Submerged arc welding method for steel sheets

A technology of submerged arc welding and steel plate, which is applied in the direction of arc welding equipment, welding equipment, welding/welding/cutting items, etc. It can solve the problems of increased device load, increased risk, and complicated device structure, and achieves a large welding bead width Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

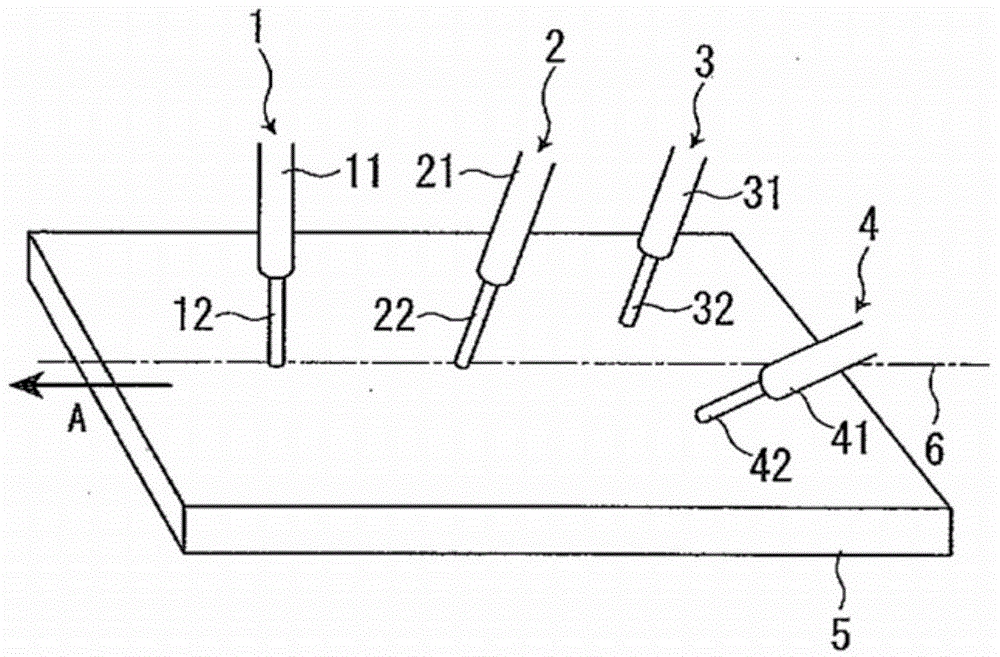

[0049] Such as Figure 4 As shown, the groove angle θ is 60°, 70°, 80°, and the groove depth D is 8mm, 10mm, 17mm on the steel plate 5 with a thickness T of 18.0mm, 25.4mm, and 38.1mm. After that, use 4 electrodes for submerged arc welding to make Figure 5 Solder joints shown. Table 1 shows the groove shape, Table 2 shows the welding conditions, Table 3 shows the arrangement of the electrodes, and Table 4 shows the setting of the welding current.

[0050] [Table 1]

[0051]

[0052] [Table 2]

[0053]

[0054] #1 to #4 represent the first electrode to the fourth electrode, respectively.

[0055] [table 3]

[0056]

[0057] #1~#4 represent the first electrode to the fourth electrode respectively

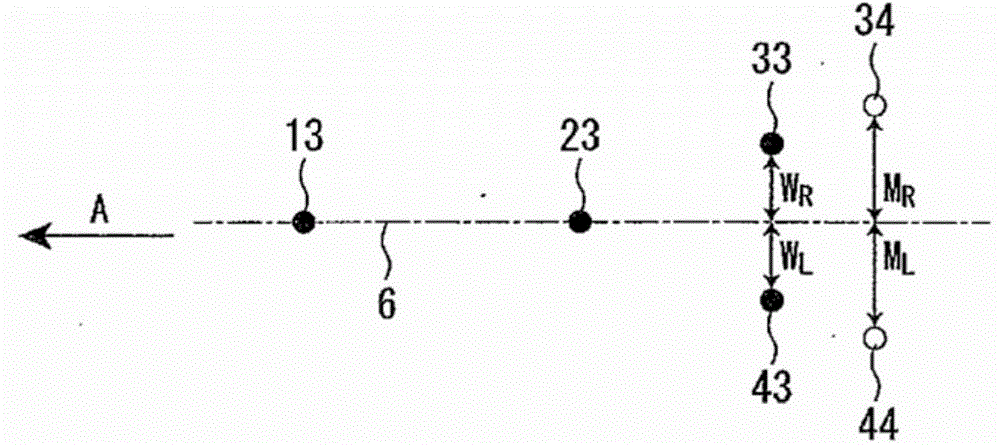

[0058] The distance between poles indicates the distance along the welding line

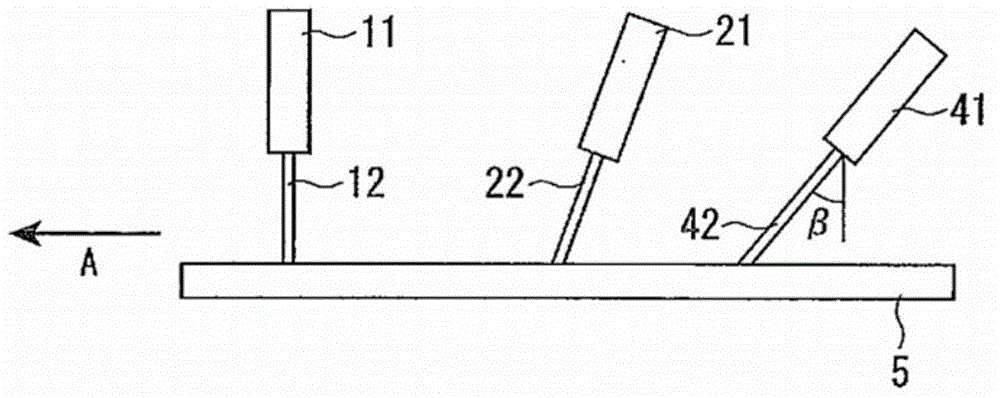

[0059] The electrode angle is indicated by a positive value for the advance angle. A negative number is used for the sweep angle

[0060] The distance from the welding line uses a posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com