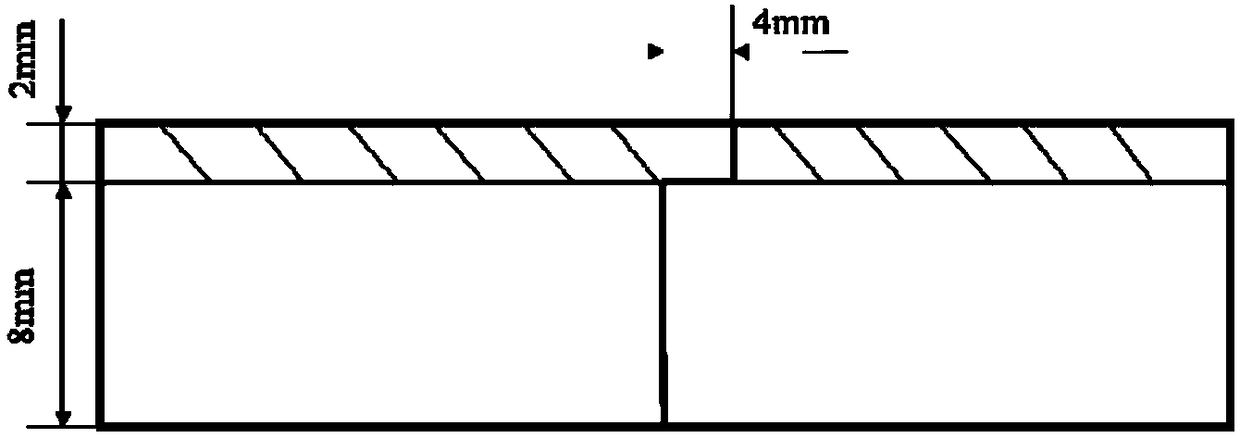

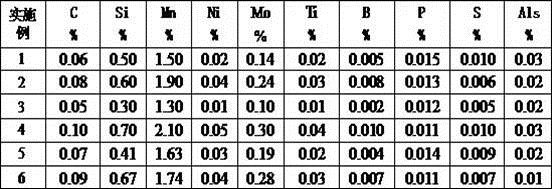

Laser and arc composite welding method of martensite precipitation-hardening stainless steel

InactiveCN110293322AUniform weld formationReduce distortionLaser beam welding apparatusButt jointMartensite

The invention relates to a laser and arc composite welding method of martensite precipitation-hardening stainless steel. The method includes the steps that butt joint connection ports of two to-be-welded workpieces are machined into grooves; the two to-be-welded workpieces are assembled and fixed, and a gap is reserved between the two to-be-welded workpieces; laser is adopted for performing backing welding on the bottoms of the grooves, and bottom weld joints are performed; and laser and arc composite welding is adopted for performing wire filling and face covering welding on the grooves, anda welding process is completed. According to the method, due to the fact that the laser backing welding is firstly performed on the bottoms of the grooves formed after machining of the to-be-welded workpieces, penetration fusion welding is achieved, through welding of the bottom of a truncated edge can be guaranteed, so that the weld joints at the bottoms of the grooves are uniform in forming, deformation is small, and the welding precision is guaranteed; then laser-arc composite welding is adopted for performing wire filling and face covering welding on the grooves, and therefore the high-quality weld joints are formed; and work procedures are simple, operation is easy, the process cost is low, and a good welding effect is achieved on the special material of the martensite precipitation-hardening stainless steel.

Owner:WUHAN JINDUN LASER TECH CO LTD

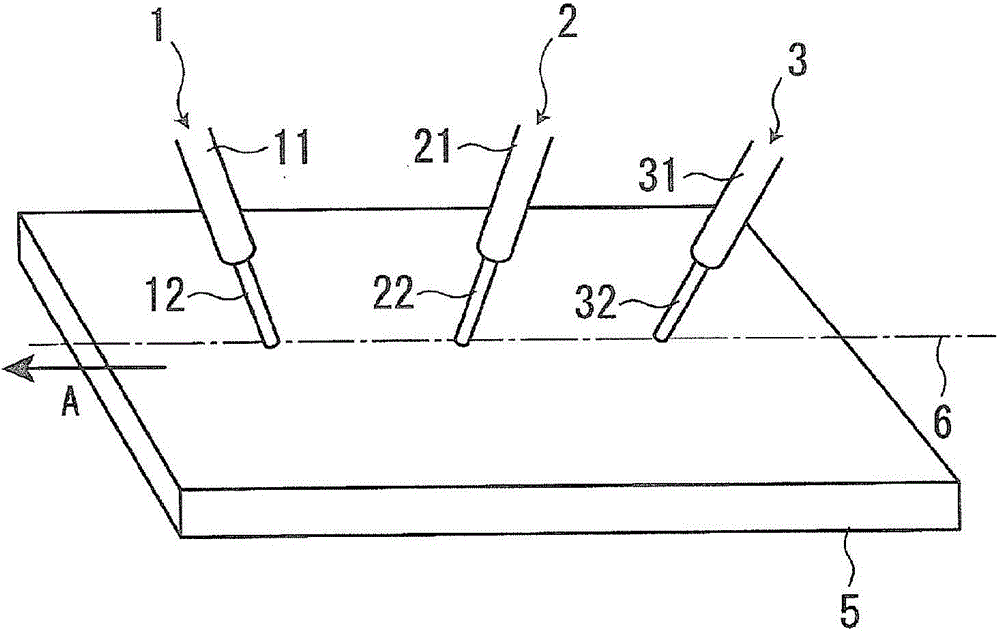

Submerged arc welding method for steel sheets

InactiveCN103958109AReduce welding heat inputEnsure penetrationArc welding apparatusWelding/soldering/cutting articlesSheet steelEngineering

Owner:JFE STEEL CORP

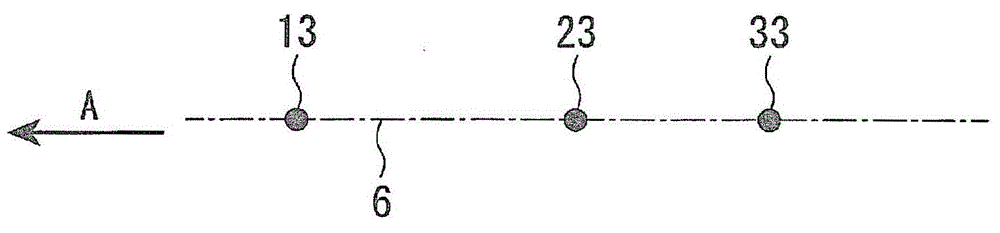

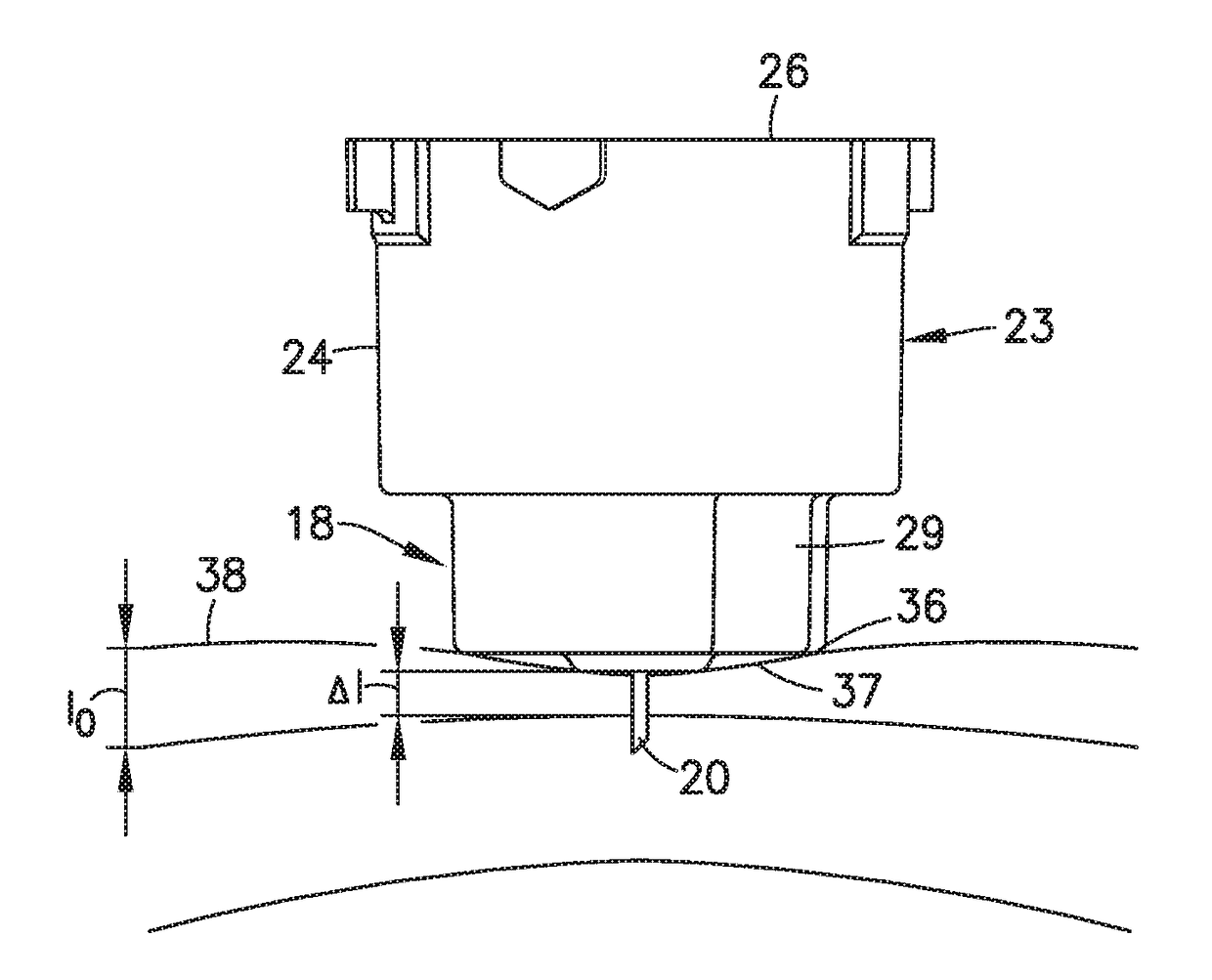

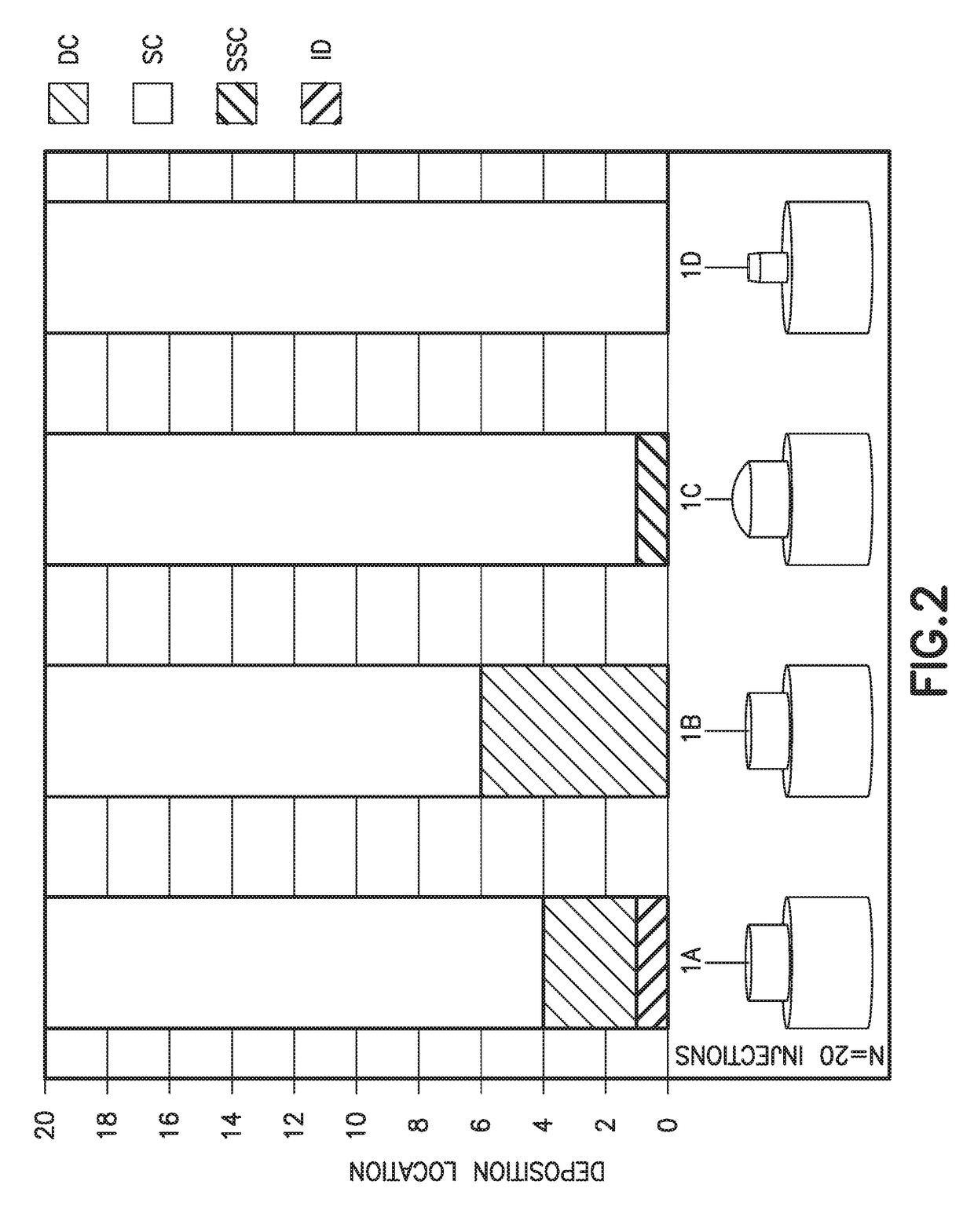

Pen needle hub with a patient contact surface

ActiveUS20180021526A1Increase surface areaLimited penetration depthInfusion syringesInfusion needlesSkin contactSurgery

A needle-bearing hub for a pen needle is provided with a distal patient-facing side having an enlarged surface for contact with the subject's skin. The enlarged surface is provided with a radius of curvature that increases the likelihood that the needle reaches full injection depth when an injection is performed at an inclined angle with respect to the surface of the skin and with to the desired depth less discomfort to the patient.

Owner:EMBECTA CORP

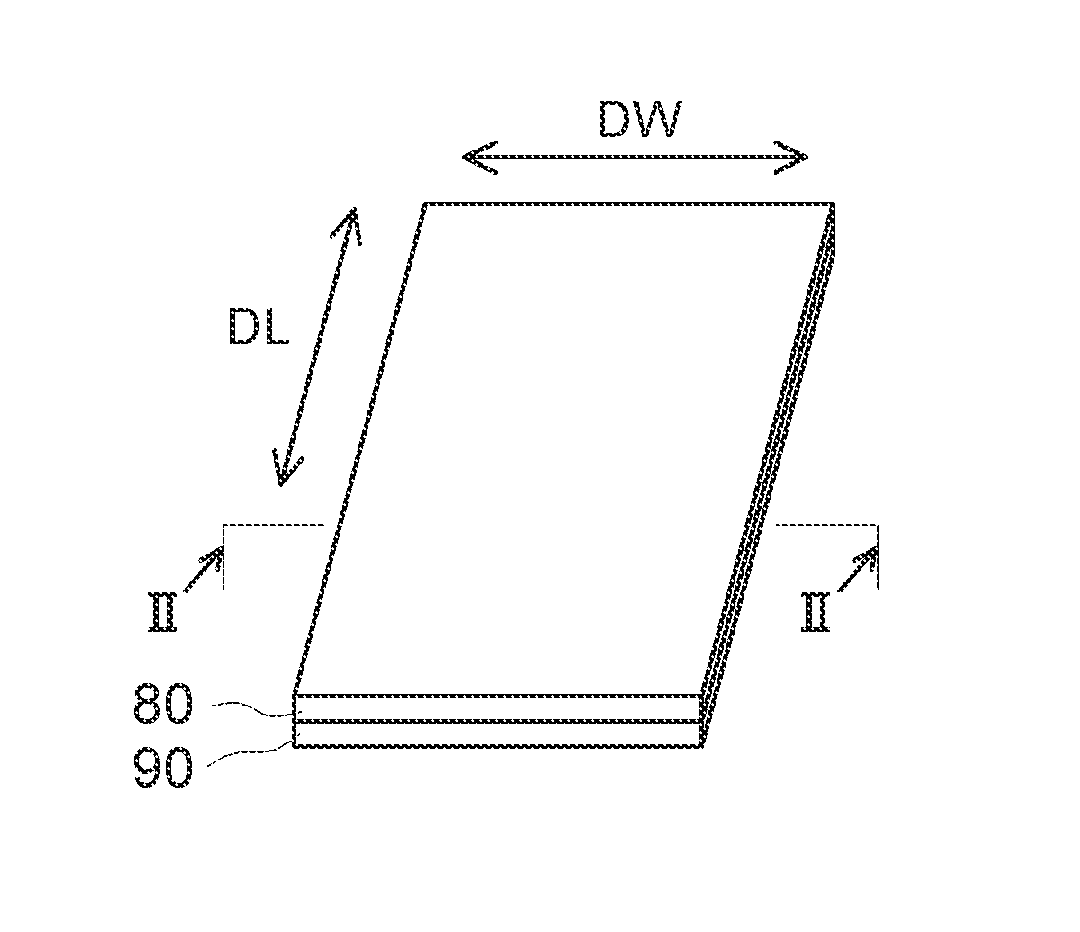

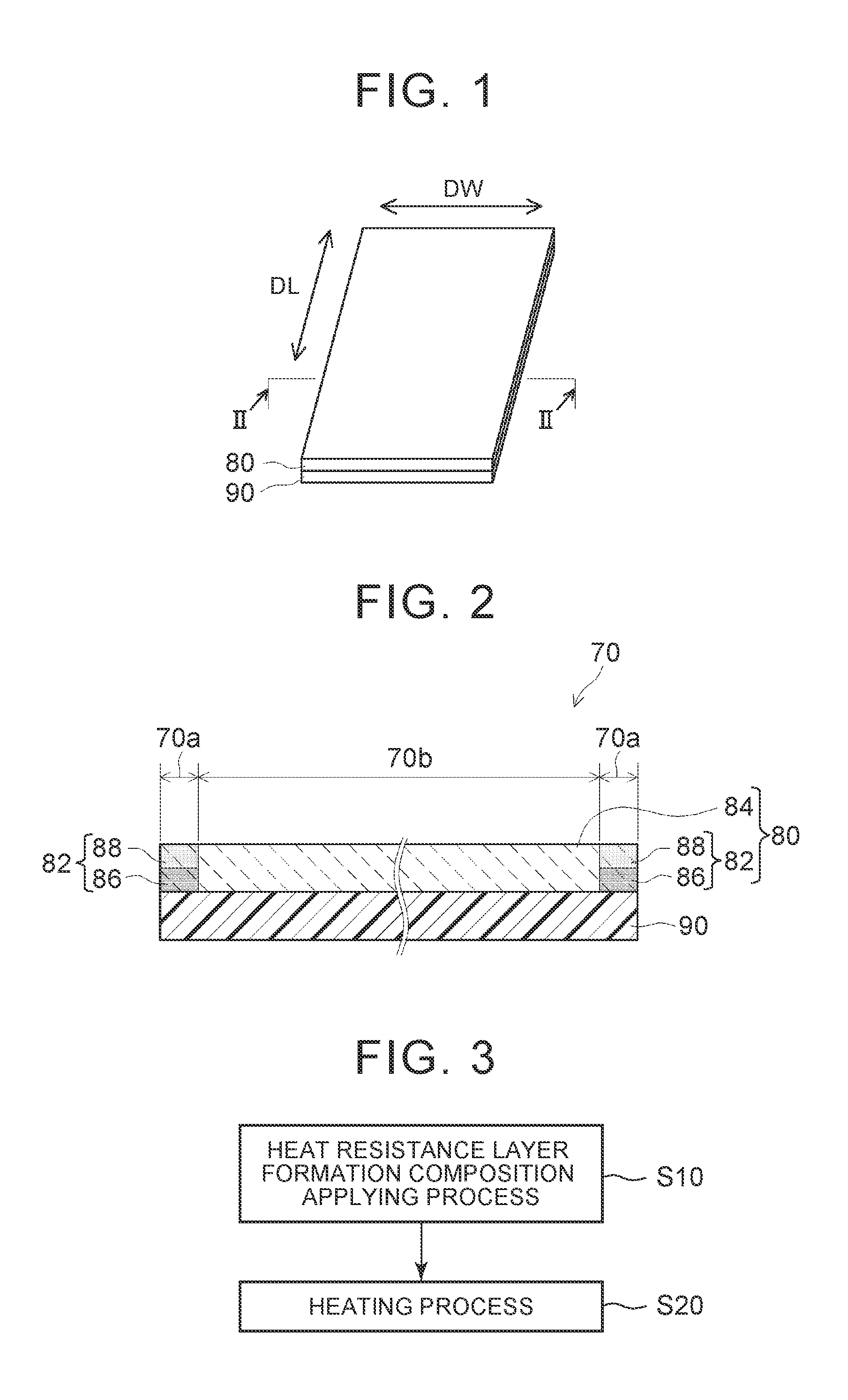

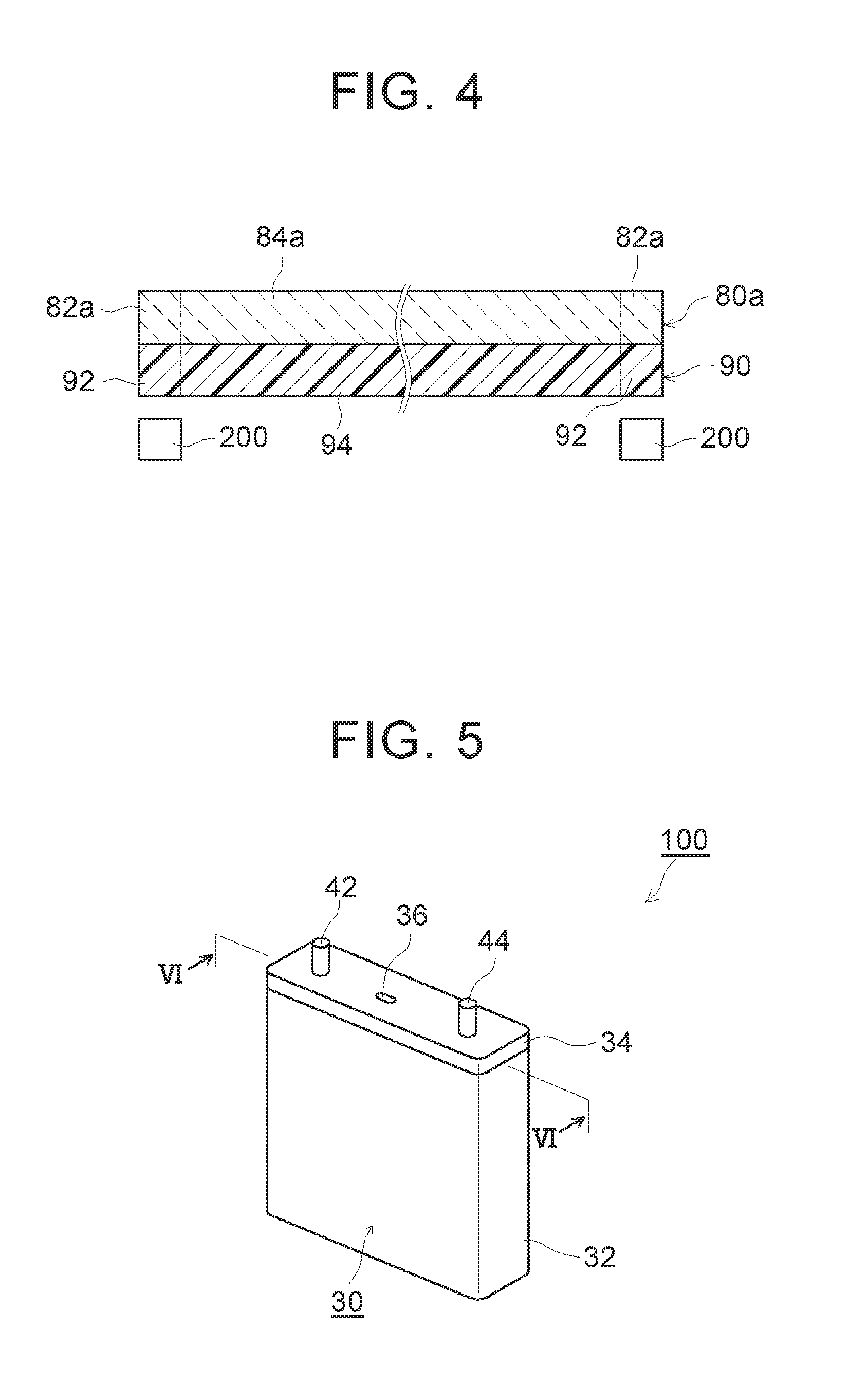

Separator for non-aqueous electrolyte secondary battery and manufacturing method thereof

ActiveUS20160308185A1Peel strengthIncrease volumeNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersPhysical chemistryAqueous electrolyte

A separator includes a substrate layer made of a resin and a heat resistance layer. The heat resistance layer contains heat-resistant fine particles and a binder. An amount of the binder contained per unit volume in the heat resistance layer positioned at an end portion in a width direction perpendicular to a longitudinal direction of the separator is higher than the amount of the binder contained per unit volume in the heat resistance layer (84) positioned at a center portion which includes the center in the width direction of the separator. In the heat resistance layer at the end portion, the amount of the binder contained per unit volume in a substrate layer side region is higher than the amount of the binder contained per unit volume in a surface region which includes a surface of the heat resistance layer.

Owner:TOYOTA JIDOSHA KK

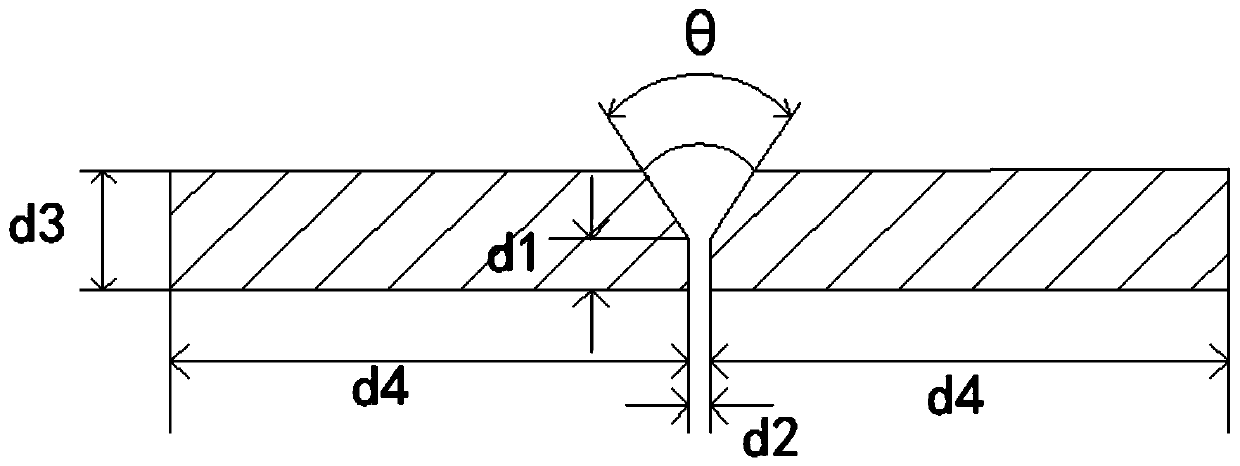

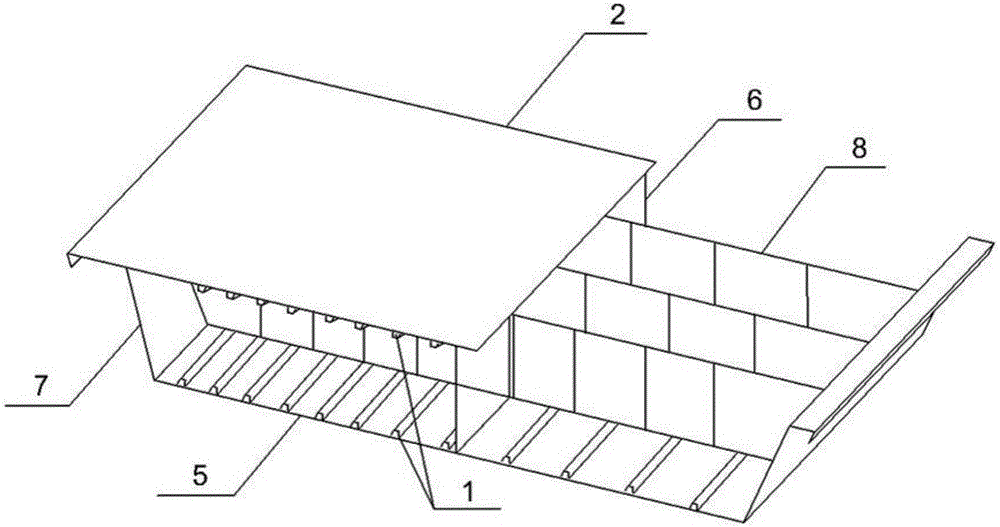

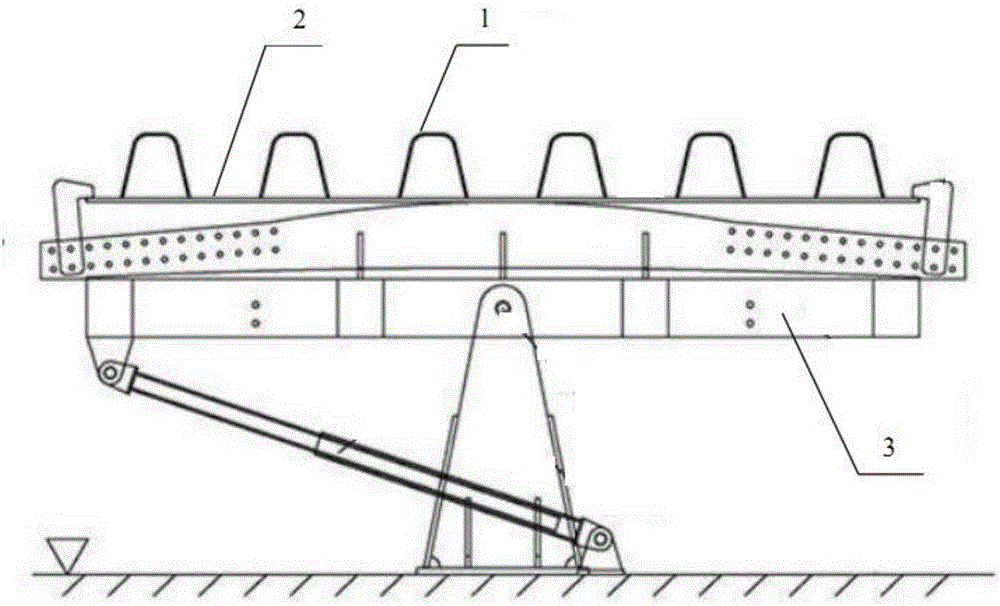

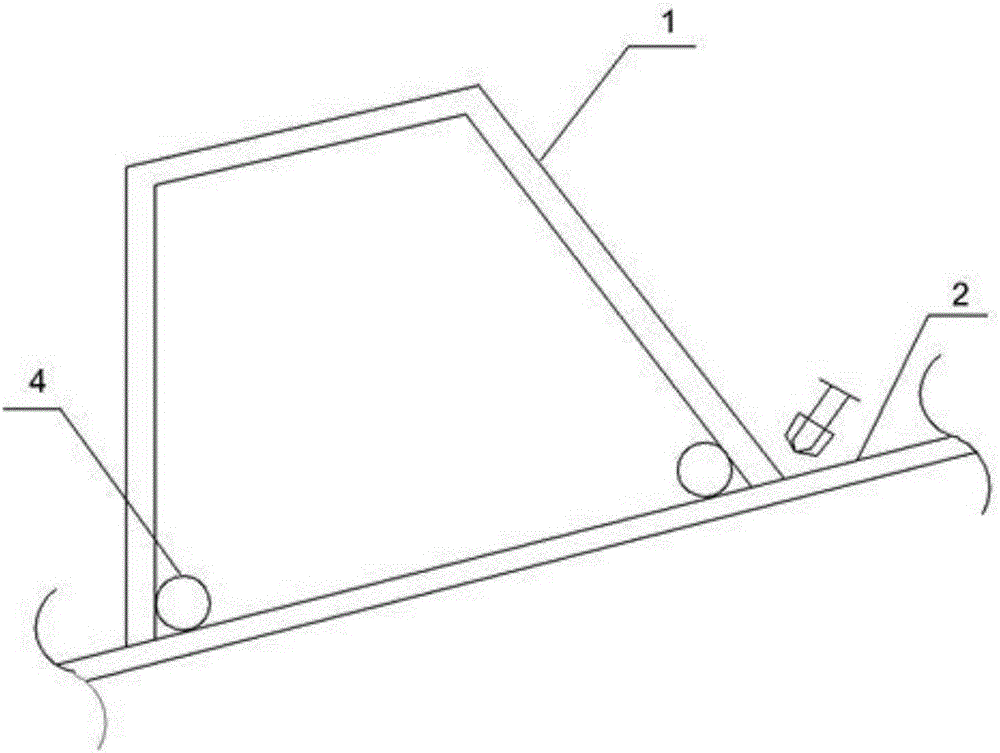

Construction method for single-side fusion-through welding of connection angle seams of closed longitudinal ribs and bridge deck slab

ActiveCN106334861ASimple structureEasy constructionArc welding apparatusWelding/cutting media/materialsFillet weldProduction line

The invention discloses a construction method for single-side fusion-through welding of connection angle seams of closed longitudinal ribs and a bridge deck slab. The construction method comprises the following construction steps that the multiple closed longitudinal ribs and the bridge deck slab are assembled so that a bridge deck slab unit can be formed, the bridge deck slab unit is installed on a bed-jig of a slab unit welding production line horizontally, and welding backings are installed at the two inside longitudinal angle seams; the longitudinal angle seam located on the outer portion is welded by rotating the bed-jig; the other longitudinal angle seam located on the outer portion is welded by rotating the beg-jig; and the bed-jig is rotated to be in the horizontal state, and the bridge deck slab unit subjected to welding is removed. By means of the construction method, the problems that due to incomplete penetration of one-side welding of closed longitudinal ribs and a bridge deck slab, a fatigue crack source exists, and consequently fatigue cracks are caused can be solved, welding penetration of fillet welds of the closed longitudinal ribs can be effectively prevented, the effect that the depth of fusion of the fillet welds of the closed longitudinal ribs meets the design requirement can be ensured, full penetration and excellent molding of the fillet welds of the closed longitudinal ribs of a steel structure are achieved while the production efficiency is improved, and the service life of the steel structure is prolonged.

Owner:武汉天高熔接股份有限公司 +3

Two-Step Process for Microbial Enhanced Oil Recovery

ActiveUS20200157408A1Improve performanceEfficient productionDrilling compositionActive agentBiotechnology

The subject invention relates to methods for post-primary oil recovery that utilize multiple mechanisms of action, wherein biochemical-producing microbes are injected into an oil well in a certain predetermined order, based on, for example, the metabolites and by-products they are capable of producing. Preferably, gas-, acid- and / or solvent-producing microbe such as a Clostridium bacterium, is injected into the well first, followed by a biosurfactant and / or biopolymer-producing microbe, such as Bacillus subtilis, Bacillus licheniformis and / or a combination thereof.

Owner:LOCUS SOLUTIONS IPCO LLC

Submerged arc welding method for steel sheets

ActiveCN103958108AAchieve penetrationEnsure penetrationArc welding apparatusWelding/soldering/cutting articlesTip positionEngineering

Owner:JFE STEEL CORP

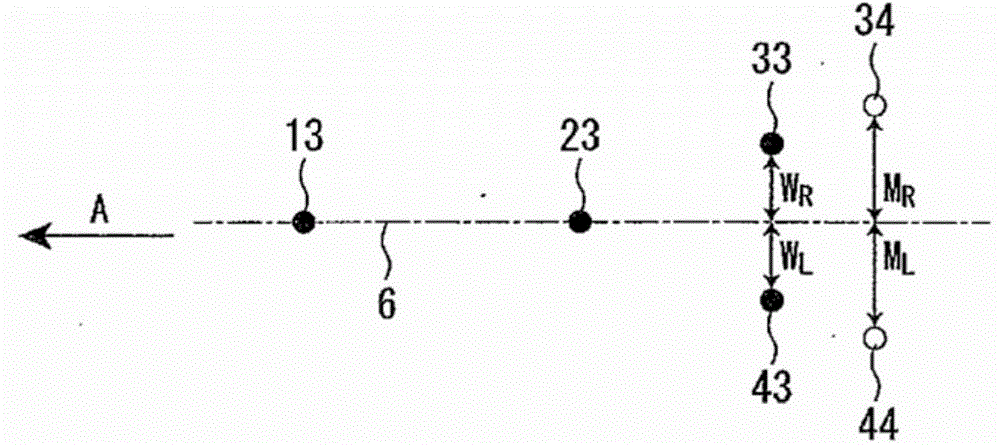

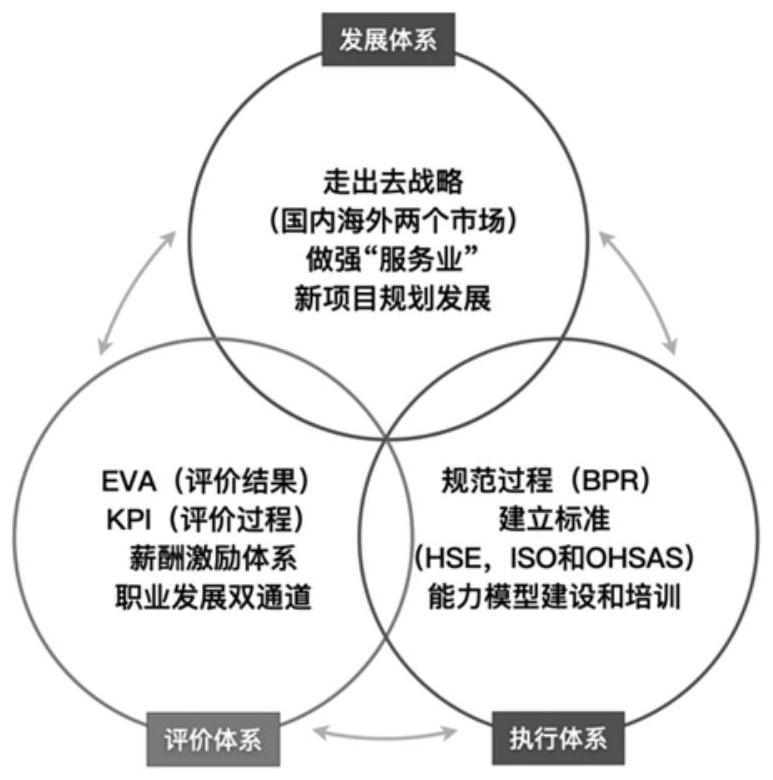

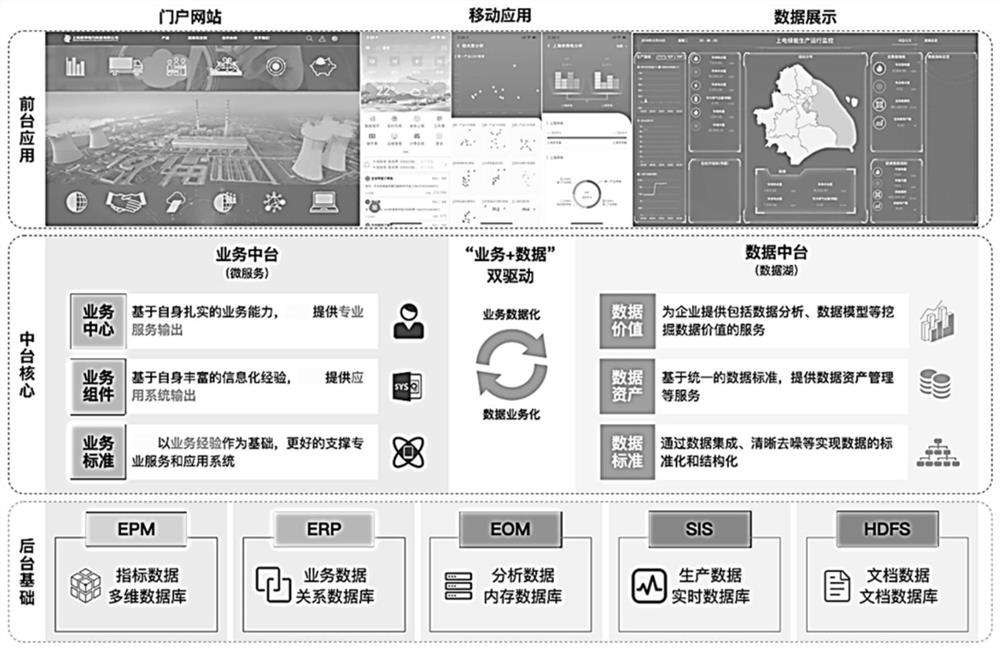

Intelligent production and operation integrated digital platform

ActiveCN111988404AMaximize value creationRealize integrationOffice automationTransmissionVirtualizationBusiness enterprise

The invention relates to an intelligent production and operation integrated digital platform, which comprises a LaaS layer used for centrally deploying infrastructure hardware facilities, integratinghardware resources of the infrastructure through a virtualization technology, and decomposing the hardware resources into virtual hardware to provide resource services for a PaaS layer; wherein the PaaS layer and the PaaS layer are constructed based on a PRO platform, the PRO platform comprises an enterprise performance management system, an enterprise operation management system and an enterpriseresource planning system which are constructed based on the combination of EVA value creation and KPI performance management and are communicated through an interface technology, and pairwise mutualconnection is realized; and an Internet of Things layer used for carrying out data acquisition and control through an edge technology and transmitting production data to the PRO platform through a security network so as to realize production operation data communication. Compared with the prior art, the intelligent production and operation integrated digital platform based on IT / OT / CT fusion has the advantages that through multi-technology and multi-dimension fusion, management, information fusion and fusion of multiple technologies are achieved, and the intelligent production and operation integrated digital platform based on IT / OT / CT fusion is built.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG +1

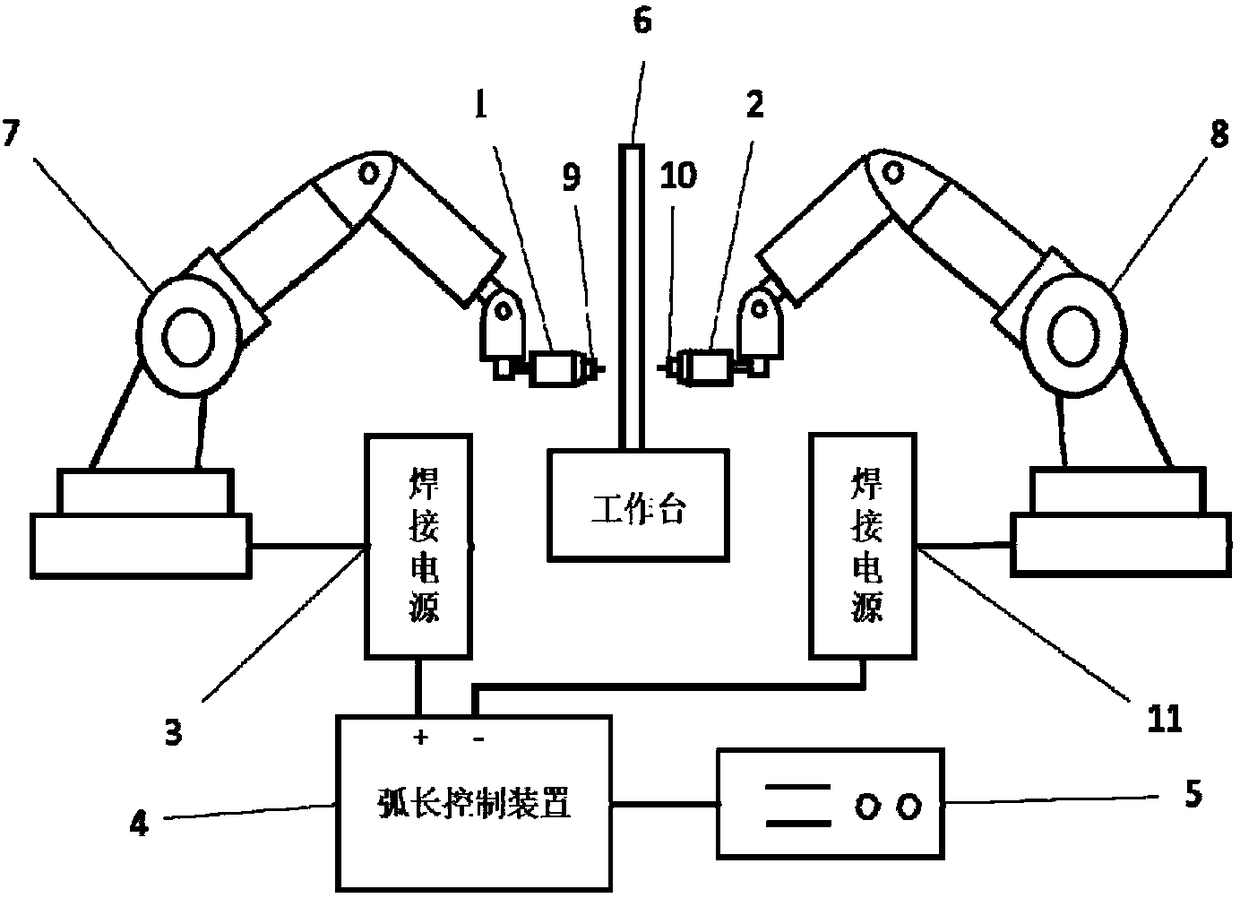

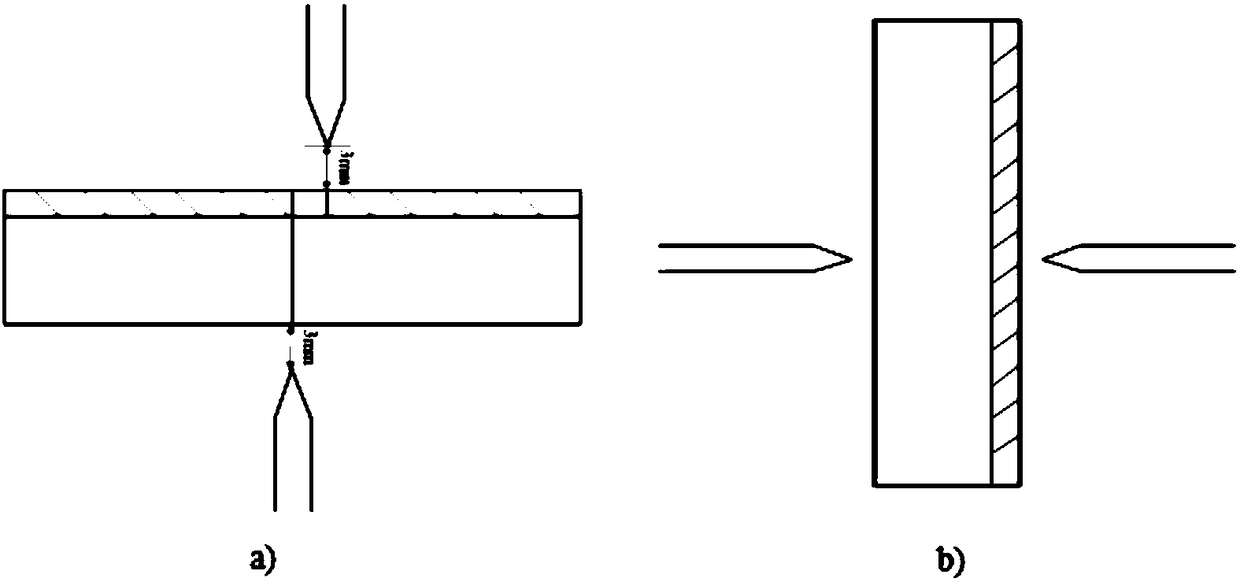

Double-side double-arc vertical welding fusion depth control device and welding method thereof

The invention discloses a double-side double-arc vertical welding fusion depth control device and method for a composite board. The double-side double-arc vertical welding fusion depth control devicecomprises dual robots, a welding power supply, an arc-length control device, an industrial personal computer and the like. The fusion depth control method mainly adopts the combination of double-sideddouble-arc vertical welding and a self-developed arc-length control device, electric-arc parameters on both sides are independently adjusted in the welding process, voltage data are collected and adjusted through the arc-length control device, and accurate control over the fusion depth on the front side and the back side of the composite board is realized. Through the double-side double-arc vertical welding fusion depth control method, one-time through welding on 5-10mm composite boards made of titanium-steel, stainless steel-steel and the like can be realized, adding of a transition layer isnot needed, the efficiency is improved, the welding deformation is small, and the generation of intermetallic compounds is reduced.

Owner:NANJING UNIV OF SCI & TECH

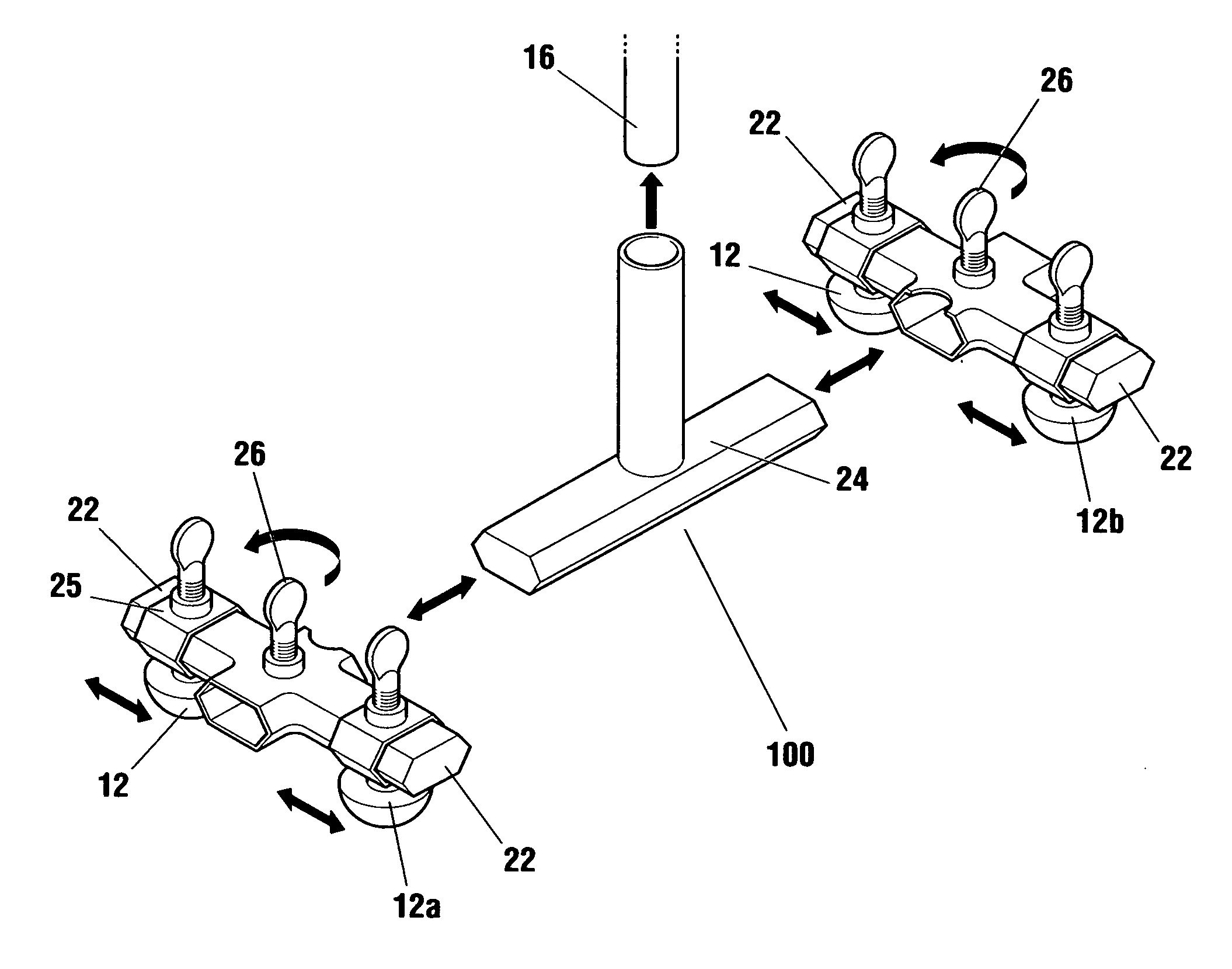

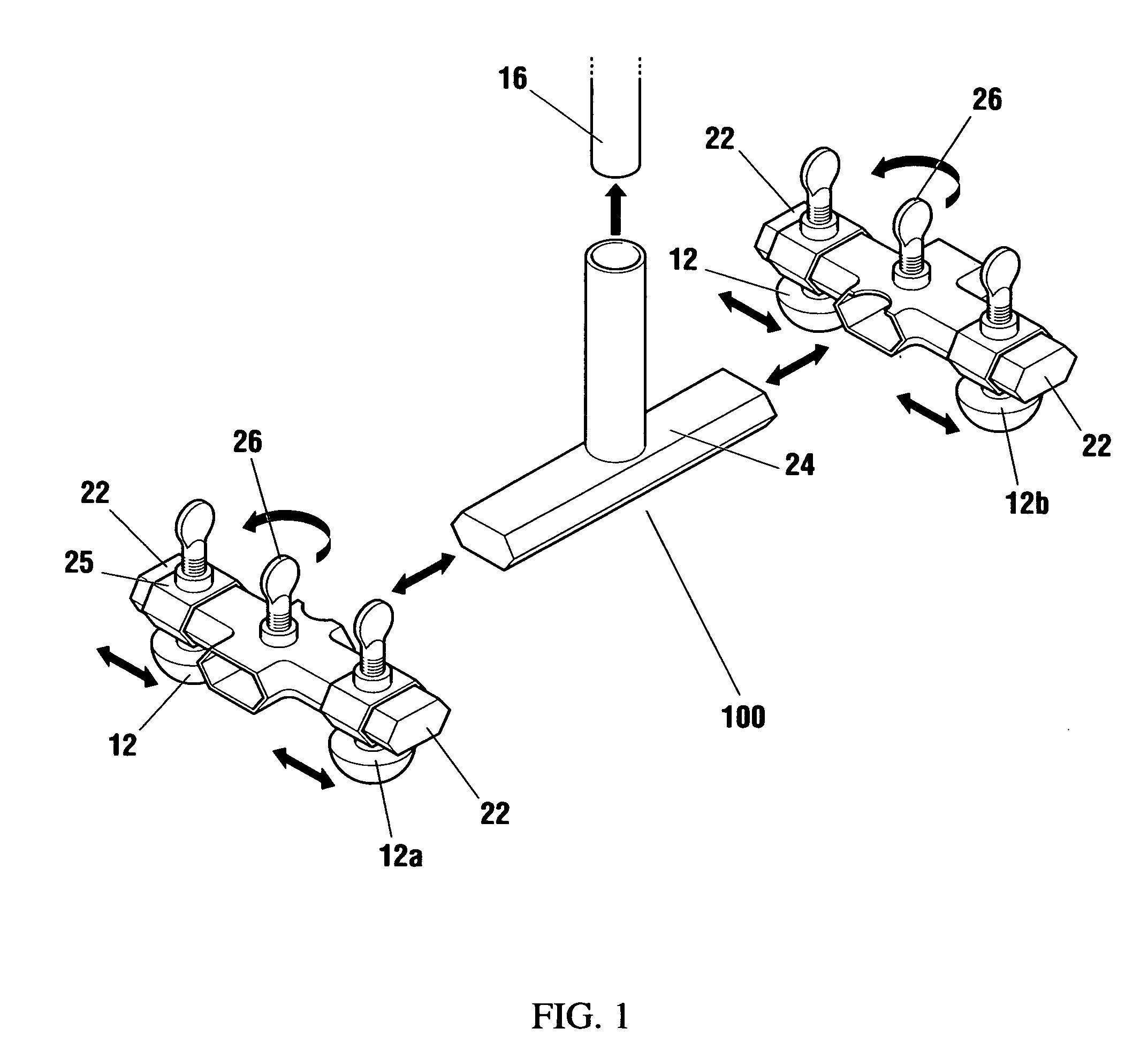

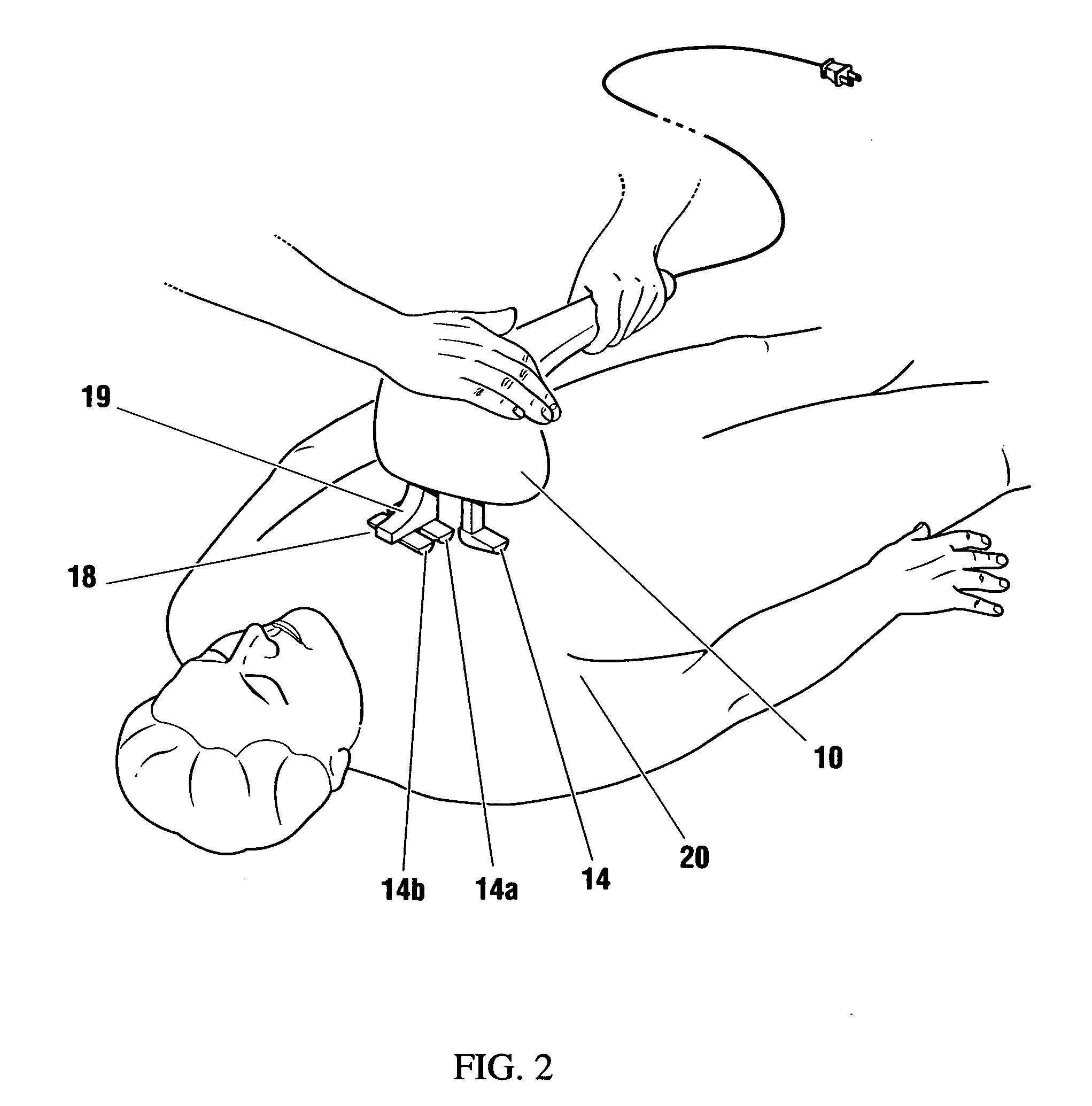

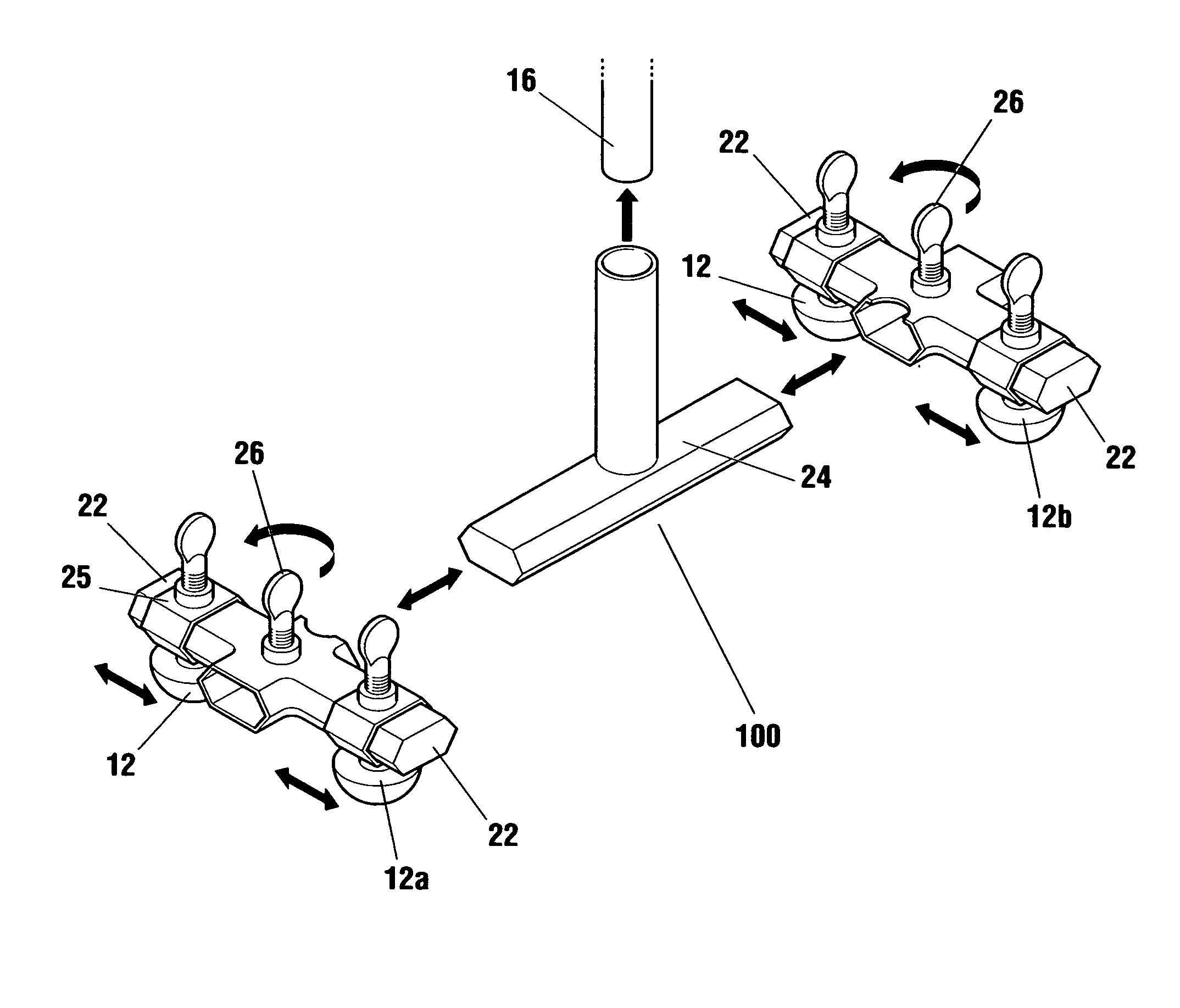

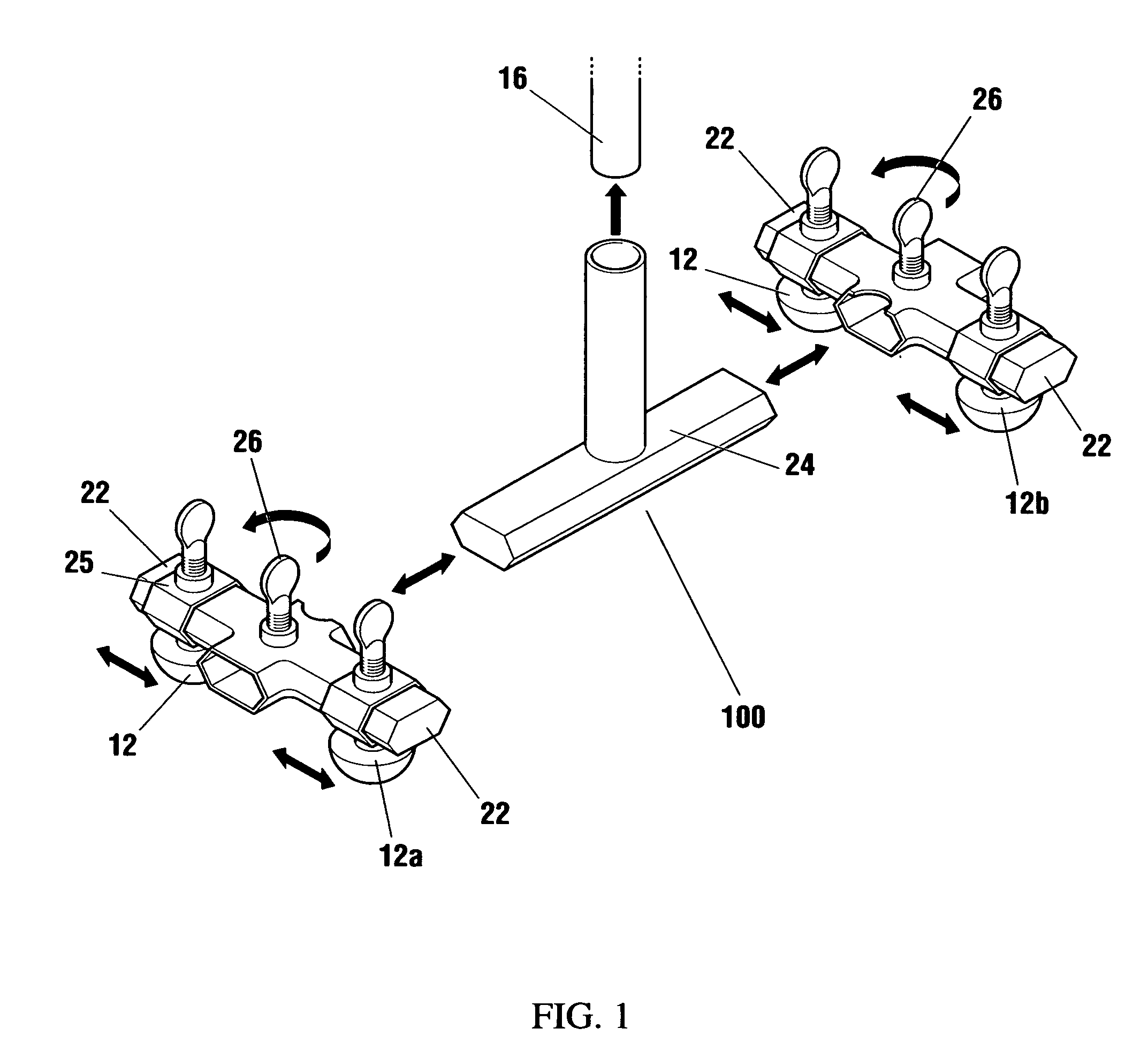

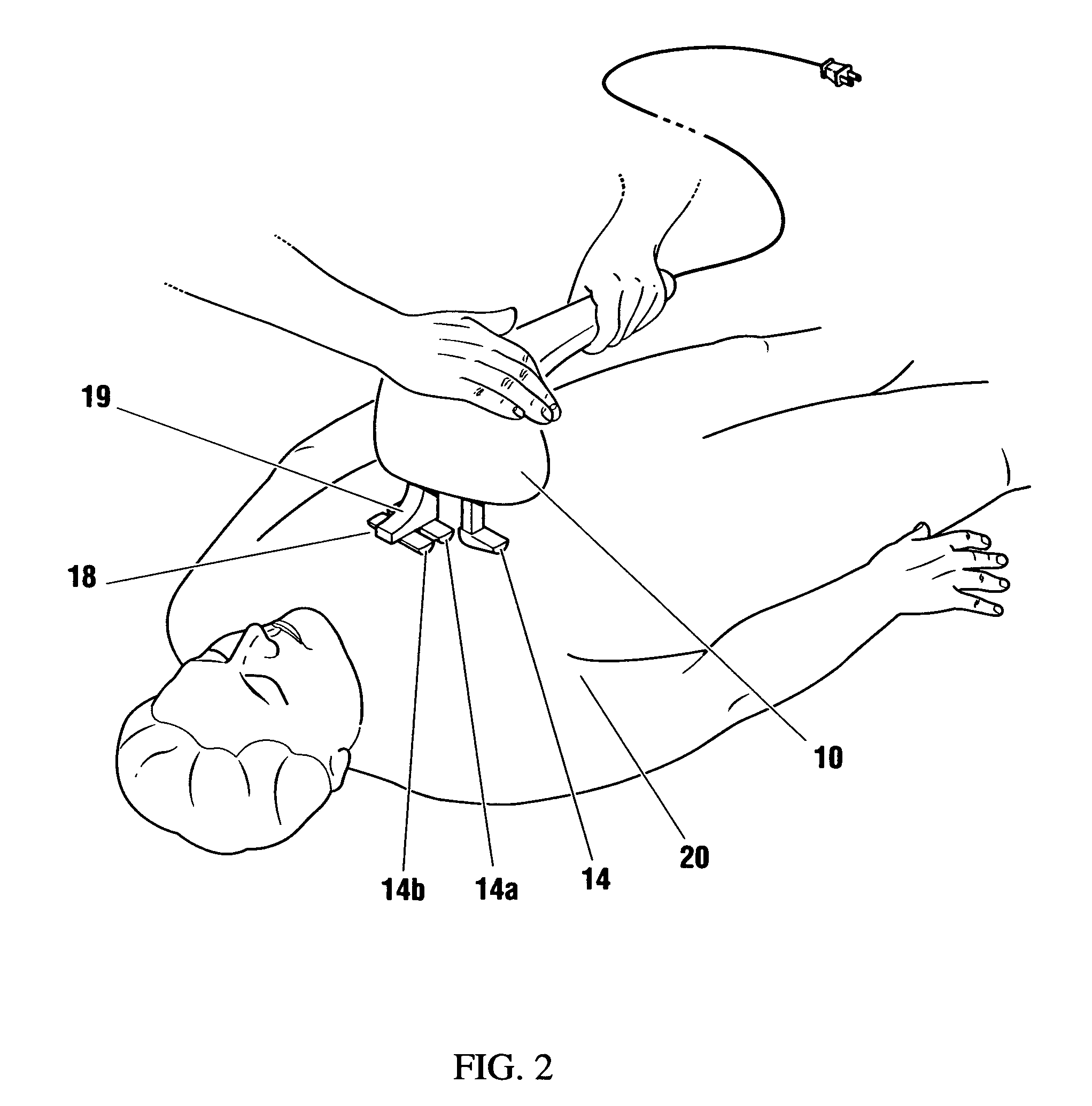

Automatically adjusting contact node for multiple rib space engagement

InactiveUS20090270773A1Increase blood flowImprove heart functionChiropractic devicesVibration massageFourth intercostal spaceEngineering

A vibratory attachment interface enabling transmission of oscillations generated by an oscillation source upon an external human body surface. The interface comprises a first contact node and a second contact node slideably mounted alongside the first contact node, wherein the contact nodes are each sized and shaped to enable seating within a human rib-space, and whereby upon forced engagement of the first contact node within a first rib-space, the second contact node automatically slides and conforms to the contour of a second differing rib-space thereby optimally nestling within the second rib-space. The attachment interface is for use in contoured application to preferably the anatomic left sternal border, third and fourth intercostal space, such as to enable and ensure an optimized vibratory transmission pathway from the chest wall to the base of the heart and coronary arteries thereupon.

Owner:HOFFMANN ANDREW KENNETH +1

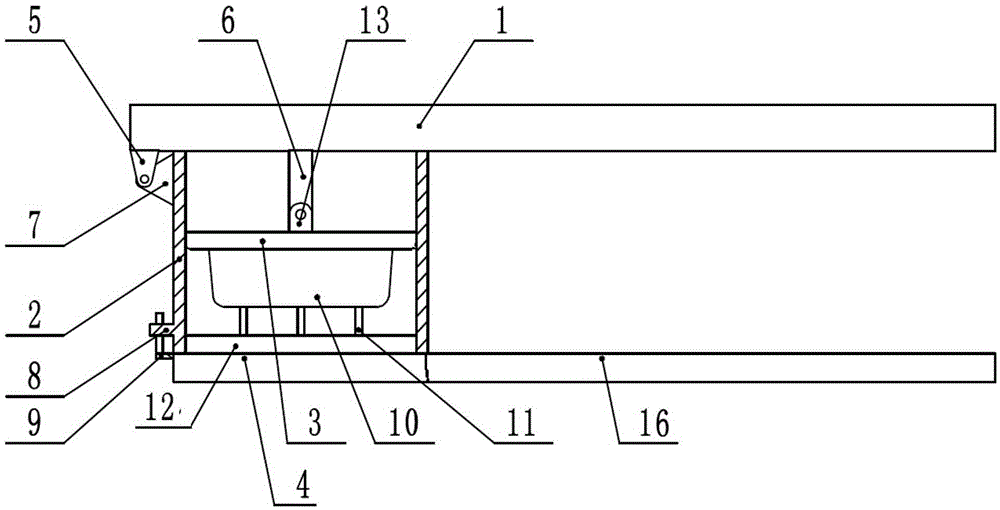

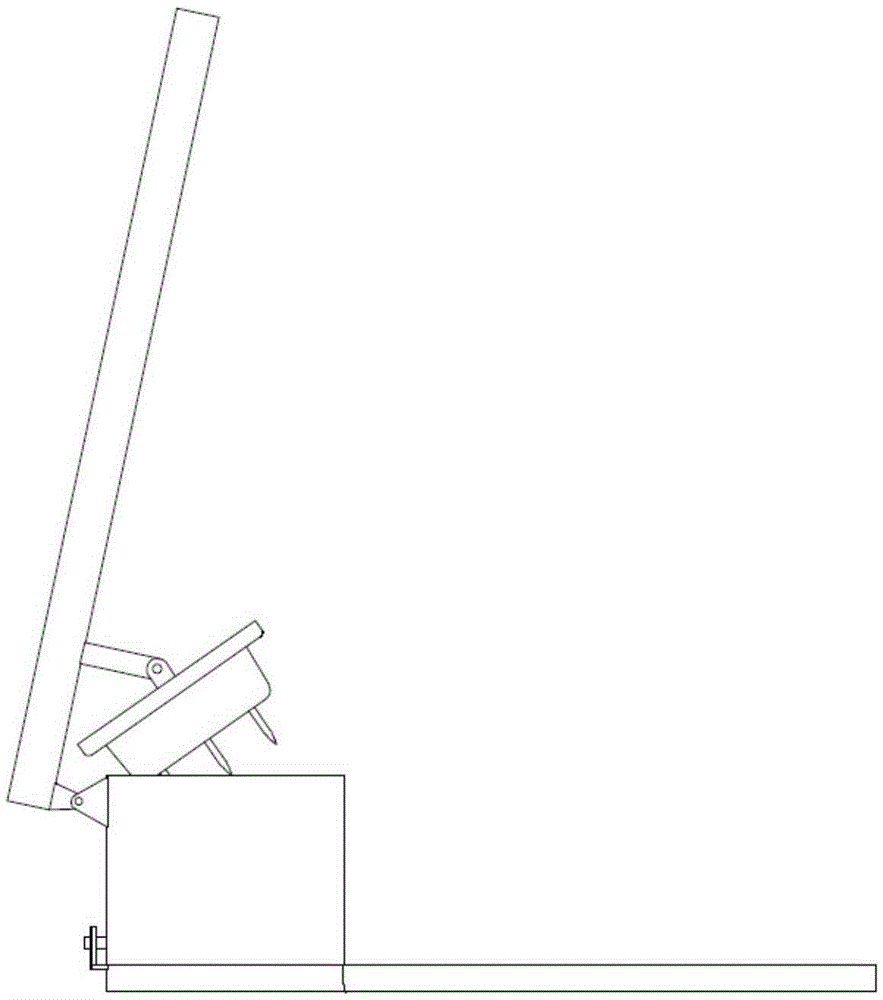

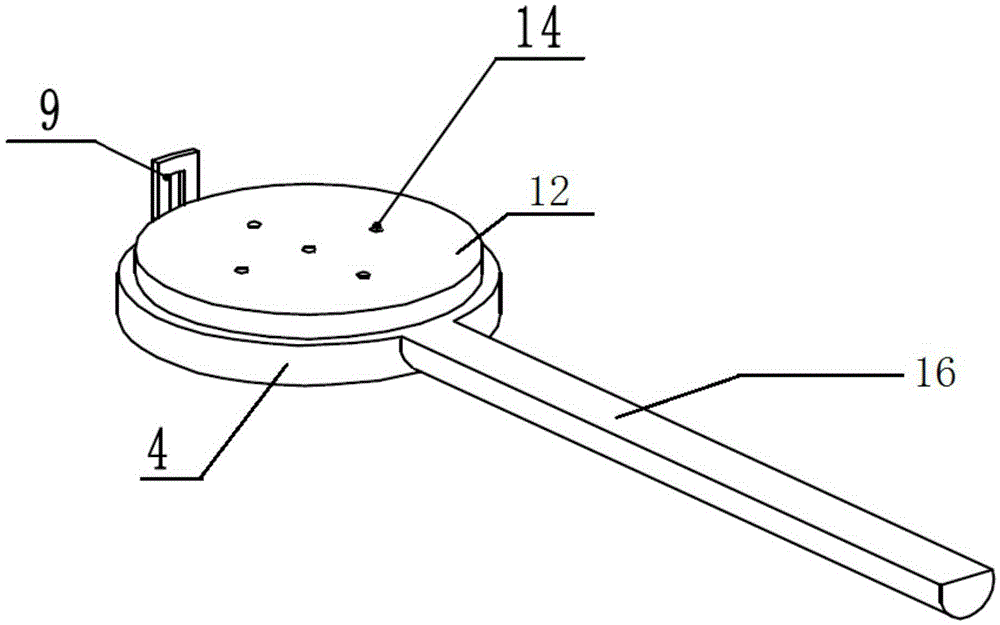

Moxibustion medicine cake making machine

InactiveCN105395360ARegular shapeQuality improvementDevices for heating/cooling reflex pointsCurative effectEngineering

The invention discloses a moxibustion medicine cake making machine, which comprises a pressing handle, a medicine cake barrel, a gland and a bottom cover. Medicinal materials are added into the medicine cake barrel; and the pressing handle and a pressing rod on the bottom cover, held in a hand, are exerted so that the gland moves downwards in the medicine cake barrel to press the medicinal materials into a medicine cake which is uniform in thickness and is formed with pin holes. A U-shaped notch is formed on the edge of the gland, so that residual medicinal materials can overflow; a bottom cover fastener and a medicine cake barrel pin are embedded and sleeved so as to facilitate an operation in a mode of holding in single hand, therefore the bottom cover is prevented from separating away from the medicine cake barrel and an effect of fixing in a peripheral direction is achieved. The medicine cake made by the machine disclosed by the invention is uniform and consistent in thickness, and pin holes are regularly distributed; the time of making the medicine cake by manpower is saved, the quality of the medicine cake is improved and the curative effect of the moxibustion medicine cake in the clinical field is enhanced.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

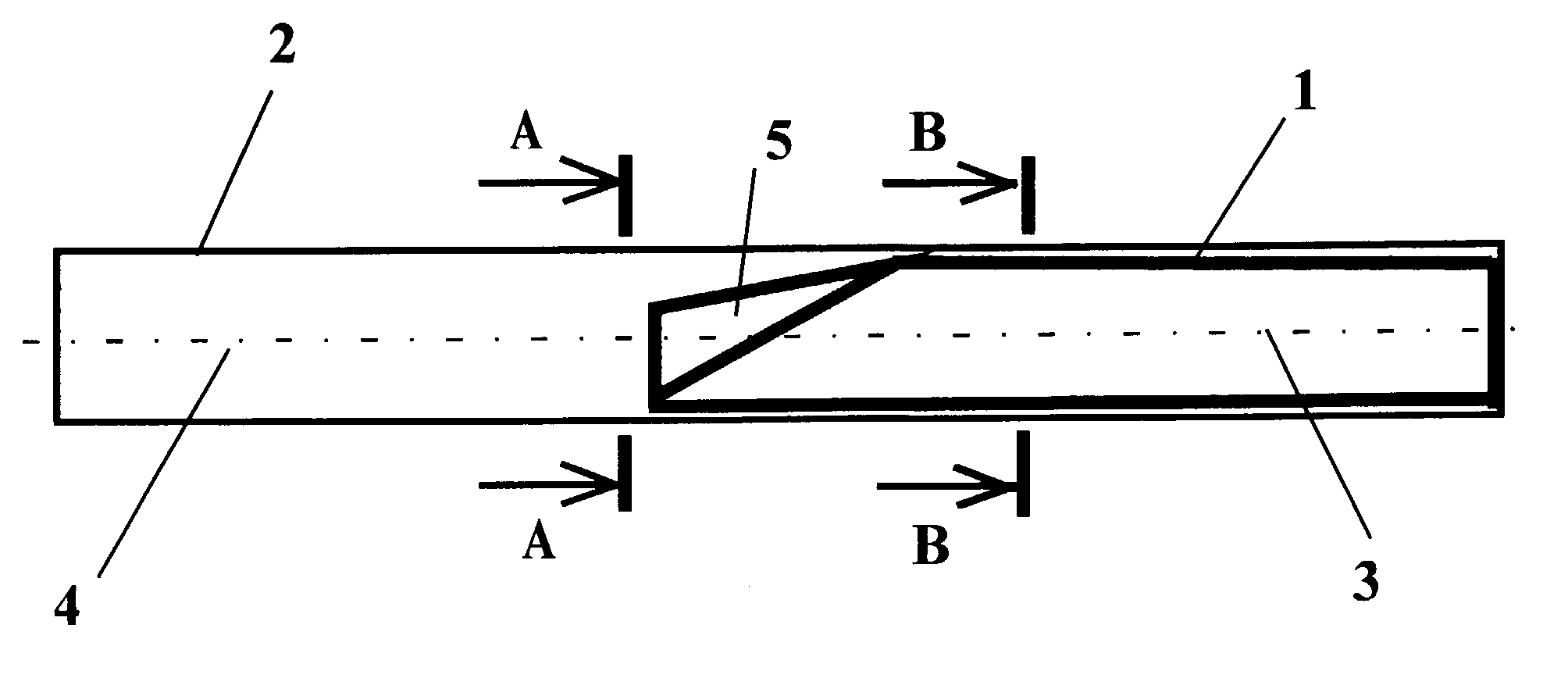

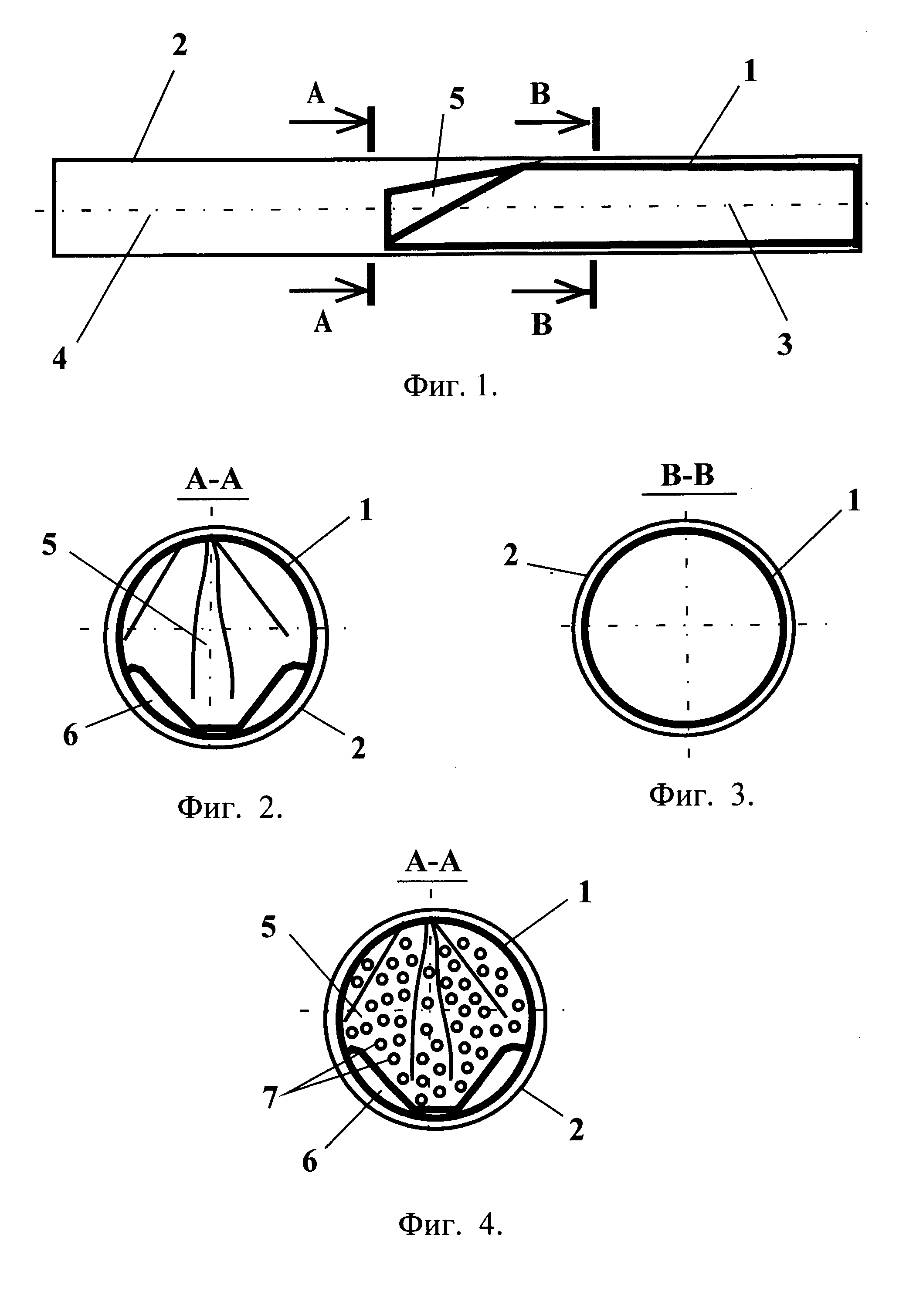

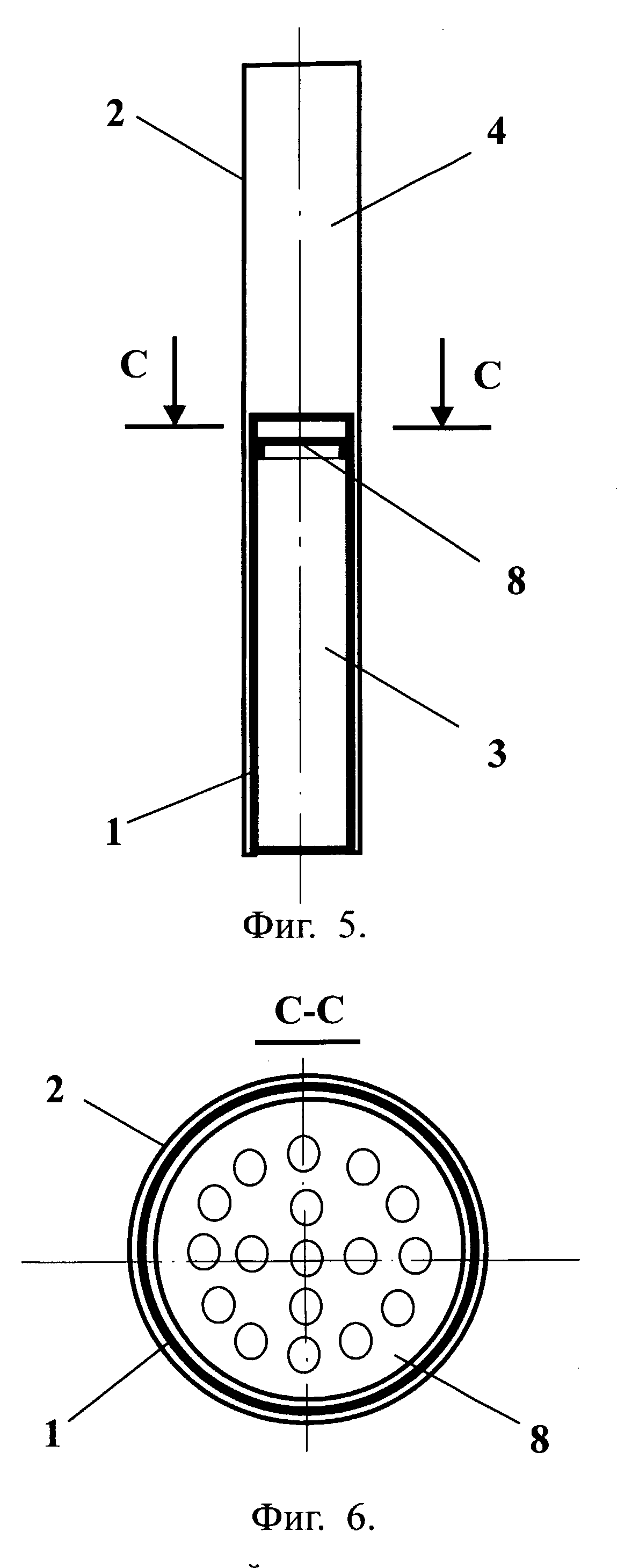

Sleeve for a russian cigarette

InactiveUS20070119466A1High propertyImprove adsorption capacityTobacco preparationCigarette manufactureSmoke compositionStructural engineering

The invention is a cigarette casing, which is intended for independent making of a <<Russian>> cigarette (papirosy) by a smoker or for bulk production. The casing of the <<Russian>> cigarette has an empty mouthpiece (1) and a connected empty envelope (2) at least a part of the cavity (4) of which is intended for the allocation of the smoking material. It contains a separating partition being selectively penetrable for the smoke, installed so that at least a part of the cavity (3) of the mouthpiece (1) could be detached from at least a part of the cavity (4) of the envelope (2) and so that it is possible to overlap at least a part of the cross section of the cavity (3) of the mouthpiece (1). Its design impedes, making minor changes in the composition of the smoke, the penetration of the particles of the smoking material located in the cavity (4) of the envelope (2) into the cavity (3) of the mouthpiece (1) while filling the casing with this smoking material and into the mouth of the smoker during smoking. The casing of the <<Russian>> cigarette has an empty mouthpiece (1) and a connected empty envelope (2), the length of the mouthpiece (1) not less than the length of the envelope (2), the envelope (2) overlaps the mouthpiece (1) with all its length, the mouthpiece (1) and the envelope (2) are installed so that it is possible to move them relative to each other along the common longitudinal axis. The mouthpiece (1) impedes the deformation of the part of the cavity (4) of the envelope (2) intended for the allocation of the smoking material before the placing of this smoking material.

Owner:BILIVITIN YURIY SERGEYEVICH +1

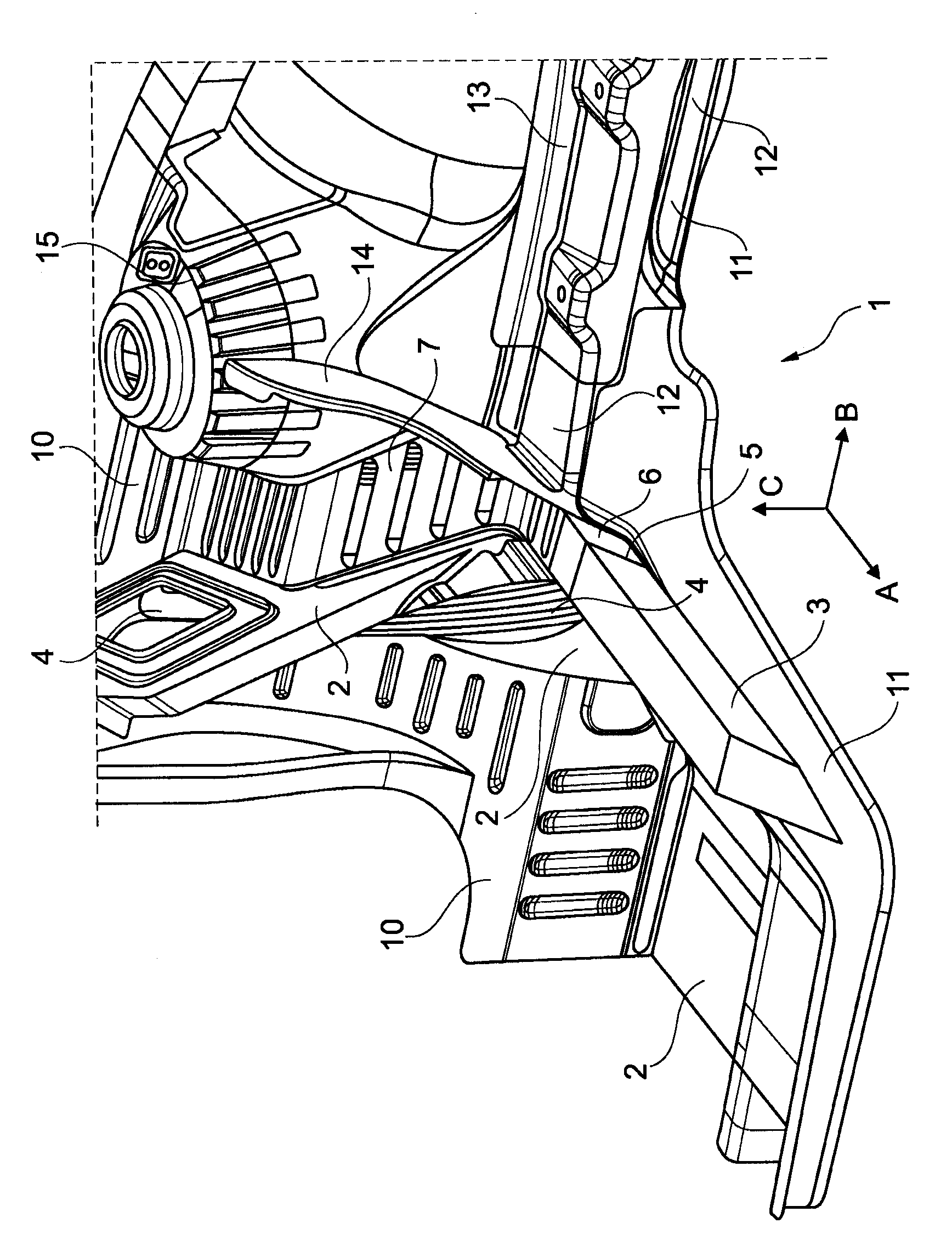

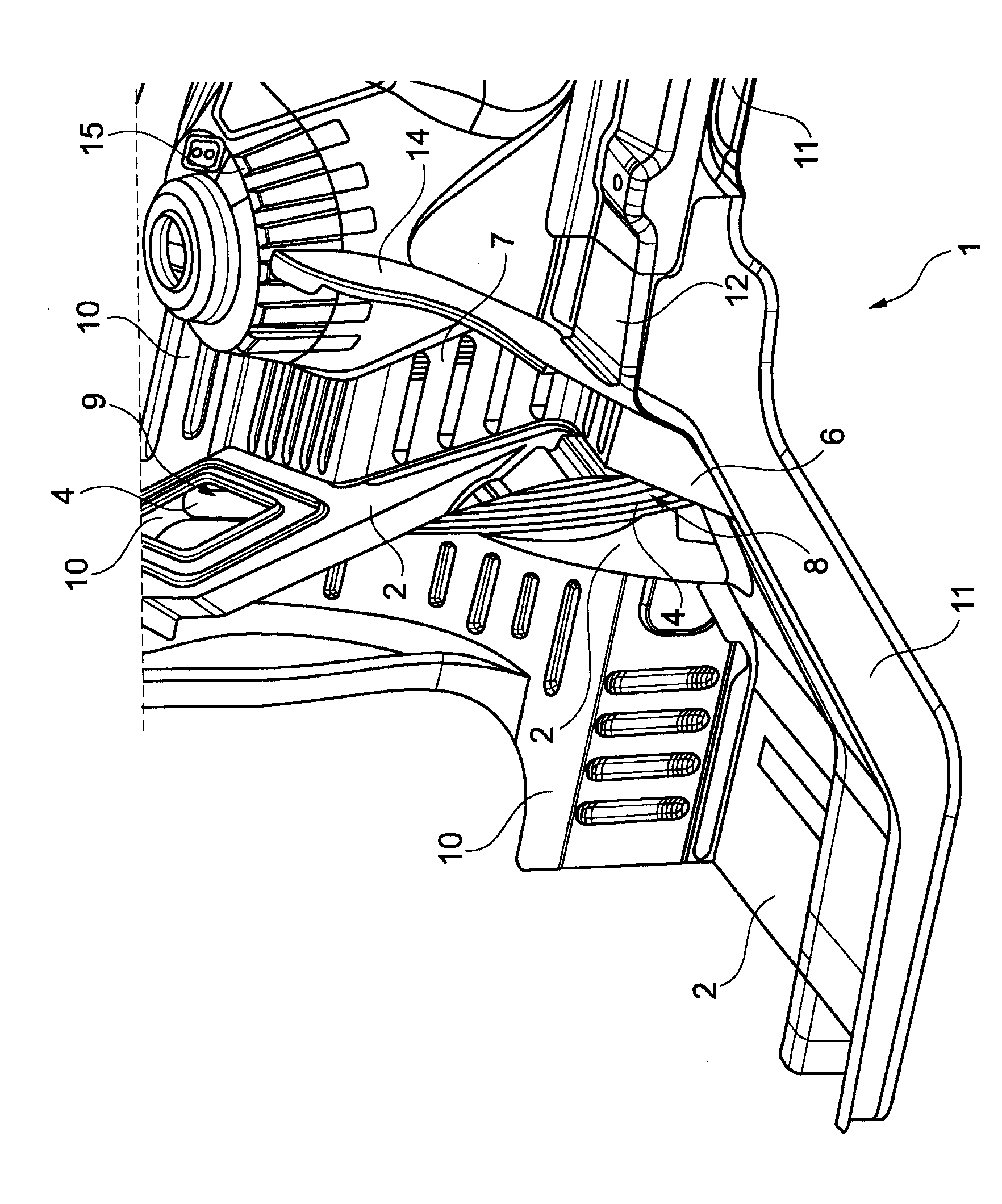

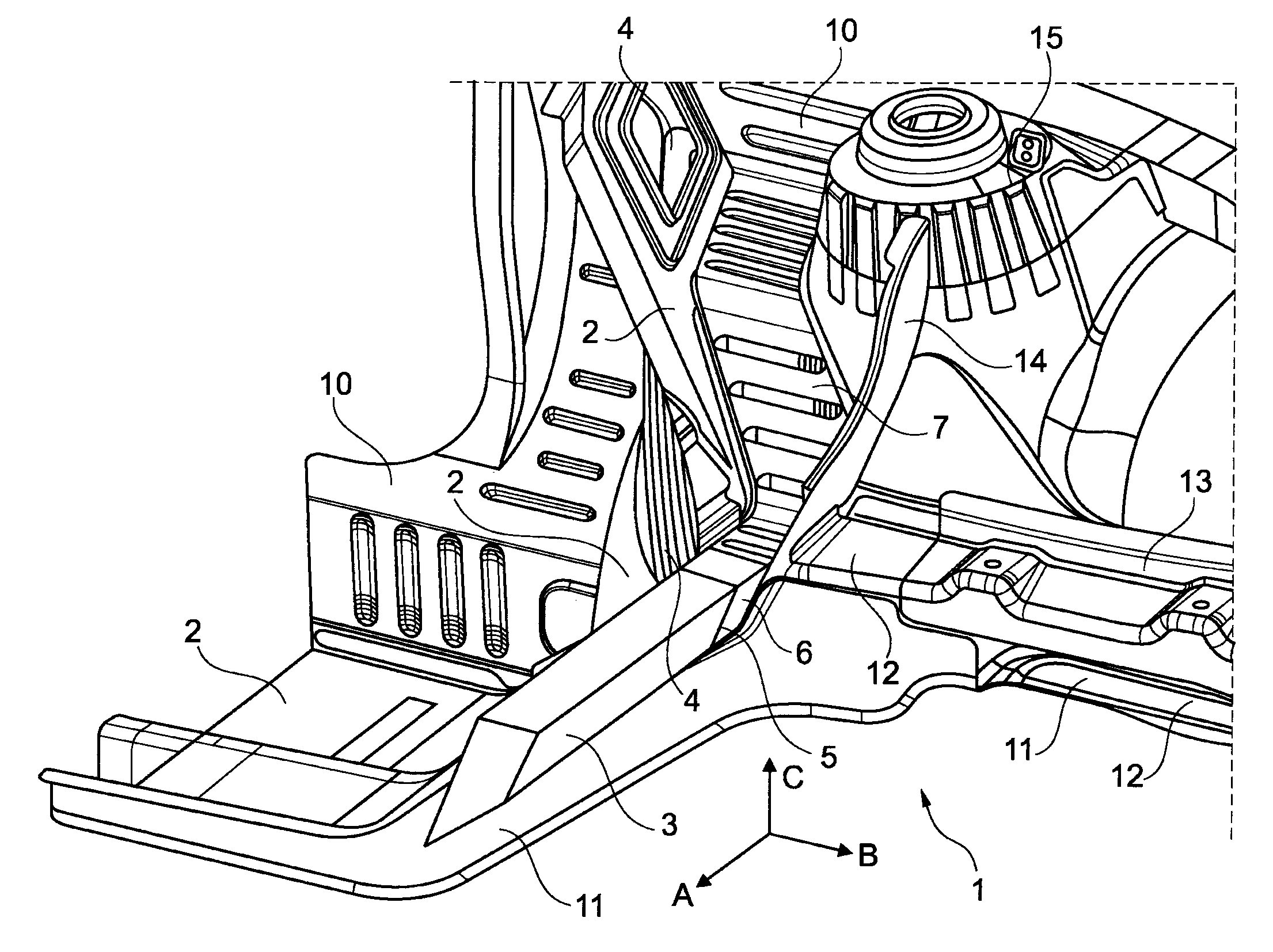

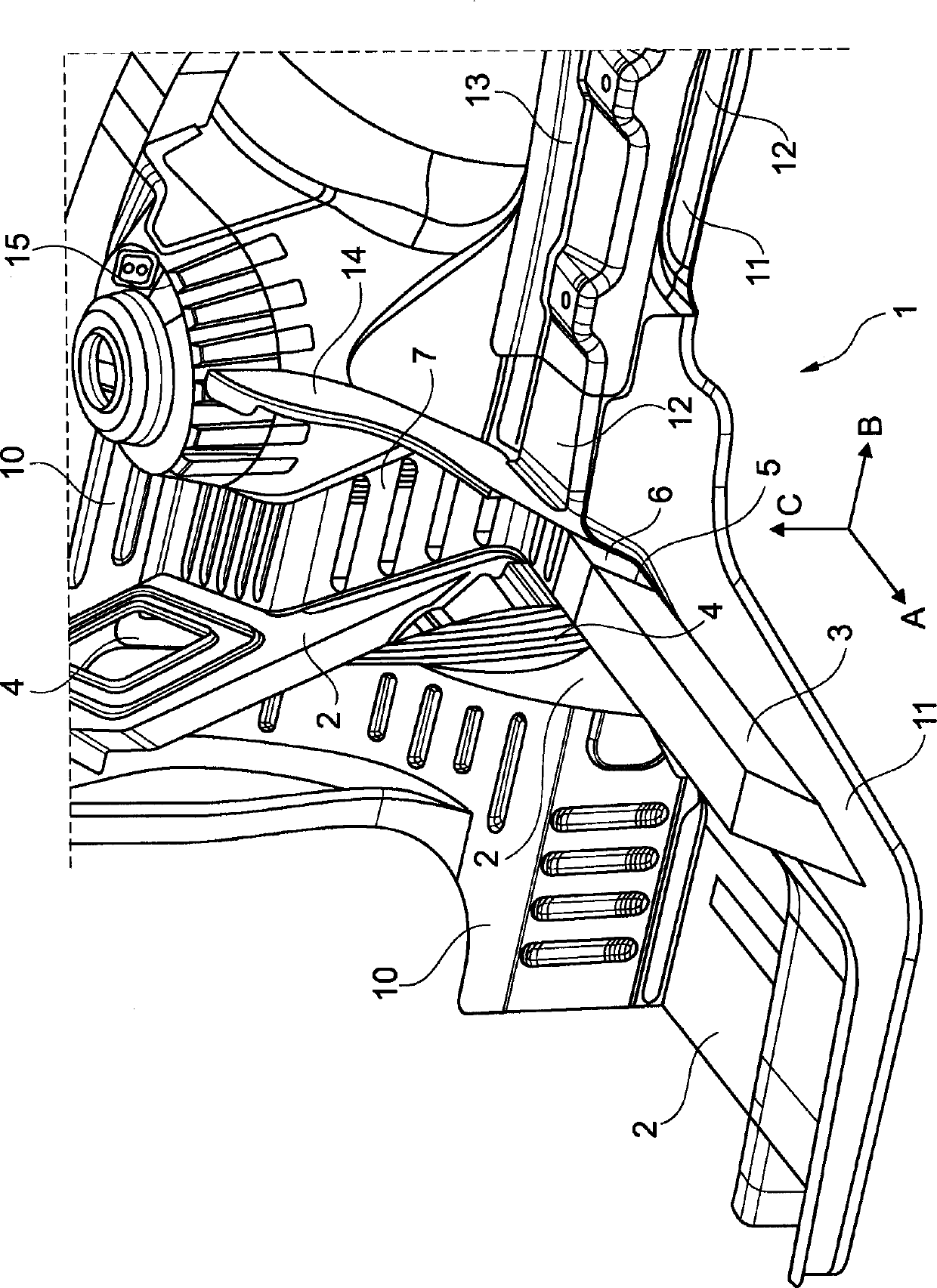

Motor vehicle front end and method for its production

InactiveCN101985304ADecrease deceleration pulsePrevent penetrationUnderstructuresSuperstructure subunitsTransverse axisStructural engineering

The invention relates to a motor vehicle front end 1 and a method for producing a motor vehicle front end 1. The motor vehicle front end 1 has a front wall 2 and a front wall crossbeam 3, the front wall crossbeam 3 essentially being situated in the direction of a vehicle transverse axis. In addition, the motor vehicle front end 1 has a first front wall girder 4, the first front wall girder 4 being situated essentially in the direction of a vehicle vertical axis. The first front wall girder 4 is supported on the front wall crossbeam 3 in a first area 5 of the front wall crossbeam 3. The first front wall girder 4 may be implemented as a hinged column strut. A reinforcement element 6 may be situated in the first area 5 of the front wall crossbeam.

Owner:GM GLOBAL TECH OPERATIONS LLC

A kind of automobile front floor assembly

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

Automatically adjusting contact node for multiple rib space engagement

InactiveUS8721573B2Ensure penetrationIncrease blood flowChiropractic devicesVibration massageCoronary arteriesFourth intercostal space

A vibratory attachment interface enabling transmission of oscillations generated by an oscillation source upon an external human body surface. The interface comprises a first contact node and a second contact node slideably mounted alongside the first contact node, wherein the contact nodes are each sized and shaped to enable seating within a human rib-space, and whereby upon forced engagement of the first contact node within a first rib-space, the second contact node automatically slides and conforms to the contour of a second differing rib-space thereby optimally nestling within the second rib-space. The attachment interface is for use in contoured application to preferably the anatomic left sternal border, third and fourth intercostal space, such as to enable and ensure an optimized vibratory transmission pathway from the chest wall to the base of the heart and coronary arteries thereupon.

Owner:HOFFMANN ANDREW KENNETH +1

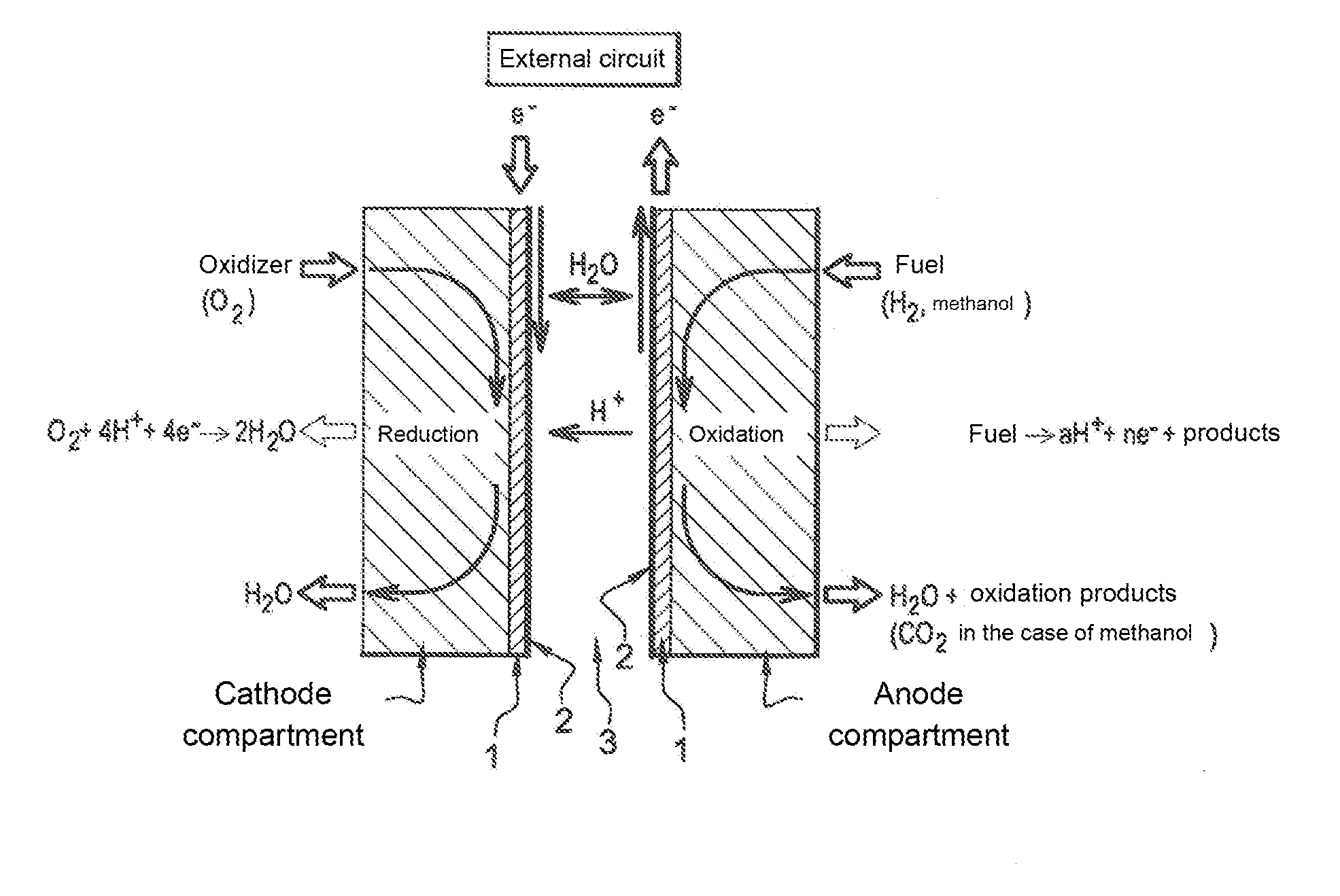

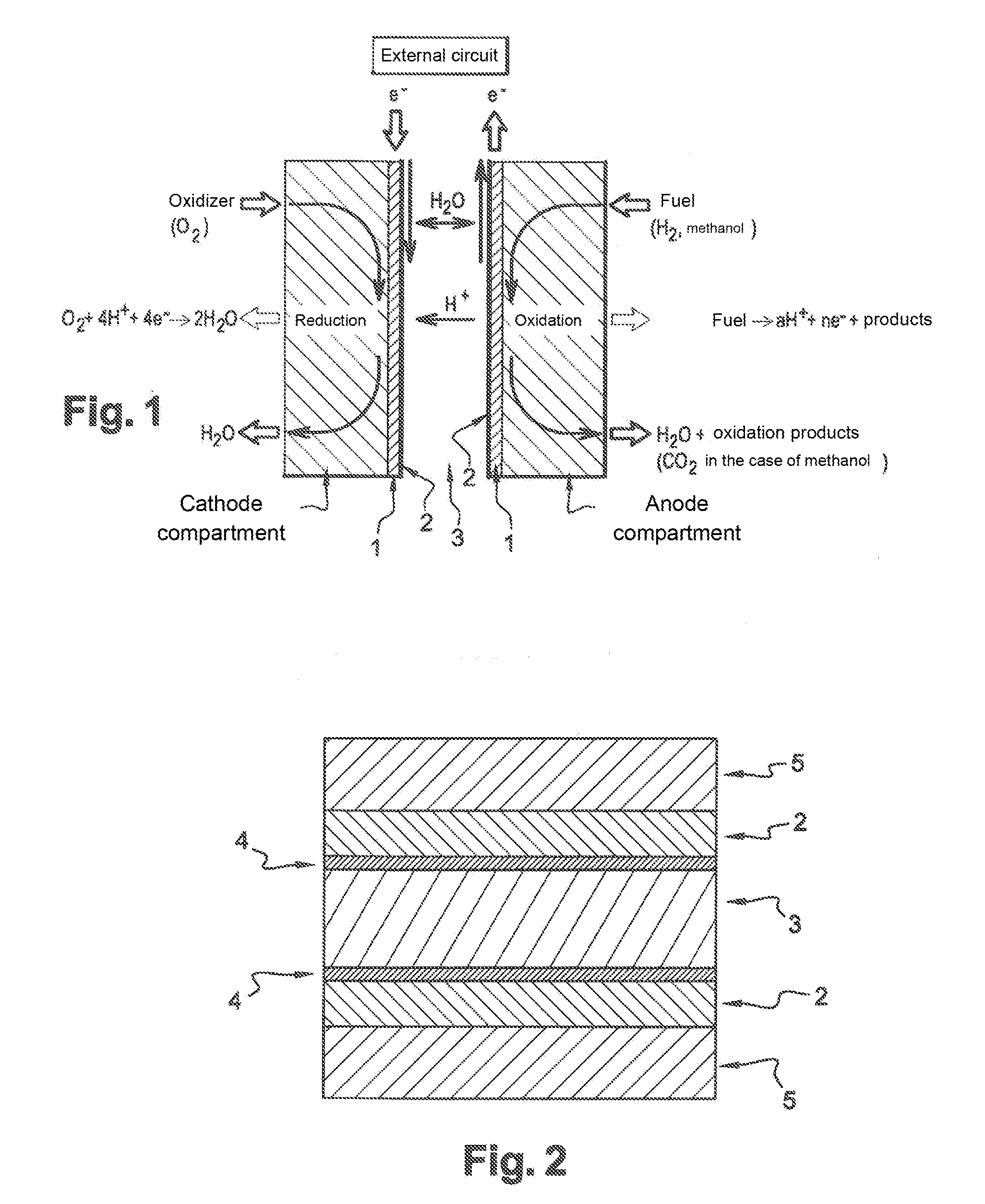

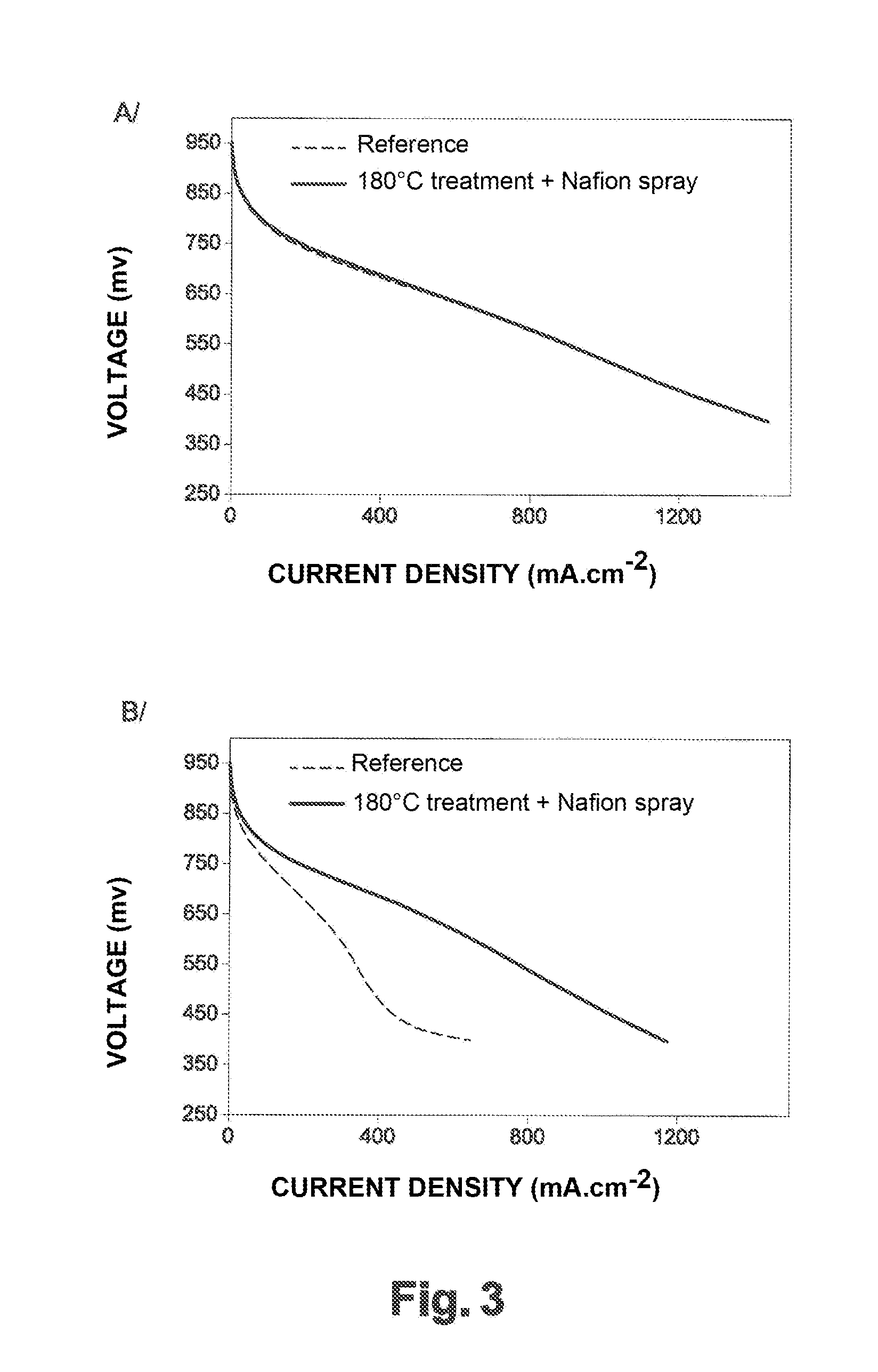

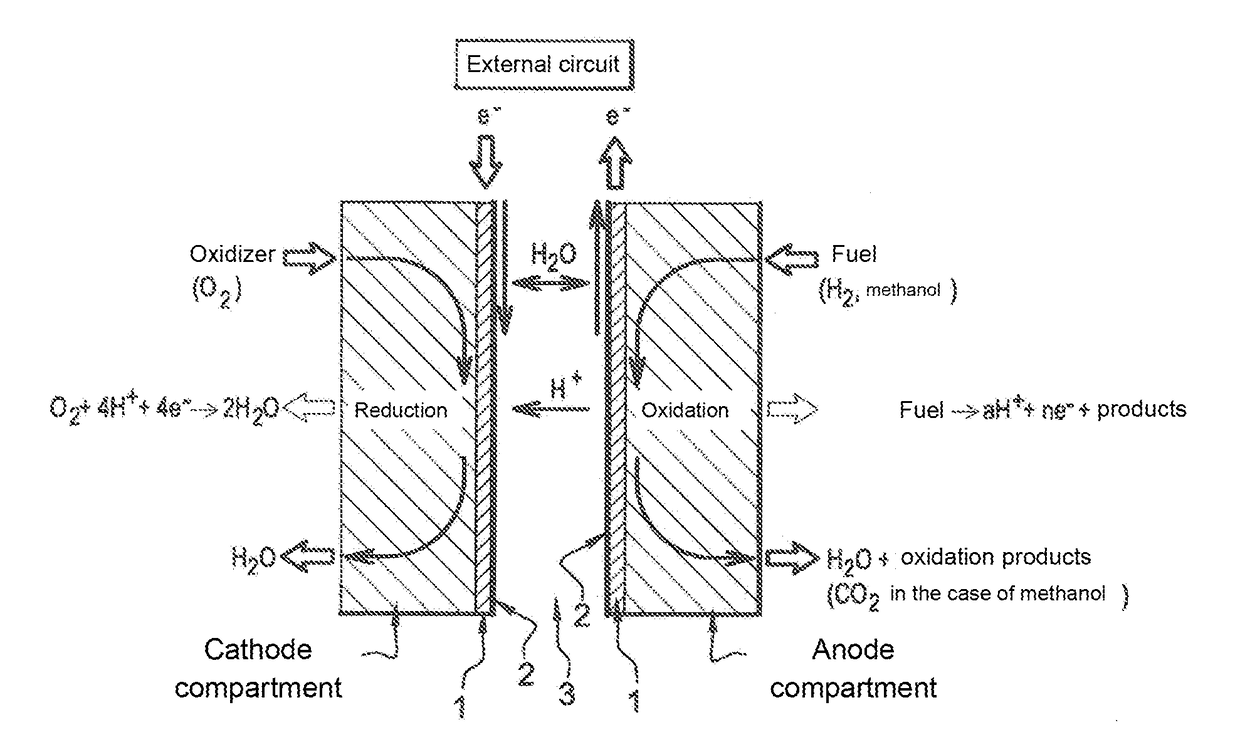

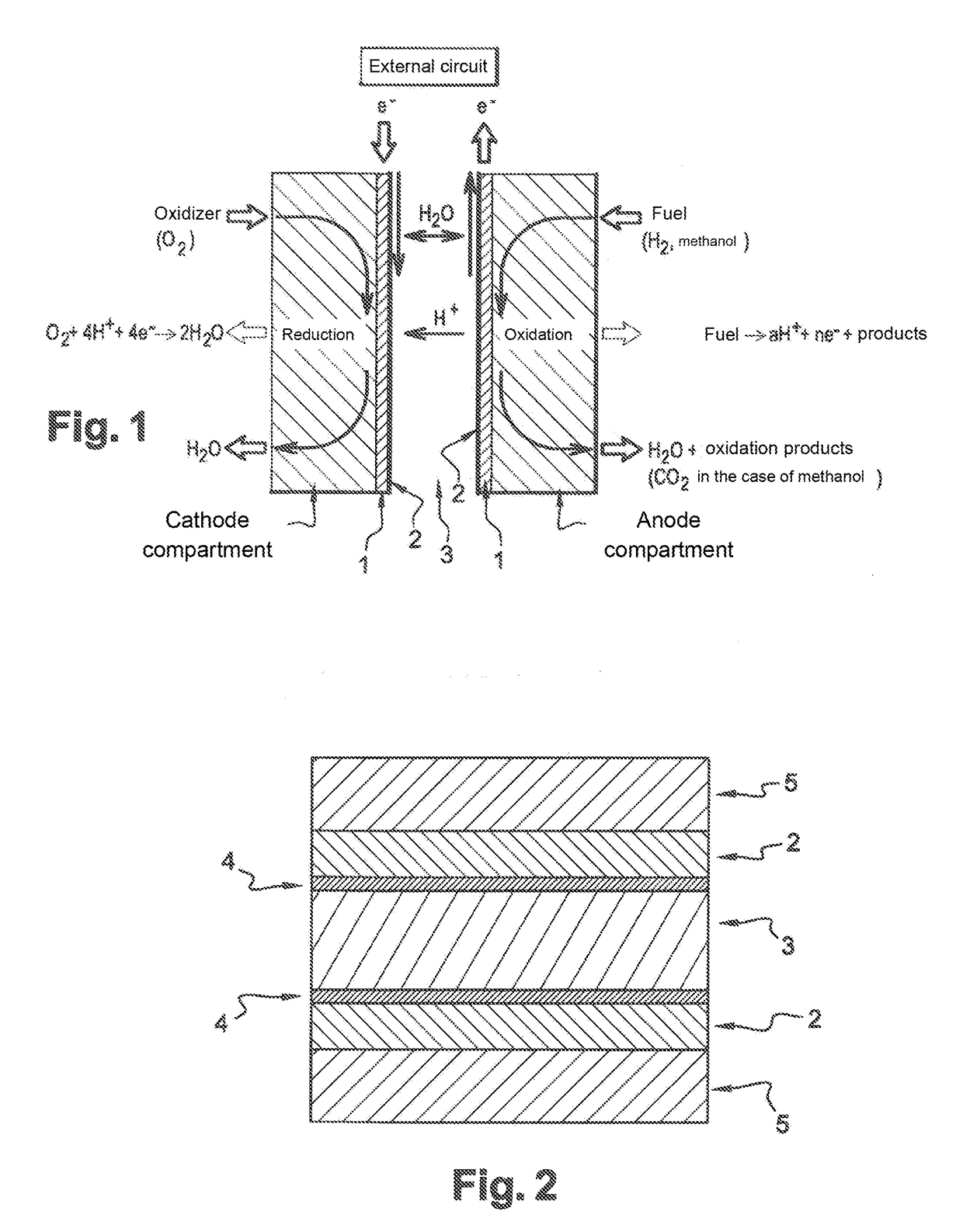

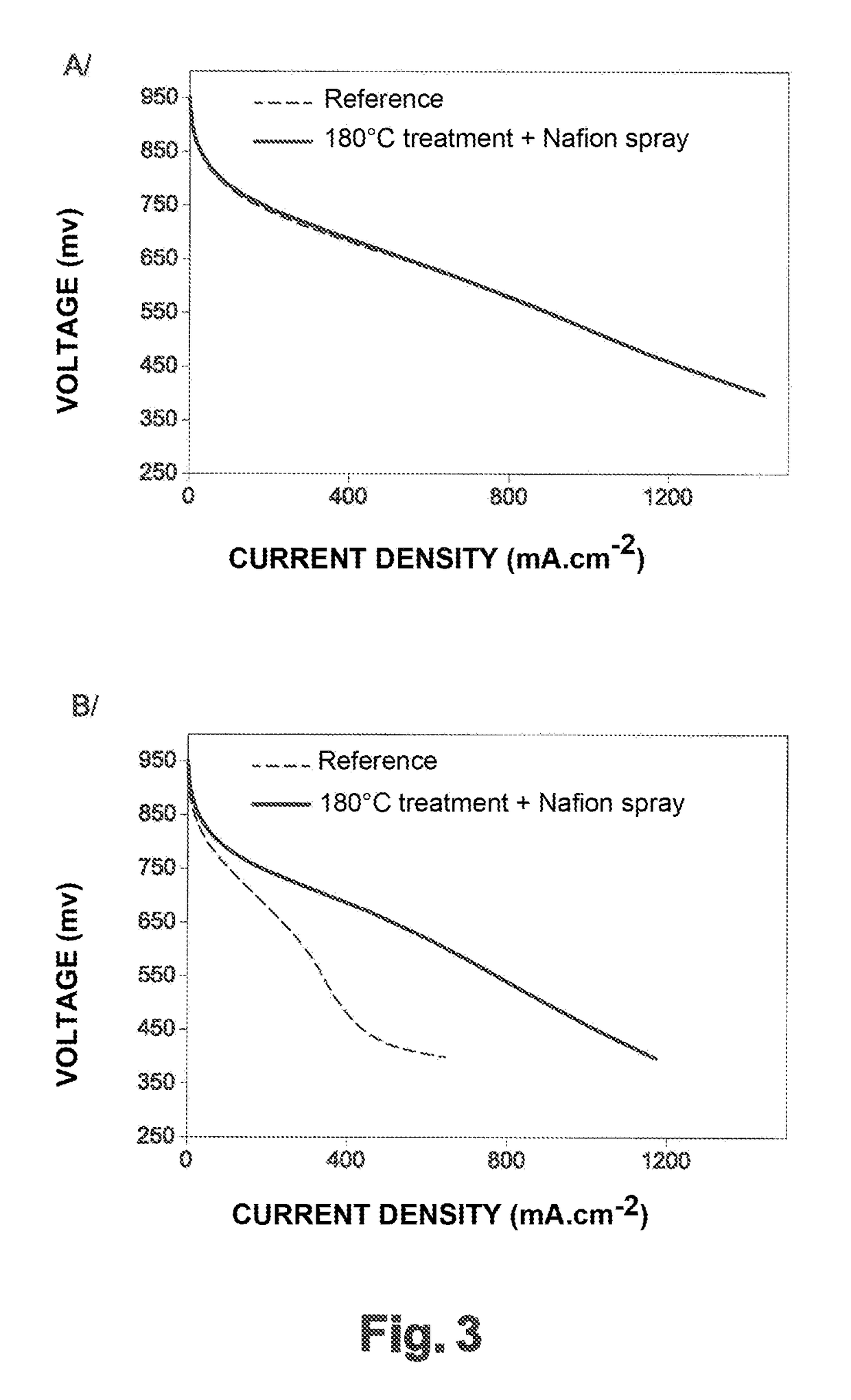

Membrane-electrodes assembly for proton exchange fuel cells (PEMFC), and manufacturing method

ActiveUS20170018780A1Improve propertiesSimple interfaceFinal product manufactureCell electrodesPolymer chemistryConductive polymer

A membrane-electrode assembly (MEA) including a membrane and two electrodes, and further at least one layer located at the interface of the membrane and of an electrode. The layer contains a proton conductive polymer which has a glass transition temperature lower than or equal to, advantageously lower than, that of the proton conductive polymer contained in the membrane.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

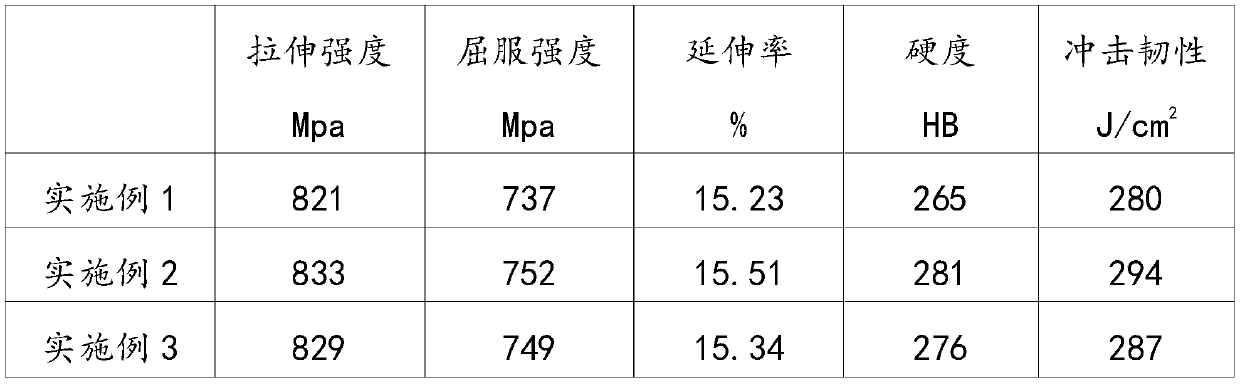

Thick plate high-efficiency gas-slag combined protection welding method

InactiveCN111761175AReduce protection requirementsIncrease structural stressWelding/soldering/cutting articlesWelding accessoriesButt weldingCopper plating

The invention discloses a thick plate high-efficiency gas-slag combined protection welding method. The method comprises the following steps that according to the base material performance, Rm is 450-600 MPa, and the thickness is 10-40 mm; vertical butt welding with equal thickness is carried out; two U-shaped grooves are adopted; a copper-free flux-cored wire is adopted, wherein the diameter of the copper-free flux-cored wire is 1.6 mm; protective gas is CO2 of 80% and O2 of 20%; a straight polarity method of a direct-current power supply is adopted; a current is 300-400 A, the voltage is 32-40 V, and the welding speed is 5-15 cm / min; a welding wire conductive nozzle is located in a closed space formed by the welding grooves, a welding seam front copper sliding block and a ceramic liner, and the vertical distance between the welding wire conductive nozzle and the top of the copper sliding block is 14+ / -0.1 mm; the intersection angle of the welding wire conductive nozzle and the weldingparallel line is 5-15 degrees; and during welding, a gap between the bottoms of the two U-shaped grooves is protected by the ceramic liner with an adhesive strip. According to the thick plate high-efficiency gas-slag combined protection welding method, the generation of welding stress and welding deformation can be effectively reduced, preheating is not needed before welding, heat treatment is not needed after welding, the consumption of welding materials is reduced by at least 50%, the heat input is reduced by at least 60%, and a weld joint is formed once.

Owner:武汉钢铁有限公司

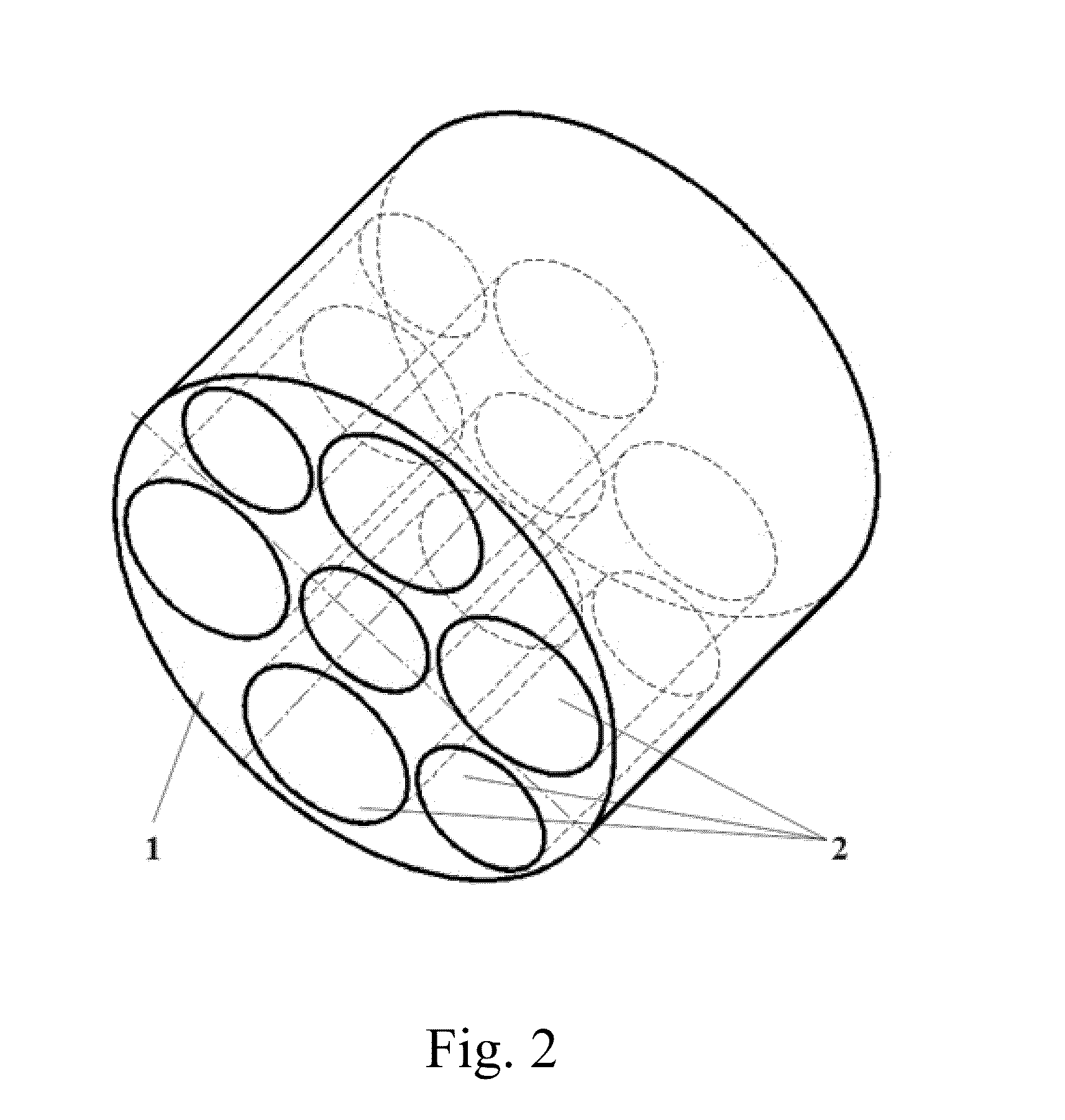

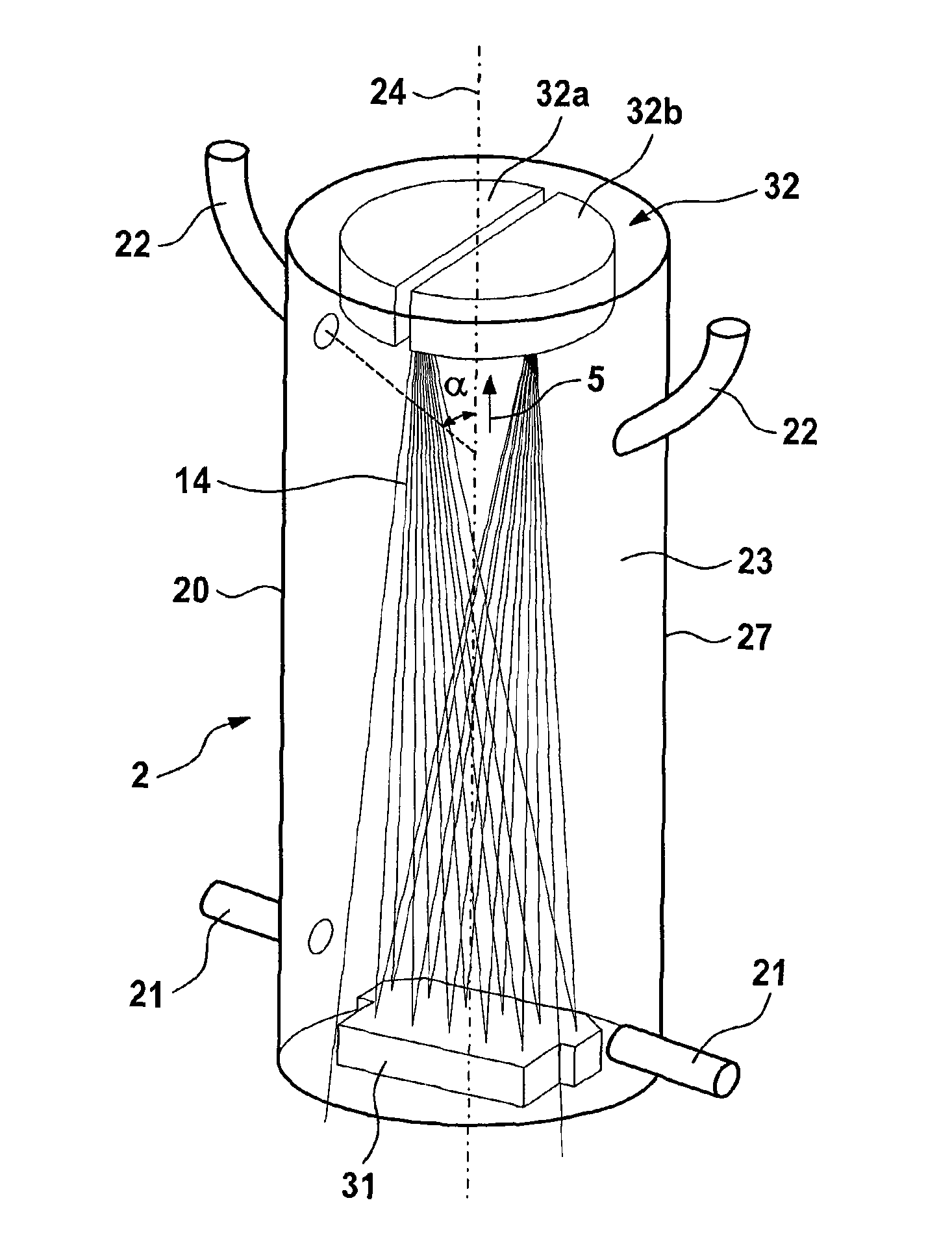

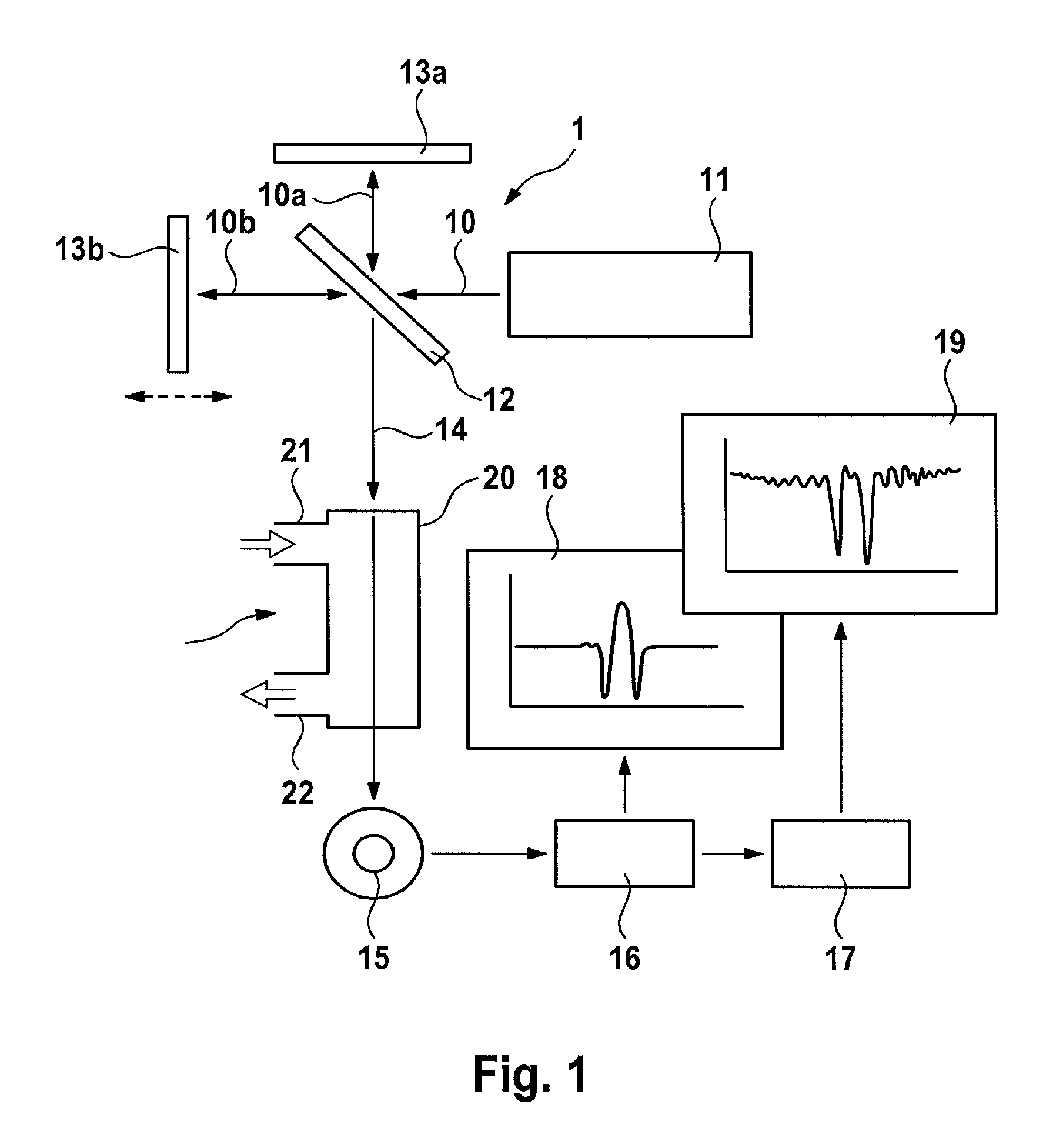

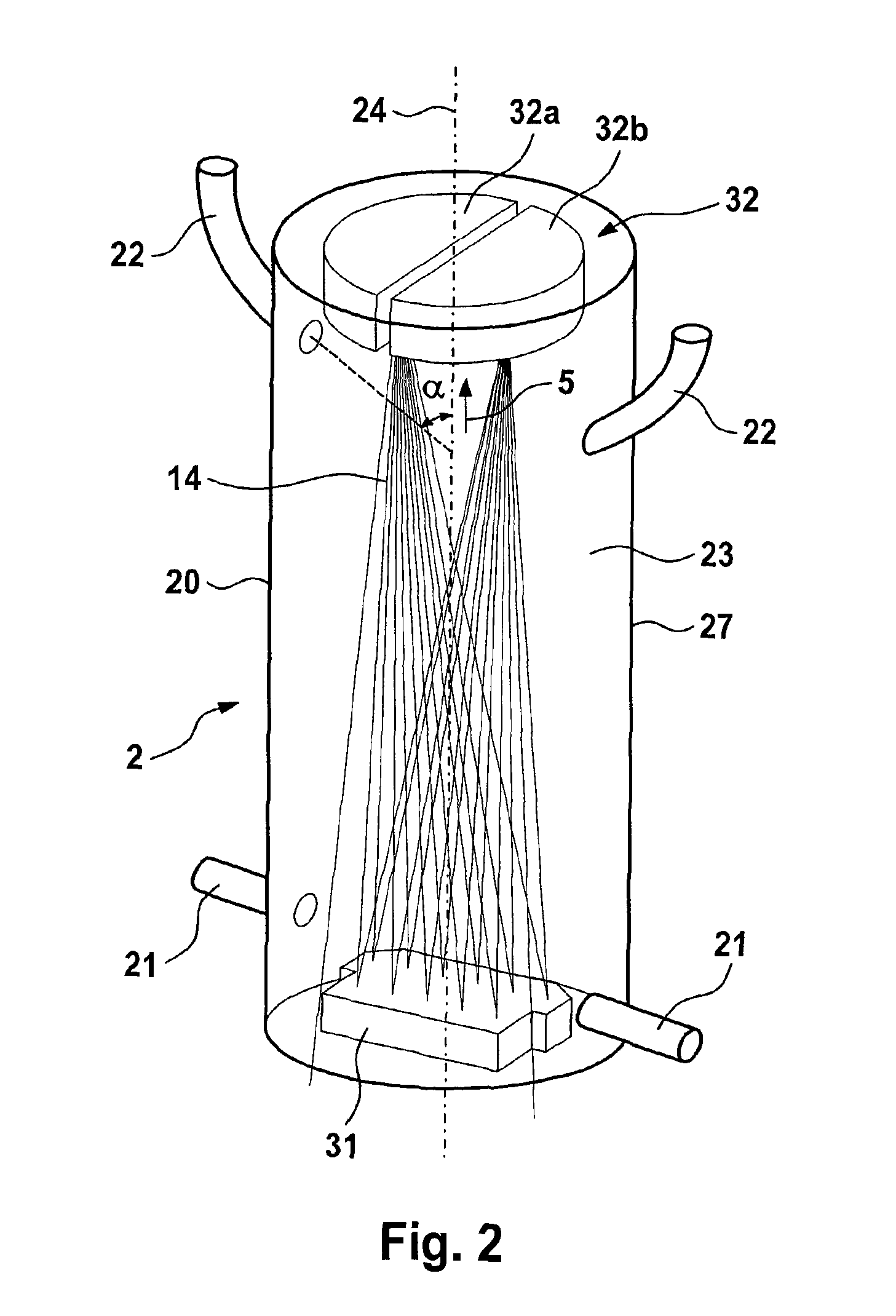

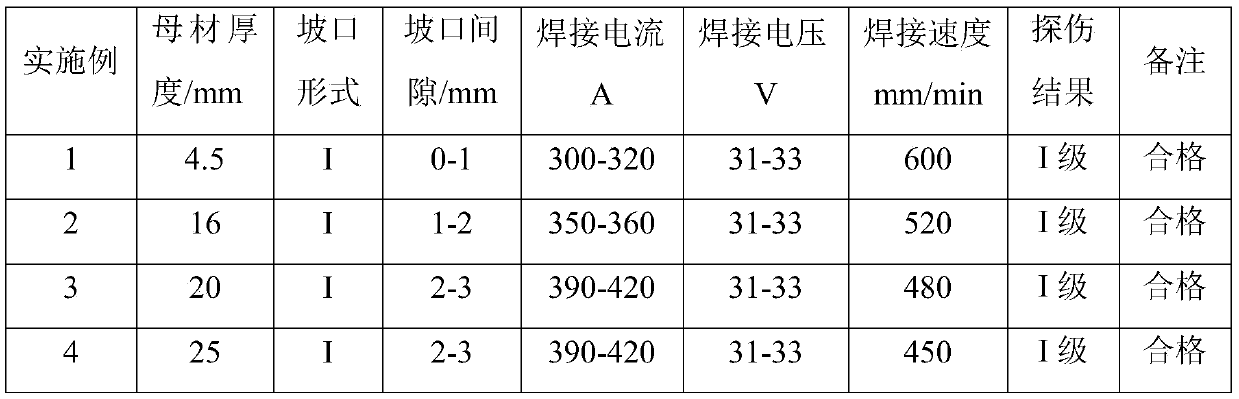

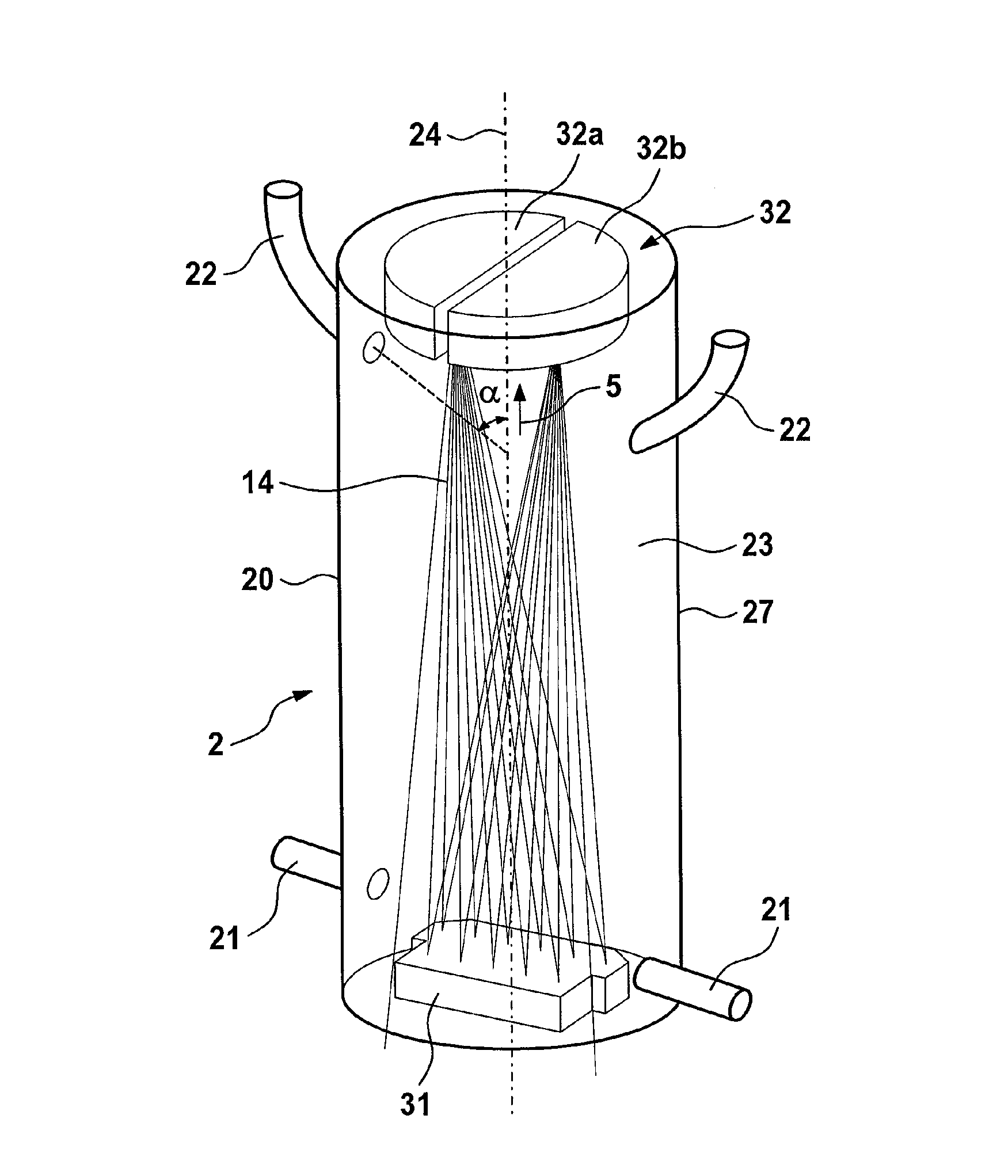

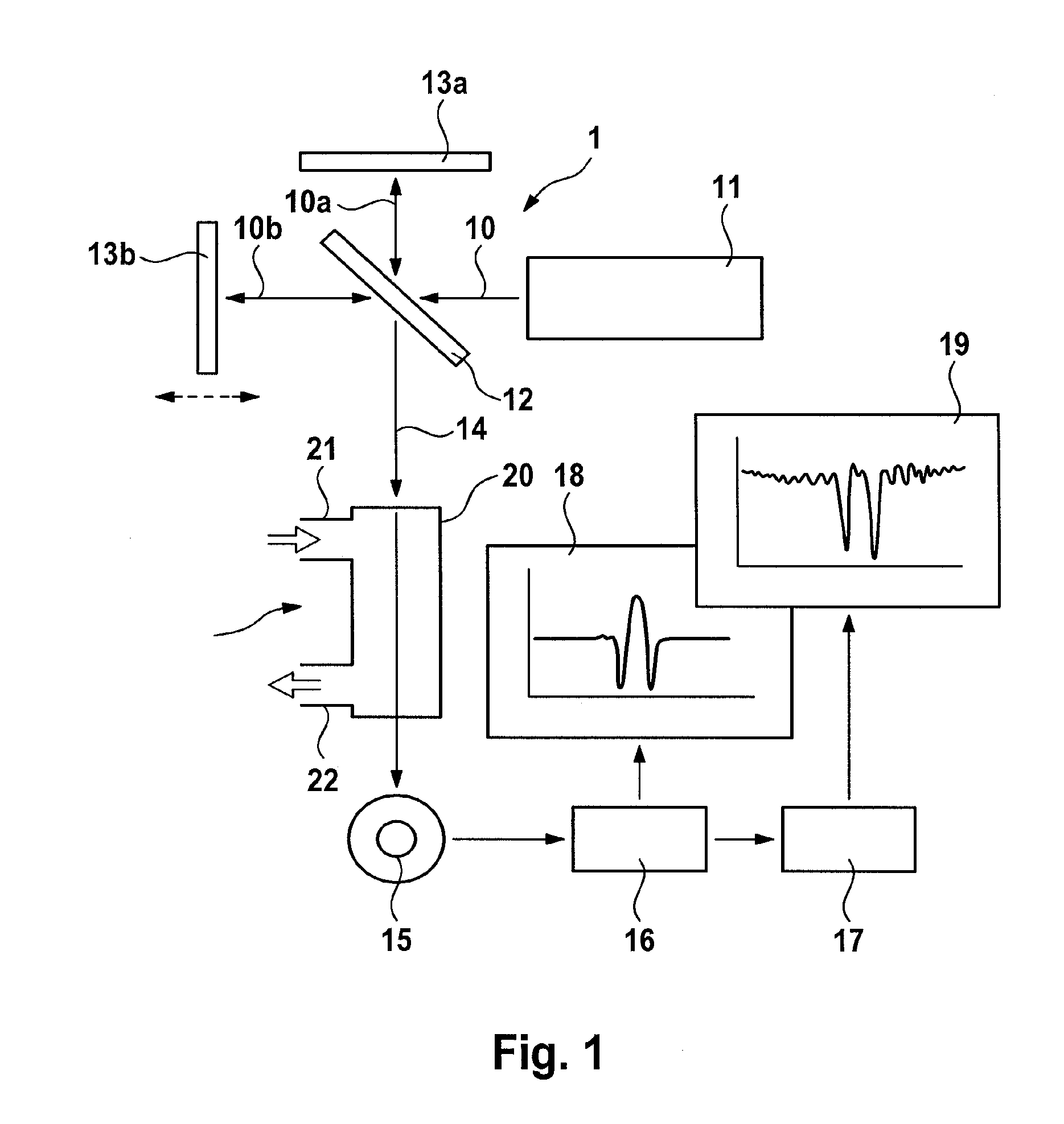

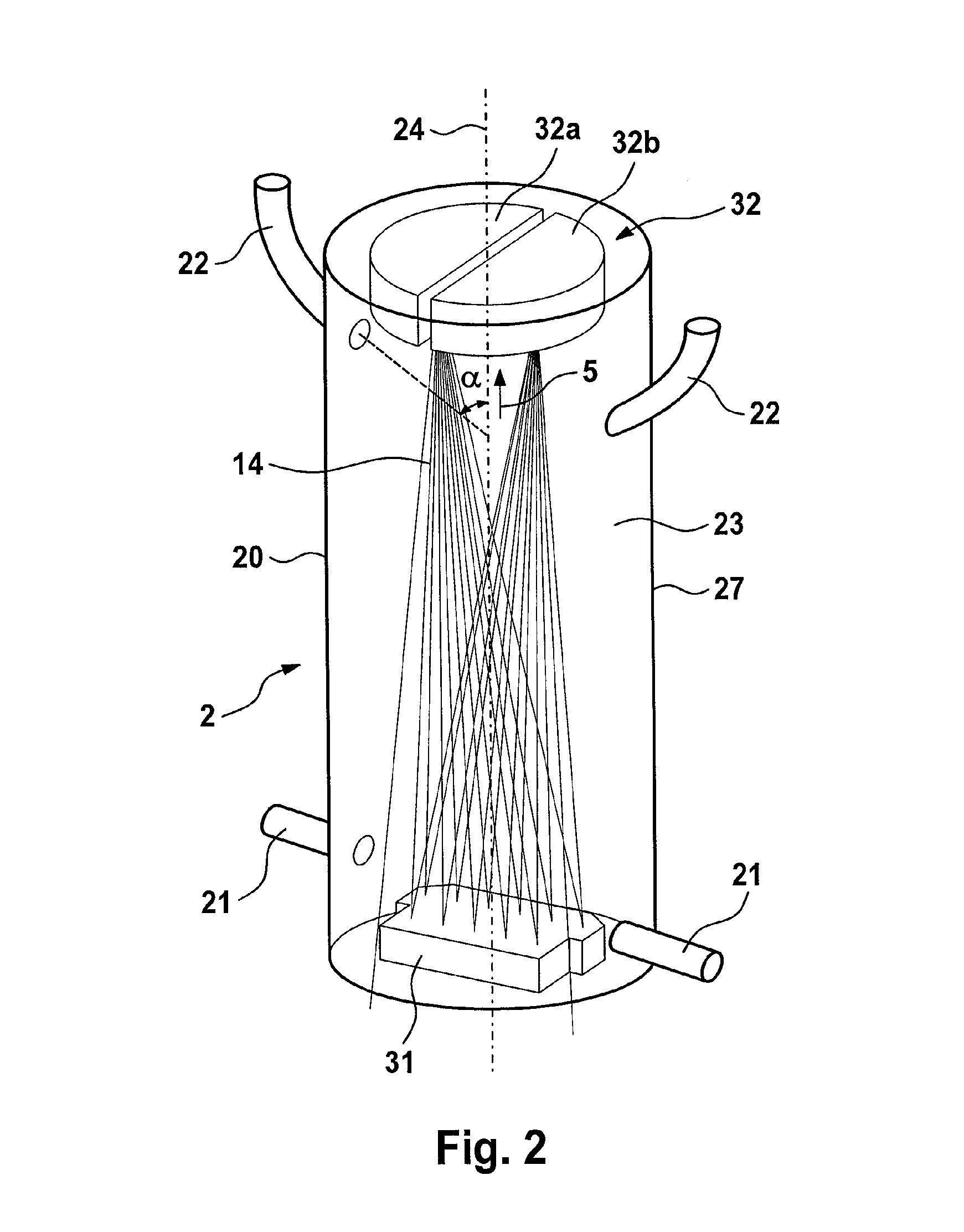

Gas cell for the optical analysis of gases

ActiveUS9279721B2Fast exchangeGood body shapeRadiation pyrometryWithdrawing sample devicesGas analysisGas exchange

A measuring cell for a gas analysis spectrometer has an inner chamber for a sample gas to be analyzed and an inlet and an outlet which are connected thereto. A traversing optical path for a measuring beam is formed in the inner chamber. The measuring cell is tubular, the inlet and the outlet are arranged at opposite ends, and the inner chamber of the measuring cell has a cross-sectional shape that is monotonic over the length of the tube and which has an oval-shape at the start, which disappears toward the end. That special shape results in fast gas exchange and thus high dynamics, even with larger measuring cells, which have high sensitivity due to the long optical paths thereof. Two characteristics which until now appeared to be conflicting are thereby combined.

Owner:CHEVROU USA INC +1

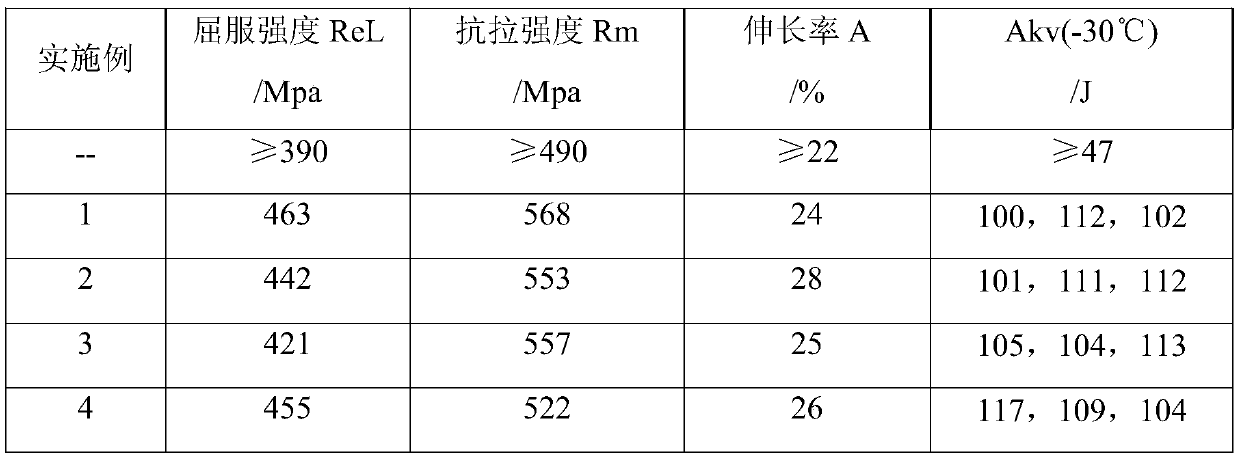

Metal powder flux-cored wire suitable for medium and thick plate beveling-free high-speed welding

ActiveCN111203674AEnsure penetrationGuaranteed weld qualityWelding/cutting media/materialsSoldering mediaFerrosiliconOxide

The invention provides a metal powder flux-cored wire suitable for medium and thick plate beveling-free high-speed welding. The metal powder flux-cored wire comprises sheet steel and a flux core wrapped by the sheet steel. The flux core is prepared from components in percent by mass including 5%-8% of silicon-manganese alloy, 2%-4% of manganite, 3%-5% of silicon iron, 1%-2% of powdered aluminium,1%-2% of graphite and the balance iron powder. According to the metal powder flux-cored wire, as the formula of the flux core is designed, a welding joint of the wire has good depth of fusion, the wire is suitable for medium and thick plate beveling-free high-speed welding, the welding speed can reach 450 mm / min-600 mm / min, and the welding working efficiency is effectively improved. The metal powder flux-cored wire has excellent welding process performance, and according to the overall performance of fused metal and a welded joint, the yield strength is larger than or equal to 390 MPa, the tensile strength is larger than or equal to 490 MPa, the elongation is larger than or equal to 22%, and the Akv under the -30 DEG C condition is larger than or equal to 47 J.

Owner:武汉铁锚焊接材料股份有限公司

Gas cell for the optical analysis of gases

ActiveUS20150185075A1Rapid gas exchangeEasy to adaptRadiation pyrometryWithdrawing sample devicesGas analysisGas exchange

A measuring cell for a gas analysis spectrometer has an inner chamber (23) for a sample gas to be analyzed and an inlet (21) and an outlet (22) which are connected thereto. A traversing optical path for a measuring beam (14) is formed in the inner chamber (23). The measuring cell is tubular, the inlet (21) and the outlet (22) are arranged at opposite ends, and the inner chamber (23) of the measuring cell has a cross-sectional shape that is monotonic over the length of the tube and which has an oval-shape at the start, which disappears toward the end. That special shape results in fast gas exchange and thus high dynamics, even with larger measuring cells, which have high sensitivity due to the long optical paths thereof. Two characteristics which until now appeared to be conflicting are thereby combined.

Owner:CHEVROU USA INC +1

Motor vehicle front end and method for its production

InactiveCN101985304BPrevent penetrationEnsure penetrationUnderstructuresSuperstructure subunitsTransverse axisVertical axis

A motor vehicle front end and a method for producing a motor vehicle front end are provided in accordance with embodiments of the invention. The motor vehicle front end has a front wall and the front wall girder, the front wall girder essentially being situated in the direction of a vehicle transverse axis. In addition, the motor vehicle front end has a first front wall girder, the first front wall girder being situated essentially in the direction of a vehicle vertical axis. The first front wall girder is supported on the front wall crossbeam in a first area of the front wall crossbeam.

Owner:GM GLOBAL TECH OPERATIONS LLC

Membrane-electrodes assembly for proton exchange fuel cells (PEMFC), and manufacturing method

ActiveUS9819031B2Improve propertiesSimple interfaceCell electrodesSecondary cellsConductive polymerProton

A membrane-electrode assembly (MEA) including a membrane and two electrodes, and further at least one layer located at the interface of the membrane and of an electrode. The layer contains a proton conductive polymer which has a glass transition temperature lower than or equal to, advantageously lower than, that of the proton conductive polymer contained in the membrane.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com